Research on an Index System for the Earthquake Disaster Resistance Capability of Highway Tunnels

Abstract

1. Introduction

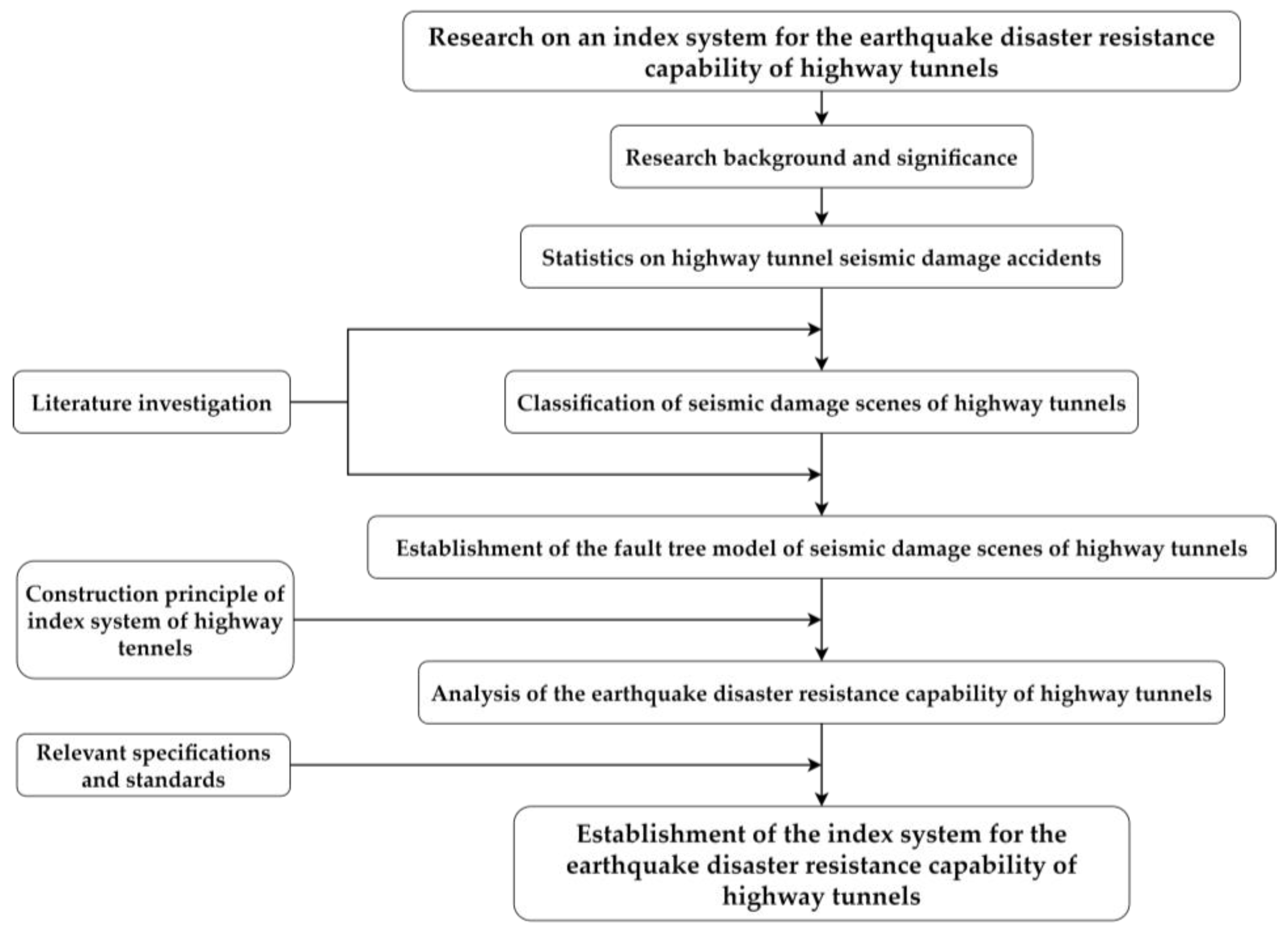

2. Analysis of Seismic Damage Scenes in Highway Tunnels

3. Identification of the Factors Influencing the Earthquake Disaster Resistance Capability of Highway Tunnels

3.1. Identification Process of the Influencing Factors of Seismic Damage in Highway Tunnels

3.2. Analysis of the Influencing Factors of Earthquake Disasters in Portal Sections of Highway Tunnels

3.2.1. Tunnel-Side Slope Collapse

3.2.2. Portal Cracking and Open Cut Tunnel Breaking

3.2.3. Lining Structure Collapse and Concrete Chipping

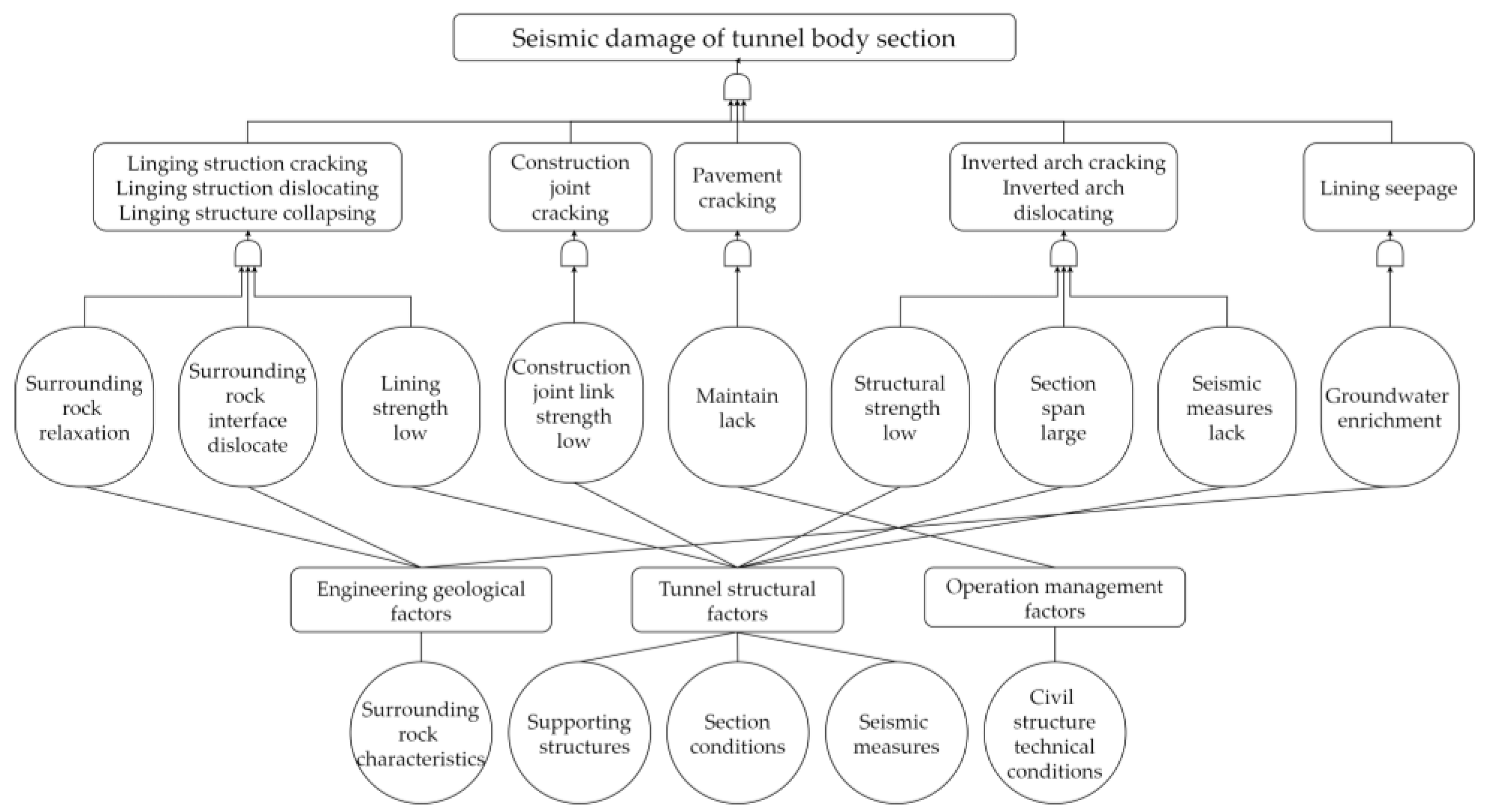

3.3. Analysis of the Factors Influencing the Seismic Damage in the Tunnel Body Section of Highway Tunnels

3.3.1. Lining Structure Cracking, Lining Structure Dislocating and Lining Structure Collapsing

3.3.2. Construction Joint Cracking

3.3.3. Pavement Cracking

3.3.4. Dislocating Inverted Arch Cracking and Inverted Arch

3.3.5. Lining Seepage

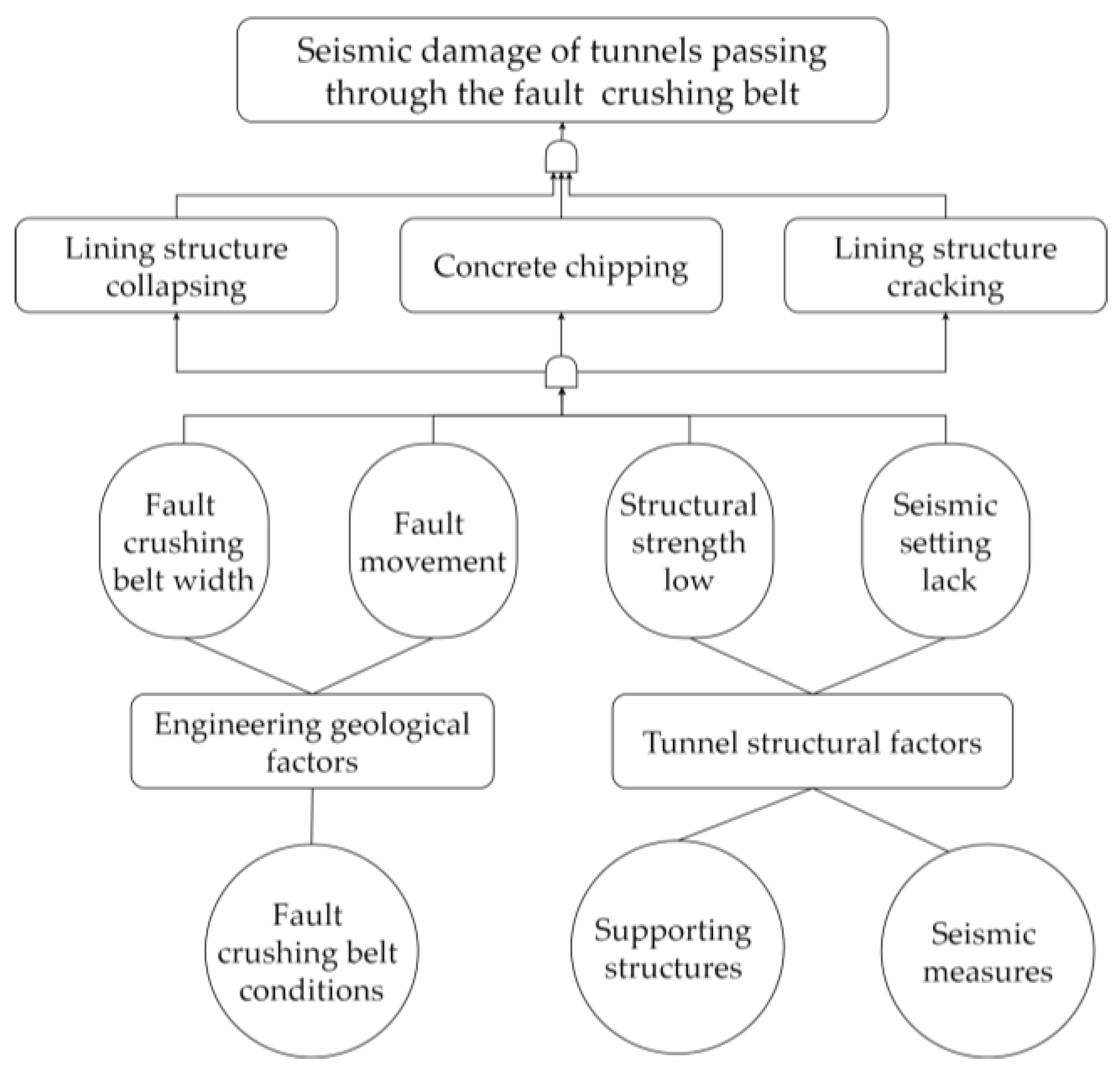

3.4. Analysis of the Factors Influencing the Seismic Damage of Highway Tunnel Sections Passing through the Fault Crushing Belt

3.4.1. Concrete Chipping and Lining Structure Collapse

3.4.2. Lining Structure Cracking

4. Seismic Capability Index System of Highway Tunnels

4.1. Analysis of the Evaluation Index

4.1.1. Index Analysis of the Engineering Geological Factors

4.1.2. Index Analysis of the Tunnel Structural Factors

4.1.3. Index Analysis of the Operation Management Factors

4.2. Construction of the Index System

5. Conclusions

- (1)

- The damage of highway tunnels in 12 earthquake disasters recorded in detail in China and abroad was investigated and counted, and 17 seismic damage scenes of highway tunnels were classified according to the types of hazard-beating bodies and damage forms. According to different damage scenes, the fault tree analysis (FTA) model was used to identify the damage-causing factors.

- (2)

- Combined with the industry standards, norms and research results related to the earthquake resistance of highway tunnels, the evaluation indices are analyzed from three perspectives: engineering geological factors, tunnel structural factors and operation management factors. According to the principle of index system construction, a four-level index system is constructed, which takes the earthquake disaster resistance capability of highway tunnels as the target layer; engineering geological factors, tunnel structural factors and operation management factors as the criterion layer indices; 12 indicators as the index layer and 35 specific indicators.

- (3)

- The establishment of an index system for the earthquake disaster resistance capability of highway tunnels provides a reference for the quantitative evaluation of the earthquake disaster resistance capability of highway tunnels and can also provide important support for the safe operation and sustainable development of highway tunnels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, G.; Zhu, W.; Zhang, W. Summarization of Tunnel Seismic Research. Traffic Stand. 2011, 2011, 44–47. [Google Scholar]

- Li, T.; Yin, Y. Seismic Damage Analysis of Tunnel Structure in Wenchuan Earthquake. Eng. Blasting 2011, 17, 24–27. [Google Scholar]

- Wang, W.L.; Wang, T.T.; Su, J.J.; Lin, C.H.; Huang, T.H. Assessment of Damage in Mountain Tunnels Due to the Taiwan Chi-Chi Earthquake. Tunnellingand Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Zhang, Z. Seismic damage classification and risk assessment of mountain tunnels with a validation for the 2008 Wenchuan earthquake. Soil Dyn. Earthq. Eng. 2013, 45, 45–55. [Google Scholar] [CrossRef]

- Yu, H.T.; Chen, J.T.; Yuan, Y.; Zhao, X. Seismic Damage of Mountain Tunnels During the 5.12 Wenchuan Earthquake. J. Mt. Sci. 2016, 13, 1958–1972. [Google Scholar] [CrossRef]

- Rodríguez, C.A.; Rodríguez-Pérez, Á.M.; López, R.; Hernández-Torres, J.A.; Caparrós-Mancera, J.J. A Finite Element Method Integrated with Terzaghi’s Principle to Estimate Settlement of a Building Due to Tunnel Construction. Buildings 2023, 13, 1343. [Google Scholar] [CrossRef]

- Rodríguez, C.A.; Rodríguez Pérez, Á.M.; López, R.; Caparrós Mancera, J.J. Comparative Analysis and Evaluation of Seismic Response in Structures: Perspectives from Non-Linear Dynamic Analysis to Pushover Analysis. Appl. Sci. 2024, 14, 2504. [Google Scholar] [CrossRef]

- Gong, Z. Study on the Aseismatic Safety Evaluation of Huangcaoping Tunnel of National Road No.318. Master’s Thesis, Chengdu University of Technology, Sichuan, China, 2007. [Google Scholar]

- Guan, M.S.; Han, D.J.; Du, H.B.; Wu, Y. A new seismic performance index for reinforced concrete frame structures. J. Shenzhen Univ. Sci. Eng. 2011, 28, 200–205. [Google Scholar]

- Wang, Z.; Zhang, Z.; Gao, B. Factors of seismic damage and fuzzy synthetic evaluation on seismic risk of mountain tunnel portals. J. Cent. South Univ. Sci. Technol. 2012, 43, 1122–1130. [Google Scholar]

- Cui, G.; Wang, M.; Yu, L. Evaluation and Suggestion of Seismic Fortification Standard Based on Earthquake Damage Characteristics of Wenchuan Earthquake Tunnel. J. Catastrophology 2013, 28, 20–24. [Google Scholar]

- Guo, Y.; Gong, S.; Kang, S. Disease Evaluation of Existing Tunnel Lining Based on AHP-Extenics Model. Tunn. Constr. Chin. Engl. 2020, 40, 115–122. [Google Scholar]

- Li, D. Construction of Safety Evaluation Management System of Highway Tunnel. Heilongjiang Jiaotong Keji 2023, 46, 118–120. [Google Scholar]

- Jin, Y.; Wang, G.; Xie, W. Health Evaluation Index and Detection Analysis of Ying Tunnel Structure. Transp. Manag. World 2023, 2023, 82–84. [Google Scholar]

- Lai, J.; He, S.; Qiu, J.; Chen, J.; Wang, L.; Wang, K.; Wang, J. Characteristics of Seismic Disasters and Aseismic Measures of Tunnels in Wenchuan Earthquake. Environ. Earth Sci. 2017, 76, 94. [Google Scholar] [CrossRef]

- Cheng, M.; Li, S.; Yin, Q. Disaster Prevention and Mitigation Technology of Yingwen Expressway Earthquake Secondary Disasters. Sichuan Archit. 2021, 41, 70–73. [Google Scholar]

- Yin, Q. Discussion on Seismic Design of Yingxiu to Wenchuan Expressway Bridge. Sichuan Archit. 2014, 34, 154–156. [Google Scholar]

- Sun, Y.; Li, P.; Bo, J. Damage Investigation and Cause Analysis of Longxi Tunnel in Wenchuan Great Earthquake. World Earthq. Eng. 2010, 26, 187–191. [Google Scholar]

- Chen, Z.; Chen, Z.; Yang, C. Statistical Analysis of Slope Collapse from Dujiangyan to Yingxiu Section of line. Highway 2015, 60, 51–56. [Google Scholar]

- Zhang, J. Earthquake Damage Diagnosis and Functional Repair of the Damaged Tunnel in Wenchuan Earthquake. J. China Foreign Highw. 2016, 36, 251–255. [Google Scholar]

- Xu, D.; Chen, Y.; Fang, J. Analysis of Deformation and Failure Causes of Longxi Tunnel on Duwen Highway. Resour. Environ. Eng. 2009, 23, 76–84. [Google Scholar]

- Zhu, J.; Deng, G.; Tan, S. Damage to Highway Tunnel Caused by Wenchuan Earthquake and Repair Measures of Road Surface in Tunnel. TranspoWorld 2021, 2021, 93–95. [Google Scholar]

- Zhu, G.Q.; Tao, J.L.; Liu, X.L. Research on Safety Evaluation System of Reinforced Concrete Structures Based on the Blasting Damage. Adv. Mater. Res. 2015, 1065, 1217–1221. [Google Scholar] [CrossRef]

- Huang, M.; Liu, M.; Wang, A. The Research of Tunnel Earthquake Damage Forms and the Reasons. Technol. Econ. Areas Commun. 2010, 12, 60–62. [Google Scholar]

- Li, J. Study on Deformation Mechanism and Treatment Measures of Longxi Tunnel’s Initial Support. Subgrade Eng. 2009, 2009, 200–201. [Google Scholar]

- Zang, W. Research on Earthquake Damage Law of Highway Tunnel in Wenchuan Earthquake. Mod. Tunn. Technol. 2017, 54, 17–25. [Google Scholar]

- Gao, F.; Wei, J. Influence of Invert Form on Seismic Response Analysis of Long-span Tunnel. West-China Explor. Eng. 2012, 24, 187–190+195. [Google Scholar]

- Kang, H.; Wang, Z.; Zhao, G. Review on Seismic Response of Cross-fault Tunnel Structures. Sichuan Archit. 2020, 40, 256–259. [Google Scholar]

- Chen, Q.; Yang, W.; Zhu, D. Analysis on Impact Factors on Seismic Responses of Tunnel. Water Resour. Hydropower Eng. 2014, 45, 60–64+68. [Google Scholar]

- Li, Z.; Meng, X.; Liu, D.; Tang, Y.; Chen, T. Disaster Risk Evaluation of Superlong Highways Tunnel Based on the Cloud and AHP Model. Adv. Civ. Eng. 2022, 2022, 8785030. [Google Scholar] [CrossRef]

- Cui, H.; Chen, G.; Zhu, M.; Su, Y.; Liu, J. Health State Assessment of Road Tunnel Based on Improved Extension Cloud Model. Appl. Sci. 2023, 13, 8554. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, W. Health and Safety Evaluation System of Tunnel Structure under Complex Geological Conditions. Sichuan Archit. 2022, 42, 184–187+190. [Google Scholar]

- Gao, Q.; Wen, Z.; Wang, D. Instability process of frozen soil slope based on direct shear test at freeze–thaw interface. Rock Soil Mech. 2018, 39, 2814–2822. [Google Scholar]

- Jiang, S.H.; Huang, J.; Griffiths, D.V.; Deng, Z.P. Advances in reliability and risk analyses of slopes in spatially variable soils: A state-of-the-art review. Comput. Geotech. 2022, 141, 104498. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, Q. Sichuan-tibet Railway Tunnel Project. Tunn. Constr. 2017, 37, 1049–1054. [Google Scholar]

- Shen, J.Y.; Karakus, M. Three-dimensional numerical analysis for rock slope stability using shear strength reduction method. Can. Geotech. J. 2013, 51, 164–172. [Google Scholar] [CrossRef]

- Xing, J.; Dong, X.; He, X. Stability Analysis of Surrounding Rock in Tunnel Construction in Fault fracture Zone. J. Catastrophol. 2018, 33, 164–168. [Google Scholar]

- Cui, G.; Ji, L.; Jin, H. Damping Shake Technology of the Shock Absorption Layer of Fault-crossing Tunnels in a Dangerous Mountainous Area with High-Intensity Earthquakes. China Earthq. Eng. J. 2019, 41, 286–291. [Google Scholar]

- Qi, W.; Gao, Y. Study on Comprehensive Construction and Monitoring Technology of Highway Tunnel Crossing Weak and Fractured Surrounding Rock. J. Highw. Transp. Res. Dev. 2021, 38, 88–96+105. [Google Scholar]

- Yang, X.; Shi, Z. Study on the Construction Technology of Tunnel Portal section Collapse Caused by Slope Instability. Yunnan Water Power 2016, 32, 83–86+91. [Google Scholar]

- Kontoe, S.; Zdravkovic, L.; Potts, D.M.; Menkiti, C.O. Case study on seismic tunnel response. Can. Geotech. J. 2008, 45, 1743–1764. [Google Scholar] [CrossRef]

- Zhang, H.; Xiang, X. Anti Liquefaction of Silty Soil Foundation and Seismic Performance of Tunnel in High Earthquake Intensity Area. Chin. J. Undergr. Space Eng. 2017, 13, 332–338. [Google Scholar]

- Li, T. Failure Characteristics and Influence Factor Analysis of Mountain Tunnels at Epicenter Zones of Great Wenchuan Earthquake. J. Eng. Geol. 2008, 16, 742–750. [Google Scholar]

- Meng, G.; Zhou, J. Limit State Design Method of Railway Tunnel Portal Based on Reliability Theory. J. Southwest Jiaotong Univ. 2016, 51, 31–35. [Google Scholar]

- Suo, R.; Wang, Y. Seismic Fortification Length of Tunnel Portal section Under Rayleigh Wave Action. Mod. Tunn. Technol. 2011, 48, 13–18. [Google Scholar]

- Cui, G.; Li, P.; Wang, Q. Analysis on the Effect of Pile-raft Anti-seismic Measures for the Tunnel Section of Weak Surrounding Rock in Strong Earthquake Area. Chin. J. Geol. Hazards Prev. 2021, 32, 106–112. [Google Scholar]

- Luo, J. Analysis of Seismic and Damping Measures for Shallow Buried Tunnel in City. Sci. Technol. Innov. Appl. 2015, 2015, 213. [Google Scholar]

- Zhou, J. Investigation and Analysis of Highway Tunnel Diseases in Henan Province and Thinking on Operation Management. Mod. Tunn. Technol. 2018, 55, 1–10. [Google Scholar]

- JTG/T 3660-2020; Technical Specifications for Construction of Highway Tunnel. China Communications Press: Beijing, China, 2020.

- JTG 3370.1-2018; Specifications for Design of Highway Tunnels Section 1 Civil Engineering. China Communications Press: Beijing, China, 2018.

- JTG/T 2232-01-2019; Specification for Seismic Design of Highway Tunnels. China Communications Press: Beijing, China, 2019.

- JTG-C20-2011; Code for Highway Engineering Geological investigation. China Communications Press: Beijing, China, 2011.

- JTG/T D70-2010; Guidelines for Design of Highway Tunnel. China Communications Press: Beijing, China, 2010.

- GB50011-2010; Code for seismic design of buildings. China Architecture & Building Press: Beijing, China, 2010.

- JTG H12-2015; Technical Specifications for Maintenance of Highway Tunnel. China Communications Press: Beijing, China, 2015.

| Index of Engineering Geological Factors | Relevant Specifications and Engineering Experience | Relevant Regulations or Experience | Specific Indicators |

|---|---|---|---|

| Characteristics of surrounding rock mass | “Technical Specifications for Construction of Highway Tunnel” (JTG/T 3660-2020) [49]; “Specifications for Design of Highway Tunnels Section 1 Civil Engineering “(JTG 3370.1-2018) [50]; “Specification for Seismic Design of Highway Tunnels” (JTG/T 2232-01-2019) [51] |

| Surrounding rock grade; Surrounding rock cavity; High ground stress; Bias; Buried depth; Underground water; Surrounding rock interface |

| Characteristics of side slope | “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018) | The slope, slope height and weathering degree of the slope determine the stability of the slope. | Side slope gradient; Side slope height; Weathering degree |

| Related engineering experience |

| ||

| Condition of fault fracture zone | “Code for Highway Engineering Geological investigation” (JTG-C20-2011) [52]; “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018); “Specification for Seismic Design of Highway Tunnels” (JTG/T 2232-01-2019) |

| Fault movement; Fault width |

| Related engineering experience |

| ||

| Engineering environment | “Guidelines for Design of Highway Tunnel” (JTG/T D70-2010) [53] | When selecting the location, the tunnel should avoid the bad engineering environment, such as collapse and landslide, according to the terrain characteristics. When it is difficult to avoid, the engineering treatment measures should be taken. | Rockfall site; Adjacent engineering activity |

| Related engineering experience |

| ||

| Foundation condition | “Specification for Seismic Design of Highway Tunnels” (JTG/T 2232-01-2019); “Code for seismic design of buildings” (GB50011-2010) [54] |

| Bearing capacity of foundation; Liquefaction possibility of foundation soil |

| Related engineering experience |

|

| Tunnel Structural Factor Index | Relevant Specifications and Engineering Experience | Relevant Regulations or Experience | Specific Indicators |

|---|---|---|---|

| Tunnel portal form | “Technical Specifications for Construction of Highway Tunnel” (JTG/T 3660-2020); “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018); “Specification for Seismic Design of Highway Tunnels” (JTG/T 2232-01-2019) |

| Tunnel portal type; Tunnel portal size |

| Related engineering experience |

| ||

| Support structure | “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018) |

| Lining material; Lining thickness; Reinforcement; Inverted arch setting; Construction joint link strength |

| Section condition | “Code for Highway Engineering Geological investigation” (JTG-C20-2011); “Specification for Seismic Design of Highway Tunnels” (JTG/T 2232-01-2019); “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018) |

| Cross-section shape; Cross-section size |

| Seismic constructions | “Specifications for Design of Highway Tunnels Section 1 Civil Engineering” (JTG 3370.1-2018); “Specification for Seismic Design of Highway Tunnels” (TG/T 2232-01-2019) |

| Seismic joint; Special seismic measure |

| Related engineering experience |

|

| Operation Management Factor Index | Relevant Specifications and Engineering Experience | Relevant Regulations or Experience | Specific Indicators |

|---|---|---|---|

| Technical conditions tunnel structure | “Technical Specifications for Maintenance of Highway Tunnel” (JTG H12-2015) [55] |

| Technical conditions of tunnel portal section structure; Technical conditions of tunnel portal structure; Technical conditions of lining structure; Technical conditions of pavement structure |

| Emergency management level | “Technical Specifications for Maintenance of Highway Tunnel” (JTG H12-2015) |

| Emergency management system; Emergency plan drill |

| Maintenance management level | “Technical Specifications for Maintenance of Highway Tunnel” (JTG H12-2015) | During the operation of the civil structure, the daily inspection of the portal, lining ceiling and other structures is carried out, and the periodic inspection cycle is divided according to the structural grade. After the inspection is completed, the defective parts are repaired in time and recorded. | Maintenance management system; Inspection and maintenance condition |

| Related engineering experience | The level of tunnel maintenance management is reflected in the management system. An excellent maintenance management system should have the characteristics of advanced maintenance concept, sufficient maintenance talents, perfect maintenance system and real-time maintenance work. |

| Goal Layer | Criterion Layer | Indicator Layer | Specific Indicator |

|---|---|---|---|

| Highway tunnel capacity of earthquake disaster resistance [U] | Engineering geological factor [U1] | Surrounding rock characteristics [U1-1] | Surrounding rock grade [U1-1-1] |

| Surrounding rock cavity [U1-1-2] | |||

| High ground stress [U1-1-3] | |||

| Bias [U1-1-4] | |||

| Buried depth [U1-1-5] | |||

| Underground water [U1-1-6] | |||

| Surrounding rock interface [U1-1-7] | |||

| Side slope characteristics [U1-2] | Slope gradient [U1-2-1] | ||

| Slope height [U1-2-2] | |||

| Degree of weathering [U1-2-3] | |||

| Condition of fault fracture zone [U1-3] | Fault movement [U1-3-1] | ||

| Fault width [U1-3-2] | |||

| Engineering environmental [U1-4] | Rockfall site [U1-4-1] | ||

| Adjacent engineering activity [U1-4-2] | |||

| Foundation conditions [U1-5] | Bearing capacity of foundation U1-5-1] | ||

| Liquefaction possibility of foundation soil [U1-5-2] | |||

| Tunnel structure factor [U2] | Portal form [U2-1] | Tunnel portal type [U2-1-1] | |

| Tunnel portal size U2-1-2] | |||

| Supporting structure [U2-2] | Lining material [U2-2-1] | ||

| Lining thickness [U2-2-2] | |||

| Reinforcement condition [U2-2-3] | |||

| Inverted arch setting [U2-2-4] | |||

| Construction joint link strength [U2-2-5] | |||

| Section condition [U2-3] | Cross-section shape [U2-3-1] | ||

| Cross-section size [U2-3-2] | |||

| Seismic measures [U2-4] | Seismic joint U2-4-1] | ||

| Special seismic measure [U2-4-2] | |||

| Operation management factor [U3] | Technical condition of civil structure [U3-1] | Technical conditions of portal section structure [U3-1-1] | |

| Technical conditions of tunnel portal structure [U3-1-2] | |||

| Technical conditions of lining structure [U3-1-3] | |||

| Technical conditions of pavement structure [U3-1-4] | |||

| Emergency management level [U3-2] | Emergency management system [U3-2-1] | ||

| Emergency plan drill [U3-2-2] | |||

| Maintenance management level [U3-3] | Maintenance management system [U3-3-1] | ||

| Inspection and maintenance condition [U3-3-2] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, F.; Zhang, N.; Lu, Z.; Zhang, Y.; Yan, X.; Yu, J. Research on an Index System for the Earthquake Disaster Resistance Capability of Highway Tunnels. Appl. Sci. 2024, 14, 4641. https://doi.org/10.3390/app14114641

Wan F, Zhang N, Lu Z, Zhang Y, Yan X, Yu J. Research on an Index System for the Earthquake Disaster Resistance Capability of Highway Tunnels. Applied Sciences. 2024; 14(11):4641. https://doi.org/10.3390/app14114641

Chicago/Turabian StyleWan, Fei, Nian Zhang, Zheng Lu, Yu Zhang, Xuehui Yan, and Jiang Yu. 2024. "Research on an Index System for the Earthquake Disaster Resistance Capability of Highway Tunnels" Applied Sciences 14, no. 11: 4641. https://doi.org/10.3390/app14114641

APA StyleWan, F., Zhang, N., Lu, Z., Zhang, Y., Yan, X., & Yu, J. (2024). Research on an Index System for the Earthquake Disaster Resistance Capability of Highway Tunnels. Applied Sciences, 14(11), 4641. https://doi.org/10.3390/app14114641