A Review of Characterization Techniques for Ferromagnetic Nanoparticles and the Magnetic Sensing Perspective

Abstract

:1. Introduction

2. Magnetic Characterization Techniques

2.1. Magnetic Susceptibility

2.2. Magnetorelaxometry (MRX)

2.3. Other Recent Novel Characterization Techniques

3. Magnetic Characterization Instruments

3.1. Vibrating Sample Magnetometers

3.2. Optically Pumped Magnetometers (OPM)

3.3. Faraday Rotation Magnetometers

3.4. Hall Effect Magnetometers

3.5. Giant Magnetoresistive (GMR) Sensors

3.6. Superconducting Quantum Interference Device (SQUID)

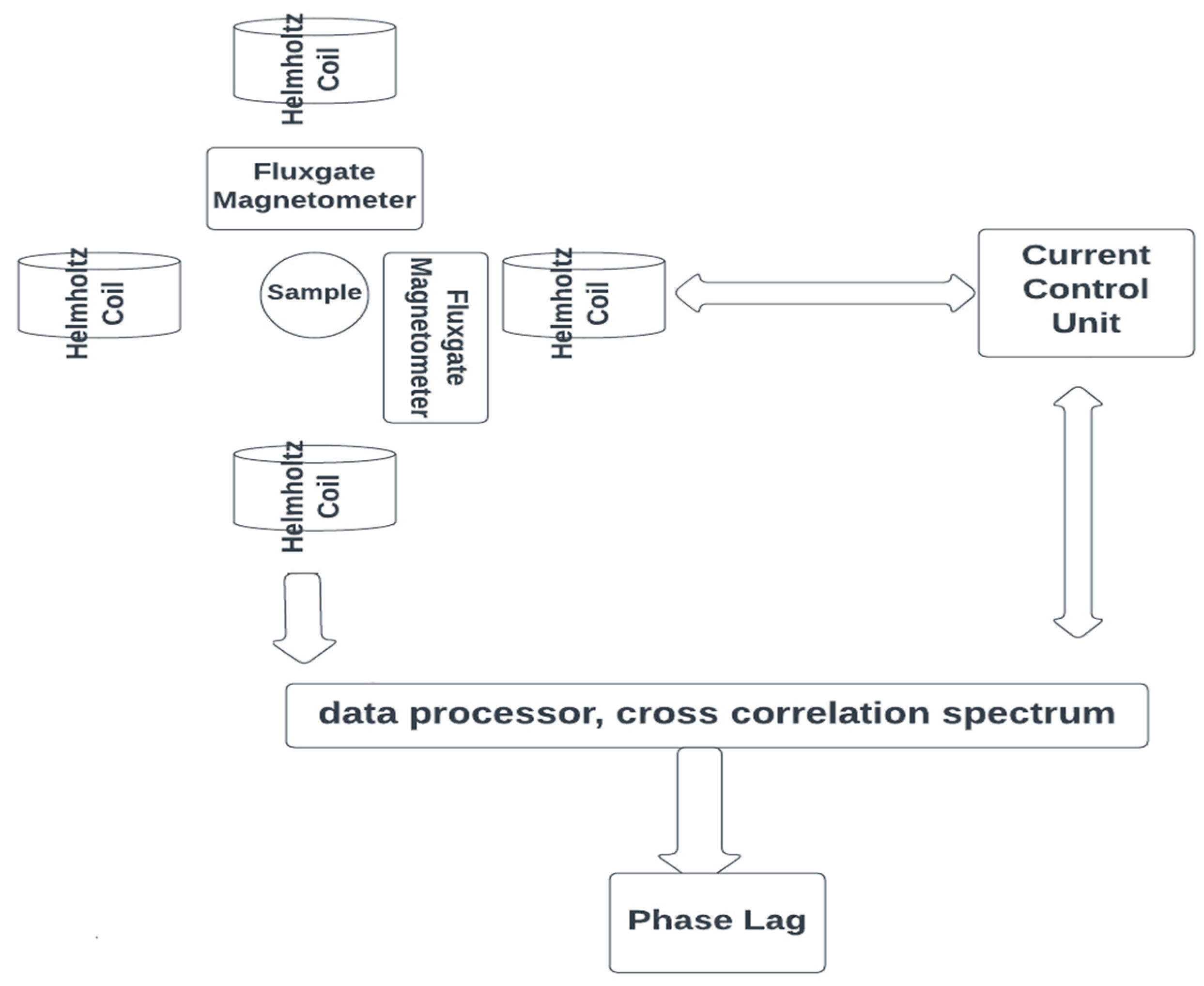

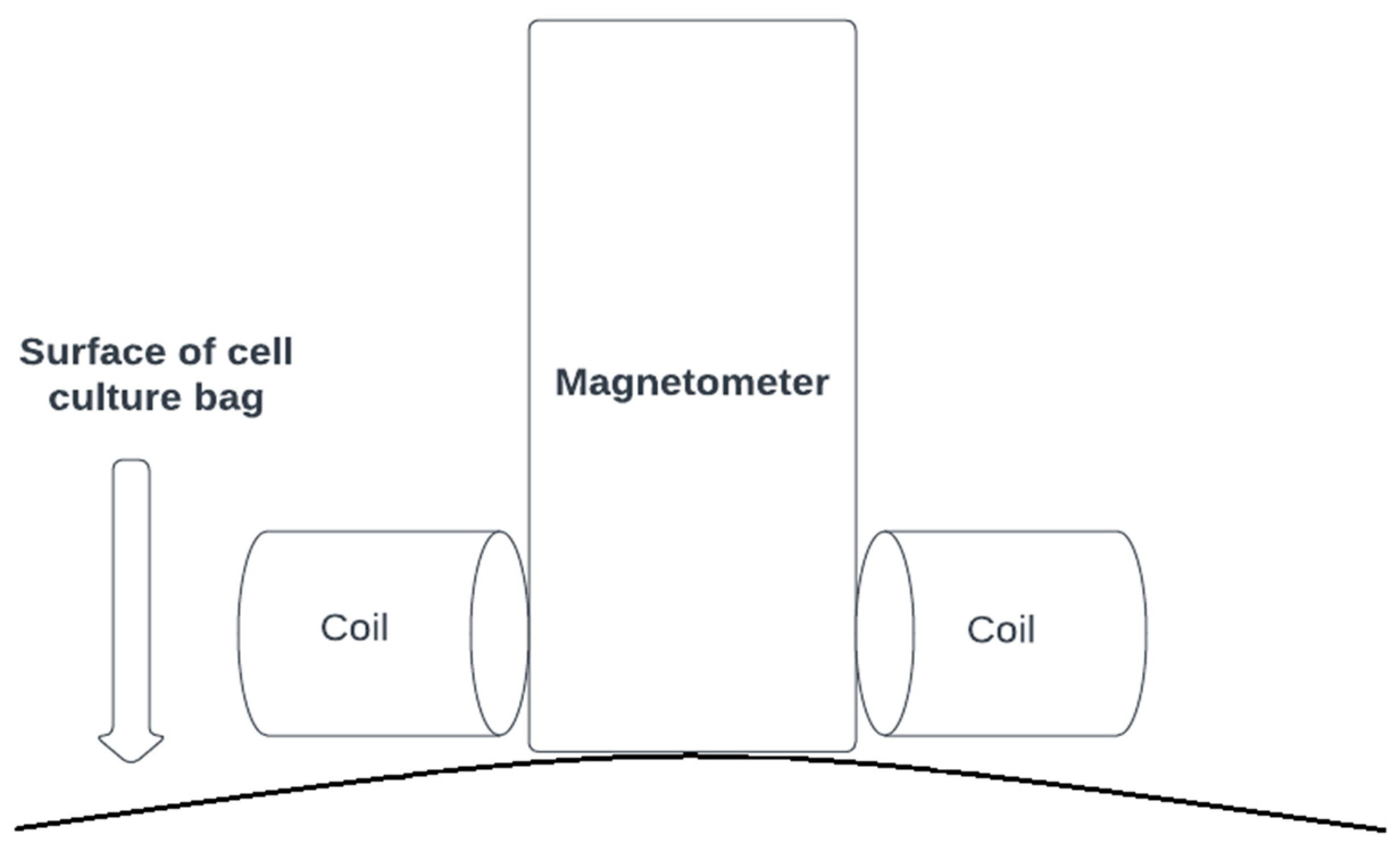

3.7. Fluxgate Magnetometers

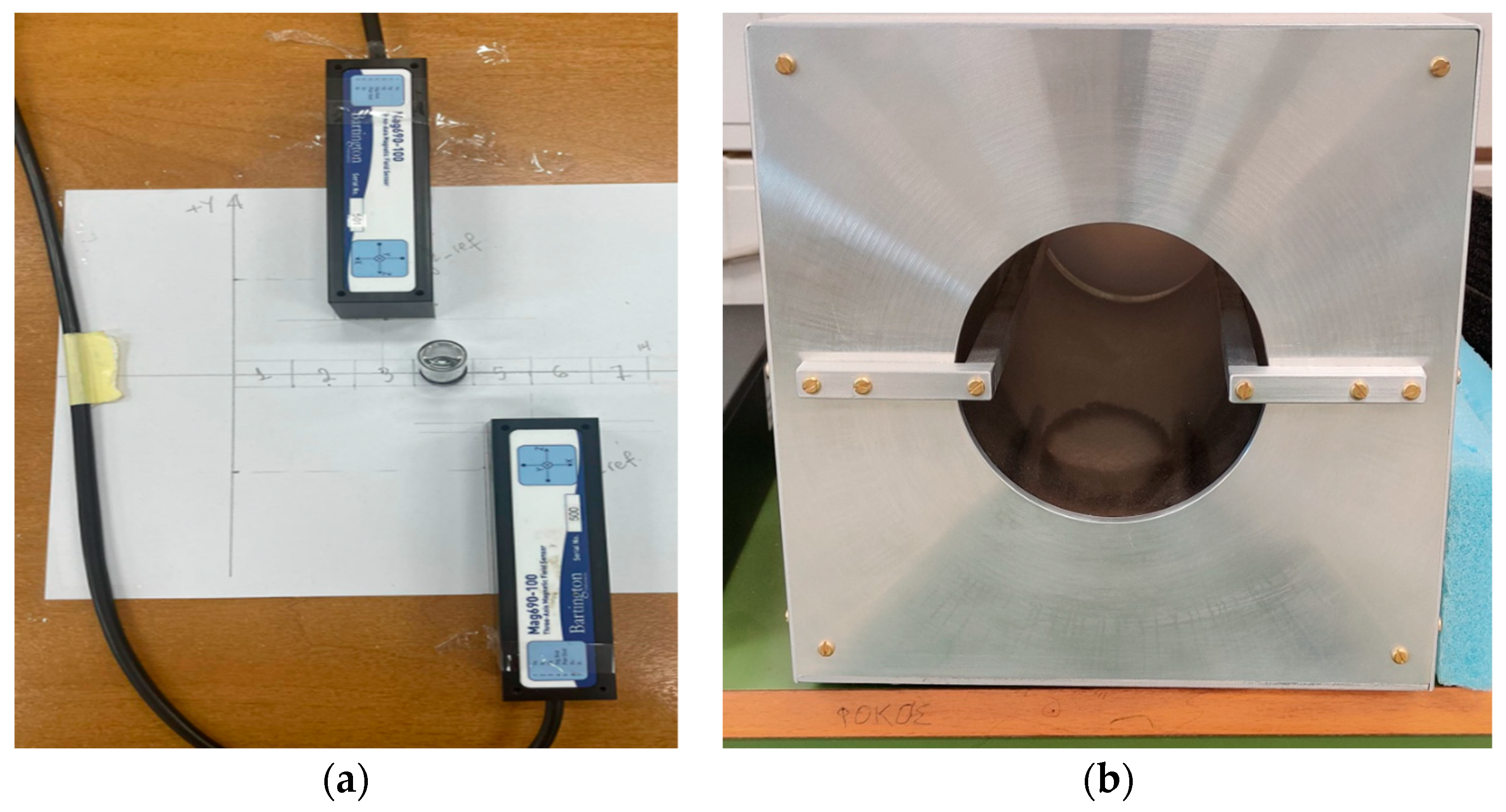

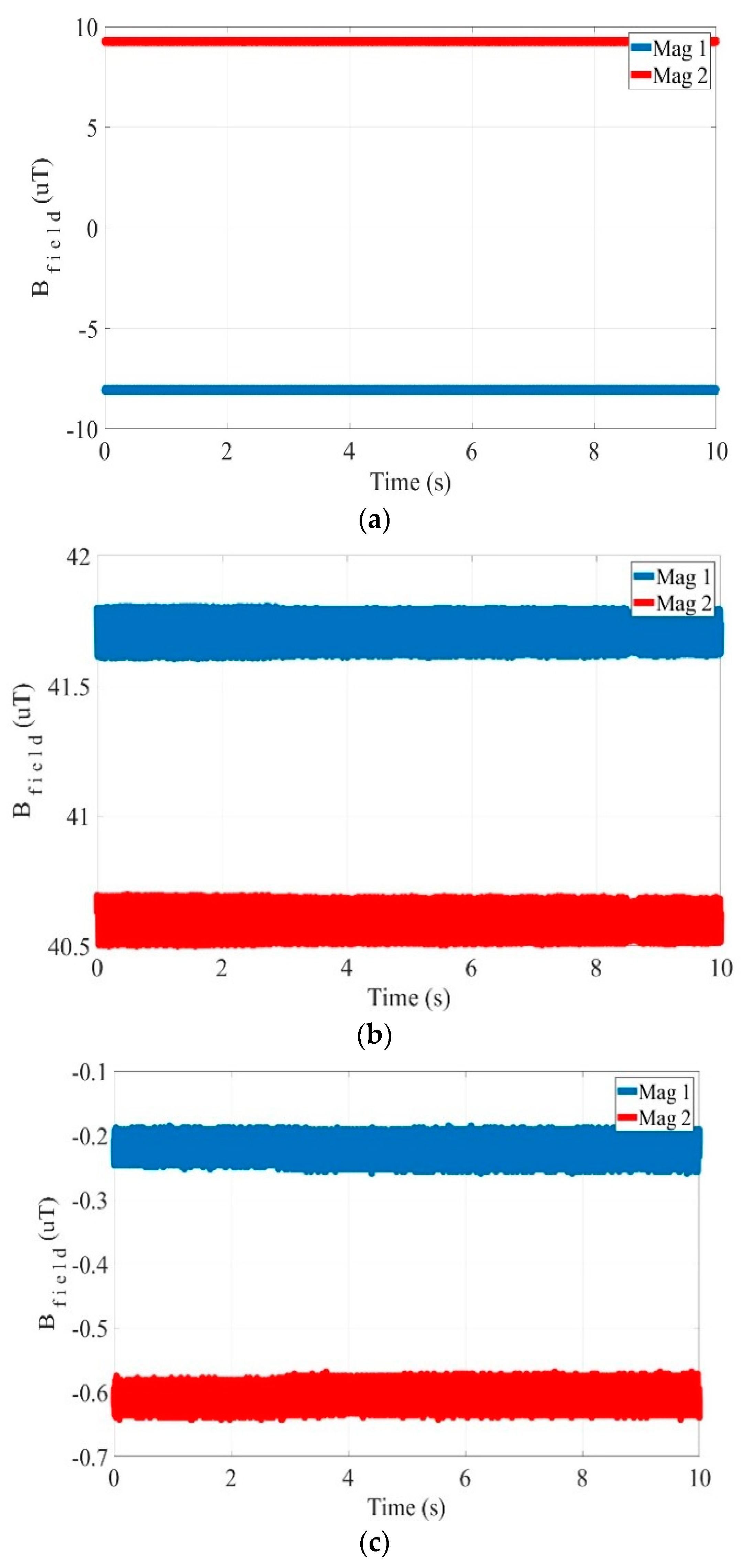

4. The Proposed Magnetic Characterization Method

5. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaufenthaler, A.; Kornack, T.; Lebedev, V.; Limes, M.E.; Körber, R.; Liebl, M.; Baumgarten, D. Pulsed Optically Pumped Magnetometers: Addressing Dead Time and Bandwidth for the Unshielded Magnetorelaxometry of Magnetic Nanoparticles. Sensors 2021, 21, 1212. [Google Scholar] [CrossRef] [PubMed]

- Materón, E.M.; Miyazaki, C.M.; Carr, O.; Joshi, N.; Picciani, P.H.S.; Dalmaschio, C.J.; Davis, F.; Shimizu, F.M. Magnetic Nanoparticles in Biomedical Applications: A Review. Appl. Surf. Sci. Adv. 2021, 6, 100163. [Google Scholar] [CrossRef]

- McNamara, K.; Tofail, S.A.M. Nanoparticles in Biomedical Applications. Adv. Phys. X 2017, 2, 54–88. [Google Scholar] [CrossRef]

- Ali, A.; Shah, T.; Ullah, R.; Zhou, P.; Guo, M.; Ovais, M.; Tan, Z.; Rui, Y.K. Review on Recent Progress in Magnetic Nanoparticles: Synthesis, Characterization, and Diverse Applications. Front. Chem. 2021, 9, 629054. [Google Scholar] [CrossRef]

- Delmon, B.; Haber, J.; Block, J.H. Manual of Methods and Procedures for Catalyst Characterization (Technical Report). Pure Appl. Chem. 1995, 67, 1257–1306. [Google Scholar] [CrossRef]

- Wani, S.U.D.; Ali, M.; Masoodi, M.H.; Khan, N.A.; Zargar, M.I.; Hassan, R.; Mir, S.A.; Gautam, S.P.; Gangadharappa, H.V.; Riyaz, R.A. A Review on Nanoparticles Categorization, Characterization and Applications in Drug Delivery Systems. Vib. Spectrosc. 2022, 121, 103407. [Google Scholar] [CrossRef]

- Jodłowski, P.; Łojewska, J. In Situ and Operando Techniques in Catalyst Characterisation and Design. Chall. Adv. Comput. Chem. Phys. 2019, 26, 333–359. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, F.; Heim, E.; Schilling, M. Characterization of Magnetic Core-Shell Nanoparticles by Fluxgate Magnetorelaxometry, Ac Susceptibility, Transmission Electron Microscopy and Photon Correlation Spectroscopy-A Comparative Study. J. Magn. Magn. Mater. 2009, 321, 1644–1647. [Google Scholar] [CrossRef]

- Akbari, B.; Tavandashti, M.P.; Zandrahimi, M. Particle Size Characterization of Nanoparticles—A Practicalapproach. Iran. J. Mater. Sci. Eng. 2011, 8, 48–56. [Google Scholar]

- Bender, P.; Balceris, C.; Ludwig, F.; Posth, O.; Bogart, L.K.; Szczerba, W.; Castro, A.; Nilsson, L.; Costo, R.; Gavilán, H.; et al. Distribution Functions of Magnetic Nanoparticles Determined by a Numerical Inversion Method. New J. Phys. 2017, 19, 073012. [Google Scholar] [CrossRef]

- Lecture 10 Catalyst Characterization. 42–46. Available online: https://www.uobabylon.edu.iq/eprints/publication_5_10702_432.pdf (accessed on 16 April 2024).

- Mohamed, R.M.; Aazam, E.S. Characterization and Catalytic Properties of Nano-Sized Au Metal Catalyst on Titanium Containing High Mesoporous Silica (Ti-HMS) Synthesized by Photo-Assisted Deposition and Impregnation Methods. Int. J. Photoenergy 2011, 2011, 137328. [Google Scholar] [CrossRef]

- Li, X.; Yang, X.; Zhang, J.; Huang, Y.; Liu, B. In Situ/Operando Techniques for Characterization of Single-Atom Catalysts. ACS Catal. 2019, 9, 2521–2531. [Google Scholar] [CrossRef]

- Leofanti, G.; Tozzola, G.; Padovan, M.; Petrini, G.; Bordiga, S.; Zecchina, A. Catalyst Characterization: Characterization Techniques. Catal. Today 1997, 34, 307–327. [Google Scholar] [CrossRef]

- Alsawalha, M. Characterization of Acidic and Basic Properties of Heterogeneous Catalysts by Test Reactions. Ph.D. Thesis, Universität Oldenburg, Oldenburg, Germany, 2004. [Google Scholar]

- Zhao, S.; Li, Y.; Stavitski, E.; Tappero, R.; Crowley, S.; Castaldi, M.J.; Zakharov, D.N.; Nuzzo, R.G.; Frenkel, A.I.; Stach, E.A. Operando Characterization of Catalysts through Use of a Portable Microreactor. ChemCatChem 2015, 7, 3683–3691. [Google Scholar] [CrossRef]

- Sytnyk, M.; Kirchschlager, R.; Bodnarchuk, M.I.; Primetzhofer, D.; Kriegner, D.; Enser, H.; Stangl, J.; Bauer, P.; Voith, M.; Hassel, A.W.; et al. Tuning the Magnetic Properties of Metal Oxide Nanocrystal Heterostructures by Cation Exchange. Nano Lett. 2013, 13, 586–593. [Google Scholar] [CrossRef] [PubMed]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T.K. Characterization Techniques for Nanoparticles: Comparison and Complementarity upon Studying Nanoparticle Properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef]

- Ludwig, F.; Heim, E.; Schilling, M. Characterization of Superparamagnetic Nanoparticles by Analyzing the Magnetization and Relaxation Dynamics Using Fluxgate Magnetometers. J. Appl. Phys. 2007, 101, 113909. [Google Scholar] [CrossRef]

- Ludwig, F.; Heim, E.; Eberbeck, D.; Schwarz, K.; Trahms, L.; Schilling, M. Comparison and Calibration of Fluxgate and Squid Magnetorelaxometry Techniques for the Characterization of Magnetic Core-Shell Nanoparticles. IEEE Trans. Magn. 2009, 45, 4857–4860. [Google Scholar] [CrossRef]

- Suturin, S.M.; Fedorov, V.V.; Korovin, A.M.; Valkovskiy, G.A.; Tabuchi, M.; Sokolov, N.S. Controllable CaF2 Nanosized Stripe Arrays on Si(001) Studied by X-ray and Electron Diffraction. Surfaces 2021, 4, 97–105. [Google Scholar] [CrossRef]

- Sauceda-Oloño, P.Y.; Cardenas-Sanchez, H.; Argüelles-Pesqueira, A.I.; Gutierrez-Valenzuela, C.; Alvarez-Ramos, M.E.; Lucero-Acuña, A.; Zavala-Rivera, P. Micelle Encapsulation of Ferromagnetic Nanoparticles of Iron Carbide@Iron Oxide in Chitosan as Possible Nanomedicine Agent. Colloids Interfaces 2020, 4, 22. [Google Scholar] [CrossRef]

- Connord, V.; Mehdaoui, B.; Tan, R.P.; Carrey, J.; Respaud, M. An Air-Cooled Litz Wire Coil for Measuring the High Frequency Hysteresis Loops of Magnetic Samples—A Useful Setup for Magnetic Hyperthermia Applications. Rev. Sci. Instrum. 2014, 85, 093904. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.L.; Sabatka, J.A.; Selwood, P.W. The Mechanism of Chemisorption: Hydrogen on Nickel. II. J. Am. Chem. Soc. 1957, 79, 5391–5397. [Google Scholar] [CrossRef]

- You, A.; Be, M.A.Y.; In, I. Magnetic Balance for Ferromagnetism. Rev. Sci. Instrum. 2004, 33, 417–422. [Google Scholar]

- Tsakoumis, N.; Baklezos, A.T.; Vardiambasis, I.O.; Kapetanakis, T.N.; Nikolopoulos, C.D. Fluxgate Configuration for Obtaining Magnetic Properties of Catalytic Nanoparticles: A Feasibility Study. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

- Dieckhoff, J.; Schilling, M.; Ludwig, F. Fluxgate Based Detection of Magnetic Nanoparticle Dynamics in a Rotating Magnetic Field. Appl. Phys. Lett. 2011, 99, 14–17. [Google Scholar] [CrossRef]

- Schrittwieser, S.; Schotter, J.; Maier, T.; Bruck, R.; Muellner, P.; Kataeva, N.; Soulantika, K.; Ludwig, F.; Huetten, A.; Brueckl, H. Homogeneous Biosensor Based on Optical Detection of the Rotational Dynamics of Anisotropic Nanoparticles. Procedia Eng. 2010, 5, 1107–1110. [Google Scholar] [CrossRef]

- Saari, M.M.; Ishihara, Y.; Tsukamoto, Y.; Kusaka, T.; Morita, K.; Sakai, K.; Kiwa, T.; Tsukada, K. Optimization of an AC/DC High-Tc SQUID Magnetometer Detection Unit for Evaluation of Magnetic Nanoparticles in Solution. IEEE Trans. Appl. Supercond. 2015, 25, 10–13. [Google Scholar] [CrossRef]

- Ludwig, F.; Balceris, C.; Jonasson, C.; Johansson, C. Analysis of AC Susceptibility Spectra for the Characterization of Magnetic Nanoparticles. IEEE Trans. Magn. 2017, 53, 6100904. [Google Scholar] [CrossRef]

- Enpuku, K.; Tanaka, T.; Tamai, Y.; Dang, F.; Enomoto, N.; Hojo, J.; Kanzaki, H.; Usuki, N. Size Distribution of Magnetic Marker Estimated from Ac Susceptibility in Solution for Biosensor Application. Jpn. J. Appl. Phys. 2008, 47, 7859–7865. [Google Scholar] [CrossRef]

- Guillaume, A.; Ludwig, F.; Scholtyssek, J.M.; Schilling, M. Field Stability of a Directly Coupled High-T\rm c Squid Design Regarding Mrx Measurements. IEEE Trans. Appl. Supercond. 2013, 23, 1600505. [Google Scholar] [CrossRef]

- Tafur, J.; Herrera, A.P.; Rinaldi, C.; Juan, E.J. Development and Validation of a 10 KHz–1 MHz Magnetic Susceptometer with Constant Excitation Field. J. Appl. Phys. 2012, 111, 07E349. [Google Scholar] [CrossRef]

- Saari, M.M.; Sulaiman, M.H.; Ahmad, H.; Lah, N.A.C.; Sakai, K.; Kiwa, T.; Tsukada, K. A Benchtop Induction-Based AC Magnetometer for a Fast Characterization of Magnetic Nanoparticles. Eng. Res. Express 2022, 4, 025047. [Google Scholar] [CrossRef]

- Ahrentorp, F.; Astalan, A.P.; Jonasson, C.; Blomgren, J.; Qi, B.; Mefford, O.T.; Yan, M.; Courtois, J.; Berret, J.F.; Fresnais, J.; et al. Sensitive High Frequency AC Susceptometry in Magnetic Nanoparticle Applications. AIP Conf. Proc. 2010, 1311, 213–223. [Google Scholar] [CrossRef]

- Saari, M.M.; Hadi Putera Zaini, M.A.; Ahmad, H.; Che Lah, N.A. An AC Magnetometer Using Automatic Frequency Switching of a Resonant Excitation Coil for Magnetic Nanoparticles Characterization. In Proceedings of the 2018 9th IEEE Control and System Graduate Research Colloquium (ICSGRC), Shah Alam, Malaysia, 3–4 August 2018; pp. 207–210. [Google Scholar] [CrossRef]

- Denouala, M.; Saeza, S.; Kauffmanb, F.; Dolabdjiana, C. Magnetorelaxometry Using Improved Giant Magneto Resistance Magnetometer. Sens. Actuators A Phys. 2010, 159, 184–188. [Google Scholar] [CrossRef]

- Liu, P.; Skucha, K.; Megens, M.; Boser, B. A CMOS Hall-Effect Sensor for the Characterization and Detection of Magnetic Nanoparticles for Biomedical Applications. IEEE Trans. Magn. 2011, 47, 3449–3451. [Google Scholar] [CrossRef] [PubMed]

- Besse, P.A.; Boero, G.; Demierre, M.; Pott, V.; Popovic, R. Detection of a Single Magnetic Microbead Using a Miniaturized Silicon Hall Sensor. Appl. Phys. Lett. 2002, 80, 4199–4201. [Google Scholar] [CrossRef]

- Florescu, O.; Mattmann, M.; Boser, B. Fully Integrated Detection of Single Magnetic Beads in Complementary Metal-Oxide-Semiconductor. J. Appl. Phys. 2008, 103, 17–20. [Google Scholar] [CrossRef]

- Schambach, J.; Warzemann, L.; Weber, P. SQUID Gradiometer Measurement System for Magnetorelaxometry in a Disturbed Environment. IEEE Trans. Appl. Supercond. 1999, 9, 3527–3530. [Google Scholar] [CrossRef]

- Ludwig, F.; Mäuselein, S.; Heim, E.; Schilling, M. Magnetorelaxometry of Magnetic Nanoparticles in Magnetically Unshielded Environment Utilizing a Differential Fluxgate Arrangement. Rev. Sci. Instrum. 2005, 76, 106102. [Google Scholar] [CrossRef]

- Kötitz, R.; Weitschies, W.; Trahms, L.; Brewer, W.; Semmler, W. Determination of the Binding Reaction between Avidin and Biotin by Relaxation Measurements of Magnetic Nanoparticles. J. Magn. Magn. Mater. 1999, 194, 62–68. [Google Scholar] [CrossRef]

- Chemla, Y.R.; Grossman, H.L.; Poon, Y.; McDermott, R.; Stevens, R.; Alper, M.D.; Clarke, J. Ultrasensitive Magnetic Biosensor for Homogeneous Immunoassay. Proc. Natl. Acad. Sci. USA 2000, 97, 14268–14272. [Google Scholar] [CrossRef]

- Ruehmer, D.; Heim, E.; Hirsch, A.; Piel, R.; Wawrzik, T.; Ludwig, F.; Schilling, M. Magnetic Relaxation Imaging with a Fluxgate Sensor Scanner. In Proceedings of the SENSOR+TEST Conferences 2009, Braunschweig, Germany, 26–28 May 2009; pp. 29–33. [Google Scholar]

- Gradiometers, D.; Büttner, M.; Schmidl, F.; Schiffler, M.; Seidel, P. Magnetorelaxation (MRX) Measurements with DC-SQUID Gradiometers. IEEE Trans. Appl. Supercond. 2011, 21, 473–476. [Google Scholar]

- Ludwig, F.; Heim, E.; Mäuselein, S.; Eberbeck, D.; Schilling, M. Magnetorelaxometry of Magnetic Nanoparticles with Fluxgate Magnetometers for the Analysis of Biological Targets. J. Magn. Magn. Mater. 2005, 293, 690–695. [Google Scholar] [CrossRef]

- Knopke, C.; Wiekhorst, F.; Eberbeck, D.; Gemeinhardt, I.; Ebert, M.; Schnorr, J.; Wagner, S.; Taupitz, M.; Trahms, L. Quantification of Magnetic Nanoparticle Uptake in Cells by Temperature Dependent Magnetorelaxometry. IEEE Trans. Magn. 2013, 49, 421–424. [Google Scholar] [CrossRef]

- Alvarez-Botero, G.; Lobato-Morales, H.; Hui, K.; Tarabay, N.; Sanchez-Vargas, J.; Velez, C.; Mendez-Jeronimo, G. Magneto-Dielectric Composites Characterization Using Resonant Sensor and Neural Network Modeling. IEEE Microw. Wirel. Technol. Lett. 2024, 34, 447–450. [Google Scholar] [CrossRef]

- Zappia, S.; Scapaticci, R.; Lodi, M.B.; Fanti, A.; Ruello, G.; Crocco, L.; Catapano, I. Nondestructive Characterization of Magnetic Polymeric Scaffolds Using Terahertz Time-of-Flight Imaging. IEEE Trans. Terahertz Sci. Technol. 2023, 13, 305–315. [Google Scholar] [CrossRef]

- Jani, M.; Czarnecka, P.; Orzechowska, Z.; Mrózek, M.; Gawlik, W.; Wojciechowski, A.M. Sensing of Magnetic-Field Gradients with Nanodiamonds on Optical Glass-Fiber Facets. ACS Appl. Nano Mater. 2023, 6, 11077–11084. [Google Scholar] [CrossRef]

- Drake, P.; Algaddafi, A.; Swift, T.; Abd-Alhameed, R.A. Design and Modelling of an Induction Heating Coil to Investigate the Thermal Response of Magnetic Nanoparticles for Hyperthermia Applications. BioMedInformatics 2024, 4, 1006–1018. [Google Scholar] [CrossRef]

- Chen, D.; Wen, Y.; Li, P.; Wang, Y. Dynamic Magnetic Excitation Detection Method for Low-Concentration Superparamagnetic Particles via Quartz Crystal Microbalance. IEEE Sens. J. 2022, 22, 22495–22502. [Google Scholar] [CrossRef]

- Guo, J.H.; Wang, W.; Dong, L.P.; Li, X.H.; Guo, Z.L.; Du, X.Z.; Zhang, J.Y. Highly Sensitive Magnetic Field Sensor Based on Few Mode Fiber Interferometry. IEEE Sens. J. 2024, 24, 16179–16187. [Google Scholar] [CrossRef]

- Yan, X.; Li, H.; Fu, R.; Hu, T.; Zhao, Y.; Wei, L.; Tang, H.; Cheng, T. Highly Sensitive Magnetic Field Sensors Based on a D-Type Fiber with Bi2O2Se Film. IEEE Sens. J. 2023, 23, 30293–30301. [Google Scholar] [CrossRef]

- Xu, R.; Xu, Y.; Luo, B.; Zhang, X.; Wei, Y.; Liu, H.; Deng, H.; Yuan, L. Vector Magnetic Field Sensing Characteristics of the Magnetofluid-Encapsulated Polarization-Maintaining Fiber Single-End Offset Fusion Spliced Hollow-Core Fiber Structure. IEEE Sens. J. 2024, 24, 10144–10155. [Google Scholar] [CrossRef]

- Koshev, N.; Kapralov, P.; Evstigneeva, S.; Leontyev, A.; Lutsenko, O.; Zharkov, M.; Pyataev, N.; Darwish, A.; Timin, A.; Ostras, M.; et al. YIG-Based Sensor System for Millisecond Time Range Magnetorelaxometry. IEEE Trans. Biomed. Eng. 2023, 71, 1640–1650. [Google Scholar] [CrossRef] [PubMed]

- Tsukada, K.; Morita, K.; Matsunaga, Y.; Saari, M.M.; Sakai, K.; Kiwa, T. Hybrid Type HTS-SQUID Magnetometer with Vibrating and Rotating Sample. IEEE Trans. Appl. Supercond. 2016, 26, 1601405. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, C.C.; Hall, D.A. Giant Magnetoresistive Biosensor Array for Detecting Magnetorelaxation. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 755–764. [Google Scholar] [CrossRef] [PubMed]

- Araujo, J.F.D.F.; Vieira, D.R.P.; Osorio, F.; Pöttker, W.E.; La Porta, F.A.; de la Presa, P.; Perez, G.; Bruno, A.C. Versatile Hall Magnetometer with Variable Sensitivity Assembly for Characterization of the Magnetic Properties of Nanoparticles. J. Magn. Magn. Mater. 2019, 489, 165431. [Google Scholar] [CrossRef]

- Blachowicz, T.; Kola, I.; Ehrmann, A.; Guenther, K.; Ehrmann, G. Magnetic Micro and Nano Sensors for Continuous Health Monitoring. Micro 2024, 4, 206–228. [Google Scholar] [CrossRef]

- Caruso, M.J.; Bratland, T.; Smith, C.H.; Schneider, R. A New Perspective on Magnetic Field Sensing. Sensors 1998, 15, 34–46. [Google Scholar]

- Dalmon, J. Magnetic Measurements and Catalysis. In Catalyst Characterization. Fundamental and Applied Catalysis; Springer: Boston, MA, USA, 1994; pp. 585–609. [Google Scholar]

- Chernavskii, P.A.; Pankina, G.V.; Lunin, V. V Magnetometric Methods of Investigation of Supported Catalysts. Russ. Chem. Rev. 2011, 80, 579–604. [Google Scholar] [CrossRef]

- Kishimoto, M.; Miyamoto, R.; Oda, T.; Ohara, Y.; Yanagihara, H.; Ohkohchi, N.; Kita, E. Measurement of Intravenously Administered γ-Fe2O3 Particle Amount in Mice Tissues Using Vibrating Sample Magnetometer. IEEE Trans. Nanobioscience 2014, 13, 425–430. [Google Scholar] [CrossRef]

- Visscher, M.; Pouw, J.J.; Van Baarlen, J.; Klaase, J.M.; Haken, B. Ten Quantitative Analysis of Superparamagnetic Contrast Agent in Sentinel Lymph Nodes Using Ex Vivo Vibrating Sample Magnetometry. IEEE Trans. Biomed. Eng. 2013, 60, 2594–2602. [Google Scholar] [CrossRef]

- Martirosyan, K.S.; Chang, L.; Rantschler, J.; Khizroev, S.; Luss, D.; Litvinov, D. Carbon Combustion Synthesis and Magnetic Properties of Cobalt Ferrite Nanoparticles. IEEE Trans. Magn. 2007, 43, 3118–3120. [Google Scholar] [CrossRef]

- Kubisztal, M.; Kubisztal, J.; Karolus, M.; Prusik, K.; Haneczok, G. Collective Superspin Glass State of Interacting Cobalt Ferrite Nanoparticles. IEEE Trans. Magn. 2019, 55, 2301306. [Google Scholar] [CrossRef]

- Gao, C.Y.; Lu, Q.; Choi, H.J. Effect of Magnetic Nanoparticle Additive on Viscoelastic Behaviors of Carbonyl Iron-Based Magnetorheological Suspension. IEEE Trans. Magn. 2018, 54, 54–57. [Google Scholar] [CrossRef]

- Halvaee, P.; Dehghani, S.; Hoghoghifard, S. Low Temperature Methanol Sensors Based on Cobalt Ferrite Nanoparticles, Nanorods, and Porous Nanoparticles. IEEE Sens. J. 2020, 20, 4056–4062. [Google Scholar] [CrossRef]

- Tsolakis, A.; Halevas, E.; Gounari, E.; Koliakos, G.; Salifoglou, A.; Litsardakis, G. Magnetic Fluorescent Nanoparticles Binding to Beta-Amyloid: Silica Coated, Thioflavin-T Functionalized Iron Oxide. In Proceedings of the 2017 IEEE International Magnetics Conference (INTERMAG), Dublin, Ireland, 24–28 April 2017; Volume 53, pp. 3–6. [Google Scholar] [CrossRef]

- Farhana, M.; Ariffin, K.; Idris, A.; Hasrul, N.; Ngadiman, A. Optimization of one-pot microwave-assisted ferrofluid nanoparticles synthesis using response surface methodology. IEEE Trans. Magn. 2018, 54, 3200606. [Google Scholar]

- Liao, S.H.; Huang, H.S.; Su, Y.K. Scaling Characteristics of the Magnetization Increments of Functionalized Nanoparticles Determined Using a Vibrating Sample Magnetometer for Liquid Magnetic Immunoassays. IEEE Sens. J. 2019, 19, 8990–8994. [Google Scholar] [CrossRef]

- Nanocrystals, Z.N.O.; Gabal, M.A.; Kosa, S.; Mutairi, T.S. Sucrose-assisted combustion synthesis and characterization of Zn-substituted NiFe2O4 nanocrystals. IEEE Trans Magn. 2016, 52, 2400104. [Google Scholar]

- Li, L.; Mak, K.Y.; Leung, C.W.; Chan, K.Y.; Chan, W.K.; Zhong, W.; Pong, P.W.T. Synthesis and Characterization of Self-Assembled Monolayer and Bilayer Carboxyl-Group Functionalized Magnetic Nanoparticles. IEEE Trans. Magn. 2012, 48, 3299–3302. [Google Scholar] [CrossRef]

- Photoemission, B.O. A Subfemtotesla Multichannel Atomic Magnetometer. Nature 2003, 422, 596–599. [Google Scholar]

- Ruan, Y.; He, X.; Ruan, L.; Liu, F.; Zhang, Z.; Weng, J.; Yan, Q.; Zhang, G.; Li, K.; Zheng, W.; et al. Drug Monitoring by Optically Pumped Atomic Magnetometer. IEEE Photonics J. 2022, 14, 3134305. [Google Scholar] [CrossRef]

- Baffa, O.; Matsuda, R.H.; Arsalani, S.; Prospero, A.; Miranda, J.R.A.; Wakai, R.T. Development of an Optical Pumped Gradiometric System to Detect Magnetic Relaxation of Magnetic Nanoparticles. J. Magn. Magn. Mater. 2019, 475, 533–538. [Google Scholar] [CrossRef]

- Tang, J.; Zhai, Y.; Cao, L.; Zhang, Y.; Li, L.; Zhao, B.; Zhou, B.; Han, B.; Liu, G. High-Sensitivity Operation of a Single-Beam Atomic Magnetometer for Three-Axis Magnetic Field Measurement. Opt. Express 2021, 29, 15641. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Tang, J.; Yang, H.; Li, L.; Zhang, Y.; Liu, Y.; Zhai, Y. High-Sensitivity Pump–Probe Atomic Magnetometer Based on Single Fiber-Coupled. Opt. Laser Technol. 2023, 159, 109025. [Google Scholar] [CrossRef]

- Oelsner, G.; Ijsselsteijn, R.; Scholtes, T.; Krüger, A.; Schultze, V.; Seyffert, G.; Werner, G.; Jäger, M.; Chwala, A.; Stolz, R. Integrated Optically Pumped Magnetometer for Measurements within Earth’s Magnetic Field. Phys. Rev. Appl. 2022, 17, 024034. [Google Scholar] [CrossRef]

- Lebedev, V.; Hartwig, S.; Middelmann, T. Fast and Robust Optically Pumped Cesium Magnetometer. Adv. Opt. Technol. 2020, 9, 275–286. [Google Scholar] [CrossRef]

- Jaufenthaler, A.; Schier, P.; Middelmann, T.; Liebl, M.; Wiekhorst, F.; Baumgarten, D. Quantitative 2D Magnetorelaxometry Imaging of Magnetic Nanoparticles Using Optically Pumped Magnetometers. Sensors 2020, 20, 753. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.; Adolphi, N.L.; Butler, K.L.; Lovato, D.M.; Larson, R.; Schwindt, P.D.D.; Flynn, E.R. Magnetic Relaxometry with an Atomic Magnetometer and SQUID Sensors on Targeted Cancer Cells. J. Magn. Magn. Mater. 2012, 324, 2613–2619. [Google Scholar] [CrossRef] [PubMed]

- Piepgras, R.; Michlmayr, S.; Egger, J.; Zagar, B.G. Measurement of Magnetic Microstructures with a Faraday Rotation Magnetometer. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.; Peng, X.; Guo, H. Amplitude Dependence on Probe Frequency Detuning in Faraday-Rotation Alkali Atomic Magnetometers. In Proceedings of the 2019 Joint Conference of the IEEE International Frequency Control Symposium and European Frequency and Time Forum (EFTF/IFC), Orlando, FL, USA, 14–18 April 2019; pp. 7–8. [Google Scholar] [CrossRef]

- Li, W.; Lin, P.; Peng, X.; Guo, H. The Optimized Probe Light Frequency Detuning for Faraday-Rotation Cesium Atomic Magnetometer. Opt. InfoBase Conf. Pap. 2014, 2, 2–3. [Google Scholar] [CrossRef]

- Rostami, K.R.; Nikitin, I.P. High-Sensitivity Two-Stage Hall Magnetometer with Enhanced Linearity and Spatial Resolution. Meas. J. Int. Meas. Confed. 2020, 153, 107423. [Google Scholar] [CrossRef]

- Volmer, M.; Avram, M. On Magnetic Nanoparticles Detection Using Planar Hall Effect Sensors. In Proceedings of the International Semiconductor Conference, CAS, Sinaia, Romania, 15–17 October 2012. [Google Scholar]

- Arajo, J.F.D.F.; Bruno, A.C.; Carvalho, H.R. Characterization of Magnetic Nanoparticles by a Modular Hall Magnetometer. J. Magn. Magn. Mater. 2010, 322, 2806–2809. [Google Scholar] [CrossRef]

- Araujo, J.F.D.F.; Costa, M.C.; Louro, S.R.W.; Bruno, A.C. A Portable Hall Magnetometer Probe for Characterization of Magnetic Iron Oxide Nanoparticles. J. Magn. Magn. Mater. 2017, 426, 159–162. [Google Scholar] [CrossRef]

- Lozanova, S.; Noykov, S.; Roumenin, C. A Novel 3-D Hall Magnetometer Using Subsequent Measurement Method. Sens. Actuators A Phys. 2009, 153, 205–211. [Google Scholar] [CrossRef]

- Xu, J.; Li, Q.; Gao, X.Y.; Leng, F.F.; Lu, M.; Guo, P.Z.; Zhao, G.X.; Li, S.D. Detection of the Concentration of MnFe2O4 Magnetic Microparticles Using Giant Magnetoresistance Sensors. IEEE Trans. Magn. 2016, 52, 5200204. [Google Scholar] [CrossRef]

- Park, J. Superparamagnetic Nanoparticle Quantification Using a Giant Magnetoresistive Sensor and Permanent Magnets. J. Magn. Magn. Mater. 2015, 389, 56–60. [Google Scholar] [CrossRef]

- Nurpriyanti, I.; Pardede, I.; Suharyadi, E.; Kato, T.; Iwata, S. Detection of Fe3O4 Magnetic Nanoparticles Using Giant Magnetoresistance (GMR) Sensor Based on Multilayer and Spin Valve Thin Films by Wheatstone Bridge Circuit. In Proceedings of the 2016 International Seminar on Sensors, Instrumentation, Measurement and Metrology (ISSIMM), Malang, Indonesia, 10–11 August 2016; pp. 32–36. [Google Scholar] [CrossRef]

- Li, L.; Mak, K.Y.; Leung, C.W.; Ng, S.M.; Lei, Z.Q.; Pong, P.W.T. Detection of 10-Nm Superparamagnetic Iron Oxide Nanoparticles Using Exchange-Biased GMR Sensors in Wheatstone Bridge. IEEE Trans. Magn. 2013, 49, 4056–4059. [Google Scholar] [CrossRef]

- Shen, H.M.; Hu, L.; Fu, X. Integrated Giant Magnetoresistance Technology for Approachable Weak Biomagnetic Signal Detections. Sensors 2018, 18, 148. [Google Scholar] [CrossRef] [PubMed]

- Carr, C.; Matlachov, A.N.; Sandin, H.; Espy, M.A.; Kraus, R.H. Magnetic Sensors for Bioassay: HTS SQUIDs or GMRs? IEEE Trans. Appl. Supercond. 2007, 17, 808–811. [Google Scholar] [CrossRef]

- Krishna, V.D.; Wu, K.; Perez, A.M.; Wang, J.P. Giant Magnetoresistance-Based Biosensor for Detection of Influenza A Virus. Front. Microbiol. 2016, 7, 400. [Google Scholar] [CrossRef]

- Esposito, E.; Granata, C.; Russo, M.; Russo, R.; Vettoliere, A. High Sensitive Magnetic Nanosensors Based on Superconducting Quantum Interference Device. IEEE Trans. Magn. 2013, 49, 140–143. [Google Scholar] [CrossRef]

- Pelizzone, M.; Treyvaud, A. A SQUID Susceptometer for Fields up to 8.5 Tesla. Appl. Phys. 1981, 24, 375–379. [Google Scholar] [CrossRef]

- Tan, I.C.; Brazdeikis, A. Novel Biomagnetic Sensing Technique for Characterization of Inflammatory Tissues. IEEE Trans. Magn. 2007, 43, 2409–2411. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Cho, E.Y.; Lefebvere, J.C.; Cybart, S.A. Measurement of Magnetic Nanoparticles Using High Transition Temperature Superconducting Quantum Interference Devices. IEEE Trans. Appl. Supercond. 2019, 29, 14–17. [Google Scholar] [CrossRef]

- Saari, M.M.; Takagi, R.; Kusaka, T.; Ishihara, Y.; Tsukamoto, Y.; Sakai, K.; Kiwa, T.; Tsukada, K. Development of Integrated AC-DC Magnetometer Using High-Tc SQUID for Magnetic Properties Evaluation of Magnetic Nanoparticles in Solution. J. Phys. Conf. Ser. 2014, 507, 042035. [Google Scholar] [CrossRef]

- Saari, M.M.; Sakai, K.; Kiwa, T.; Tsukada, K. Optimization of the Detection Technique for a Vibrating-Sample Magnetometer Using High-Tc SQUID. IEEE Trans. Appl. Supercond. 2012, 23, 1600204. [Google Scholar] [CrossRef]

- Carvalho, H.R.; Bruno, A.C. A Compact SQUID Magnetometer for Thermoremanent Magnetization Immunoassays. IEEE Trans. Appl. Supercond. 2011, 21, 481–484. [Google Scholar] [CrossRef]

- Romanus, E.; Berkov, D.V.; Prass, S.; Groß, C.; Weitschies, W.; Weber, P. Determination of Energy Barrier Distributions of Magnetic Nanoparticles by Temperature Dependent Magnetorelaxometry. Nanotechnology 2003, 14, 1251–1254. [Google Scholar] [CrossRef] [PubMed]

- Grossman, H.L.; Myers, W.R.; Vreeland, V.J.; Bruehl, R.; Alper, M.D.; Bertozzi, C.R.; Clarke, J. Detection of Bacteria in Suspension by Using a Superconducting Quantum Interference Device. Proc. Natl. Acad. Sci. USA 2004, 101, 129–134. [Google Scholar] [CrossRef]

- Wernsdorfer, W.; Hasselbach, K.; Mailly, D.; Barbara, B.; Benoit, A.; Thomas, L.; Suran, G. DC-SQUID Magnetization Measurements of Single Magnetic Particles. J. Magn. Magn. Mater. 1995, 145, 33–39. [Google Scholar] [CrossRef]

- Elrefai, A.L.; Sasada, I.; Yoshida, T. Fluxgate Gradiometer for Magnetic Nanoparticle Magnetorelaxometry in Unshielded Environment. In Proceedings of the 2015 IEEE International Magnetics Conference (INTERMAG), Beijing, China, 11–15 May 2015. [Google Scholar] [CrossRef]

- Dantsker, E.; Tanaka, S.; Nilsson, P.Å.; Kleiner, R.; Clarke, J. Reduction of 1/f Noise in High-Tc Dc Superconducting Quantum Interference Devices Cooled in an Ambient Magnetic Field. Appl. Phys. Lett. 1996, 69, 4099–4101. [Google Scholar] [CrossRef]

- Koch, R.H.; Sun, J.Z.; Foglietta, V.; Gallagher, W.J. Flux Dam, a Method to Reduce Extra Low Frequency Noise When a Superconducting Magnetometer Is Exposed to a Magnetic Field. Appl. Phys. Lett. 1995, 67, 709. [Google Scholar] [CrossRef]

- Cho, H.M.; Andresen, Y.T.; Clarke, J.; Dilorio, M.S.; Yang, K.Y.; Yoshizumi, S. Low-Frequency Noise in High-Transition-Temperature Superconducting Multilayer Magnetometers in Ambient Magnetic Fields. Appl. Phys. Lett. 2001, 79, 2438–2440. [Google Scholar] [CrossRef]

- Krey, S.; Barthelmess, H.J.; Schilling, M. Low-Frequency Noise and Linearity of a YBa2Cu3O7 Dc Superconducting Quantum Interference Device Magnetometer in Static Magnetic Fields. J. Appl. Phys. 1999, 86, 6602–6604. [Google Scholar] [CrossRef]

- Ludwig, F.; Drung, D. Low-Frequency Noise of Improved Direct-Coupled High-Tc Superconducting Quantum Interference Device Magnetometers in Ac and Dc Magnetic Fields. Appl. Phys. Lett. 1999, 75, 2821–2823. [Google Scholar] [CrossRef]

- Anderson, W.H.; Flynn, E.R.; Karaulanov, T.; Matlashov, A.N.; Nettles, C.; Radigan, W. Comparison of Axial Wire-Wound and Planar Thin-Film SQUID-Based Gradiometers for Super-Paramagnetic Relaxometry Measurements. IEEE Trans. Appl. Supercond. 2017, 27, 22–25. [Google Scholar] [CrossRef]

- Isshiki, R.; Nakamura, Y.; Takeuchi, S.; Hirata, T.; Sakai, K.; Kiwa, T.; Tsukada, K. Evaluation of the Magnetization Properties of Magnetic Nanoparticles in Serum Using HTS-SQUID. IEEE Trans. Appl. Supercond. 2018, 28, 1600605. [Google Scholar] [CrossRef]

- Kiwa, T.; Morita, K.; Matsunaga, Y.; Saari, M.M.; Sakai, K.; Tsukada, K. High-Resolution Laser-Assisted Magnetic Nanoparticle Imaging Using a High-TC SQUID Magnetometer. IEEE Trans. Appl. Supercond. 2017, 27, 1601804. [Google Scholar] [CrossRef]

- Carvalho, H.R.; Bruno, A.C.; Anderson, W.H.; Flynn, E.R.; Karaulanov, T.; Matlashov, A.N.; Nettles, C.; Radigan, W.; Isshiki, R.; Nakamura, Y.; et al. Measurement of Magnetic Nanoparticles by Small HTS SQUID Array. IEEE Trans. Appl. Supercond. 2013, 49, 10–13. [Google Scholar] [CrossRef]

- Cho, E.Y.; Li, H.; Lefebvre, J.C.; Zhou, Y.W.; Dynes, R.C.; Cybart, S.A. Direct-Coupled Micro-Magnetometer with Y-Ba-Cu-O Nano-Slit SQUID Fabricated with a Focused Helium Ion Beam. Appl. Phys. Lett. 2018, 113, 162602. [Google Scholar] [CrossRef]

- Hrakova, D.; Ripka, P.; Laposa, A.; Novotny, D.; Kroutil, J.; Povolný, V.; Kaman, O.; Veverka, P. Inkjet-Printed Mn-Zn Ferrite Nanoparticle Core for Fluxgate. J. Magn. Magn. Mater. 2022, 563, 170003. [Google Scholar] [CrossRef]

- Al-Milaji, K.N.; Hadimani, R.L.; Gupta, S.; Pecharsky, V.K.; Zhao, H. Inkjet Printing of Magnetic Particles Toward Anisotropic Magnetic Properties. Sci. Rep. 2019, 9, 16261. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.; Leveneur, J.; Turner, J.; Futter, J.; Williams, G.V.M. Applications of Nanoparticle-Based Fluxgate Magnetometers for Positioning and Location. In Proceedings of the 2014 IEEE Sensors Applications Symposium (SAS), Queenstown, New Zealand, 18–20 February 2014; pp. 228–232. [Google Scholar] [CrossRef]

- Karo, H.; Sasada, I. Superparamagnetic Nanoparticle Detection System by Using a Fundamental Mode Orthogonal Fluxgate (FM-OFG) Gradiometer. AIP Adv. 2017, 7, 056716. [Google Scholar] [CrossRef]

- Macharet, D.G.; Perez-Imaz, H.I.A.; Rezeck, P.A.F.; Potje, G.A.; Benyosef, L.C.C.; Wiermann, A.; Freitas, G.M.; Garcia, L.G.U.; Campos, M.F.M. Autonomous Aeromagnetic Surveys Using a Fluxgate Magnetometer. Sensors 2016, 16, 2169. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zeng, T. Faint Magnetic Field Measurement Based on Fluxgate Sensor. In Proceedings of the 2017 First International Conference on Electronics Instrumentation & Information Systems (EIIS), Harbin, China, 3–5 June 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Ficko, B.W.; Nadar, P.M.; Hoopes, P.J.; Diamond, S.G. Development of a Magnetic Nanoparticle Susceptibility Magnitude Imaging Array. Phys. Med. Biol. 2014, 59, 1047–1071. [Google Scholar] [CrossRef] [PubMed]

- Dieckhoff, J.H.; Yoshida, T.; Enpuku, K.; Schilling, M.; Ludwig, F. Homogeneous Bioassays Based on the Manipulation of Magnetic Nanoparticles by Rotating and Alternating Magnetic FieldsA Comparison. IEEE Trans. Magn. 2012, 48, 3792–3795. [Google Scholar] [CrossRef]

- Sebbes, P.; Ludwig, F.; Schilling, M. Fluxgate Magnetometer for Temperatures up to 180 °C. J. Electr. Eng. 2013, 61, 21–23. [Google Scholar]

- Barmpatza, A.C.; Baklezos, A.T.; Vardiambasis, I.O.; Nikolopoulos, C.D. Estimation of the Magnetic Signature of Ferromagnetic Nanoparticles by Earth’s Magnetic Field. IEEE Access 2023, 11, 14832–14840. [Google Scholar] [CrossRef]

- Baklezos, A.T.; Nikolopoulos, C.D.; Spantideas, S.T.; Chatzineofytou, E.G.; Nicoletto, M.; Marziali, I.; Boschetti, D.; Capsalis, C.N. Steady State Emissions Modeling of Low Frequency Magnetic and Electric Fields Generated by GOCE CDMU. In Proceedings of the 2019 ESA Workshop on Aerospace EMC (Aerospace EMC), Budapest, Hungary, 20–22 May 2019. [Google Scholar]

| Magnetic Sensor Technology | Detectable Field Range (Gauss) |

|---|---|

| Squid | ≈10−9–105 |

| Fiber-Optic | ≈10−6–101 |

| Optically Pumped | ≈10−8–100 |

| Nuclear Procession | ≈10−7–102 |

| Search-Coil | ≈10−8–1010 |

| Anisotropic Magnetoresistive | ≈10−7–101 |

| Fluxgate | ≈10−6–102 |

| Magnetotransistor | ≈10−1–104 |

| Magnetodiode | ≈10−1–104 |

| Giant Magnetoresistive | ≈10−1–108 |

| Hall Effect Sensor | ≈101–106 |

| Fluxgate Magnetometer Type | Advantages | Disadvantages |

|---|---|---|

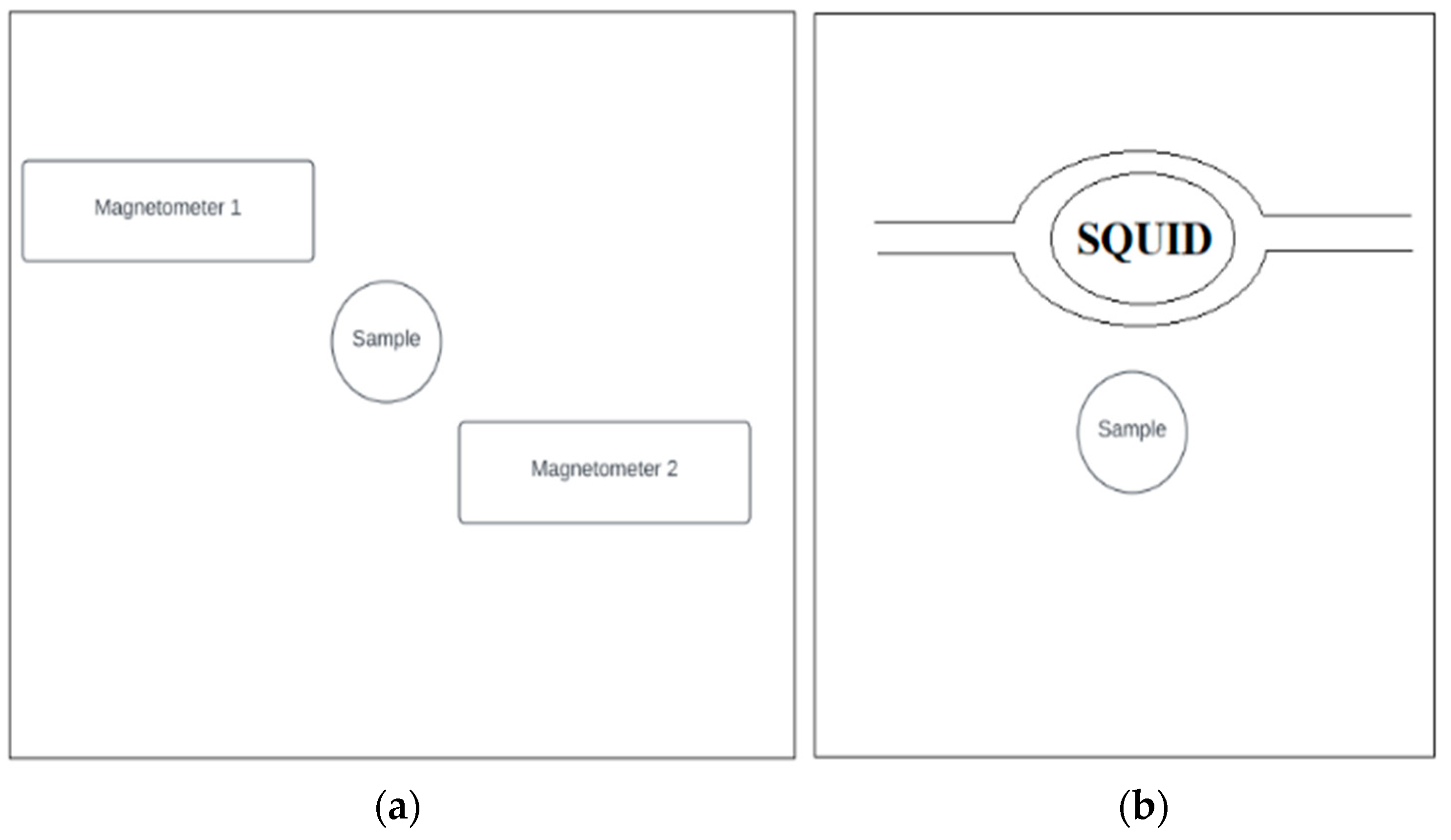

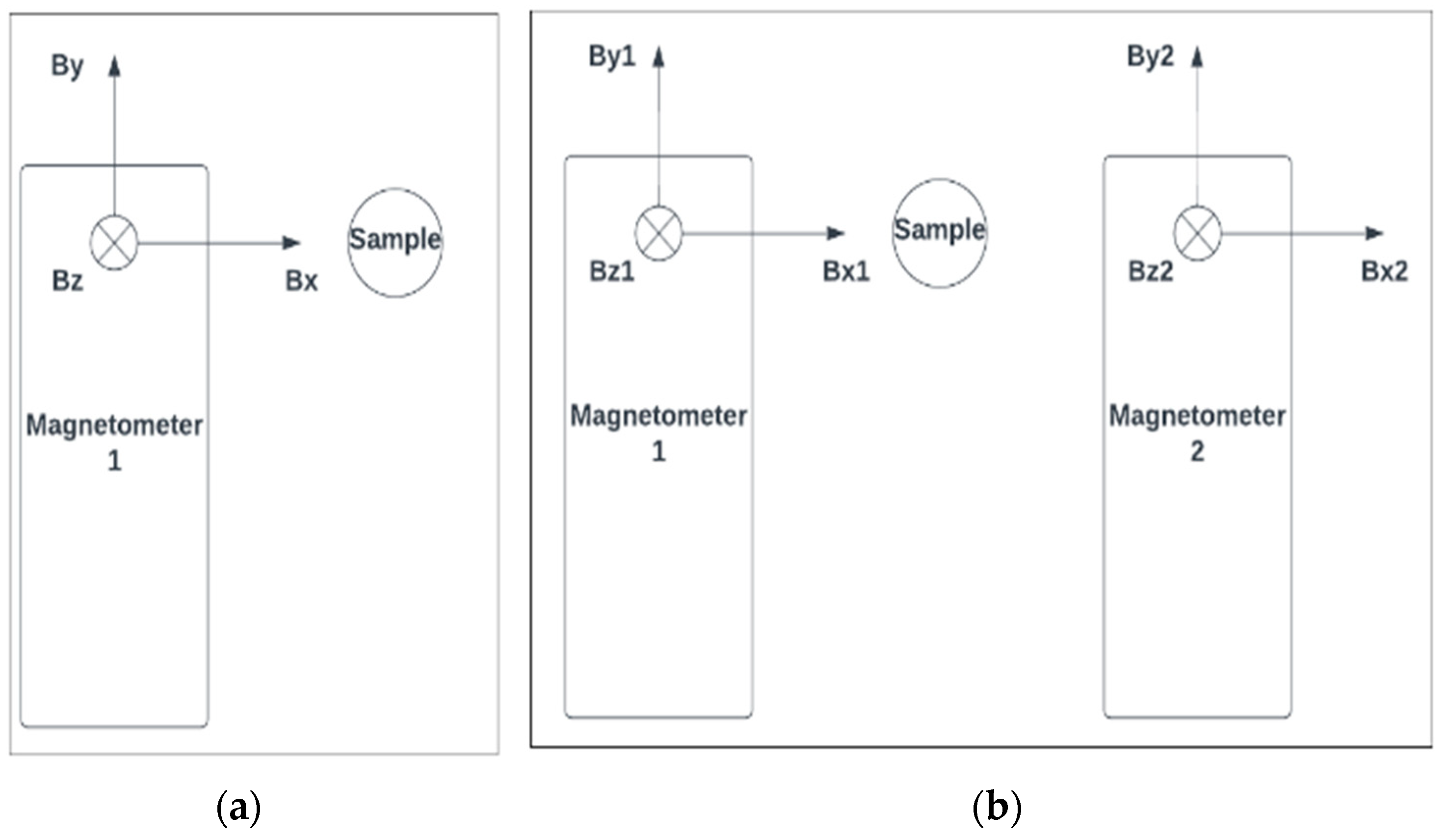

| Simple Fluxgate Magnetometer | Need for only one magnetometer | Only nanoparticles located close enough to the fluxgate sensor contribute to the output signal |

| Differential Fluxgate Magnetometer | SNR increases by a factor of √2 More accurate measurements | Need for two complete electronic sets |

| Magnetometer Type | Advantages | Disadvantages | Related References |

|---|---|---|---|

| Vibrating Sample Magnetometer | Old and widely used technology | Costly Low sensitivity Contains bulky electromagnets Contains moving parts Overall complex construction The low time resolution of the signal Bad quality of signal-to-noise ratio | [65,66,67,68,69,70,71,72,73,74,75] |

| Optically Pumped Magnetometer | Provides reduced target-field distance Flexibility in the positioning Absence of cryogenic cooling Measures the absolute magnetic field | High recovery time | [1,77,78,79,80,81,82,83,84] |

| Faraday Rotation Magnetometer | Provide rapid and non-destructive measurements | Limited use for quantitative measurements High level of noise Long-term displacements of the signal | [85,86,87] |

| Hall-Effect Magnetometer | Small dead time, less than 1 μs Can characterize the nanoparticles with accuracy, even if the distance between the sensor and the target is small | High level of noise | [36,49,76,78,79,80] |

| Giant Magnetoresistive Sensor | Compact Economical High sensitivity Large-scale device Work at room temperature Demand low power consumption Appear high thermal stability Relatively simple structure High transduction efficiency | High noise level (in the range of 0.1–1 nT/) | [37,59,93,94,95,96,99] |

| Superconducting Quantum Interference Device Magnetometer | High sensitivity (the most sensitive field sensor [62]) High bandwidths (of the order of MHz) Function range between 1 fT–9 T Enables measurements with close distance between the source and the sample Low noise level (0.1–10 pT/) | Not suitable for room temperature measurements Needs Cooling Needs Insulation Measures variations on the field and not the absolute magnetic fields Susceptibility to magnetic disturbances Need of heavy magnetic shielding Restrictions to the nanoparticle detection ability Dead zone time greater than 300 μs The signal is proportional to the average magnetic flux Vector magnetometer | [20,29,32,41,46,100,102,103,104,106,111,112,113,114,115,116,117,118,119,120] |

| Fluxgate Magnetometer | The signal has a proportional relationship with the magnetic flux density Highly sensitive device Low noise levels (1 pT to 1 nT/ at 1 Hz) White-noise values in the range of a few pT/Hz1/2 Able to work at room temperatures Simple structure without moving items High precision 3D device No need for cryogenic cooling No need for magnetic shielding Measure the absolute value of the magnetic field Able to know the signal before its deactivation Application in the magnetic fields between 20 pT and 100 μΤ | Are limited by their bandwidth in the lower kHz range | [8,19,26,27,42,45,47,110,121,122,123,124,125,126,127,128,129] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barmpatza, A.C.; Baklezos, A.T.; Vardiambasis, I.O.; Nikolopoulos, C.D. A Review of Characterization Techniques for Ferromagnetic Nanoparticles and the Magnetic Sensing Perspective. Appl. Sci. 2024, 14, 5134. https://doi.org/10.3390/app14125134

Barmpatza AC, Baklezos AT, Vardiambasis IO, Nikolopoulos CD. A Review of Characterization Techniques for Ferromagnetic Nanoparticles and the Magnetic Sensing Perspective. Applied Sciences. 2024; 14(12):5134. https://doi.org/10.3390/app14125134

Chicago/Turabian StyleBarmpatza, Alexandra C., Anargyros T. Baklezos, Ioannis O. Vardiambasis, and Christos D. Nikolopoulos. 2024. "A Review of Characterization Techniques for Ferromagnetic Nanoparticles and the Magnetic Sensing Perspective" Applied Sciences 14, no. 12: 5134. https://doi.org/10.3390/app14125134