Intelligent Identification of Liquid Aluminum Leakage in Deep Well Casting Production Based on Image Segmentation

Abstract

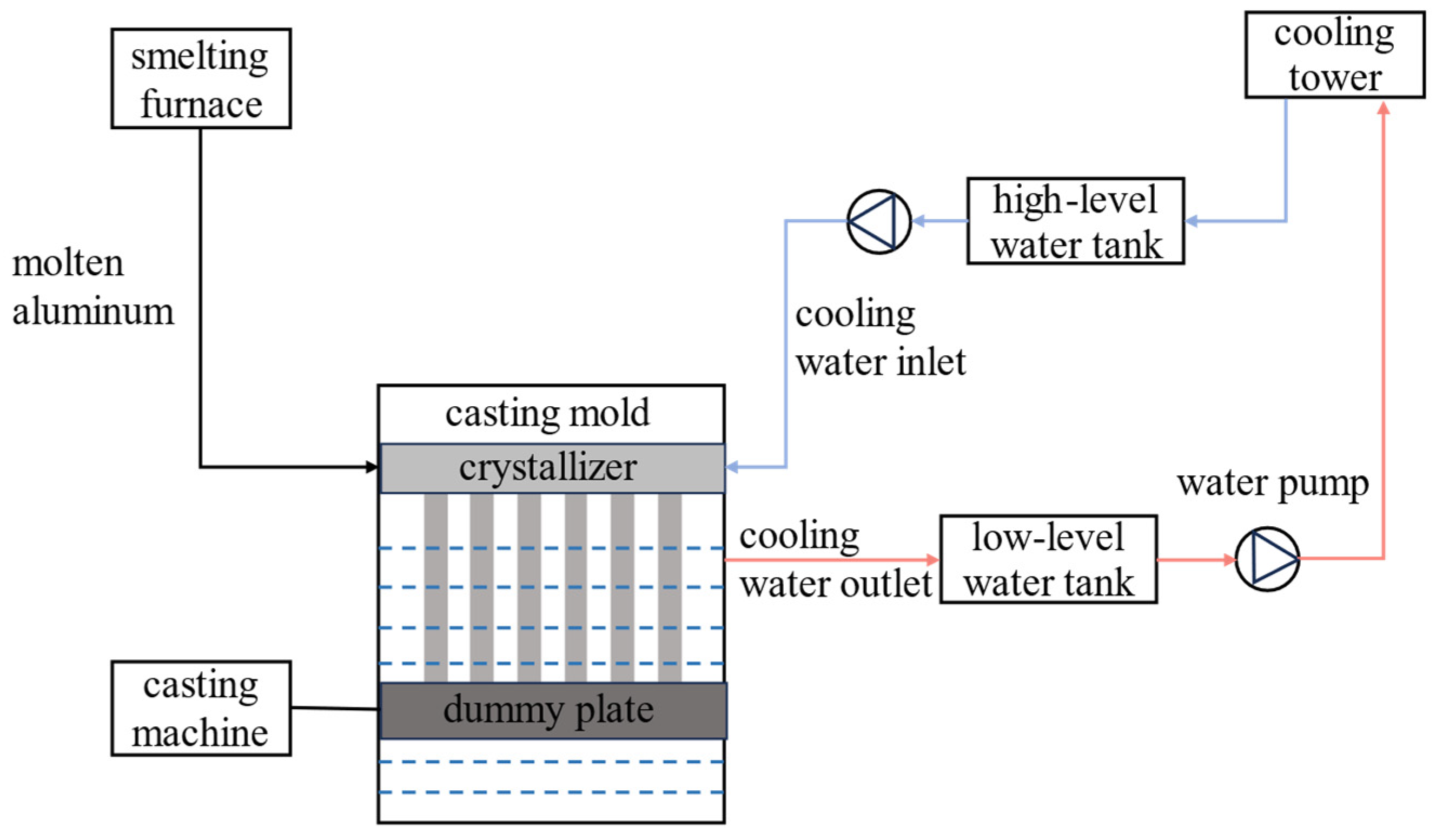

1. Introduction

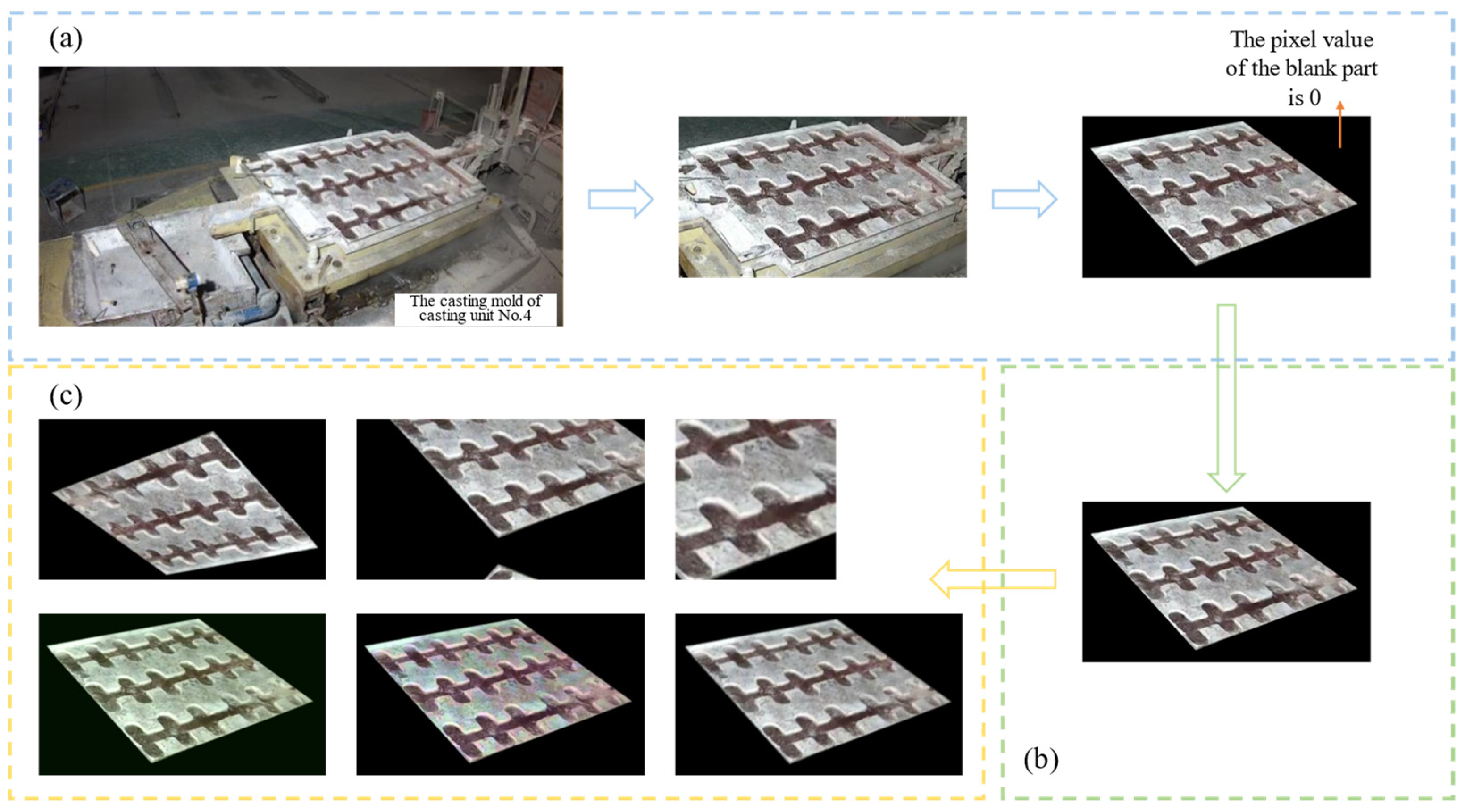

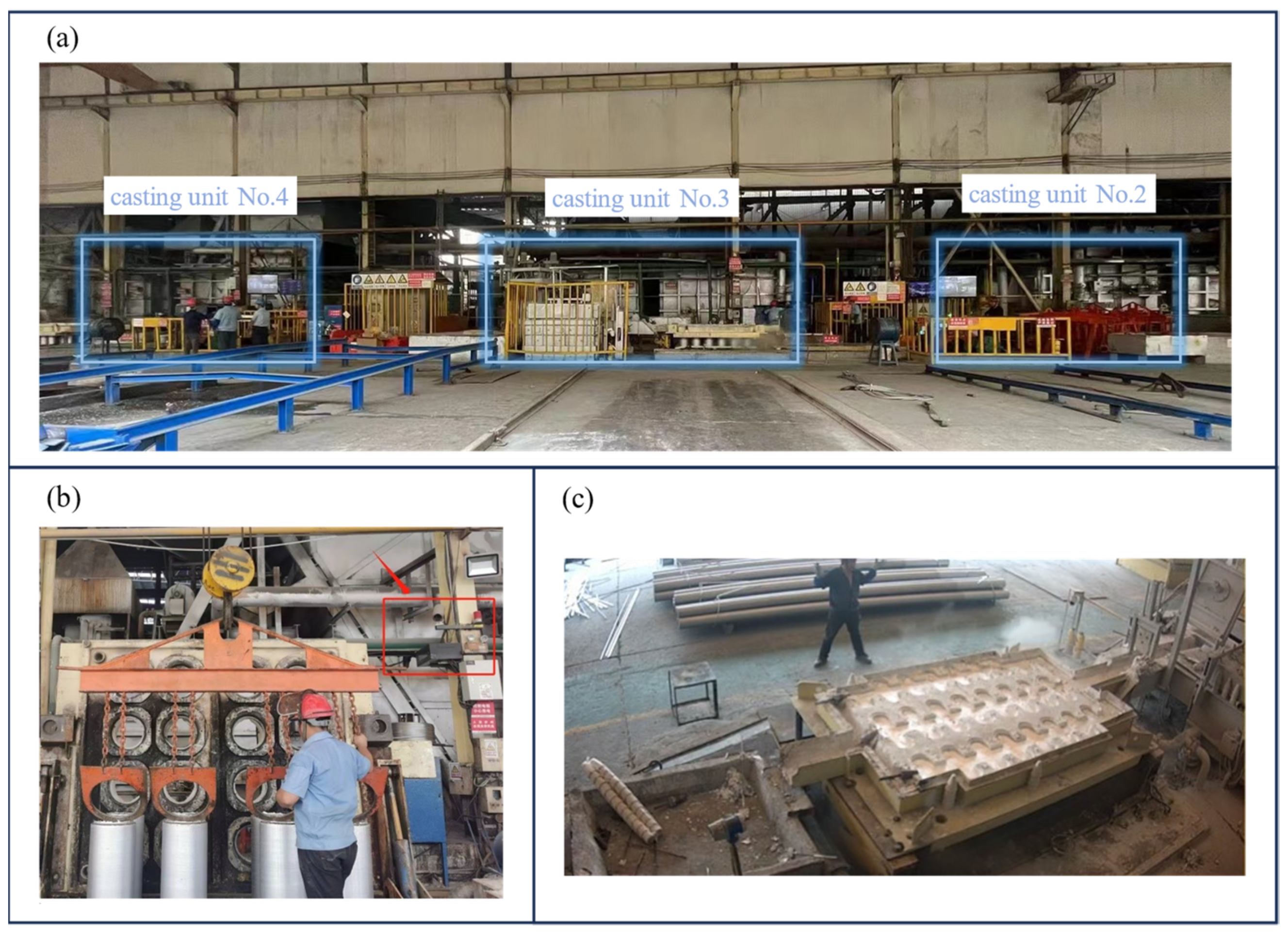

- This project specifically targets an aluminum facility in South China to address the challenges of limited datasets of casting mold liquid surface images and the expensive nature of manual annotation. A collection of casting mold photos from different time periods and casting units is gathered. Several data preparation activities are performed to create the casting mold liquid surface image dataset, such as region extraction, image annotation, and data augmentation.

- The method aims to overcome the challenges of lengthy training time, high data demands, and inadequate learning of casting mold liquid surface features in traditional DeepLabV3+ models. To enhance the model, this study replaces the original feature extraction network with ResNet-50 and integrates CBAM attention mechanisms and transfer learning methods.

- In order to address the intricacy of identifying comprehensive liquid aluminum leakage, a solution is suggested that involves calculating the surface area of the casting mold liquid using OpenCV. In addition, it establishes a measurement for variations in the liquid surface area of the casting mold and calculates an abnormal threshold using the IQR approach. Ultimately, the strategy is verified by employing production data.

2. Methods

2.1. Overall Algorithm Design

2.2. Pre-Processing

- (1)

- Region Extraction

- (2)

- Gaussian Filtering

- (3)

- Data Augmentation

2.3. Improved DeepLabV3+ Casting Mold Liquid Surface Segmentation Model

2.3.1. Improved DeepLabV3+ Model Structure

2.3.2. ResNet-50 Backbone Network

2.3.3. CBAM Attention Mechanism

2.4. Casting Mold Liquid Surface Area Change Threshold Calculation Method

2.4.1. Casting Mold Liquid Surface Area Calculation Based on OpenCV

| Algorithm 1. OpenCV implements casting mold liquid surface area calculation steps. |

| Input: Capture the surveillance video image at the current time T at a frame rate of 1 frame/s; |

| Output: Image casting mold liquid surface area ST at current time T; |

| Process: |

| (1) Pass the surveillance video liquid surface image at the current time T into the configured DeepLabV3+ network for prediction: pr = self.net(images)[0]; |

| (2) Since the input model training and prediction image size is [512, 512], adjust the predicted image to the original size: R pr = cv2.resize(pr, (original_w, original_h), interpolation = cv2.INTER_LINEAR); |

| (3) Obtain the type of each pixel: pr = pr.argmax(axis = −1); (4) Open the text file named current_area and write the real-time casting mold liquid surface area in appended format: With open (file_path, ‘a’) as file: file.write(f’{str(np.sum(pr = = 1))}/n’); |

2.4.2. Casting Mold Liquid Surface Area Change Threshold

2.5. Experimental Design

2.5.1. Experimental Environment and Training Parameter

2.5.2. Evaluation Index

3. Case Study

3.1. Study Object and Data Collection

3.2. Casting Mold Liquid Surface Segmentation Experiment and Result Analysis

3.2.1. Casting Mold Liquid Surface Segmentation Dataset Description

3.2.2. Training Strategy

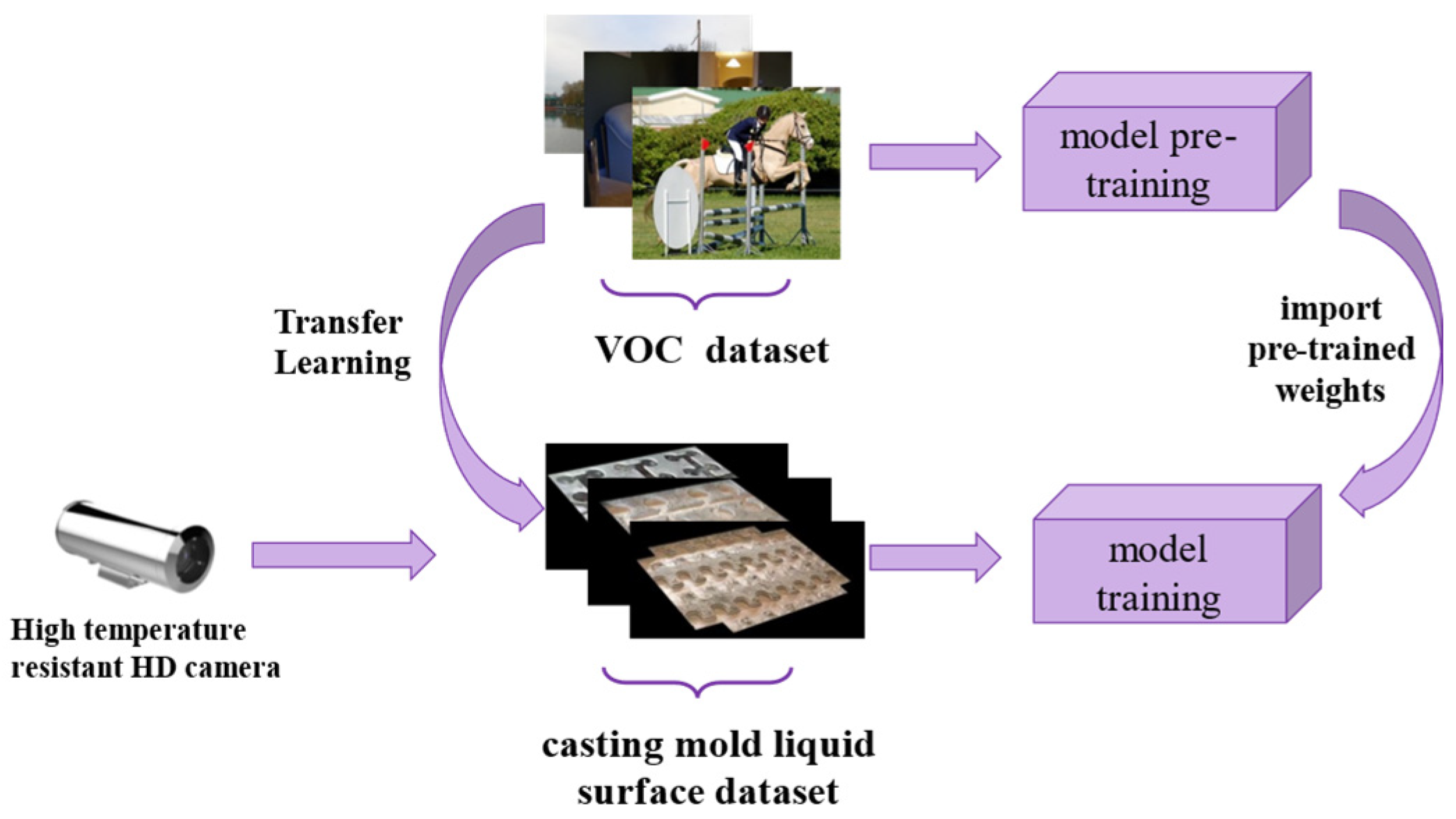

- Model pre-training: This paper adopts a transfer learning strategy for feature extraction, as illustrated in Figure 10. The model undergoes pretraining on the VOC dataset to create pretraining files in .pth format, after which the pre-trained weights are loaded into the model.

- Model training: The imported pre-trained model weights are used as input for retraining with the casting mold liquid surface dataset. The training process continues until the model reaches convergence.

3.2.3. Ablation Experiment

3.2.4. Comparative Experiment

3.3. Casting Mold Liquid Surface Area Change Threshold Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.; Zhang, L.; Chen, Z.; Gao, Y.; Xu, Z. Dynamic material flow analysis of aluminum from automobiles in China during 2000–2050 for standardized recycling management. J. Clean. Prod. 2022, 337, 130544. [Google Scholar] [CrossRef]

- Echarri-Iribarren, V.; Echarri-Iribarren, F.; Rizo-Maestre, C. Ceramic panels versus aluminium in buildings: Energy consumption and environmental impact assessment with a new methodology. Appl. Energy 2019, 233–234, 959–974. [Google Scholar] [CrossRef]

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Sundararajan, M.; Devarajan, M.; Jaafar, M. Investigation of surface and mechanical properties of Anodic Aluminium Oxide (AAO) Developed on Al Substrate for an Electronic Package Enclosure. Surf. Coat. Technol. 2020, 401, 126273. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Katgerman, L.; Du, Q.; Zhang, J.; Zhuang, L. Recent advances in hot tearing during casting of aluminium Alloys. Prog. Mater. Sci. 2021, 117, 100741. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, H.; Chen, D.; Wang, D.; Lyu, Z.; Huang, F. Analysis of factors affacting steam explosion in semi-confined space. China Saf. Sci. J. 2018, 28, 52–57. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M. Research on Dynamic Evaluation and Grading Alarm Method of Safety Production Risks in Deep Well Casting of Aluminum Processing. Master’s Thesis, South China University of Technology, Guangzhou, China, 2023. (In Chinese). [Google Scholar]

- Li, X.; Yang, C.; Chen, B.; Zhou, N.; Liu, X.; Huang, W.; Zhao, H.; Rasouli, V. Experiment research on explosion process of high-temperature molten aluminum in contact with water. Heat Transf. Res. 2022, 53, 75–90. [Google Scholar] [CrossRef]

- Epstein, M.; Fauske, H.K.; Theofanous, T.G. On the mechanism of aluminum ignition in steam explosions. Nucl. Eng. Des. 2000, 201, 71–82. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, Z.; Hou, Y.; Gao, D.; Li, Z. Hazard identification & risk control in aluminum production. Process Saf. Environ. Prot. 2022, 165, 336–346. [Google Scholar] [CrossRef]

- Li, L.; Xu, K.; Yao, X.; Chen, S. Probabilistic analysis of aluminium production explosion accidents based on a fuzzy bayesian network. J. Loss Prev. Process Ind. 2021, 73, 104618. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, K.; Zhang, Q.; Xu, G.; Wang, W.; Huo, Y. Simulated leakage monitoring algorithm for high-temperature molten aluminum based on the infrared image feature fusion. J. Saf. Environ. 2020, 20, 518–523. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Zhang, Z.; Deng, F. Deep learning in image segmentation for mineral production: A review. Comput. Geosci. 2023, 180, 105455. [Google Scholar] [CrossRef]

- Yuan, X.; Shi, J.; Gu, L. A review of deep learning methods for semantic segmentation of remote sensing imagery. Expert Syst. Appl. 2021, 169, 114417. [Google Scholar] [CrossRef]

- Long, J.; Shelhamer, E.; Darrell, T. Fully convolutional networks for semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 3431–3440. [Google Scholar]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional networks for biomedical image segmentation. In Proceedings of the Medical Image Computing and Computer-Assisted Intervention-MICCAI 2015, Munich, Germany, 5–9 October 2015; Volume 9351, pp. 234–241. [Google Scholar]

- Zhao, H.; Shi, J.; Qi, X.; Wang, X.; Jia, J. Pyramid scene parsing network. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 6230–6239. [Google Scholar]

- Wu, J.; Liu, B.; Zhang, H.; He, S.; Yang, Q. Fault detection based on Fully Convolutional Networks (FCN). J. Mar. Sci. Eng. 2021, 9, 259. [Google Scholar] [CrossRef]

- Almalki, S.A.; Alsubai, S.; Alqahtani, A.; Alenazi, A.A. Denoised encoder-based residual U-Net for precise teeth image segmentation and damage prediction on panoramic radiographs. J. Dent. 2023, 137, 104651. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Y.; Wang, S.; Cheng, G.; Wang, X.; He, L. Rapid detection of incomplete coal and gangue based on improved PSPNet. Measurement 2022, 201, 111646. [Google Scholar] [CrossRef]

- Chen, L.-C.; Papandreou, G.; Kokkinos, I.; Murphy, K.; Yuille, A.L. Semantic image segmentation with deep convolutional nets and fully connected CRFs. In Proceedings of the International Conference on Learning Representations (ICLR), San Diego, CA, USA, 7–9 May 2015; pp. 21:1–21:14. [Google Scholar]

- Chen, L.-C.; Papandreou, G.; Kokkinos, I.; Murphy, K.; Yuille, A.L. DeepLab: Semantic image segmentation with deep convolutional nets, atrous convolution, and fully connected CRFs. IEEE Trans. Pattern Anal. Mach. Intell. 2018, 40, 834–848. [Google Scholar] [CrossRef]

- Chen, L.-C.; Papandreou, G.; Schroff, F.; Adam, H. Rethinking atrous convolution for semantic image segmentation. arXiv 2017, arXiv:1706.05587. [Google Scholar]

- Chen, L.-C.; Zhu, Y.; Papandreou, G.; Schroff, F.; Adam, H. Encoder-decoder with atrous separable convolution for semantic image segmentation. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; Volume 11211, pp. 833–851. [Google Scholar]

- Gangrade, S.; Sharma, P.C.; Sharma, A.K.; Singh, Y.P. Modified DeeplabV3+ with multi-level context attention mechanism for colonoscopy polyp segmentation. Comput. Biol. Med. 2024, 170, 108096. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, K.; Hu, X.; Lu, Y. Crop type recognition of VGI road-side images via hierarchy structure based on semantic segmentation model Deeplabv3+. Displays 2024, 81, 102574. [Google Scholar] [CrossRef]

- Wang, X.; Wang, T.; Li, J. Advanced crack detection and quantification strategy based on CLAHE enhanced DeepLabv3+. Eng. Appl. Artif. Intell. 2023, 126, 106880. [Google Scholar] [CrossRef]

- Zeng, L.; Zhang, S.; Wang, P.; Li, Z.; Hu, Y.; Xie, T. Defect detection algorithm for magnetic particle inspection of aviation ferromagnetic parts based on improved DeepLabv3+. Meas. Sci. Technol. 2023, 34, 065401. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, R.; Gao, F.; Wang, W.; Fu, L.; Li, R. Segmentation of abnormal leaves of hydroponic lettuce based on DeepLabV3+ for robotic sorting. Comput. Electron. Agric. 2021, 190, 106443. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Y.; Hu, K.; Jia, X.; Gang, C. A detection method for densely distributed coal and gangue with uneven particle based on DeepLabV3+. Measurement 2024, 235, 114756. [Google Scholar] [CrossRef]

- Buslaev, A.; Iglovikov, V.I.; Khvedchenya, E.; Parinov, A.; Druzhinin, M.; Kalinin, A.A. Albumentations: Fast and flexible image augmentations. Information 2020, 11, 125. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; IEEE: Las Vegas, NV, USA, 2016; pp. 770–778. [Google Scholar]

- Woo, S.; Park, J.; Lee, J.-Y.; Kweon, I.S. CBAM: Convolutional block attention module. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; Volume 11211, pp. 3–19. [Google Scholar]

- Wang, W.; Zhou, T.; Yu, F.; Dai, J.; Konukoglu, E.; Gool, L.V. Exploring cross-image pixel contrast for semantic segmentation. In Proceedings of the 2021 IEEE/CVF International Conference on Computer Vision (ICCV), Montreal, BC, Canada, 11–17 October 2021; pp. 7283–7293. [Google Scholar]

| Parameters | Settings |

|---|---|

| batch_size | 4 |

| Learning rate | 7 × 10−3 |

| Epoch | 80 |

| Optimizer | SGD (Stochastic Gradient Descent) |

| Momentum | 0.9 |

| Loss function | CE Loss |

| Input shape | [512, 512] |

| Dataset Serial Number | Casting Date | Recording Duration | Whether Liquid Aluminum Leakage Occurs |

|---|---|---|---|

| 1 | 11 March 2023 | 1 min 20 s | Yes |

| 2 | 16 March 2023 | 50 s | No |

| 3 | 21 March 2023 | 50 s | Yes |

| 4 | 7 April 2023 | 56 s | Yes |

| 5 | 13 April 2023 | 48 s | Yes |

| 6 | 15 April 2023 | 2 min 10 s | Yes |

| 7 | 18 April 2023 | 53 s | No |

| 8 | 20 May 2023 | 1 min 43 s | Yes |

| 9 | 28 May 2023 | 2 min 15 s | Yes |

| 10 | 5 June 2023 | 58 s | No |

| 11 | 20 July 2023 | 1 min 12 s | No |

| Network Models | MIoU/% | Liquid-IoU/% | MPA/% |

|---|---|---|---|

| DeeplabV3+ (ResNet50) | 90.4 | 84.7 | 95.85 |

| DeeplabV3+ (ResNet-50+CBAM) | 91.0 | 85.55 | 96 |

| DeeplabV3+ (ResNet-50+CBAM+transfer learning) | 91.88 | 86.97 | 96.53 |

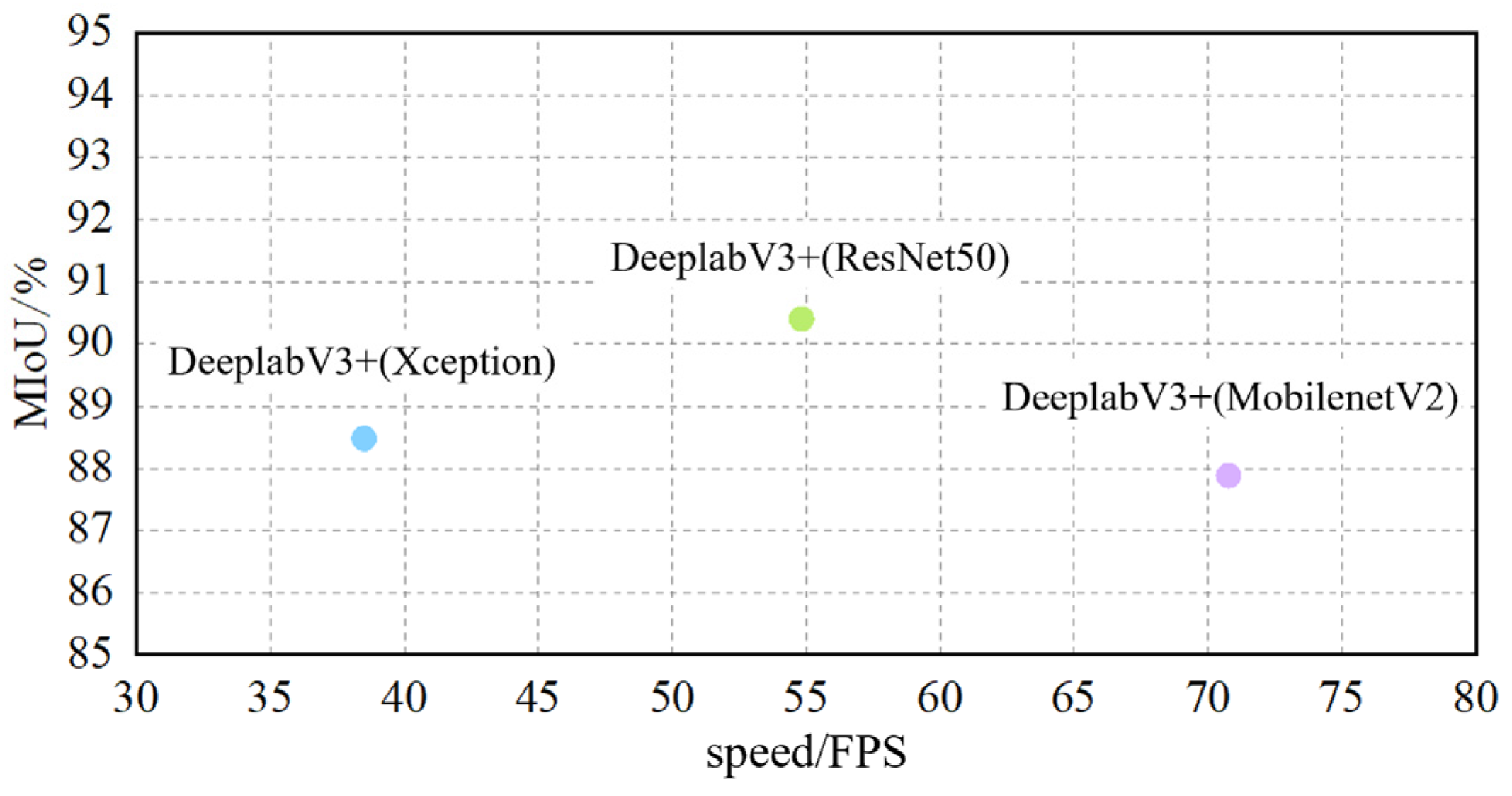

| Network Models | Accuracy/% | Speed/FPS | ||

|---|---|---|---|---|

| MIoU | MPA | Liquid-IoU | ||

| DeeplabV3+ | 88.48 | 95.71 | 81.73 | 37.84 |

| UNet | 90.37 | 94.81 | 84.76 | 24.64 |

| PSPNet | 84.96 | 92.11 | 76.03 | 34.66 |

| Ours | 91.88 | 96.53 | 86.97 | 55.05 |

| Index | Results |

|---|---|

| Accuracy | 95.5% |

| FAR | 8.3% |

| MAR | 12.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Li, X.; Zhou, X. Intelligent Identification of Liquid Aluminum Leakage in Deep Well Casting Production Based on Image Segmentation. Appl. Sci. 2024, 14, 5470. https://doi.org/10.3390/app14135470

Yan J, Li X, Zhou X. Intelligent Identification of Liquid Aluminum Leakage in Deep Well Casting Production Based on Image Segmentation. Applied Sciences. 2024; 14(13):5470. https://doi.org/10.3390/app14135470

Chicago/Turabian StyleYan, Junwei, Xin Li, and Xuan Zhou. 2024. "Intelligent Identification of Liquid Aluminum Leakage in Deep Well Casting Production Based on Image Segmentation" Applied Sciences 14, no. 13: 5470. https://doi.org/10.3390/app14135470

APA StyleYan, J., Li, X., & Zhou, X. (2024). Intelligent Identification of Liquid Aluminum Leakage in Deep Well Casting Production Based on Image Segmentation. Applied Sciences, 14(13), 5470. https://doi.org/10.3390/app14135470