InSAR-CTPIM-Based 3D Deformation Prediction in Coal Mining Areas of the Baisha Reservoir, China

Abstract

:1. Introduction

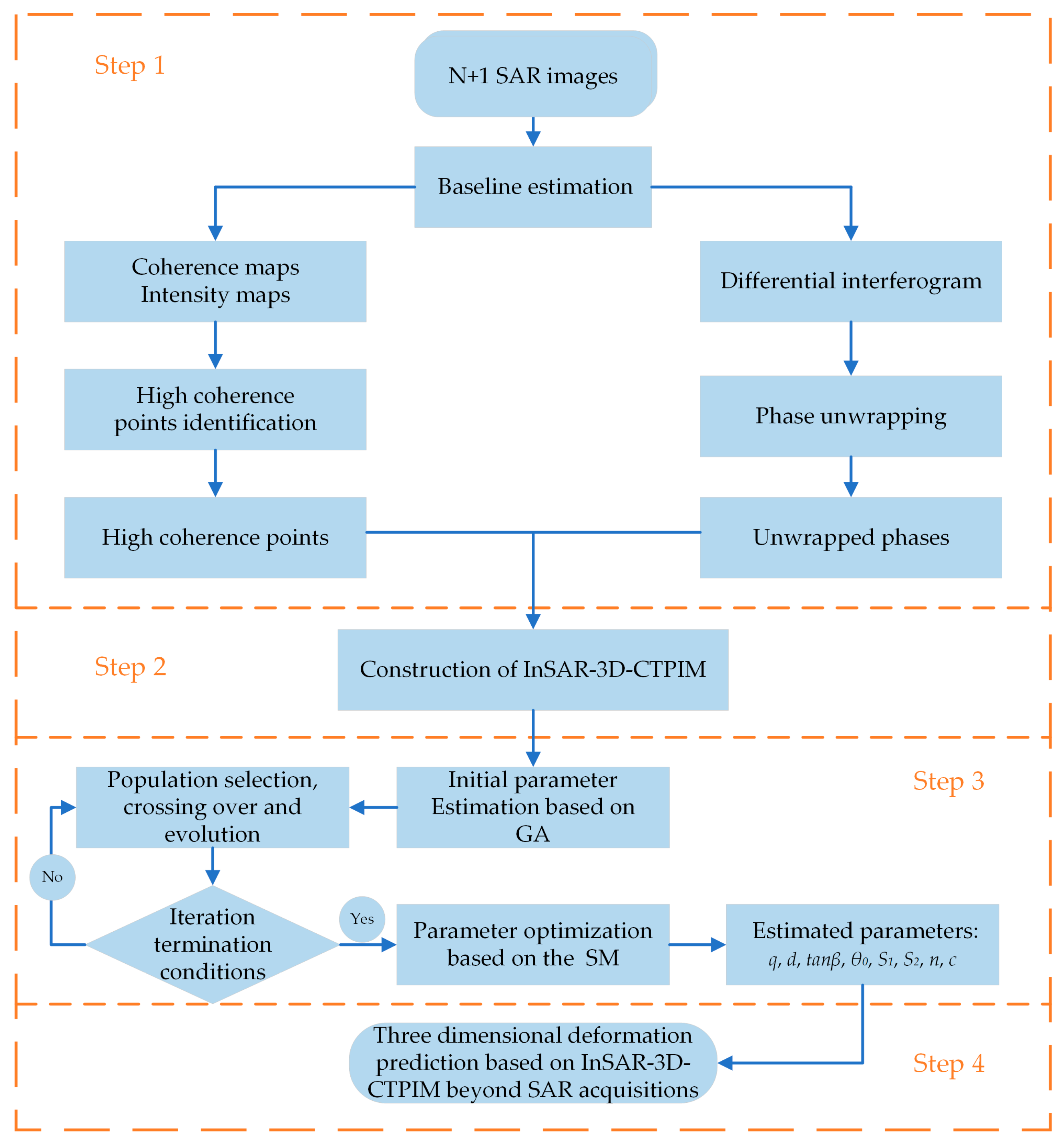

2. Methods

2.1. SBAS-Based Estimation of Line-of-Sight Deformation

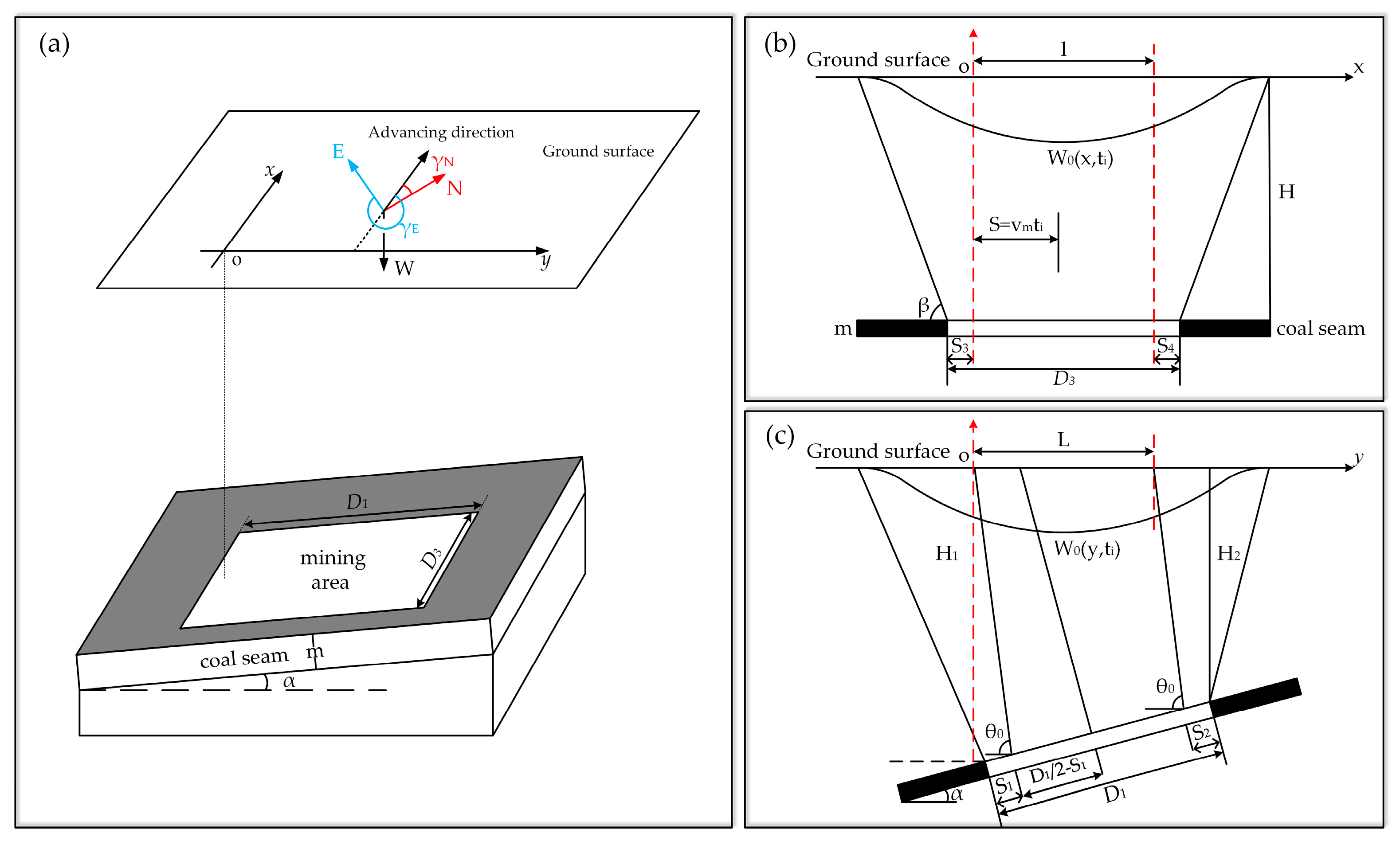

2.2. Three-Dimensional CTPIM Modeling Based on Coordinate-Time Functions

- When the mining tendency of the mine is fully mined and the strike is not fully mined, the in Equation (4) can be expressed as follows [16]:

- 2.

- When the mining strike is fully mined and the tendency is not fully mined, W0(y, ti) in Equation (4) and U0(y, ti) in Equation (5) can be expressed as follows:

2.3. InSAR-3D-CTPIM

2.4. InSAR-3D-CTPIM Parameter Estimation by GA-SM

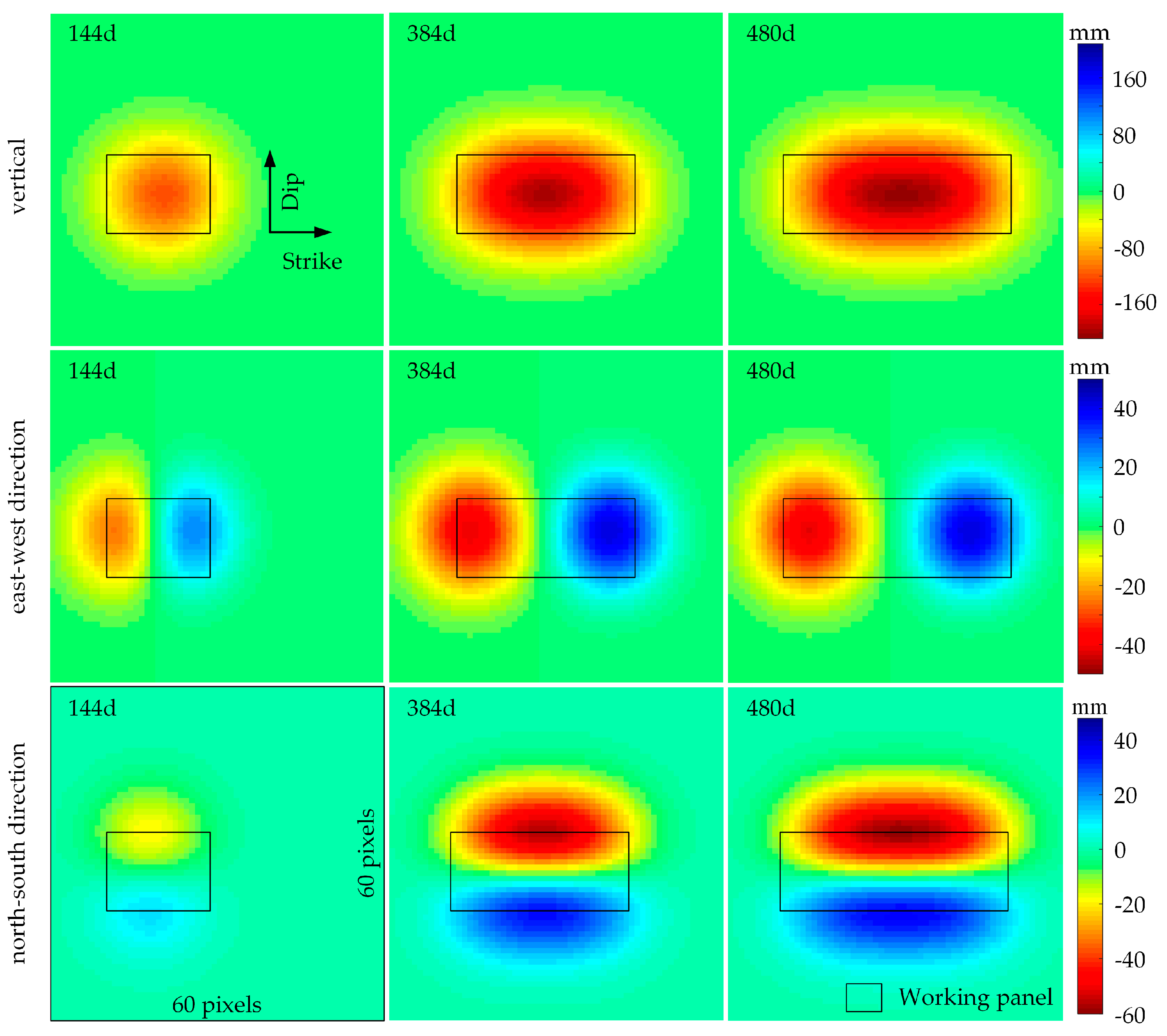

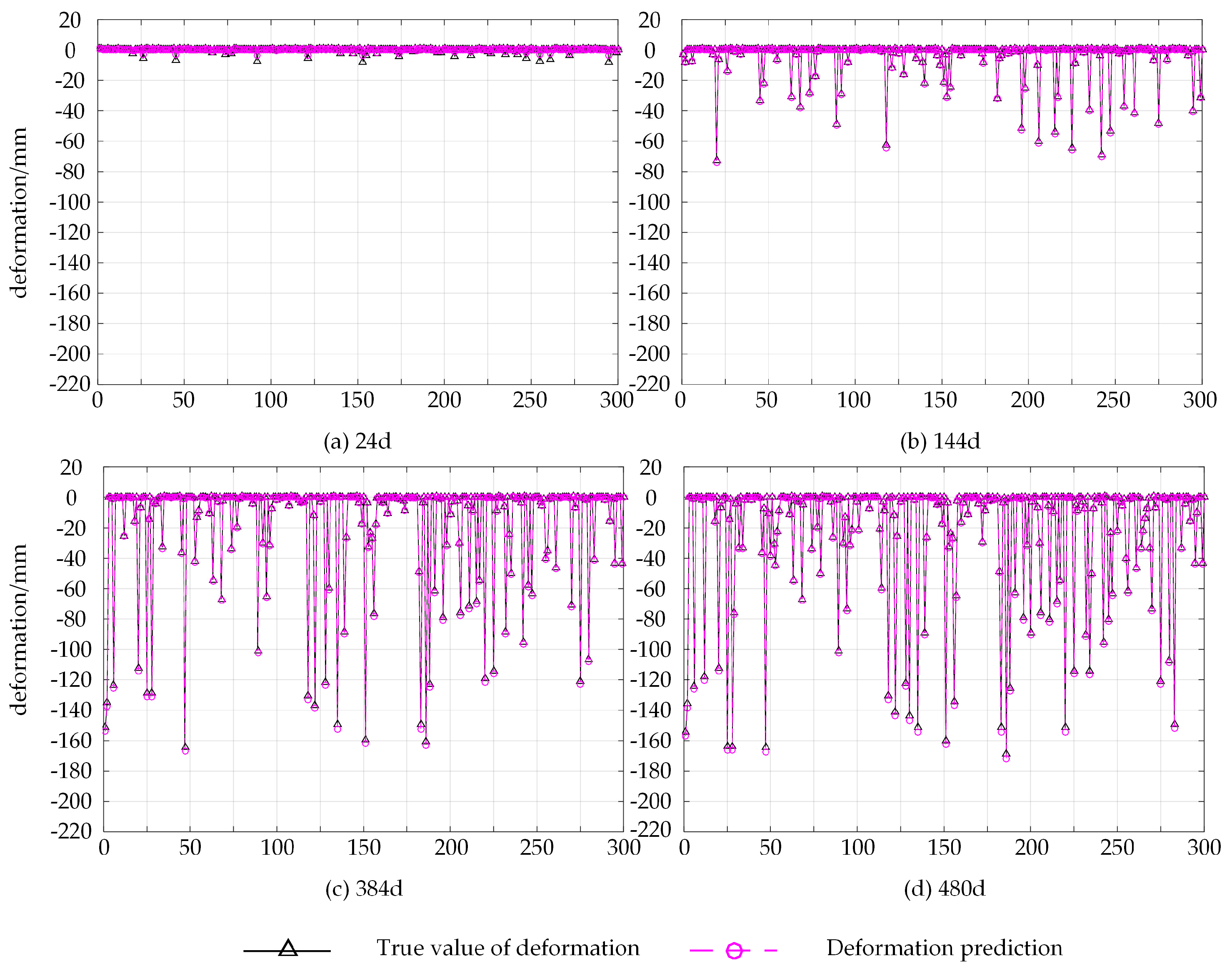

3. Simulation Experiment

4. Real Experiments

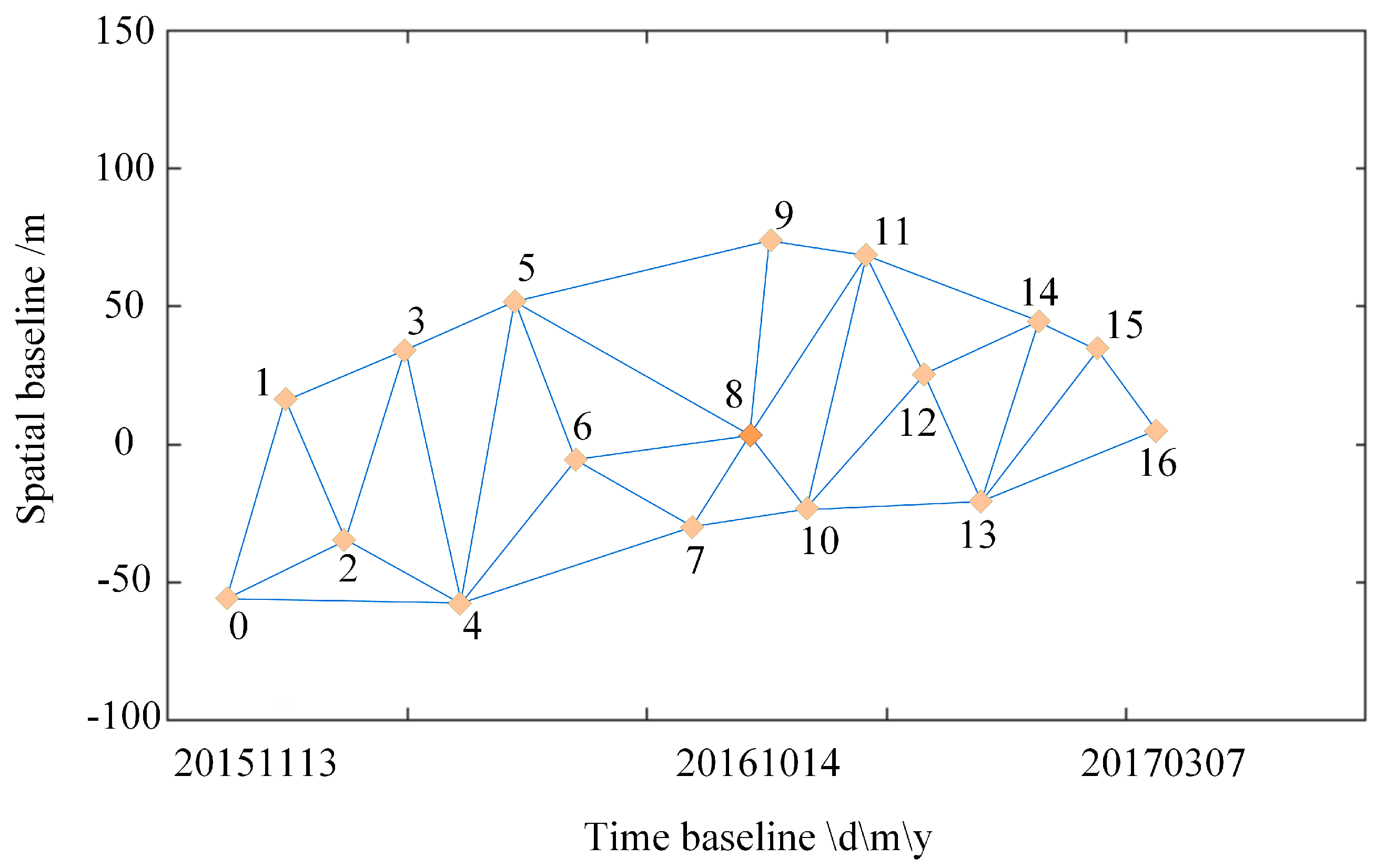

4.1. Experimental Area and Experimental Data

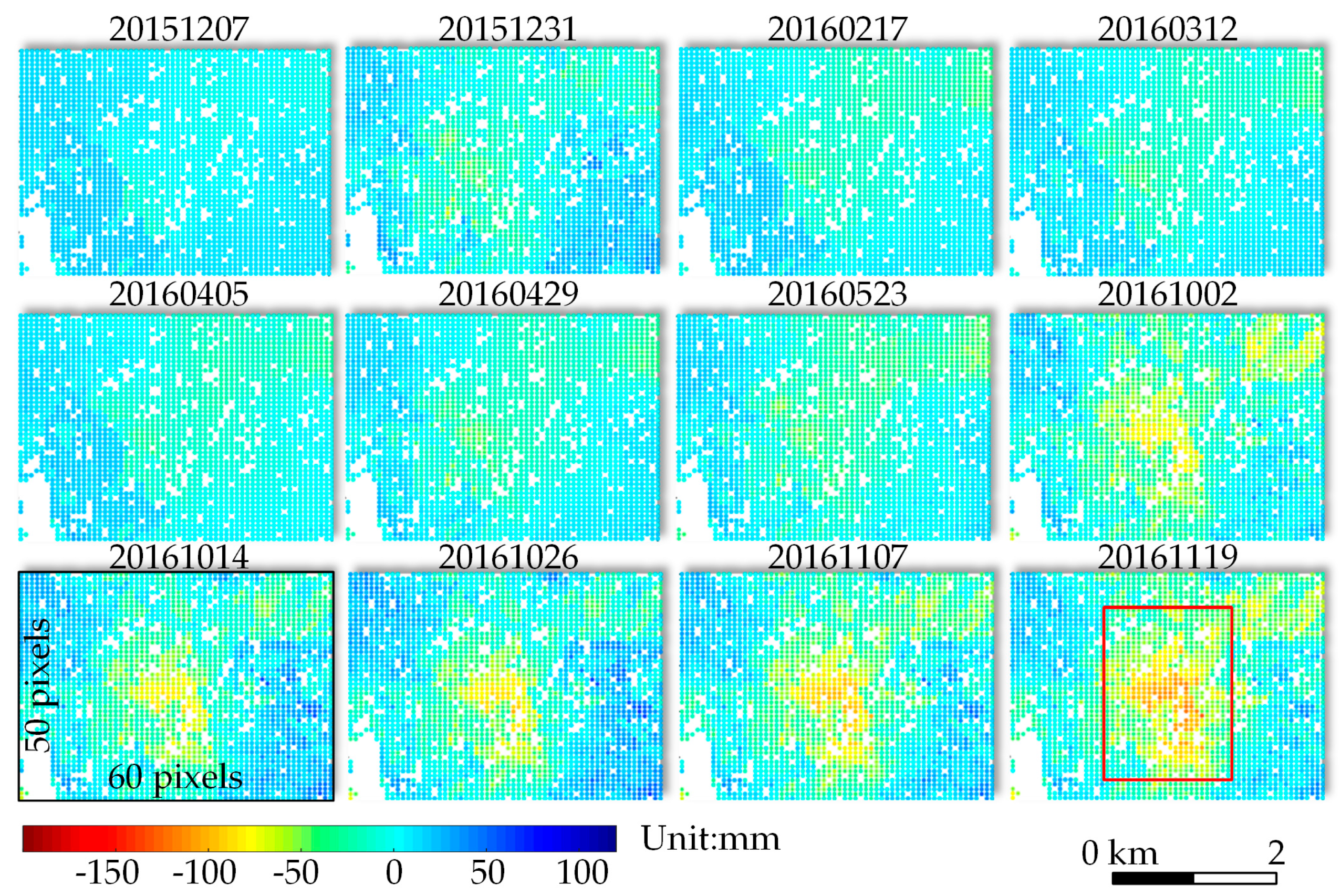

4.2. Time Series Deformation Monitoring Based on SBAS-InSAR Technique

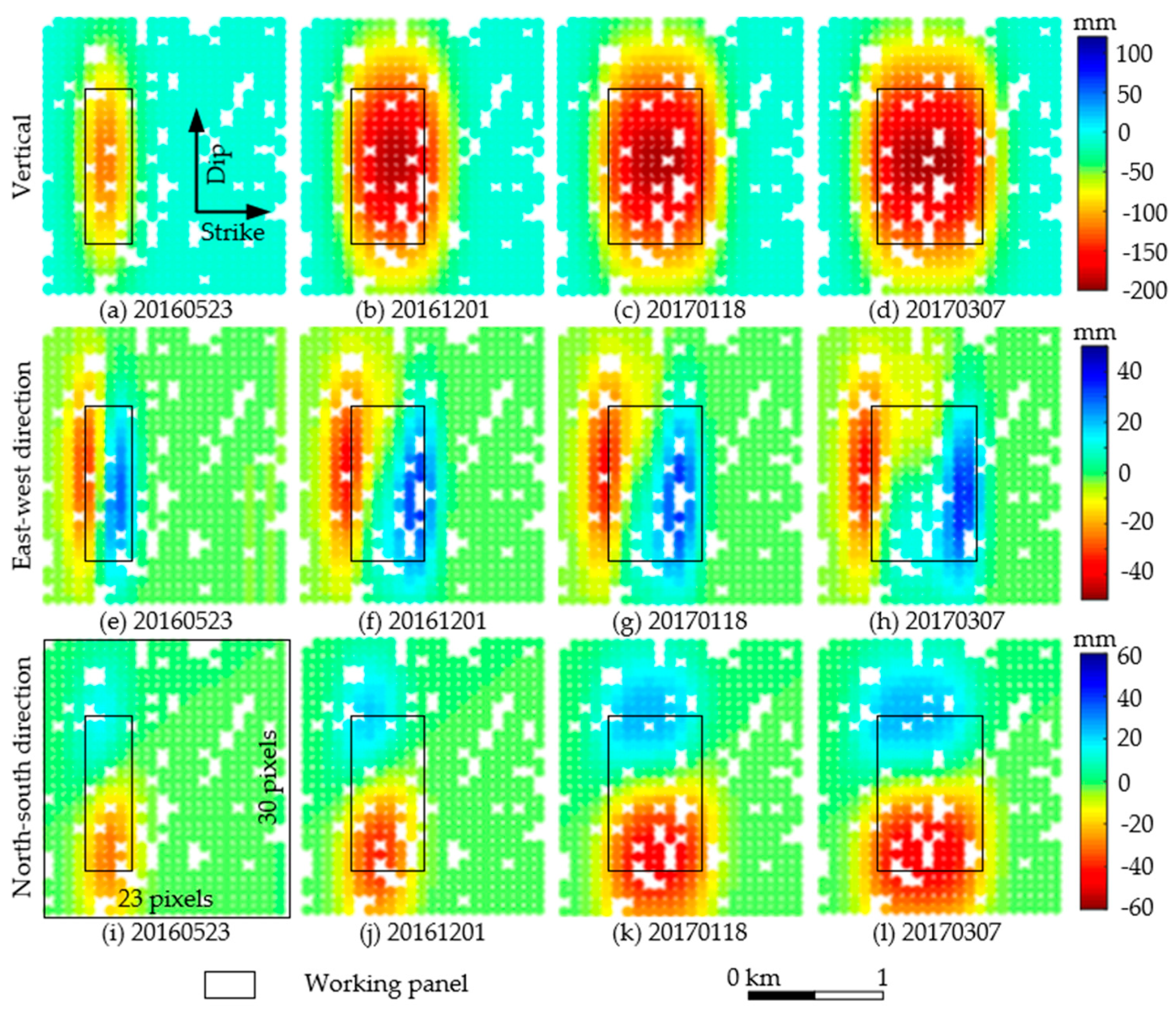

4.3. Analysis of 3D-CTPIM Deformation Prediction Results

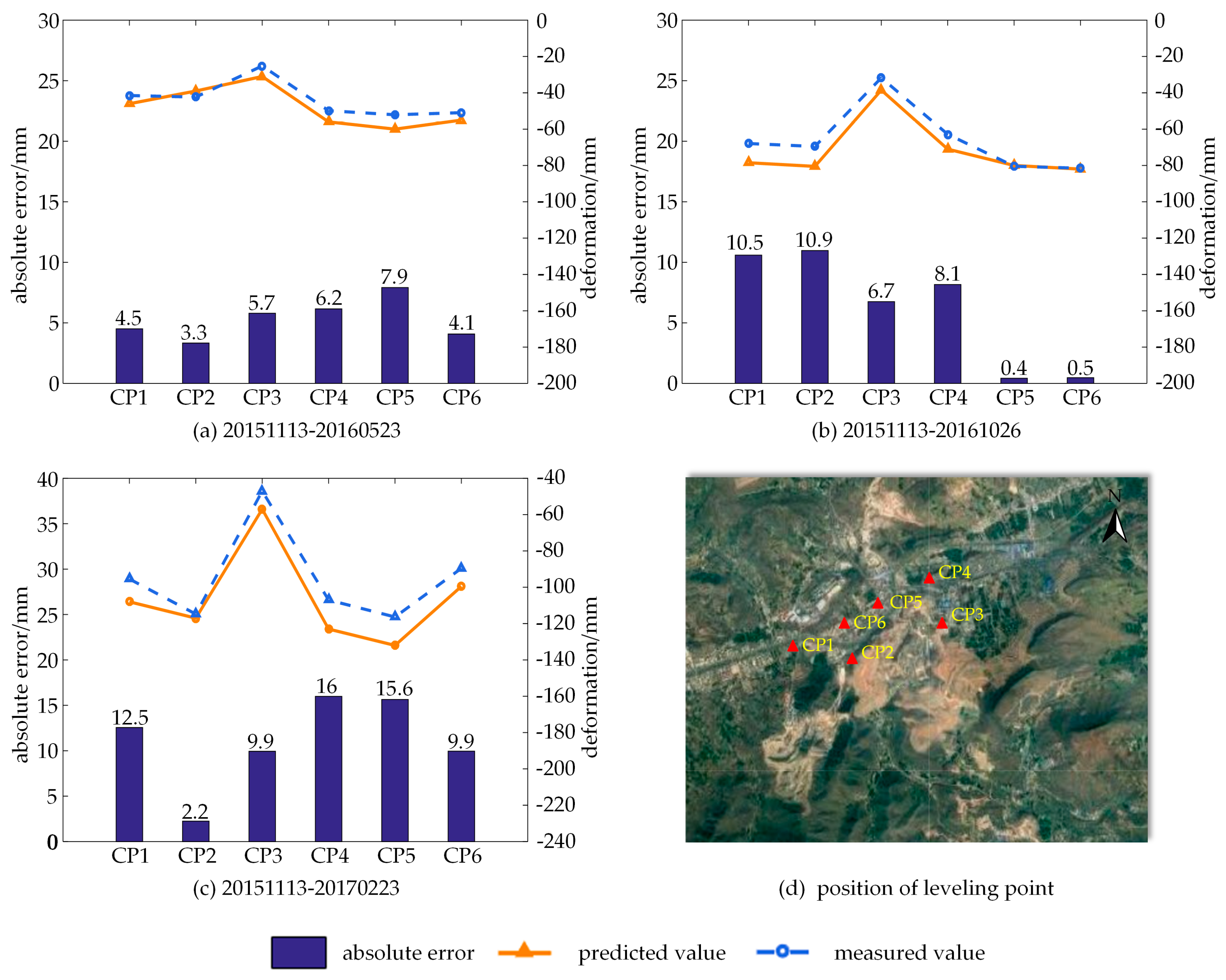

5. Accuracy Validation

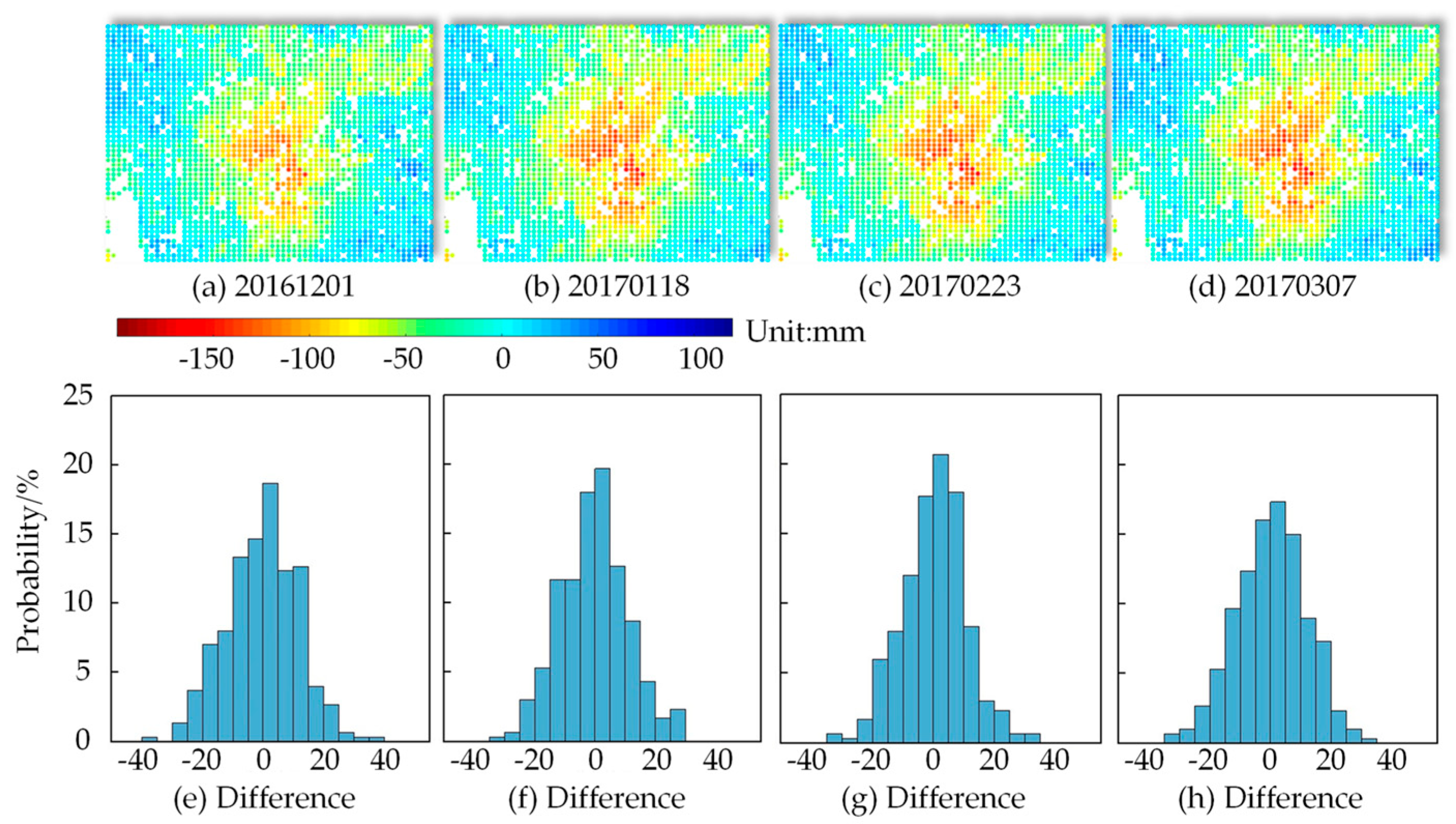

5.1. Deformation Monitoring Accuracy

5.2. Deformation Modeling Accuracy

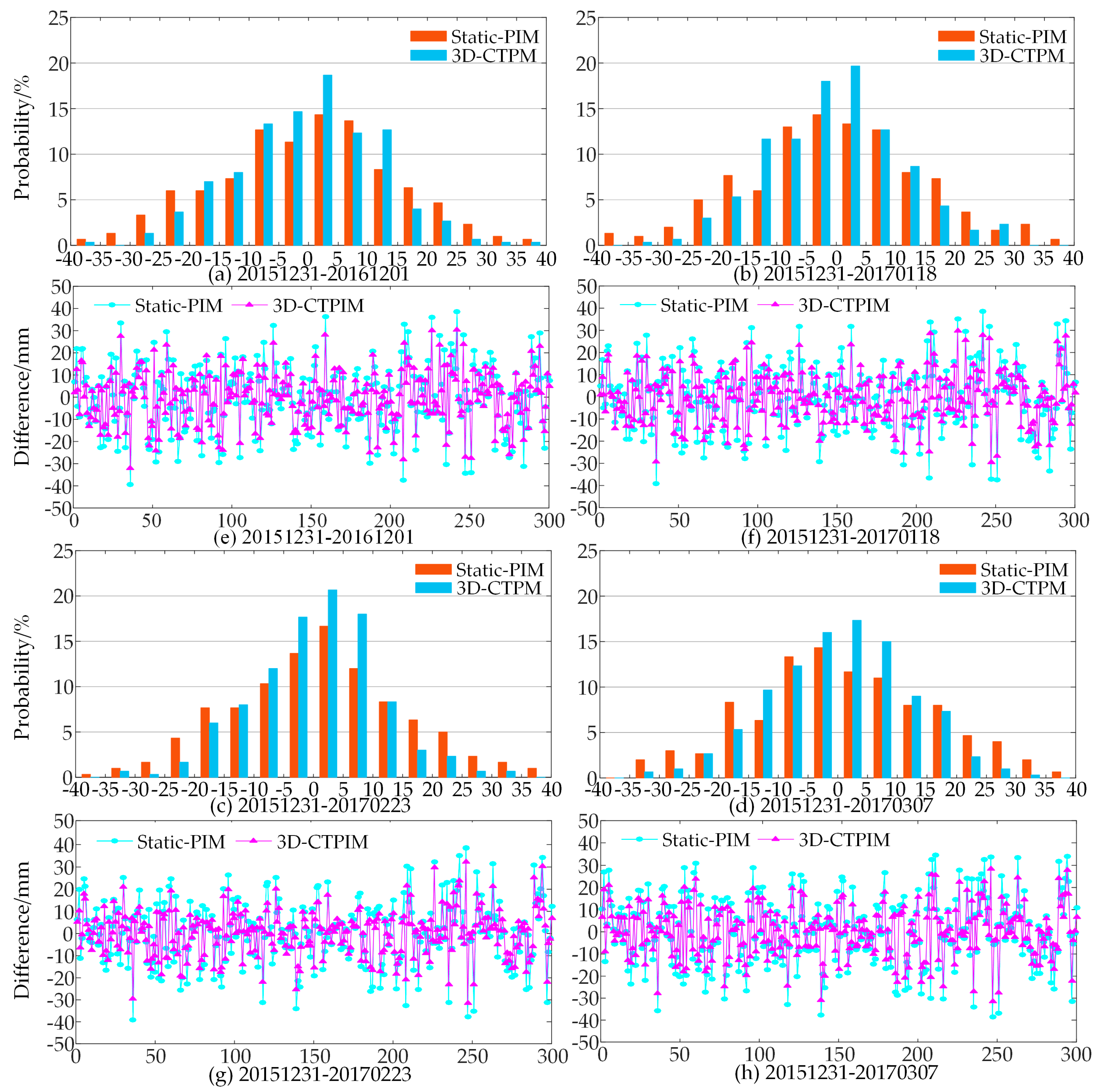

5.3. Comparison of Accuracy with Static PIM Prediction Methods

6. Discussion and Analysis

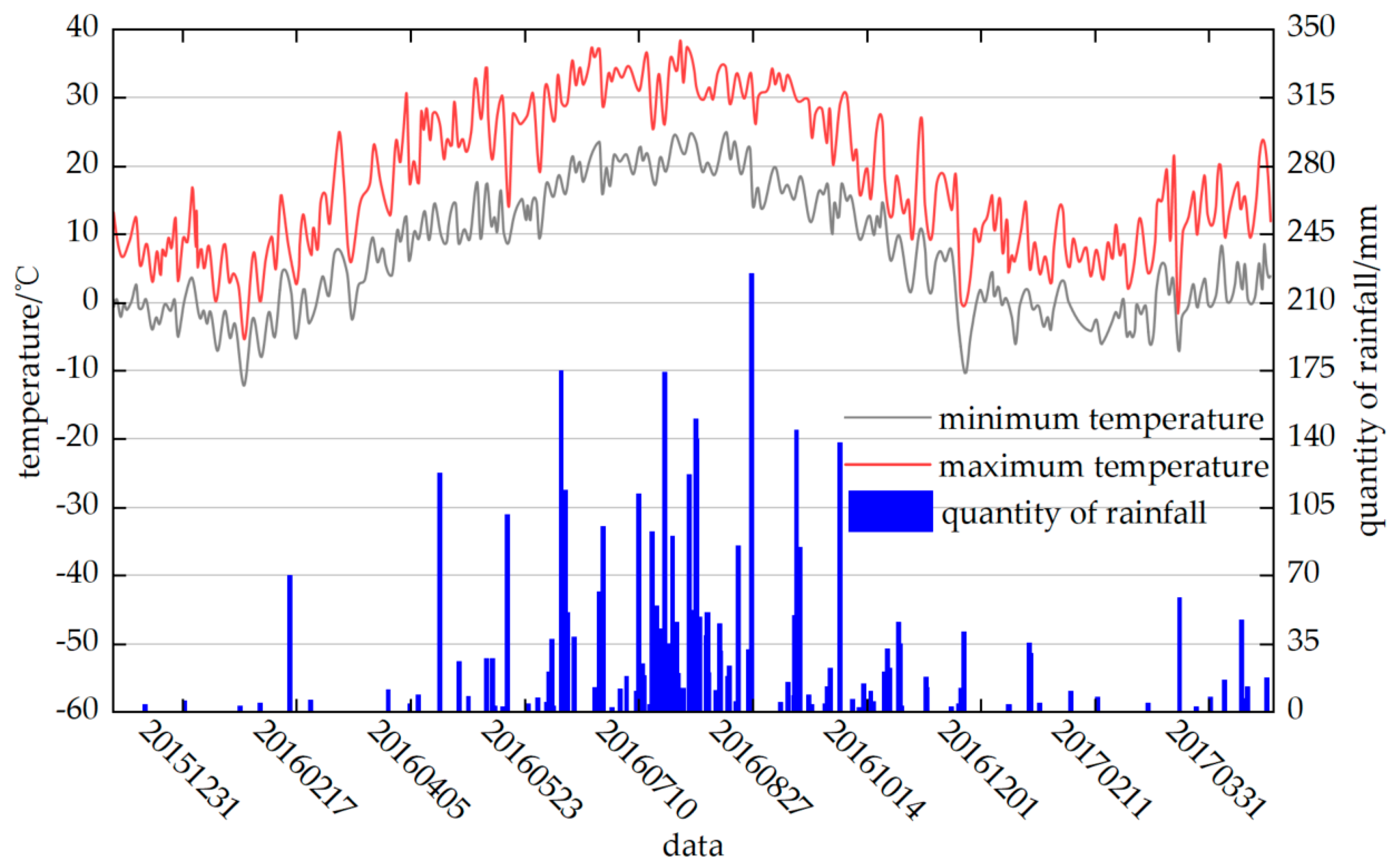

6.1. Analysis of the Causes of Deformation

- (1)

- Long-term coal mining activities in the Jiansheng coal mine area have formed obvious voids; due to the existence of these voids within the rock body, the overlying rock layer has deformed after being subjected to its own gravity and the role of the overlying rock layer. This deformation further affects the state of stress distribution in the surrounding rock mass [36]. When the mining activity reaches a certain level, the surface will show obvious signs of deformation, such as geological phenomena like collapses and cracks.

- (2)

- Considering that the Jiansheng coal mine is located on the southwest side of the Baisha Reservoir, and that the underground aquifers in the area of the Henan Jiansheng coal mine are relatively rich in water content, continuous coal mining activities have damaged the original geological stability, resulting in a gradual lowering of the groundwater level. As the groundwater level drops, the pressure on the rock and soil layers gradually increases. Particularly in the hydrophobic area, the increase in pressure has caused the overlying layers of rock and soil to subside, eventually triggering the phenomenon of land subsidence.

- (3)

- The study area is located at the northern end of the Qinling–Huaihe line in China, with a typical temperate monsoon climate. The climate is cold and dry in winter, and hot and rainy in summer. Especially during the hot and rainy season, the shallow aquifer is effectively recharged, which is the main reason for the small rise in the ground surface level between 2 October and 14 October 2016 [37].

- (4)

- During the annual Spring Festival, a large number of miners choose to return home due to the cold weather, resulting in a significant reduction in mining activity in the coal mines. The reduction in mining activity also effectively slows down the rate of deformation of the mine surface. This is also an important reason why the overall deformation of the mine surface remained relatively stable during the period from December 2015 to March 2016.

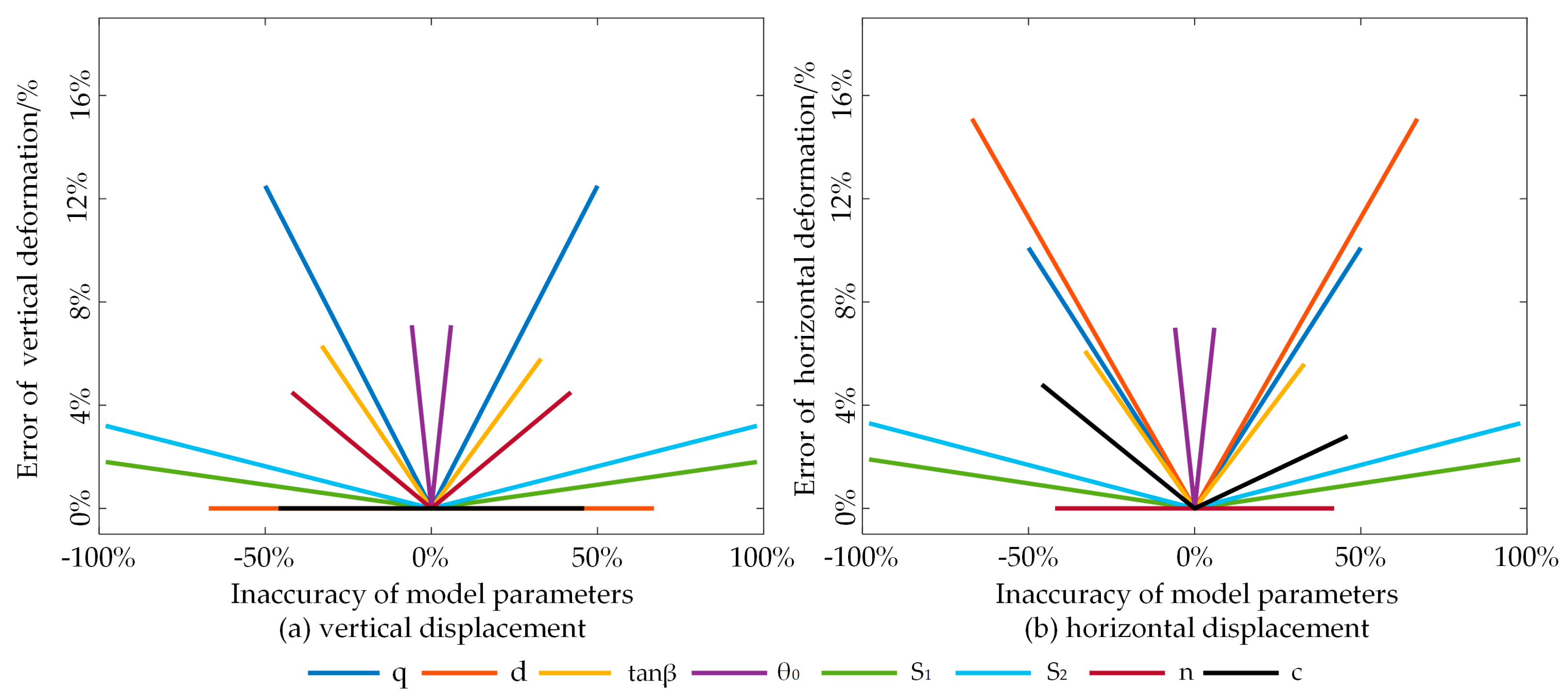

6.2. Sensitivity Analysis of Model Parameters

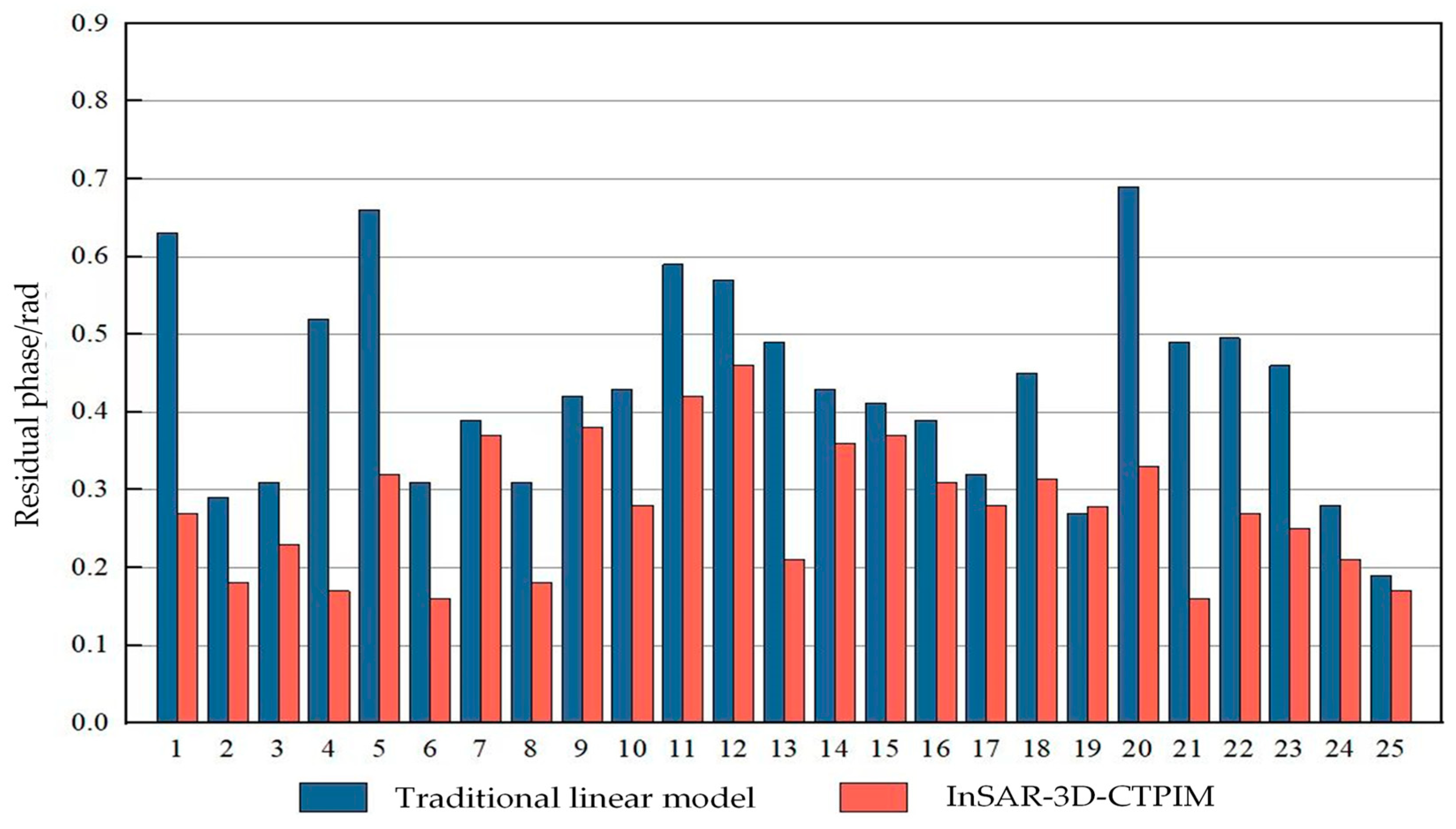

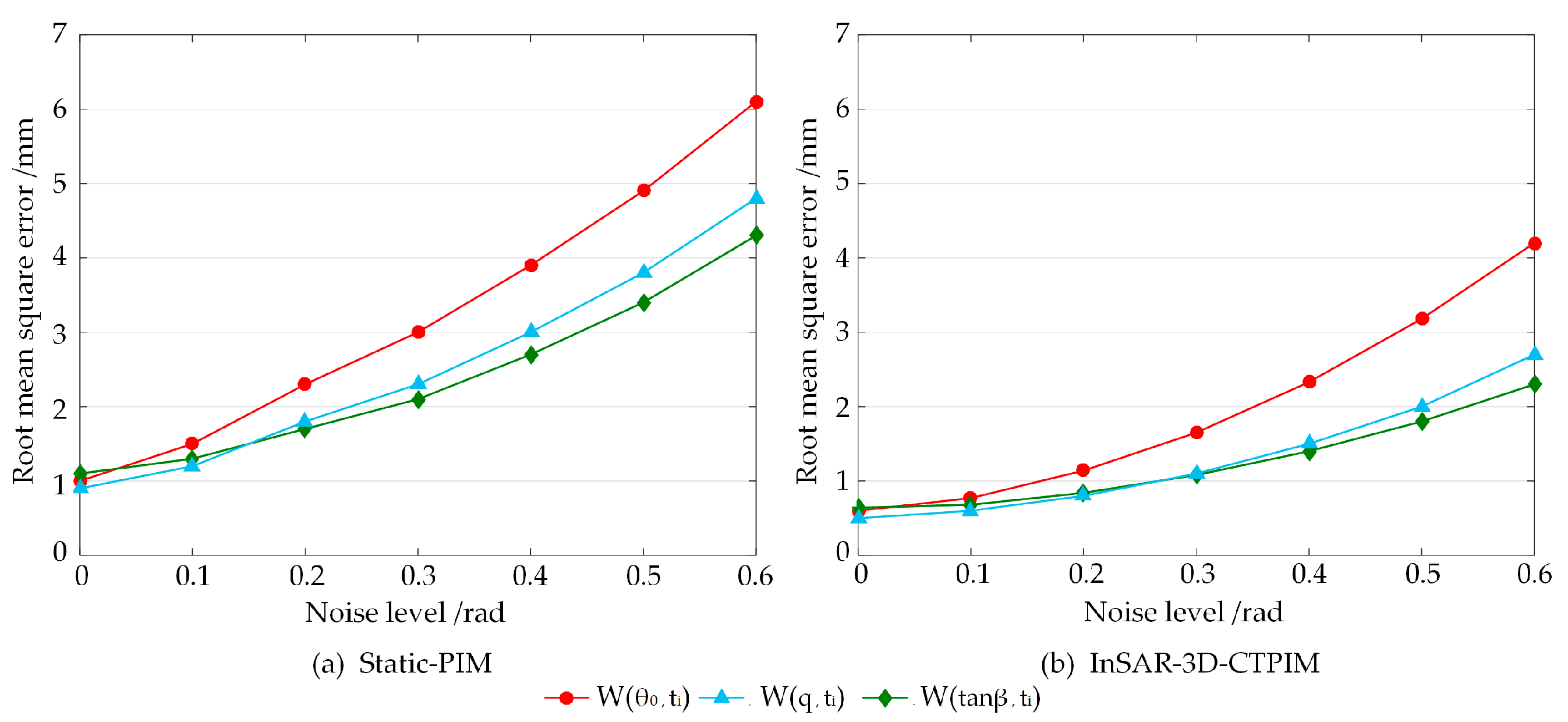

6.3. Effect of Phase Error on Deformation Prediction Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Natural Resources, PRC. China Mineral Resources Report; Geology Press: Beijing, China, 2023; pp. 2–6. [Google Scholar]

- Zhu, J.; Yang, Z.; Hu, J. Recent progress in retrieving and predicting mining induced 3D displacements using InSAR. Acta Geod. Cartogr. Sin. 2019, 48, 135–144. [Google Scholar] [CrossRef]

- Whittaker, B.; Reddish, D. Subsidence: Occurrence, Prediction and Control; Elsevier: Amsterdam, The Netherlands, 1989; pp. 51–82. [Google Scholar]

- Kratzsch, I. Mining subsidence engineering. Environ. Geol. Water Sci. 1986, 8, 133–136. [Google Scholar] [CrossRef]

- State Ministry of Coal Industry, PRC. Regulations on Coal Pillar Retention and Coal Pressure Mining in Buildings, Water Bodies, Railroads and Major Shafts; Coal Industry Press: Beijing, China, 2000; pp. 33–45. [Google Scholar]

- Li, Y.; Ren, Y.; Peng, S.S.; Cheng, H.; Wang, N.; Luo, J. Measurement of overburden failure zones in close-multiple coal seams mining. Int. J. Min. Sci. Technol. 2021, 31, 43–50. [Google Scholar] [CrossRef]

- Li, Z.; Xu, W.; Hu, J.; Feng, G.; Yang, Z.; Li, J.; Zhang, H.; Chen, Q.; Zhu, J.; Wang, Q.; et al. Partial geoscience parameters inversion from InSAR observation. Acta Geod. Cartogr. Sin. 2022, 51, 1458–1475. [Google Scholar]

- Chen, L.; Zhao, X. Recent advances of large gradient deformation monitoring in the mining area combined with InSAR. Bull. Surv. Mapp. 2018, 7, 18–23. [Google Scholar]

- Chen, R.; Wang, H.; Diao, X.; Zhang, B. Application of InSAR deformation monitoring in mining subsidence damage identification and stability evaluation. Bull. Surv. Mapp. 2023, 12, 106–111. [Google Scholar]

- Zhou, S.; Wang, H.; Shan, C.; Liu, H.; Li, Y.; Li, G.; Yang, F.; Kang, H.; Xie, G. Dynamic Monitoring and Analysis of Mining Land Subsidence in Multiple Coal Seams in the Ehuobulake Coal Mine Based on FLAC3D and SBAS-InSAR Technology. Appl. Sci. 2023, 13, 8804. [Google Scholar] [CrossRef]

- Li, D.; Deng, K.; Gao, X.; Niu, H. Monitoring and analysis of surface subsidence in mining area based on SBAS-InSAR. Geomat. Inf. Sci. Wuhan Univ. 2018, 43, 1531–1537. [Google Scholar]

- Schaefer, L.N.; Di Traglia, F.; Chaussard, E.; Lu, Z.; Nolesini, T.; Casagli, N. Monitoring volcano slope instability with synthetic aperture radar: A review and new data from Pacaya (Guatemala) and Stromboli (Italy) volcanoes. Earth-Sci. Rev. 2019, 192, 236–257. [Google Scholar] [CrossRef]

- He, P.; Wen, Y.; Xu, C.; Chen, Y. Complete Three-dimensional Near-field surface displacements from imaging geodesy techniques applied to the 2016 Kumamoto Earthquake. Remote Sens. Environ. 2019, 232, 111321. [Google Scholar] [CrossRef]

- Fan, H.D.; Cheng, D.; Deng, K.Z.; Chen, B.Q.; Zhu, C.G. Subsidence monitoring using D-InSAR and probability integral prediction modelling in deep mining areas. Surv. Rev. 2015, 47, 438–455. [Google Scholar] [CrossRef]

- Plattner, C.; Wdowinski, S.; Dixon, T.H.; Biggs, J. Surface subsidence induced by the Crandall Canyon Mine(Utah) collapse: InSAR observations and elasto-pastic modelling. Geophys. J. Int. 2010, 3, 1089–1096. [Google Scholar] [CrossRef]

- Zhang, T.; Xing, X.; Peng, W.; Zhu, J.; Liu, X.; Ge, J.; Lei, M. Time series InSAR deformation prediction for salt mining area based on coordinate-time function (CT-PIM)—A case study of Huaian Salt mine. Natl. Remote Sens. Bull. 2022, 1–16. [Google Scholar] [CrossRef]

- Zhu, G.; Shen, H.; Wang, L. Study of dynamic prediction function of surface movement and de-formation. Chin. J. Rock Mech. Eng. 2011, 30, 1889–1895. [Google Scholar]

- Yang, Z.F.; Li, Z.W.; Zhu, J.J.; Hu, J.; Wang, Y.J.; Chen, G.L. InSAR-based model parameter estimation of probability integral method and its application for predicting mining-induced horizontal and vertical displacements. IEEE Trans. Geosci. Remote Sens. 2016, 54, 4818–4832. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Z.; Zhu, J.; Preusse, A.; Hu, J.; Feng, G.; Wang, Y.; Papst, M. An InSAR-based temporal probability integral method and its application for predicting mining-induced dynamic deformations and assessing progressive damage to surface buildings. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 472–484. [Google Scholar] [CrossRef]

- Xing, X.; Zhu, Y.; Xu, W.; Peng, W.; Yuan, Z. Measuring subsidence over soft clay highways using a novel time-series InSAR deformation model with an emphasis on rheological properties and environmental factors (NREM). IEEE Trans. Geosci. Remote Sens. 2022, 60, 4601319. [Google Scholar] [CrossRef]

- Xing, X.; Zhang, T.; Chen, L.; Yang, Z.; Liu, X.; Peng, W.; Yuan, Z. InSAR modeling and deformation prediction for salt solution mining using a novel CT-PIM function. Remote Sens. 2022, 14, 842. [Google Scholar] [CrossRef]

- Berardino, P.; Fornaro, G.; Lanari, R.; Sansosti, E. A new algorithm for surface deformation monitoring based on small baseline differential SAR interferograms. IEEE Trans. Geosci. Remote Sens. 2002, 40, 2375–2383. [Google Scholar] [CrossRef]

- Furst, S.L.; Doucet, S.; Vernant, P.; Champollion, C.; Carme, J.-L. Monitoring surface deformation of deep salt mining in vauvert(france), combining InSAR and leveling data for multi-source inversion. Solid Earth. 2021, 12, 15–34. [Google Scholar] [CrossRef]

- Zheng, M.; Deng, K.; Fan, H.; Du, S. Monitoring and analysis of surface deformation in mining area based on InSAR and GRACE. Remote Sens. 2018, 10, 1392. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, Y.; Tan, K. Coal mining deformation monitoring using SBAS-InSAR and offset tracking: A case study of Yu County, China. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2020, 13, 6077–6087. [Google Scholar] [CrossRef]

- Fan, H. Monitoring and Solving Method of Synthetic Aperture Radar Interferometry for Surface Mining Subsidence in Mining Area. China Patent 103,091,676, 15 May 2013. [Google Scholar]

- Yang, Z.; Li, Z.; Zhu, J.; Yi, H.; Hu, J.; Feng, G. Deriving dynamic subsidence of coal mining areas using InSAR and logistic model. Remote Sens. 2017, 9, 125. [Google Scholar] [CrossRef]

- Liu, B.; Liao, G. Basic Law of Surface Movement of Coal Mine; Industry Press: Beijing, China, 1965; pp. 50–56. (In Chinese) [Google Scholar]

- Hooper, A.; Bekaert, D.; Spaans, K.; Arıkan, M. Recent advances in SAR interferometry time series analysis for measuring crustal deformation. Tectonophysics 2012, 514–517, 1–13. [Google Scholar] [CrossRef]

- Liu, X.; Xing, X.; Wen, D.; Chen, L.; Yuan, Z.; Liu, B.; Tan, J. Mining-induced time-series deformation investigation based on SBAS-InSAR technique: A case study of drilling water solution rock salt mine. Sensors 2019, 19, 5511–5527. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Yu, X.; Tan, H.; Xie, S.; Yang, X.; Han, Y. Prediction Parameters for Mining Subsidence Based on Interferometric Synthetic Aperture Radar and Unmanned Aerial Vehicle Collaborative Monitoring. Appl. Sci. 2023, 13, 11128. [Google Scholar] [CrossRef]

- Xiao, H.; Tan, G. Study on fusing simplex search into genetic algorithm. Comput. Eng. Appl. 2008, 44, 30–33. [Google Scholar]

- Xing, X.; Yang, D.; Liu, X.; Huang, L. Deformation monitoring using MT-InSAR for Baisha reservoir coal mine area in Henan Province. J. Chang. Univ. Sci. Technol. 2023, 20, 1–10. [Google Scholar]

- Zhao, R.; Li, Z.-W.; Feng, G.-C.; Wang, Q.-J.; Hu, J. Monitoring surface deformation over permafrost with an improved SBAS-InSAR algorithm: With emphasis on climatic factors modeling. Remote Sens. Environ. 2016, 184, 276–287. [Google Scholar] [CrossRef]

- Fomelis, M.; Papageorgiou, E.; Stamatopoulos, C. Episodic ground deformation signals in Thessaly Plain (Greece) revealed by data mining of SAR interferometry time series. Int. J. Remote Sens. 2016, 37, 3696–3711. [Google Scholar] [CrossRef]

- Pawluszek-filipak, K.; Borkowski, A. Integration of DInSAR and SBAS techniques to determine mining-related deformations using sentinel-1 data: The case study of rydultowy mine in Poland. Remote Sens. 2020, 12, 242. [Google Scholar] [CrossRef]

- Xu, F.; Hu, H.; Lin, H.; Xie, L. Bedding Slope Destabilization under Rainfall: A Case Study of Zhuquedong Slope in Hunan Province, China. Appl. Sci. 2024, 14, 1394. [Google Scholar] [CrossRef]

| Parameters | Range of Values |

|---|---|

| q | 0–1 |

| d | 0.1–0.5 |

| tanβ | 1–3.8 |

| θ0 | 80–90 |

| S1 (m) | 5–30 |

| S2 (m) | 5–30 |

| n | 1/7–1/2 |

| c | 6–17 |

| Parameters | Analog Value | Real Value | Inaccuracies | Relative Error |

|---|---|---|---|---|

| q | 0.711 | 0.722 | 0.011 | 1.5% |

| d | 0.326 | 0.335 | 0.009 | 0.9% |

| tanβ | 1.251 | 1.239 | 0.012 | 2.7% |

| θ0 | 83.29 | 81.14 | 2.15 | 2.5% |

| S1(m) | 7.71 | 8.04 | 0.33 | 4.2% |

| S2(m) | 11.22 | 11.85 | 0.63 | 5.6% |

| n | 0.167 | 0.175 | 0.008 | 4.8% |

| c | 8.261 | 8.443 | 0.182 | 2.2% |

| Serial Number | Acquisition Time | Orbital Direction | Polarization Mode | Absolute Orbit |

|---|---|---|---|---|

| 0 | 2015/11/13 | Ascending | VV | 8585 |

| 1 | 2015/12/07 | Ascending | VV | 8935 |

| 2 | 2015/12/31 | Ascending | VV | 9285 |

| 3 | 2016/02/17 | Ascending | VV | 9985 |

| 4 | 2016/03/12 | Ascending | VV | 10,335 |

| 5 | 2016/04/05 | Ascending | VV | 10,685 |

| 6 | 2016/04/29 | Ascending | VV | 11,035 |

| 7 | 2016/05/23 | Ascending | VV | 11,385 |

| 8 | 2016/10/02 | Ascending | VV | 13,310 |

| 9 | 2016/10/14 | Ascending | VV | 13,485 |

| 10 | 2016/10/26 | Ascending | VV | 13,660 |

| 11 | 2016/11/07 | Ascending | VV | 13,835 |

| 12 | 2016/11/19 | Ascending | VV | 14,010 |

| 13 | 2016/12/01 | Ascending | VV | 14,185 |

| 14 | 2017/01/18 | Ascending | VV | 14,885 |

| 15 | 2017/02/23 | Ascending | VV | 15,410 |

| 16 | 2017/03/07 | Ascending | VV | 15,585 |

| Parameters | Parameter Analog Values (UP 1) | Tolerance Range (UP 2) | Parametric Uncertainty |

|---|---|---|---|

| q | 0.5 | 0.25~0.75 | −50~50% |

| d | 0.3 | 0.1~0.5 | −67~67% |

| tanβ | 1.5 | 1~2 | −33~33% |

| θ0 | 85 | 80~90 | −5.9~5.9% |

| S1 | 20 | 0~40 | −100~100% |

| S2 | 20 | 0~40 | −100~100% |

| n | 0.35 | 0.2~0.5 | −42~42% |

| c | 11.5 | 6~17 | −46~46% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, M.; Zhang, T.; Shi, J.; Yu, J. InSAR-CTPIM-Based 3D Deformation Prediction in Coal Mining Areas of the Baisha Reservoir, China. Appl. Sci. 2024, 14, 5199. https://doi.org/10.3390/app14125199

Lei M, Zhang T, Shi J, Yu J. InSAR-CTPIM-Based 3D Deformation Prediction in Coal Mining Areas of the Baisha Reservoir, China. Applied Sciences. 2024; 14(12):5199. https://doi.org/10.3390/app14125199

Chicago/Turabian StyleLei, Minchao, Tengfei Zhang, Jiancun Shi, and Jing Yu. 2024. "InSAR-CTPIM-Based 3D Deformation Prediction in Coal Mining Areas of the Baisha Reservoir, China" Applied Sciences 14, no. 12: 5199. https://doi.org/10.3390/app14125199