Evaluating the Energy Efficiency of Combining Heat Pumps and Photovoltaic Panels in Eco-Friendly Housing

Abstract

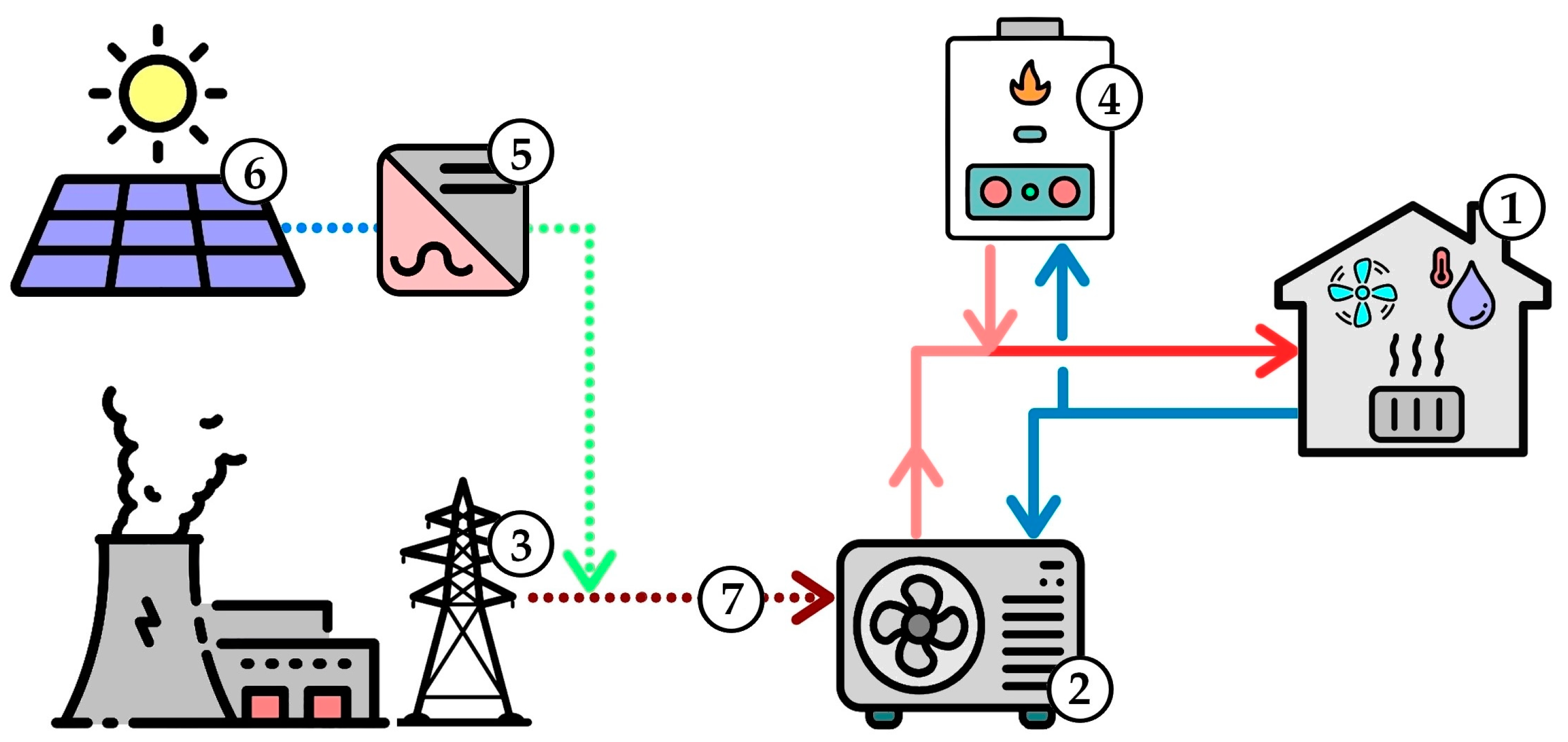

:1. Introduction

2. Review of the Literature

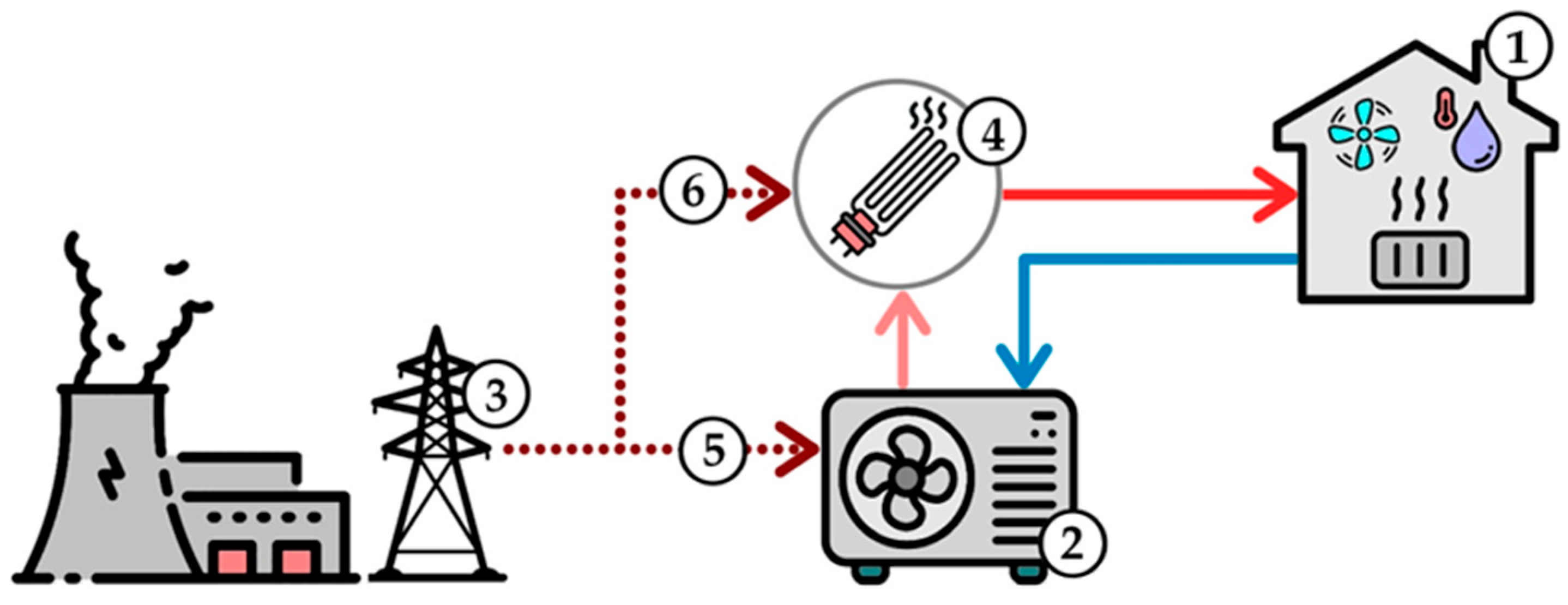

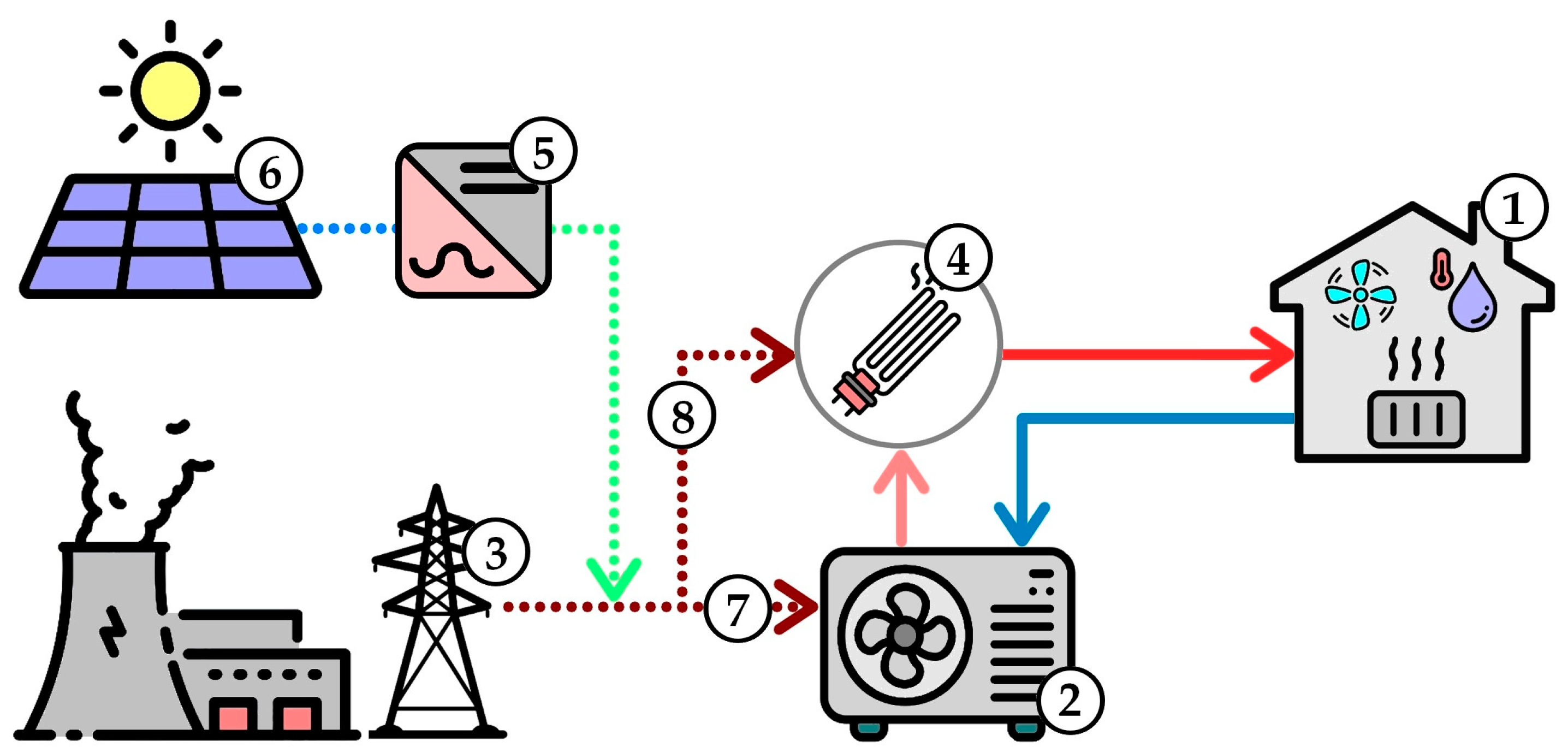

3. Materials and Methods

4. Results

4.1. Heat Demand

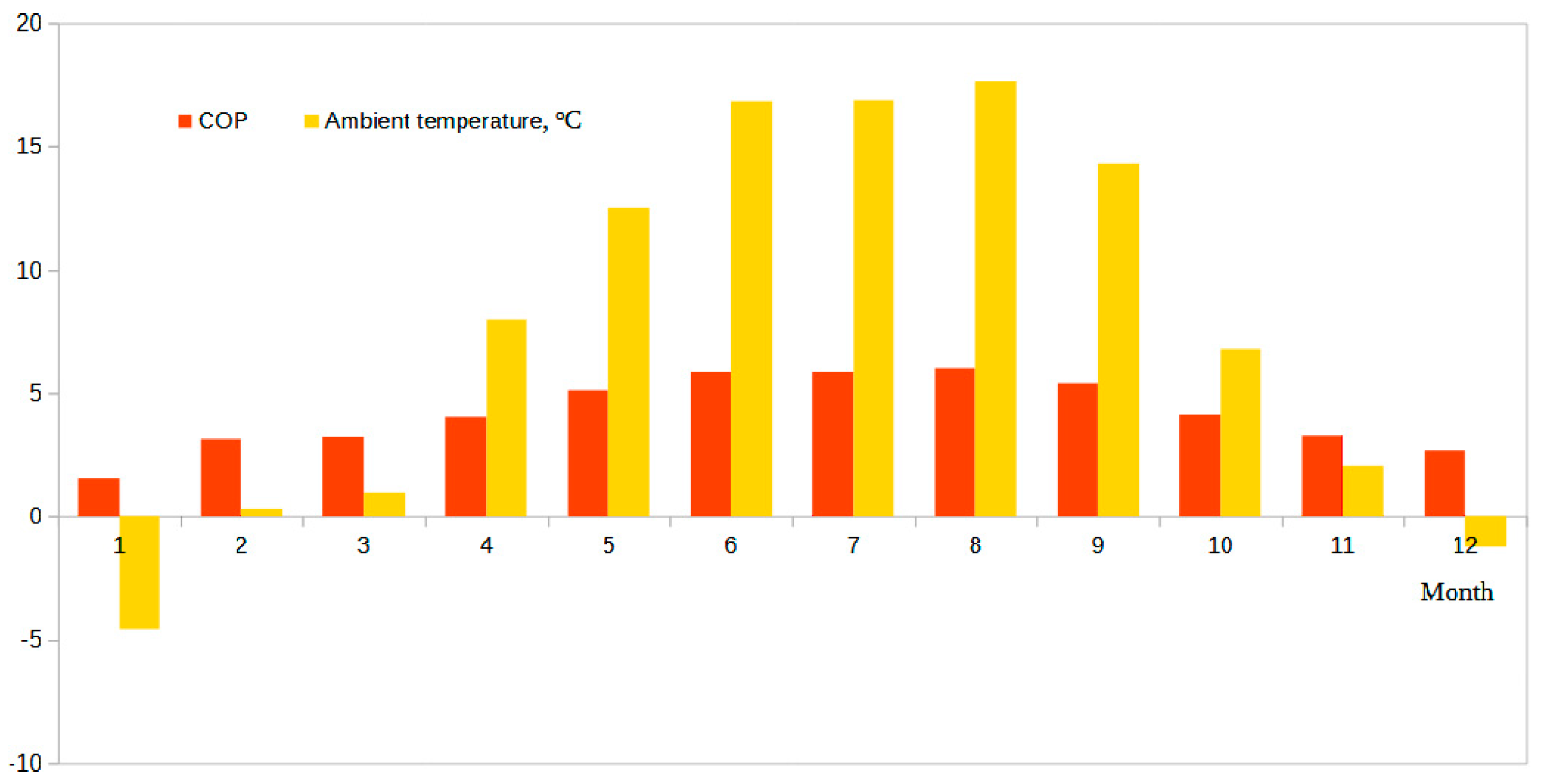

4.2. Coefficient of Performance (COP)

4.3. Cost Analysis

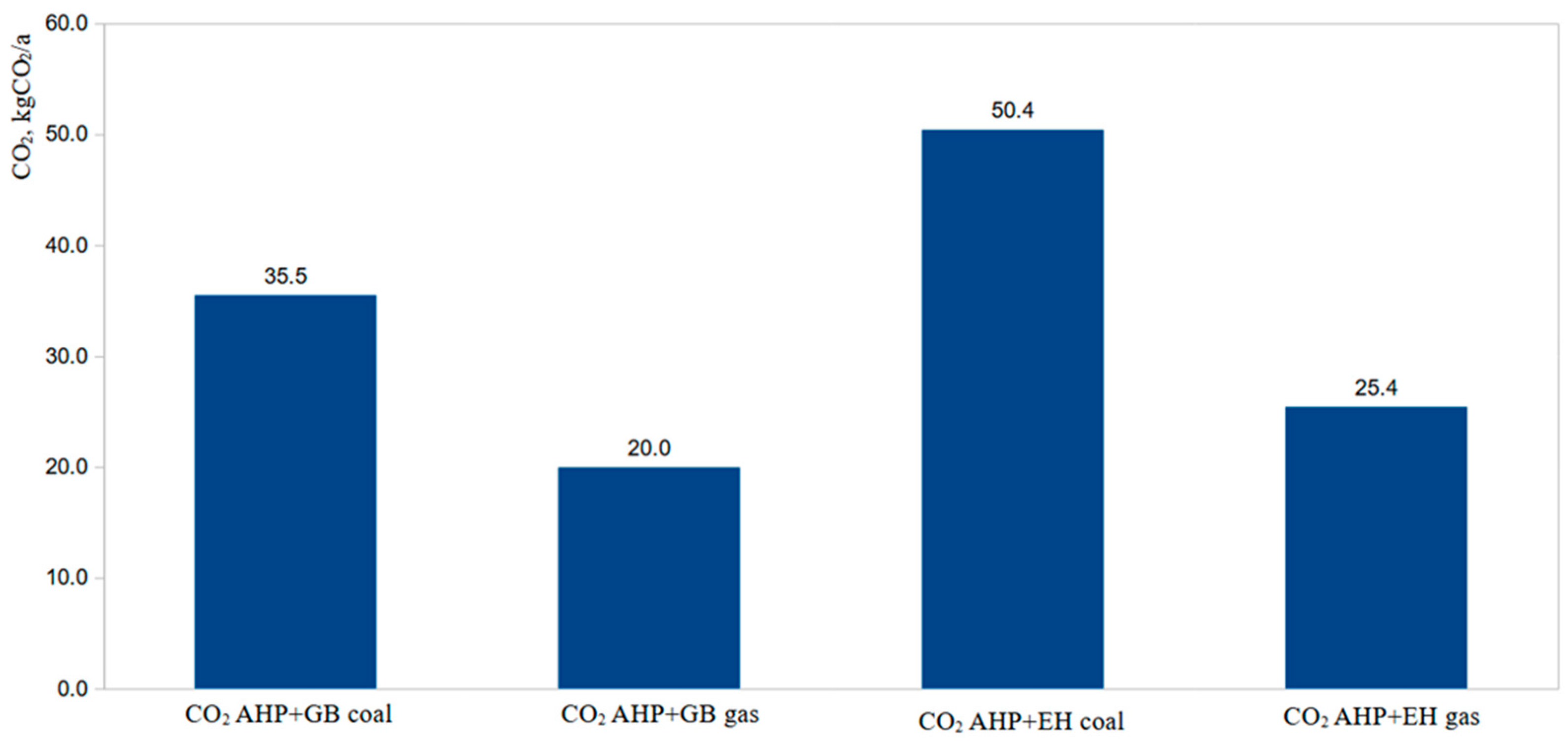

4.4. CO2 Emissions

4.5. System with PV Panels

5. Conclusions

- Financial aspects:

- The gas boiler solution is cheaper to operate;

- PV panel investment return in 6–7 years;

- Electric heater (EH) installation has no annual gas fuel fee;

- EH installation saves nearly €3000 more over a 15-year lifespan.

- Ecological aspects:

- Gas boiler installation reduces CO2 emissions by 21.5–29.6% without PV panels;

- PV panels reduce CO2 emissions by 88.3% (coal-fired power) and 79.1% (natural gas-fired power) for AHP + EH.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | constant of the equation (-) |

| AHP | air source heat pump |

| B | constant of the equation (-) |

| COP | coefficient of performance (-) |

| MVS | mechanical ventilation system |

| DWS | domestic hot water system |

| CHS | central heating system |

| EH | electric heater |

| EHM | electric power for the electric heater (kWh/month) |

| EHP | percentage of electricity demand covered by the electric heater (%) |

| GB | gas boiler |

| GBM | costs of gas fuel (Euro/month) |

| NAHP | electric power for the air heat pump (kWh/month) |

| NAHPM | costs of electricity for the heat pump (Euro/month) |

| PV | photovoltaic system |

| Qannual | annual costs for heat demand (kWh/a) |

| QDHS | heat demand for district heating system (kWh/month) |

| QDWS | heat demand for district water system (kWh/month) |

| QDVS | heat demand for ventilation system (kWh/month) |

| Qtotal | total annual heat demand (kWh/month) |

| SCOP | seasonal coefficient of performance for heating (-) |

| Tz | value of the external temperature (°C) |

References

- Jåstad, E.O.; Bolkesjø, T.F.; Trømborg, E.; Rørstad, P.K. The Role of Woody Biomass for Reduction of Fossil GHG Emissions in the Future North European Energy Sector. Appl. Energy 2020, 274, 115360. [Google Scholar] [CrossRef]

- Alobaid, F.; Busch, J.-P.; Stroh, A.; Ströhle, J.; Epple, B. Experimental Measurements for Torrefied Biomass Co-Combustion in a 1 MWth Pulverized Coal-Fired Furnace. J. Energy Inst. 2020, 93, 833–846. [Google Scholar] [CrossRef]

- Garcia-Fernandez, B.; Omar, O. Sustainable Performance in Public Buildings Supported by Daylighting Technology. Sol. Energy 2023, 264, 112068. [Google Scholar] [CrossRef]

- El Sayary, S.; Omar, O. Designing a BIM Energy-Consumption Template to Calculate and Achieve a Net-Zero-Energy House. Sol. Energy 2021, 216, 315–320. [Google Scholar] [CrossRef]

- Rabelo, S.N.; Paulino, T.F.; Machado, L.; Duarte, W.M. Economic Analysis and Design Optimization of a Direct Expansion Solar Assisted Heat Pump. Sol. Energy 2019, 188, 164–174. [Google Scholar] [CrossRef]

- Rabczak, S.; Nowak, K. Evaluating the Efficiency of Surface-Based Air Heating Systems. Energies 2024, 17, 1252. [Google Scholar] [CrossRef]

- Péan, T.; Costa-Castelló, R.; Fuentes, E.; Salom, J. Experimental Testing of Variable Speed Heat Pump Control Strategies for Enhancing Energy Flexibility in Buildings. IEEE Access 2019, 7, 37071–37087. [Google Scholar] [CrossRef]

- Peña Asensio, A.; Arnaltes Gómez, S.; Rodriguez-Amenedo, J.L. Black-Start Capability of PV Power Plants through a Grid-Forming Control Based on Reactive Power Synchronization. Int. J. Electr. Power Energy Syst. 2023, 146, 108730. [Google Scholar] [CrossRef]

- Long, J.; Xia, K.; Zhong, H.; Lu, H.; Yongga, A. Study on Energy-Saving Operation of a Combined Heating System of Solar Hot Water and Air Source Heat Pump. Energy Convers. Manag. 2021, 229, 113624. [Google Scholar] [CrossRef]

- Dolgun, G.K.; Güler, O.V.; Georgiev, A.G.; Keçebaş, A. Experimental Investigation of a Concentrating Bifacial Photovoltaic/Thermal Heat Pump System with a Triangular Trough. Energies 2023, 16, 649. [Google Scholar] [CrossRef]

- Kut, P.; Pietrucha-Urbanik, K. Most Searched Topics in the Scientific Literature on Failures in Photovoltaic Installations. Energies 2022, 15, 8108. [Google Scholar] [CrossRef]

- Licharz, H.; Rösmann, P.; Krommweh, M.S.; Mostafa, E.; Büscher, W. Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies 2020, 13, 662. [Google Scholar] [CrossRef]

- Pearce, J.M.; Sommerfeldt, N. Economics of Grid-Tied Solar Photovoltaic Systems Coupled to Heat Pumps: The Case of Northern Climates of the U.S. and Canada. Energies 2021, 14, 834. [Google Scholar] [CrossRef]

- Pater, S. Increasing Energy Self-Consumption in Residential Photovoltaic Systems with Heat Pumps in Poland. Energies 2023, 16, 4003. [Google Scholar] [CrossRef]

- Ghasemipour, S.; Sameti, M.; Sharma, M.K. Annual Comparative Performance of Direct Expansion Solar-Assisted and Air-Source Heat Pumps for Residential Water Heating. Int. J. Thermofluids 2024, 22, 100651. [Google Scholar] [CrossRef]

- Sameti, M.; Syron, E. 100% Renewable Industrial Decarbonization: Optimal Integration of Solar Heat and Photovoltaics. Smart Energy 2022, 8, 100087. [Google Scholar] [CrossRef]

- Verma, V.; Meena, C.S.; Thangavel, S.; Kumar, A.; Choudhary, T.; Dwivedi, G. Ground and Solar Assisted Heat Pump Systems for Space Heating and Cooling Applications in the Northern Region of India—A Study on Energy and CO2 Saving Potential. Sustain. Energy Technol. Assess. 2023, 59, 103405. [Google Scholar] [CrossRef]

- Reffat, R.M.; Ezzat, R. Impacts of Design Configurations and Movements of PV Attached to Building Facades on Increasing Generated Renewable Energy. Sol. Energy 2023, 252, 50–71. [Google Scholar] [CrossRef]

- Kemmler, T.; Thomas, B. Design of Heat-Pump Systems for Single- and Multi-Family Houses Using a Heuristic Scheduling for the Optimization of PV Self-Consumption. Energies 2020, 13, 1118. [Google Scholar] [CrossRef]

- Rashid, K.; Safdarnejad, S.M.; Ellingwood, K.; Powell, K.M. Techno-Economic Evaluation of Different Hybridization Schemes for a Solar Thermal/Gas Power Plant. Energy 2019, 181, 91–106. [Google Scholar] [CrossRef]

- THE 17 GOALS | Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 7 June 2024).

- Wang, Y.; He, X.; Liu, Q.; Razmjooy, S. Economic and Technical Analysis of an HRES (Hybrid Renewable Energy System) Comprising Wind, PV, and Fuel Cells Using an Improved Subtraction-Average-Based Optimizer. Heliyon 2024, 10, e32712. [Google Scholar] [CrossRef]

- Franco, A.; Fantozzi, F. Optimal Sizing of Solar-Assisted Heat Pump Systems for Residential Buildings. Buildings 2020, 10, 175. [Google Scholar] [CrossRef]

- Ciuman, P.; Kaczmarczyk, J.; Jastrzębska, M. Simulation Analysis of Heat Pumps Application for the Purposes of the Silesian Botanical Garden Facilities in Poland. Energies 2023, 16, 340. [Google Scholar] [CrossRef]

- Kurz, D.; Nowak, A. Analysis of the Impact of the Level of Self-Consumption of Electricity from a Prosumer Photovoltaic Installation on Its Profitability under Different Energy Billing Scenarios in Poland. Energies 2023, 16, 946. [Google Scholar] [CrossRef]

- Grębosz-Krawczyk, M.; Zakrzewska-Bielawska, A.; Glinka, B.; Glińska-Neweś, A. Why Do Consumers Choose Photovoltaic Panels? Identification of the Factors Influencing Consumers’ Choice Behavior Regarding Photovoltaic Panel Installations. Energies 2021, 14, 2674. [Google Scholar] [CrossRef]

- Busu, M.; Nedelcu, A.C. Analyzing the Renewable Energy and CO2 Emission Levels Nexus at an EU Level: A Panel Data Regression Approach. Processes 2021, 9, 130. [Google Scholar] [CrossRef]

- European Heat Pump Association. Market Data-EHPA 2023. Available online: https://www.ehpa.org/market-data/ (accessed on 24 April 2024).

- Ziabina, Y.; Kwilinski, A.; Lyulyov, O.; Pimonenko, T.; Us, Y. Convergence of Energy Policies between the EU and Ukraine under the Green Deal Policy. Energies 2023, 16, 998. [Google Scholar] [CrossRef]

- Available online: https://sklep.pkn.pl/pn-en-14511-1-2012e.html (accessed on 24 April 2024).

- Available online: https://sklep.pkn.pl/pn-en-14825-2014-02e.html (accessed on 24 April 2024).

- Available online: https://sklep.pkn.pl/pn-en-12102-1-2022-12e.html (accessed on 24 April 2024).

- Data for Energy Calculations of Buildings. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 24 April 2024).

- Available online: https://www.kobize.pl/pl/article/monitorowanie-raportowanie-weryfikacja-emisji/id/318/tabele-wo-i-we (accessed on 24 April 2024).

- Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 24 April 2024).

| Energy efficiency class of the heat pump W35 | A+++ |

| Heating power at A7/W35 (EN 14511 [30]) | 7.84 kW |

| Heating power at A2/W35 (EN 14511 [30]) | 8.33 kW |

| Heating power at A-7/W35 (EN 14511 [30]) | 9.54 kW |

| Coefficient of Performance at A7/W35 (EN 14511 [30]) | 5.09 |

| Coefficient of Performance at A2/W35 (EN 14511 [30]) | 4.14 |

| Coefficient of Performance at A-7/W35 (EN 14511 [30]) | 3.26 |

| SCOP 35 °C (EN 14825 [31]) | 4.70 |

| Sound power level (EN 12102 [32]) | 55 dB (A) |

| Limit of use of lower source min./max. | −20/40 °C |

| Limit of use on the heating side max. | 65 °C |

| Refrigerant | R410A |

| Month | QCHS | QDWS | QMVS | Qtotal |

|---|---|---|---|---|

| kWh/month | kWh/month | kWh/month | kWh/month | |

| 1 | 3656 | 271 | 503 | 4430 |

| 2 | 2644 | 245 | 364 | 3253 |

| 3 | 2834 | 271 | 390 | 3495 |

| 4 | 1708 | 263 | 235 | 2206 |

| 5 | 0 | 271 | 149 | 420 |

| 6 | 0 | 263 | 75 | 338 |

| 7 | 0 | 271 | 62 | 333 |

| 8 | 0 | 271 | 59 | 330 |

| 9 | 0 | 263 | 111 | 373 |

| 10 | 1953 | 271 | 269 | 2493 |

| 11 | 2588 | 263 | 356 | 3206 |

| 12 | 3159 | 271 | 435 | 3865 |

| Qannual, kWh/a | 18,541 | 3194 | 3009 | 24,743 |

| Qannual, GJ/a | 66.8 | 11.5 | 10.8 | 89.1 |

| Month | NAHP | EHM | EHM + NAHP | EHP |

|---|---|---|---|---|

| kWh/m | kWh/m | Euro/m | % | |

| 1 | 633 | 3163 | 949 | 83.3 |

| 2 | 1030 | 34 | 266 | 3.2 |

| 3 | 1082 | 19 | 275 | 1.8 |

| 4 | 570 | 0 | 142 | 0.0 |

| 5 | 414 | 0 | 104 | 0.0 |

| 6 | 222 | 0 | 55 | 0.0 |

| 7 | 186 | 0 | 47 | 0.0 |

| 8 | 174 | 0 | 44 | 0.0 |

| 9 | 303 | 0 | 76 | 0.0 |

| 10 | 754 | 0 | 189 | 0.0 |

| 11 | 959 | 76 | 259 | 7.4 |

| 12 | 1001 | 1169 | 542 | 53.9 |

| Total | 7328 (26.4) * | 4462 (16.1) * | 1947 | 149.6 |

| Month | Qtotal | NAHP | GB | NAHPM | GBM | NAHPM + GBM |

|---|---|---|---|---|---|---|

| kWh/m | kWh/m | kWh/m | Euro/m | Euro/m | Euro/m | |

| 1 | 4430 | 633 | 3163 | 158 | 348 | 506 |

| 2 | 3253 | 1030 | 34 | 257 | 4 | 261 |

| 3 | 3495 | 1082 | 19 | 271 | 0 | 271 |

| 4 | 2206 | 570 | 0 | 142 | 0 | 142 |

| 5 | 420 | 414 | 0 | 104 | 0 | 104 |

| 6 | 338 | 222 | 0 | 55 | 0 | 55 |

| 7 | 333 | 186 | 0 | 47 | 0 | 47 |

| 8 | 330 | 174 | 0 | 44 | 0 | 44 |

| 9 | 373 | 303 | 0 | 76 | 0 | 76 |

| 10 | 2493 | 754 | 0 | 189 | 0 | 189 |

| 11 | 3206 | 959 | 76 | 240 | 8 | 248 |

| 12 | 3865 | 1001 | 1169 | 250 | 129 | 379 |

| Total | 24,743 (89.1) * | 7328 (26.4) * | 4462 (16.1) * | 1832 | 489 | 2 321 |

| AHP + EH | AHP + GB | |||||

|---|---|---|---|---|---|---|

| Year | PV Installation Cost | Yearly Cost without PV | Cash Flow | PV Installation Cost | Yearly Cost with PV | Cash Flow |

| Euro | Euro/a | Euro/a | Euro | Euro/a | Euro/a | |

| 1 | 14,800 | 2947 | −17,747 | 9500 | 2321 | −11,821 |

| 2 | 0 | 2947 | −14,800 | 0 | 2321 | −9500 |

| 3 | 0 | 2947 | −11,853 | 0 | 2321 | −7179 |

| 4 | 0 | 2947 | −8905 | 0 | 2321 | −4859 |

| 5 | 0 | 2947 | −5958 | 0 | 2321 | −2538 |

| 6 | 0 | 2947 | −3010 | 0 | 2321 | −218 |

| 7 | 0 | 2947 | −63 | 0 | 2321 | 2103 |

| 8 | 0 | 2947 | 2884 | 0 | 2321 | 4424 |

| 9 | 0 | 2947 | 5832 | 0 | 2321 | 6744 |

| 10 | 0 | 2947 | 8779 | 0 | 2321 | 9065 |

| 11 | 0 | 2947 | 11,727 | 0 | 2321 | 11,385 |

| 12 | 0 | 2947 | 14,674 | 0 | 2321 | 13,706 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabczak, S.; Mateichyk, V.; Smieszek, M.; Nowak, K.; Kolomiiets, S. Evaluating the Energy Efficiency of Combining Heat Pumps and Photovoltaic Panels in Eco-Friendly Housing. Appl. Sci. 2024, 14, 5575. https://doi.org/10.3390/app14135575

Rabczak S, Mateichyk V, Smieszek M, Nowak K, Kolomiiets S. Evaluating the Energy Efficiency of Combining Heat Pumps and Photovoltaic Panels in Eco-Friendly Housing. Applied Sciences. 2024; 14(13):5575. https://doi.org/10.3390/app14135575

Chicago/Turabian StyleRabczak, Sławomir, Vasyl Mateichyk, Miroslaw Smieszek, Krzysztof Nowak, and Serhii Kolomiiets. 2024. "Evaluating the Energy Efficiency of Combining Heat Pumps and Photovoltaic Panels in Eco-Friendly Housing" Applied Sciences 14, no. 13: 5575. https://doi.org/10.3390/app14135575