Application of Convolutional Neural Networks for Classifying Penetration Conditions in GMAW Processes Using STFT of Welding Data

Abstract

:1. Introduction

2. Experimental Setup

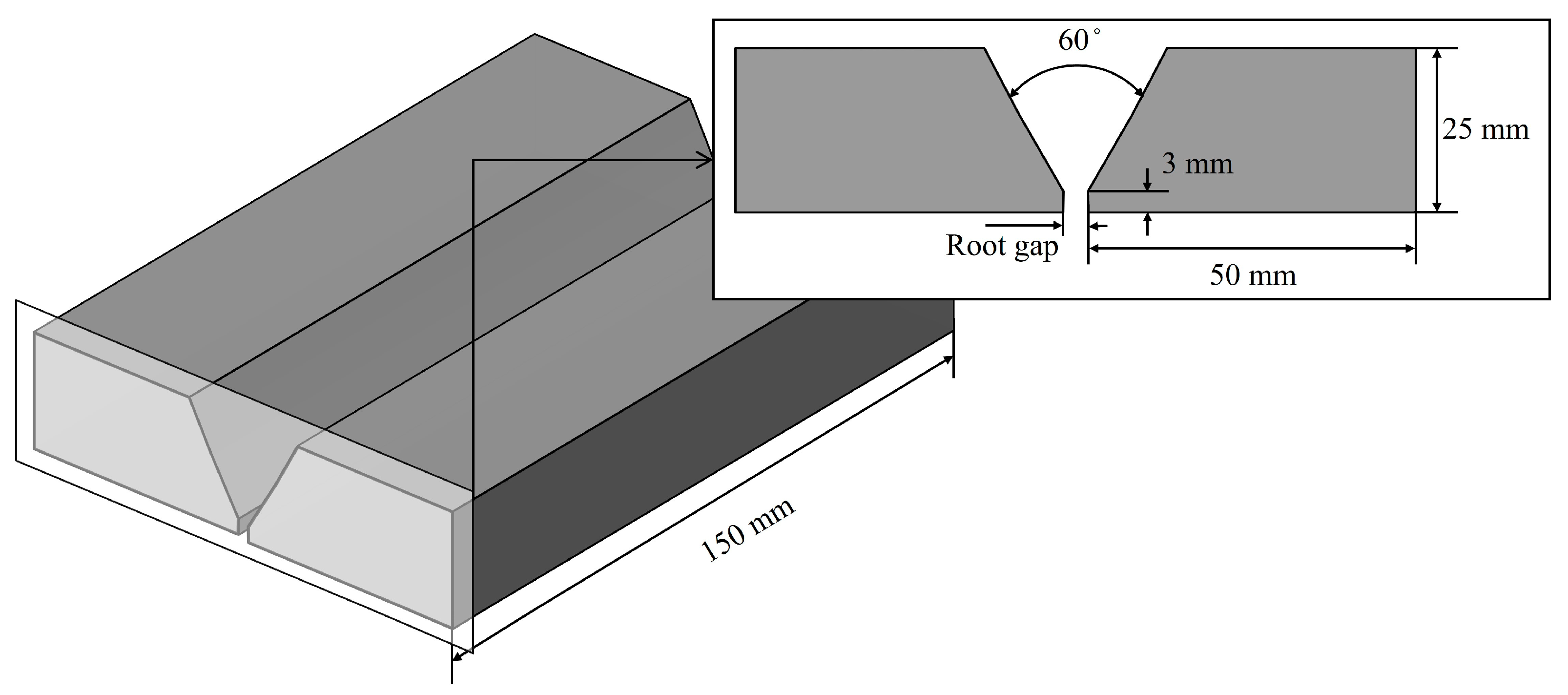

2.1. Joint Shape and Weld Methods

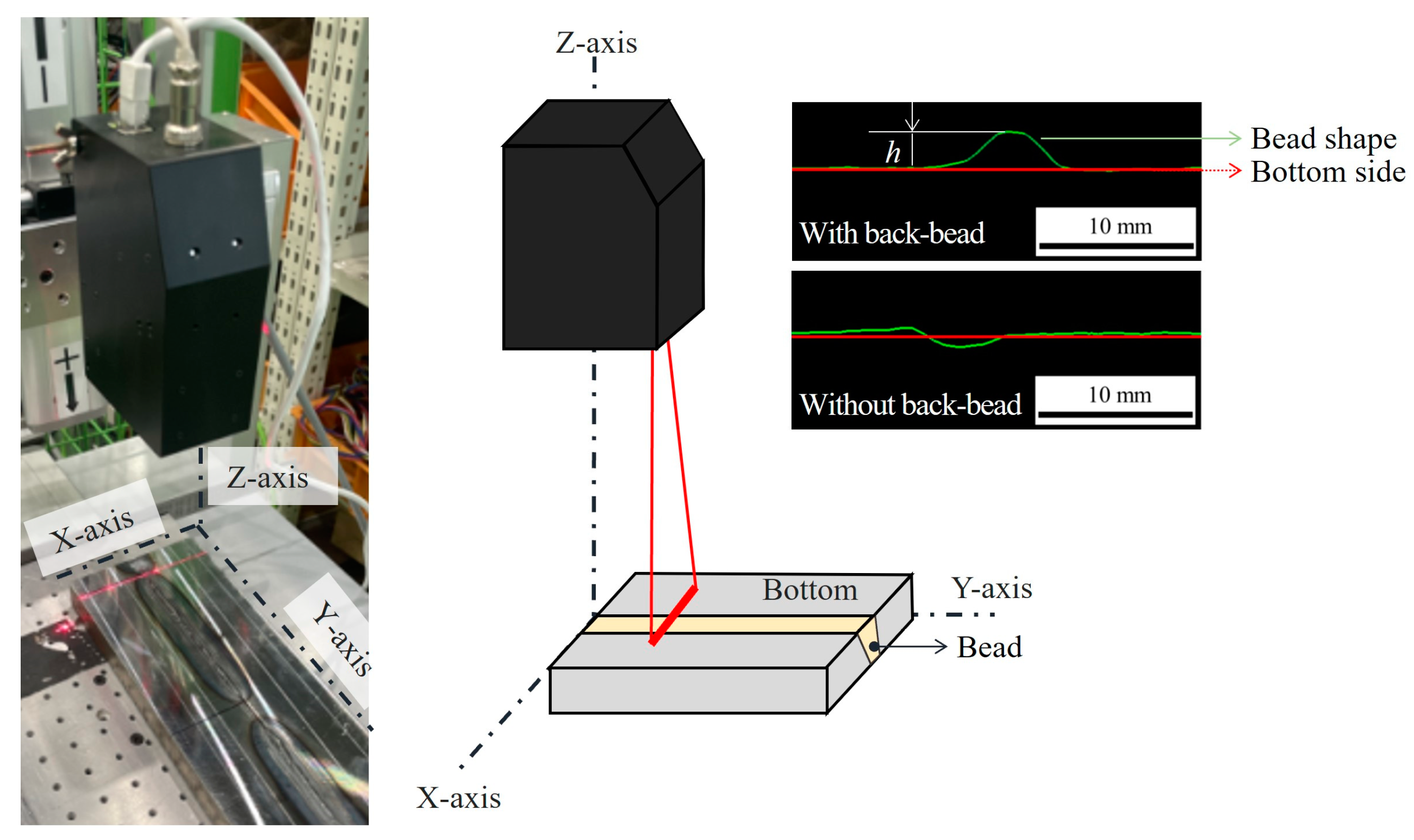

2.2. Input and Output Data Structuring Method

2.3. CNN-Based Learning Model for Classification of Penetration Condition

3. Results and Discussion

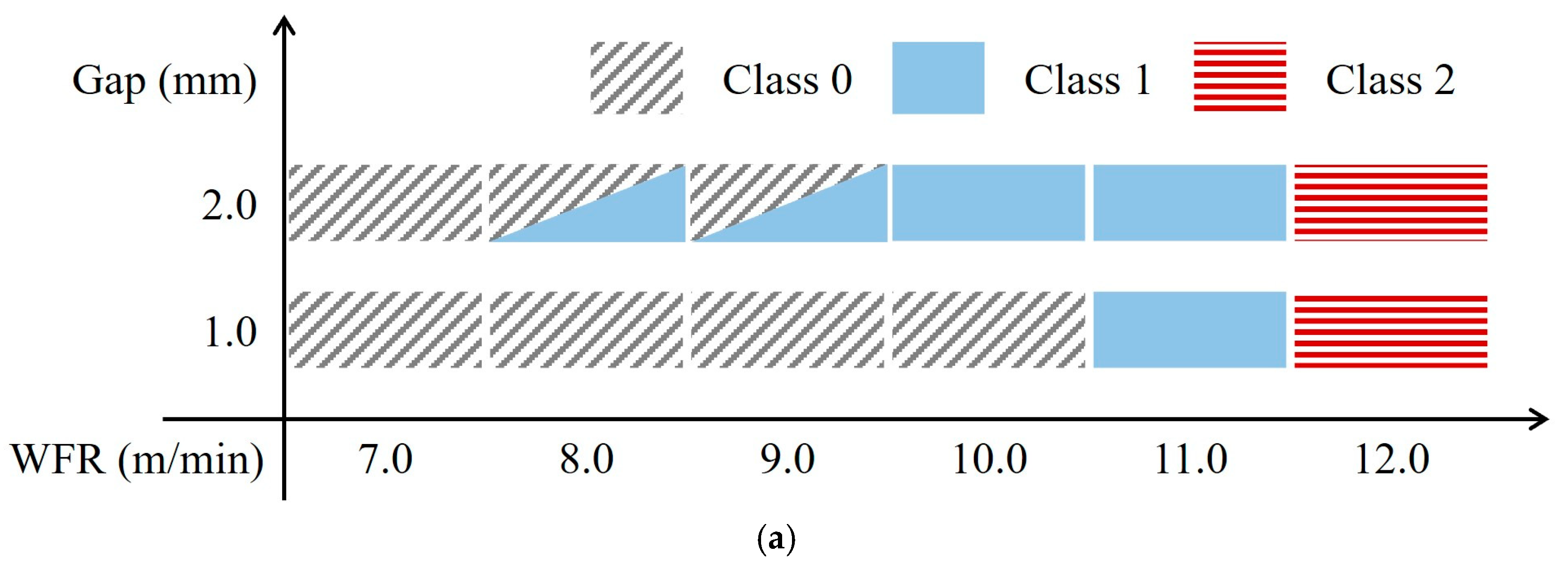

3.1. Input/Output Data for Prediction of Penetration Condition

3.2. Data Processing and Classification

3.3. CNN-Based Prediction Model for Classification of Penetration Condition

3.3.1. CNN Model for Predicting Penetration Condition

3.3.2. Evaluation of CNN Model Training

4. Conclusions

- (1)

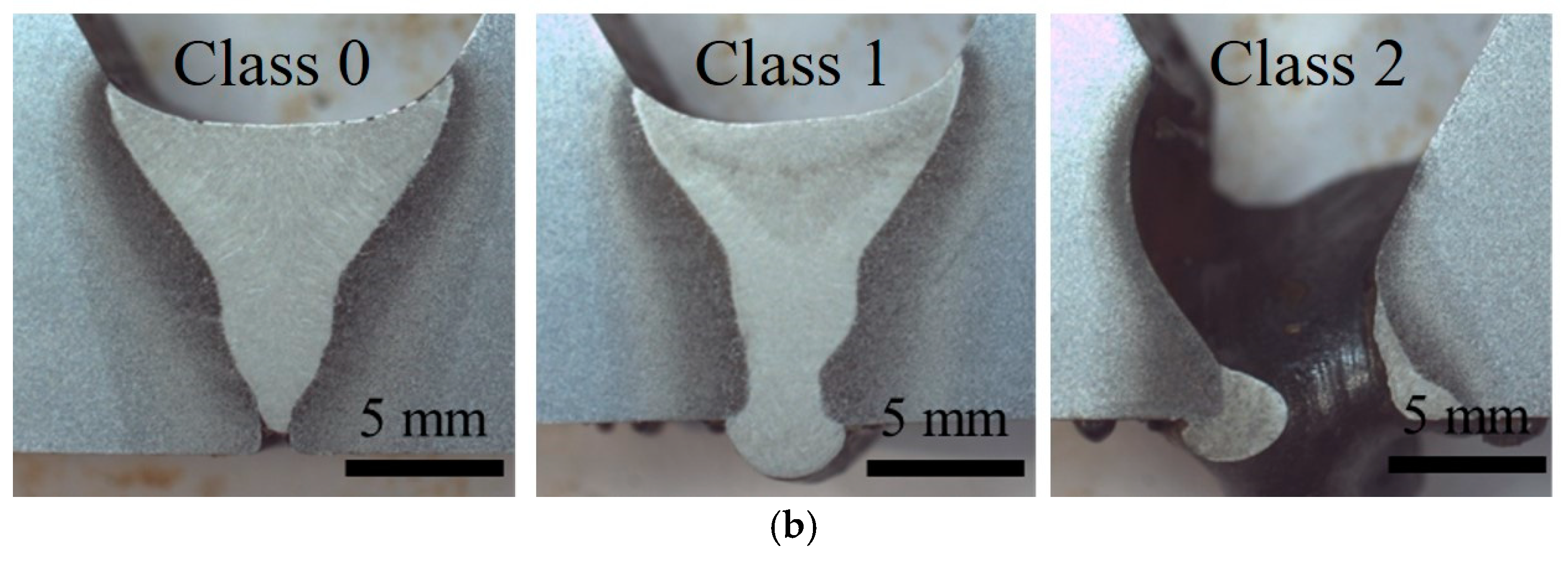

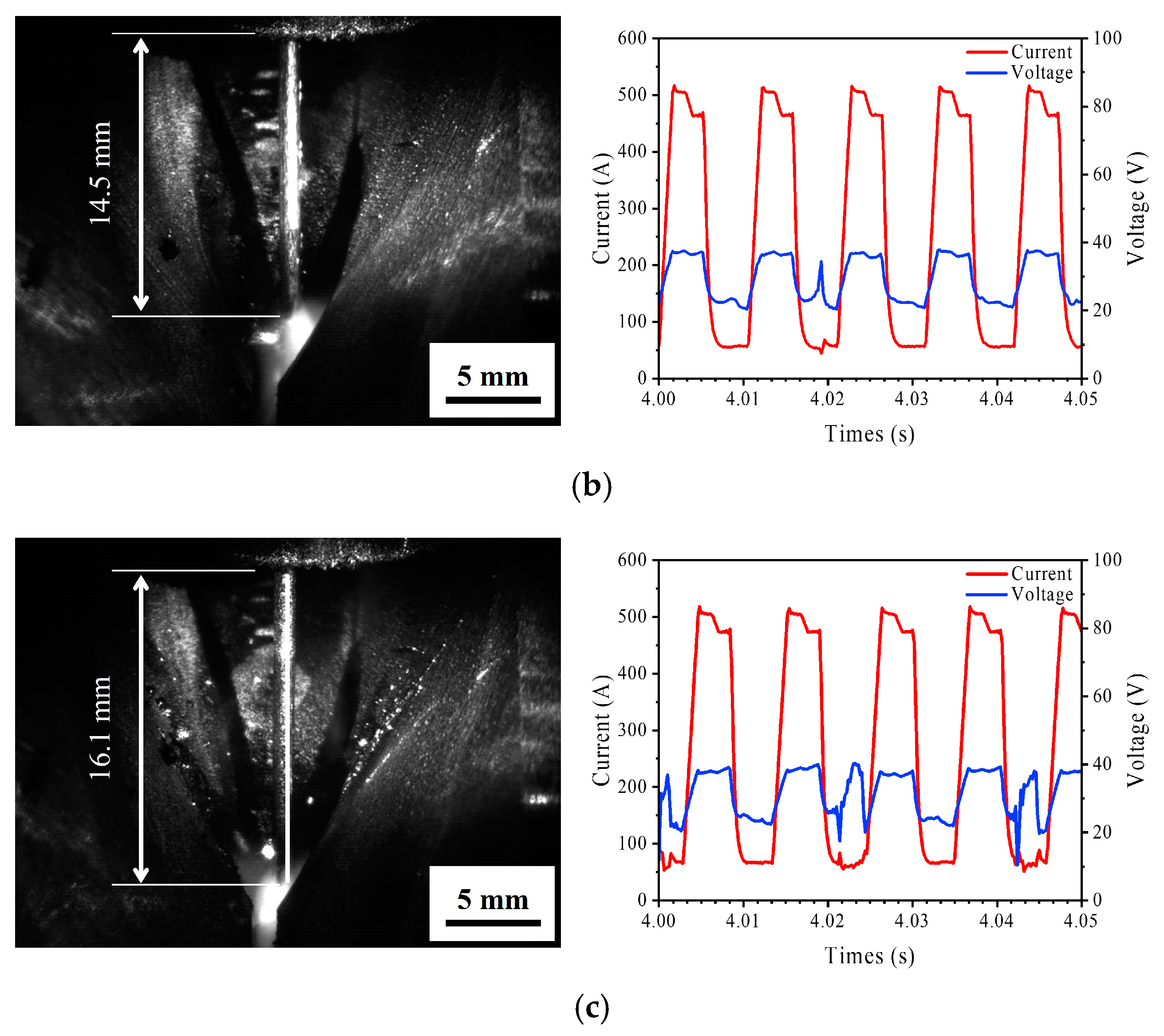

- In root-pass welding, penetration conditions such as PJP, CJP, and burn-through were observed. The high-speed camera footage confirmed that as the penetration condition changed, the wire extension length also varied. Consequently, changes in the welding voltage were observed.

- (2)

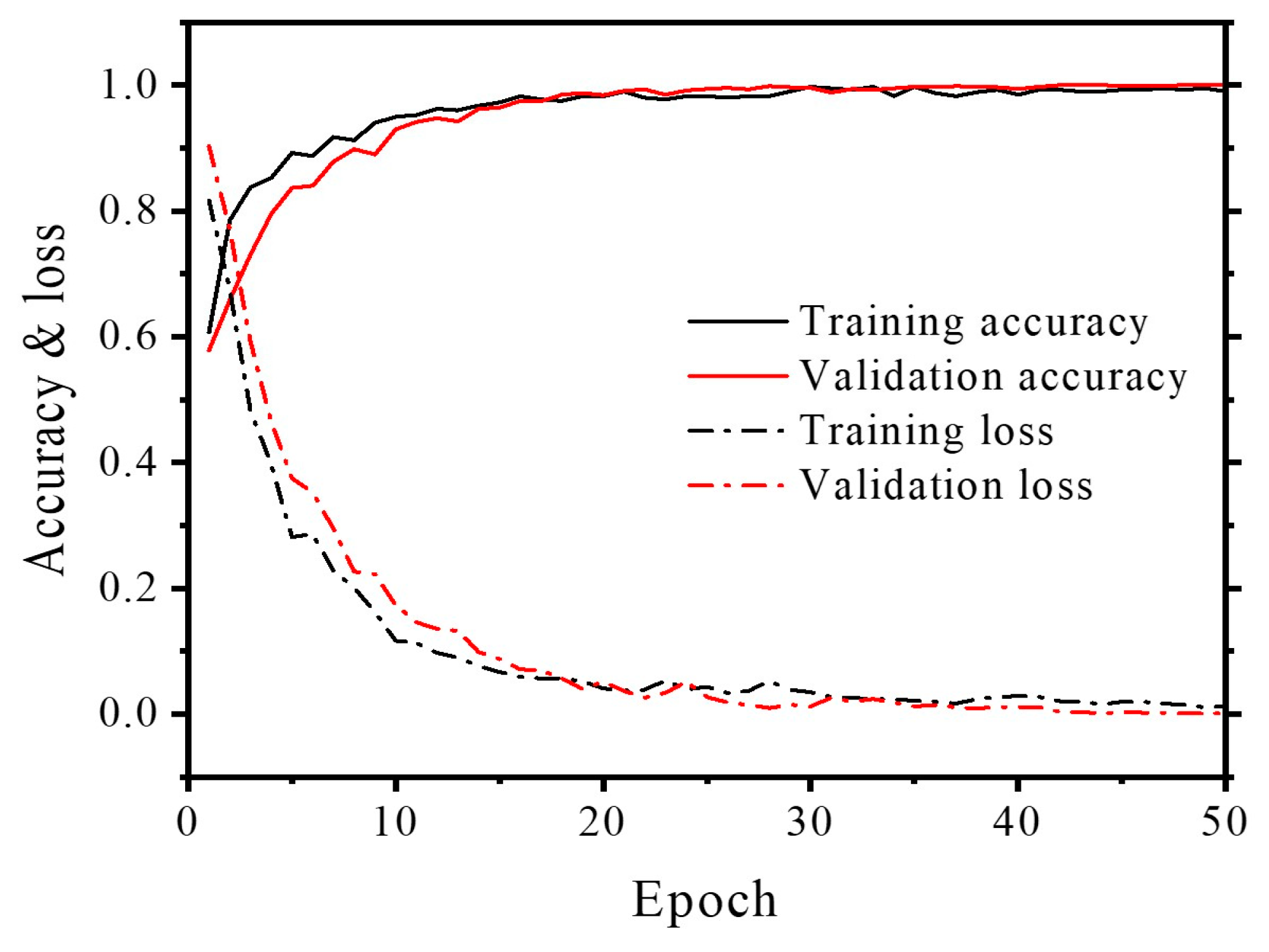

- The current and voltage were measured for 30 s at 10 kHz. A window size of 0.4 s was set, considering the deepest position of the weld pool. The STFT of dynamic resistance for this 0.4-s window was utilized as an input variable for the CNN model.

- (3)

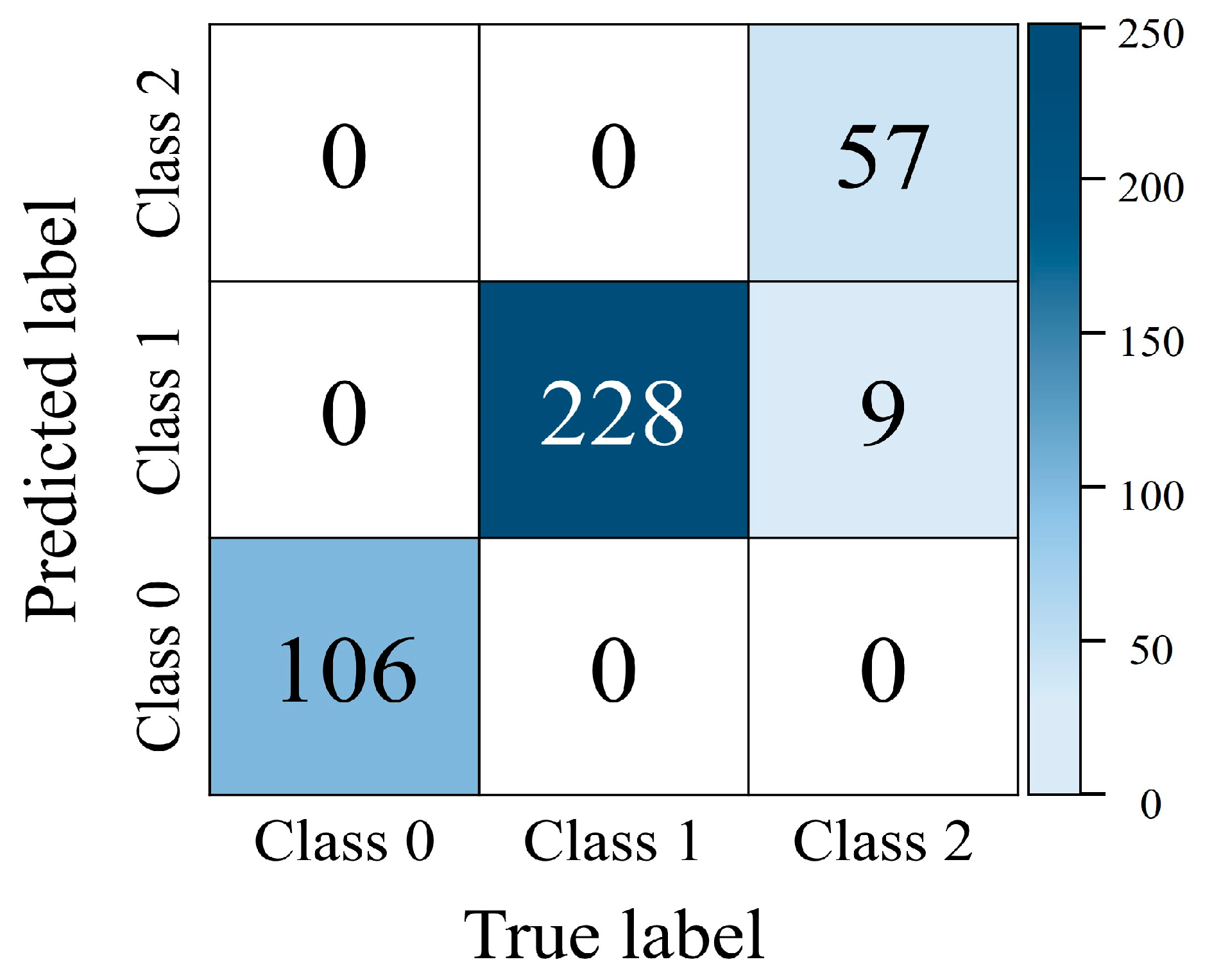

- The bottom side of the test piece was scanned using a laser vision system after the welding was completed. Based on the back-bead appearance profile, PJP was classified as class 0, CJP as class 1, and burn-through as class 2; these were used as output variables for the CNN model.

- (4)

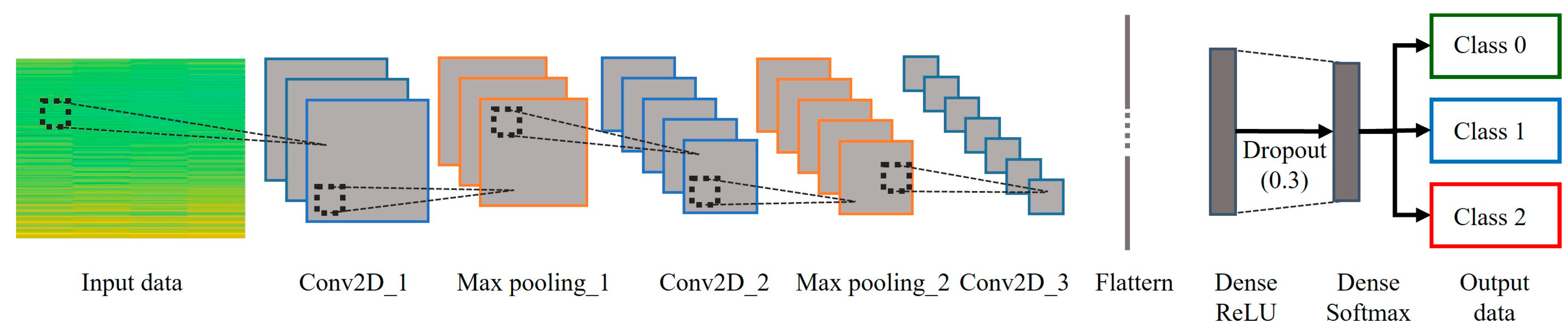

- The size of the dynamic resistance STFT was adjusted to enhance the computational speed of the CNN model. A CNN model consisting of three convolutional layers and two pooling layers was adopted, and classification training was performed on the input variables.

- (5)

- The CNN model achieved a prediction accuracy of 97.7% in predicting the occurrence of penetration conditions in weld joints. For precision, it was 100% for class 0 and class 2, and 96.2% for class 1. For recall, it was 100% for class 0 and class 1 and 86.3% for class 2. For the F1-score, it was 100% for class 0, 98.1% for class 1 and 92.7% for class 2. The developed CNN model was evaluated as a suitable model for the prediction of the occurrence of penetration conditions in weld joints and welding conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, T.; Xue, S.; Wang, B.; Zhai, P.; Long, W. Study on short-circuiting GMAW pool behavior and microstructure of the weld with different waveform control methods. Metals 2019, 9, 1326. [Google Scholar] [CrossRef]

- Shen, X.; Ma, G.; Chen, P. Effect of welding process parameters on hybrid GMAW-GTAW welding process of AZ31B magnesium alloy. Int. J. Adv. Manuf. Technol. 2018, 94, 2811–2819. [Google Scholar] [CrossRef]

- Wu, K.; Ding, N.; Yin, T.; Zeng, M.; Liang, Z. Effects of single and double pulses on microstructure and mechanical properties of weld joints during high-power double-wire GMAW. J. Manuf. Process. 2018, 35, 728–734. [Google Scholar] [CrossRef]

- Ikram, A.; Chung, H. The effect of EN ratio and current on microstructural and mechanical properties of weld joined by AC-GMAW on square groove butt joints. Appl. Sci. 2017, 7, 261. [Google Scholar] [CrossRef]

- Su, L.; Fei, Z.; Davis, B.; Li, H.; Bornstein, H. Digital image correlation study on tensile properties of high strength quenched and tempered steel weld joints prepared by K-TIG and GMAW. Mate. Sci. Eng. A 2021, 827, 142033. [Google Scholar] [CrossRef]

- Datta, R.; Mukerjee, D.; Rohira, K.L.; Veeraraghavan, R. Weldability evaluation of high tensile plates using GMAW process. J. Mater. Eng. Perform. 1999, 8, 455–462. [Google Scholar] [CrossRef]

- Kim, D.Y.; Kim, G.G.; Yu, J.; Kim, D.; Kim, Y.M.; Park, J. Improvement of fatigue performance by applying tandem GMAW in lap joints with gaps. Int. J. Adv. Manuf. Technol. 2023, 128, 2123–2135. [Google Scholar] [CrossRef]

- Svoboda, H.G.; Nadale, H.C. Fatigue life of GMAW and PAW welding joints of boron microalloyed steels. Procedia Mater. Sci. 2015, 9, 419–427. [Google Scholar] [CrossRef]

- Kim, D.Y.; Hwang, I.; Jeong, G.; Kang, M.; Kim, D.; Seo, J.; Kim, Y.M. Effect of porosity on the fatigue behavior of gas metal arc welding lap fillet joint in GA 590 MPa steel sheets. Metals 2018, 8, 241. [Google Scholar] [CrossRef]

- Kim, D.Y.; Kim, G.G.; Yu, J.; Kim, D.; Kim, Y.M.; Park, J. Weld fatigue behavior of gas metal arc welded steel sheets based on porosity and gap size. Int. J. Adv. Manuf. Technol. 2023, 124, 1141–1153. [Google Scholar] [CrossRef]

- AWS D1.1/D1.1M; Structural Welding Code—Steel. American Welding Society: Miami, FL, USA, 2020.

- EN ISO 5817: 2006-10; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. ISO: Geneva, Switzerland, 2006.

- Pradhan, R.; Joshi, A.P.; Sunny, M.R.; Sarkar, A. Performance of predictive models to determine weld bead shape parameters for shielded gas metal arc welded T-joints. Mar. Struct. 2022, 86, 103290. [Google Scholar] [CrossRef]

- Nagesh, D.S.; Datta, G.L. Genetic algorithm for optimization of welding variables for height to width ratio and application of ANN for prediction of bead geometry for TIG welding process. Appl. Soft. Comput. 2010, 10, 897–907. [Google Scholar] [CrossRef]

- Sarkar, A.; Dey, P.; Rai, R.N.; Saha, S.C. A comparative study of multiple regression analysis and back propagation neural network approaches on plain carbon steel in submerged-arc welding. Sādhanā 2016, 41, 549–559. [Google Scholar] [CrossRef]

- Xu, W.H.; Lin, S.B.; Fan, C.L.; Yang, C.L. Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int. J. Adv. Manuf. Technol. 2015, 79, 183–196. [Google Scholar] [CrossRef]

- Abioye, T.E.; Mustar, N.; Zuhailawati, H.; Suhaina, I. Prediction of the tensile strength of aluminium alloy 5052-H32 fibre laser weldments using regression analysis. Int. J. Adv. Manuf. Technol. 2019, 102, 1951–1962. [Google Scholar] [CrossRef]

- Achebo, J.I.; Eki, M.U. Prediction of mild steel weld properties using artificial neural network and regression analysis. Trop. Technol. J. 2020, 1, 37–49. [Google Scholar] [CrossRef]

- Jung, J.S.; Lee, H.K.; Park, Y.H. Prediction of tensile strength for Plasma-MIG hybrid welding using statistical regression model and neural network algorithm. J. Weld. Join. 2016, 34, 67–72. [Google Scholar] [CrossRef]

- Kim, D.Y.; Hwang, J.H.; Kim, G.G.; Kim, Y.M.; Yu, J.; Park, J. Prediction of weld tensile-shear strength using ANN based on the weld shape in Aluminum alloy GMAW. J. Weld. Join. 2023, 41, 17–27. [Google Scholar] [CrossRef]

- Alvarez Bestard, G.; Absi Alfaro, S.C. Measurement and estimation of the weld bead geometry in arc welding processes: The last 50 years of development. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 444. [Google Scholar] [CrossRef]

- Yu, R.; Zhao, Z.; Bai, L.; Han, J. Prediction of weld reinforcement based on vision sensing in GMA additive manufacturing process. Metals 2020, 10, 1041. [Google Scholar] [CrossRef]

- Dong, H.; Cong, M.; Zhang, Y.; Liu, Y.; Chen, H. Modeling and real-time prediction for complex welding process based on weld pool. Int. J. Adv. Manuf. Technol. 2018, 96, 2495–2508. [Google Scholar] [CrossRef]

- Jiao, W.; Wang, Q.; Cheng, Y.; Zhang, Y. End-to-end prediction of weld penetration: A deep learning and transfer learning based method. J. Manuf. Process. 2021, 63, 191–197. [Google Scholar] [CrossRef]

- Liang, R.; Yu, R.; Luo, Y.; Zhang, Y. Machine learning of weld joint penetration from weld pool surface using support vector regression. J. Manuf. Process. 2019, 41, 23–28. [Google Scholar] [CrossRef]

- Lu, J.; Shi, Y.; Bai, L.; Zhao, Z.; Han, J. Collaborative and quantitative prediction for reinforcement and penetration depth of weld bead based on molten pool image and deep residual network. IEEE Access 2020, 8, 126138–126148. [Google Scholar] [CrossRef]

- Pal, S.; Pal, S.K.; Samantaray, A.K. Neurowavelet packet analysis based on current signature for weld joint strength prediction in pulsed metal inert gas welding process. Sci. Technol. Weld. Join. 2008, 13, 638–645. [Google Scholar] [CrossRef]

- Pal, S.; Pal, S.K.; Samantaray, A.K. Sensor based weld bead geometry prediction in pulsed metal inert gas welding process through artificial neural networks. Int. J. Knowl.-Based Intell. Eng. Syst. 2008, 12, 101–114. [Google Scholar] [CrossRef]

- Jeong, H.; Park, K.; Baek, S.; Kim, D.Y.; Kang, M.J.; Cho, J. Three-dimensional numerical analysis of weld pool in GMAW with fillet joint. J. Precis. Eng. Manuf. 2018, 19, 1171–1177. [Google Scholar] [CrossRef]

- Hu, Z.; Hua, L.; Qin, X.; Ni, M.; Ji, F.; Wu, M. Molten pool behaviors and forming appearance of robotic GMAW on complex surface with various welding positions. J. Manuf. Process. 2021, 64, 1359–1376. [Google Scholar] [CrossRef]

- Cho, D.W.; Park, J.H.; Moon, H.S. A study on molten pool behavior in the one pulse one drop GMAW process using computational fluid dynamics. Int. J. Heat Mass Transf. 2019, 139, 848–859. [Google Scholar] [CrossRef]

- Zong, R.; Chen, J.; Wu, C.; Lou, D. Numerical analysis of molten metal behavior and undercut formation in high-speed GMAW. J. Mater. Process. Technol. 2021, 297, 117266. [Google Scholar] [CrossRef]

| Waveform | DC Pulse |

|---|---|

| WFR | 7.0–12.0 m/min |

| Welding speed | 30 cm/min |

| CTWD | 20 mm |

| Shielding gas (Flow rate) | 90% Ar + 10% CO2 (25 L/min) |

| WFR (m/min) | 7.0 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 | |

|---|---|---|---|---|---|---|---|

| Average (A/V) | 212/26.4 | 241/27.4 | 267/28.1 | 289/29.2 | 314/29.8 | 351/31.1 | |

| Pulse cycle (ms) | 5.77 | 5.12 | 4.79 | 4.46 | 4.13 | 3.85 | |

| Current | IP (A) | 466 | 465 | 464 | 465 | 463 | 466 |

| IB (A) | 36 | 38 | 43 | 47 | 55 | 65 | |

| TIP (ms) | 1.79 | 1.77 | 1.78 | 1.78 | 1.76 | 1.80 | |

| TIB (ms) | 2.14 | 1.67 | 1.09 | 0.92 | 0.36 | 0.12 | |

| Voltage | VP (V) | 33.2 | 34.0 | 34.3 | 33.6 | 33.8 | 34.2 |

| Vb (V) | 20.8 | 21.2 | 21.6 | 21.5 | 22.6 | 22.9 | |

| TVP (ms) | 1.60 | 1.62 | 1.58 | 1.61 | 1.62 | 1.57 | |

| TVB (ms) | 3.33 | 2.81 | 2.22 | 1.94 | 1.44 | 1.21 | |

| Layer | Type | Parameter | Number of Parameters | Arguments |

|---|---|---|---|---|

| 0 | Input | 175 × 131 | ||

| 1 | Conv2D_1 | 173 × 129 | 896 | Filter = 32, Size = 3 × 3, Stride = 1, Activation function = ReLU |

| 2 | Max_pooling2D_1 | 86 × 64 | Filter = 32, Size = 2 × 2, Stride = 2 | |

| 3 | Conv2D_2 | 84 × 62 | 18,496 | Filter = 64, Size = 3 × 3, Stride = 1, Activation function = ReLU |

| 4 | Max_pooling2D_2 | 42 × 31 | Filter = 64, Size = 2 × 2, Stride = 2 | |

| 5 | Conv2D_3 | 40 × 29 | 73,856 | Filter = 128, Size = 3 × 3, Stride = 1, Activation function = ReLU |

| 6 | Flatten | 148,480 | ||

| 7 | Dense_1 | 128 | 19,005,568 | Activation function = ReLU |

| 8 | Dropout | 128 | Probability = 0.3 | |

| 9 | Dense_2 | 3 | 387 | Activation function = Softmax |

| Class | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) |

|---|---|---|---|---|

| 0 | 97.8 | 100 | 100 | 100 |

| 1 | 96.2 | 100 | 98.1 | |

| 2 | 100 | 86.3 | 92.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-Y.; Lee, H.W.; Yu, J.; Park, J.-K. Application of Convolutional Neural Networks for Classifying Penetration Conditions in GMAW Processes Using STFT of Welding Data. Appl. Sci. 2024, 14, 4883. https://doi.org/10.3390/app14114883

Kim D-Y, Lee HW, Yu J, Park J-K. Application of Convolutional Neural Networks for Classifying Penetration Conditions in GMAW Processes Using STFT of Welding Data. Applied Sciences. 2024; 14(11):4883. https://doi.org/10.3390/app14114883

Chicago/Turabian StyleKim, Dong-Yoon, Hyung Won Lee, Jiyoung Yu, and Jong-Kyu Park. 2024. "Application of Convolutional Neural Networks for Classifying Penetration Conditions in GMAW Processes Using STFT of Welding Data" Applied Sciences 14, no. 11: 4883. https://doi.org/10.3390/app14114883