DIC-Based Hydration Absorption Detection and Displacement Field Evolution of Outcrop Porous Sandstone

Abstract

:1. Introduction

2. Pressure-Less Hydration Absorption Characteristics of Outcrop Porous Sandstone

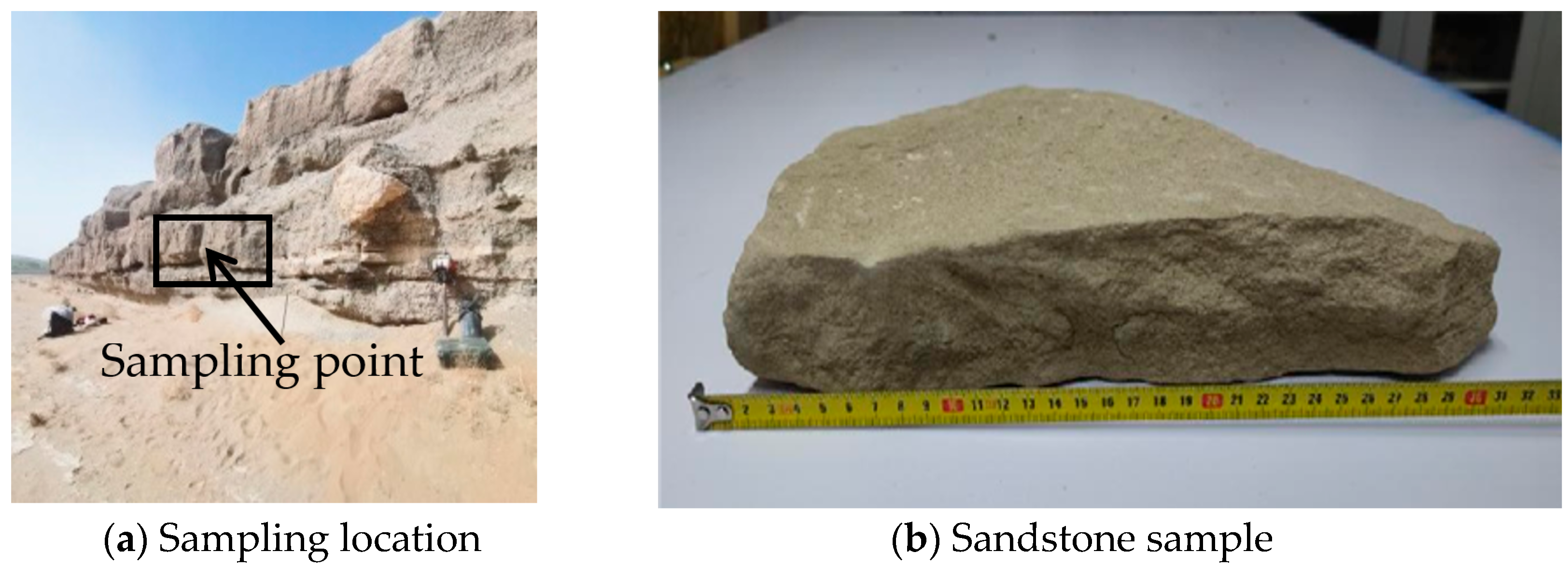

2.1. Preparation of Outcrop Porous Sandstone Samples

2.2. Mercury Intrusion Porosimetry Test Results and XRD Test Results of the Sandstone Samples

2.2.1. Mercury Intrusion Porosimetry Test Results

2.2.2. XRD Test Results

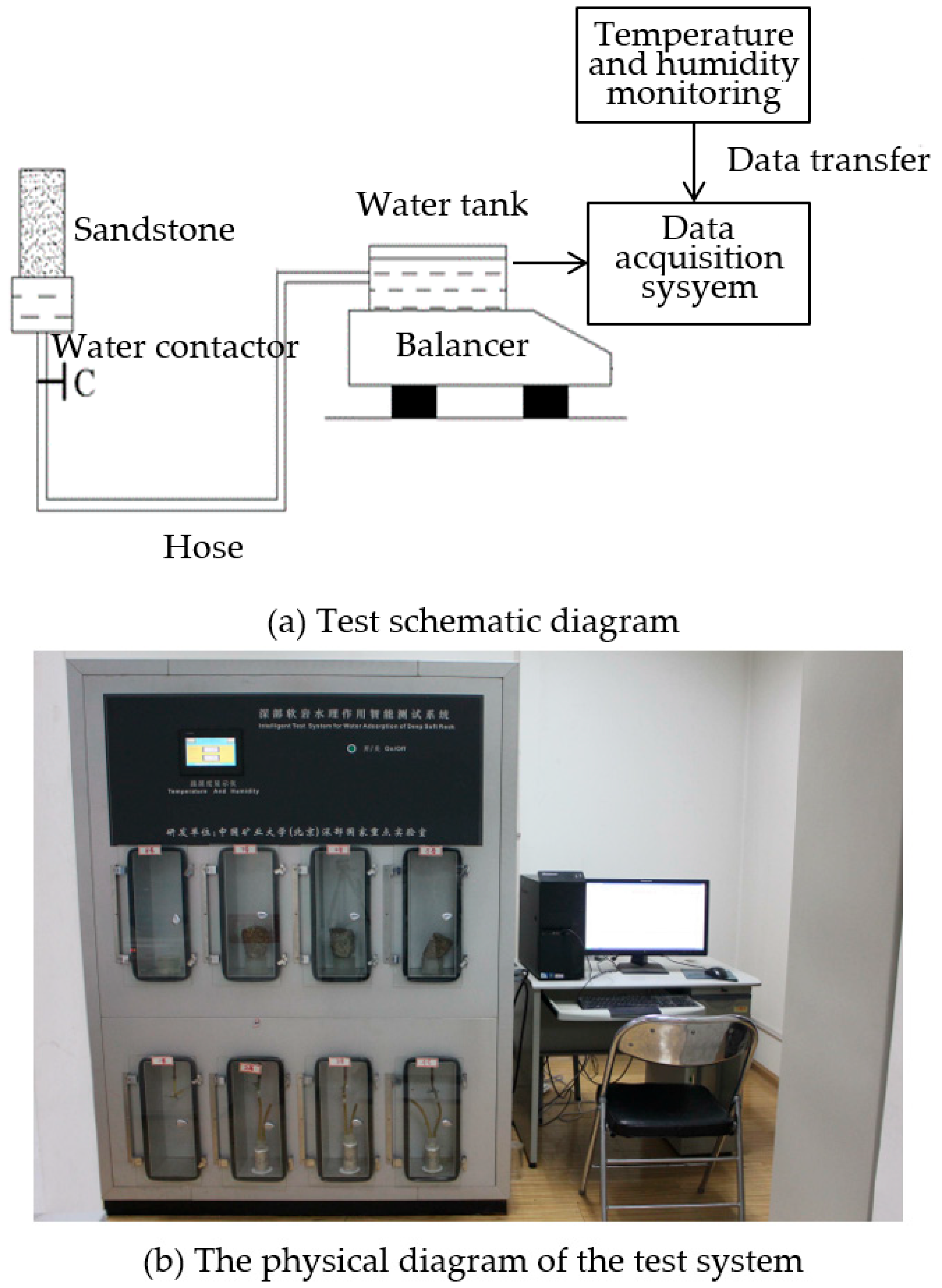

2.3. Pressure-Less Hydration Absorption Principle and Detection Scheme of Sandstone Samples

2.3.1. Principle of Pressure-Less Hydration Absorption

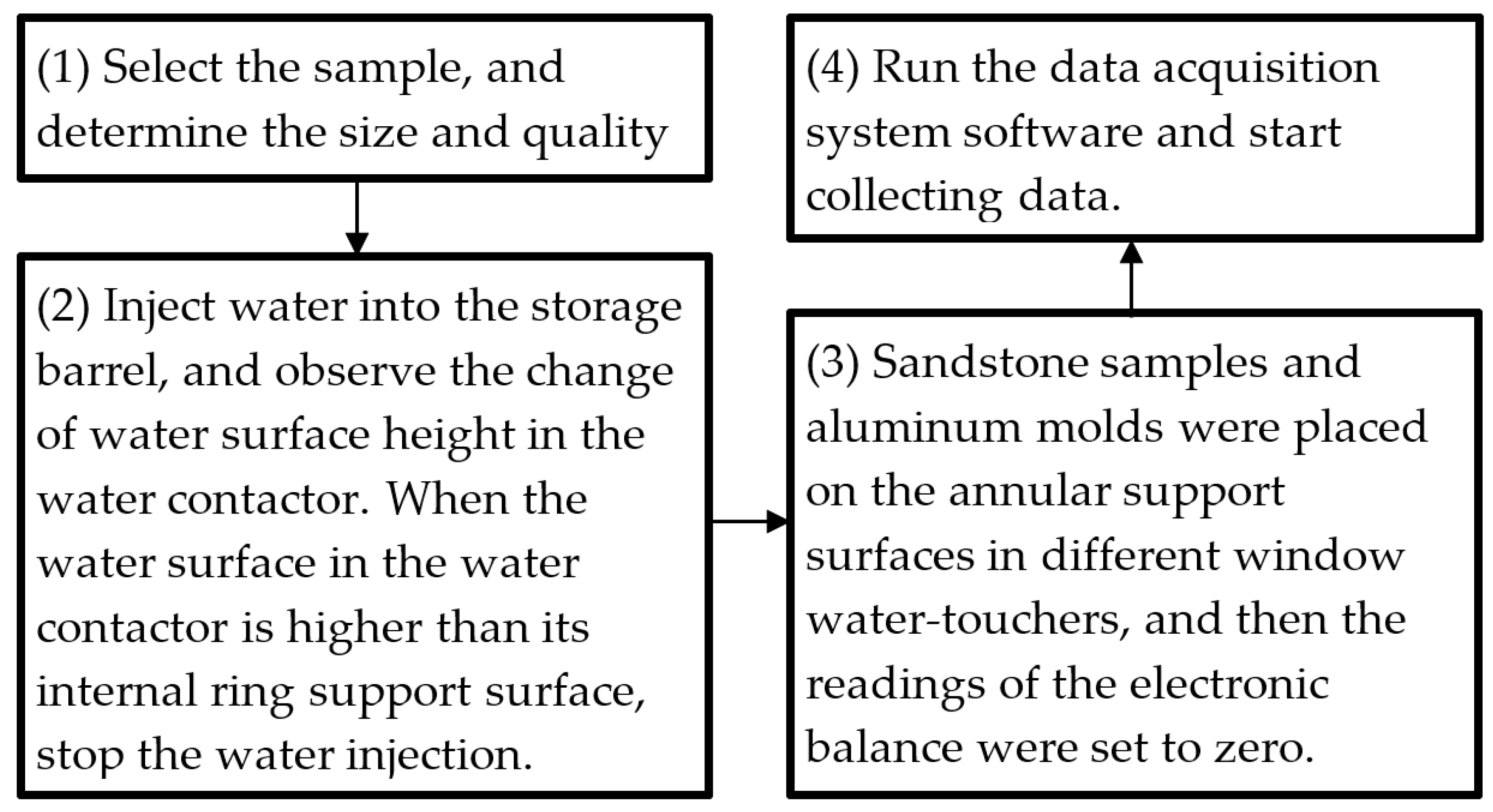

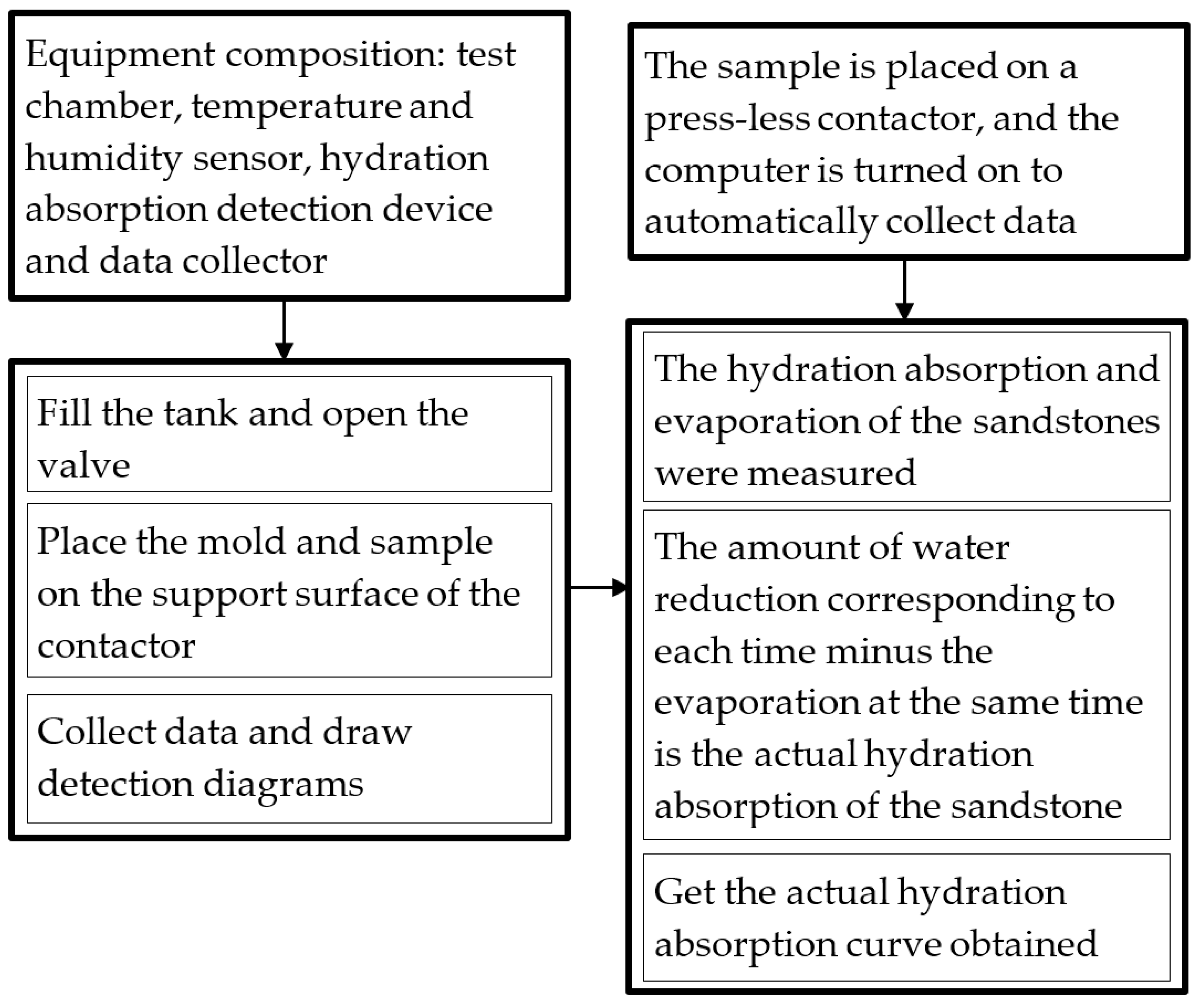

2.3.2. Pressure-Less Hydration Absorption Detection Scheme

2.4. Results and Analysis for Pressure-Less Hydration Absorption Characteristics of Sandstone

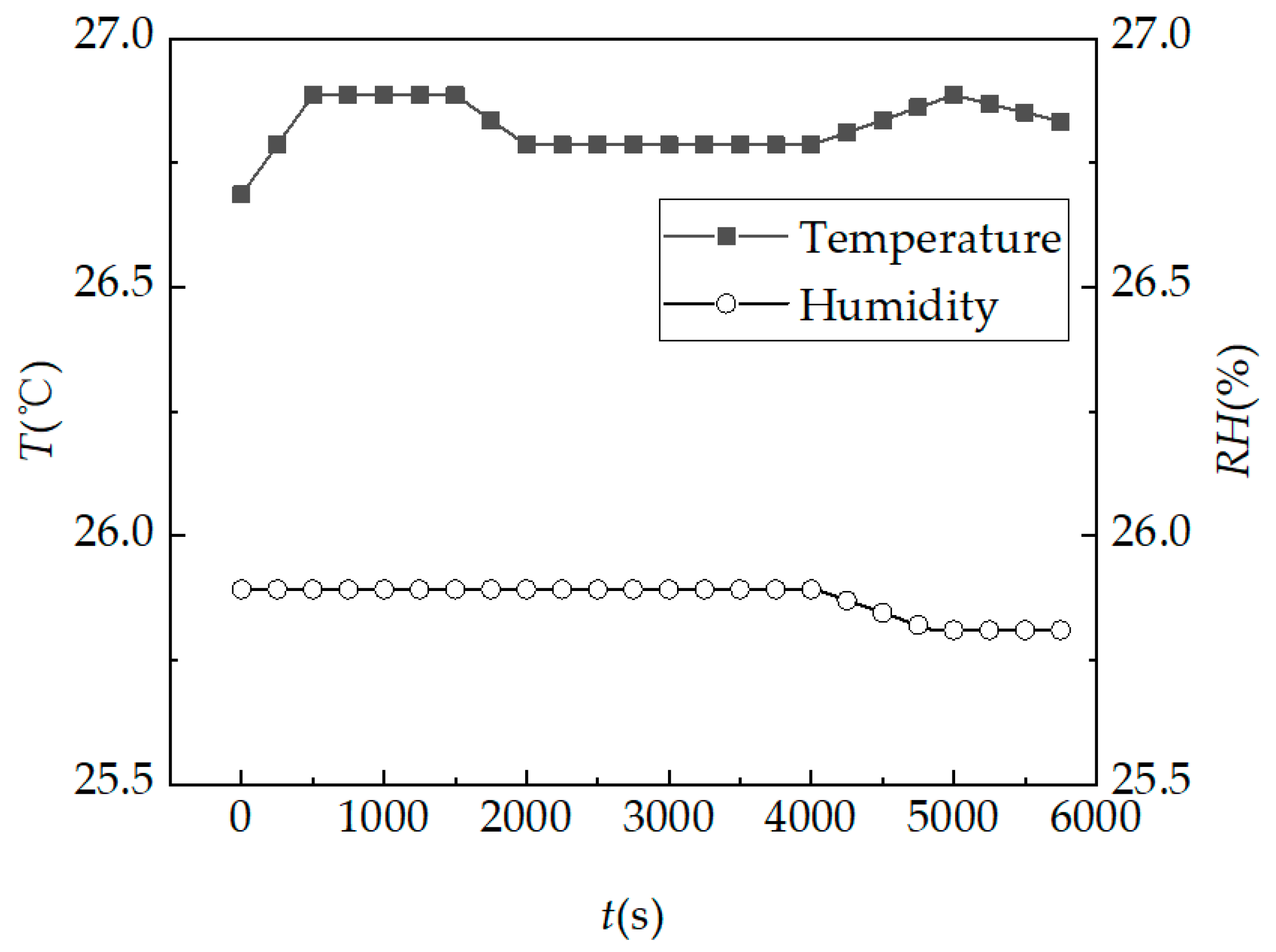

2.4.1. Environmental Temperature and Humidity Curve

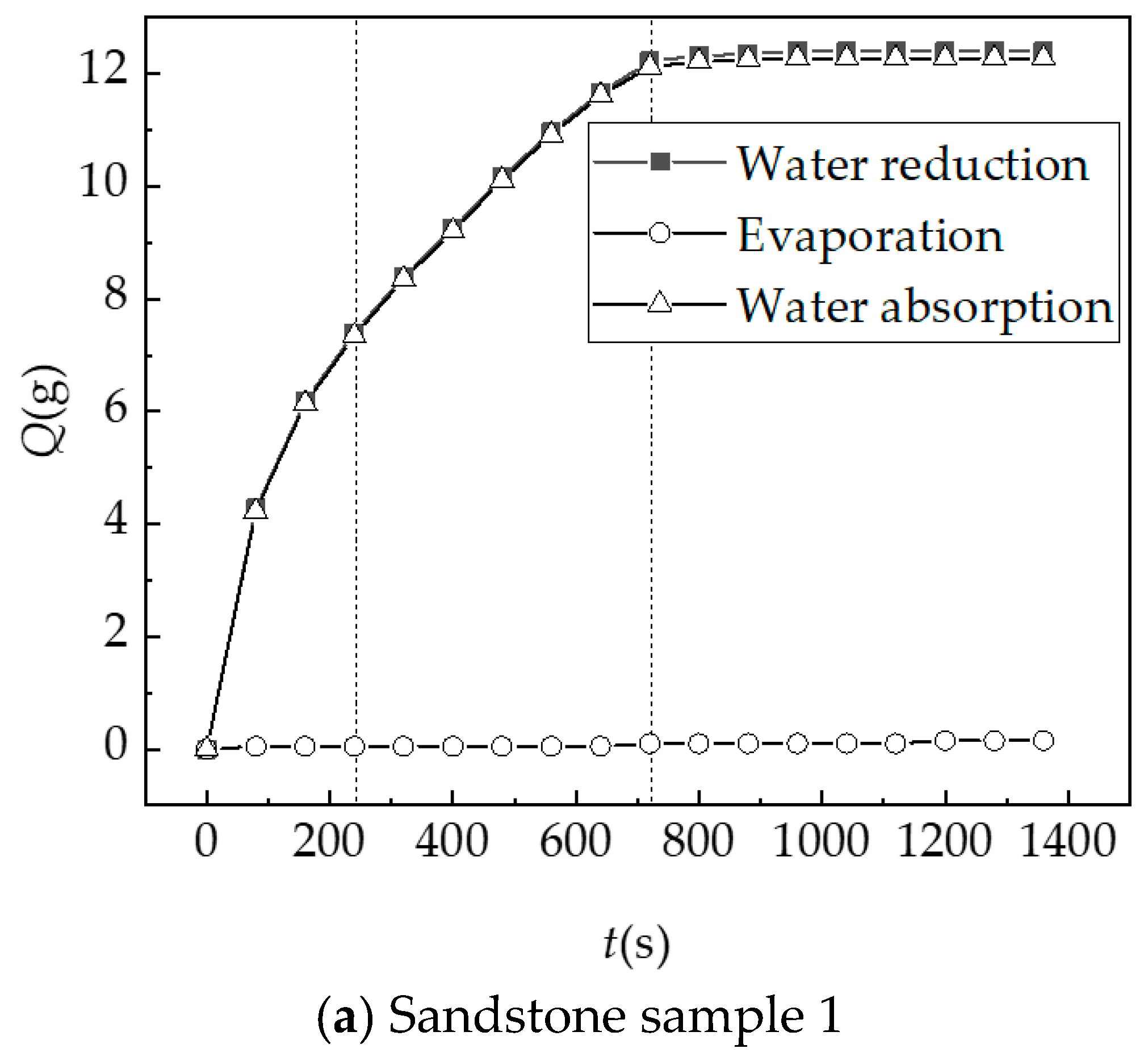

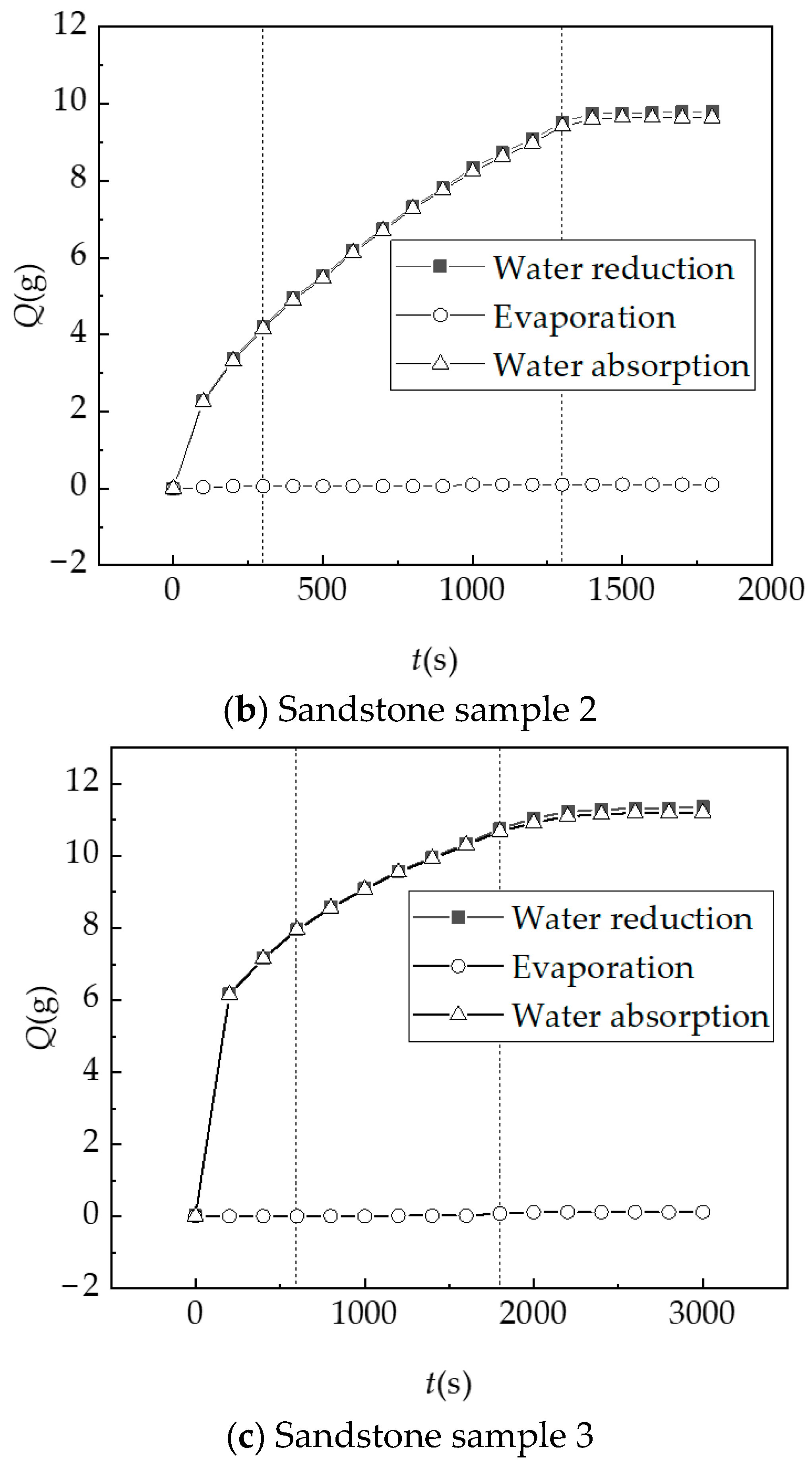

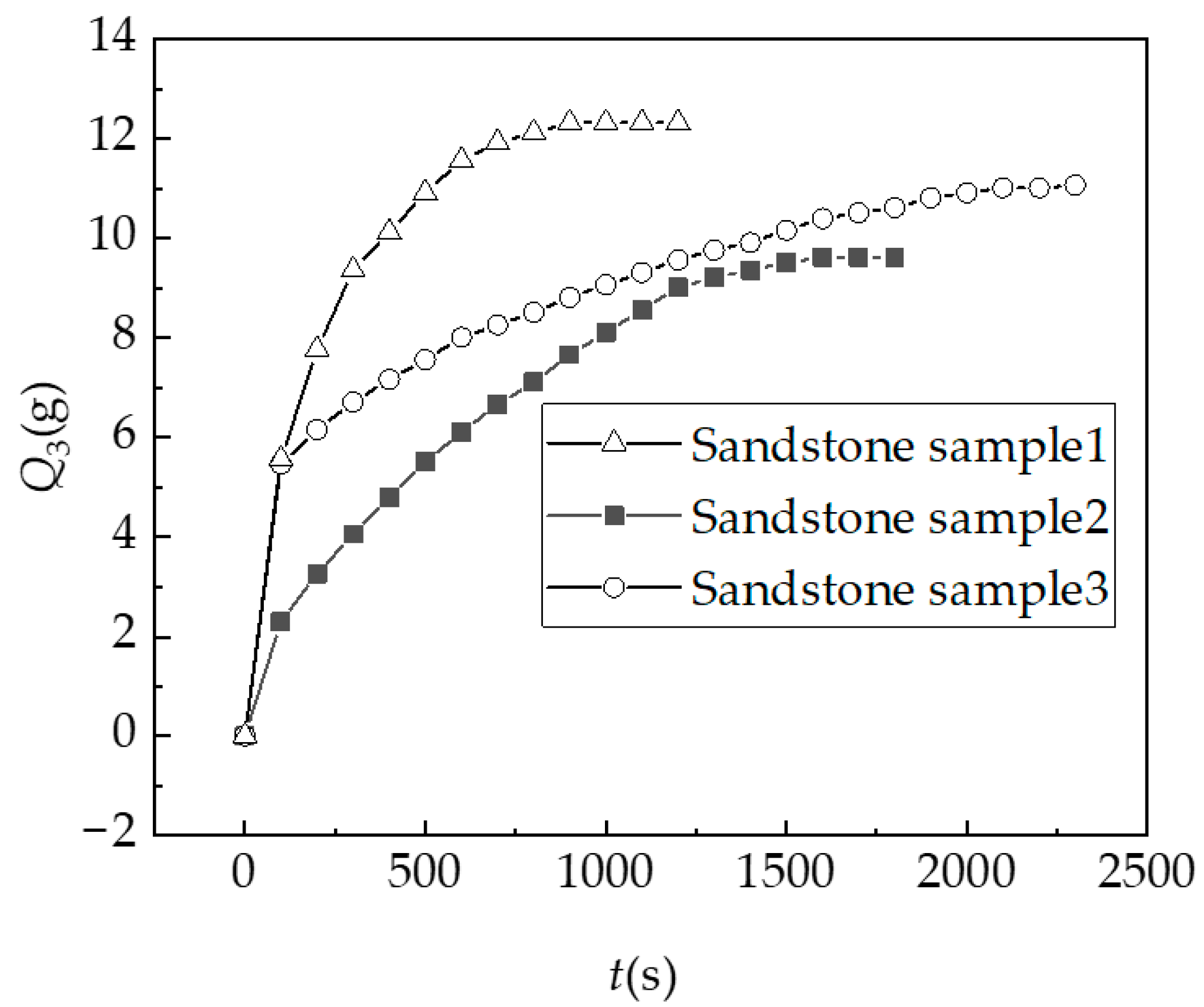

2.4.2. Relationship between Sandstone Hydration Absorption and Time

3. Hydration Absorption Deformation Characteristics of Outcrop Porous Sandstone

3.1. DIC Measurement Principle

3.2. Automatic Shooting Detection Device and Detection Scheme

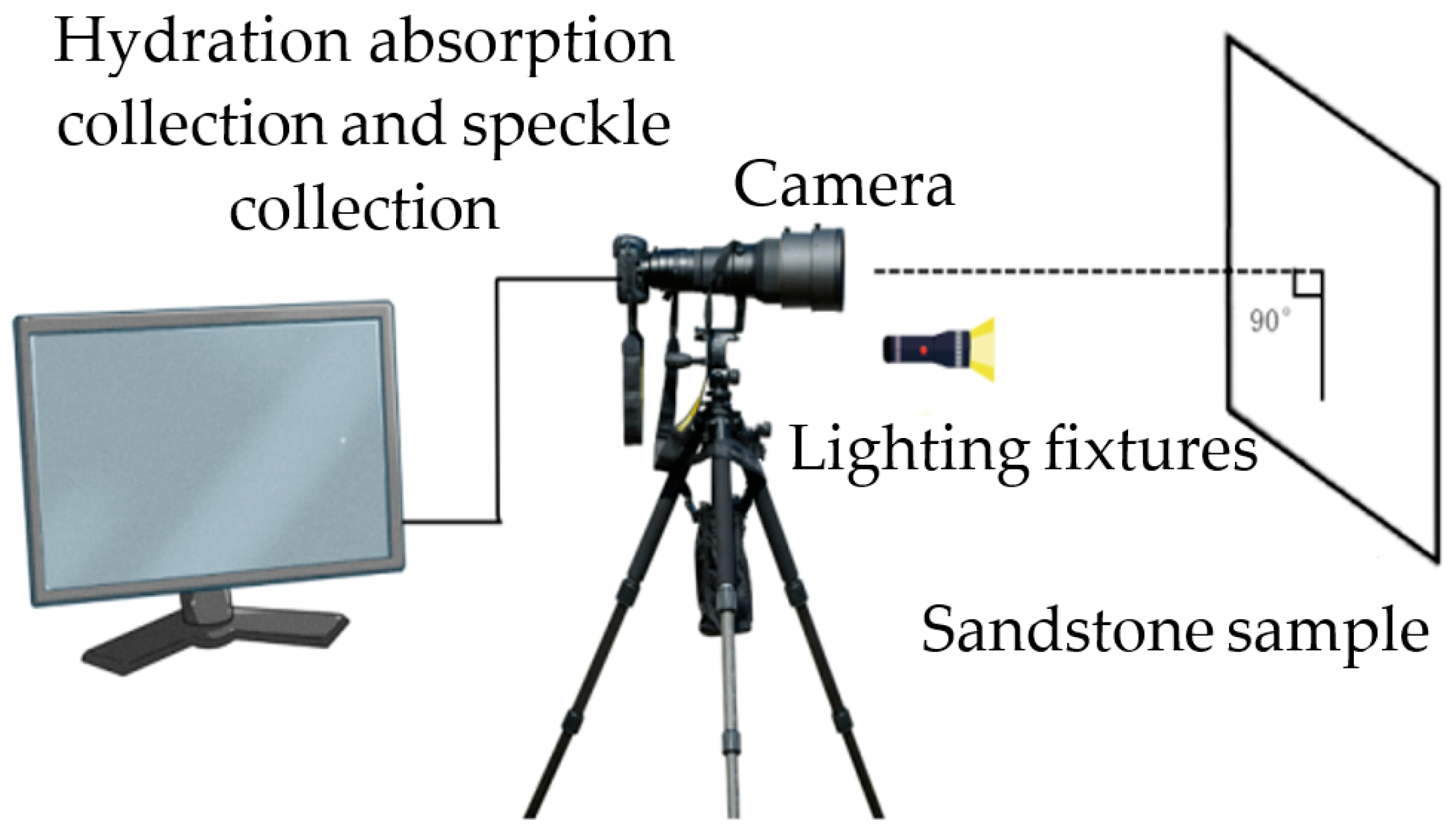

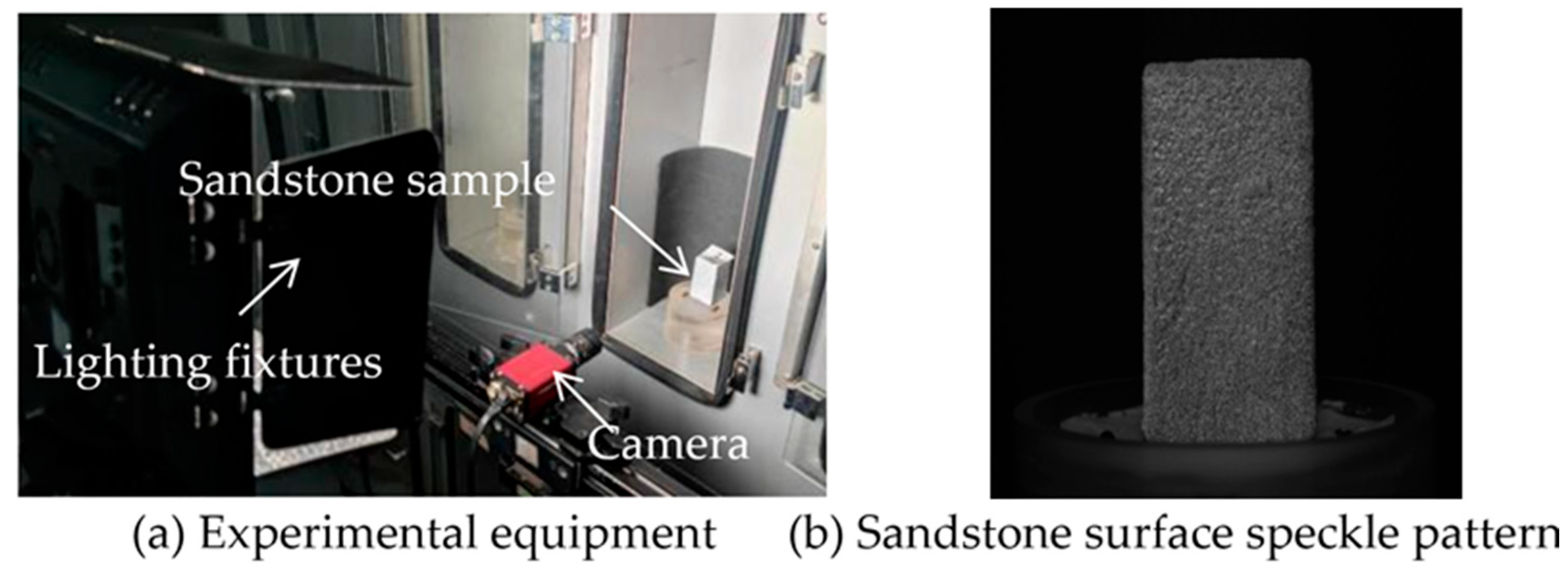

3.2.1. Automatic Shooting Detection Device

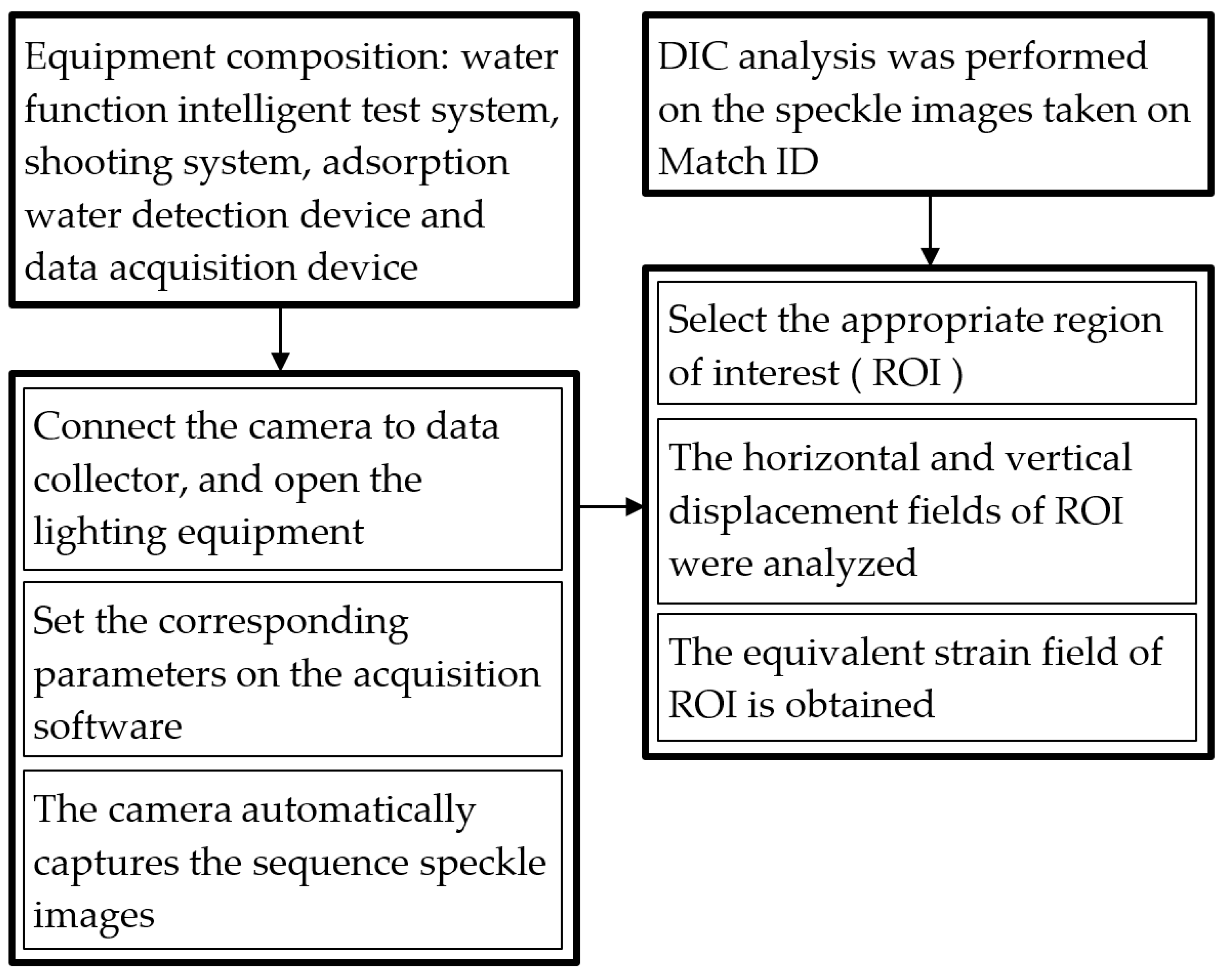

3.2.2. Detection Scheme

3.3. Results and Analysis for Pressure-Less Hydration Absorption Deformation Characteristics of Sandstone

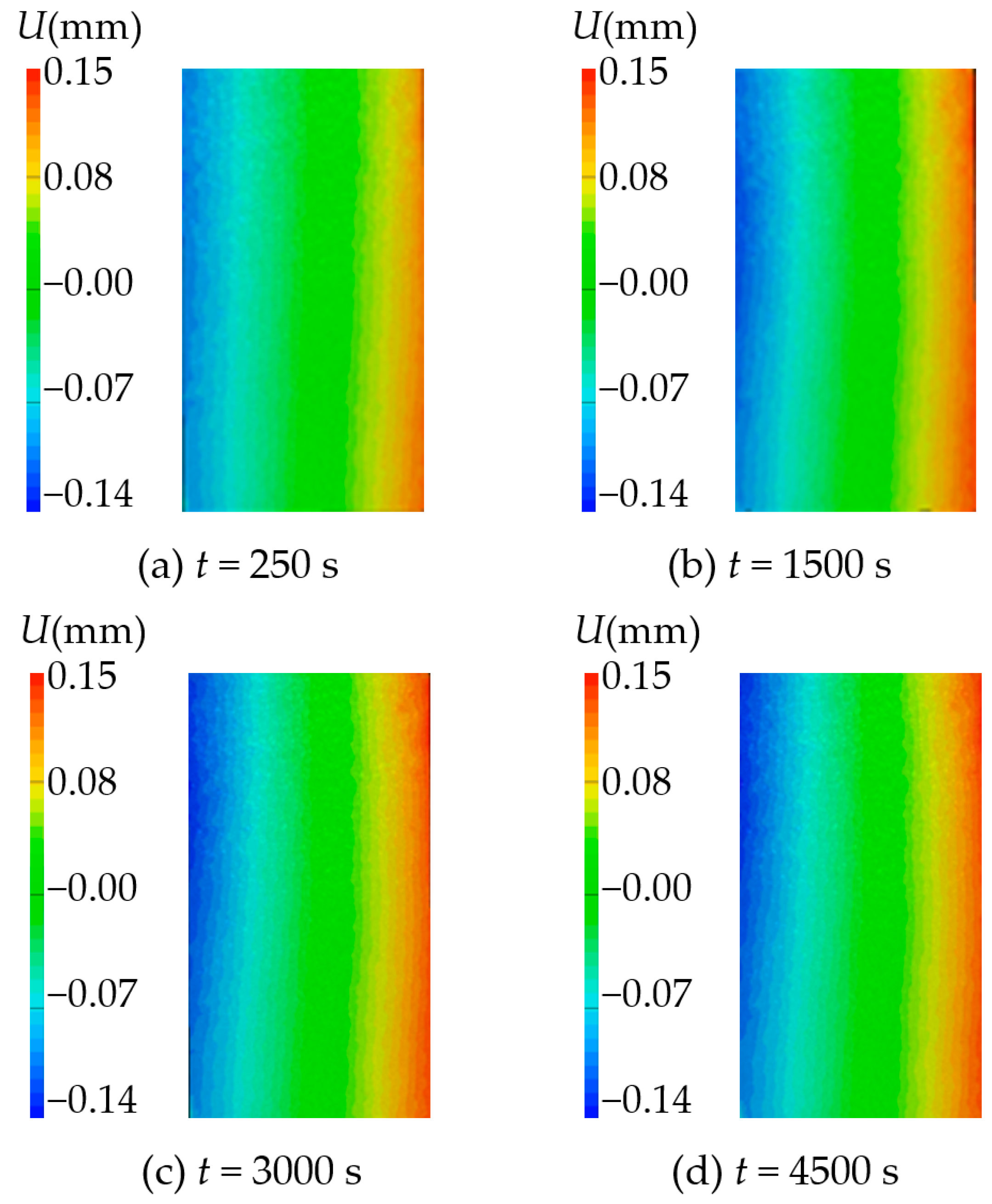

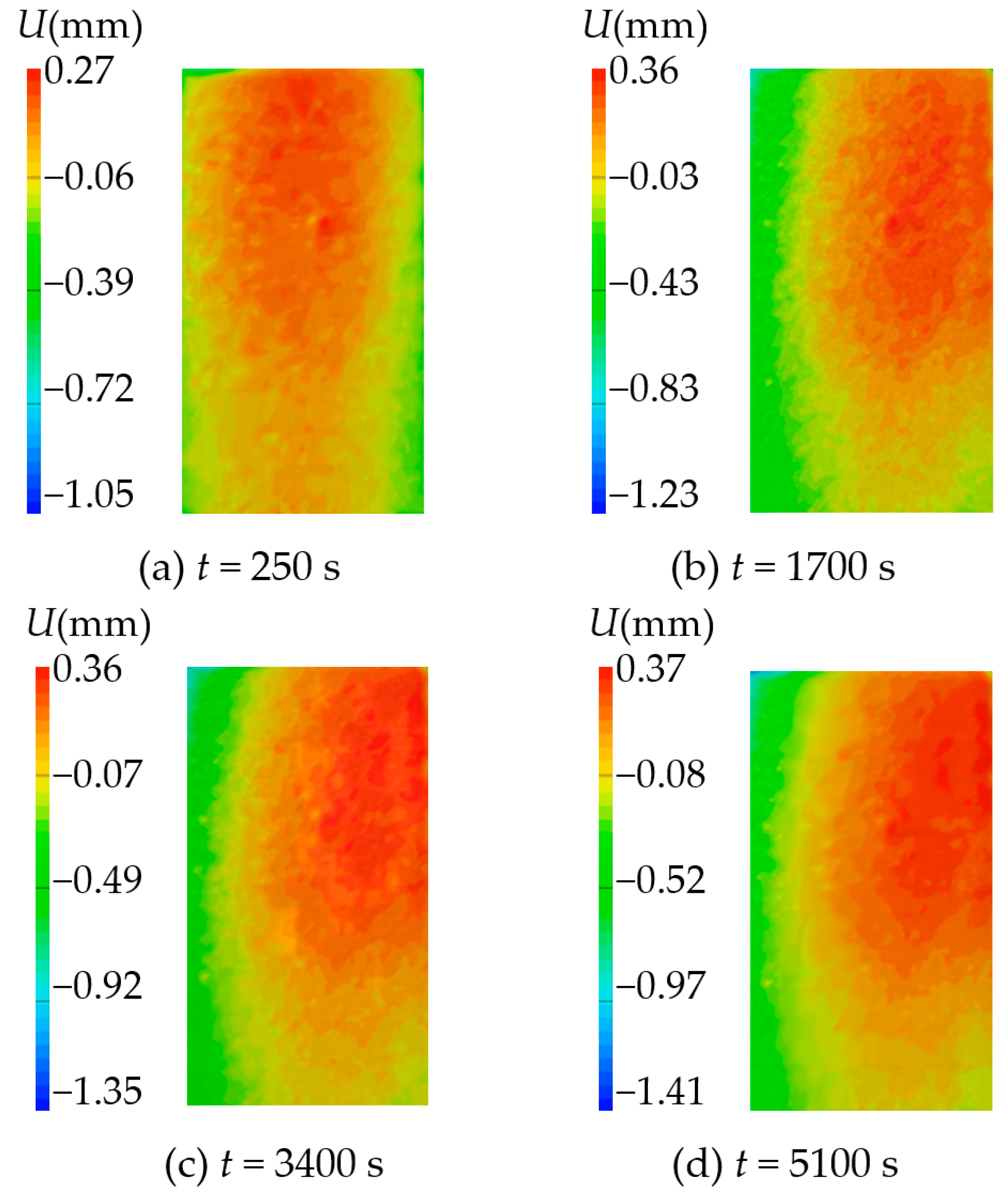

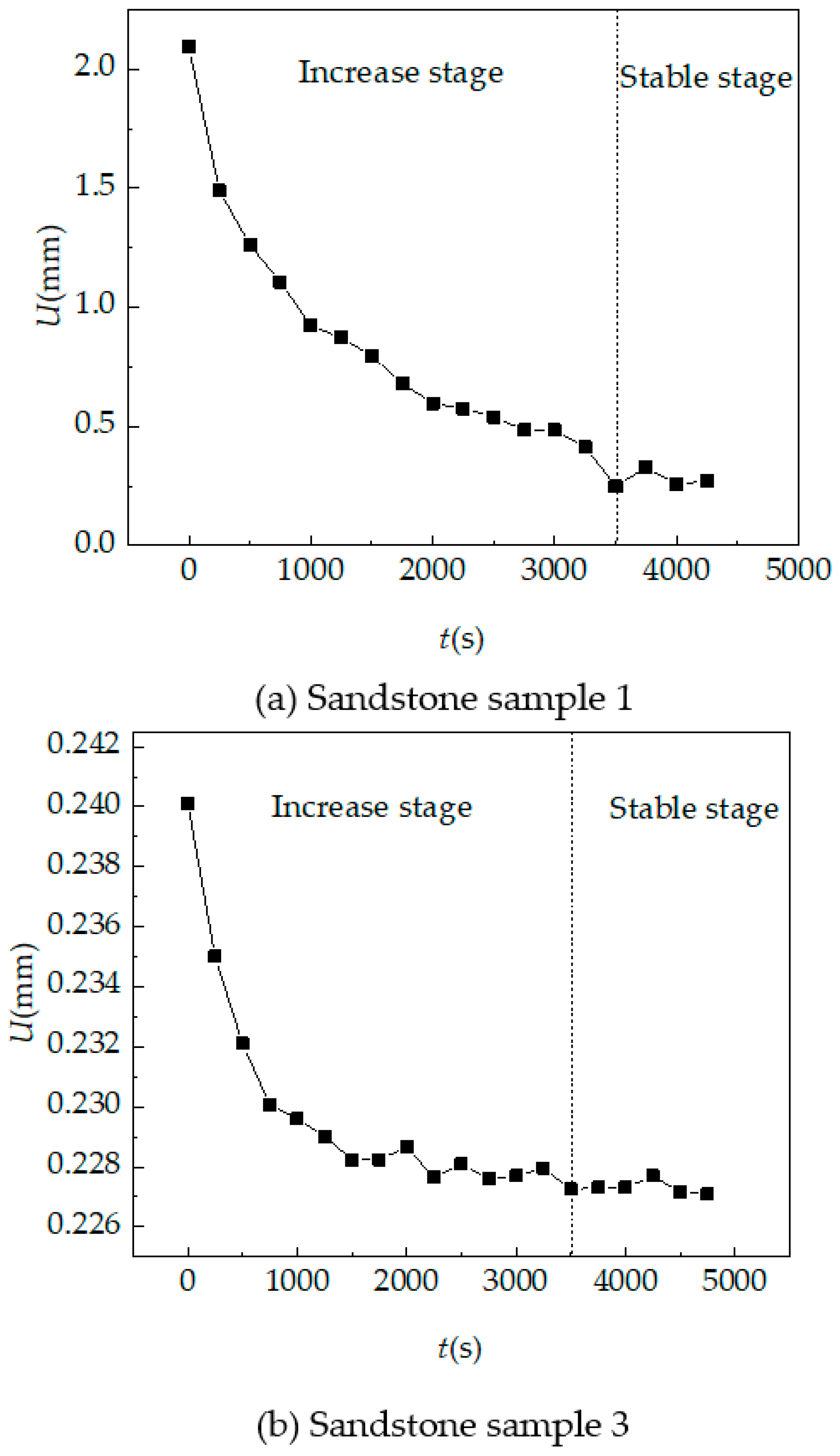

3.3.1. Displacement Field and Variation Curve

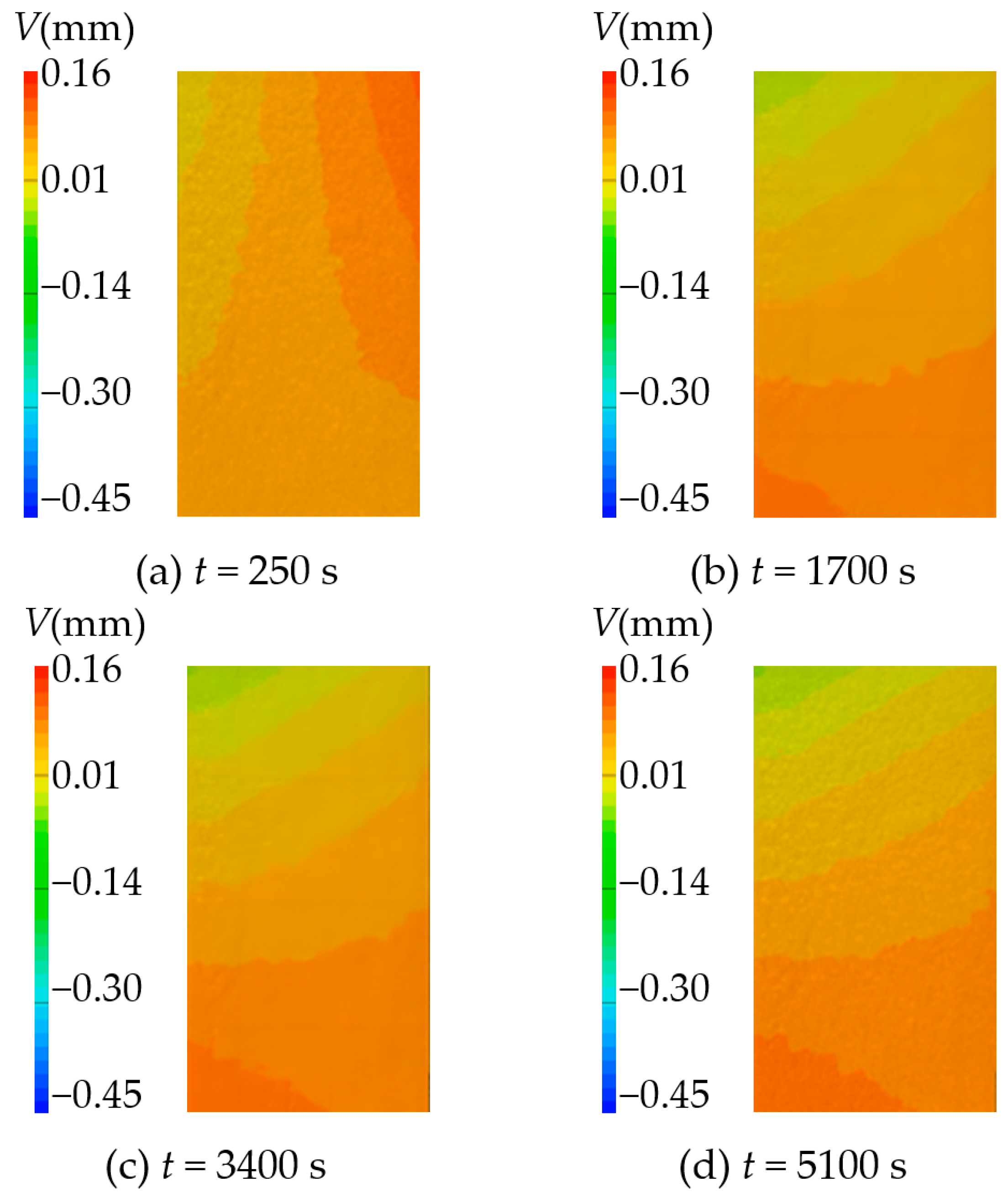

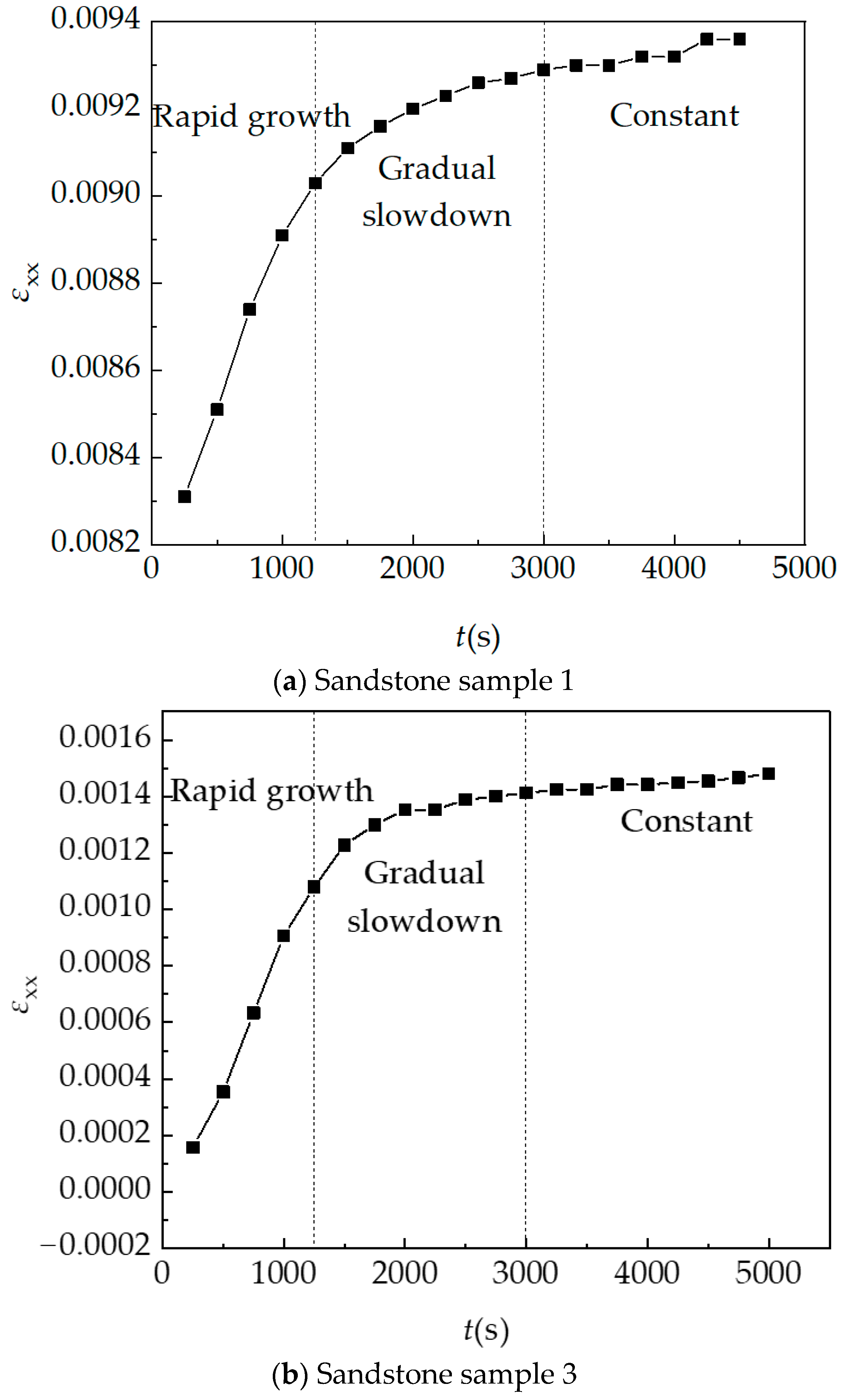

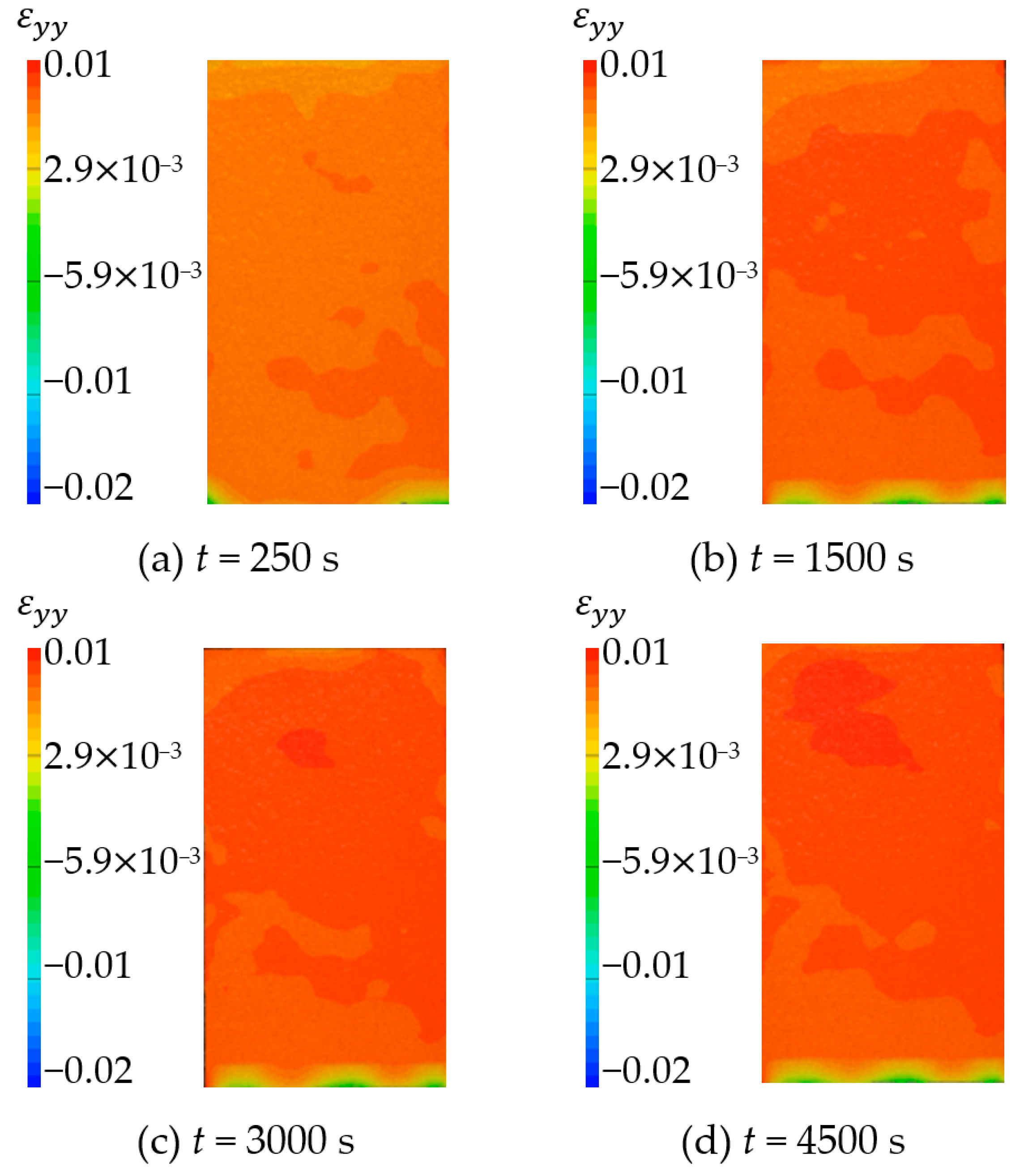

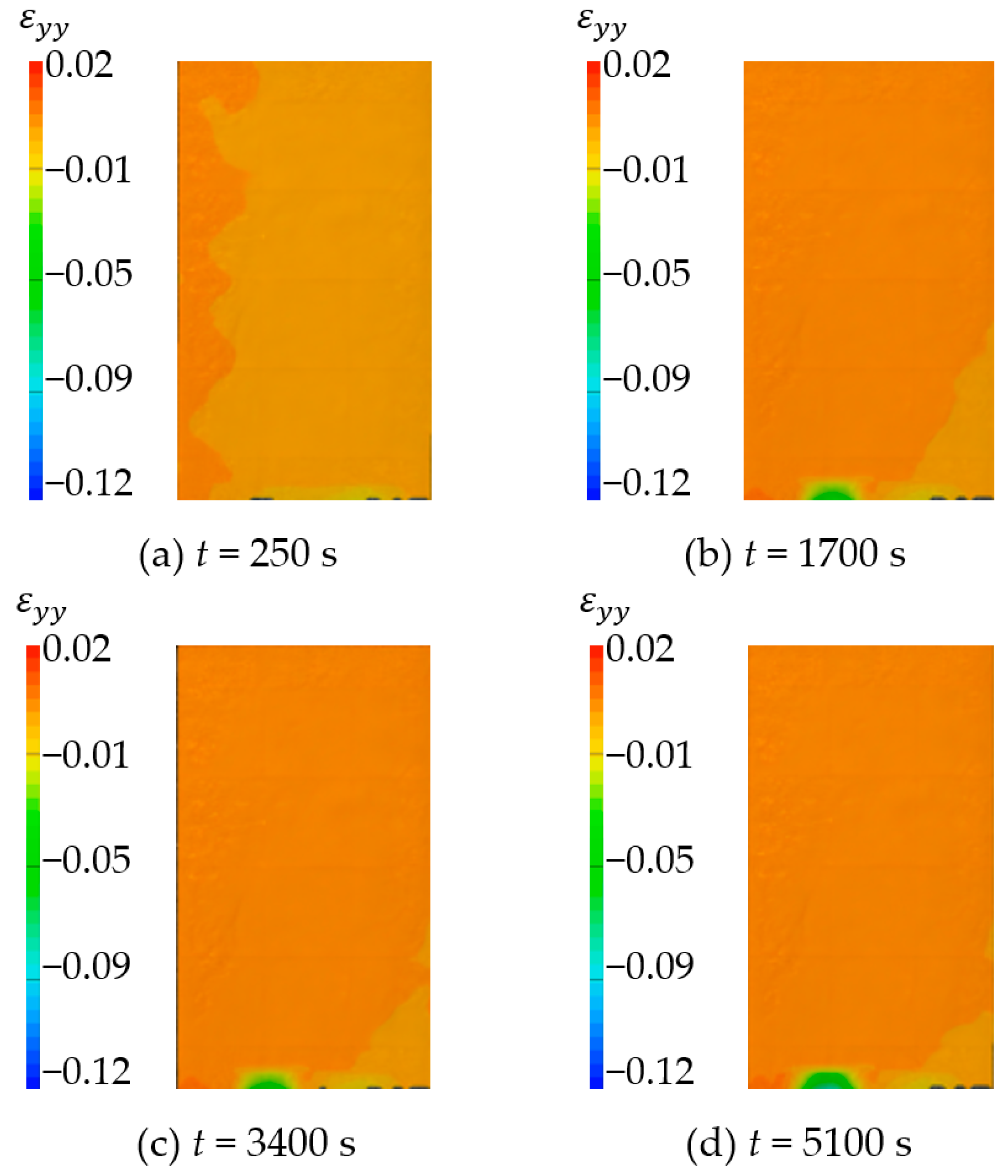

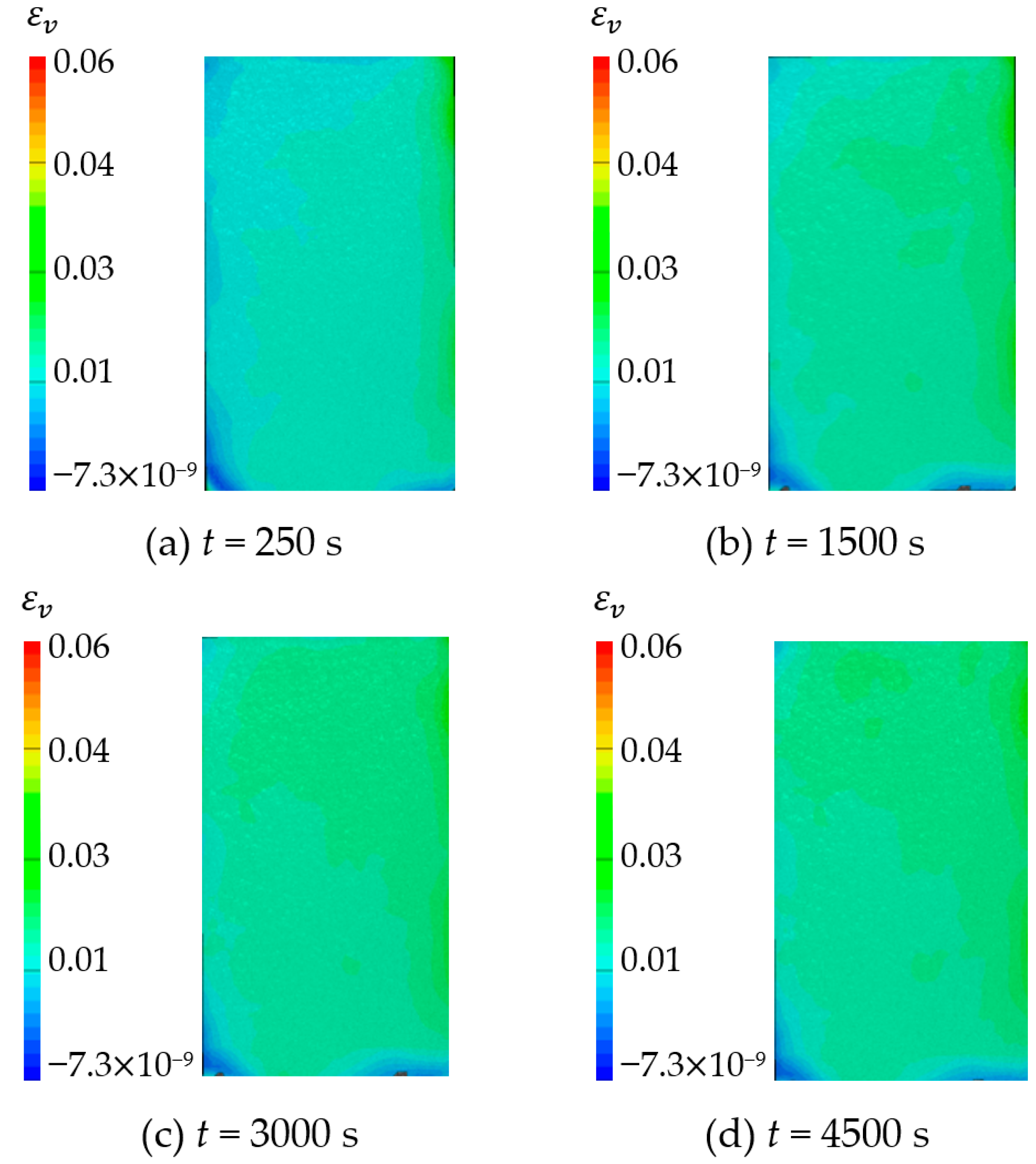

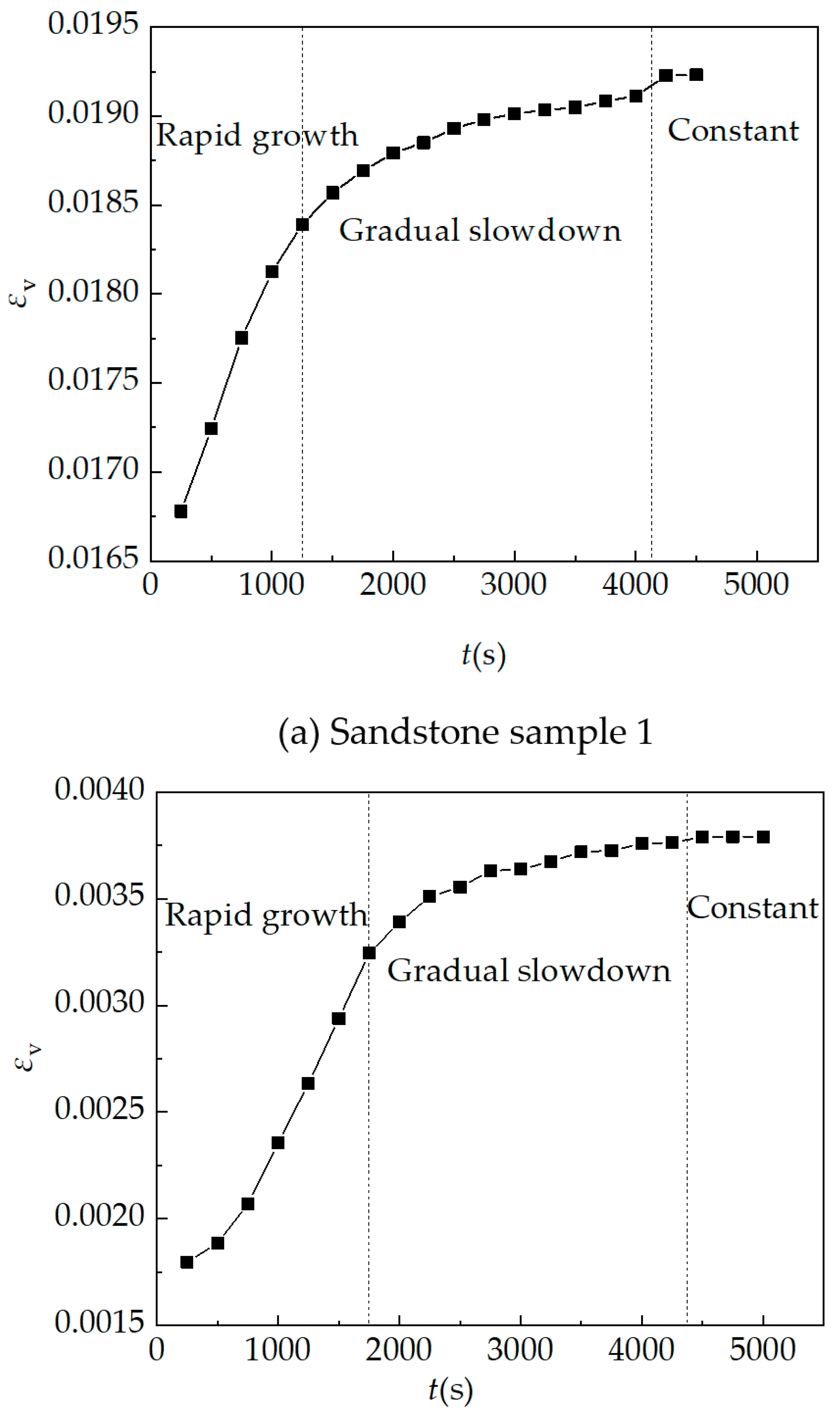

3.3.2. Strain Field and Strain Variation Curve

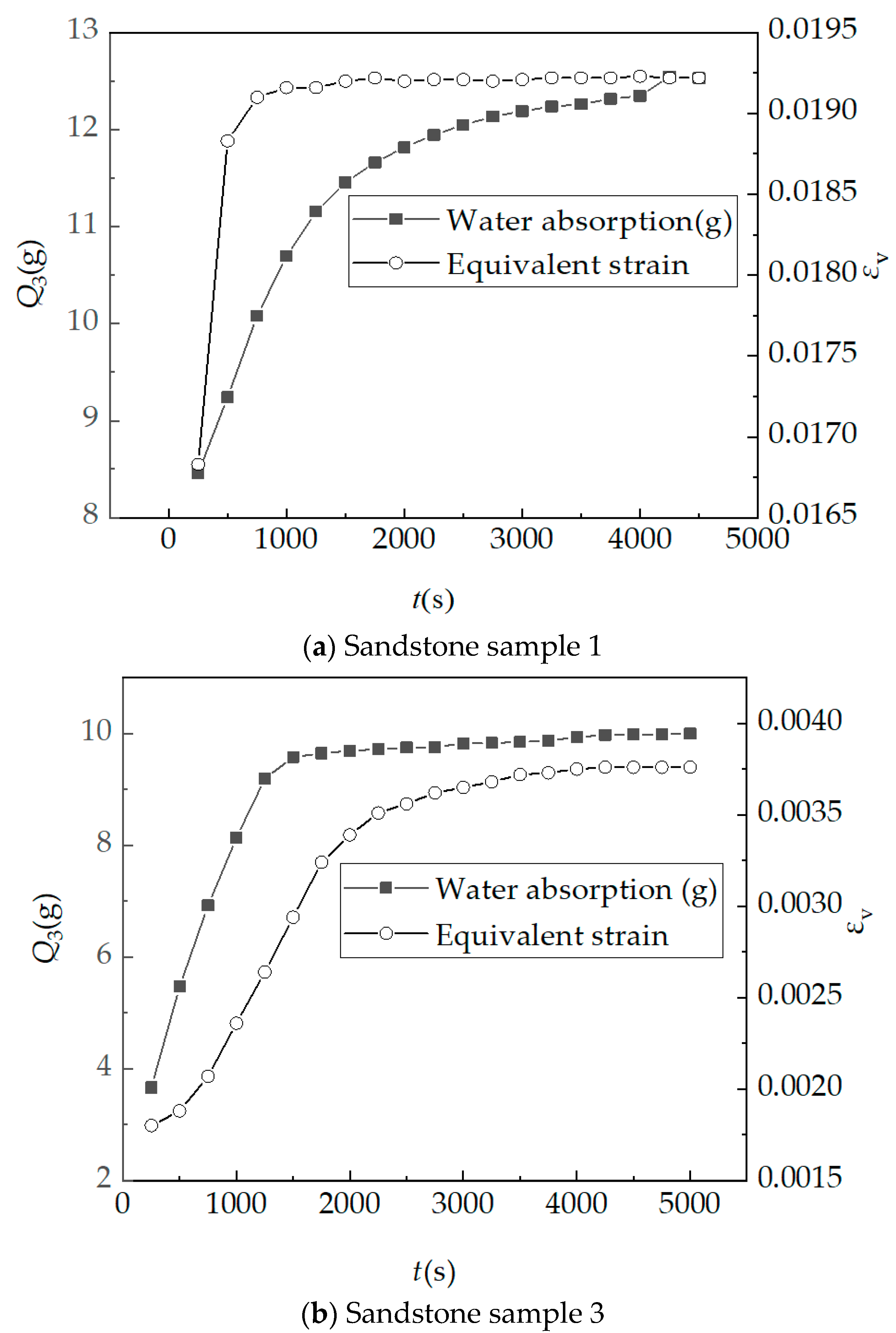

3.3.3. Relationship between Hydration Absorption and Deformation

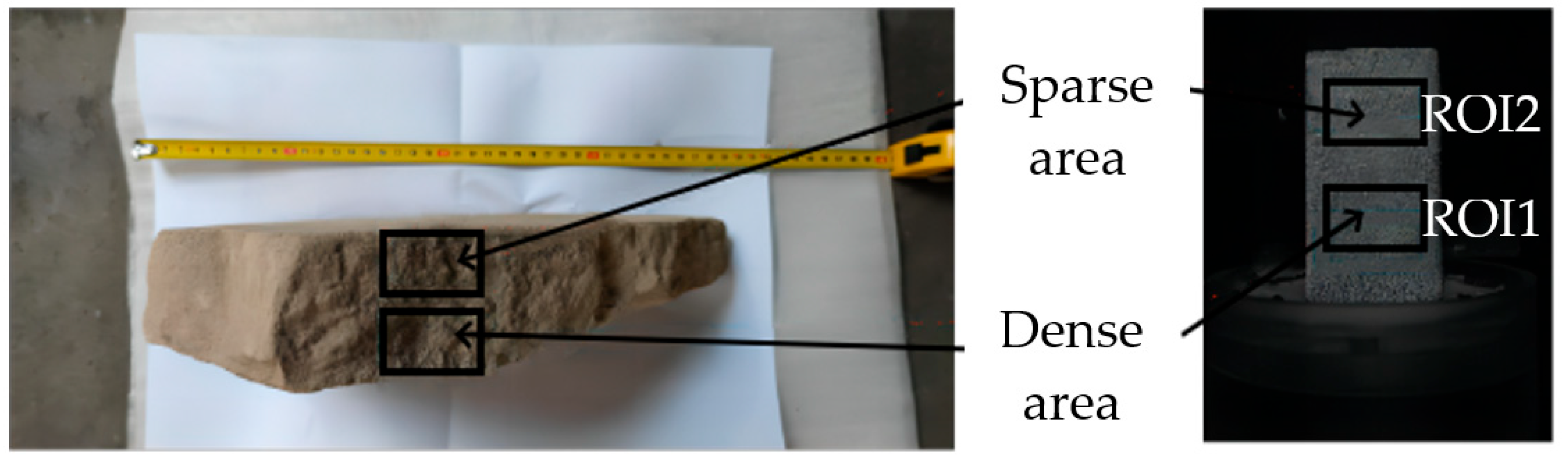

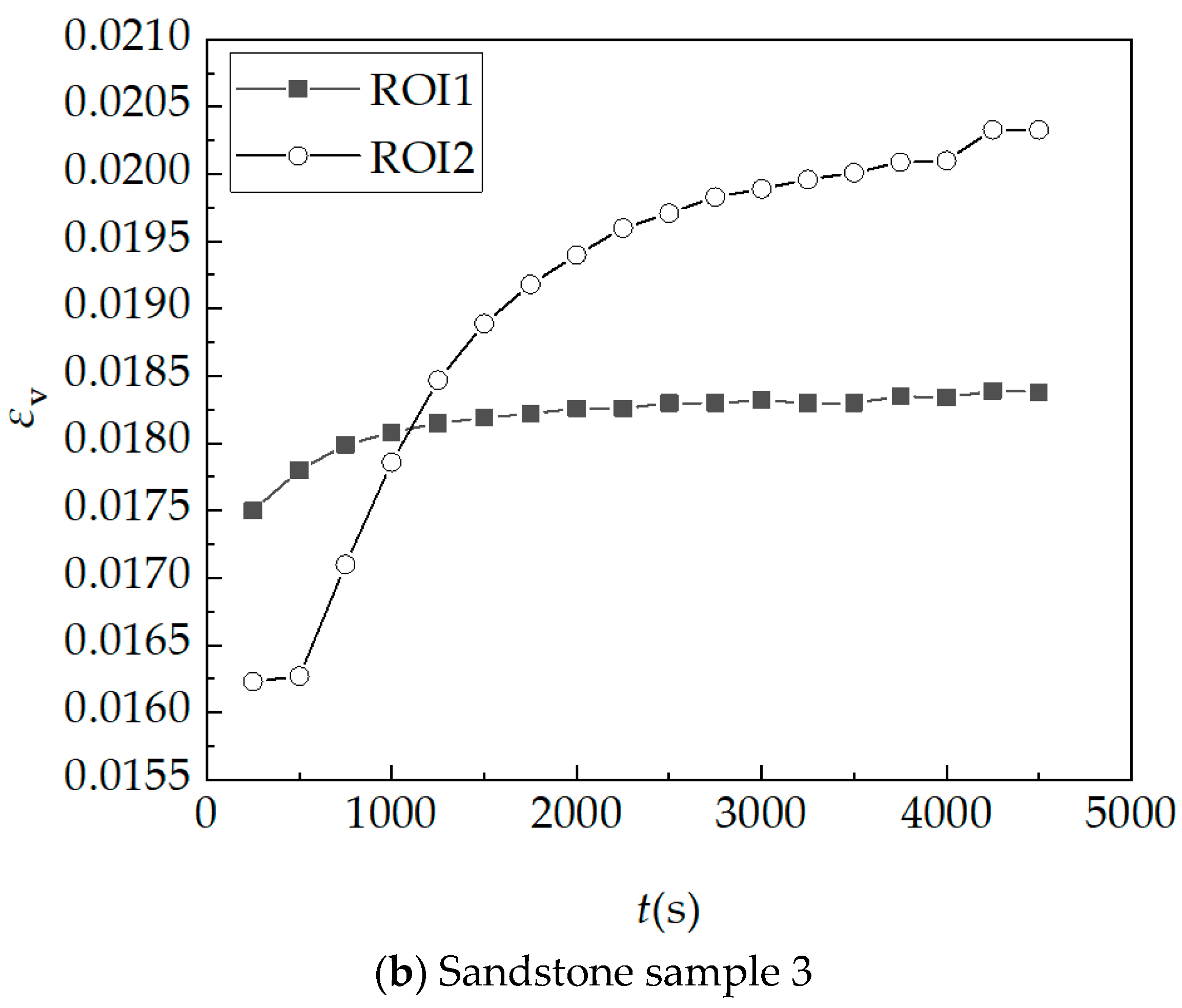

3.3.4. Deformation Curve in Different Density Areas

4. Conclusions

- (1)

- Through the real-time monitoring system, the pressure-less hydration absorption experiment of Mogao Grottoes sandstone under capillary action was carried out, and the water absorption curve of sandstone was obtained. The curve results show that the hydration absorption of sandstone can be divided into three stages: the initial stage increases rapidly, the intermediate stage increases slowly, and the final stage tends to be stable. The actual hydration absorption curve of sandstone can be well fitted using the exponential function.

- (2)

- The deformation characteristics of sandstone in the process of hydration absorption were analyzed using the DIC method, and the relationship between the pressure-less hydration absorption and deformation of sandstone was obtained. The deformation of sandstone increases rapidly in the initial stage, and the deformation of sandstone gradually slows down in the middle stage. When the water absorption reaches saturation, the interaction between water and sandstone still exists, and the sample continues to deform for a period of time before stopping. The bedding structure and particle composition of sandstone will affect the deformation of sandstone, resulting in uneven changes in sandstone.

- (3)

- The sandstone samples are divided into sparse and dense areas. The results of the mercury intrusion test and the XRD test show that the porosity of the sparse area is larger than that of the dense area, and the particle content of the dense area is lower. When the sandstone is saturated with water, the liquid is immersed in the pores between the solid particles, which makes the sparse area more prone to stress concentration, and the deformation in the sparse area is larger. Therefore, when analyzing the water absorption deformation of sandstone, the porosity should be considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y. Adaptive Analysis of Damage and Fracture in Rock with Multiphysical Fields Coupling; Springer Press: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Hao, N.; Wang, Y.; Wu, X.; Duan, Y.; Li, P.; He, M. Real-Time Experimental Monitoring for Hydration absorption Evolution Behaviors of Sandstone in Mogao Grottoes, China. Energies 2022, 15, 8504. [Google Scholar] [CrossRef]

- Yu, F.; Tong, K.; Dai, Z.; Feng, G.; Zhou, Z.; Chen, S. Macro and Micro research on Swelling Characteristics and Deformation Mechanism of Red-Bed Mudstone in Central Sichuan, China. Geofluids 2022, 2022, 6431590. [Google Scholar] [CrossRef]

- Yao, W.; Li, C.; Zhan, H.; Zhou, J.; Criss, R.; Xiong, S.; Jiang, X. Multiscale study of physical and mechanical properties of sandstone in three Gorges reservoir region subjected to cyclic wetting–drying of yangtze river water. Rock Mech. Rock Eng. 2020, 53, 2215–2231. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, M.; Li, X.; Zhang, B. Experimental Research on Coupling of Swelling Rock between Swelling and Creep. Appl. Mech. Mater. 2013, 353–356, 293–302. [Google Scholar] [CrossRef]

- Lin, Y.; Zhou, K.; Li, J.; Ke, B.; Gao, R. Weakening laws of mechanical properties of sandstone under the effect of chemical corrosion. Rock Mech. Rock Eng. 2020, 53, 1857–1877. [Google Scholar] [CrossRef]

- Sun, X.; Shi, F.; Ding, J.; Tao, Z.; Zhang, Y.; Miao, C.; Cui, L. Study on Microscopic Mechanism and Failure Mode of Water–Rock Coupling in Fine Sandstone Under Uniaxial Compression. Rock Mech. Rock Eng. 2023, 56, 6823–6842. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L.; Sun, X.; Wang, J. Experimental study of the influence of water and temperature on the mechanical behavior of mudstone and sandstone. Bull. Eng. Geol. Environ. 2017, 76, 645–660. [Google Scholar] [CrossRef]

- Yuan, P.; Wei, N.; Ma, Q.; Chang, J. Coupled effect of water temperature and cyclic wetting and drying on dynamic mechanical characteristics of sandstone. Adv. Civ. Eng. 2019, 2019, 8167651. [Google Scholar] [CrossRef]

- Peters, W.; Ranson, W. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Sutton, M.; Orteu, J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Yang, D.; Bornert, M.; Chanchole, S.; Wang, L.; Valli, P.; Gatmiri, B. Experimental investigation of the delayed behavior of unsaturated argillaceous rocks by means of digital image correlation techniques. Appl. Clay Sci. 2011, 54, 53–62. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Song, H.; Kang, Y. Experimental investigation of deformation and failure mechanisms in rock under indentation by digital image correlation. Eng. Fract. Mech. 2012, 96, 667–675. [Google Scholar] [CrossRef]

- Wang, L.; Bornert, M.; Héripré, E.; Yang, D.; Chanchole, S. Irreversible deformation and damage in argillaceous rocks induced by wetting/drying. Appl. Geophys. 2014, 107, 108–118. [Google Scholar] [CrossRef]

- Wang, L.L.; Bornert, M.; Héripré, E.; Chanchole, S.; Pouya, A.; Halphen, B. The mechanisms of deformation and damage of mudstones: A micro-scale study combining ESEM and DIC. Rock Mech. Rock Eng. 2015, 48, 1913–1926. [Google Scholar] [CrossRef]

- Wang, L.; Yang, R.; Chanchole, S.; Zhang, G. The time-dependent swelling of argillaceous rock under resaturated conditions. Appl. Clay Sci. 2017, 146, 186–194. [Google Scholar] [CrossRef]

- Luo, P.; Wang, L.; Li, D.; Yang, J.; Lv, X. Deformation and failure mechanism of horizontal soft and hard interlayered rock under uniaxial compression based on digital image correlation method. Eng. Fail. Anal. 2022, 142, 106823. [Google Scholar] [CrossRef]

- Ji, X.; Zhang, T.; Ji, B.; Zhang, L.; Pang, M.; Pan, H.; Ji, B. Gray characteristics analysis of strain field of coal and rock bodies around boreholes during progressive damage based on digital image. Rock Mech. Rock Eng. 2023, 56, 5607–5620. [Google Scholar] [CrossRef]

- Yang, P.; Miao, S.; Ma, Y.; Yu, W.; Shang, X. Multi-dimensional non-uniform deformation and failure of siltstone determined using acoustic, 3D-digital image correlation, and computed tomography. Theor. Appl. Fract. Mech. 2023, 125, 103800. [Google Scholar]

- Xin, C.; Yang, Y.; Yang, M.; Liang, P.; Sun, Y.; Shen, H. Study on Strain Field Evolution of Uniaxial Compression Sandstone Based on Digital Image Correlation Technology. Appl. Sci. 2022, 12, 11939. [Google Scholar] [CrossRef]

- Yao, G.; Wang, G.; Tan, L.; Zhang, Y.; Wang, R.; Yang, X. Fracture Evolution and Mechanical Properties of Mortar Containing Different Inclusions. Appl. Sci. 2024, 14, 3166. [Google Scholar] [CrossRef]

- Jin, T.; Sun, X.; Liu, K.; Lin, S.; Yang, S.; Xie, J. Experimental Study of the Multiple Fractalisation of Coal and Rock Failure Subjected to the Coupled Effects of Water, Temperature and Dynamic Loads. Appl. Sci. 2023, 13, 13004. [Google Scholar] [CrossRef]

- Hagara, M.; Huňady, R.; Lengvarský, P.; Vocetka, M.; Palička, P. The Calibration Process and Setting of Image Brightness to Achieve Optimum Strain Measurement Accuracy Using Stereo-Camera Digital Image Correlation. Appl. Sci. 2023, 13, 9512. [Google Scholar] [CrossRef]

- Yan, F.; Qi, C.; Shan, R. Spatial-Temporal Heterogeneity in the Deformation and Damage of Rock Samples: Experimental Study Using Digital Image Correlation Analysis. Appl. Sci. 2022, 12, 1364. [Google Scholar] [CrossRef]

| Sandstone Samples | Length/mm | Width/mm | Height/mm | Dry Quality/g |

|---|---|---|---|---|

| 1 | 29.50 | 29.00 | 51.90 | 83.87 |

| 2 | 29.60 | 29.00 | 52.00 | 83.49 |

| 3 | 29.70 | 29.50 | 51.80 | 83.53 |

| Average | 29.60 | 29.20 | 51.90 | 83.63 |

| Parameter | Value | Units |

|---|---|---|

| Total intrusion volume at 57,958.05 psia | 0.1842 | mL/g |

| Total pore area at 57,958.05 psia | 0.548 | m2/g |

| Median pore diameter (volume) at 8.26 psia and 0.092 mL/g | 21,890.11 | nm |

| Median pore diameter (area) at 4045.16 psia and 0.274 m2/g | 44.71 | nm |

| Average pore diameter (4 V/A) | 1344.78 | nm |

| Bulk density at 0.52 psia | 1.7817 | g/mL |

| Apparent (skeletal) density at 57,958.05 psia | 2.6525 | g/mL |

| Porosity | 32.8271 | % |

| Mineral Content (%) | ||||||

|---|---|---|---|---|---|---|

| Quartz | Potassium Feldspar | Plagioclase | Calcite | Dolomite | Hornblende | Clay Mineral |

| 29.0 | 4.1 | 31.9 | 12.3 | 7.6 | 4.9 | 10.2 |

| Relative Content of Clay Minerals (%) | Mixed Layer Ratio (S,%) | ||||||

|---|---|---|---|---|---|---|---|

| S | I/S | It | Kao | C | C/S | I/S | C/S |

| / | / | 65 | 6 | 29 | / | / | / |

| Sandstone Sample | Fitting Parameters | |||||

|---|---|---|---|---|---|---|

| 1 | 0.006 | 11.330 | 1.777 | 250.754 | 11.618 | 0.994 |

| 2 | 11.644 | −5.812 | −4.793 | 901.038 | 31.262 | 0.994 |

| 3 | 12.318 | −5.272 | −7.204 | 21.583 | 1230.442 | 0.999 |

| Sandstone Sample | Time | Moisture Reduces Quality | Evaporation Water Quality | Automatic Measurement of Hydration Absorption Quality | Initial Quality before Detection | Saturated Mass after Detection | Artificial Measurement of Hydration Absorption Quality | Hydration Absorption Error |

|---|---|---|---|---|---|---|---|---|

| 1 | 946 | 12.61 | 0.20 | 12.41 | 83.87 | 95.98 | 12.11 | 2.47 |

| 2 | 1613 | 9.76 | 0.14 | 9.62 | 83.49 | 94.40 | 10.91 | −11.80 |

| 3 | 1990 | 11.39 | 0.28 | 11.11 | 83.53 | 94.20 | 10.67 | 3.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, N.; Wang, Y.; Zhao, Y.; Jiang, W.; Li, P.; Liu, N. DIC-Based Hydration Absorption Detection and Displacement Field Evolution of Outcrop Porous Sandstone. Appl. Sci. 2024, 14, 4490. https://doi.org/10.3390/app14114490

Hao N, Wang Y, Zhao Y, Jiang W, Li P, Liu N. DIC-Based Hydration Absorption Detection and Displacement Field Evolution of Outcrop Porous Sandstone. Applied Sciences. 2024; 14(11):4490. https://doi.org/10.3390/app14114490

Chicago/Turabian StyleHao, Nai, Yongliang Wang, Yi Zhao, Wujie Jiang, Panshun Li, and Nana Liu. 2024. "DIC-Based Hydration Absorption Detection and Displacement Field Evolution of Outcrop Porous Sandstone" Applied Sciences 14, no. 11: 4490. https://doi.org/10.3390/app14114490