Binder System Composition on the Rheological and Magnetic Properties of Nd-Fe-B Feedstocks for Metal Injection Molding

Abstract

:1. Introduction

2. Experimental Procedures

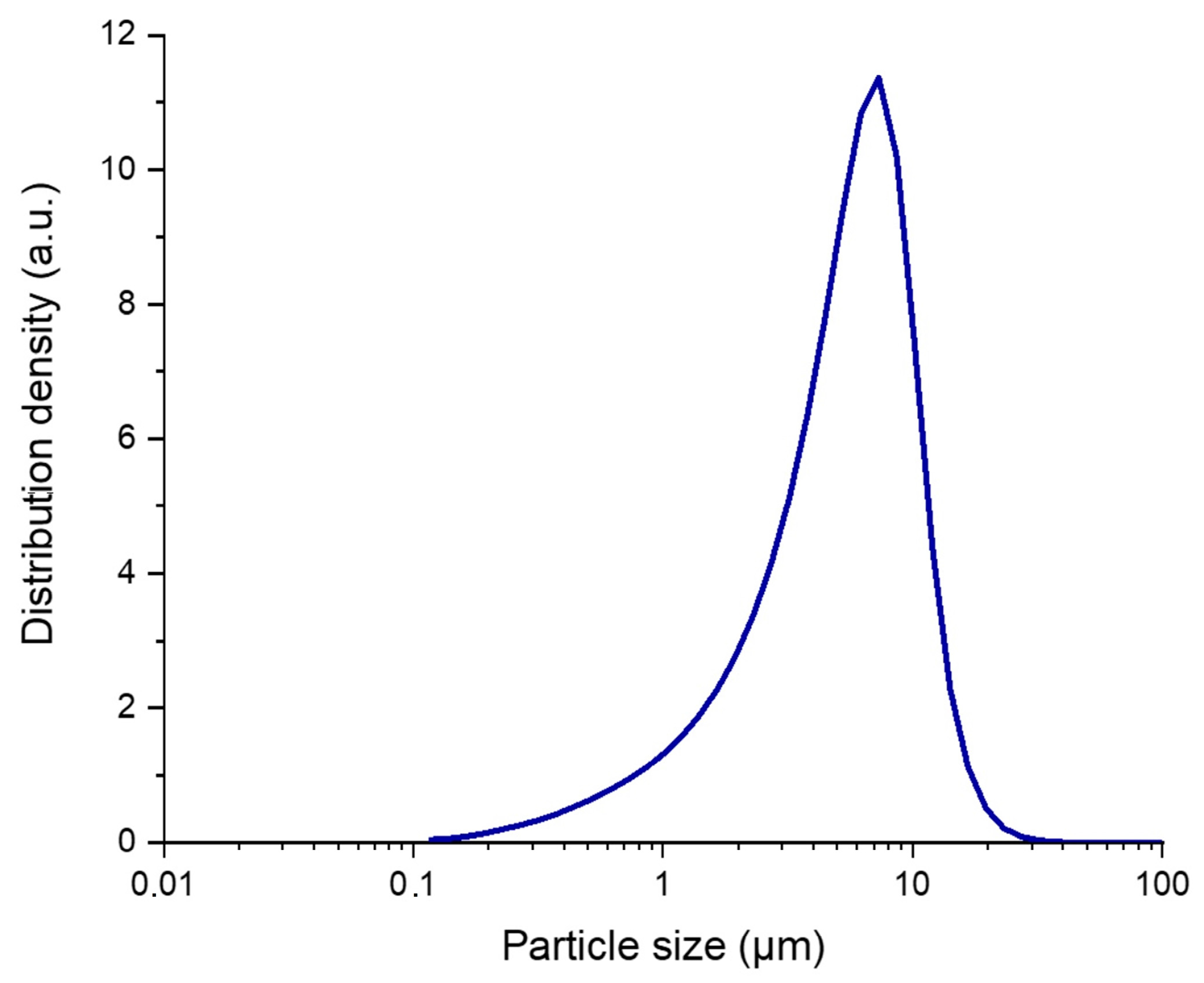

2.1. Materials

2.2. Feedstock and Parts Preparation

2.3. Rheological Measurements

2.4. Debinding and Sintering

2.5. Density, Contamination, and Magnetic Properties

3. Results and Discussion

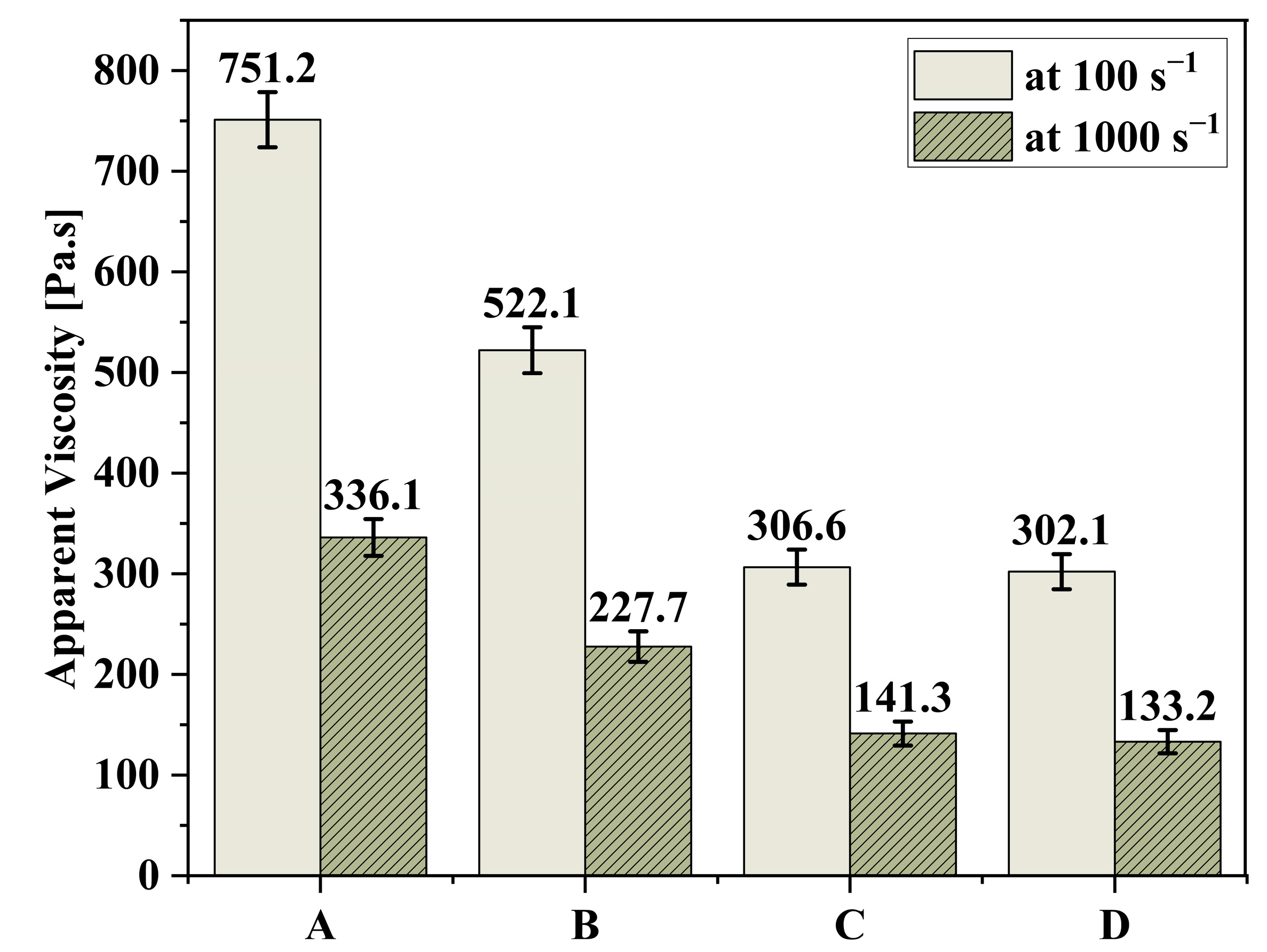

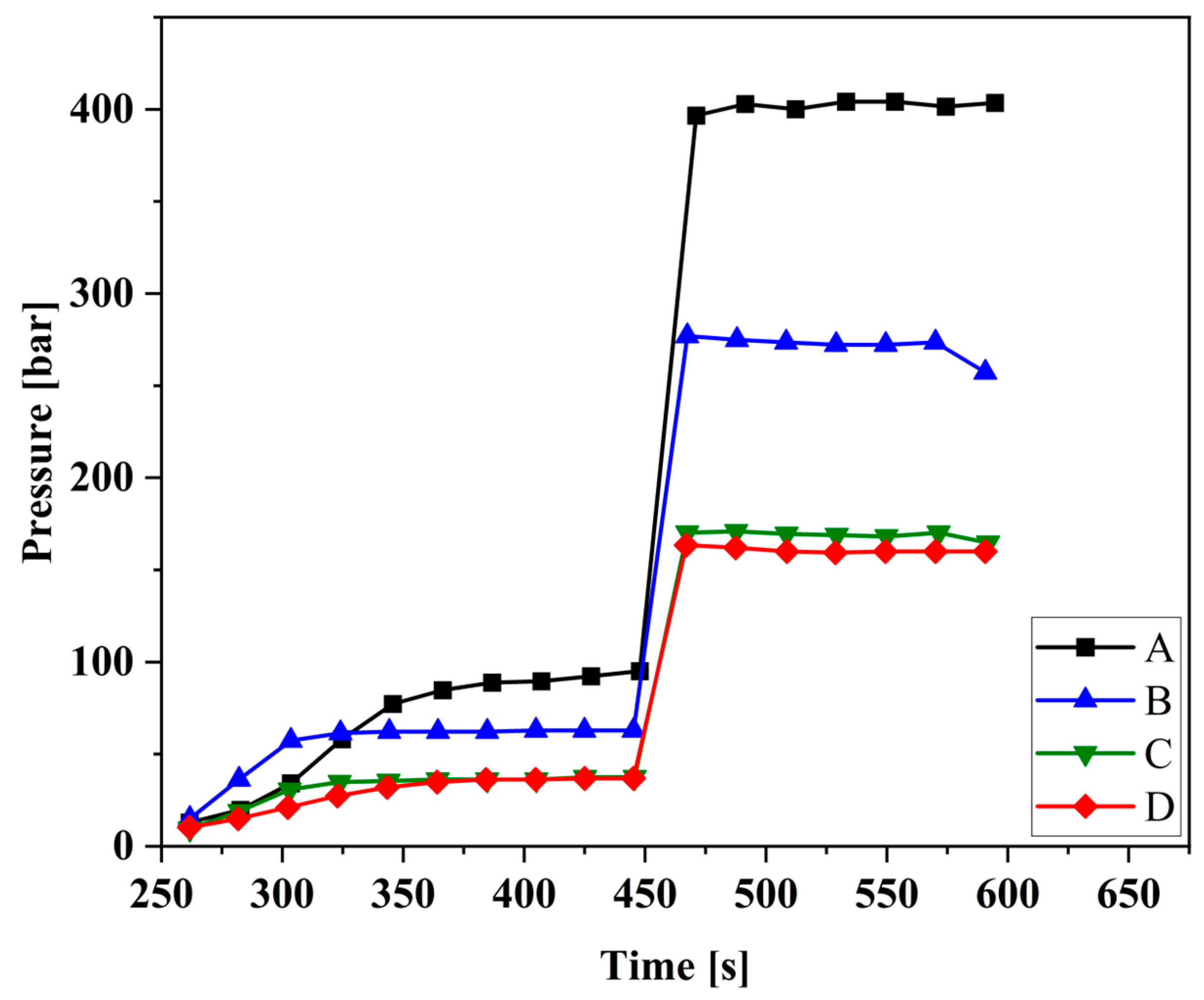

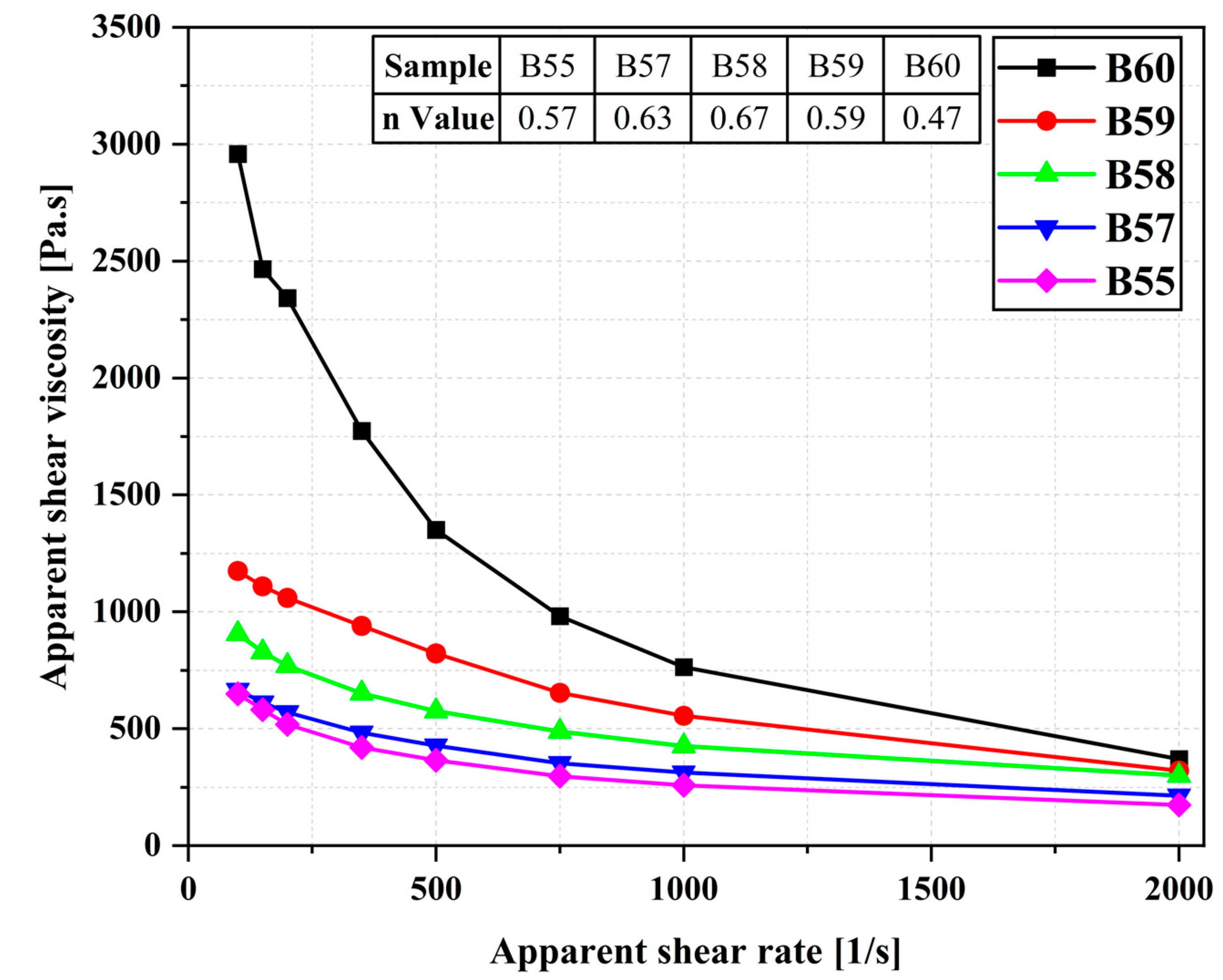

3.1. Rheological Properties

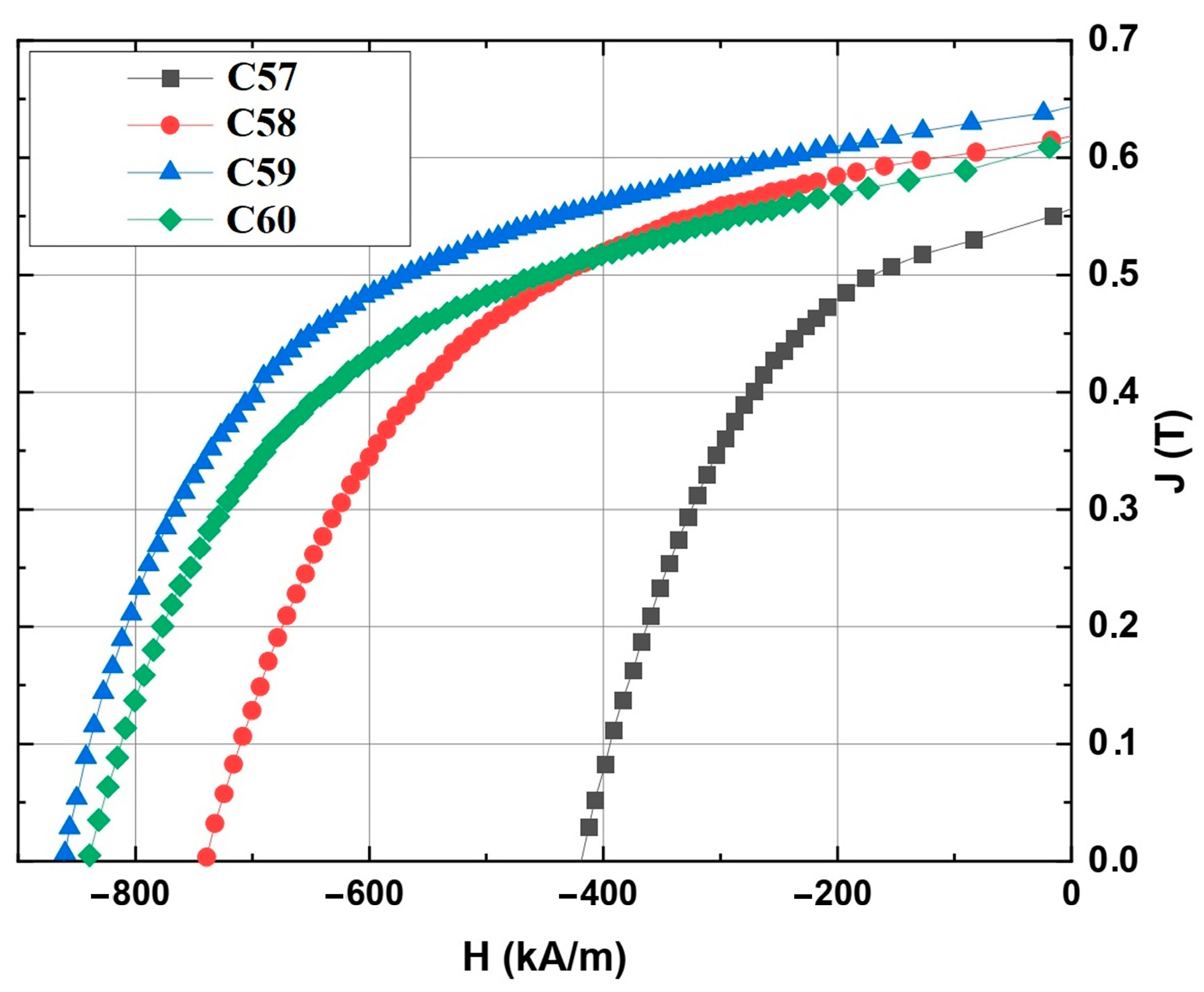

3.2. Density, Contamination, and Magnetic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

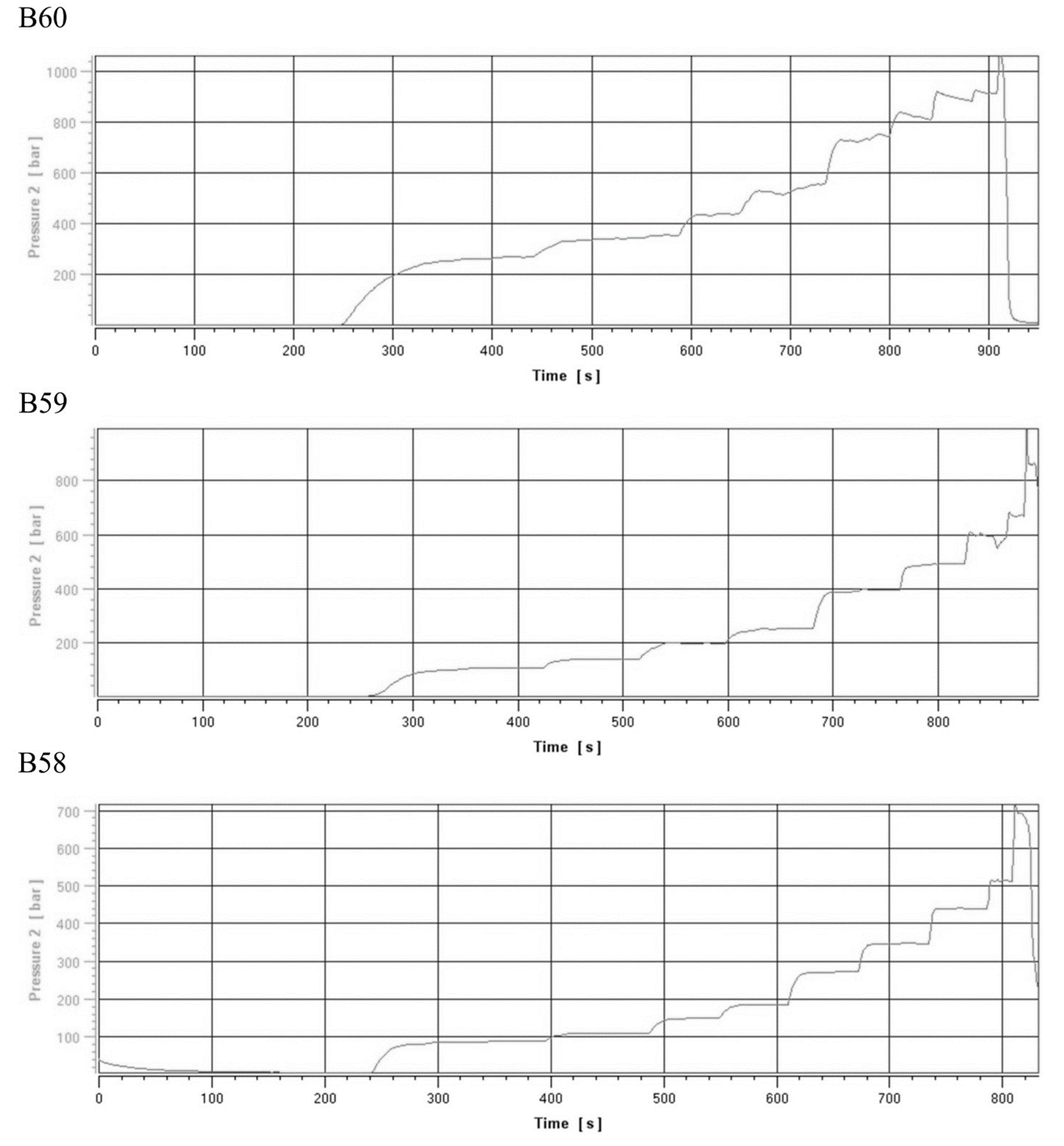

Appendix A

References

- Nesbitt, E.A.; Wernick, J.H. (Eds.) Rare Earth Permanent Magnets; Academic Press: New York, NY, USA, 1973. [Google Scholar]

- Widmer, J.D.; Martin, R.; Kimiabeigi, M. Electric vehicle traction motors without rare earth magnets. Sustain. Mater. Technol. 2015, 3, 7–13. [Google Scholar] [CrossRef]

- Sykes, J.P.; Wright, J.P.; Trench, A. Discovery, supply and demand: From Metals of Antiquity to critical metals. Appl. Earth Sci. 2016, 125, 3–20. [Google Scholar] [CrossRef]

- Pavel, C.C.; Lacal-Arántegui, R.; Marmier, A.; Schüler, D.; Tzimas, E.; Buchert, M.; Jenseit, W.; Blagoeva, D. Substitution strategies for reducing the use of rare earths in wind turbines. Resour. Policy 2017, 52, 349–357. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Li, J.; Sepehri-Amin, H.; Sasaki, T.; Ohkubo, T.; Hono, K. Most frequently asked questions about the coercivity of Nd-Fe-B permanent magnets. Sci. Technol. Adv. Mater. 2021, 22, 386–403. [Google Scholar] [CrossRef] [PubMed]

- Fastenau, R.H.; van Loenen, E.J. Applications of rare earth permanent magnets. J. Magn. Magn. Mater. 1996, 157–158, 1–6. [Google Scholar] [CrossRef]

- Nakamura, H. The current and future status of rare earth permanent magnets. Scr. Mater. 2018, 154, 273–276. [Google Scholar] [CrossRef]

- Sugimoto, S. Current status and recent topics of rare-earth permanent magnets. J. Phys. D Appl. Phys. 2011, 44, 64001. [Google Scholar] [CrossRef]

- Constantinides, S. The demand for rare earth materials in permanent magnets. In 51st Annual Conference of Metallurgists, Niagara, ON, Canada, 30 September–3 October 2012; The Metallurgy and Materials Society: Westmount, QC, Canada, 2012; Volume 7546, p. 476. [Google Scholar]

- Tian, J.; Tao, S.; Qu, X.; Zhang, S. 2:17-type SmCo magnets prepared by powder injection molding using a water-based binder. J. Magn. Magn. Mater. 2008, 320, 2168–2171. [Google Scholar] [CrossRef]

- Dent, P.C. Rare earth elements and permanent magnets (invited). J. Appl. Phys. 2012, 111, 07A721. [Google Scholar] [CrossRef]

- Trench, A.; Sykes, J.P. Rare Earth Permanent Magnets and Their Place in the Future Economy. Engineering 2020, 6, 115–118. [Google Scholar] [CrossRef]

- Sagawa, M.; Une, Y. Chapter 5—The status of sintered NdFeB magnets. In Modern Permanent Magnets; Woodhead Publishing Series in Electronic and Optical Materials; Croat, J., Ormerod, J., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 135–168. [Google Scholar]

- Pathak, A.K.; Khan, M.; Gschneidner, K.A.; McCallum, R.W.; Zhou, L.; Sun, K.; Dennis, K.W.; Zhou, C.; Pinkerton, F.E.; Kramer, M.J.; et al. Cerium: An unlikely replacement of dysprosium in high performance Nd-Fe-B permanent magnets. Adv. Mater. 2015, 27, 2663–2667. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Liu, W.; Zha, S.; Li, Y.; Wang, Y.; Zhang, D.; Yue, M.; Zhang, J. Effects of lanthanum substitution on microstructures and intrinsic magnetic properties of Nd-Fe-B alloy. J. Rare Earths 2015, 33, 961–964. [Google Scholar] [CrossRef]

- Lopes, L.U.; Hartwig, T.; Wendhausen, P.A.P. Evaluation of Process Variables in the Alignment Factor of Nd-Fe-B Magnets Made by Metal Injection Molding. IEEE Trans. Magn. 2013, 49, 4618–4621. [Google Scholar] [CrossRef]

- Burkhardt, C.; Weber, O.; Podmiljsak, B.; Gonzalez-Gutierrez, J.; Kukla, C.; Degri, M.; Harris, I.R.; Walton, A. Tailored metal injection moulding of isotropic NdFeB hard magnets based on recycled powders with and without Nd-additions. In International Powder Metallurgy Congress and Exhibition; Euro PM: Milan, Italy; European Powder Metallurgy Association: Chantilly, France, 2017. [Google Scholar]

- Lee, S.H.; Lee, W.; Jeung, W.Y.; Moon, T.J. Properties of Anisotropic Nd(Fe, Co)B Type Sintered Magnets Produced by Powder Injection Moulding. Powder Met. 1998, 41, 185–188. [Google Scholar] [CrossRef]

- Lopes, L.U.; Carvalho, M.A.; Chaves, R.S.; Trevisan, M.P.; Wendhausen, P.A.; Takiishi, H. Study of Carbon Influence on Magnetic Properties of Metal Injection Molding Nd-Fe-B Based Magnets. MSF 2012, 727–728, 124–129. [Google Scholar] [CrossRef]

- Momeni, V.; Askari, A.; Alaei, M.H.; Rahimi, A.H.; Nekouee, K.; Zangi, H. The Effect of Powder Loading and Binder System on the Mechanical, Rheological and Microstructural Properties of 4605 Powder in MIM Process. Trans. Indian Inst. Met. 2019, 72, 1245–1254. [Google Scholar] [CrossRef]

- Momeni, V.; Zangi, H.; Allaei, M.H. Effect of polypropylene as the backbone of MIM feedstock on the micro-structural phase constituents, mechanical and rheological properties of 4605 low alloy steel compacts. Powder Metall. 2020, 63, 27–34. [Google Scholar] [CrossRef]

- Setasuwon, P.; Bunchavimonchet, A.; Danchaivijit, S. The effects of binder components in wax/oil systems for metal injection molding. J. Mater. Process. Technol. 2008, 196, 94–100. [Google Scholar] [CrossRef]

- Enneti, R.K.; Onbattuvelli, V.P.; Gulsoy, O.; Kate, K.H.; Atre, S.V. Powder-binder formulation and compound manufacture in metal injection molding (MIM). In Handbook of Metal Injection Molding; Heaney, D.F., Ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 57–88. [Google Scholar] [CrossRef]

- Momeni, V.; Askari, A.; Allaei, M.H.; Zangi, H. Investigating the Effect of Stearic Acid on the Mechanical, Rheological, and Microstructural Properties of AISI 4605 Feedstock for Metal Injection Molding Process. Trans. Indian Inst. Met. 2021, 74, 2161–2170. [Google Scholar] [CrossRef]

- Askari, A.; Momeni, V. Rheological investigation and injection optimization of Fe–2Ni–2Cu feedstock for metal injection molding process. Mater. Chem. Phys. 2021, 271, 124926. [Google Scholar] [CrossRef]

- Ghasemi-Mobarakeh, L.; Cano, S.; Momeni, V.; Liu, D.; Duretek, I.; Riess, G.; Kukla, C.; Holzer, C. Effect of Increased Powder-Binder Adhesion by Backbone Grafting on the Properties of Feedstocks for Ceramic Injection Molding. Polymers 2022, 14, 3653. [Google Scholar] [CrossRef]

- Ammosova, L.; Cano, S.C.; Schuschnigg, S.; Kukla, C.; Mönkkönen, K.; Suvanto, M.; Gonzalez-Gutierrez, J. Effect of metal particle size and powder volume fraction on the filling performance of powder injection moulded parts with a microtextured surface. Precis. Eng. 2021, 72, 604–612. [Google Scholar] [CrossRef]

- Bek, M.; Gonzalez-Gutierrez, J.; Kukla, C.; Črešnar, K.P.; Maroh, B.; Perše, L.S. Rheological Behaviour of Highly Filled Materials for Injection Moulding and Additive Manufacturing: Effect of Particle Material and Loading. Appl. Sci. 2020, 10, 7993. [Google Scholar] [CrossRef]

- Kukla, C.; Duretek, I.; Gonzalez-Gutierrez, J.; Holzer, C. Rheology of PIM feedstocks. Met. Powder Rep. 2017, 72, 39–44. [Google Scholar] [CrossRef]

- Jabir, S.M.; Noorsyakirah, A.; Afian, O.M.; Nurazilah, M.Z.; Aswad, M.A.; Afiq, N.M.; Mazlan, M. Analysis of the Rheological Behavior of Copper Metal Injection Molding (MIM) Feedstock. Procedia Chem. 2016, 19, 148–152. [Google Scholar] [CrossRef]

- Prasad, T.S.; Yuvaraj, C.; Rao, K.P. Analysis and Optimization of Metal Injection Molding Feedstock SS 316L for Rheological Properties. J. Inst. Eng. India Ser. D 2018, 99, 177–184. [Google Scholar] [CrossRef]

- Mahmud, N.N.; Azam, F.A.A.; Ramli, M.I.; Foudzi, F.M.; Ameyama, K.; Sulong, A.B. Rheological properties of irregular-shaped titanium-hydroxyapatite bimodal powder composite moulded by powder injection moulding. J. Mater. Res. Technol. 2021, 11, 2255–2264. [Google Scholar] [CrossRef]

- Lin, D.; Sanetrnik, D.; Cho, H.; Chung, S.T.; Kwon, Y.S.; Kate, K.H.; Hausnerova, B.; Atre, S.V.; Park, S.J. Rheological and thermal debinding properties of blended elemental Ti-6Al-4V powder injection molding feedstock. Powder Technol. 2017, 311, 357–363. [Google Scholar] [CrossRef]

- Tosello, G. Micro Injection Molding; Hanser Publishers: Munich, Germany, 2018. [Google Scholar]

- Momeni, V.; Alaei, M.H.; Askari, A.; Rahimi, A.H.; Nekouee, K. Effect of the Fraction of Steel 4605 Powder in the Load in Injection Molding with the Use of a Polymer-Based Binder. Met. Sci. Heat Treat. 2020, 61, 777–781. [Google Scholar] [CrossRef]

- Momeni, V.; Zangi, H.; Alaei, M.H. Effect of thermal debinding and sintering parameters on the mechanical properties of 4605 MIM compact using the RSM. Adv. Mater. Process. Technol. 2021, 3, 3199–3214. [Google Scholar] [CrossRef]

- Minowa, T.; Shimao, M.; Honshima, M. Microstructure of Nd-rich phase in Nd-Fe-B magnet containing oxygen and carbon impurities. J. Magn. Magn. Mater. 1991, 97, 107–111. [Google Scholar] [CrossRef]

- Xia, M.; Abrahamsen, A.B.; Bahl, C.; Veluri, B.; Søegaard, A.I.; Bøjsøe, P.; Millot, S. The influence of carbon and oxygen on the magnetic characteristics of press-less sintered NdFeB magnets. J. Magn. Magn. Mater. 2017, 422, 232–236. [Google Scholar] [CrossRef]

- Kim, A.S. Effect of oxygen on magnetic properties of Nd-Fe-B magnets. J. Appl. Phys. 1988, 64, 5571–5573. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Une, Y.; Kubo, H.; Sagawa, M.; Hono, K. Effect of carbon on the coercivity and microstructure in fine-grained Nd–Fe–B sintered magnet. Acta Mater. 2015, 84, 506–514. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Sercombe, T.B.; Schaffer, G.B. Metal injection moulding of aluminium alloy 6061 with tin. Powder Metall. 2008, 51, 78–83. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, J.W.; Jeung, W.Y.; Moon, T.J. Effects of binder and thermal debinding parameters on residual carbon in injection moulding of Nd(Fe, Co)B powder. Powder Metall. 1999, 42, 41–44. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; StJohn, D.; Dargusch, M.; Chen, Y.; Sun, J.F.; Qian, M. Metal injection moulding of non-spherical titanium powders: Processing, microstructure and mechanical properties. J. Manuf. Process. 2018, 31, 416–423. [Google Scholar] [CrossRef]

- Moghadam, M.S.; Fayyaz, A.; Ardestani, M. Fabrication of titanium components by low-pressure powder injection moulding using hydride-dehydride titanium powder. Powder Technol. 2021, 377, 70–79. [Google Scholar] [CrossRef]

- Côté, R.; Azzouni, M.; Demers, V. Impact of binder constituents on the moldability of titanium-based feedstocks used in low-pressure powder injection molding. Powder Technol. 2021, 381, 255–268. [Google Scholar] [CrossRef]

- Weil, K.S.; Nyberg, E.; Simmons, K. A new binder for powder injection molding titanium and other reactive metals. J. Mater. Process. Technol. 2006, 176, 205–209. [Google Scholar] [CrossRef]

- Zhao, D.; Chang, K.; Ebel, T.; Qian, M.; Willumeit, R.; Yan, M.; Pyczak, F. Microstructure and mechanical behavior of metal injection molded Ti–Nb binary alloys as biomedical material. J. Mech. Behav. Biomed. Mater. 2013, 28, 171–182. [Google Scholar] [CrossRef] [PubMed]

- Abdoos, H.; Khorsand, H.; Yousefi, A.A. Nano-particles in powder injection molding of an aluminum matrix composite: Rheological behavior, production and properties. Int. J. Mater. Res. 2017, 108, 237–244. [Google Scholar] [CrossRef]

- Schaper, J.G.; Wolff, M.; Wiese, B.; Ebel, T.; Willumeit-Römer, R. Powder metal injection moulding and heat treatment of AZ81 Mg alloy. J. Mater. Process. Technol. 2019, 267, 241–246. [Google Scholar] [CrossRef]

- Guo, S.B.; Qu, X.H.; He, X.B. Influence of Sintering Temperature on Mechanical Properties of Ti-6Al-4V Compacts by Metal Injection Molding. MSF 2005, 475–479, 2639–2642. [Google Scholar] [CrossRef]

- Cicek, B.; Sun, Y.; Turen, Y.; Ahlatci, H. Investigation of microstructural evolution of gas-assisted metal injection molded and sintered Mg-0.5Ca alloy. Sci. Sinter. 2022, 54, 25–37. [Google Scholar] [CrossRef]

- Chen, G.; Cao, P.; Wen, G.; Edmonds, N. Debinding behaviour of a water soluble PEG/PMMA binder for Ti metal injection moulding. Mater. Chem. Phys. 2013, 139, 557–565. [Google Scholar] [CrossRef]

- Hayat, M.D.; Wen, G.; Zulkifli, M.F.; Cao, P. Effect of PEG molecular weight on rheological properties of Ti-MIM feedstocks and water debinding behaviour. Powder Technol. 2015, 270, 296–301. [Google Scholar] [CrossRef]

- Hayat, M.D.; Zhang, H.; Karumbaiah, K.M.; Singh, H.; Xu, Y.; Zou, L.; Qu, X.; Ray, S.; Cao, P. A novel PEG/PMMA based binder composition for void-free metal injection moulding of Ti components. Powder Technol. 2021, 382, 431–440. [Google Scholar] [CrossRef]

- Hartwig, T.; Lopes, L.; Wendhausen, P.; Ünal, N. Metal Injection Molding (MIM) of NdFeB Magnets. EPJ Web Conf. 2014, 75, 4002. [Google Scholar] [CrossRef]

- Hartwig, T.; Lopes, L.; Ünal, N. Powder Injection Moulding Materials 1: Anisotropic NdFeB Hard Magnets by MIM. In European Congress and Exhibition on Powder Metallurgy, European PM Conference Proceedings; European Powder Metallurgy Association: Chantilly, France, 2013. [Google Scholar]

- Crozier-Bioud, T.; Momeni, V.; Gonzalez-Gutierrez, J.; Kukla, C.; Luca, S.; Rolere, S. Current challenges in NdFeB permanent magnets manufacturing by Powder Injection Molding (PIM): A review. Mater. Today Phys. 2023, 34, 101082. [Google Scholar] [CrossRef]

- Heaney, D.F. (Ed.) Handbook of Metal Injection Molding, 2nd ed.; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Tafti, A.A.; Demers, V.; Vachon, G.; Brailovski, V. Influence of powder size on the moldability and sintered properties of irregular iron-based feedstock used in low-pressure powder injection molding. Powder Technol. 2023, 420, 118395. [Google Scholar] [CrossRef]

- Aslam, M.; Ahmad, F.; Yusoff; Megat, P.S.M.B.; Altaf, K.; Omar, M.A.; German, R.M. Powder injection molding of biocompatible stainless steel biodevices. Powder Technol. 2016, 295, 84–95. [Google Scholar] [CrossRef]

- Felgel-Farnholz, A.; Schweighuber, A.; Klampfl, C.W.; Fischer, J. Comparative study on the degradation of HDPE, LLDPE and LDPE during multiple extrusions. Polym. Degrad. Stab. 2023, 216, 110486. [Google Scholar] [CrossRef]

- ISO 11443:2021; Plastics—Determination of the Fluidity of Plastics Using Capillary and Slit-Die Rheometers. International Organization for Standardization (ISO): Geneve, Switzerland, 2021.

- Gal, C.W.; Oh, J.W.; Song, G.W.; Da Shin, S.; Park, S.J. Rheological and thermal debinding behaviors of silicon nitride in powder injection molding. Ceram. Int. 2019, 45, 16982–16991. [Google Scholar] [CrossRef]

- Abolhasani, H.; Muhamad, N. Rheological investigation of a starch-based binder and feedstock for metal injection molding. Int. J. Mech. Mater. Eng. 2009, 4, 294–299. [Google Scholar]

- Wen, J.; Xie, Z.P.; Cao, W.; Yang, X.F. Effects of different backbone binders on the characteristics of zirconia parts using wax-based binder system via ceramic injection molding. J. Adv. Ceram 2016, 5, 321–328. [Google Scholar] [CrossRef]

- Hausnerova, B.; Kasparkova, V.; Hnatkova, E. Effect of backbone binders on rheological performance of ceramic injection molding feedstocks. Polym. Eng. Sci. 2017, 57, 739–745. [Google Scholar] [CrossRef]

- Momeni, V.; Hufnagl, M.; Shahroodi, Z.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Holzer, C. Research Progress on Low-Pressure Powder Injection Molding. Materials 2022, 16, 379. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Hon, M.-H. Effects of PEG molecular weights on rheological behavior of alumina injection molding feedstocks. Mater. Chem. Phys. 2003, 78, 416–424. [Google Scholar] [CrossRef]

- Dihoru, L.V.; Smith, L.N.; German, R.M. Experimental analysis and neural network modelling of the rheological behaviour of powder injection moulding feedstocks formed with bimodal powder mixtures. Powder Met. 2000, 43, 31–36. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Khalil, K.A. Effect of powder loading on metal injection molding stainless steels. J. Mater. Process. Technol. 2007, 183, 432–439. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Luo, F.; Yue, J. Effects of surfactant on properties of MIM feedstock. Trans. Nonferrous Met. Soc. China 2007, 17, 1–8. [Google Scholar] [CrossRef]

- Bioud, T.; Ollivier, M.; Favergeon, L.; Luca, S.; Rolere, S. Net-Shaped NdFeB Magnets Made by Powder Injection Molding: Lowering the Organic Contamination. In Proceedings of World PM 2022, Lyon, France; European Powder Metallurgy Association: Chantilly, France, 2022. [Google Scholar]

| Feedstock | LLDPE (vol.%) | PW (vol.%) | SA (vol.%) |

|---|---|---|---|

| A | 52.5 | 41.25 | 6.25 |

| B | 45 | 47.5 | 7.5 |

| C | 37.5 | 53.75 | 8.75 |

| D | 35 | 60 | 5 |

| Feedstock | Density (g/cm3) | Oxygen (ppm) | Carbon (ppm) |

|---|---|---|---|

| A | 6.83 | 6097 ± 922 | 1356 ± 63 |

| B | 6.85 | 4468 ± 292 | 2012 ± 182 |

| C | 6.94 | 5121 ± 1345 | 1949 ± 91 |

| D | 6.61 | 4966 ± 587 | 1165 ± 104 |

| Feedstock | Remanence (Br) (T) | Coercivity (Hcj (kA/m)) | Maximum Energy Product (BH)max (MGOe) |

|---|---|---|---|

| A | 0.572 | 356.6 | 6.35 |

| B | 0.591 | 744.6 | 7.11 |

| C | 0.587 | 461.4 | 6.5 |

| D | 0.537 | 499.3 | 5.43 |

| Feedstocks | Density (g/cm3) | Oxygen (ppm) | Carbon (ppm) | Remanence (Br) (T) | Coercivity (Hcj (kA/m)) |

|---|---|---|---|---|---|

| B55 | 6.83 | 4468 | 2012 | 0.591 | 744.6 |

| B57 | 7.27 | 8384 | 1045 | 0.556 | 418.8 |

| B58 | 7.54 | 7177 | 982 | 0.618 | 740.1 |

| B59 | 7.47 | 6917 | 997 | 0.637 | 828.3 |

| B60 | 7.42 | 6825 | 1064 | 0.578 | 852.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Momeni, V.; Luca, S.; Gonzalez-Gutierrez, J.; Cano, S.; Sueur, E.; Shahroodi, Z.; Schuschnigg, S.; Kukla, C.; Holzer, C. Binder System Composition on the Rheological and Magnetic Properties of Nd-Fe-B Feedstocks for Metal Injection Molding. Appl. Sci. 2024, 14, 5638. https://doi.org/10.3390/app14135638

Momeni V, Luca S, Gonzalez-Gutierrez J, Cano S, Sueur E, Shahroodi Z, Schuschnigg S, Kukla C, Holzer C. Binder System Composition on the Rheological and Magnetic Properties of Nd-Fe-B Feedstocks for Metal Injection Molding. Applied Sciences. 2024; 14(13):5638. https://doi.org/10.3390/app14135638

Chicago/Turabian StyleMomeni, Vahid, Sorana Luca, Joamin Gonzalez-Gutierrez, Santiago Cano, Emilie Sueur, Zahra Shahroodi, Stephan Schuschnigg, Christian Kukla, and Clemens Holzer. 2024. "Binder System Composition on the Rheological and Magnetic Properties of Nd-Fe-B Feedstocks for Metal Injection Molding" Applied Sciences 14, no. 13: 5638. https://doi.org/10.3390/app14135638