Design of a New Supersonic Shock Wave Generator and Application in Power Generation

Abstract

:Featured Application

Abstract

1. Introduction

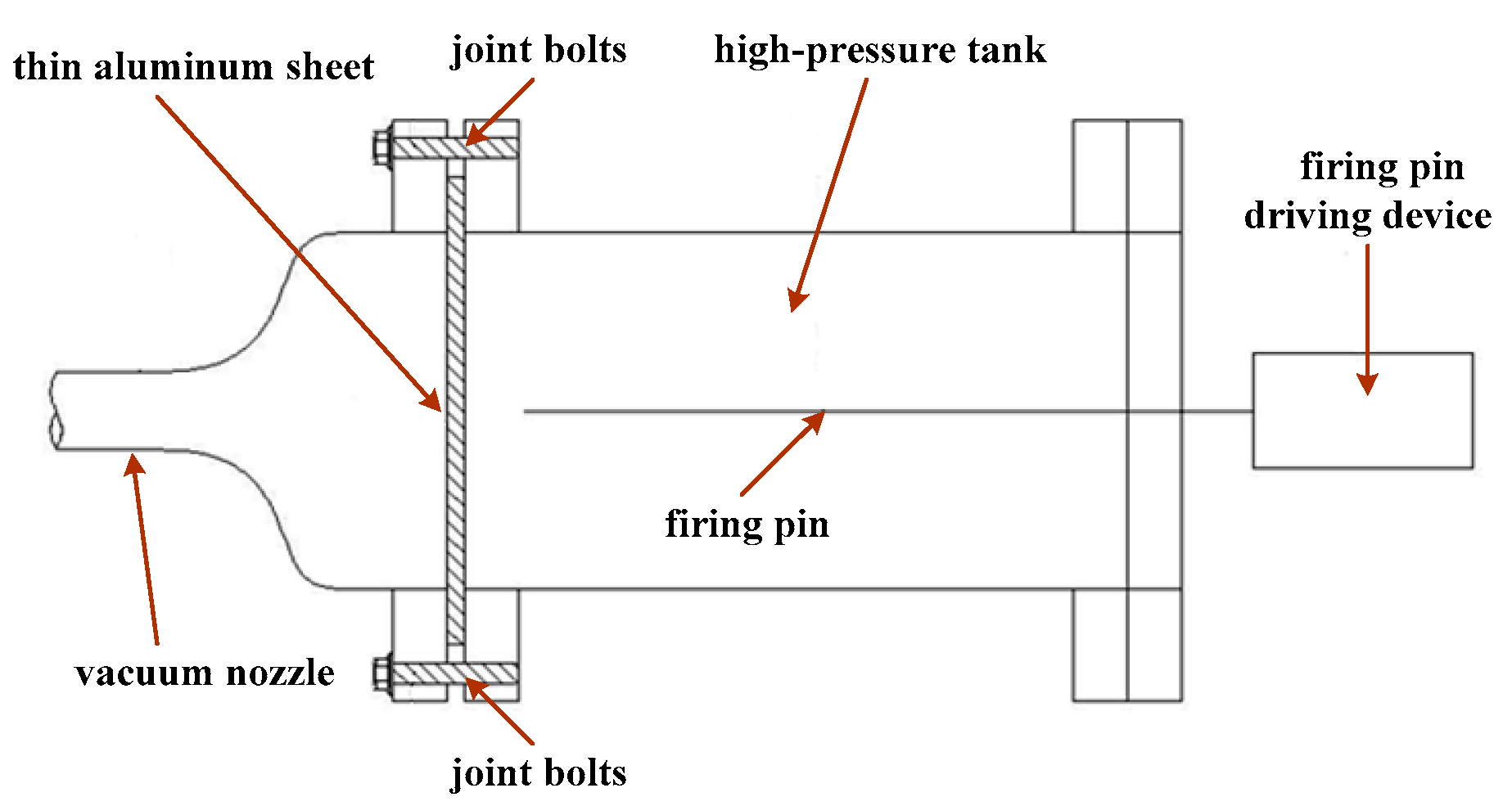

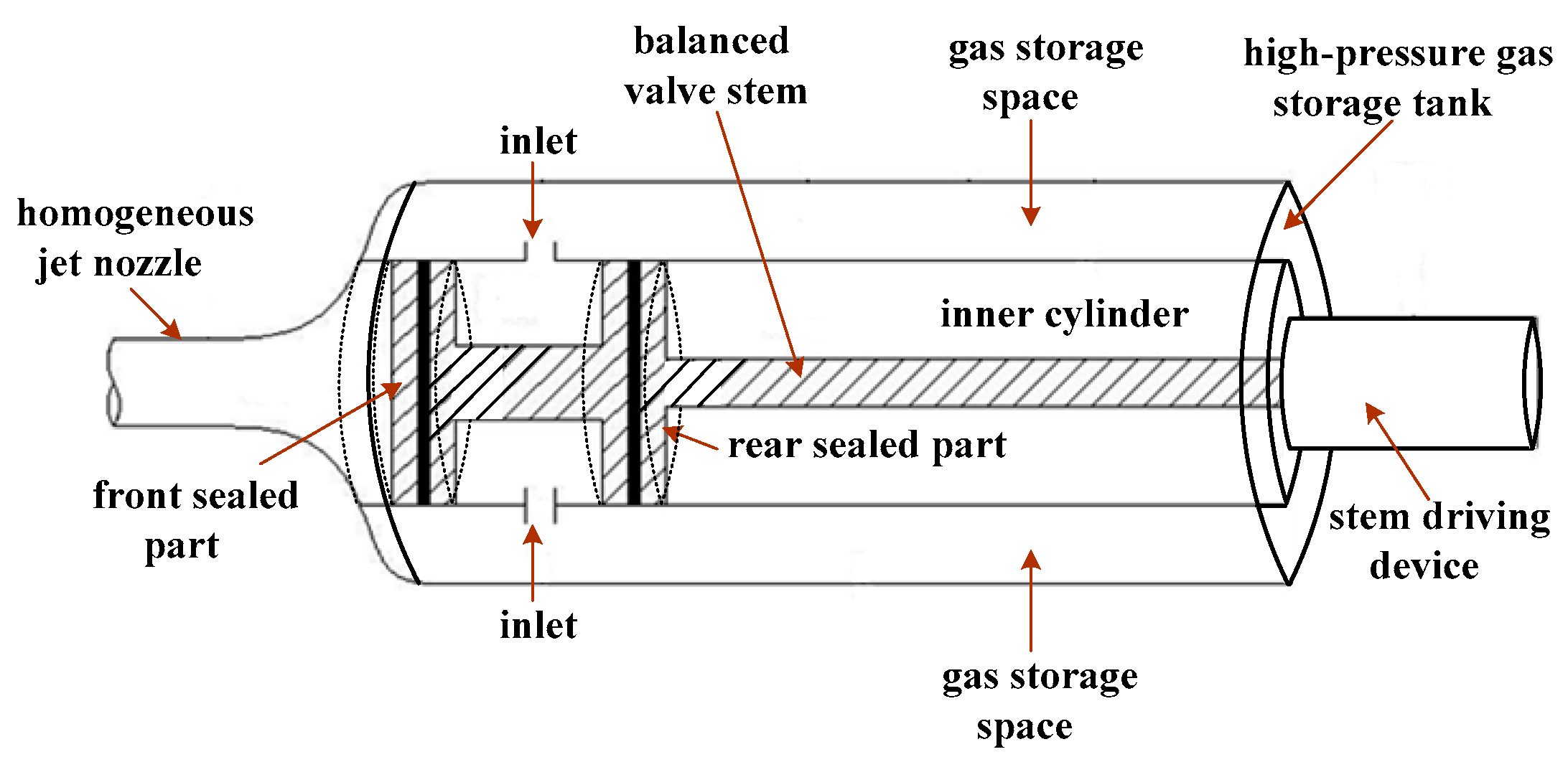

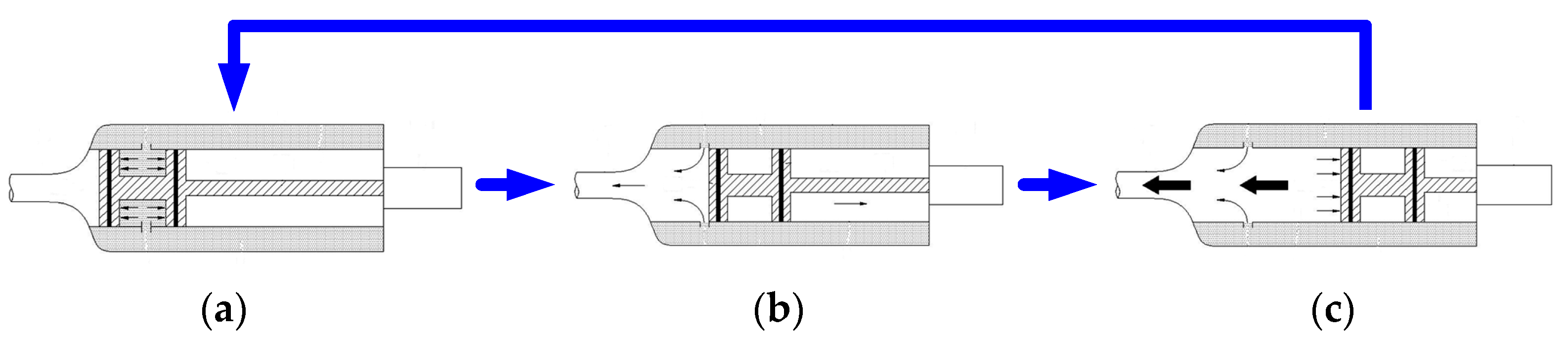

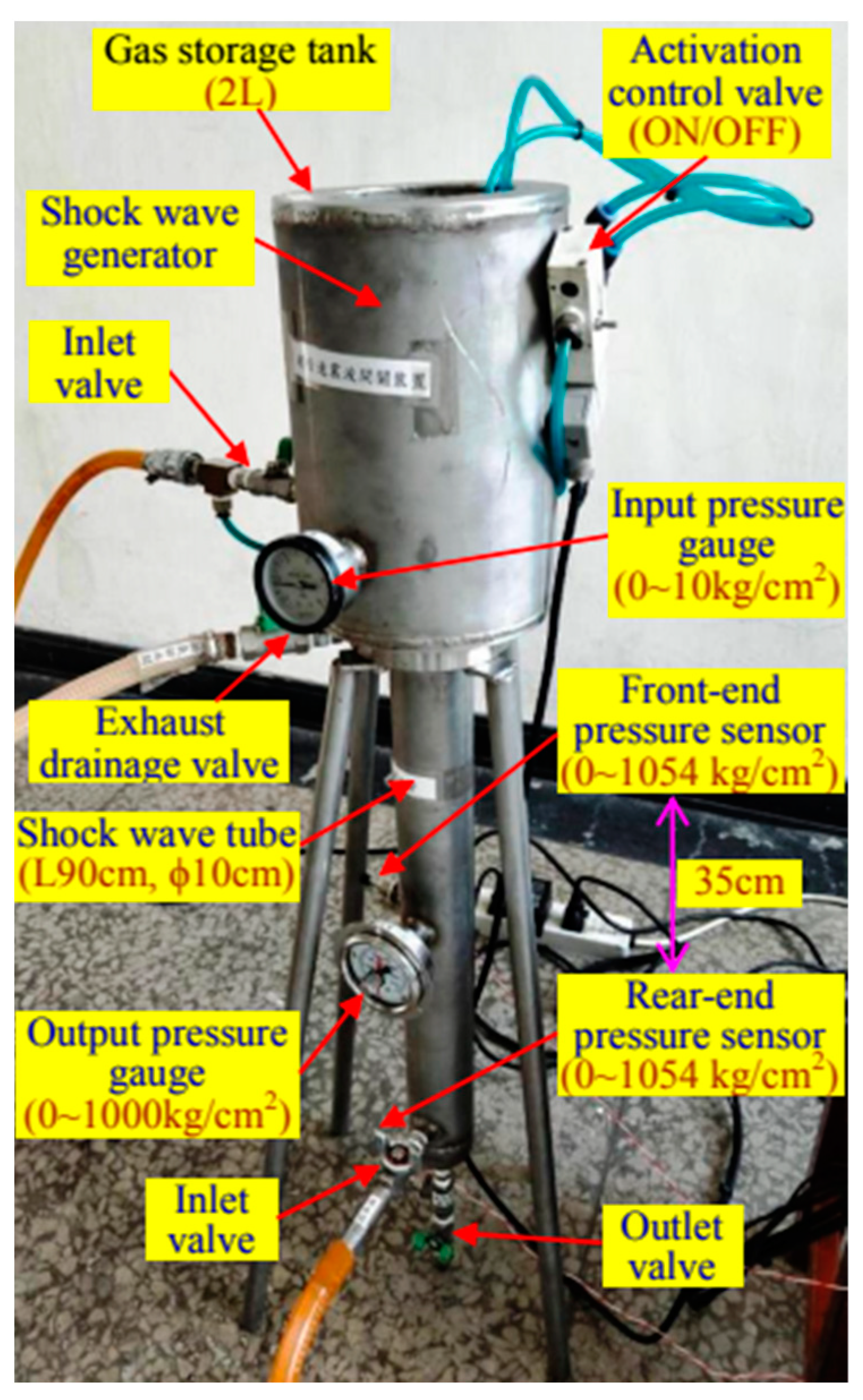

2. Design of a New Shock Wave Generator

3. Supersonic Shock Wave Monitoring

3.1. Monitoring System Architecture

- (1)

- Shock wave generator: this is a device used to generate supersonic shock waves.

- (2)

- Activation control valve: this is controlled by the monitoring host and is used to activate the shock wave generator to generate supersonic shock waves.

- (3)

- Shock tube: this is a cylindrical steel tube, with water as the carrier, and the shock waves generated enter the steel tube to be moved and reflected quickly.

- (4)

- High-pressure gas supply unit: this is used to generate high-pressure gases and provide gases to the shock wave generator to generate shock waves. It can be an air compressor or a high-pressure gas cylinder.

- (5)

- Inlet valve: this is used to control high-pressure gases entering the gas storage tank of the shock wave generator.

- (6)

- Input pressure gauge: this is used to monitor the pressure of the gases entering the gas storage tank of the shock wave generator.

- (7)

- Output pressure gauge: this is a mechanical pressure gauge with residual pressure used to monitor and display the maximum pressure in the shock tube.

- (8)

- Front-end pressure sensor: this is a high-pressure and high-speed pressure sensor installed at the front end of the shock tube.

- (9)

- Rear-end pressure sensor: this is also a high-pressure and high-speed pressure sensor installed at the rear end of the shock tube.

- (10)

- Water inlet valve: this is used to assess and control whether to input water into the shock tube and is installed below the shock tube.

- (11)

- Water source: this provides water for the shock tube and is used as a water bucket or tap.

- (12)

- Exhaust drainage valve: this is a control valve installed at the top of the shock tube for exhaust or drainage, so the shock tube is filled with water when water flows out of the valve.

- (13)

- Drainage tank: this is used to receive water or gases from the exhaust drainage valve.

- (14)

- Drainage valve: this is a control valve for removing residual water from the shock tube.

- (15)

- Signal transformation unit: This is a data acquisition and control card for acquiring pressure signals measured by the front-end and rear-end pressure sensors and then transmitting them to the monitoring host for processing. It also transmits the command of the monitoring host to the activation control valve to activate the shock wave generator to generate supersonic shock waves.

- (16)

- Monitoring host: This is a personal computer that executes monitoring software developed with LabVIEW 2014 SPI. Through the signal transformation unit, the monitoring host commands the activation control valve to activate the shock wave generator to generate supersonic shock waves. Additionally, it synchronously acquires the pressure signals measured by the front-end and rear-end pressure sensors. It then calculates and analyzes supersonic shock waves’ movement speed and output pressure in the shock tube.

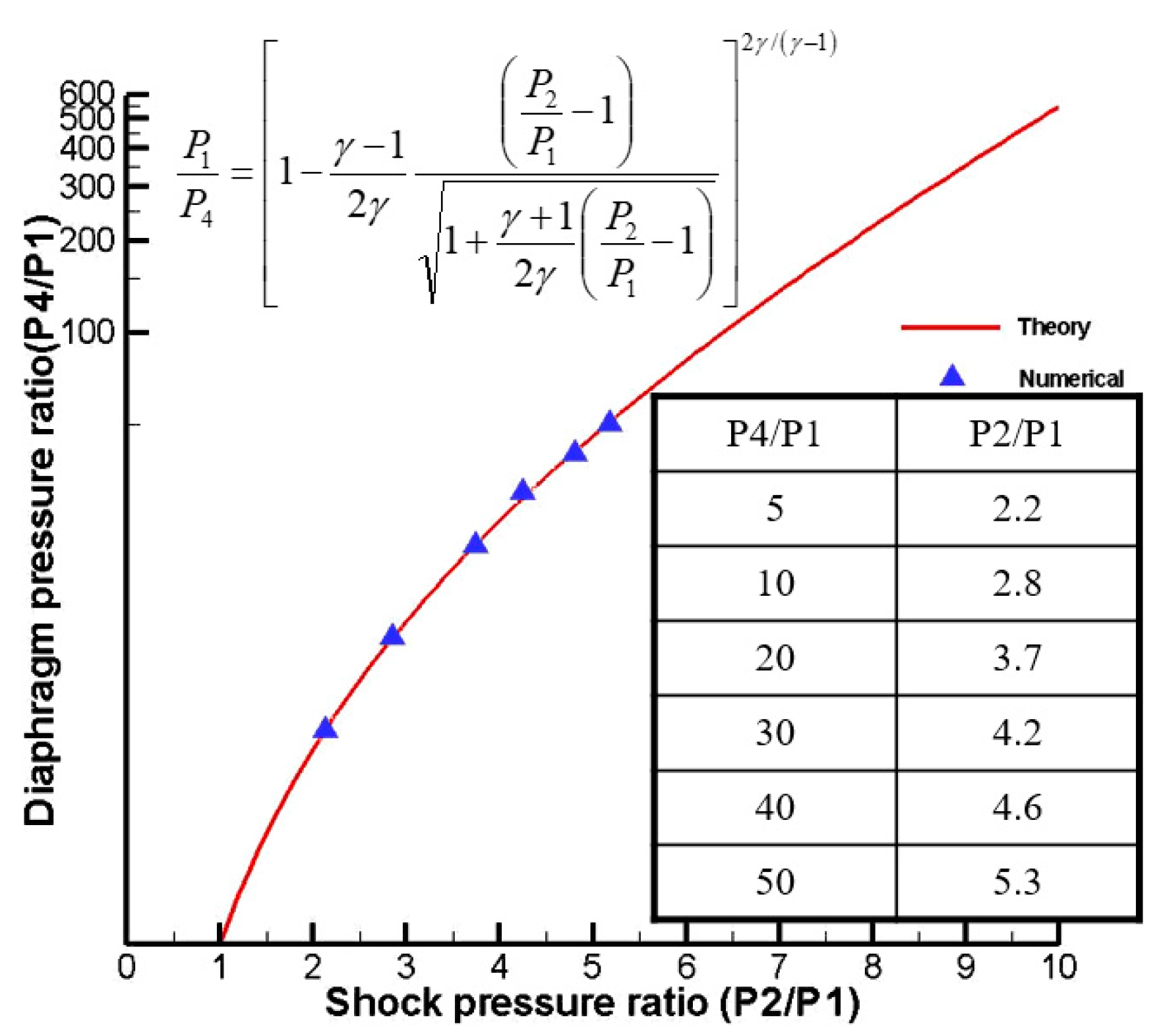

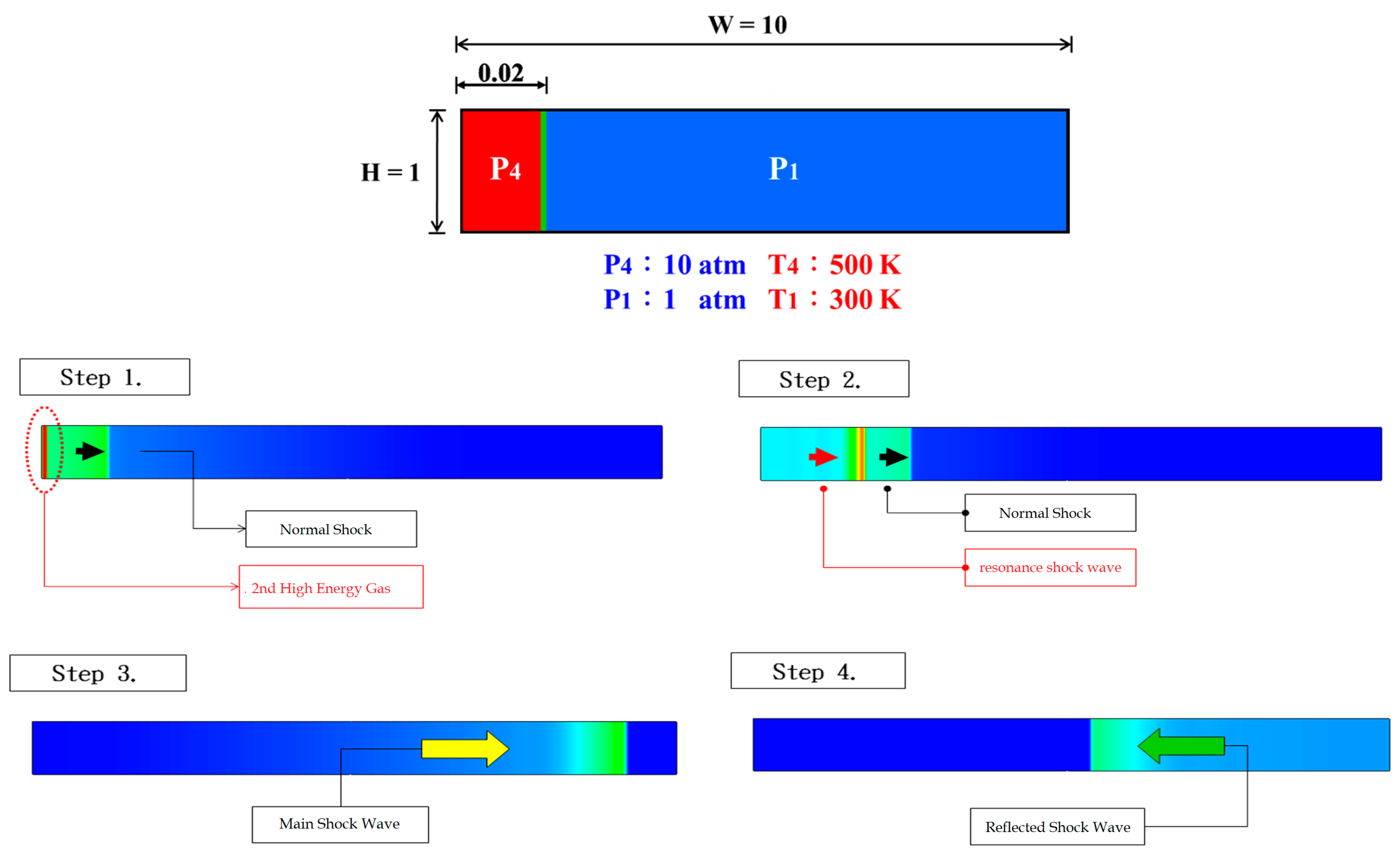

3.2. Numerical Simulation of the Shock Wave Monitoring

3.2.1. Governing Equations and Preconditioning System

3.2.2. Scheme Validation

- The fluid is compressible flow.

- The viscous effect (inviscid) is not considered.

- The fluid is a perfect ideal gas.

- We do not consider chemical reactions.

3.2.3. Resonance Shock Wave Monitoring

3.3. Development of the Shock Wave Monitoring System

3.4. Experimental Analysis of Supersonic Shock Wave Monitoring

- (1)

- Maximum voltage measured: The maximum peak voltage of the pressure pulse measured appears at the peak, where “Ch1 Max” represents the maximum voltage (vfmax) of the front-end pressure curve (channel 1), and “Ch2 Max” represents the maximum voltage (vrmax) of the rear-end pressure curve (channel 2). At this point, vfmax = 6.756 V and vrmax = 6.728 V.

- (2)

- Location with the maximum pressure: “Ch1 Max Pos” represents the location (lfmax) with the maximum value of the front-end pressure curve, and “Ch2 Max Pos” represents the location (lrmax) with the maximum value of the rear-end pressure curve. At this point, lfmax = 8959 Pt and lrmax = 8983 Pt.

- (3)

- Distance and time differences between both ends: The distance Δd between the front-end pressure sensor and the rear-end pressure sensor was 0.35 m, and the system calculates the time difference Δt of two pressure pulses based on the difference between the rear end and the front end in positions of the maximum pressure, namely,Δt = (lrmax − lfmax) × tsTherefore, Δt = (8983 − 8959) × 0.00001 = 24 × 0.00001 = 0.00024 s, where ts is the time of each sampling (0.00001 s).

- (4)

- Shock wave velocity and Mach: The shock wave velocity in the x direction can be calculated by dividing the distance between the front end and rear end by the time difference between the shock wave passing through the front-end and rear-end sensors. Namely, shock wave velocity vx (m/s) was calculated as follows:vx = Δd/ΔtTherefore, vx = 0.35 m/0.00024 s = 1458.33 m/s. In addition, because Mach 1 (Ma) was about 340.3 m/s, the shock wave velocity Mx in Mach was calculated as follows:Mx = vx/340.3 = 1458.33/340.3 = 4.29 (Mach)

- (5)

- Input pressure and output pressure: We fixed the input pressure pin at 5 kg/cm2 in the shock wave monitoring. However, the maximum peak voltage of the pressure pulse measured appeared at the peak. Therefore, the output pressure pout of the shock wave was calculated from the maximum peak voltage (Vfpeak) of the front-end pressure pulse or the maximum peak voltage (Vrpeak) of the rear-end pressure pulse. The equation is as follows:Vpeak = max(Vfpeak, Vrpeak)Since Vfpeak = 6.756 V and Vrpeak = 6.728 V, Vpeak = 6.756 V. And, Vmin = 0 V, Vmax = 7.5 V, Pmin = 0 kg/cm2, and Pmax = 1054 kg/cm2; therefore, the calculated output pressure is pout = (6.756 V/7.5 V) × 1054 kg/cm2 = 945.51 kg/cm2. We can compare the output pressure of the shock wave measured by this monitoring system with the value measured by the magnetic output pressure gauge on the shock tube for verification. The data measured by the output pressure gauge on the shock tube were all about 945 kg/cm2, verifying the pressure measured by this monitoring system.

- (6)

- Magnification ratio: The pressure magnification ratio rp is the ratio of the output pressure pout to the input pressure pin, namelyrp = pout/pinTherefore, the pressure magnification ratio rp = 945.51/5 = 188.3 (times).

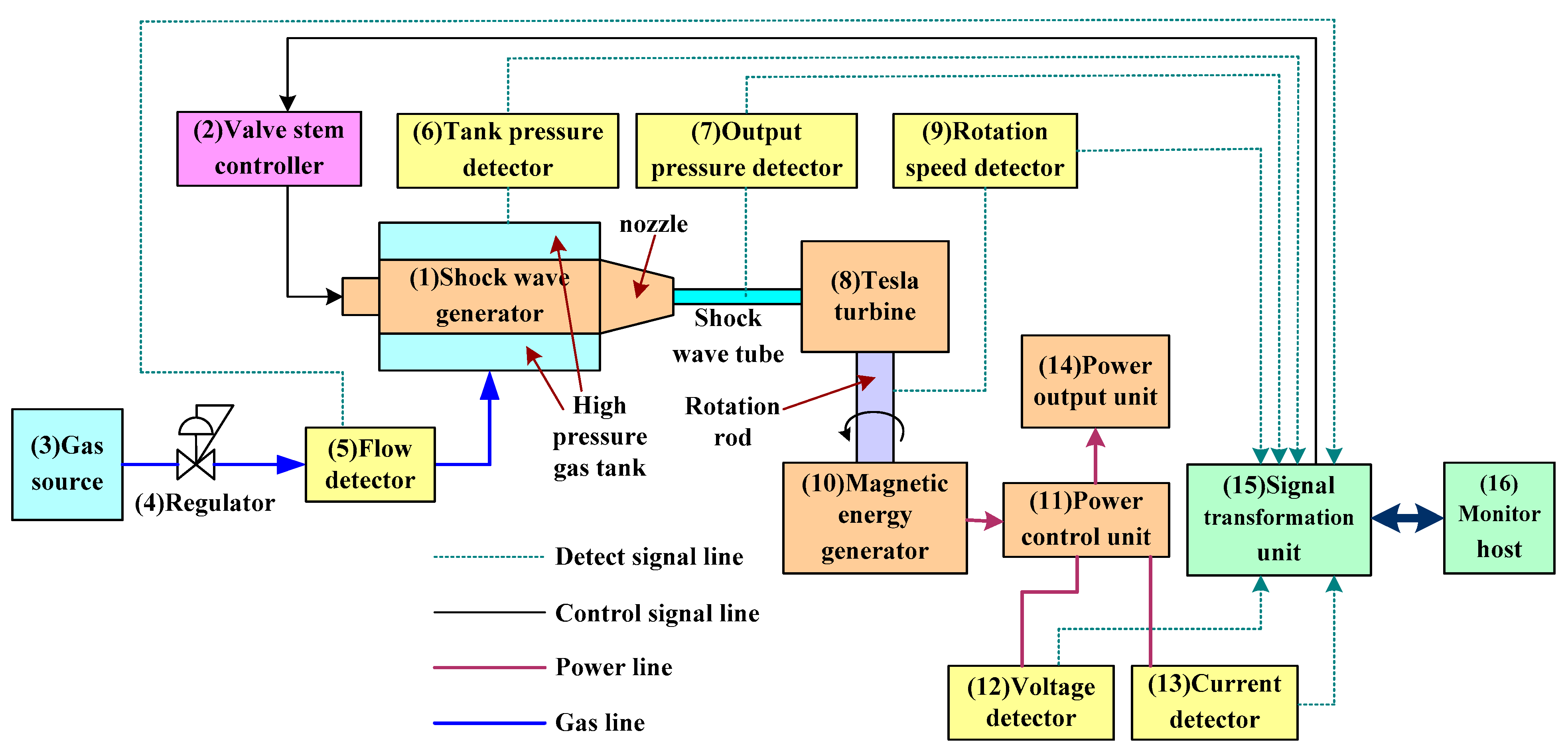

4. Design of a Power Generation System Driven by Supersonic Shock Waves

4.1. System Design

- (1)

- Shock wave generator: This comprises a high-pressure storage tank and a balanced valve stem. When the balanced valve stem moves backward and the gases in the high-pressure storage tank reach the set pressure, the generator can generate shock waves that rush out of the homogeneous jet nozzle.

- (2)

- Valve stem controller: This can drive the balanced valve stem of the shock wave generator forward and backward. When the balanced valve stem moves backward (ON), the generator generates a shock wave, and high-pressure gas rushes out to drive the Tesla turbine to rotate. When the balanced valve stem moves forward (OFF), the output of high-pressure gases stops.

- (3)

- Gas source: this is a high-pressure gas cylinder or an air compressor that provides high-pressure gases for the high-pressure storage tank of the shock wave generator.

- (4)

- Regulator: this can adjust the gas pressure output from the gas source.

- (5)

- Flow detector: this detects the gas flow fg delivered from the gas source to the high-pressure gas storage tank. The flow signals detected can be transmitted to the monitoring host through the signal transformation unit.

- (6)

- Tank pressure detector: This can detect the gas pressure pt in the high-pressure storage tank of the shock wave generator. The pressure signals detected can be transmitted to the monitoring host through the signal transformation unit.

- (7)

- Output pressure detector: This can detect the gas pressure po output from the shock wave generator. The pressure signals detected are transmitted to the monitoring host through the signal transformation unit.

- (8)

- Tesla turbine: The turbine can rotate through the impact of shock waves and high-pressure gas and can continue to rotate after the high-pressure gas stops through its energy storage inertia. The rotated turbine can rotate the rotating rod and then drive the magnetic energy generator to work.

- (9)

- Rotation speed detector: This can detect the rotation speed sr of the rotation rod. The speed signals detected are transmitted to the monitoring host through the signal transformation unit.

- (10)

- Magnetic energy generator: This comprises a rotating permanent magnet and a stationary coil. The rotating rod rotates to rotate the magnet to cut magnetic lines and generate power. According to the principle that magnet motors can rotate sustainably due to magnetic action, it can supplement the heat consumed by friction, increase the continuous high-speed magnet rotation time, and improve the power generation efficiency.

- (11)

- Power control unit: this can convert the alternating current generated by the magnetic energy generator into direct current and provide it to the power output unit.

- (12)

- Voltage detector: This can detect the voltage Vp of power generated by the magnetic energy generator. The voltage signals detected are transmitted to the monitoring host through the signal transformation unit.

- (13)

- Current detector: This can detect the current Ip of power generated by the magnetic energy generator. The current signals detected are transmitted to the monitoring host through the signal transformation unit.

- (14)

- Power output unit: This contains an energy storage battery and a load unit. The load unit is a light bulb box containing three parallel light bulbs. Users can turn each light bulb on or off. The power provided by the power control unit can charge the energy storage battery or directly supply the power required by the load unit.

- (15)

- Signal transformation unit: This is an Advantech USB-4711A multi-functional high-speed signal acquisition and control card [33]. It can transmit signals measured by the tank pressure detector, output pressure detector, rotation detector, and power control unit to the monitoring host for processing. It further transmits driving commands from the monitoring host to drive the valve stem controller.

- (16)

- Monitoring host: This is a personal computer that executes LabVIEW monitoring software. It receives the signals of tank pressure, output pressure, gas flow, rotation speed, voltage and current. Then, it sends the control signals to drive the valve stem controller to carry out the control process of power generation driven by shock waves.

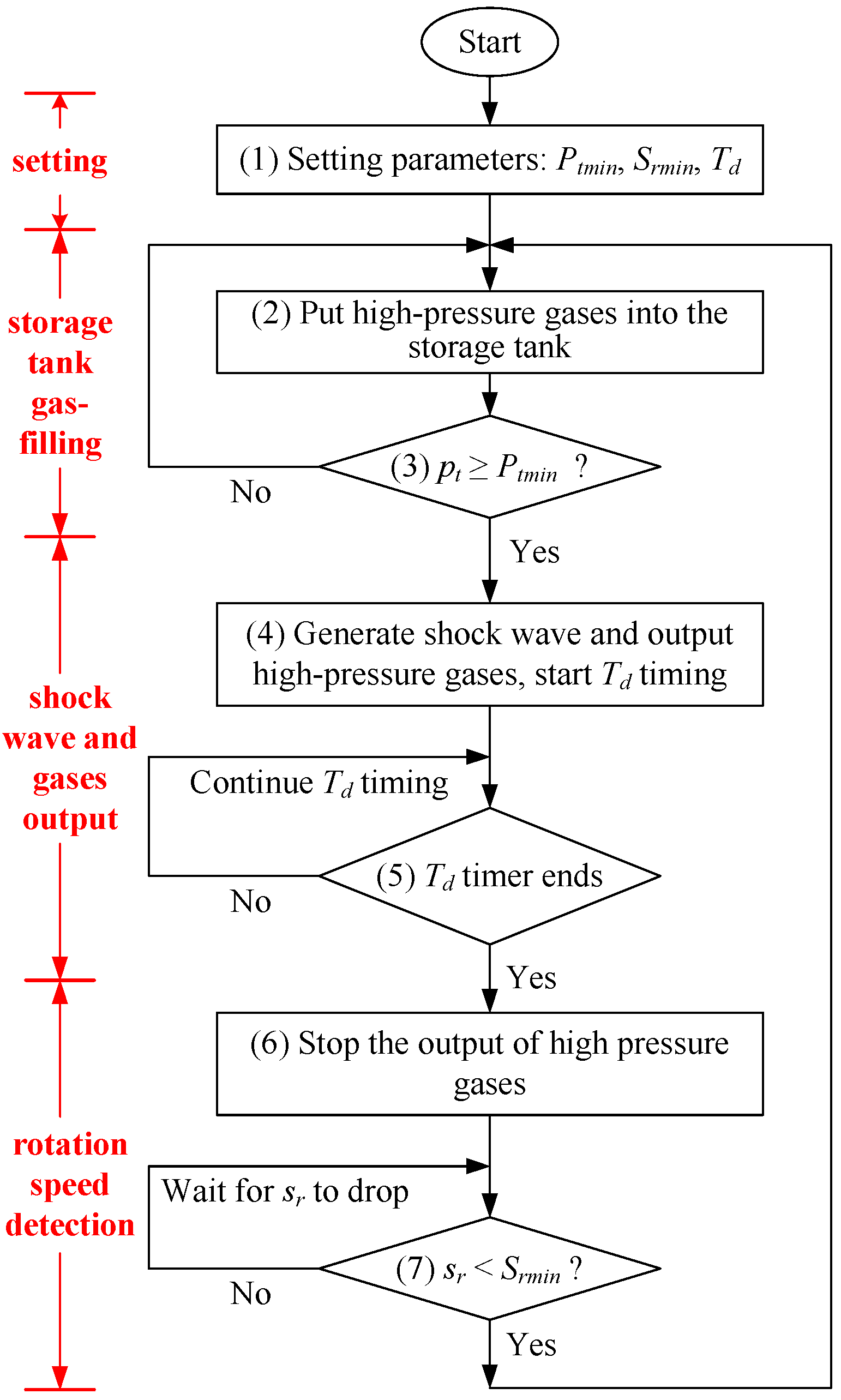

4.2. Shock Wave-Driven Control Process

4.3. Power Generation Experiments and Analysis

- (1)

- When there is no load (the number of bulbs is zero), the output current Ip and power Ep are zero.

- (2)

- It can be seen from Equation (24) that when the number of light bulbs that are turned on increases, the frequency of the generated shock waves also increases, which means that the greater the load, the greater the aerodynamic force that needs to be supplied.

- (3)

- (4)

- Equations (25) and (27) show that when the rotational speed Srmin is the same, the greater the number of bulbs, the lower the voltage that can be generated.

- (5)

- Equation (26) shows that when the number of bulbs increases, to maintain a fixed speed, more high-pressure gas needs to be consumed so that the flow rate will increase significantly, and the greater the number of bulbs, the higher the gas flow rate.

- (6)

- Equations (28) and (29) indicate that when the number of light bulbs increases, both Ip-avg and Ep-avg become larger. For example, when Srmin = 1200 rpm, the Ip-avg and Ep-avg generated by turning on one, two, and three bulbs are 51.33, 98.63, and 143.26 (mA) and 1375.13, 2514.68, and 3501.05 (mW), respectively, and their ratios are all about 1:2:3. There is a similar ratio when Srmin = 1500 rpm.

- (7)

- When users turn on a light bulb, its average load resistance Rl-avg-1 is calculated as follows:Rl-avg-1 = Vp-avg-1/Ip-avg-1 = 26.79/0.05133 = 521.92Ω (for Srmin = 1200 rpm)Rl-avg-1 = Vp-avg-1/Ip-avg-1 = 38.85/0.07744 = 521.89Ω (for Srmin = 1500 rpm)

- (8)

- When turning on two or three bulbs connected in parallel, if R1, R2, and R3 are bulb resistors, Rl2 and Rl3 represent the load resistance of two bulbs and three bulbs connected in parallel. We can express the load resistors Rl2 and Rl3 as Expressions (30) and (31) (since R1 = R2 = R3):

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, W.K.; Chang, C.E.; Lee, E.F.; Yue, P. Wind Energy and Wind Power Technology; Wu-Nan Culture Enterprise: Taipei, Taiwan, 2009. [Google Scholar]

- Bensalah, A.; Benhamida, M.A.; Barakat, G.; Amara, Y. Large wind turbine generators: State-of-the-art review. In Proceedings of the IEEE 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018. [Google Scholar]

- Gimenez, R.B.; Hsieh, H.Y.; Lin, F.J. Development Trend of Large Wind Turbine Technology; Department of Electrical Engineering, National Central University: Taoyuan, Taiwan, 2013. [Google Scholar]

- Green Trade Project Office. Current Situation and Future Prospect of Taiwan’s Wind Power Industry; Industrial Technology Research Institute IEK: Hsinchu, Taiwan, 2018. [Google Scholar]

- Wang, R.H. Wind Power Promotion Policies of Major Countries and Wind Power Market and Industry Trend Analysis in 2017, Achievements Report on Promotion of Thousands of Onshore and Offshore Wind Turbines and Key Technology Development Plan of the Energy Technology Development Program by the Ministry of Economic Affairs (2/3); Industrial Technology Research Institute: Hsinchu, Taiwan, 28 April 2017. [Google Scholar]

- Yeh, T.H.; Wang, L. A Study on Generator Capacity for Wind Turbines Under Various Tower Heights and Rated Wind Speeds Using Weibull Distribution. IEEE Trans. Energy Convers. 2008, 23, 592–602. [Google Scholar]

- Gerdes, J. Kissing the Sky: The Pros and Cons of Ultra-Tall Wind Turbine Towers; Wood Mackenzie: Singapore, 5 September 2019. [Google Scholar]

- Ben-Dor, G. Shockwave Reflections Phenomena; Springer: New York, NY, USA, 1991. [Google Scholar]

- Smoller, J. Shock Waves and Reaction—Diffusion Equations; Springer: New York, NY, USA; Berlin/Heidelberg, Germany, 1983; ISBN 3-540-90752-1. [Google Scholar]

- Von, N.J. Oblique Reflection of Shock, Explosion Research Reports 12; Navy Dept., Bureau of Ordnance: Washington, DC, USA, 1943. [Google Scholar]

- Tang, M.J.; Baker, Q.A. A New Set of Blast Curves from Vapor Cloud Explosion, Process Safety Progress. Winter 1999, 18, 235–240. [Google Scholar]

- Igra, O.; Hu, G.; Falcovitz, J.; Heilig, W. Blast Wave Reflection from Wedges. J. Fluids Eng. 2003, 125, 510–519. [Google Scholar] [CrossRef]

- Mazarak, O.; Martins, C.; Amanatides, J. Animating Exploding Objects. Graph. Interface 1999, 99, 211–218. [Google Scholar]

- Yngve, G.D.; O’Brien, J.F.; Hodgins, J.K. Animating Explosions. In Proceedings of the 27th Annual Conference on Computer Graphics and Interactive Techniques, New Orleans, LA, USA, 23–28 July 2000; CM Press/Addison-Wesley Publishing Co.: San Francisco, CA, USA, 2000; pp. 29–36. [Google Scholar]

- Tai, C.H.; Hsu, U.K.; Lai, C.C. Design and Simulation of an Opposed-piston Engine Worked by the Resonant and Focusing of the Shock Wave. Int. J. Mech. Prod. Eng. 2017, 5, 7–11. [Google Scholar]

- Shih, C.H.; Tsai, Y.Y.; Tai, C.H.; Hsu, U.K. Numerical Studies on the Explosion Shock Waves of a Large Truck Tires in Airport. In Proceedings of the 2020AASRC, Hsinchu, Taiwan, 12 November 2020. [Google Scholar]

- Fadai, N.T.; Simpson, M.J. New travelling wave solutions of the Porous–Fisher model with a moving boundary. J. Phys. A Math. Theor. 2020, 53, 095601. [Google Scholar] [CrossRef]

- Li, Y.; Heijster, P.V.; Simpson, M.J.; Wechselberger, M. Shock-fronted travelling waves in a reaction-diffusion model with nonlinear forward-backward-forward diffusion. Phys. D Nonlinear Phenom. 2021, 423, 132916. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Z.; Zhang, Y.; Cheng, D.; Tan, H.; Wang, K.; Gao, S. Control of Cowl Shock/Boundary Layer Interaction in Supersonic Inlet Based on Dynamic Vortex Generator. Aerospace 2023, 10, 729. [Google Scholar] [CrossRef]

- Dai, T.; Zhang, B. Effect of Air Jet Vortex Generators on the Shock Wave Boundary Layer Interaction of Transonic Wing. Aerospace 2023, 10, 553. [Google Scholar] [CrossRef]

- Wen, C.Y. Pilot Supersonic Combustion Ramjet Engine Research Project (II), Achievements Report on the Special Research Program of the National Science Council; NSC 99-2623-E-006-010-D; National Science Council: Taipei, Taiwan, 2011. [Google Scholar]

- Hu, M.S.; Su, R.H. Generating Device for Supersonic Shock Waves. R.O.C. New Patent M553377, 21 December 2017. [Google Scholar]

- Hsu, U.K. Numerical and Experimental Investigation of a Supersonic Flow Field around Solid Fuel on an Inclined Flat Plate. Model. Simul. Eng. 2009, 2009, 823874. [Google Scholar] [CrossRef]

- Liou, M.S. A Continuing Search for a Near-Perfect Numerical Flux Scheme, Part I: AUSM+, NASA TM 106524; NASA: Washington, DC, USA, March 1994. [Google Scholar]

- Choi, Y.H.; Merkle, C.L. The application of preconditioning in viscous flows. J. Comput. Phys. 1993, 105, 207–233. [Google Scholar] [CrossRef]

- Weiss, J.M.; Smith, W.A. Preconditioning applied to variable and constant density flows. AIAA J. 1995, 33, 2050–2057. [Google Scholar] [CrossRef]

- Model 113B23, ICP® Pressure Sensor, Installation and Operating Manual, PCB Piezotronics, Inc. Available online: https://www.manualslib.com/manual/3034764/Pcb-Piezotronics-113b23.html (accessed on 15 March 2024).

- NI USB-6341, X Series Multifunction DAQ (16AI, 24DIO, 2AO), 500kS/s Single-Channel Sampling Rate, NI USB Multifunction I/O Device. Available online: https://www.apexwaves.com/modular-systems/national-instruments/usb-multifunction-devices/USB-6341 (accessed on 15 March 2024).

- Hsiao, T.C.; Wang, C.Y.; Chu, J.W. Virtual Instrument Control Programming-LabVIEW 8X; Gao Li Book Corp. Ltd.: New Taipei, Taiwan, 2014. [Google Scholar]

- Chen, C.C. LabVIEW Applications (Include Automatic Measurement and Remote Control); Chuan Yua Book Corp. Ltd.: Taipei, Taiwan, 2014. [Google Scholar]

- Hsu, Y.H. Interface Design and Practice—Using LabVIEW; Chuan Yua Book Corp. Ltd.: Taipei, Taiwan, 2014. [Google Scholar]

- Hu, M.S.; Su, R.H.; Hsu, U.K.; Tai, C.H. Power Generation System Driven by Dual-Cycle Supersonic Shock Waves. R.O.C. Invention Patent I700432, 1 August 2020. [Google Scholar]

- Advantech USB-4711A User Manual, 150 KS/s, 12-Bit Multifunction USB Data Acquisition Module, Advantech. Available online: https://www.advantech.com/en/support/details/manual?id=1-2HOQR5 (accessed on 15 March 2024).

- Kuo, B.C. Automatic Control Systems, Holt; Rinehart and Winston, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Nise, N.S. Control System Engineering, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2004. [Google Scholar]

- Su, R.H.; Chung, L.Y.; Hu, M.S.; Jia, Z.M. Geothermal Well Productivity Enhancement Method and System. R.O.C. Invention Patent I601874, 11 October 2017. [Google Scholar]

- Hu, M.S.; Su, Y.L. Portable Supersonic Shock Wave Rock Crusher. R.O.C. New Patent M608193, 21 February 2021. [Google Scholar]

- Hu, M.S.; Su, Y.L.; Chen Yang, Z.G. Lightweight Supersonic Shock Wave Hard Ground Excavator. R.O.C. New Patent M615448, 11 August 2021. [Google Scholar]

- Hu, M.S.; Su, Y.L. Pipeline Obstruction Clearing Device Using Supersonic Shock Waves. R.O.C. New Patent M646343, 1 July 2023. [Google Scholar]

- Hu, M.S.; Su, Y.L.; Tsai, S.H.; Hsu, U.K. Supersonic Shock Wave Soil Loosening and Hole Fertilization Device. R.O.C. New Patent M646343, 21 September 2023. [Google Scholar]

| No. | Δt (s) | vx (m/s) | Mx (Mach) | pout (kg/cm2) | rp |

|---|---|---|---|---|---|

| 1 | 0.00025 | 1400 | 4.12 | 935.7 | 187.14 |

| 2 | 0.00024 | 1458.33 | 4.29 | 942.85 | 188.57 |

| 3 | 0.00024 | 1458.33 | 4.29 | 943.27 | 188.65 |

| 4 | 0.00027 | 1296.3 | 3.81 | 906.01 | 181.2 |

| 5 | 0.00027 | 1296.3 | 3.81 | 908.49 | 181.7 |

| 6 | 0.00021 | 1666.67 | 4.9 | 964.94 | 192.99 |

| 7 | 0.00022 | 1590.91 | 4.68 | 956.19 | 191.24 |

| 8 | 0.00022 | 1590.91 | 4.68 | 956.57 | 191.31 |

| 9 | 0.00022 | 1590.91 | 4.68 | 956.01 | 191.2 |

| 10 | 0.00023 | 1521.74 | 4.48 | 951.92 | 190.38 |

| 11 | 0.00026 | 1346.15 | 3.96 | 931.17 | 186.23 |

| 12 | 0.00025 | 1400 | 4.12 | 938.37 | 187.67 |

| 13 | 0.00026 | 1346.15 | 3.96 | 926.23 | 185.25 |

| 14 | 0.00026 | 1346.15 | 3.96 | 928.19 | 185.64 |

| 15 | 0.00021 | 1666.67 | 4.9 | 965.08 | 193.02 |

| 16 | 0.00022 | 1590.91 | 4.68 | 957.25 | 191.45 |

| 17 | 0.00022 | 1590.91 | 4.68 | 958.81 | 191.76 |

| 18 | 0.00022 | 1590.91 | 4.68 | 958.75 | 191.75 |

| 19 | 0.00023 | 1521.74 | 4.48 | 950.7 | 190.14 |

| 20 | 0.00025 | 1400 | 4.12 | 939.33 | 187.87 |

| Avg | 0.00024 | 1480.33 | 4.36 | 943.31 | 188.7 |

| Period | Zero Bulbs | One Bulb | Two Bulbs | Three Bulbs |

|---|---|---|---|---|

| fs-avg-k (Hz) | 0.42 | 0.54 | 0.68 | 0.81 |

| sr-avg-k (rpm) | 1262.52 | 1243.65 | 1204.34 | 1170.82 |

| fg-avg-k (L/min) | 143.83 | 176.79 | 197.15 | 233.27 |

| Vp-avg-k (V) | 28.38 | 26.79 | 25.46 | 24.44 |

| Ip-avg-k (mA) | 0 | 51.33 | 98.63 | 143.26 |

| Ep-avg-k (mW) | 0 | 1375.13 | 2514.68 | 3501.15 |

| Period | Zero Bulbs | One Bulb | Two Bulbs | Three Bulbs |

|---|---|---|---|---|

| fs-avg-k (Hz) | 0.53 | 0.65 | 0.79 | 0.88 |

| sr-avg-k (rpm) | 1546.24 | 1523.75 | 1508.42 | 1482.67 |

| fg-avg-k (L/min) | 186.64 | 213.58 | 238.75 | 274.89 |

| Vp-avg-k (V) | 40.46 | 38.85 | 37.78 | 36.64 |

| Ip-avg-k (mA) | 0 | 74.44 | 145.24 | 211.01 |

| Ep-avg-k (mW) | 0 | 2891.99 | 5487.17 | 7731.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.-S.; Hsu, U.-K. Design of a New Supersonic Shock Wave Generator and Application in Power Generation. Appl. Sci. 2024, 14, 5074. https://doi.org/10.3390/app14125074

Hu M-S, Hsu U-K. Design of a New Supersonic Shock Wave Generator and Application in Power Generation. Applied Sciences. 2024; 14(12):5074. https://doi.org/10.3390/app14125074

Chicago/Turabian StyleHu, Ming-Sen, and Uzu-Kuei Hsu. 2024. "Design of a New Supersonic Shock Wave Generator and Application in Power Generation" Applied Sciences 14, no. 12: 5074. https://doi.org/10.3390/app14125074

APA StyleHu, M.-S., & Hsu, U.-K. (2024). Design of a New Supersonic Shock Wave Generator and Application in Power Generation. Applied Sciences, 14(12), 5074. https://doi.org/10.3390/app14125074