Numerical and Experimental Investigation on Performance of Thermal Energy Storage Integrated Micro-Cold Storage Unit

Abstract

:1. Introduction

2. System Description

3. Materials and Methods

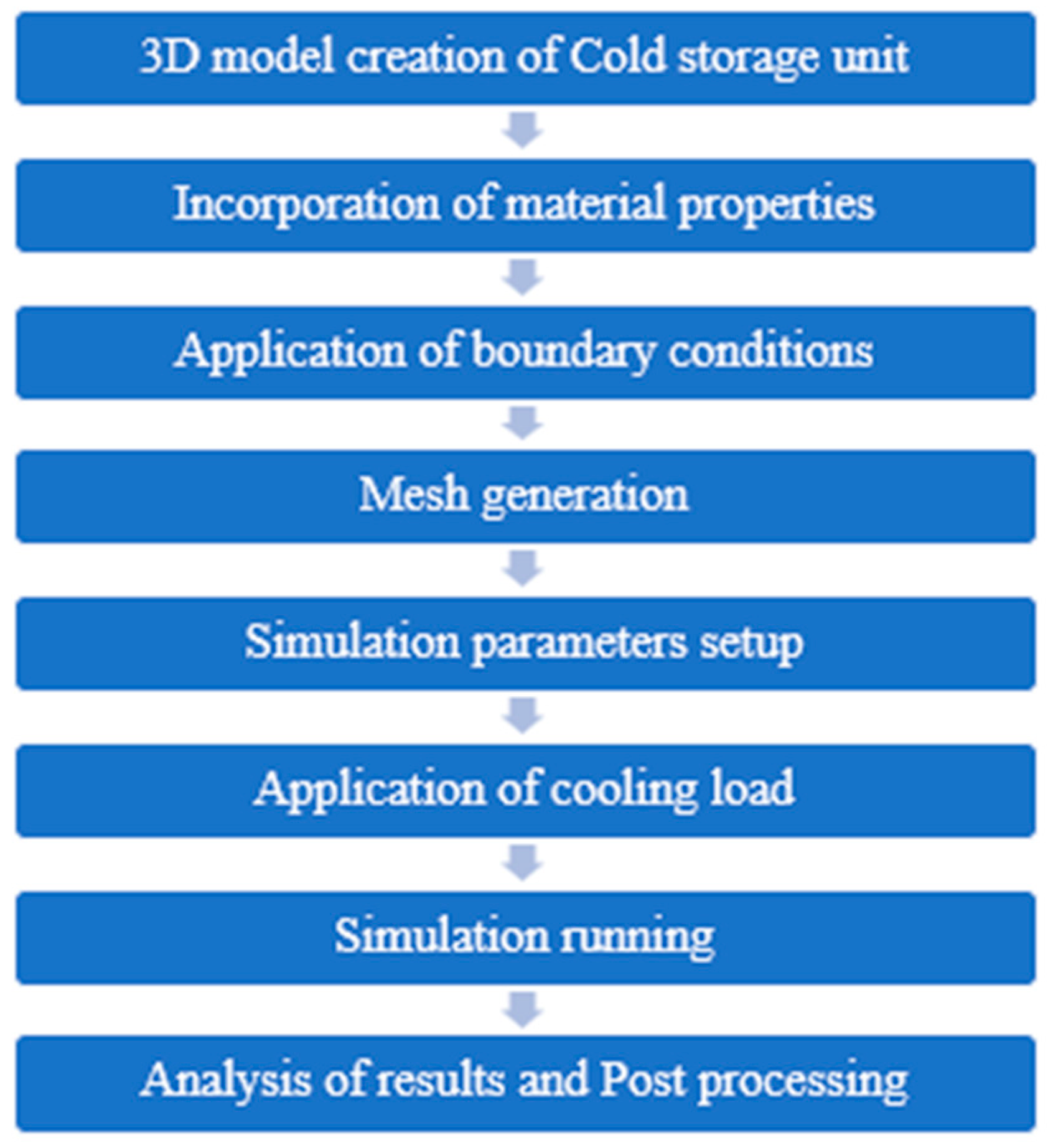

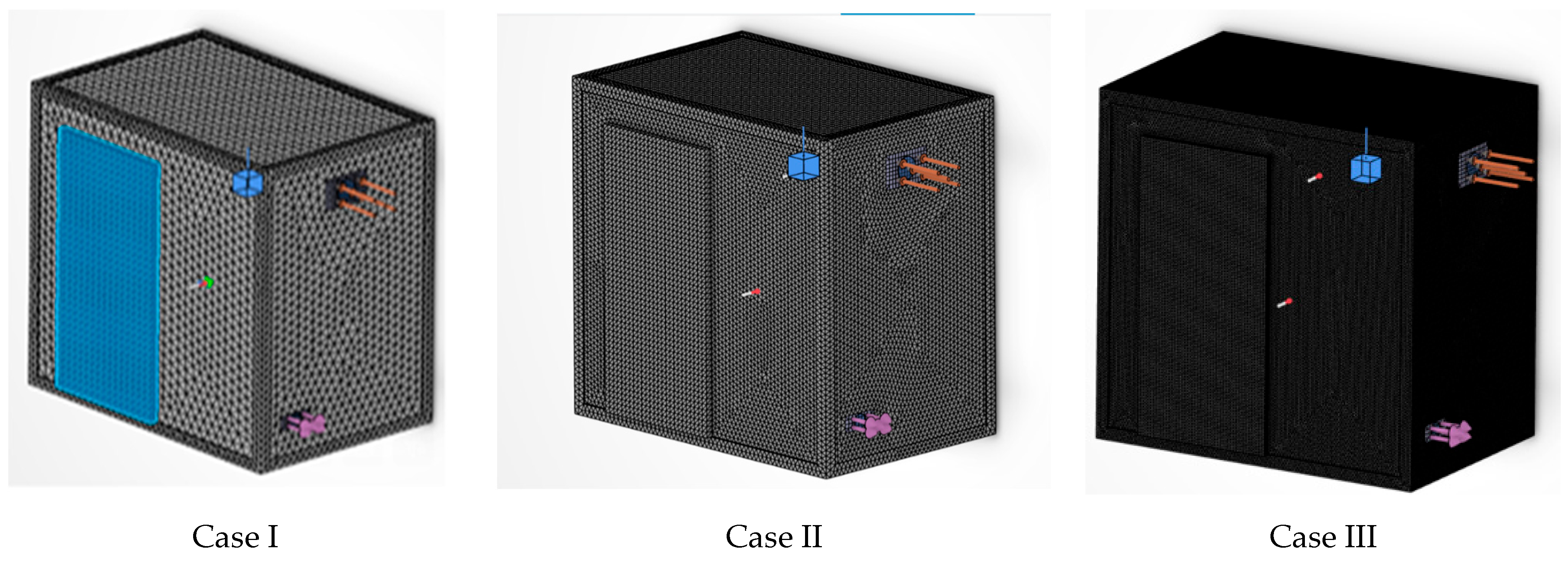

3.1. Numerical Analysis

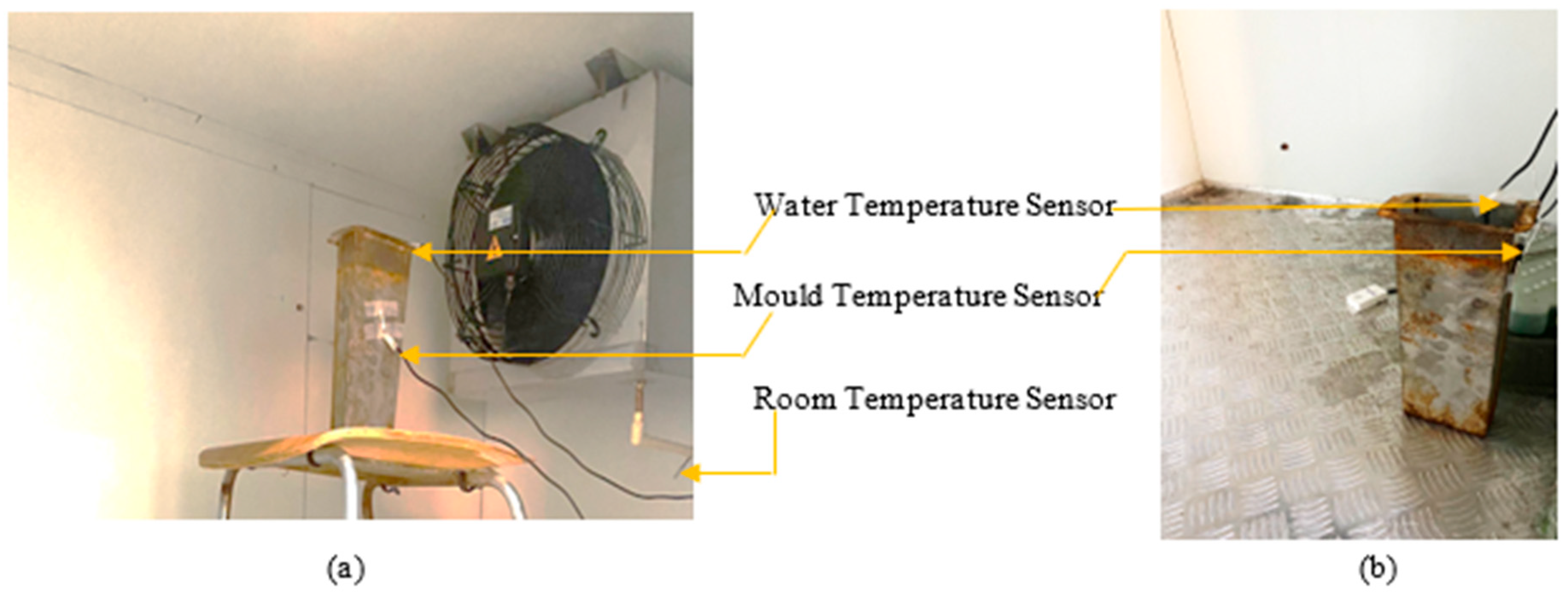

3.2. Experimental Procedure

4. Results and Discussion

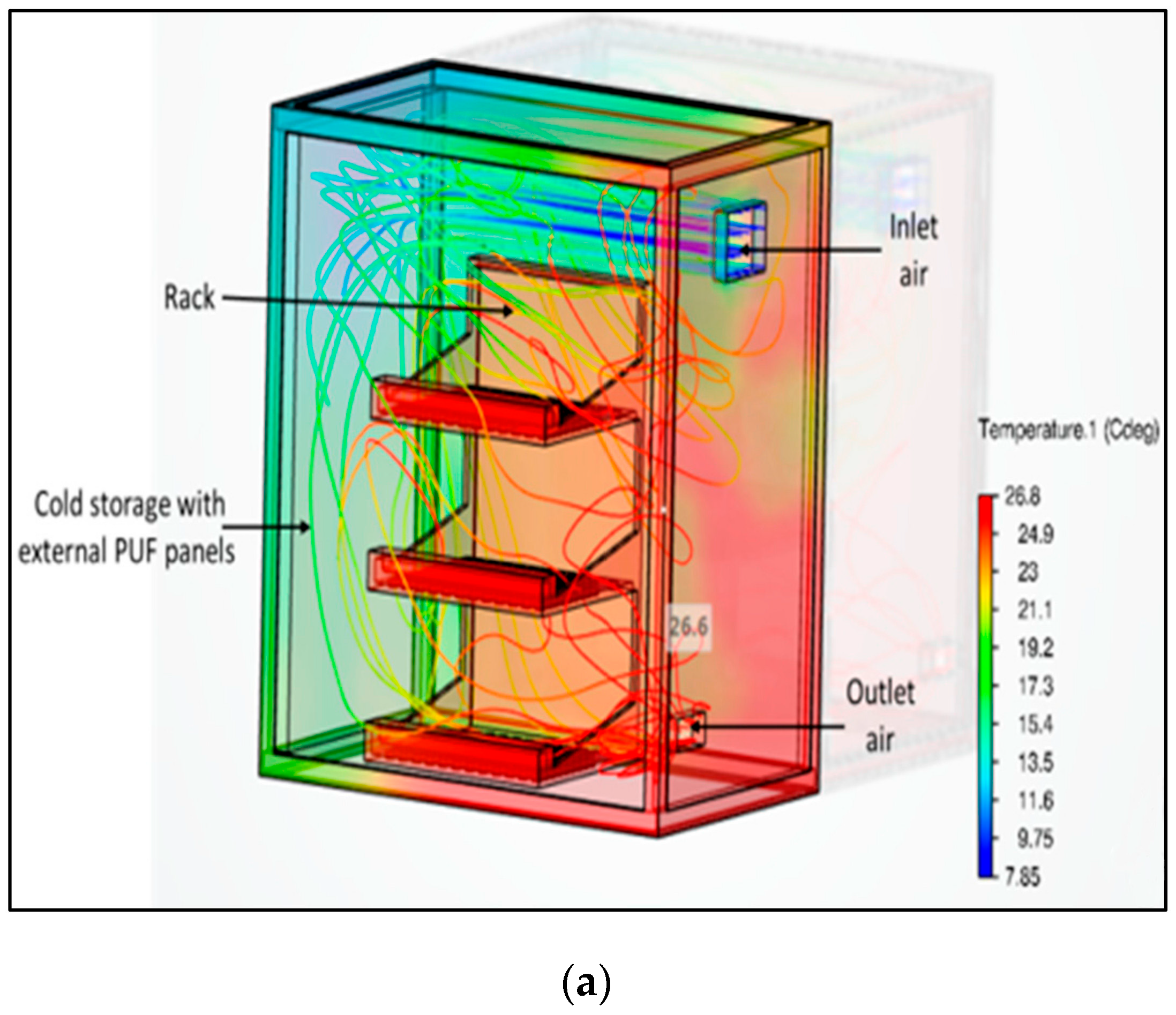

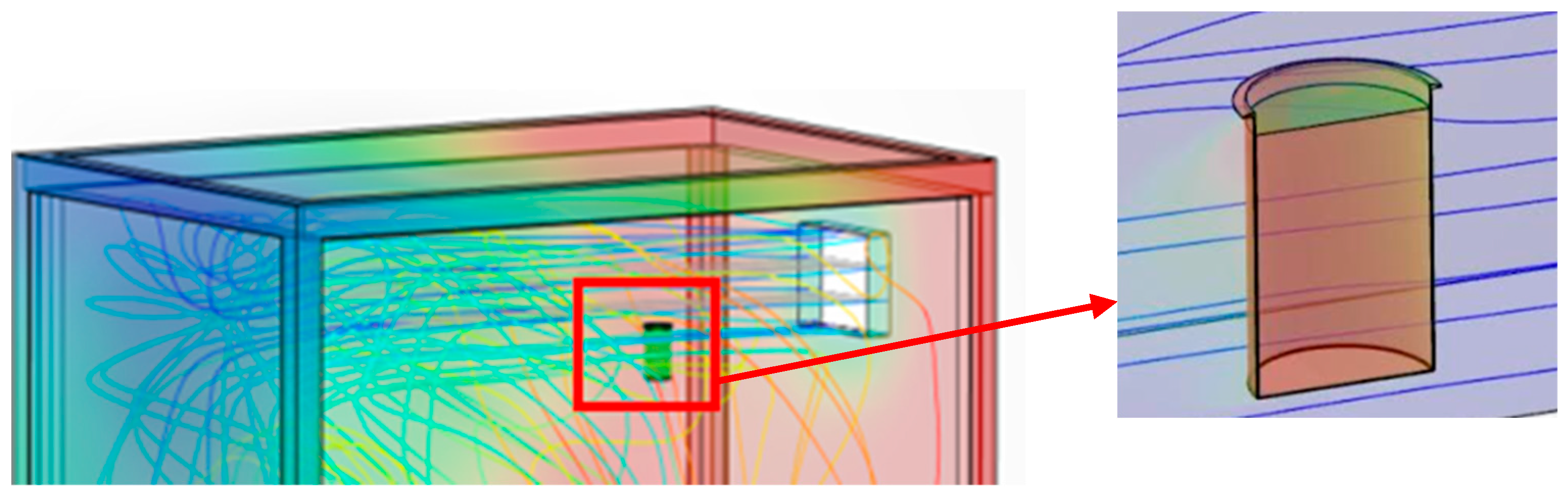

4.1. Numerical Simulation for the Cold Room Temperature Distribution Profile

4.2. Numerical Simulation with Varying PCM Encapsulation Material

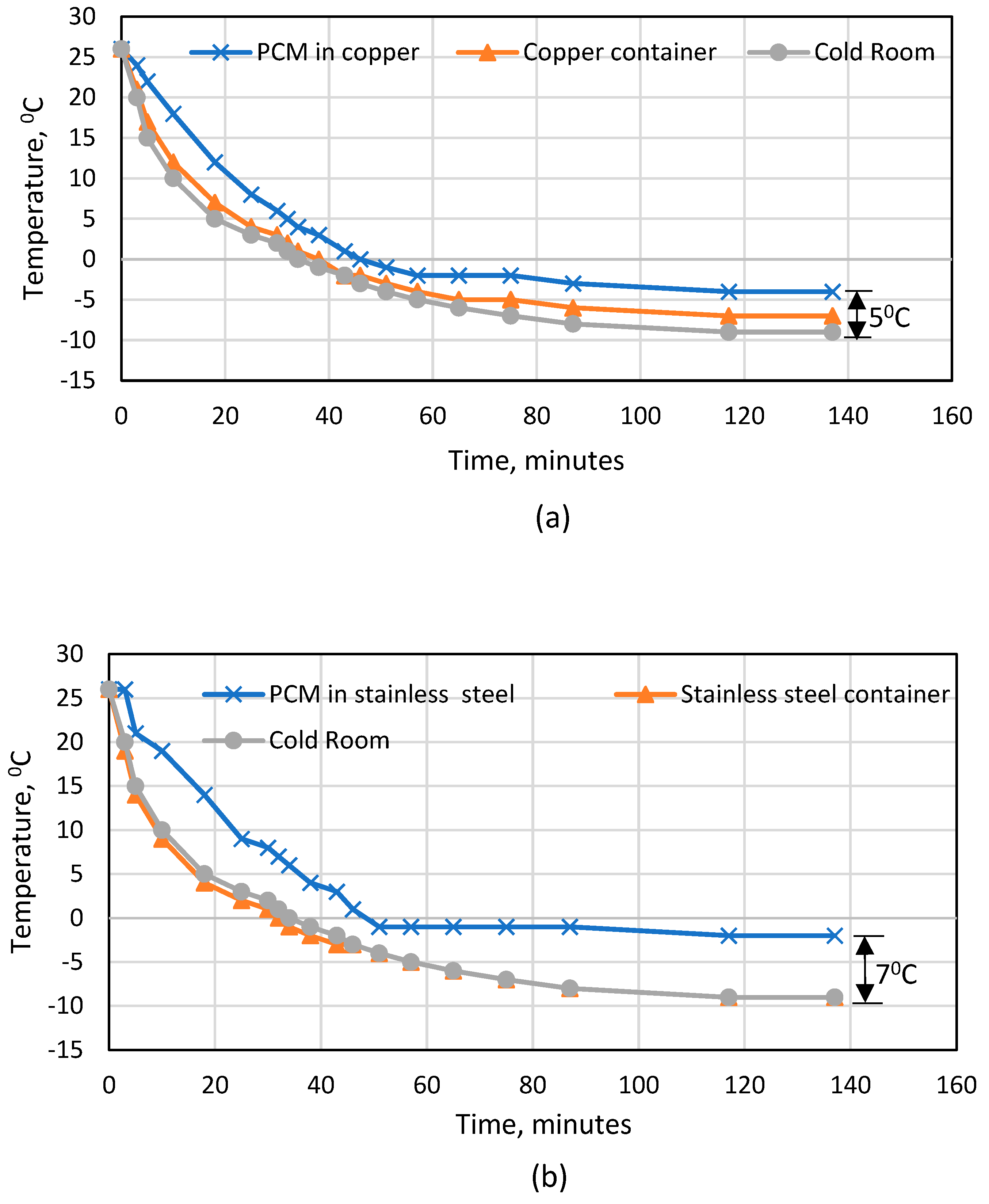

4.3. No-Load Test

4.4. Water Sample Test

4.5. PCM Sample Test

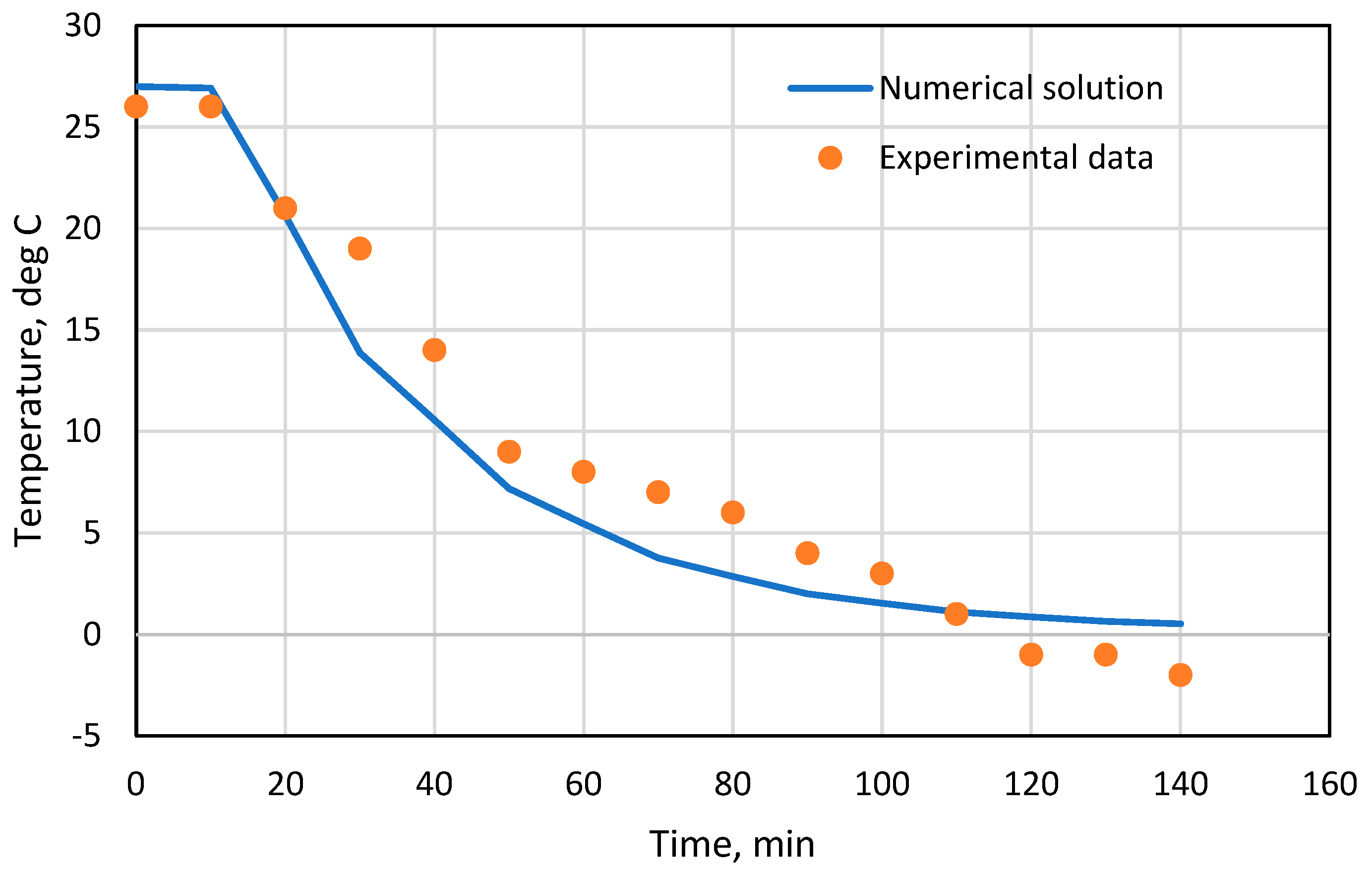

4.6. Comparison between Numerical and Experimental Results

5. Conclusions

- Numerical simulation carried out using 3D experience highlighted that the temperature distribution inside the cold room varied from 26.8 °C to 7.8 °C at the beginning of the storage cycle, and the maximum heat transfer was observed in the upper zone of the cold room where the evaporator cooling effect was seen to be maximum. The mesh independence study was carried out, and it was observed that changing the mesh sizes impacted the simulation by affecting the display resolution with negligible change in temperature profile; however, the time taken for the simulation was almost 1.5 times with a higher mesh count;

- This study was also undertaken to select the appropriate encapsulation material for PCM, where copper and stainless steel were compared both numerically and experimentally. The experimental results indicated that SS offered an excess thermal resistance of 4 °C in comparison to copper, inferring improved cooling effect penetration into the copper heat exchanger. Numerical simulations, as well as analytical computations, were found to be in conformity with the experimental results. The maximum cooling effect was obtained when copper containers as PCM encapsulations were positioned on the wall opposite the evaporator and its adjacent wall, providing the necessary thermal backup;

- The total energy consumption was found to be 1.1 kWh, where the maximum compressor cycle recorded was 17 min with 7 min of compressor ON-time. A steep rise in temperature was observed as soon as the compressor was stopped, highlighting the inability of a simple VCR cycle to maintain the set temperature even for a short duration of compressor OFF-time, which could be overcome by appropriate selection of PCM, its encapsulation material, and its mounting location;

- A temperature difference ranging from 5 to 7 °C is observed between the phase change temperature of PCM and the optimal storage temperature. This observation is important from the point of view of appropriate PCM selection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Natarajan, B.; Kathiresan, A.C.; Subramanium, S.K. Development and performance evaluation of a hybrid portable solar cold storage system for the preservation of vegetables and fruits in remote areas. J. Energy Storage 2023, 72, 108292. [Google Scholar] [CrossRef]

- Parida, S.; Roy, A.; Anjankar, P. Design and experimental study of prototype cold storage for various vegetables stored. In Techno-Societal 2018: Proceedings of the 2nd International Conference on Advanced Technologies for Societal Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; Volume 1, pp. 447–455. [Google Scholar] [CrossRef]

- Ministry of Commerce and Industry. Fresh Fruits and Vegetables FFV @ apeda.gov.in. Agricultural and Processed Food Products Export Development. 2023. Available online: https://apeda.gov.in/apedawebsite/six_head_product/FFV.htm (accessed on 10 June 2024).

- Ministry of Agriculture & Farmers Welfare. Cold Storage Facilities in the Country, PressReleasePage @ pib.gov.in. Ministry of Agriculture & Farmers Welfare, GoI. 2020. Available online: https://pib.gov.in/PressReleasePage.aspx?PRID=1606341 (accessed on 10 June 2024).

- Amjad, W.; Munir, A.; Akram, F.; Parmar, A.; Precoppe, M.; Asghar, F.; Mahmood, F. Decentralized solar-powered cooling systems for fresh fruit and vegetables to reduce post-harvest losses in developing regions: A review. Clean Energy 2023, 7, 635–653. [Google Scholar] [CrossRef]

- Tachajapong, W.; Wiratkasem, K.; Kammuang-lue, N.; Pattana, S. Preliminary study on specific energy consumption of cold storage room in Thailand’s cold chain. Energy Rep. 2022, 8, 336–341. [Google Scholar] [CrossRef]

- Joybari, M.M.; Haghighat, F.; Moffat, J.; Sra, P. Heat and cold storage using phase change materials in domestic refrigeration systems: The state-of-the-art review. Energy Build. 2015, 106, 111–124. [Google Scholar] [CrossRef]

- Talukdar, S.; Afroz, H.M.M.; Hossain, M.A.; Aziz, M.A.; Hossain, M.M. Heat transfer enhancement of charging and discharging of phase change materials and size optimization of a latent thermal energy storage system for solar cold storage application. J. Energy Storage 2019, 24, 100797. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, Q.; Chi, Y.; Zhang, L. Étude Sur La Performance D’Un Réfrigérateur Domestique Refroidi Par Air Utilisant Des Matériaux À Changement De Phase Pour L’Entreposage Frigorifique. Int. J. Refrig. 2017, 79, 130–142. [Google Scholar] [CrossRef]

- Pirdavari, P.; Hossainpour, S. Numerical study of a Phase Change Material (PCM) embedded solar thermal energy operated cool store: A feasibility study. Int. J. Refrig. 2020, 117, 114–123. [Google Scholar] [CrossRef]

- Sonnenrein, G.; Baumhögger, E.; Elsner, A.; Fieback, K.; Morbach, A.; Paul, A.; Vrabec, J. Copolymer-bound phase change materials for household refrigerating appliances: Experimental investigation of power consumption, temperature distribution and demand side management potential. Int. J. Refrig. 2015, 60, 166–173. [Google Scholar] [CrossRef]

- Roy, A.; Kale, S.; Lingayat, A.B.; Sur, A.; Arun, S.; Sengar, D.; Gawade, S.; Wavhal, A. Evaluating energy-saving potential in micro-cold storage units integrated with phase change material. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 514. [Google Scholar] [CrossRef]

- Oró, E.; Miró, L.; Farid, M.M.; Cabeza, L.F. Improving thermal performance of freezers using phase change materials. Int. J. Refrig. 2012, 35, 984–991. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Enhancing the performance of household refrigerators with latent heat storage: An experimental investigation. Int. J. Refrig. 2009, 32, 1634–1644. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Performance enhancement of a household refrigerator by addition of latent heat storage. Int. J. Refrig. 2008, 31, 892–901. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Afroz, H.M. Afroz experimental investigation of performance improvement of household refrigerator using phase change material. Int. J. Air-Cond. Refrig. 2013, 21, 1350029. [Google Scholar] [CrossRef]

- Ezan, M.A.; Doganay, E.O.; Yavuz, F.E.; Tavman, I.H. A numerical study on the usage of phase change material (PCM) to prolong compressor off period in a beverage cooler. Energy Convers. Manag. 2017, 142, 95–106. [Google Scholar] [CrossRef]

- Maiorino, A.; Del Duca, M.G.; Mota-Babiloni, A.; Greco, A.; Aprea, C. The thermal performances of a refrigerator incorporating a phase change material. Int. J. Refrig. 2019, 100, 255–264. [Google Scholar] [CrossRef]

- Ben-Abdallah, R.; Leducq, D.; Hoang, H.M.; Fournaison, L.; Pateau, O.; Ballot-Miguet, B.; Delahaye, A. Experimental investigation of the use of PCM in an open display cabinet for energy management purposes. Energy Convers. Manag. 2019, 198, 111909. [Google Scholar] [CrossRef]

- Munir, A.; Ashraf, T.; Amjad, W.; Ghafoor, A.; Rehman, S.; Malik, A.U.; Hensel, O.; Sultan, M.; Morosuk, T. Solar-hybrid cold energy storage system coupled with cooling pads backup: A step towards decentralized storage of perishables. Energies 2021, 14, 7633. [Google Scholar] [CrossRef]

- Wang, C.; He, Z.; Li, H.; Wennerstern, R.; Sun, Q. Evaluation on Performance of a Phase Change Material Based Cold Storage House. Energy Procedia 2017, 105, 3947–3952. [Google Scholar] [CrossRef]

- Yang, T.; Wang, C.; Sun, Q.; Wennersten, R. Study on the application of latent heat cold storage in a refrigerated warehouse. Energy Procedia 2017, 142, 3546–3552. [Google Scholar] [CrossRef]

- Tiwari, A.; Harischander, H.; Rane, M.V. Cold Storage in India for Small Farmers—Current Status and Challenges. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 10–14 July 2022; p. 2472. [Google Scholar]

- Rostamizadeh, M.; Khanlarkhani, M.; Sadrameli, S.M. Simulation of energy storage system with phase change material (PCM). Energy Build. 2012, 49, 419–422. [Google Scholar] [CrossRef]

| Parameters | Specifications |

|---|---|

| Dimensions | 1.83 m × 1.22 m × 1.83 m (6 feet × 4 feet × 6 feet) |

| Storage volume | 3.4 m3 (122 ft3) |

| Storage capacity | 0.5 MT |

| Temperature range | −15 °C to 10 °C |

| Humidity range | 80–95% |

| Cooling capacity | 0.63 TR |

| Refrigerant used | R134a |

| Compressor type | Hermetically sealed rotary-type |

| Compressor rating | 1.5 kW |

| Properties | Units | Air (Inlet) | Stainless Steel | Copper |

|---|---|---|---|---|

| Density (ρ) | kg/m3 | 1.176 | 8000 | 8196 |

| Specific Heat (Cp) | J/kgK | 1005 | 500 | 385 |

| Thermal Conductivity (k) | W/mK | 0.0275 | 19 | 400 |

| Thermal Expansion Coefficient (β) | /°C | 0.00367 | 16 × 10−6 | 17 × 10−6 |

| Dynamic Viscosity (μ) | Pa.s | 18.4 × 10−6 | - | - |

| Kinematic Viscosity (ν) | m2/s | 15.7 × 10−6 | - | - |

| Cold Storage Parts | Mesh Type | Case | Maximum Mesh Size (mm) | Absolute Sag (mm) | Simulation Time (min) |

|---|---|---|---|---|---|

| PUF External Panels | Tetrahedron Mesh | I | 59.206 | 11.841 | 79 |

| II | 30 | 5 | 93 | ||

| III | 15 | 2.5 | 115 | ||

| Cold storage frame | Tetrahedron Mesh | I | 44.403 | 8.881 | 79 |

| II | 30 | 5 | 93 | ||

| III | 15 | 2.5 | 115 | ||

| PCM SS container | Tetrahedron Mesh | I | 32.607 | 5.231 | 79 |

| II | 32.607 | 5.231 | 93 | ||

| III | 12.5 | 1.5 | 115 | ||

| PCM copper container | Tetrahedron Mesh | I | 62.814 | 12.563 | 79 |

| II | 32.607 | 5.231 | 93 | ||

| III | 27.4 | 2.5 | 115 | ||

| Cold room inside cool air | HEX Mesh | I | 74.85 | 7.44 | 79 |

| II | 54.85 | 5 | 93 | ||

| III | 27.4 | 2.5 | 115 |

| Parameters | Value |

|---|---|

| Make | Multitech |

| Measurement Range | −50 °C to 150 °C |

| Measuring accuracy | ±1% FSA |

| Resolution | 0.1 °C |

| Configuration | PT 100 3 Wire |

| Response time | <10 s |

| Probe type | 304-SS, 6 mm diameter |

| Properties | Value |

|---|---|

| Melting temperature | −2 °C |

| Freezing temperature | −3 °C |

| Latent heat | 329 kJ/kg |

| Solid density | 1060 kg/m3 |

| Liquid density | 985 kg/m3 |

| Solid thermal conductivity | 2.2 W/mK |

| Liquid thermal conductivity | 0.35 W/mK |

| Thermal stability | ~1000 cycles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arun, S.; Boche, R.J.; Nambiar, P.; Ekka, P.; Panalkar, P.; Kumar, V.; Roy, A.; Landini, S. Numerical and Experimental Investigation on Performance of Thermal Energy Storage Integrated Micro-Cold Storage Unit. Appl. Sci. 2024, 14, 5166. https://doi.org/10.3390/app14125166

Arun S, Boche RJ, Nambiar P, Ekka P, Panalkar P, Kumar V, Roy A, Landini S. Numerical and Experimental Investigation on Performance of Thermal Energy Storage Integrated Micro-Cold Storage Unit. Applied Sciences. 2024; 14(12):5166. https://doi.org/10.3390/app14125166

Chicago/Turabian StyleArun, Sreelekha, Rushikesh J. Boche, Prahas Nambiar, Prince Ekka, Pratham Panalkar, Vaibhav Kumar, Anindita Roy, and Stefano Landini. 2024. "Numerical and Experimental Investigation on Performance of Thermal Energy Storage Integrated Micro-Cold Storage Unit" Applied Sciences 14, no. 12: 5166. https://doi.org/10.3390/app14125166