Abstract

Obtaining mathematical models of nonlinear cyber–physical systems for use in controller design is both difficult and time consuming. In this paper, an ANN-based method is proposed to design a controller for a nonlinear system that does not require a mathematical model. The developed ANN-based control algorithm is implemented directly on a real-time field controller, and its performance is evaluated without the use of auxiliary devices, such as PCs or workstations. By executing machine learning algorithms on local devices or embedded systems, edge artificial intelligence (Edge AI) with transfer learning gives priority to processing data at the source, minimizing the necessity for continuous connectivity to remote servers. The control algorithm was developed using the Matlab Simulink environment. The first and second ANNs were cascaded, wherein the first ANN computes the appropriate pressure signal for the given displacement, while the second predicts the force based on the pressure value from the first ANN. Subsequently, the ANN-based control algorithm was converted to SCL code using the Simulink PLC Coder and deployed on the PLC for operation. The algorithm was tested using two different scenarios. The conducted tests demonstrated the successful prediction of pressure signals corresponding to the targeted displacement values and accurate estimation of force values. Experimental work was carried out on PAM manipulators as a nonlinear model application, and the obtained results were discussed.

1. Introduction

An artificial neural network (ANN) is a category of algorithms within the domain of artificial intelligence (AI). It emerged in the 1980s as a result of significant progress in both cognitive science and computer science research [1]. Extensive research utilizing computer simulations has demonstrated the capacity of ANNs to map, model, simulate, and categorize nonlinear systems [2]. The unique attributes of ANNs, including their ability to learn from case observations, adaptability, parallel processing, robustness against noise, and fault tolerance, have led their implementation in diverse domains, such as engineering, science, economics, and beyond. Explicitly, in engineering, the ANN is utilized in the speed control of AC motors [3], oil, petroleum, and gas industries [4,5,6], solar power forecasting [7], stand-alone power system controllers [8], robotic manipulator controller design [9], and the control of a pneumatic artificial muscle (PAM) [10]. Controller design and algorithms establish minimal challenges when industrial applications utilize actuators with linear characteristics. However, controller and control algorithm design become challenging when the response of the actuator in the system is nonlinear and the characteristics of the other components in the system cannot be accurately modeled. Artificial pneumatic muscles are frequently preferred in industrial applications due to their high-capacity force characteristics and high accuracy and repeatability, but they are one of the actuators with nonlinear characteristics. PAM-based actuators exhibit high nonlinearity due to their complex joint geometry. Static and dynamic modeling of these types of actuators are extensively studied in the literature [11,12,13].

Programmable logic controllers (PLCs) are often the preferred option for real-time controllers used in automation systems and field applications due to their inherent advantages, including flexibility, reliability, and cost-effectiveness when managing complex systems [14,15]. Whether it is a single task or an entire system with nonlinear output responses determined by inputs, the use of real-time algorithms within PLCs is essential for effective control. The complexity of the control algorithm design increases consistently with the specific tasks to be controlled and the quantity of discrete or dependent variables involved.

The process of modeling nonlinear systems and designing real-time control algorithms for use in the field is time consuming and challenging. The application of ANNs to obtain responses from nonlinear systems or predict and manage outputs in unforeseen system situations can offer significant advantages in terms of efficiency and reductions in modeling time and associated costs. Consequently, this eliminates the requirement for complex system modeling. A well-trained ANN implemented on PLCs can be beneficial in generating responses for unexpected system inputs and generating functions based on field-collected data. In a structural context, earlier studies can be categorized into two main sections: embedded neural network systems utilizing PLCs [16,17,18] and hybrid systems [15,19,20,21], which include an additional controller, such as a PC or workstation, in communication with the PLCs.

This paper focuses on the multilayer perceptron (MLP) neural network in the ANN-based embedded data-driven controller design for a complete fluidic muscle station that uses PAM as an actuator. A control algorithm was crafted with an ANN without establishing a model of a nonlinear system, the experimentally obtained data were trained, and the code of the ANN algorithm was then embedded in the PLC. By employing machine learning algorithms on local devices or embedded systems, edge artificial intelligence (Edge AI) with transfer learning prioritizes data processing at the source, where AI computations are executed and data are generated, thereby reducing the reliance on continuous connectivity to remote servers. In this study, tests were carried out on PAM manipulators as a nonlinear model application, and the obtained results were discussed.

In the structural hierarchy of this study, in Section 2, we gave a brief introduction to the literature on the cooperation of ANNs with PLCs and the advantages of ANNs in real-time nonlinear system modeling and control. In Section 3, we investigated the structure of the PAM-operated fluidic press unit as a nonlinear system model. The mathematical models proposed in the literature for PAM are examined, and a detailed pipeline of the data collection, neural network training, and deployment processes is provided. In the results section, the commissioning and experimental results of the controller embedded in the PLC are presented. In the discussion section, we compare the errors produced by the ANN-based controller with the proposed mathematical models in the literature. The conclusion section provides a summary of the findings and insights gained from this study.

2. Related Work

2.1. Artificial Neural Networks

An artificial neural network is a computational model inspired by the neural circuitry in the brains of animals. ANNs aim to emulate some of the adaptability and computational power seen in biological brains. They simulate the functioning of real neurons and the transmission of electrical signals between input processing and final output in animal brains. ANNs are renowned for their capacity to represent intricate input–output relationships that are challenging for traditional computational methods. The backpropagation algorithm, discovered by Werbos in 1974 [22], enhances the capabilities of the multilayer perceptron in solving nonlinear problems. Ever since, ANNs have found widespread applications in addressing a multitude of real-world challenges. The artificial neural network has found extensive application in control systems owing to its distinctive model structure and nonlinear simulation capabilities, coupled with its remarkable adaptability and fault tolerance [23]. By incorporating a nonlinear adaptive learning mechanism into the framework of various controllers, performance can be improved.

The ANN has a standardized approach that facilitates the modeling of complex and nonlinear functions. In [24], an ANN model was developed to determine the nonlinear stress concentration factor for a crankshaft under bending stress using the data transferred to a database from the stress concentration factor charts. An ANN model was constructed utilizing stress–strain data derived from various design types and loading conditions specific to leaf springs in [25]. Through this model, both the spring constant and true stress–strain values with nonlinear characteristics were accurately estimated with high precision.

The nonlinear nature of the ANN imparts greater computational power to it than linear modeling, which is widely adopted due to its easy optimization with high precision. Nevertheless, the linear model exhibits significant errors, particularly when attempting to model highly nonlinear devices, such as thermistors, pressure sensors, and robotic and PAM manipulators. In contrast, ANNs prove to be compelling tools for modeling nonlinear systems. What makes ANNs user friendly is their learning process, which requires minimal user expertise. The network learns by example, and a user only needs to gather and organize training data and initiate the learning algorithm to commence the network’s learning. This simplifies the process compared to traditional nonlinear system models.

Owing to the distributed structure of neural networks and the presence of inherently nonlinear neurons within them, ANNs are inherently nonlinear. This distributed nonlinearity influences the network and is particularly important when the input systems feeding the network are themselves nonlinear.

2.2. Neuron Computational Model

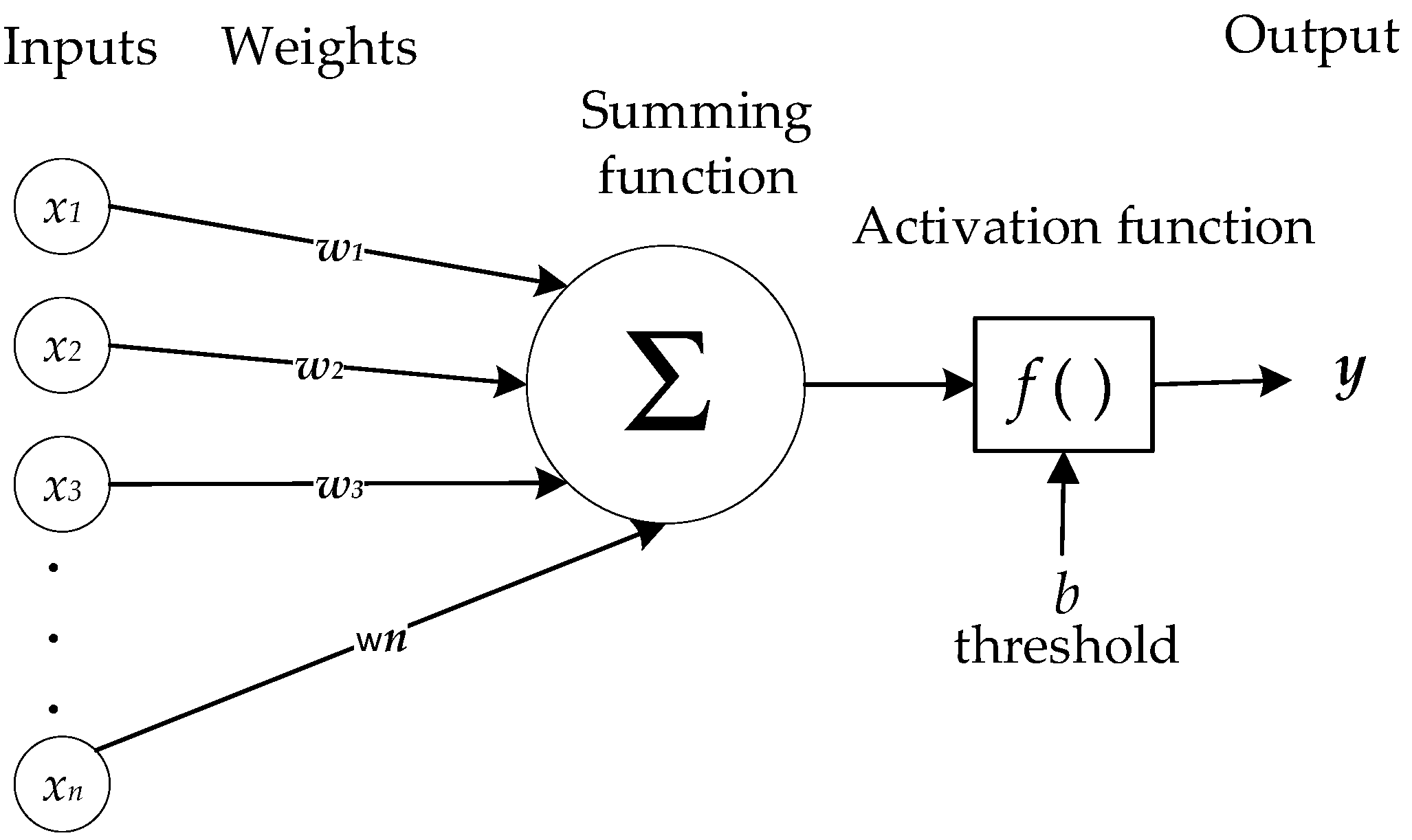

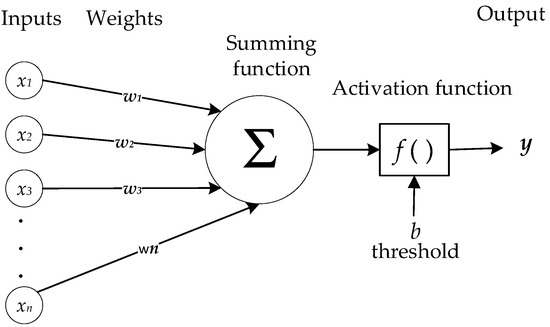

The neuron is the essential computational unit in an ANN, which is modeled according to the concept introduced by McCulloch and Pitts [26]. The computational model of a neuron comprises two essential elements: a summing function and an activation function. Data are conveyed to a neuron through n inputs. Initially, the neuron computes the weighted sum of these inputs, and subsequently, the neuron output is determined by this weighted sum and the activation function. A graphical representation of this neuron model can be observed in Figure 1.

Figure 1.

A graphical representation of the mathematical model of a neuron.

The mathematical model of a neuron is expressed in (1).

In (1), the summing function calculates the sum of each input, , multiplied by its corresponding weight, . The neuron’s threshold (or bias), b, can be regarded as a weight with a factor of −1. The neuron will fire if the weighted sum of its inputs exceeds the threshold. The binary result is the output of the neuron’s model and is denoted by y. The activation function, f, serves as a squashing function for the weighted sum, constraining the allowable range of the output signal’s amplitude. The activation functions utilized for generating continuous or discrete output values are as follows:

and

In (2), λ (λ > 0) is proportional to the neuron gain, and it plays a critical role in identifying the steepness of the continuous function f(v) when v is near 0. It is worth noting that as λ approaches infinity (λ → ∞), the continuous function converges towards the function stated in (3).

2.3. Multilayer Perceptron Neural Network

Although individual neurons are limited to performing basic computations, a network of neurons can provide emergent computational capabilities. In the field of artificial neural networks, this concept is characterized by a directed graph where neurons function as nodes and the weighted connections between them serve as edges. The output of each neuron serves as input for other neurons in the network.

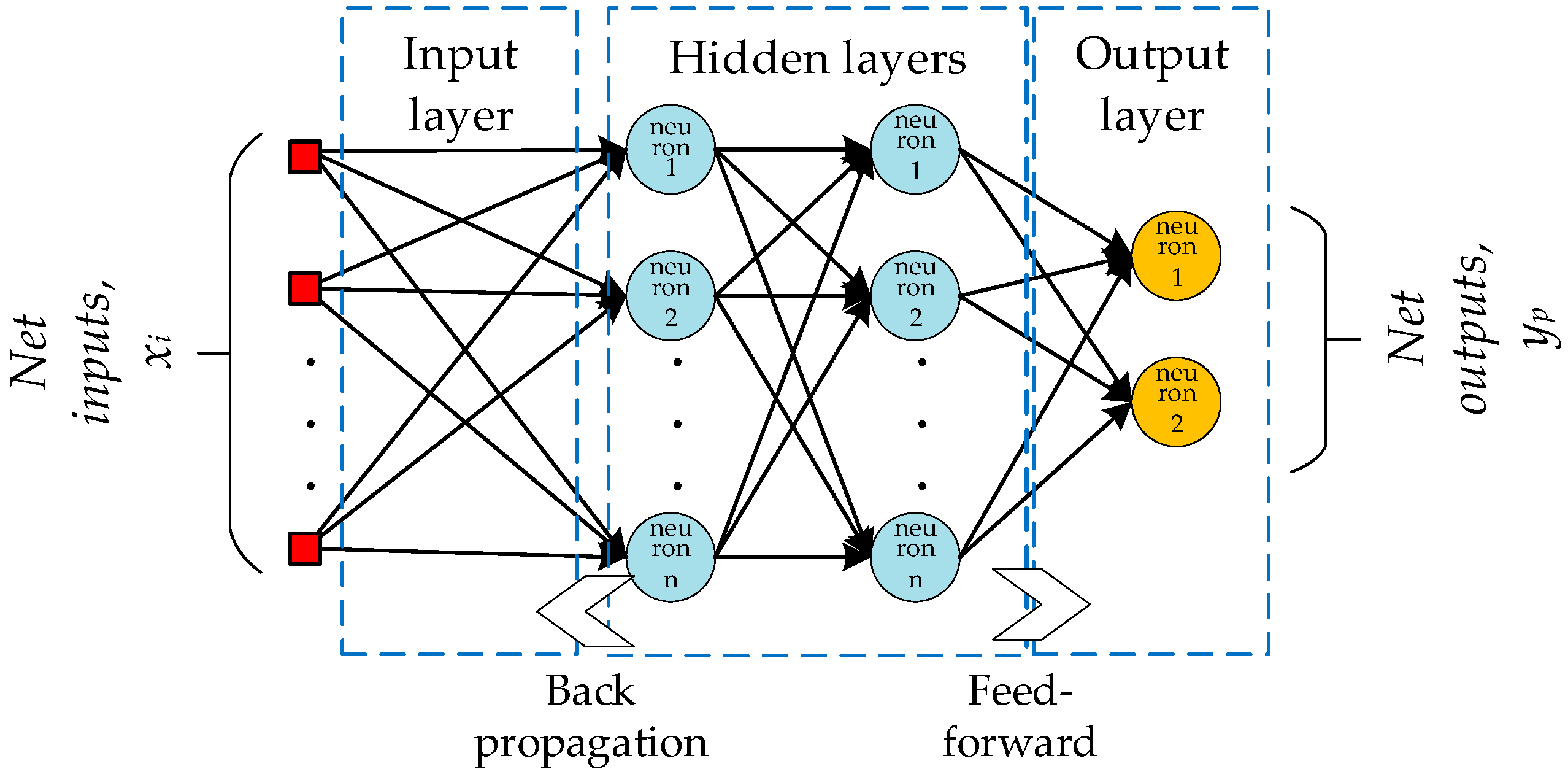

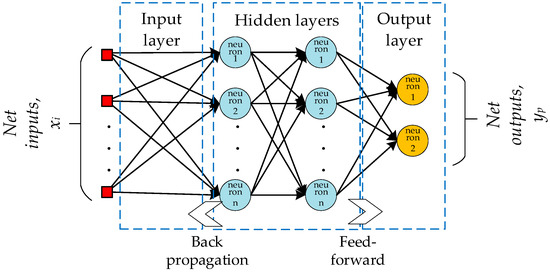

An MLP has a minimum of three layers: an input layer, one or more hidden layers, and an output layer, as shown in Figure 2. It is worth mentioning that the input layer does not function as a “true” layer because it does not perform computations; instead, it receives task-specific inputs from the external environment. The MLP incorporates one or more hidden layers that receive inputs from the preceding layers, whether input or hidden layers, and their outputs are connected to the next layers, either output or hidden layers. Each neuron in a hidden layer employs a differentiable nonlinear activation function. The output layer presents the final computation result to the external world.

Figure 2.

A graphical representation of a three-layer MLP neural network with n neurons.

The network exhibits a high degree of connectivity, where each neuron in a layer is linked to every neuron in the subsequent layer. The MLP functions as a feedforward ANN, meaning that data progress in a unidirectional manner.

In its basic configuration, an MLP neural network utilizes the backpropagation method for supervised learning to train the network. The training process involves two primary phases: the forward and backward phases. During the forward phase, the network processes input data, propagating it forward through the ANN from the input layer to the output layer while keeping the weights unchanged. At the onset of the backward phase, an error signal vector is computed for the output layer neurons based on the disparity between the desired and computed output values. This vector is then propagated back through the hidden layers. Subsequently, the error signal vector for the hidden layers is determined. The network’s weights are updated using the error signal and the input values. Backpropagation conducts a gradient descent search in the weight space to minimize the error function. There are multiple variations of backpropagation error correction methods based on gradient descent.

2.4. AI Application on Programmable Logic Controllers

Real-time field applications often involve complex systems that are typically composed of interconnected subsystems when examined from a conceptual perspective. While certain subsystems may exhibit linearity, the supra-system that encompasses them all ultimately takes on a nonlinear structural configuration. In these field applications, it is customary for each individual subsystem to possess a dedicated embedded controller for managing work cells. Communication among these subsystems can occur directly or through master controllers, as well as supervisory control and data acquisition (SCADA) systems.

One of the early investigations on the integration of artificial neural networks into PLCs was conducted by Wegmann [27]. In this study, the advantages of employing fuzzy and neural networks in PLCs were explored conceptually. The research primarily focused on the pH neutralization of chemical wastewater and hot dip galvanizing plant scenarios. Jung et al. [15] conducted a study in which an ANN was trained using a dataset obtained from PLCs to predict logic errors. The training and prediction tasks were executed using MATLAB, while the PLC was utilized for field device monitoring and data collection. Li et al. [18] developed a neural network algorithm for configuring Proportional–Integral–Derivative (PID) tuning, employing Octave software (https://octave.org/). They implemented the ANN on an unspecified model of a Siemens PLC in a simulation environment. To simulate a plant scenario, Factory I/O software (https://factoryio.com/) was employed. This work was tested solely in a simulated environment, and the results were not validated with physical devices. The outcomes of the ANN PID tuning algorithm indicated the potential for improved performance compared to conventional PID tuning methods. Interestingly, they observed that their method, when compared to the Ziegler–Nichols closed-loop tuning method, did not achieve a steady state in their tests, which is uncommon in practical applications. Topalova et al. [17] proposed an optimization method using MLP neural networks for the recognition of 2D images of objects captured by CCD matrix cameras. These trained networks were then transferred to Siemens S7-300 PLCs via PROFIBUS, a simplified timed token (TT) protocol [28]. Guo et al. [19] designed a PID control system based on a fuzzy neural network and compared it with a conventional PID algorithm in a temperature control experiment. During the application phase, a personal computer running the fuzzy neural network algorithm and a simulated Siemens S7-200 PLC program for system control exchanged data through the handshake process. The results indicated that the fuzzy neural network PID controller exhibited superior adjustment times compared to the classical PID algorithm. Topalova et al. [20] trained an MLP neural network using histograms within Siemens Neuro Systems and implemented PLCs’ native neural network functions for texture classification of marble shades. The designed system operated in tandem with a personal computer as a workstation and a PLC. Fonseca et al. [21] harnessed artificial neural networks, operating within the MATLAB environment, to enhance the computational capabilities of PLCs in the field of fault detection in electrical distribution substations. The processes were divided into two primary tasks: field tasks and neural network-based computational tasks. Communication between the PC and the PLCs was facilitated through the Open Platform Communications (OPC) protocol utilized as an industrial interoperability standard. In summary, these studies encompass a range of applications involving the integration of artificial neural networks and PLCs, spanning fields such as process control, image recognition, and fault detection in diverse industrial contexts.

Developing a model for a nonlinear system that is compatible with embedded controllers for real-time field applications, or designing a new subsystem by integrating existing subsystems, is a complex and time-consuming task. The literature search indicates that solutions based on ANNs are valuable for controlling or diagnosing nonlinear systems in such scenarios.

Since the PLCs have advantages regarding reliability and easy diagnostics, it makes them widely used devices in real-time applications on the market. When you combine the capabilities of ANNs to design control systems using existing input–output (I/O) datasets with the robust diagnostic and control capabilities of PLCs, this collaboration offers undeniable advantages in field applications.

The aim of this research is to develop a control algorithm for a nonlinear system using ANNs and relying solely on I/O variables, without the need for a complete system model. The developed ANN-based control algorithm is implemented directly on a real-time field controller, and its performance is evaluated without the use of auxiliary devices, such as PCs or workstations. Emulating real-time field scenarios, our emphasis was on developing a standalone embedded ANN controller, exclusively utilizing PLCs within a system that has nonlinearities due to its actuator. By executing machine learning algorithms on local devices or embedded systems, edge artificial intelligence (Edge AI) with transfer learning gives priority to processing data at the source, minimizing the necessity for continuous connectivity to remote servers. Edge AI provides intelligence directly to edge devices, such as IoT devices and embedded systems, where AI computations are performed and data are generated, contrasting traditional AI systems that apply integrated data processing in the cloud. Moreover, difficulties arise when an excess of devices congest the network traffic on the internet. This can occur due to an accumulation of traffic on the local Wi-Fi or an excessive amount of data being transmitted to the remote server. To confront these issues, a realistic approach is to implement less computationally intensive machine learning algorithms on a local server or even directly on the devices themselves. This approach not only eases the strain on network resources but also enables quicker decision making and responsiveness, especially in scenarios where real-time processing is critical.

This decentralization of AI processing offers several advantages, including decreased latency, enhanced privacy, and greater efficiency for applications across sectors, such as healthcare, industrial processes, manufacturing, transportation, and smart infrastructure.

3. The Proposed Model and Methods

3.1. PAM for a Nonlinear System Model

Modeling and designing the control algorithm for a nonlinear system is not always a straightforward operation, and the complexity further intensifies when dealing with multivariable systems. PAM has a nonlinear displacement, force, and damping characteristic, with the stimulation pressure used for contraction considered as the independent variable. Although the applied pressure is considered as input with a linear and proportional increase, the output parameters do not respond in the same way. Considering this challenge, we have used the inverse problem of a modular assembly system that includes a single-acting actuator known as the McKibben muscle.

Inverse Modeling of a PAM-Based Pressing Unit for a Nonlinear Case

To achieve the desired results and maintain control over a system, it is essential to accurately model the impact of the input signal from the control device on the actuator’s output. This requires a precise and deterministic approach. In the modular pressing and assembly station selected as a case study, PAM is used as the actuator. For the PAM’s force–displacement characteristic, the static system models in [29], as depicted in (4), and the derived total displacement models in (5) have been proposed, but the experimentally obtained curves do not exactly fit the various system models [12]. The expressions , , and in the equation represent, respectively, the initial values of radius, nominal length, and braid angle, which are the structural variables of the PAM. In addition to the structural variables of the system, is the resultant force, is the applied inlet pressure, is the strain, and is the resultant length after the elongation. Accurate and precise measurements or knowledge of all the structural variables of the actuator used in the system is needed for the use of the proposed models.

where , ,

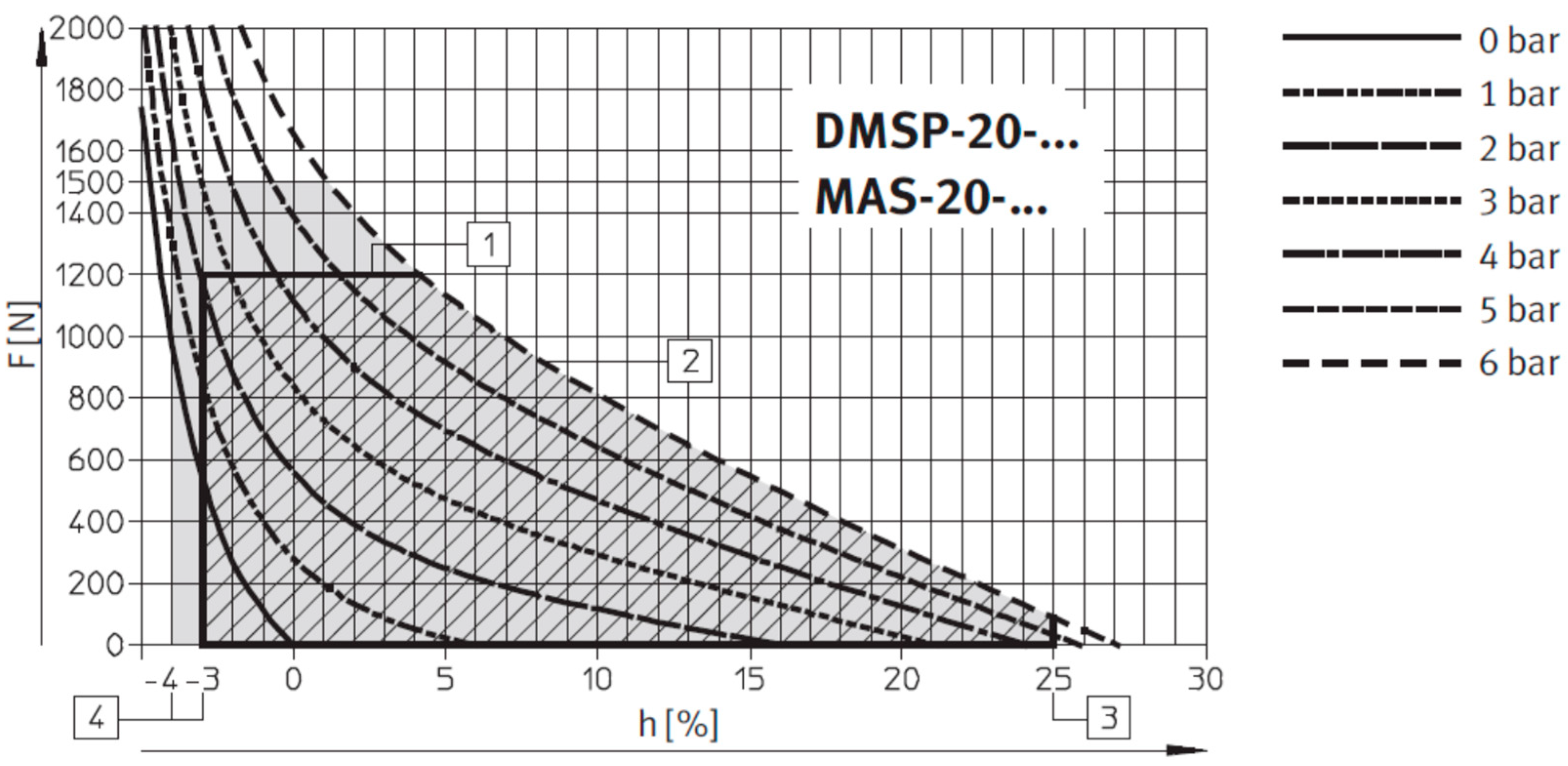

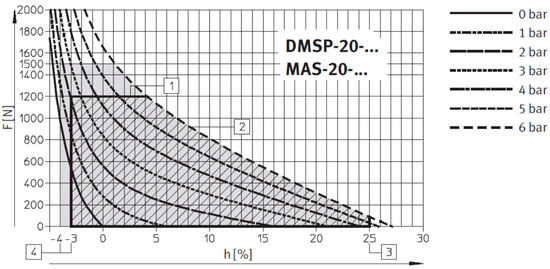

Furthermore, while Festo provides a force–contraction plot for nonlinear PAM characteristics, as shown in Figure 3, it is essential to re-test its accuracy in applications with different components to ensure precise position control.

Figure 3.

Force and contraction characteristic of Festo DMSP-20 [30].

PAM is a flexible actuator that can be used as a spring with variable values, showing different characteristics for different pressure inputs. This feature has practical benefits in terms of use in field applications but presents a mathematical modeling challenge. Different pressure values applied to the PAM input affect the displacement and force characteristics of the muscle, leading to different nonlinear characteristics for each pressure condition. Additionally, mathematical models proposed in the literature generate errors ranging from 4% to 46% for the static force of the muscle [11]. When the system includes any damping or stiffness elements other than the pneumatic muscle actuator and static mass, their displacement and force characteristic curves under different inlet pressures will cause the system to deviate from linearity.

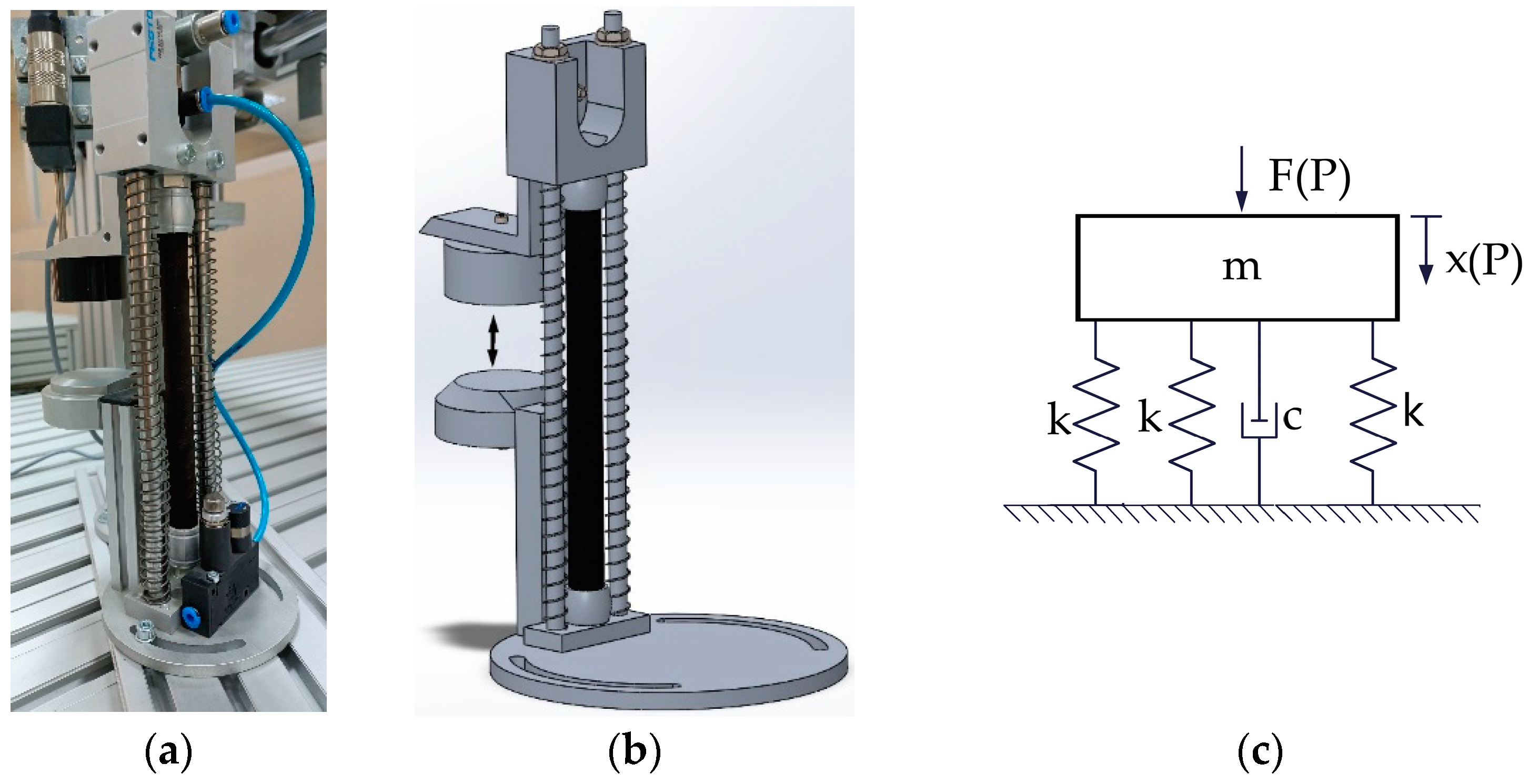

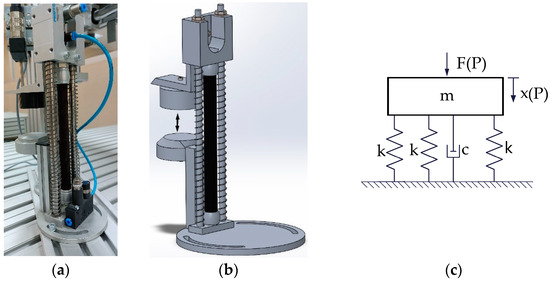

In the scope of this study, a modular pressing unit consisting of two pre-tensioning springs and a PAM (Festo DMSP-20) was used as a case study, as shown in Figure 4. In the system model shown in Figure 4c, the force is generated by the combination of the contraction caused by the pressure applied to the PAM and the mass of the aluminum body holding the assembled components. Depending on the pressure applied to the PAM, the displacement during assembly and the resulting static force will vary. The PAM is modeled with a variable capacity damping element [29] and spring combination and parallel prestressing springs are also considered. The mathematical model of the system is given in (6), where and correspond to the constants of the pre-tensioning springs on both sides of the PAM, and refers to the spring behavior due to the internal structure of the PAM. Among the other variables defined in Equation (6), and are the initial and final position, respectively, and is the static force resulting from the applied inlet pressure. For each spring used as a system component, the spring constant is modeled by calculating with (7), where R is the radius of the spring coil, n is the number of turnings, G is the shear modulus of the spring material, and d is the diameter of the wire. Thus, the stiffness value of the system with constant coefficient springs can be obtained.

Figure 4.

Modular pressing unit: (a) physical system; (b) CAD model; (c) system model.

Even when all components of the system are modeled with damping and spring characteristic elements, precise modeling requires approximations through the determination of damping and stiffness coefficients for each element [11,12,27], and still, experimental validation is decisive. For the control algorithm of a system that is already in active use with its design phase completed, the most effortless approach to developing the control algorithm is through a data-driven method. Artificial neural networks offer superior advantages over other methods for obtaining experimental coefficients in the given system, providing practical benefits. With the obtained discrete measurement results, an embedded data-driven controller can be designed without the need to model the entire system, making it suitable for real-time control applications.

3.2. ANN-Based Embedded Data-Driven Controller Design

The primary advantage of data-driven controller design lies in its approach of handling the impact of control variables on the outputs to be controlled through a black box model, rather than analyzing the system with its sub-components. The fundamental starting point of data-driven controller design involves establishing a data acquisition setup to collect the necessary data for controller design and collecting discrete data in a uniformly randomized manner.

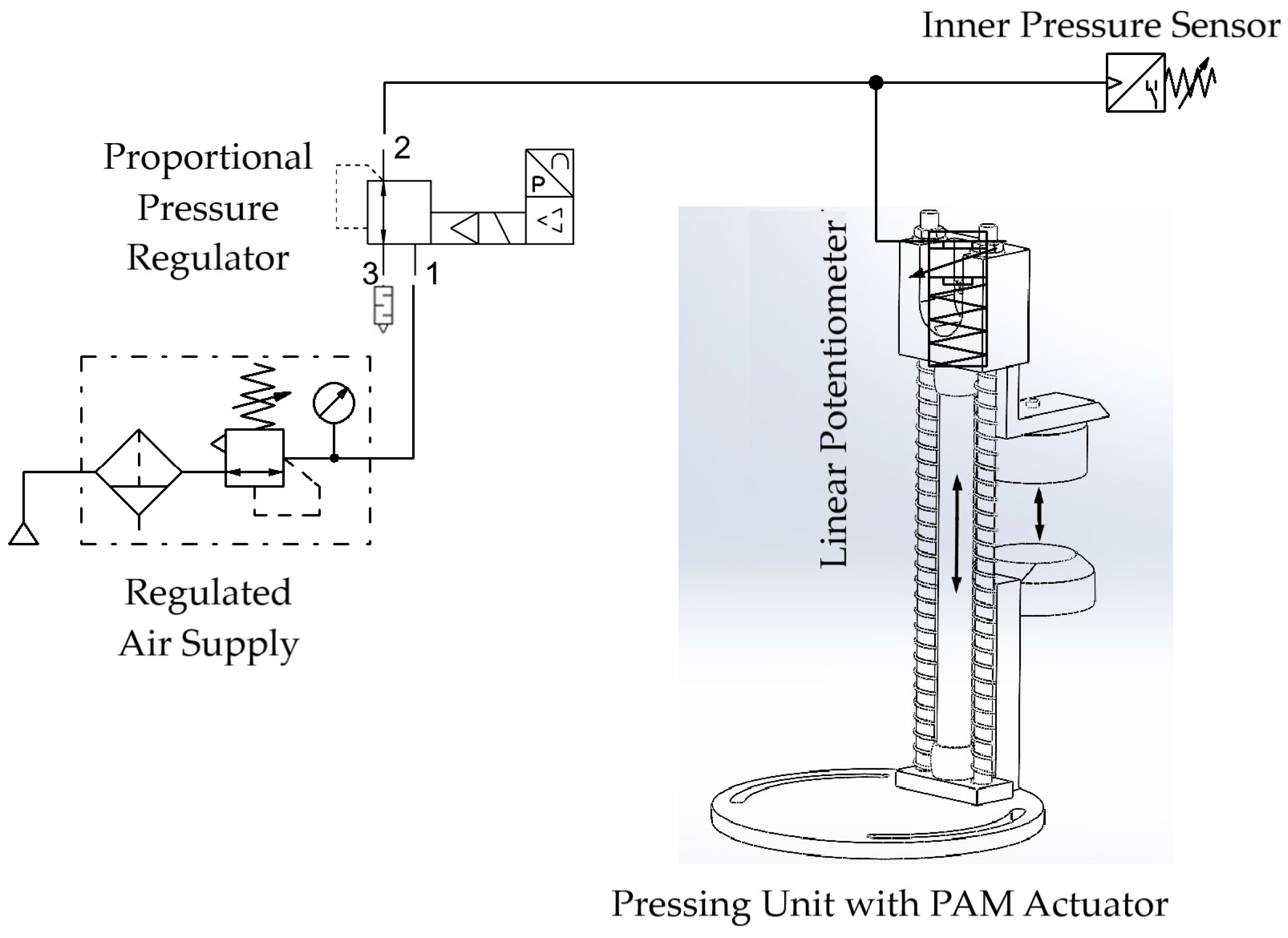

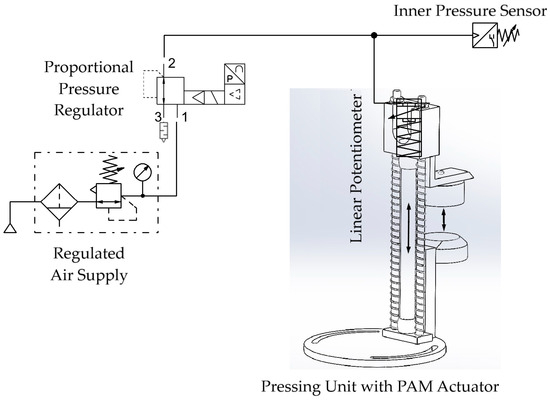

The system to be controlled using proportional pressure variation is a pressing unit. The system consists of a PAM serving as a single-acting actuator, along with two springs employed to accelerate the return to the initial position. Additionally, there is a mass constructed of a rigid aluminum block that interconnects all components within the system. In the pressing unit, the control variable is the compressed air to be applied with the assistance of a proportional regulator. The pneumatic schematic of the PAM used as an actuator is illustrated in Figure 5.

Figure 5.

Pneumatic schematic and measurement system of the pressing unit.

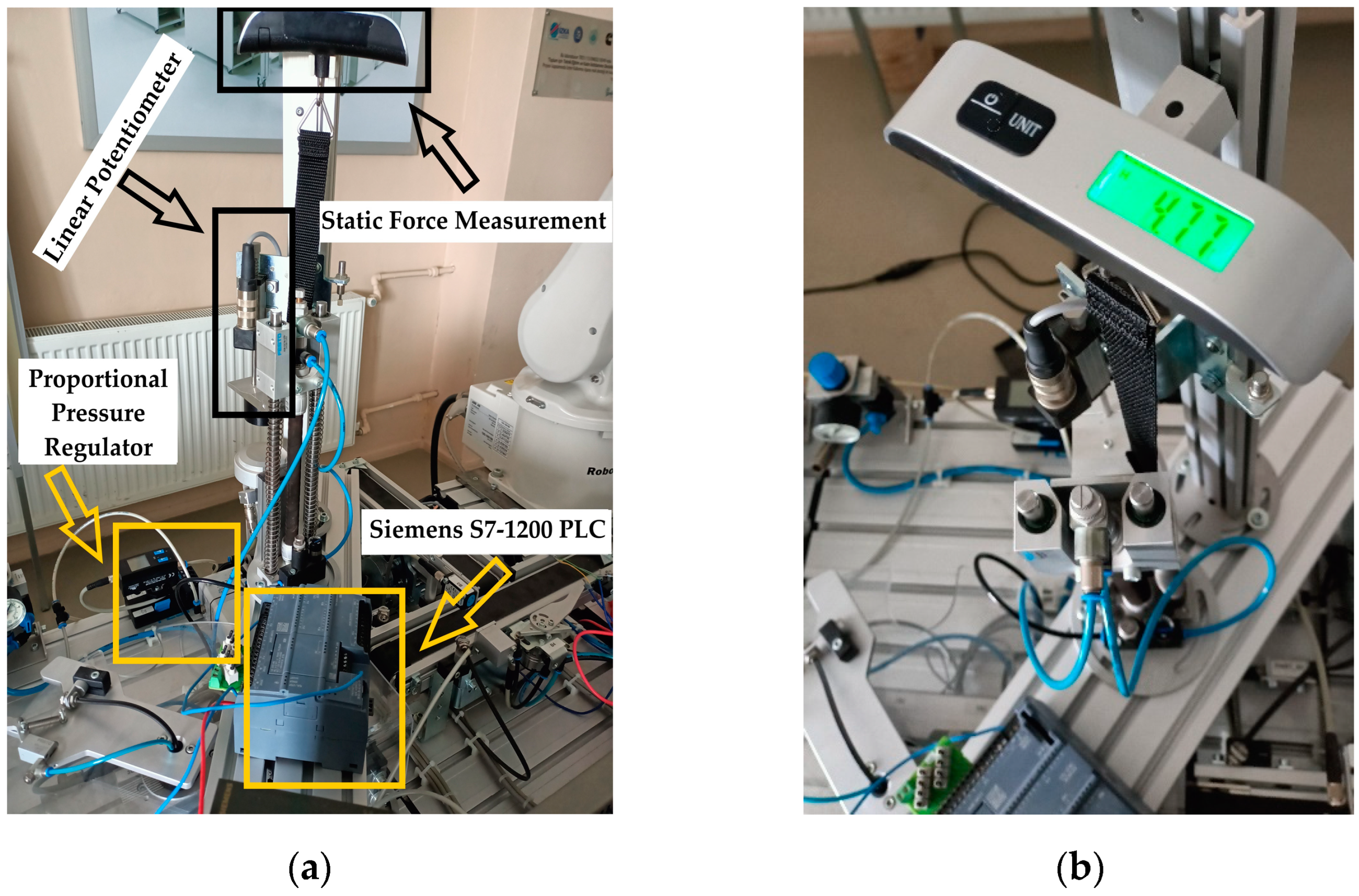

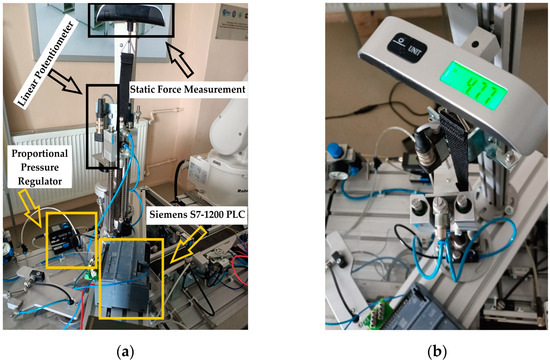

3.2.1. Preparing Data Set for Training

An experimental setup, shown in Figure 6, was constructed for collecting ANN training data. Pressure control for data collection was achieved by regulating the PAM pressure using a proportional regulator, which generated compressed air output ranging from 0 to 6 bar in response to a 0–10 V analog input. Position feedback during the pressing operation, resulting from PAM contraction, was obtained using a linear potentiometer, producing a 0–10 V analog voltage signal. Additionally, a load cell-based force measurement device was utilized to measure the force resulting from PAM contraction.

Figure 6.

(a) Experimental setup used in discrete data acquisition; (b) static force measurement obtained from the contraction with applied pressure.

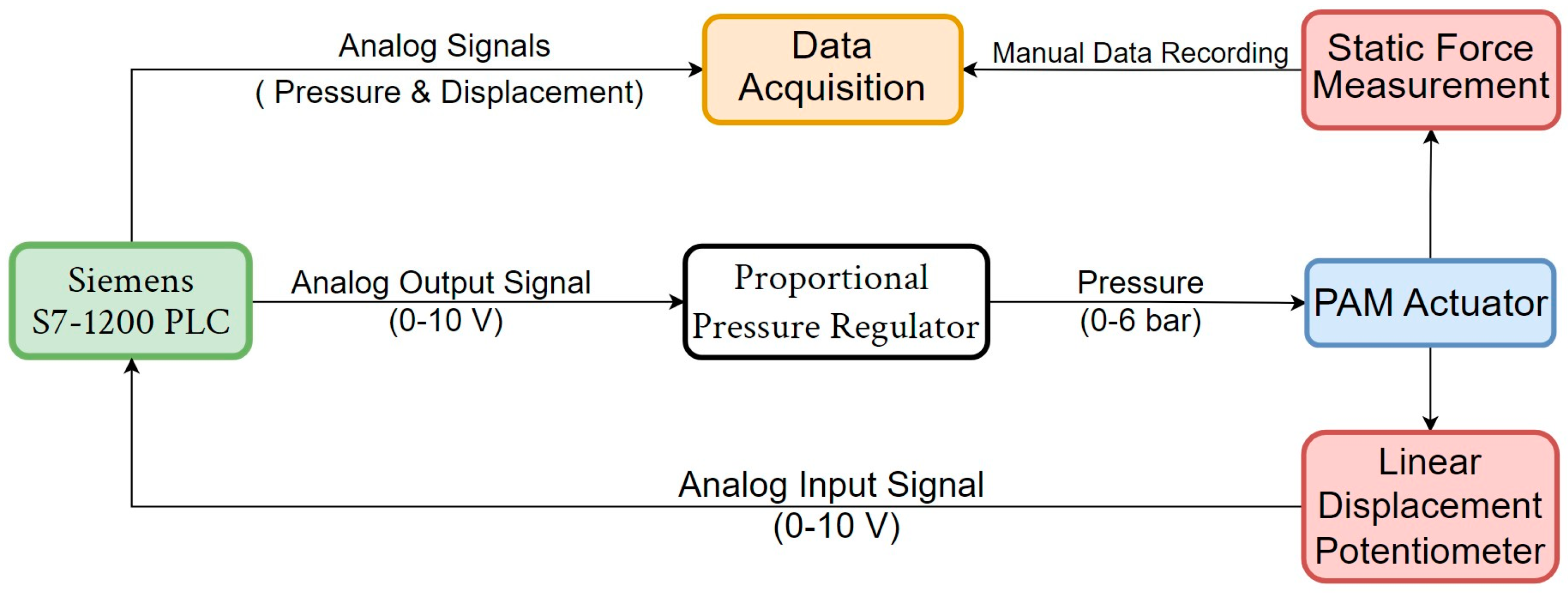

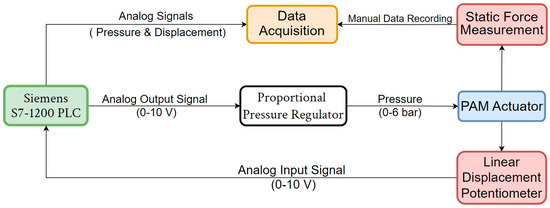

The data collection process, depicted in the schematic diagram in Figure 7, involved several steps. Initially, to adjust the inlet pressure of the PAM actuator, a FESTO VPPE-3-1/8-6-010 proportional pressure regulator was employed, converting the Siemens S7-1200 PLC’s 0–10 V analog output into a compressed air supply ranging from 0 to 6 bar. The displacement resulting from the PAM actuator’s contraction was measured using a linear displacement sensor connected to the analog input of the PLC. Simultaneously, the static force generated by the actuator’s contraction was quantified using a load cell-based static force measuring unit, with readings manually retrieved from a digital display and recorded accordingly.

Figure 7.

Data acquisition process of the experimental setup.

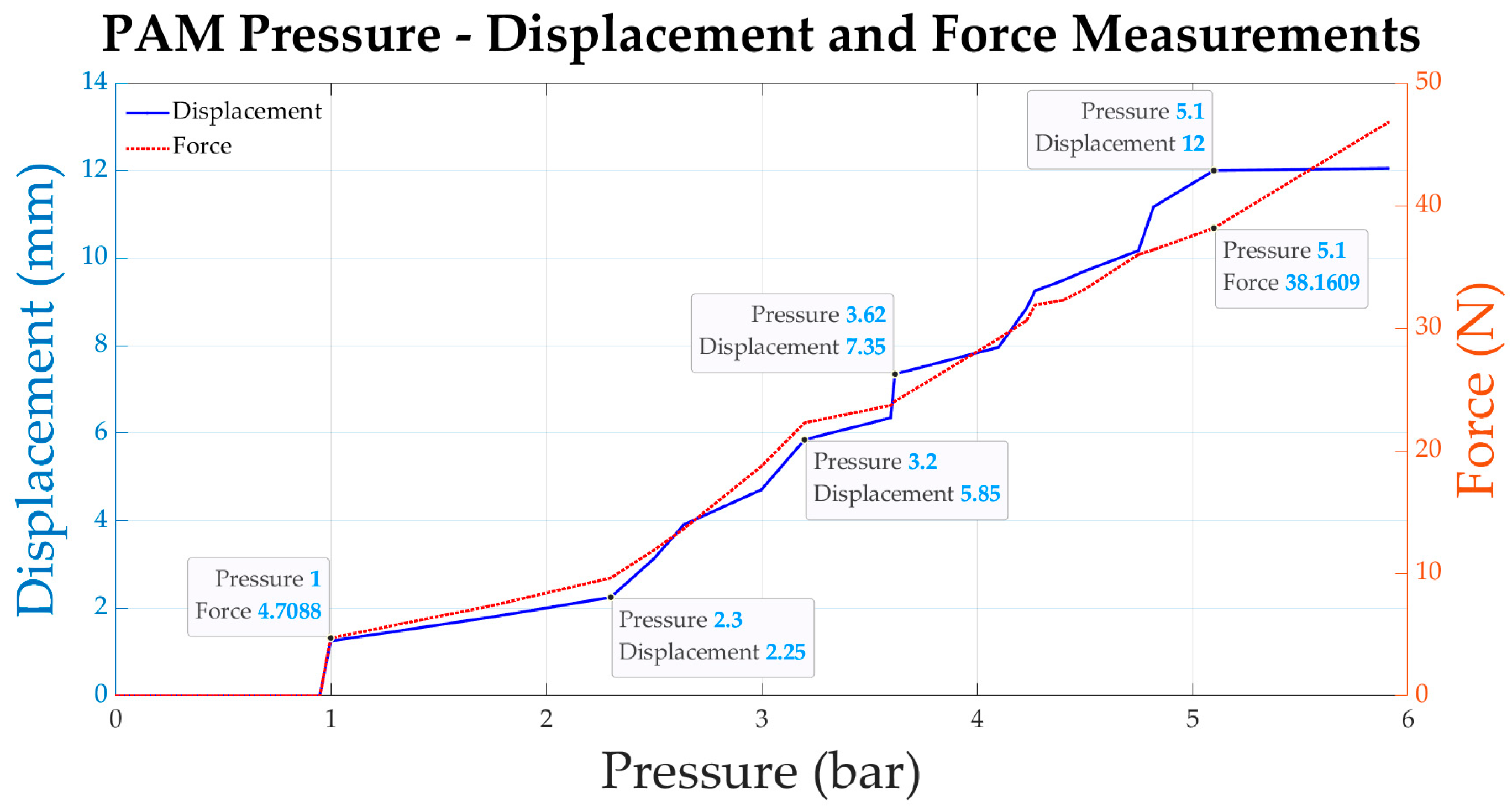

The experimental setup was used to measure and record the displacement and static force values corresponding to 25 different randomly selected pressure values. At the initial stage of data acquisition, the distance between the fixed base and the movable upper part of the Fluid Muscle Press module was measured as 40.4 mm, when no pressure was applied. In the non-pressured condition, the analog value read from the linear displacement sensor to be used for displacement measurement was recorded as an analog voltage signal of 2.27 V. In order to collect the subsequent 24 data, the compressed air controlled by the analog output signal of the PLC was gradually increased at randomly selected intervals, and the analog voltage signals obtained from the displacement sensor were collected. The displacement and the resulting contraction force at each inlet pressure change were read from the load cell-based measuring unit display and recorded manually. In this way, all of the training data shown in Table 1 were obtained.

Table 1.

Experimental data collection of the PAM.

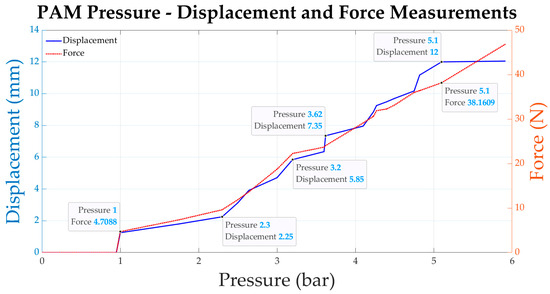

Due to the stochastic collection of data and incremental pressure changes from the experimental setup, the force–displacement graph depicting the system’s response to pressure variations was obtained and given in Figure 8. The graph illustrates that the system’s response to the input signal applied to the actuator is not linearly characterized.

Figure 8.

Displacement and force response of the PAM-actuated pressing unit.

3.2.2. Training of the ANN for the PLC Algorithm

Nonlinear systems, like the fluidic muscle press station, generate multiple system responses from the control variable. In the fluidic muscle press station case, static force and displacement outputs were obtained from the applied input pressure. Instead of using a single neural network model for estimating the force and displacement responses, we divided the neural network (NN) training process into two discrete sections: one for displacement and the other for generated static force. The employment of two separate artificial neural networks (ANNs) in a cascaded manner is driven by the advantages of modularity and customization. The selection of multiple ANNs allows for each to fulfill a specific task, facilitating easier training and the fine tuning of each network individually.

The first neural network was trained to generate the required pressure output for the desired displacement, and the second neural network predicted the generated static force according to the pressure control signal. After the training process, the first neural network’s output is connected to the second one’s input. With this method, a nonlinear system with one input and two outputs can be easily trained as two discrete single-input, single-output networks with limited training data. After training, it aims to reduce the system to a single control block by cascading the two networks. Thus, the input of the second network, which predicts the force to be produced as a result of contraction, will be the pressure control signal generated by the first network instead of the desired displacement value provided as raw data. As a result, the separately trained system can be expressed in a single control block and consistent outputs can be obtained.

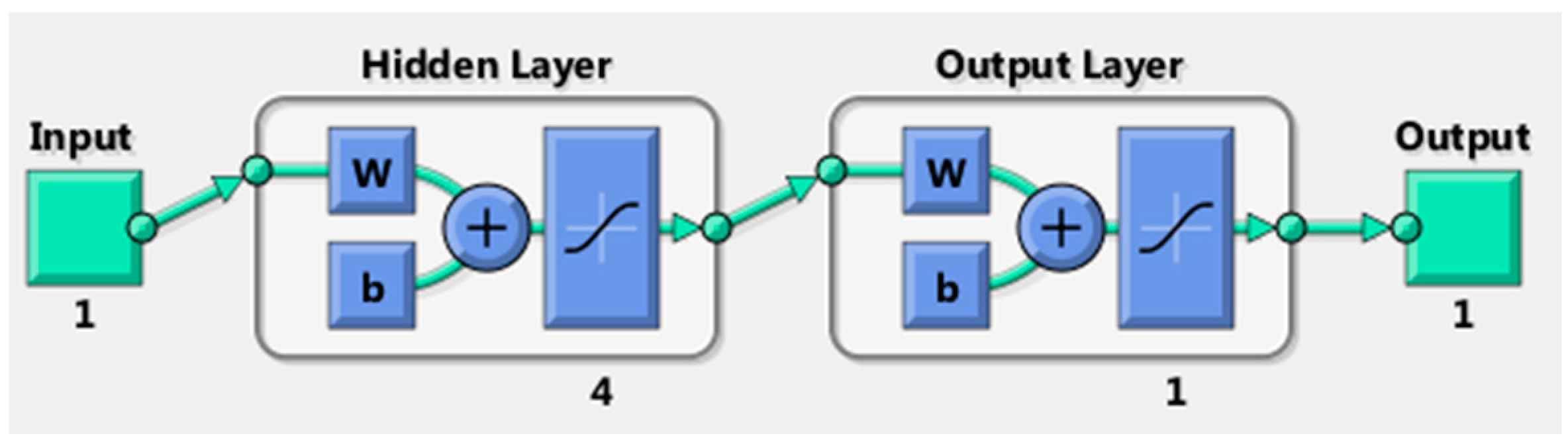

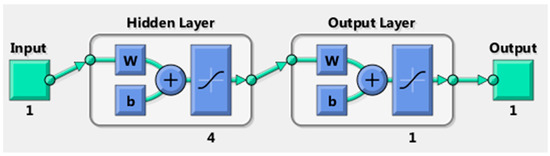

The hyperparameter of the feedforward backpropagation neural network architecture, as illustrated in Figure 9, is selected empirically as a single hidden layer containing four neurons with the Hyperbolic Tangent Sigmoid transfer function given in (8) for both networks.

Figure 9.

Feedforward backpropagated NN model for both displacement and static force.

The selection of a single-layered architecture with four neurons is motivated by the desire to mitigate the risk of overfitting associated with more complex structures, thus enhancing the model’s generalization capability. One of the primary motivations for selecting the sigmoid transfer function is its bounded output range and linearity. Additionally, its suitability for practical implementation in Simulink for generating PLC code is a significant factor. Given its smooth and continuous nature, the sigmoid function aligns well with the requirements of Simulink-based control system design, facilitating seamless integration into the PLC code generation process for embedded controller design for Edge AI.

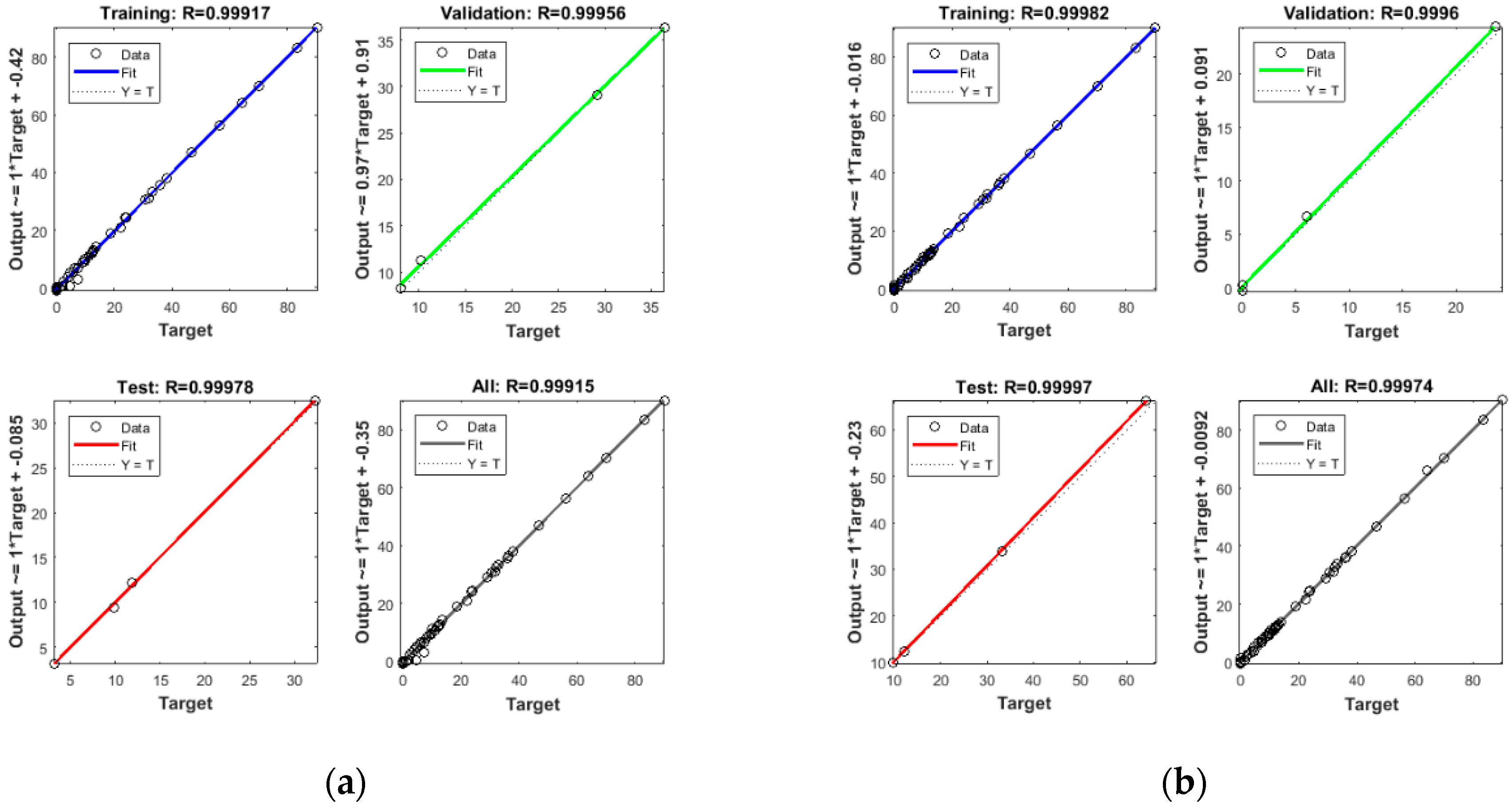

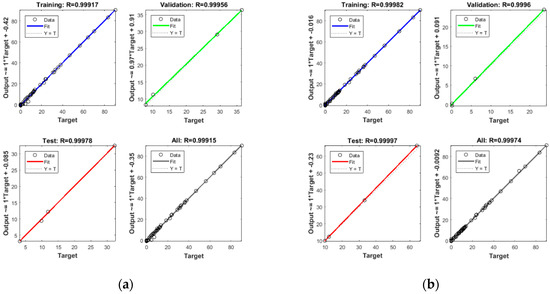

The MATLAB 2017b with Neural Network Toolbox 11.0 was used to train the network. The Levenberg–Marquardt algorithm was used for training processes due to its well-established efficiency in optimizing neural network parameters, especially in scenarios with complex and nonlinear relationships between input and output variables [31]. The experimentally collected data were randomly partitioned into 70% for training, 15% for validation, and 15% for testing purposes. Subsequently, the network training procedure was executed, iteratively adjusting network weights and biases to minimize the discrepancy between predicted and actual outputs. The performance of the neural networks was evaluated based on the Mean Square Error (MSE), with the results depicted in Figure 10a for displacement–pressure and Figure 10b for pressure–static force relationships. Figure 10 shows the relationship between the output of the networks developed for modeling and the targeted values obtained from the experimental results, as visualized through regression charts during the training, validation, and testing phases.

Figure 10.

Training and validation performance of neural networks: (a) pressure–force; (b) displacement–pressure.

4. Experimental Work

4.1. Embedded ANNs on PLCs

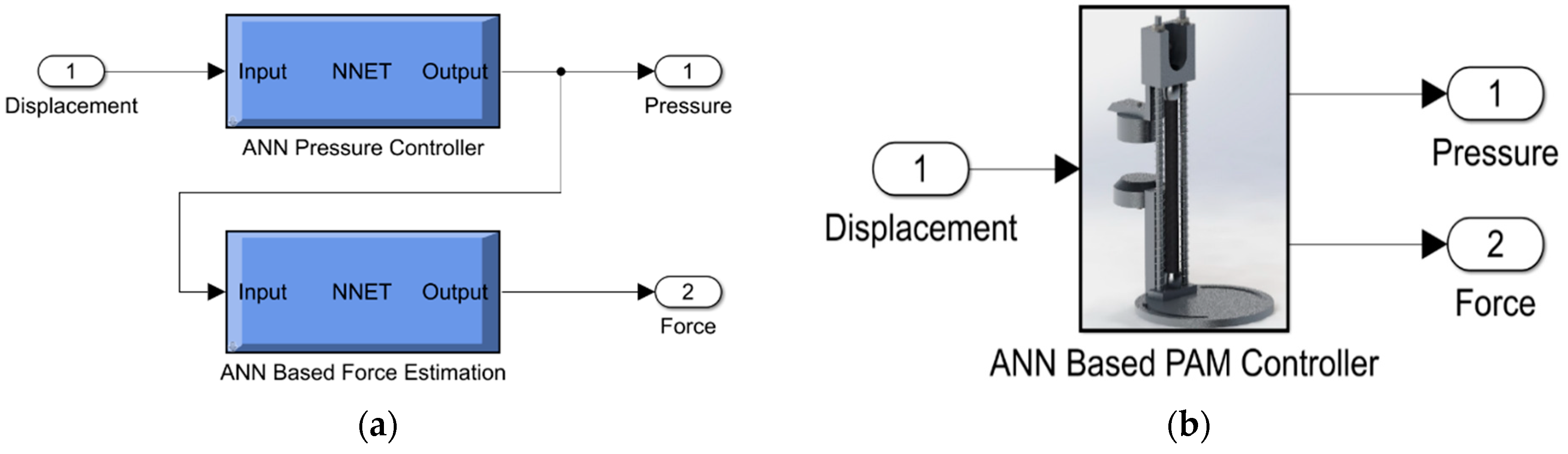

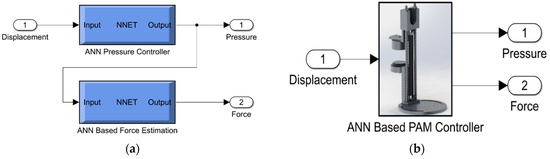

Discretely trained artificial neural networks were generated using the “gensim” function in MATLAB and then merged into a single model after being transferred to a Simulink environment. Since the targeted displacement will be used as input in the controller design and the static force will be generated by the pressure required for displacement, the two networks cascade, as shown in Figure 11.

Figure 11.

Simulink model of the controller: (a) subsystems; (b) masked main controller.

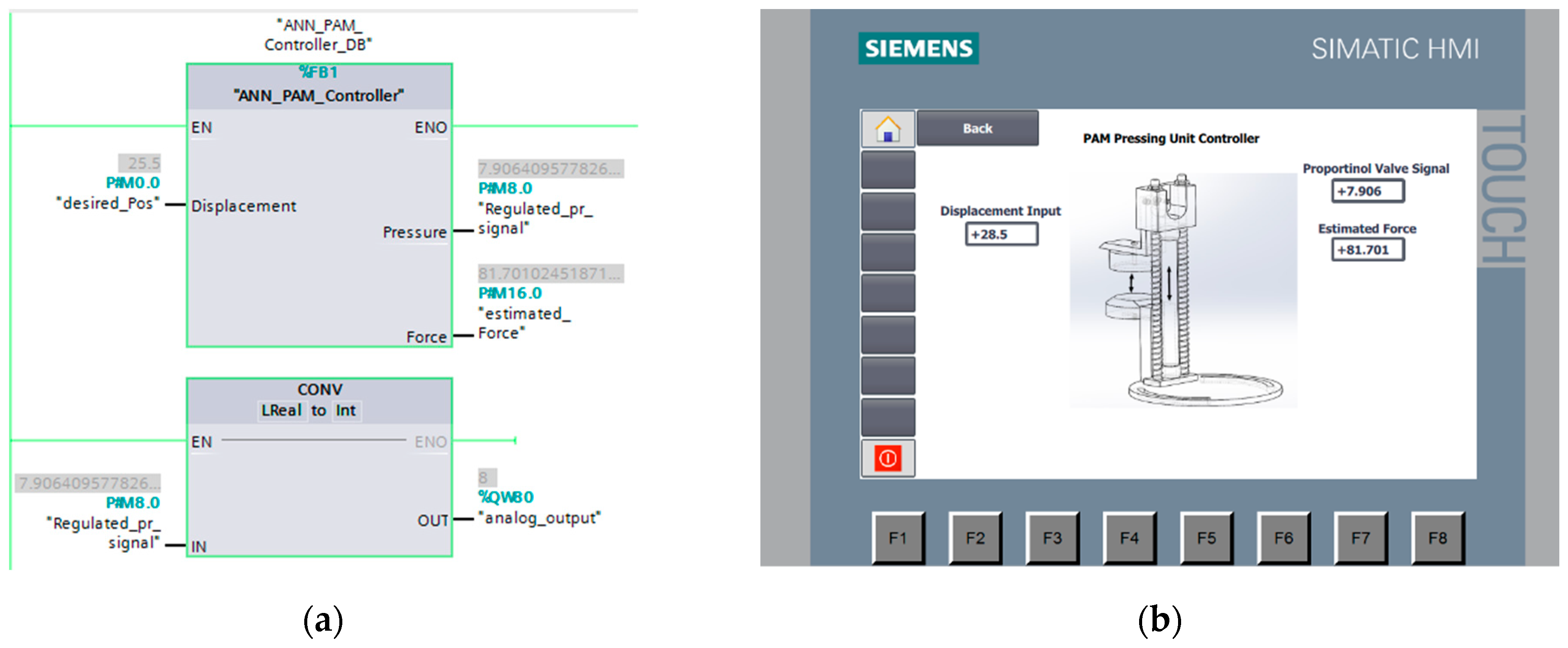

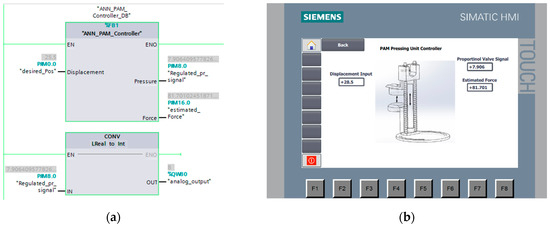

The neural networks were integrated into a subsystem that operates as a controller, with a pressure control signal and resultant force as the output and targeted displacement as the input. The subsystem was set up with the “treat as an atomic unit” preference, and the “target IDE” was adjusted to “TIA Portal Double precision” to create a Structured Control Language (SCL) output code that was used to create a function block for the Siemens S7-1200 PLC. The obtained SCL code was deployed as an external source code in the TIA Portal to generate the function block depicted in Figure 12a. PLC tags were assigned long real numbers for the Human–Machine Interface (HMI) to display the displacement input and generated pressure signal output of the proportional pressure regulator, as shown in Figure 12b.

Figure 12.

Embedded ANN-based data-driven controller on a PLC: (a) function block; (b) HMI design.

Without modeling a nonlinear system, a control algorithm was prepared with the ANN, the experimentally obtained data were trained, and the code of the ANN algorithm was then embedded in the PLC. Edge AI with transfer learning is embedded in the local PLC, prioritizing data processing at the source where the AI calculations are executed and control data are generated, thus avoiding the need for constant connectivity to remote servers.

4.2. Operation of the Embedded ANN on the PLC

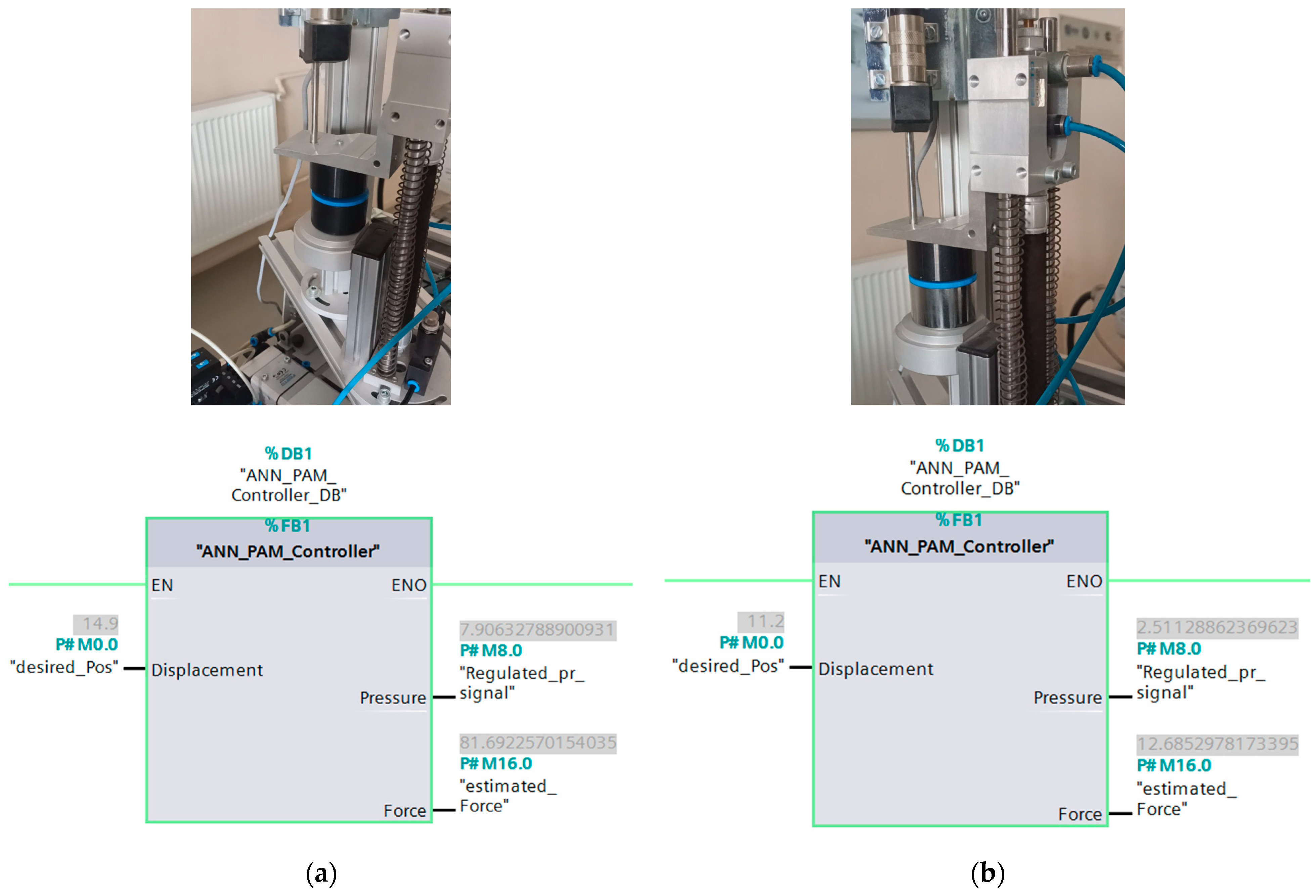

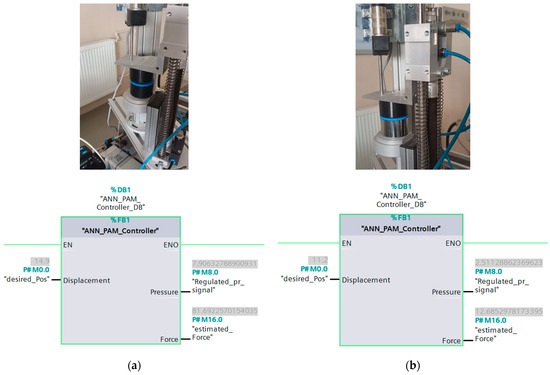

The designed ANN-based data-driven control algorithm was tested on the fluidic muscle station with twenty different positions and demonstrated over two different cylindrical test pieces, as shown in Figure 13, with a height of 25.5 mm for the aluminum part and 29.2 mm for the polymer-based part. Since the initial distance between the fixed lower support and the movable upper part of the pressing unit was 40.4 mm, the displacements required for the pressing process were 11.2 mm for the aluminum test piece and 14.9 mm for the polymer-based test piece.

Figure 13.

Test of the control algorithm and fluidic muscle station on two different test specimens: (a) polymer-based test piece; (b) aluminum test piece.

As shown in Figure 13, the position values used in the test parts are data not previously used in neural network training, and the desired position was achieved with the signal generated for the proportional pressure controller. The performance of the PAM-actuated pressing unit was observed to be satisfactory when positioning the aluminum test piece, achieving a displacement of 11.2 mm as desired. However, when attempting to position the polymer-based test piece, which required a displacement of 14.9 mm, the desired position could not be attained as it exceeded the contractile limits of the PAM. Nevertheless, the control algorithm managed to produce a result through extrapolation. The force exerted by the PAM due to contraction, necessary for positioning the polymer-based test piece, was estimated to be 81.7 N as a secondary output, whereas it was 12.68 N for the aluminum test piece.

5. Results

The primary aim of this study was to develop an ANN-supported open-loop control algorithm for a PAM-based system, which faces challenges in mathematical modeling due to its nonlinear characteristics, and to execute the obtained algorithm on a real-time embedded system. Hence, the design of an ANN-based control algorithm for the PAM model is anticipated to address this gap.

In order to test the success of the obtained ANN-based controller in building the system model and to test the generated results by comparing them with actual measurements, 20 different target displacement values were used. The displacement values used during the test were selected from the values not used during ANN training. Thus, we aimed to evaluate the generalization capabilities of the ANN-based controller at interpolation and extrapolation points.

The selected target displacement values were used as the input, and the control signals generated by the ANN-based function block were fed to the analog output of the PLC. The PAM was pressurized with the help of a proportional pressure regulator controlled by the analog output. The displacement of the PAM as a result of the applied pressure input was measured with a linear potentiometer. In order to compare the static force prediction of the ANN-based controller after the displacement, static force values were read with the force-measuring device at the final position. The differences between the measured and targeted displacement values, the resulting static force, and the predicted force were achieved, as shown in Table 2.

Table 2.

Results and comparisons of the ANN-based controller in the experimental setup.

To calculate the absolute errors of the displacement values, the differences between the target displacement and the actual displacement were used. In the same manner, to calculate the static force errors resulting from the displacement, the difference between the force value measured at the final position and the prediction of the ANN-based controller was used.

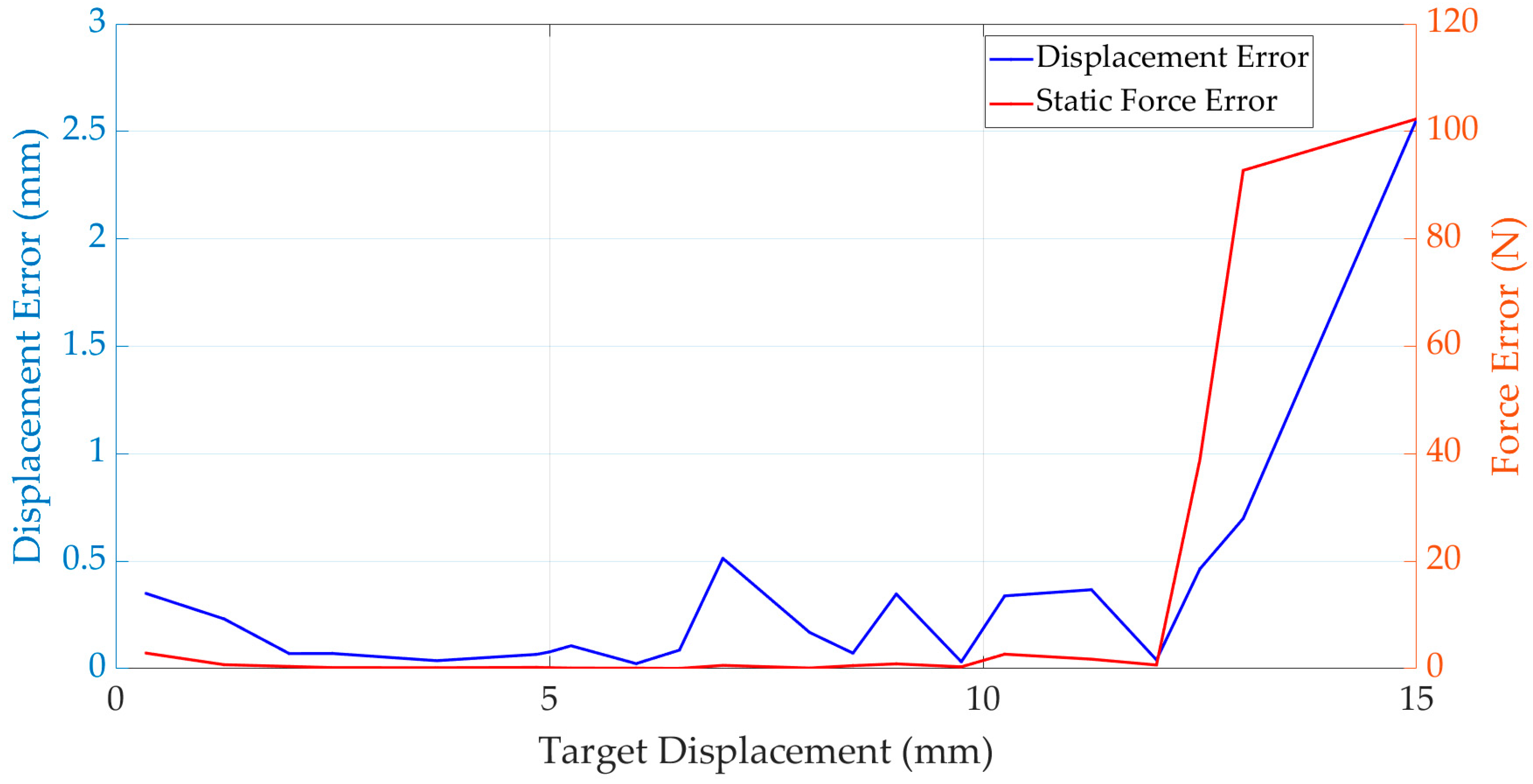

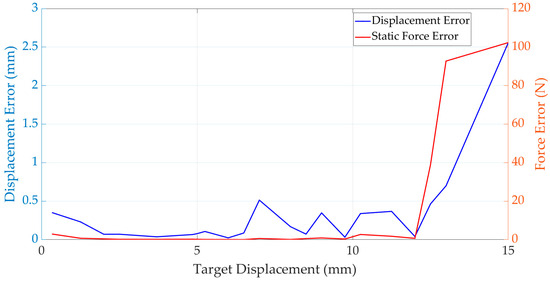

Figure 14 shows the errors produced by the fluidic muscle station actuated with the pressure input controlled by the PLC in response to the target displacement values.

Figure 14.

Displacement and force prediction errors of the controller.

It is seen that the greatest displacement error occurs when the obtained displacement is 12.44 mm while the targeted displacement is 15 mm. The desired displacement value is beyond the physical contraction limits of the PAM, but the ANN-based controller still produced an output, so the PAM could not move to the desired position. The point where the largest displacement error occurs also has a greater value than the upper boundary of the ANN training data previously shared in Table 1. When the errors within the boundaries of the training data are analyzed, it is seen that the second largest error occurs when a 7.51 mm displacement is reached at a target displacement value of 7 mm.

Similar situations were found for the static force errors shown in Table 2 and Figure 6. The ANN-based control algorithm calculates the force values using the displacement results. Therefore, if the desired displacement exceeds the contraction limits of the PAM, the controller produces results even though the target point cannot be reached. For the reasons mentioned, the largest error between the expected and measured values for static forces was 102.33 N in the scenario where a target displacement of 15 mm outside the contraction limits was used. The largest error within the contraction limits is the calculation of the force as 37.55 N in the case where a 10.25 mm displacement is desired, but the measurement result is 34.85 N.

As a result of the tests performed, it is seen that the ANN-based controller shows an acceptable level of modeling capability for points within the physical limits of the PAM-based system, but as the training data and physical limits are exceeded, the model becomes error prone.

6. Discussion

In this study, a fully data-driven-based open-loop controller design has been implemented for PAM-actuated systems that have nonlinear characteristics and have differences between the proposed mathematical models and experimental test results. The controller, which is embedded in a PLC (Siemens S7-1200), one of the control devices frequently used in field applications due to its reliability, is designed with input variable pressure value and the output force and displacement responses instead of analyzing the sub-components of the system one by one.

Utilizing the gathered data, two distinct artificial neural networks were trained to delineate the relationships between displacement and pressure, as well as pressure and force. Subsequently, a cascade controller was formulated, wherein the pressure signal, derived from the artificial neural network estimating the displacement–pressure model from the two discrete models, serves as input to another artificial neural network defining the pressure–force relationship. Consequently, by inputting the desired position of the pressing unit, the cascade controller generates the requisite control signal for the proportional control regulator, facilitating the regulation of pressure. Additionally, the static force exerted on the PAM due to displacement is acquired as an additional output.

A comparison of the experimental results obtained in our study with those from the literature [11] that uses DMSP-20 reveals notable differences in the modeling approaches and error magnitudes. Our experimental setup involved the utilization of a PAM actuator in combination with pre-tensioning springs and an aluminum block, constituting a more comprehensive system than the focus on the PAM alone in previous studies. While previous studies have primarily focused on modeling the PAM’s behavior, our approach aimed to capture the model of the entire system through a data-driven approach. Despite the differences in system composition, we compared the errors of various force models from the literature to assess the efficacy of our approach. Table 3 presents the percentage errors of these force models computed based on (9) with the measured and predicted force values [11].

Table 3.

Force errors of different models from the literature.

The fact that the analytical models proposed for the calculation of the force to be produced by the contraction of the DMSP-20 PAM used in the fluidic muscle station also perform calculations with margins of error is a consequence of the nonlinear characteristics of the system. In the McKibben, Andrikopoulos, and Wickramatunge model, the difference between the experimental results and the results produced by the system model is more than 8%, while the errors are reduced in the models proposed by Hildebrandt, Sarosi, and Martens. The results produced by the ANN-based controller proposed in this study were observed to produce acceptable results with an error rate of 7.72%, despite the fact that other components of the system, in addition to the DMSP-20 PAM, increased the nonlinearity of the model. The calculated error rate of 7.72% occurred when the system produced a static force of 34.85 N, although the PAM was predicted to produce a force of 37.55 N in the case where a displacement of 10.25 mm was required. However, it should be noted that the error calculation was performed by considering only the values of the points where the system can move within the physical limits from the results produced by the ANN-based controller. When a displacement outside the contraction limits of the PAM is desired, the controller will still calculate a force value, but since the PAM cannot reach the desired point anyway, it will not be possible to reach the predicted force. If these scenarios are considered, the increase in the margin of error in the system will increase drastically, as shown in Table 2.

Similar to the calculation of the absolute error of the static force, when the desired and actual displacements are considered, the controller’s error when the target value is 7 mm and the measured value is 7.513 mm will give the largest proportional error. The maximum deviation value of 6.83% will be reached with the ratio of the absolute error to the measured displacement in the results produced for displacement.

Taking into account that the studied system is composed of mass and pre-tension springs other than PAM, and that the controller is trained only with inputs and outputs without knowing the value of any component in the controller design in a priori, the error values may be considered acceptable. Even the proposed models for systems with only PAMs produce results with different deviations, so it can be concluded that the obtained results are quite satisfying.

7. Conclusions

In this study, the ANN-based approach has been integrated into a PLC-based embedded system for the open-loop control algorithm of a fluidic muscle station with a PAM actuator, which makes it difficult to construct a mathematical model due to its nonlinear characteristics. The proposed control algorithm was built and integrated into the PLC without the need for any mathematical modeling of the system components, only with the help of the data collected from the experimental setup. The data acquisition phase needed for the training of the ANN-based controller, the training of the artificial neural network and parameter selection, the integration of the controller into the embedded system, and the test phases performed in the physical system are shared in a sequential manner.

As a result, a pipeline has been established for the development and experimental validation of an ANN-based control algorithm, designed to address the challenges faced in obtaining the mathematical model of systems with nonlinear characteristics, particularly those utilizing the PAM. The success of the real-time embedded system with the ANN-based control algorithm, functioning without the need for modeling other system components alongside the nonlinear PAM, has been supported by experimental findings.

Future work will investigate the effectiveness of different activation functions, hyperparameters, and complex neural network architectures in improving the performance of embedded controllers designed for nonlinear systems. In addition, we aim to produce more accurate and generalizable models using an expanded dataset collected from systems with multiple PAMs and different training algorithms. Thus, the effects of hyperparameter and network structure choices on the success of the trained models in representing any PAM, generalization ability, accuracy, and possible performance improvement will be examined.

Author Contributions

M.E., investigation, designed the overall methodology, writing—original draft, reviewing, and editing; O.D., investigation, designed the overall methodology, designed and performed the experiments; D.E., investigation, designed the overall methodology, writing—original draft, reviewing, and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yang, Z.R.; Yang, Z. Artificial Neural Networks. In Comprehensive Biomedical Physics, 1st ed.; Budinger, T.F., Panetta, D., Demi, M., Belkić, D., Belkić, K., Alves, F., Kiessling, F., McAdams, E., Gehin, C., Uesaka, M., et al., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 6, pp. 1–17. [Google Scholar] [CrossRef]

- Himavathi, S.; Anitha, D.; Muthuramalingam, A. Feedforward neural network implementation in FPGA using layer multiplexing for effective resource utilization. IEEE Trans. Neural. Netw. 2007, 18, 880–888. [Google Scholar] [CrossRef] [PubMed]

- Partal, S.; Şenol, I.; Bakan, A.F.; Bekiroǧlu, K.N. Online speed control of a brushless AC servomotor based on artificial neural networks. Turk. J. Electr. Eng. Comput. Sci. 2011, 19, 373–383. [Google Scholar] [CrossRef]

- Alblawi, A. Fault diagnosis of an industrial gas turbine based on the thermodynamic model coupled with a multi feedforward artificial neural networks. Energy Rep. 2020, 6, 1083–1096. [Google Scholar] [CrossRef]

- Shaik, N.B.; Pedapati, S.R.; Ammar Taqvi, S.A.; Othman, A.R.; Abd Dzubir, F.A. A Feed-Forward Back Propagation Neural Network Approach to Predict the Life Condition of Crude Oil Pipeline. Processes 2020, 8, 661. [Google Scholar] [CrossRef]

- Rahmanifard, H.; Plaksina, T. Application of artificial intelligence techniques in the petroleum industry: A review. Artif. Intell. Rev. 2018, 52, 2295–2318. [Google Scholar] [CrossRef]

- Bozkurt, H.; Macit, R.; Çelik, Ö.; Teke, A. Evaluation of artificial neural network methods to forecast short-term solar power generation: A case study in Eastern Mediterranean Region. Turk. J. Electr. Eng. Comput. Sci. 2022, 30, 2013–2030. [Google Scholar] [CrossRef]

- Boujoudar, Y.; Azeroual, M.; El Moussaoui, H.; Lamhamdi, T. Intelligent controller based energy management for stand-alone power system using artificial neural network. Int. Trans. Electr. Energy Syst. 2020, 30, e12579. [Google Scholar] [CrossRef]

- Liu, Z.; Peng, K.; Han, L.; Guan, S. Modeling and Control of Robotic Manipulators Based on Artificial Neural Networks: A Review. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023, 47, 1307–1347. [Google Scholar] [CrossRef]

- Robinson, R.M.; Kothera, C.S.; Sanner, R.M.; Wereley, N.M. Nonlinear Control of Robotic Manipulators Driven by Pneumatic Artificial Muscles. IEEE-ASME Trans. Mechatron. 2016, 21, 55–68. [Google Scholar] [CrossRef]

- Martens, M.; Boblan, I. Modeling the static force of a Festo pneumatic muscle actuator: A new approach and a comparison to existing models. Actuators 2017, 6, 33. [Google Scholar] [CrossRef]

- Dzahir, M.A.M.; Yamamoto, S.I. Dynamic modeling of McKibben muscle using empirical model and particle swarm optimization method. Appl. Sci. 2019, 9, 2538. [Google Scholar] [CrossRef]

- Kalita, B.; Dwivedy, S.K. Nonlinear dynamics of a parametrically excited pneumatic artificial muscle (PAM) actuator with simultaneous resonance condition. Mech. Mach. Theory 2019, 135, 281–297. [Google Scholar] [CrossRef]

- Mokhtarname, R.; Safavi, A.A.; Hassanpour, M.A.; Arefi, M.M. Design and implementation of an industrial generalized predictive controller on multivariable processes via programmable logic controllers. In Proceedings of the 2015 10th Asian Control Conference: Emerging Control Techniques for a Sustainable World, ASCC 2015, Kota Kinabalu, Malaysia, 31 May–3 June 2015. [Google Scholar] [CrossRef]

- Jung, I.-S.; Mulman, B.M.; Thapa, D.; Koo, L.-J.; Bae, J.-H.; Hong, S.-H.; Yeo, S.; Park, C.M.; Park, S.C.; Wang, G.-N. PLC control logic error monitoring and prediction using Neural Network. In Proceedings of the Fourth International Conference on Natural Computation, Jinan, China, 18–20 October 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Schwung, D.; Yuwono, S.; Schwung, A.; Ding, S.X. Decentralized learning of energy optimal production policies using PLC-informed reinforcement learning. Comput. Chem. Eng. 2021, 152, 107382. [Google Scholar] [CrossRef]

- Topalova, I.; Tzokev, A. Optimization of a MLP network structure for a real-time PLC application. In Proceedings of the IEEE Convention of Electrical and Electronics Engineers, Eilat, Israel, 3–5 December 2008. [Google Scholar] [CrossRef]

- Li, J.; Gomez-Espinosa, A. Improving PID Control Based on Neural Network. In Proceedings of the 2018 International Conference on Mechatronics, Electronics and Automotive Engineering, ICMEAE 2018, Cuernavaca, Mexico, 26–29 November 2018. [Google Scholar] [CrossRef]

- Hui, G.; Cheng-Hua, F.; Shu-Chuan, G. A Fuzzy Neural Network Algorithm applied to S7-200 PLC. In Proceedings of the 2011 Eighth International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Shanghai, China, 26–28 July 2011. [Google Scholar] [CrossRef]

- Topalova, I.; Tzokev, A. Automated texture classification of marble shades with real-time PLC neural network implementation. In Proceedings of the International Joint Conference on Neural Networks, Barcelona, Spain, 18–23 July 2010. [Google Scholar] [CrossRef]

- Fonseca, J.V.; Ferreira EF, M. Increase of PLC computability with neural network for recovery of faults in electrical distribution substation. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013. [Google Scholar] [CrossRef]

- Werbos, P.J. Beyond Regression: New Tools for Prediction and Analysis in the Behavioral Science. Ph.D. Thesis, Harvard University, Cambridge, MA, USA, 1974. [Google Scholar]

- Wu, Y.C.; Feng, J.W. Development and Application of Artificial Neural Network. Wirel. Pers. Commun. 2018, 102, 1645–1656. [Google Scholar] [CrossRef]

- Toktaş, İ.; Özkan, M.T.; Erdemir, F.; Yuksel, N. Determination of Stress Concentration Factor (Kt) for a Crankshaft Under Bending Loading: An Artificial Neural Networks Approach. J. Polytech. 2020, 23, 813–819. [Google Scholar] [CrossRef]

- Yavuz, S.; Özkan, M.T. Yaprak Yayların Parametrik Sonlu Elemanlar Analizi ve Yapay Sinir Ağı ile Modellenmesi. J. Polytech. 2022, 25, 827–842. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Wegmann, H. Fuzzy control and neural networks industrial applications in the world of PLCs. In Proceedings of the IEEE Conference on Control Applications, Glasgow, UK, 24–26 August 1994. [Google Scholar] [CrossRef]

- Tovar, E.; Vasques, F. Real-time fieldbus communications using Profibus networks. IEEE Trans. Ind. Electron. 1999, 46, 1241–1251. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Nikolakopoulos, G.; Arvanitakis, I.; Manesis, S. Piecewise affine modeling and constrained optimal control for a pneumatic artificial muscle. IEEE Trans. Ind. Electron. 2014, 61, 904–916. [Google Scholar] [CrossRef]

- Festo. Fluidic Muscle DMSP/MAS. 2008. Available online: https://www.festo.com/net/SupportPortal/Files/704660/DMSP-MAS_EN.PDF (accessed on 24 April 2024).

- Moré, J.J. The Levenberg–Marquardt algorithm: Implementation and theory. In Numerical Analysis. Lecture Notes in Mathematics, 1st ed.; Watson, G.A., Ed.; Springer: Berlin/Heidelberg, Germany, 1978; Volume 630, pp. 106–116. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).