Analytical Evaluation of Laser Cleaning Effectiveness in the Context of Contemporary Muralism

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

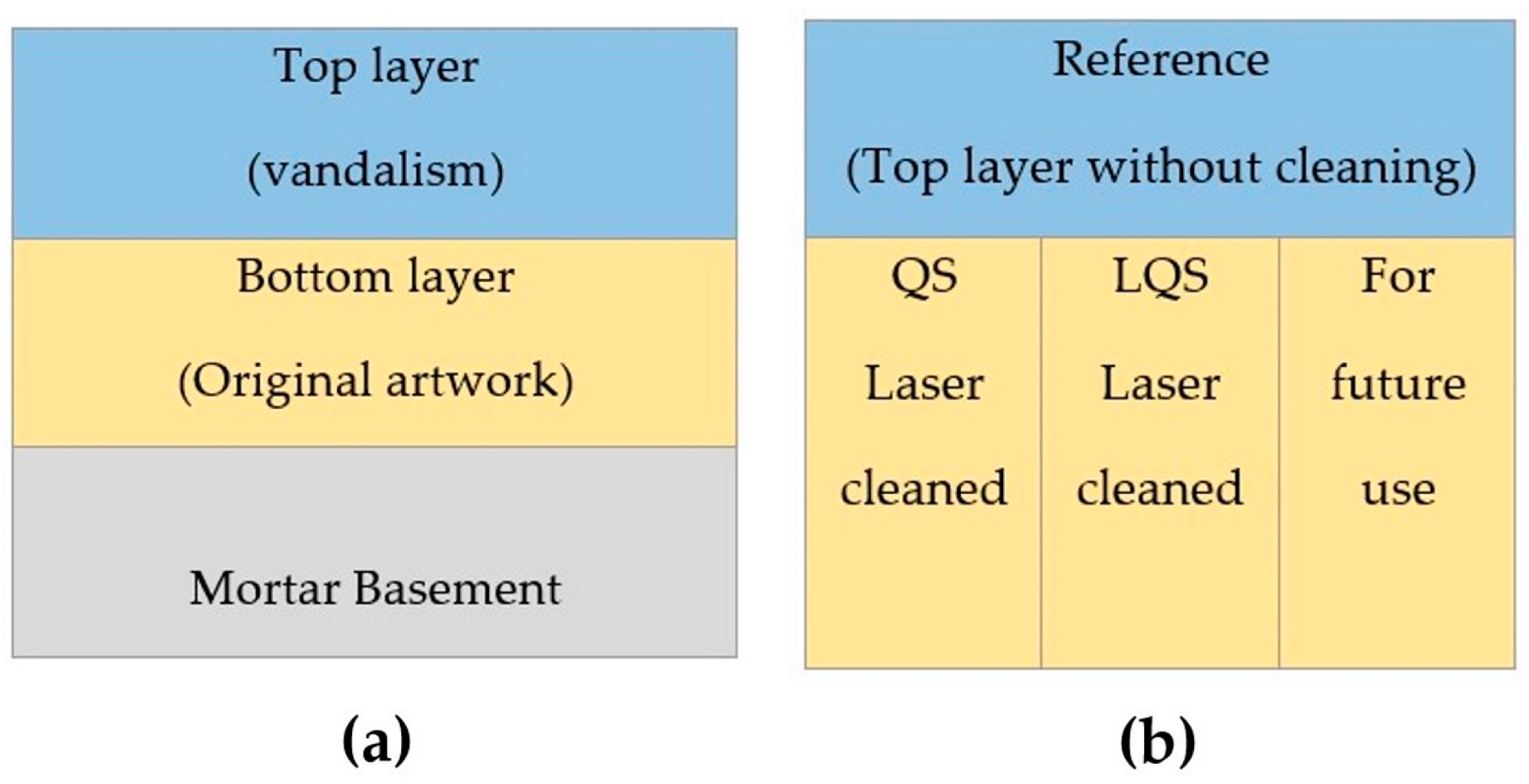

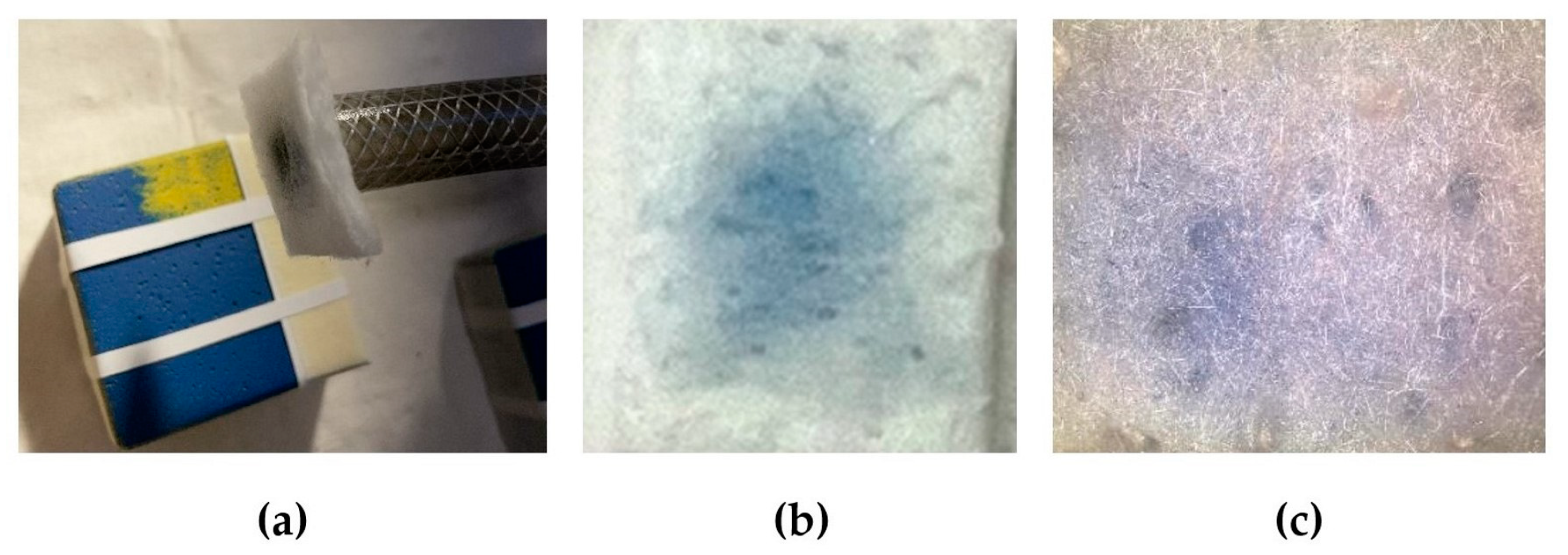

2.1.1. Sample Preparation

2.1.2. Cleaning Instrument

2.1.3. Cleaning Method

2.2. Instrumentation

2.2.1. Optical Microscope

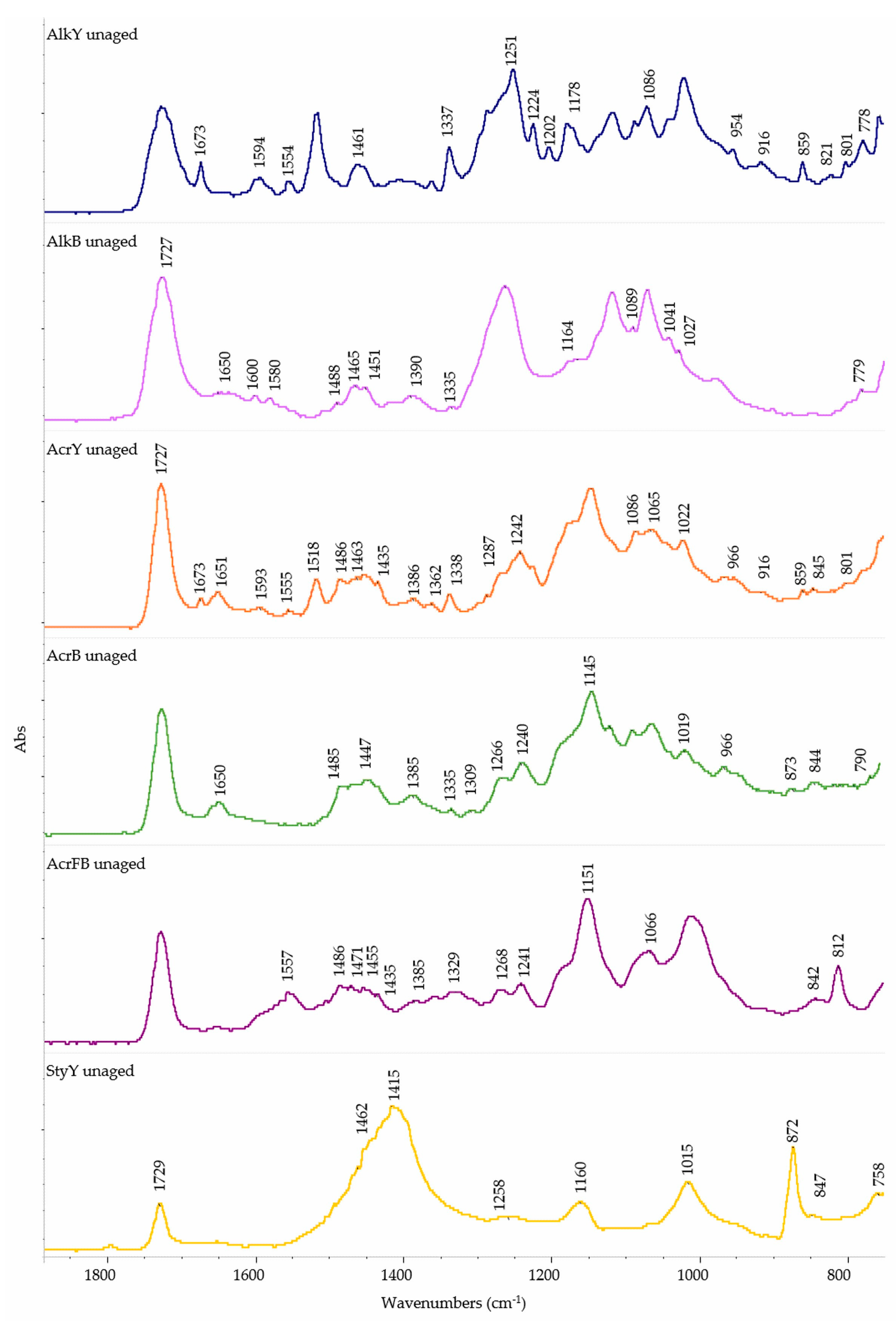

2.2.2. Micro-Attenuated Total Reflection-Fourier Transform Infrared (Micro–ATR–FTIR)

2.2.3. Raking Light Photography (RLP)

2.2.4. Colorimetric Measurement

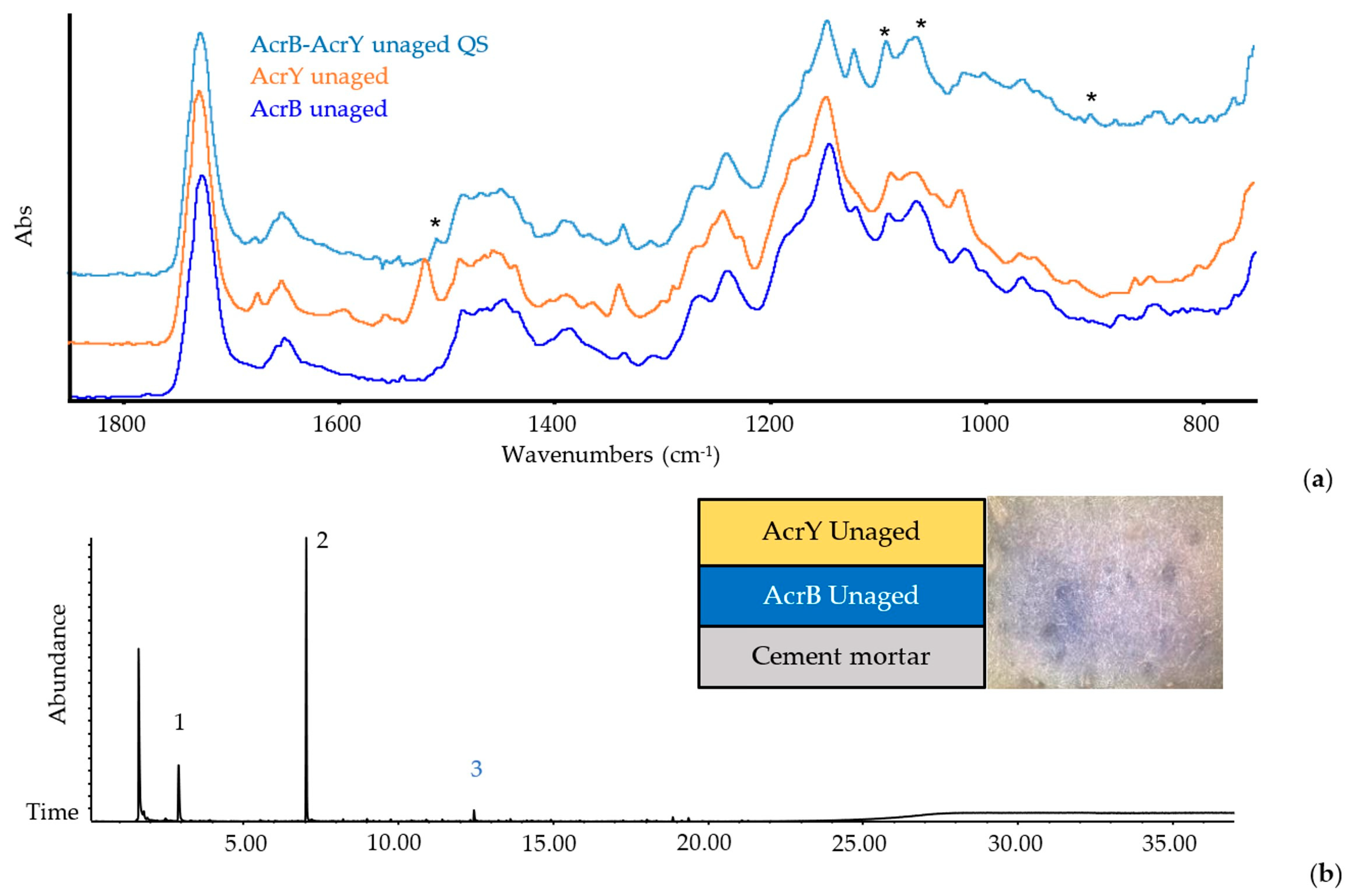

2.2.5. Pyrolysis-Gas Chromatography/Mass Spectrometry (Py–GC/MS)

3. Results

3.1. Characterization of Painting Material

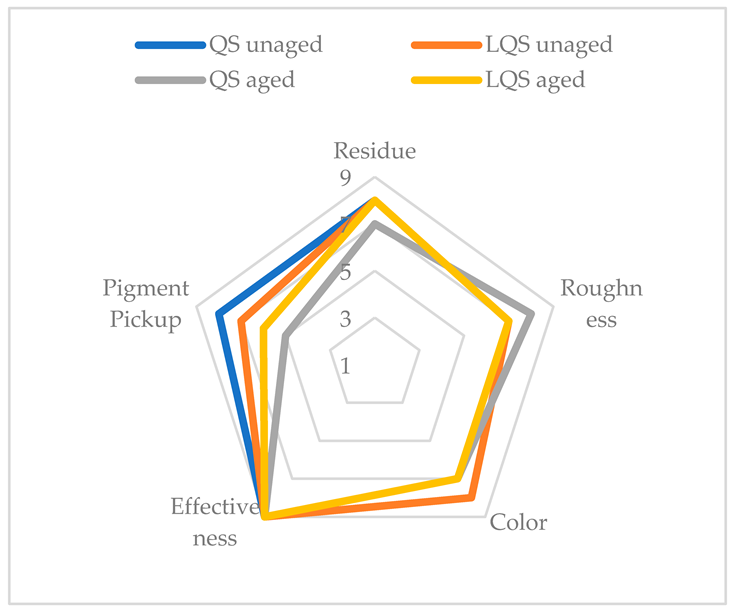

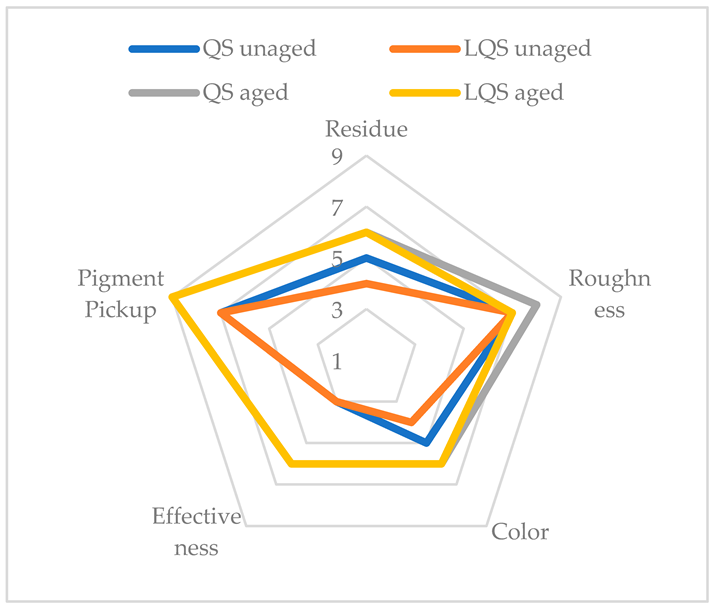

3.2. Empirical Evaluation

- Presence of residues, i.e., the presence of uncleaned residues assessed with the naked eye during the cleaning procedure and under an optical microscope;

- Roughness of the surface (topography integrity), i.e., the conservation state of the cleaned surface evaluated using grazing light photography;

- Color change, evaluated by the naked eye, comparing color changes before and after cleaning, and then further verified by colorimetric measurements;

- Cleaning effectiveness, i.e., the minimum cleaning cycles needed to achieve an acceptable result;

- Pigment pickup, assessed as the color of the bottom layer of paint absorbed onto the quartz fiber membrane during the cleaning process. This material is then analyzed by Py-GC/MS in a second stage.

3.3. Analytical Results

3.3.1. Color Change: Colorimetric Measurements

3.3.2. Roughness: Raking Light Photography

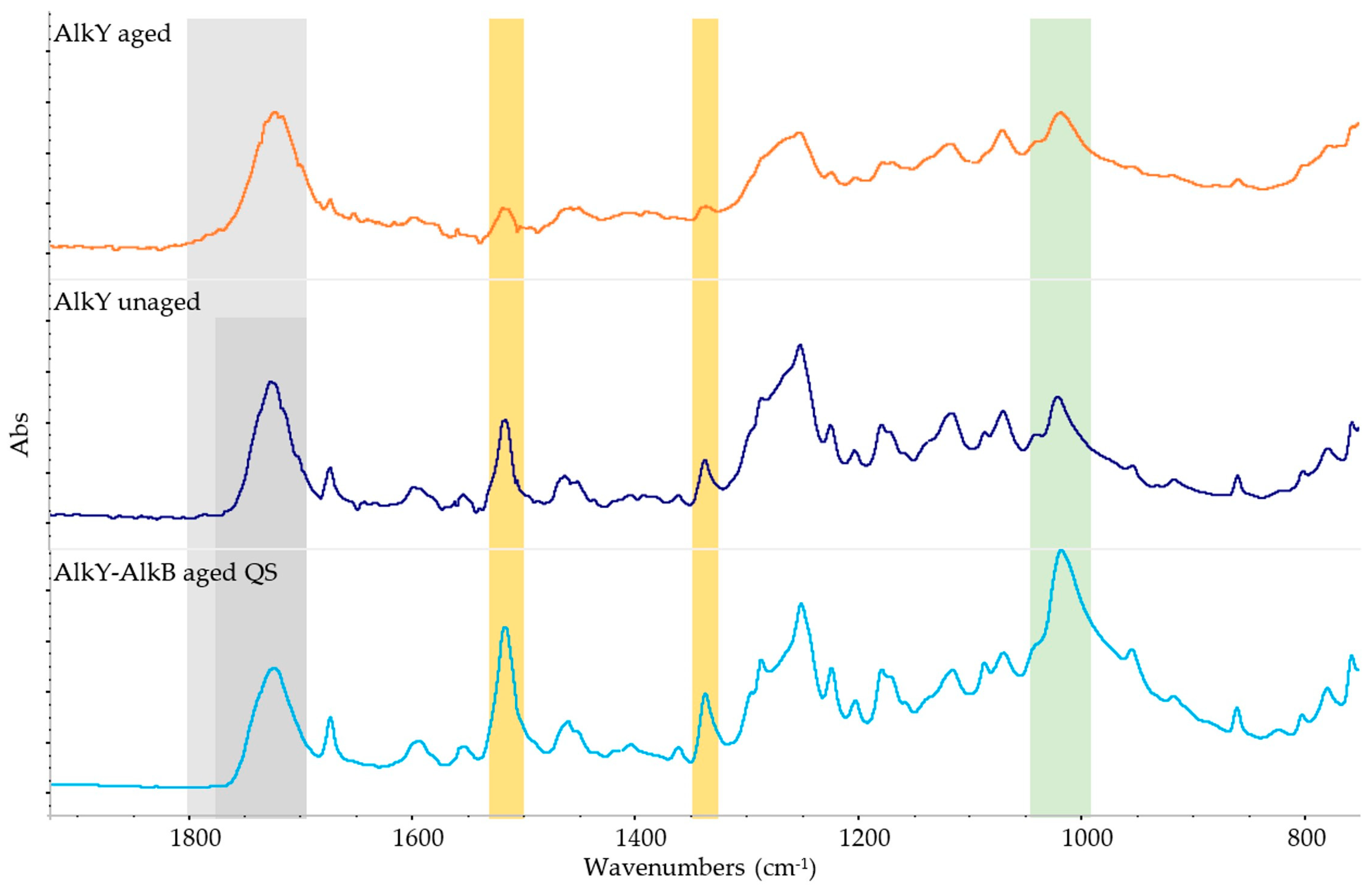

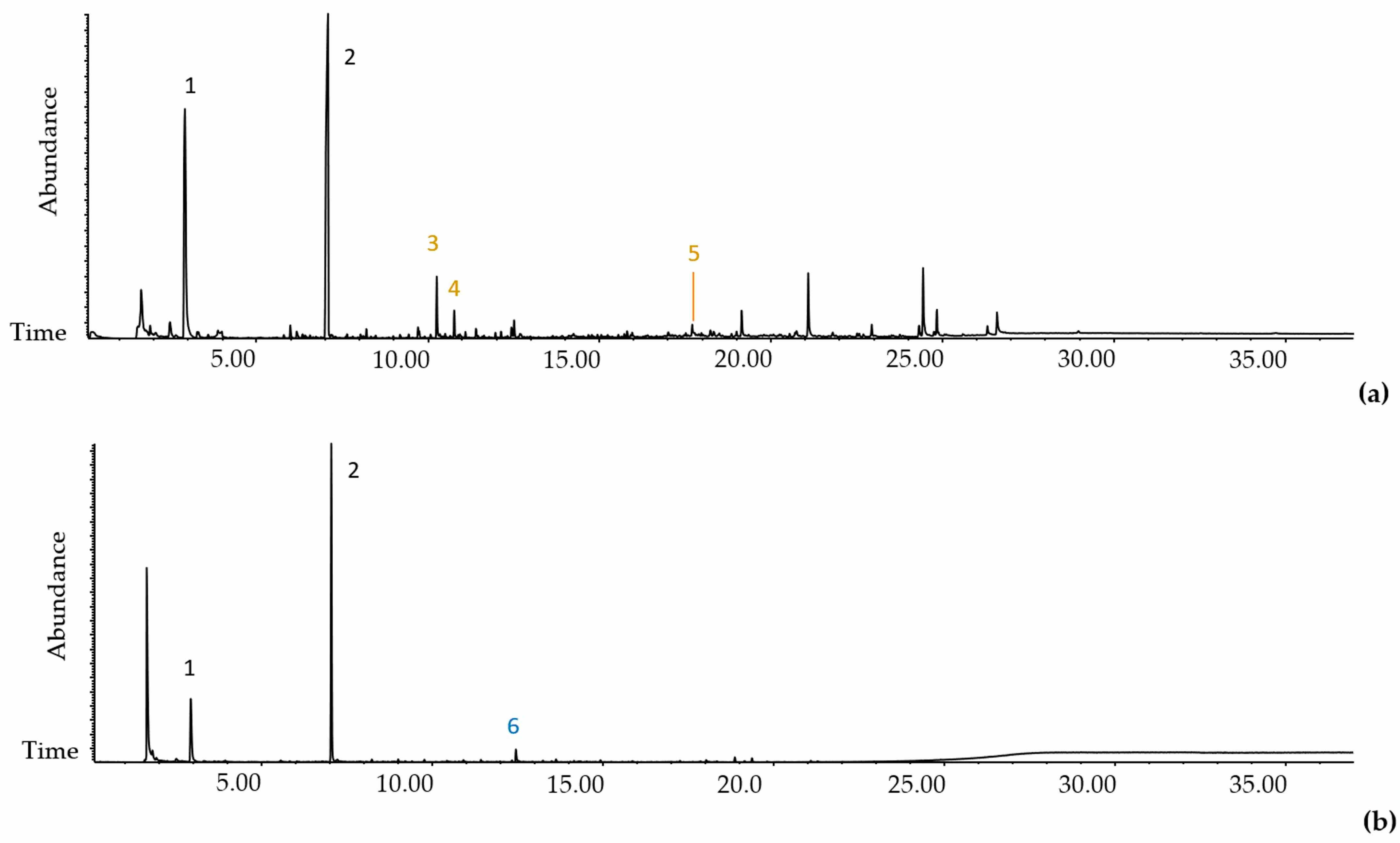

3.3.3. Residues and Effectiveness: ATR–FTIR and Py–GC/MS

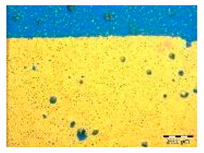

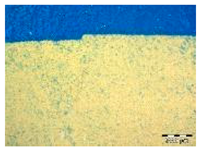

3.3.4. Pigment Pickup and Cleaning Cycle

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zanini, A.; Trafeli, V.; Bartoli, L. The Laser as a Tool for the Cleaning of Cultural Heritage. IOP Conf. Ser. Mater. Sci. Eng. 2018, 364, 012078. [Google Scholar] [CrossRef]

- Prokuratov, D.; Samokhvalov, A.; Pankin, D.; Vereshchagin, O.; Kurganov, N.; Povolotckaia, A.; Shimko, A.; Mikhailova, A.; Balmashnov, R.; Reveguk, A.; et al. Investigation towards Laser Cleaning of Corrosion Products from Lead Objects. Heritage 2023, 6, 1293–1307. [Google Scholar] [CrossRef]

- Martínez-Weinbaum, M.; Lozano-Carbó, M.; Maestro-Guijarro, L.; Carmona-Quiroga, P.M.; Oujja, M.; Castillejo, M. Comparison of the Use of Traditional Solvents and Nanosecond 213 Nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting. Heritage 2023, 6, 957–967. [Google Scholar] [CrossRef]

- Rahman, M.A.; de la Fuente, G.F.; Miguel Carretero, J.; Abad, M.P.A.; Alcalde, R.A.; Chapoulie, R.; Schiavon, N.; Angurel, L.A. Ultra-Short Pulse Laser Cleaning of Contaminated Pleistocene Bone: A Comprehensive Study on the Influence of Pulse Duration and Wavelength. Heritage 2023, 6, 2503–2519. [Google Scholar] [CrossRef]

- Maingi, E.M.; Alonso, M.P.; Angurel, L.A.; de la Fuente, G.F.; Dubernet, S.; Chapoulie, R.; Mellouët, O.; Vally, E. Chemical and Laser Cleaning of Corrosion Encrustations on Historical Stained Glass: A Comparative Study. Heritage 2023, 6, 1942–1957. [Google Scholar] [CrossRef]

- Scaglia, V.; Zenucchini, F.; Piccirillo, A.; Ricci, C. Laser Cleaning of an Eighteenth-Century Waistcoat from the Civic Museums of Modena: Preserving Silk and Metallic Threads. In Lasers in the Conservation of Artworks XIII, Proceedings of the Lasers in the Conservation of Artworks XIII, Florence, Italy, 12–16 September 2022; CRC Press/Balkema: Boca Raton, FL, USA, 2024; pp. 173–182. [Google Scholar]

- Zenucchini, F.; Ricci, C.; Piccirillo, A.; Cavaleri, T.; Cacciari, I.; Borla, M.; Aicardi, S.; Buscaglia, P. Laser Cleaning in the Conservation of Archaeological Artifacts: Polychrome Wooden Objects from Ancient Egypt. In Lasers in the Conservation of Artworks XIII, Proceedings of the Lasers in the Conservation of Artworks XIII, Florence, Italy, 12–16 September 2022; CRC Press/Balkema: Boca Raton, FL, USA, 2024; pp. 79–95. [Google Scholar]

- Cooper, M. Lasers in the Preservation of Cultural Heritage: Principles and Applications. Phys. Today 2007, 60, 58–59. [Google Scholar] [CrossRef]

- Lopez, M.; Bai, X.; Wilkie-Chancellier, N.; Detalle, V. Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser. Heritage 2023, 6, 3307–3323. [Google Scholar] [CrossRef]

- Kokkinaki, O.; Dimitroulaki, E.; Melessanaki, K.; Anglos, D.; Pouli, P. Laser-Induced Fluorescence as a Non-Invasive Tool to Monitor Laser-Assisted Thinning of Aged Varnish Layers on Paintings: Fundamental Issues and Critical Thresholds. Eur. Phys. J. Plus 2021, 136, 938. [Google Scholar] [CrossRef]

- Gomes, V.; Dionísio, A.; Pozo-Antonio, J.S. Conservation Strategies against Graffiti Vandalism on Cultural Heritage Stones: Protective Coatings and Cleaning Methods. Prog. Org. Coat. 2017, 113, 90–109. [Google Scholar] [CrossRef]

- Siano, S.; Giamello, M.; Bartoli, L.; Mencaglia, A.; Parfenov, V.; Salimbeni, R. Laser Cleaning of Stone by Different Laser Pulse Duration and Wavelength. Laser Phys. 2008, 18, 27–36. [Google Scholar] [CrossRef]

- Siano, S.; Agresti, J.; Cacciari, I.; Ciofini, D.; Mascalchi, M.; Osticioli, I.; Mencaglia, A.A. Laser Cleaning in Conservation of Stone, Metal, and Painted Artifacts: State of the Art and New Insights on the Use of the Nd:YAG Lasers. Appl. Phys. A Mater. Sci. Process 2012, 106, 419–446. [Google Scholar] [CrossRef]

- Pereira-Pardo, L.; Korenberg, C. The Use of Erbium Lasers for the Conservation of Cultural Heritage: A Review. J. Cult. Herit. 2018, 31, 236–247. [Google Scholar] [CrossRef]

- Pereira-Pardo, L.; Melita, L.N.; Korenberg, C. Tackling Conservation Challenges Using Erbium Lasers: Case Studies at the British Museum. J. Inst. Conserv. 2020, 43, 25–43. [Google Scholar] [CrossRef]

- Samolik, S.; Walczak, M.; Plotek, M.; Sarzynski, A.; Pluska, I.; Marczak, J. Investigation into the Removal of Graffiti on Mineral Supports: Comparison of Nanosecond Nd:YAG Laser Cleaning with Traditional Mechanical and Chemical Methods. Stud. Conserv. 2015, 60 (Suppl. S1), S58–S64. [Google Scholar] [CrossRef]

- Ramil, A.; Pozo-Antonio, J.S.; Fiorucci, M.P.; López, A.J.; Rivas, T. Detection of the Optimal Laser Fluence Ranges to Clean Graffiti on Silicates. Constr. Build. Mater. 2017, 148, 122–130. [Google Scholar] [CrossRef]

- Ricci, C.; Gambino, F.; Nervo, M.; Piccirillo, A.; Scarcella, A.; Zenucchini, F.; Pozo-Antonio, J.S. Developing New Cleaning Strategies of Cultural Heritage Stones: Are Synergistic Combinations of a Low-Toxic Solvent Ternary Mixtures Followed by Laser the Solution? Coatings 2020, 10, 466. [Google Scholar] [CrossRef]

- Ocakçı, M. A Survey about the Effects of the Commissioned Street Art on Physical and Social Spaces. İdealkent 2020, 11, 938–962. [Google Scholar] [CrossRef]

- Chatzidakis, M. Street Art Conservation in Athens: Critical Conservation in a Time of Crisis. Stud. Conserv. 2016, 61, 17–23. [Google Scholar] [CrossRef]

- Bertasa, M.; Ricci, C.; Scarcella, A.; Zenucchini, F.; Pellis, G.; Croveri, P.; Scalarone, D. Overcoming Challenges in Street Art Murals Conservation: A Comparative Study on Cleaning Approach and Methodology. Coatings 2020, 10, 1019. [Google Scholar] [CrossRef]

- Germinario, G.; van der Werf, I.D.; Sabbatini, L. Chemical Characterisation of Spray Paints by a Multi-Analytical (Py/GC–MS, FTIR, μ-Raman) Approach. Microchem. J. 2016, 124, 929–939. [Google Scholar] [CrossRef]

- Bosi, A.; Ciccola, A.; Serafini, I.; Guiso, M.; Ripanti, F.; Postorino, P.; Curini, R.; Bianco, A. Street Art Graffiti: Discovering Their Composition and Alteration by FTIR and Micro-Raman Spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2020, 225, 117474. [Google Scholar] [CrossRef]

- Marazioti, V.; Douvas, A.M.; Katsaros, F.; Koralli, P.; Chochos, C.; Gregoriou, V.G.; Boyatzis, S.; Facorellis, Y. Chemical Characterisation of Artists’ Spray-Paints: A Diagnostic Tool for Urban Art Conservation. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2023, 291, 122375. [Google Scholar] [CrossRef] [PubMed]

- La Nasa, J.; Orsini, S.; Degano, I.; Rava, A.; Modugno, F.; Colombini, M.P. A Chemical Study of Organic Materials in Three Murals by Keith Haring: A Comparison of Painting Techniques. Microchem. J. 2016, 124, 940–948. [Google Scholar] [CrossRef]

- Siano, S.; Osticioli, I.; Pavia, A.; Ciofini, D. Overpaint Removal from Easel Paintings Using an LQS Nd:YAG Laser: The First Validation Study. Stud. Conserv. 2015, 60, S49–S57. [Google Scholar] [CrossRef]

- Schnell, G.; Duenow, U.; Seitz, H. Effect of Laser Pulse Overlap and Scanning Line Overlap on Femtosecond Laser-Structured Ti6Al4V Surfaces. Materials 2020, 13, 969. [Google Scholar] [CrossRef]

- Lanteri, L.; Calandra, S.; Briani, F.; Germinario, C.; Izzo, F.; Pagano, S.; Pelosi, C.; Santo, A.P. 3D Photogrammetric Survey, Raking Light Photography and Mapping of Degradation Phenomena of the Early Renaissance Wall Paintings by Saturnino Gatti—Case Study of the St. Panfilo Church in Tornimparte (L’Aquila, Italy). Appl. Sci. 2023, 13, 5689. [Google Scholar] [CrossRef]

- Pintus, V.; Wei, S.; Schreiner, M. Accelerated UV Ageing Studies of Acrylic, Alkyd, and Polyvinyl Acetate Paints: Influence of Inorganic Pigments. Microchem. J. 2016, 124, 949–961. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Joosten, I.; Voor, R.; Erfgoed, C. Dry Cleaning Approaches for Unvarnished Paint Surfaces. In Proceedings of the Cleaning 2010 Conference, Valencia, Spain, 26–28 May 2010; Smithsonian Institute: Washington, DC, USA, 2013. [Google Scholar]

- Pellis, G.; Bertasa, M.; Ricci, C.; Scarcella, A.; Croveri, P.; Poli, T.; Scalarone, D. A Multi-Analytical Approach for Precise Identification of Alkyd Spray Paints and for a Better Understanding of Their Ageing Behaviour in Graffiti and Urban Artworks. J. Anal. Appl. 2022, 165, 105576. [Google Scholar] [CrossRef]

- Ghelardi, E.; Degano, I.; Colombini, M.P.; Mazurek, J.; Schilling, M.; Learner, T. Py-GC/MS Applied to the Analysis of Synthetic Organic Pigments: Characterization and Identification in Paint Samples. Anal. Bioanal. Chem. 2015, 407, 1415–1431. [Google Scholar] [CrossRef]

- Sonoda, N. Characterization of Organic Azo-Pigments by Pyrolysis–Gas Chromatography. Stud. Conserv. 1999, 44, 195–208. [Google Scholar] [CrossRef]

| Materials | Manufacturer | Product | Color | Ref. Code |

|---|---|---|---|---|

| Cement mortar | Italcementi | i.work TECNOCEM A-LL 32,5 R—type II limestone Portland cement | - | - |

| Axton | Fine natural river sand (Granulometry: 0–1 mm) | - | - | |

| Coarse sand | - | - | ||

| Spray paint | Molotow | Flame Orange | FO-102 Zinc Yellow | 558.002 |

| FO-514 True Blue | 558.059 | |||

| Montana Colors | Montana 94 | RV 1021 Light Yellow | EX0141021M | |

| RV 154 Tornado Blue | EX019W0154M | |||

| Molotow | Urban Fine-Art Neon | 404 Neon Blue Fluorescent | 337.304 | |

| Paint (brush, roll) | Sikkens | Alpha Acrilmat | G3.46.83 Yellow | - |

| Laser Type | Q-Switch | Long Q-Switch |

|---|---|---|

| Model | Thunder Art | EOS 1000 |

| System | Nd:YAG | Nd:YAG |

| Wavelength | 1064 nm | 1064 nm |

| 532 nm | ||

| 355 nm | ||

| Pulse duration | 8 ns | 100 ns–200 µs |

| Frequency | 1–20 Hz | 1–10 Hz |

| 15 Hz | ||

| 20 Hz | ||

| Energy | 0–900 mJ | 130 mJ (1 pulse) |

| 250 mJ (2 pulses) | ||

| 380 mJ (3 pulses) | ||

| Spot size | 4–10 mm | 1–6 mm |

| Beam delivering | 7-mirror articulated arm | Optic fiber |

| Laser System | Q-Switch | Long Q-Switch |

|---|---|---|

| Frequency | 5 Hz | 5 Hz |

| Pulse duration | 8 ns | 100 ns |

| Energy setting | 266 mJ | 130 mJ |

| Spot size | 10 mm | 4.5 mm |

| Fluence | 0.34 J/cm2 | 1.17 J/cm2 |

| Mock-Up Name | Bottom Layer | Top Layer | ||||

|---|---|---|---|---|---|---|

| Product | Color | Main Binder | Product | Color | Binder | |

| AlkY–AlkB | Montana 94 | Yellow | Alkyd | Montana 94 | Blue | Alkyd |

| AlkY–AcrB | Montana 94 | Yellow | Alkyd | Flame Orange | Blue | Acrylic |

| AklY–AcrFB | Montana 94 | Yellow | Alkyd | Urban Fine-Art Neon | Blue Fluorescent | Acrylic |

| AlkB–AlkY | Montana 94 | Blue | Alkyd | Montana 94 | Yellow | Alkyd |

| AlkB–AcrY | Montana 94 | Blue | Alkyd | Flame Orange | Yellow | Acrylic |

| AcrY–AlkB | Flame Orange | Yellow | Acrylic | Montana 94 | Blue | Alkyd |

| AcrY–AcrB | Flame Orange | Yellow | Acrylic | Flame Orange | Blue | Acrylic |

| AcrY–AcrFB | Flame Orange | Yellow | Acrylic | Urban Fine-Art Neon | Blue Fluorescent | Acrylic |

| AcrB–AlkY | Flame Orange | Blue | Acrylic | Montana 94 | Yellow | Alkyd |

| AcrB–AcrY | Flame Orange | Blue | Acrylic | Flame Orange | Yellow | Acrylic |

| StyY–AlkB | Alpha Acrilmat | Yellow | Styrene Acrylic | Montana 94 | Blue | Alkyd |

| StyY–AcrB | Alpha Acrilmat | Yellow | Styrene Acrylic | Flame Orange | Blue | Acrylic |

| StyY–AcrFB | Alpha Acrilmat | Yellow | Styrene Acrylic | Urban Fine-Art Neon | Blue Fluorescent | Acrylic |

| Sample | Condition | Laser | Residue | Roughness | Color | Effectiveness | Pigment Pickup | Total |

|---|---|---|---|---|---|---|---|---|

| AlkY–AlkB | Unaged | QS | 8 | 7 | 6 | 9 | 8 | 38 |

| LQS | 6 | 6 | 6 | 9 | 7 | 34 | ||

| Aged | QS | 8 | 8 | 5 | 6 | 6 | 33 | |

| LQS | 7 | 7 | 6 | 9 | 7 | 36 | ||

| AlkY–AcrB | Unaged | QS | 6 | 7 | 6 | 6 | 8 | 33 |

| LQS | 6 | 6 | 6 | 6 | 7 | 31 | ||

| Aged | QS | 7 | 8 | 5 | 6 | 7 | 33 | |

| LQS | 7 | 7 | 6 | 6 | 8 | 34 | ||

| AlkY–AcrFB | Unaged | QS | 6 | 7 | 7 | 9 | 6 | 35 |

| LQS | 6 | 7 | 8 | 9 | 7 | 37 | ||

| Aged | QS | 9 | 7 | 6 | 9 | 6 | 37 | |

| LQS | 8 | 6 | 7 | 9 | 7 | 37 | ||

| AlkB–AlkY | Unaged | QS | 6 | 6 | 7 | 6 | 5 | 30 |

| LQS | 6 | 6 | 7 | 6 | 8 | 33 | ||

| Aged | QS | 6 | 7 | 8 | 6 | 6 | 33 | |

| LQS | 5 | 5 | 6 | 6 | 7 | 29 | ||

| AlkB–AcrY | Unaged | QS | 7 | 7 | 7 | 6 | 6 | 33 |

| LQS | 6 | 6 | 7 | 6 | 8 | 33 | ||

| Aged | QS | 8 | 7 | 9 | 6 | 7 | 37 | |

| LQS | 6 | 6 | 7 | 6 | 8 | 33 | ||

| AcrY–AcrB | Unaged | QS | 7 | 6 | 6 | 9 | 9 | 37 |

| LQS | 5 | 5 | 6 | 6 | 7 | 29 | ||

| Aged | QS | 4 | 6 | 4 | 6 | 8 | 28 | |

| LQS | 5 | 5 | 5 | 6 | 7 | 28 | ||

| AcrY–AlkB | Unaged | QS | 8 | 7 | 6 | 9 | 7 | 37 |

| LQS | 6 | 6 | 6 | 6 | 6 | 30 | ||

| Aged | QS | 6 | 5 | 5 | 6 | 6 | 28 | |

| LQS | 6 | 6 | 6 | 9 | 7 | 34 | ||

| AcrY–AcrFB | Unaged | QS | 8 | 7 | 7 | 9 | 8 | 39 |

| LQS | 8 | 7 | 8 | 9 | 7 | 39 | ||

| Aged | QS | 7 | 8 | 7 | 9 | 5 | 36 | |

| LQS | 8 | 7 | 7 | 9 | 6 | 37 | ||

| AcrB–AcrY | Unaged | QS | 9 | 8 | 7 | 6 | 8 | 38 |

| LQS | 7 | 7 | 7 | 6 | 6 | 33 | ||

| Aged | QS | 8 | 8 | 7 | 6 | 6 | 35 | |

| LQS | 7 | 7 | 7 | 6 | 7 | 34 | ||

| AcrB–AlkY | Unaged | QS | 7 | 7 | 8 | 6 | 6 | 34 |

| LQS | 7 | 7 | 7 | 9 | 7 | 37 | ||

| Aged | QS | 6 | 8 | 8 | 6 | 6 | 34 | |

| LQS | 6 | 9 | 7 | 9 | 9 | 40 | ||

| StyY–AcrB | Unaged | QS | 5 | 7 | 5 | 3 | 7 | 27 |

| LQS | 4 | 7 | 4 | 3 | 7 | 25 | ||

| Aged | QS | 6 | 8 | 6 | 6 | 9 | 35 | |

| LQS | 6 | 7 | 6 | 6 | 9 | 34 | ||

| StyY–AlkB | Unaged | QS | 6 | 7 | 5 | 6 | 8 | 32 |

| LQS | 4 | 7 | 3 | 3 | 8 | 25 | ||

| Aged | QS | 7 | 8 | 6 | 6 | 9 | 36 | |

| LQS | 7 | 7 | 6 | 6 | 8 | 34 | ||

| StyY–AcrFB | Unaged | QS | 6 | 7 | 6 | 9 | 8 | 36 |

| LQS | 5 | 6 | 5 | 6 | 9 | 31 | ||

| Aged | QS | 7 | 8 | 6 | 9 | 8 | 38 | |

| LQS | 7 | 7 | 6 | 6 | 9 | 35 |

| Sample | AcrY–AcrFB | StyY–AcrB | ||||

|---|---|---|---|---|---|---|

| Instrument | QS | LQS | Raking Light | QS | LQS | Raking Light |

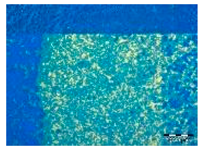

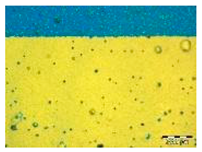

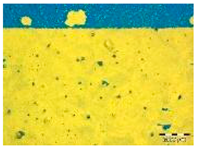

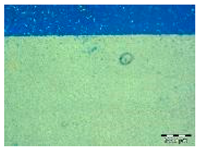

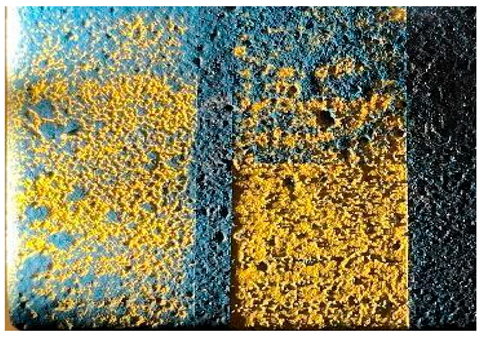

| Unaged |  |  |  |  |  |  |

| Aged |  |  |  |  |  |  |

| Radar chart |  |  | ||||

| Condition | Unaged | Aged | ||||||

|---|---|---|---|---|---|---|---|---|

| Laser | QS ∆E | QS σΔE | LQS ∆E | LQS σΔE | QS ∆E | QS σΔE | LQS ∆E | LQS σΔE |

| StyY–AcrB | 34.85 | 3.09 | 50.90 | 6.56 | 25.17 | 0.74 | 21.19 | 0.97 |

| StyY–AcrFB | 26.39 | 1.33 | 32.10 | 7.67 | 22.02 | 0.82 | 19.80 | 1.07 |

| StyY–AlkB | 29.40 | 0.93 | 52.27 | 2.38 | 24.00 | 1.01 | 17.68 | 0.78 |

| AlkY–AlkB | 13.03 | 0.82 | 11.13 | 0.99 | 12.93 | 0.86 | 10.49 | 1.25 |

| AlkY–AcrFB | 16.48 | 0.62 | 14.09 | 1.84 | 13.73 | 0.66 | 9.24 | 0.48 |

| AlkY–AcrB | 19.52 | 1.50 | 15.40 | 1.52 | 13.51 | 0.72 | 10.20 | 0.28 |

| AcrY–AlkB | 10.60 | 2.06 | 7.29 | 1.92 | 11.83 | 2.19 | 9.95 | 2.17 |

| AcrY–AcrB | 15.52 | 0.94 | 15.77 | 1.90 | 24.64 | 1.53 | 12.77 | 1.05 |

| AcrY–AcrFB | 14.82 | 1.77 | 9.71 | 0.53 | 11.67 | 0.88 | 11.88 | 1.13 |

| AcrB–AlkY | 4.48 | 0.46 | 8.76 | 0.50 | 5.07 | 0.57 | 6.93 | 1.45 |

| AcrB–AcrY | 5.19 | 0.89 | 8.25 | 0.68 | 6.17 | 0.37 | 7.12 | 2.70 |

| AlkB–AlkY | 4.62 | 2.38 | 6.34 | 1.86 | 4.13 | 3.25 | 18.47 | 1.06 |

| AlkB–AcrY | 2.97 | 0.53 | 3.27 | 0.63 | 3.73 | 0.72 | 3.22 | 0.44 |

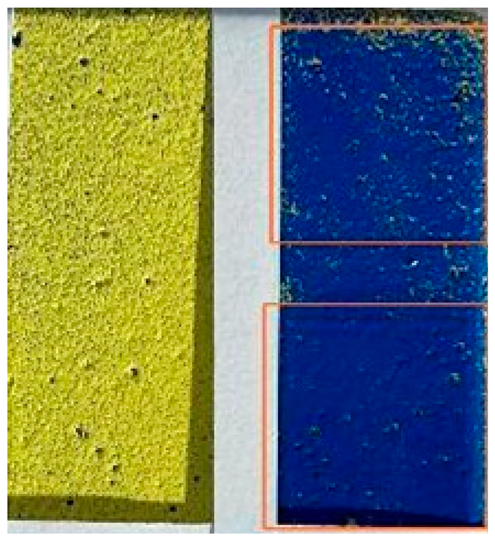

| Condition | Unaged | Aged | ||

|---|---|---|---|---|

| AcrY-AcrB |  |  | ||

| Laser type | QS | LQS | QS | LQS |

| Score | 6 | 5 | 6 | 5 |

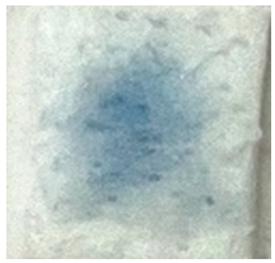

| AcrB–AcrY Unaged | Cleaning Cycle | Pigment Pickup |

|---|---|---|

| QS laser (zone a) one cleaning cycle |  |

| QS laser (zone b) two cleaning cycles |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zenucchini, F.; Ricci, C.; Croveri, P.; Scalarone, D. Analytical Evaluation of Laser Cleaning Effectiveness in the Context of Contemporary Muralism. Appl. Sci. 2024, 14, 4799. https://doi.org/10.3390/app14114799

Zhang Y, Zenucchini F, Ricci C, Croveri P, Scalarone D. Analytical Evaluation of Laser Cleaning Effectiveness in the Context of Contemporary Muralism. Applied Sciences. 2024; 14(11):4799. https://doi.org/10.3390/app14114799

Chicago/Turabian StyleZhang, Yezi, Francesca Zenucchini, Chiara Ricci, Paola Croveri, and Dominique Scalarone. 2024. "Analytical Evaluation of Laser Cleaning Effectiveness in the Context of Contemporary Muralism" Applied Sciences 14, no. 11: 4799. https://doi.org/10.3390/app14114799