Analysis and Experiment of Thermal Field Distribution and Thermal Deformation of Nut Rotary Ball Screw Transmission Mechanism

Abstract

1. Introduction

2. Temperature Field and Thermal Error Modeling of Nut-Rotating Ball Screw Transmission Mechanism

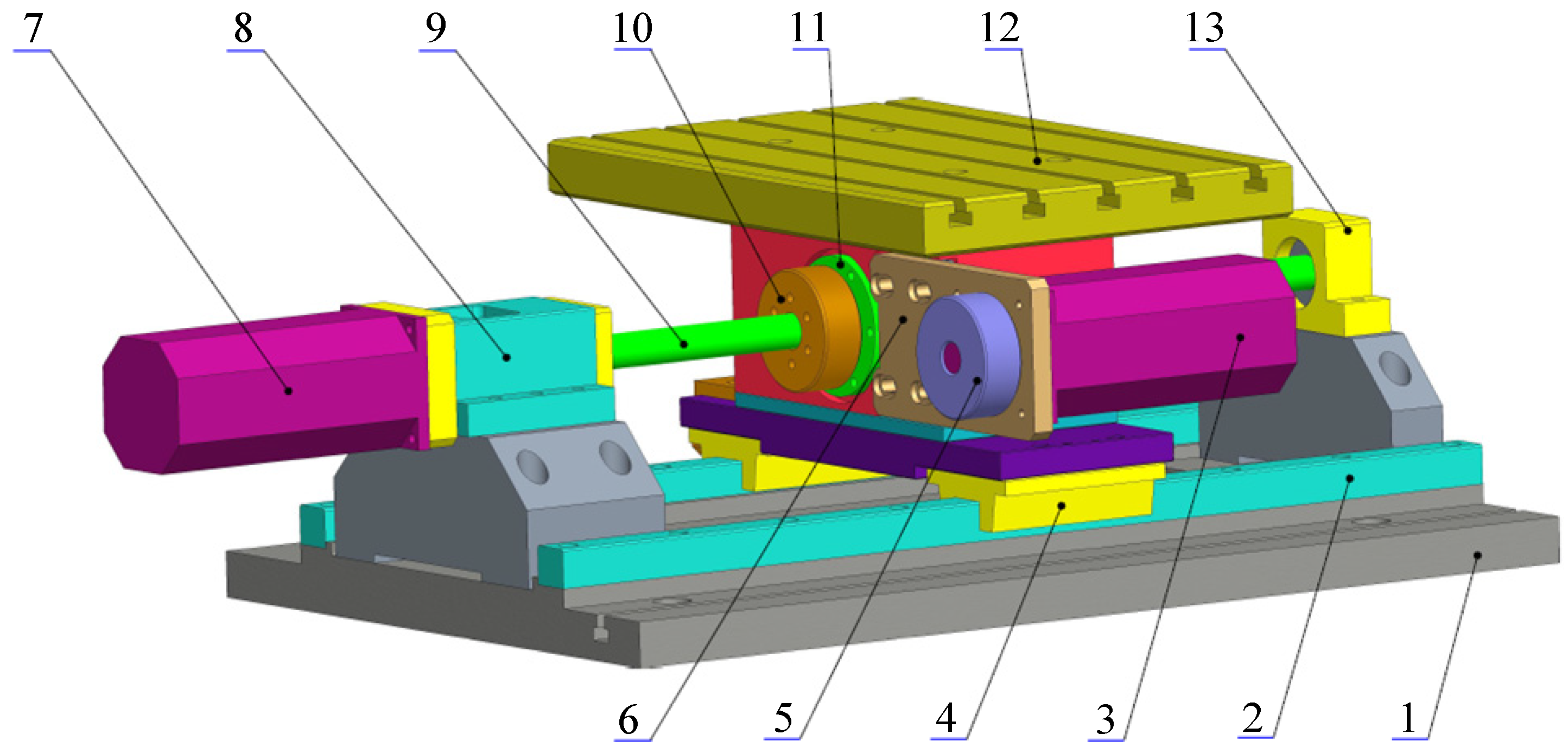

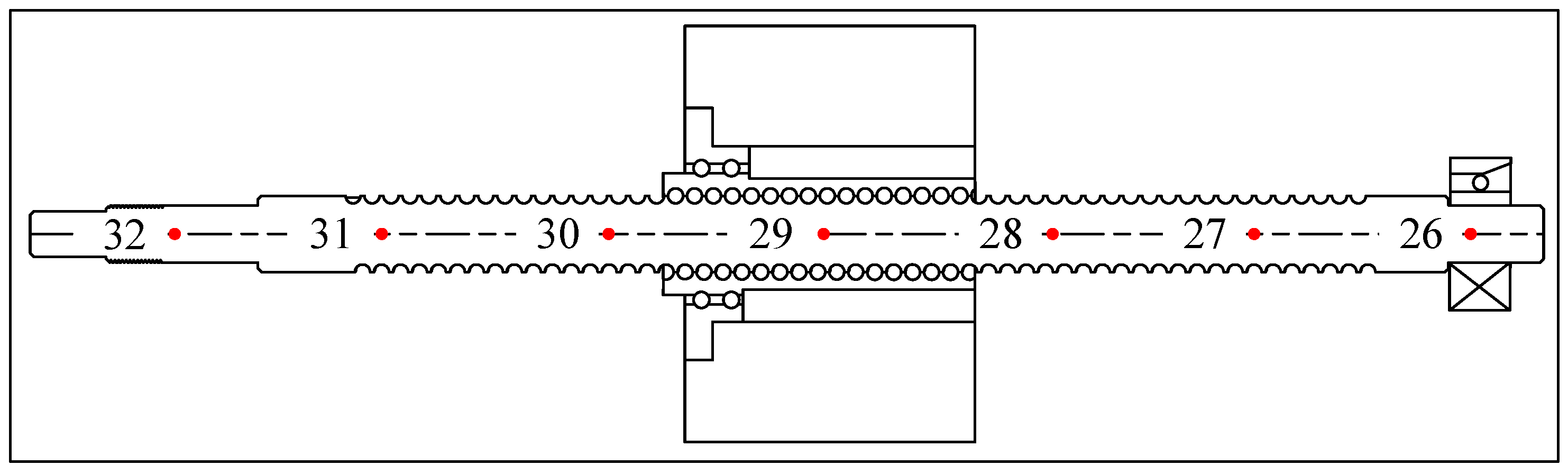

2.1. Nut Rotating Ball Screw Precision Transmission Mechanism

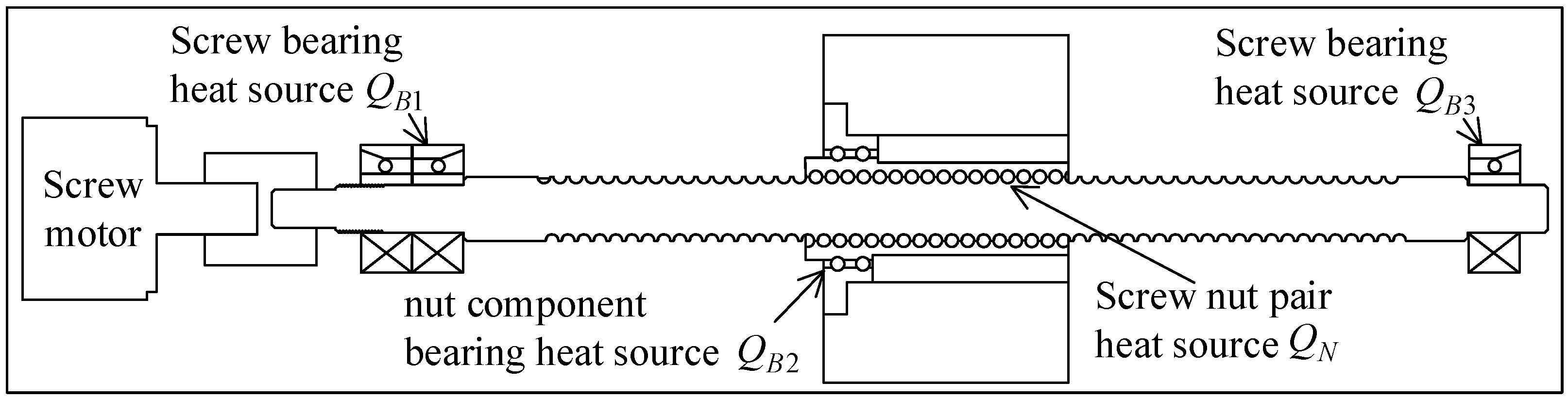

2.2. Heat Conduction Analysis of Nut-Rotating Ball Screw Pairs

2.3. Analysis of Temperature Field of the Nut-Rotating Ball Screw Pair under the Action of Heat Source

2.3.1. Constant Heat Source Temperature Response

2.3.2. Periodic Variation in Heat Source Temperature Response

2.3.3. Any Heat Source Temperature Response

2.4. Thermal Resistance Network Analysis of Nut-Rotating Ball Screw Transmission Mechanism

2.4.1. Heat Transfer Analysis

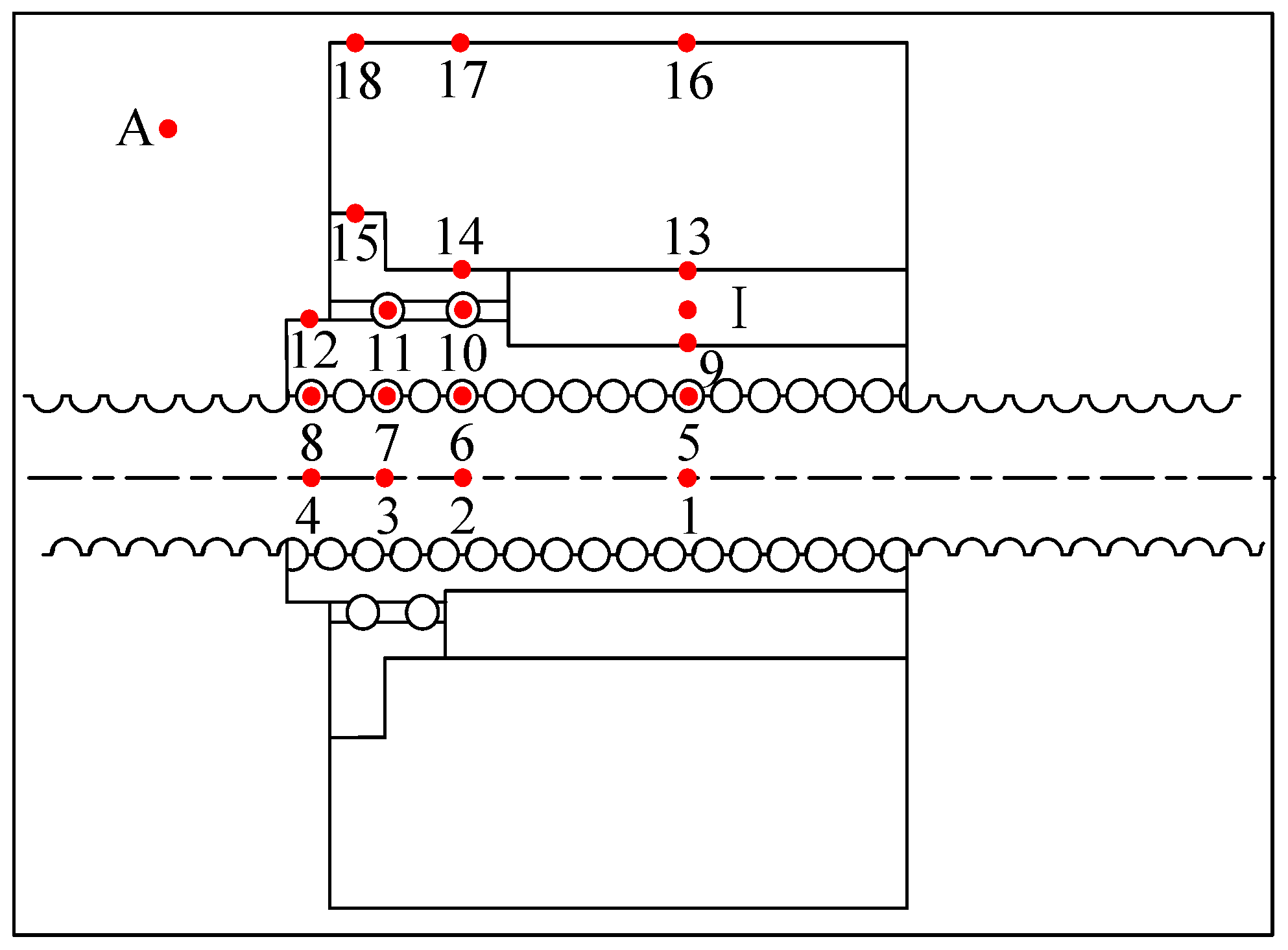

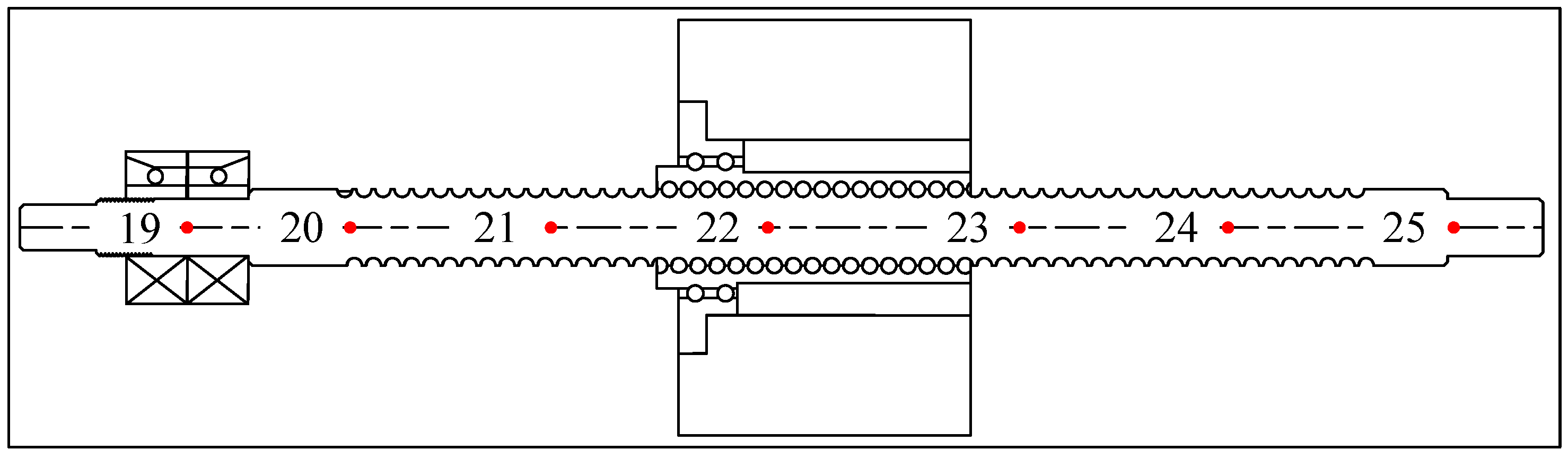

2.4.2. Hot Node Layout

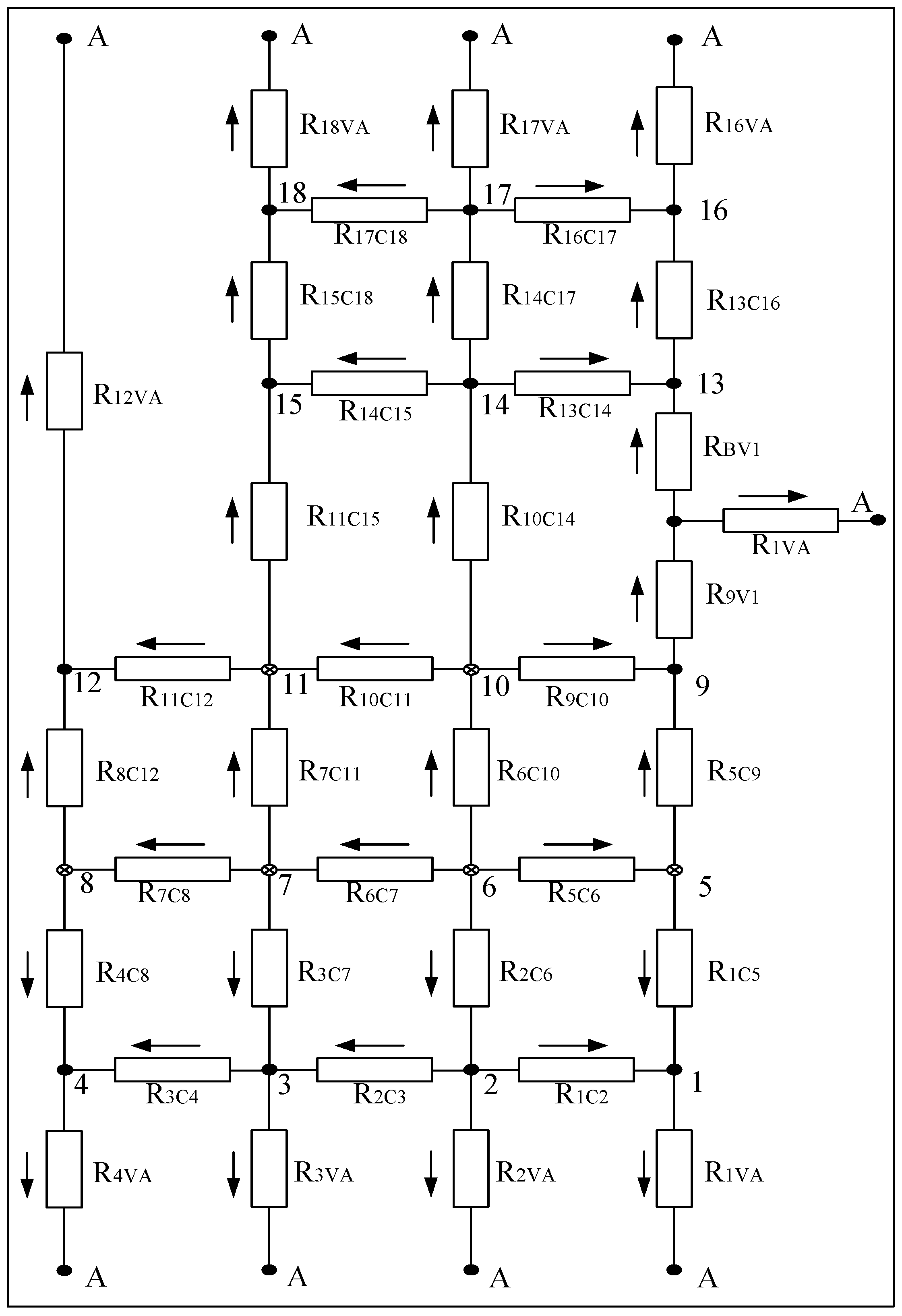

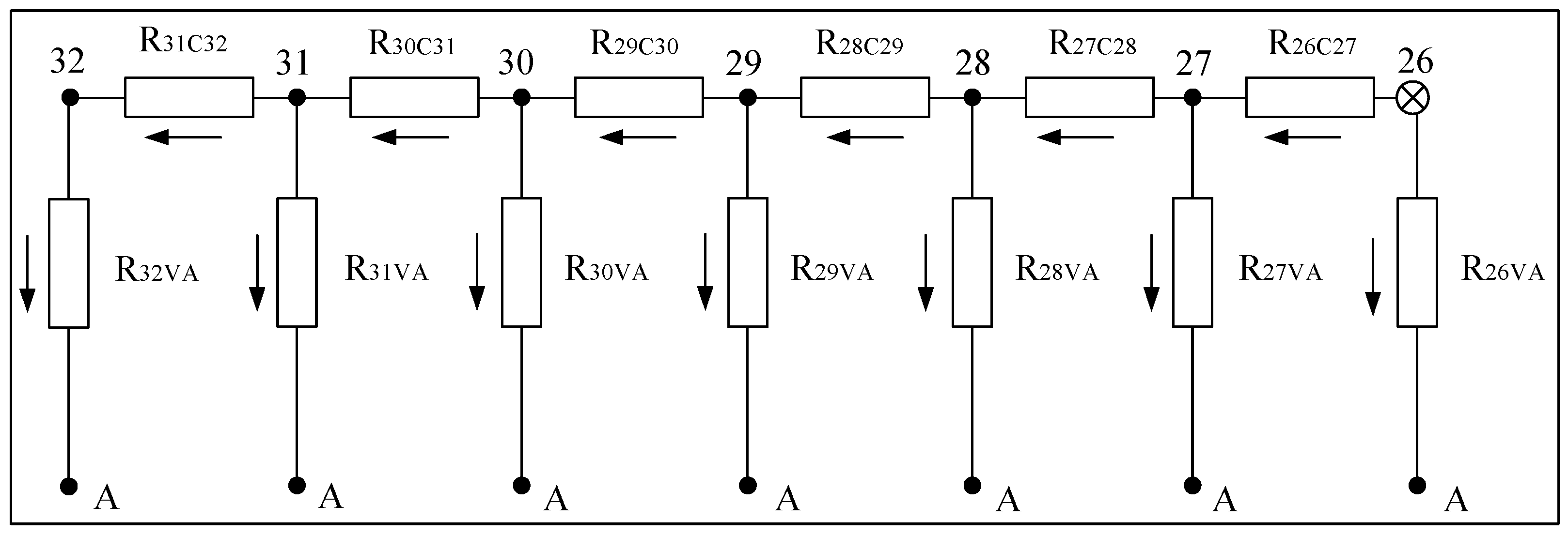

2.4.3. Establishment of a Thermal Resistance Network

2.4.4. Heat Balance Equation

- (1)

- The dual drive nut rotating ball screw pair has reached a thermal equilibrium state;

- (2)

- Due to the temperature difference between various components in the mechanical transmission process being less than 200 °C, the influence of thermal radiation is ignored;

- (3)

- The material of the components in the nut-rotating ball screw pair is isotropic, thus the heat flow direction does not affect the magnitude of thermal resistance;

- (4)

- The thermal conductivity of each component in the system remains constant during temperature changes;

- (5)

- Contact thermal resistance across various components in the nut-rotating ball screw pair is neglected;

- (6)

- The external environment in which the system is located is at a constant temperature of 25 °C;

2.5. Thermal Error Analysis of Nut-Rotating Ball Screw

3. Numerical Analysis and Simulation Calculation

3.1. Thermodynamic Model Parameter Calculation of the Nut-Rotating Ball Screw Transmission Mechanism

3.1.1. Heat Generation Calculation

- Heat generation calculation for rolling bearings

- 2.

- Calculation of heat generation at the contact point of the screw and the nut

3.1.2. Thermal Resistance Calculation

- 3.

- Calculation of conduction thermal resistance of thin-walled cylinders

- 4.

- Calculation of Conduction Thermal Resistance of Solid Bodies

- 5.

- Calculation of convective heat transfer resistance

3.1.3. Calculation of Convective Heat Transfer Coefficient

- 6.

- Calculating the convective heat transfer coefficient of rotating components with the external environment

- 7.

- Calculating natural convection heat transfer coefficient

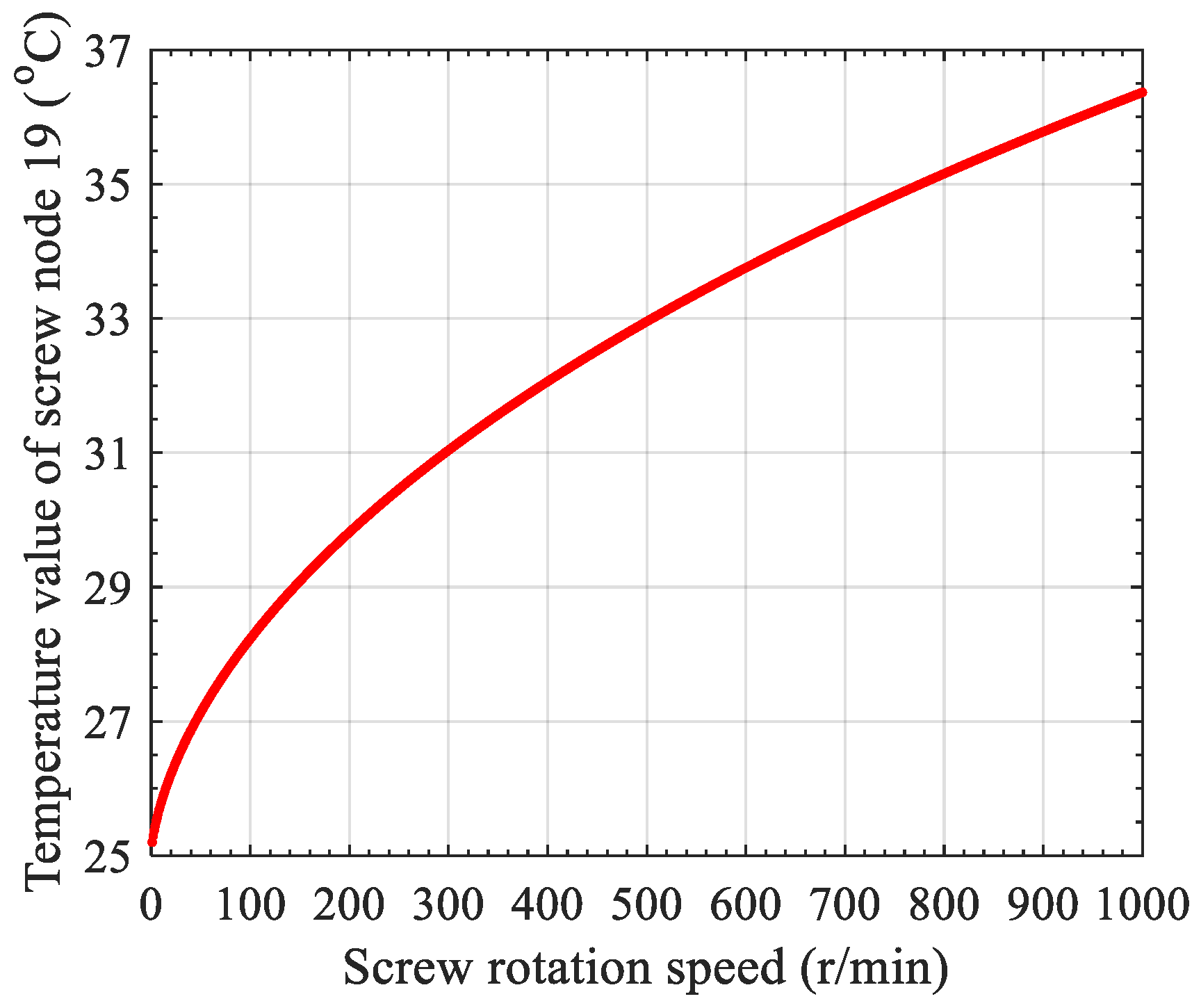

3.2. Node Temperature of Nut-Rotating Ball Screw under a Single Heat Source Condition for Bearing

3.3. Node Temperature of Screw under a Single Heat Source Condition for Nut–Screw Pair

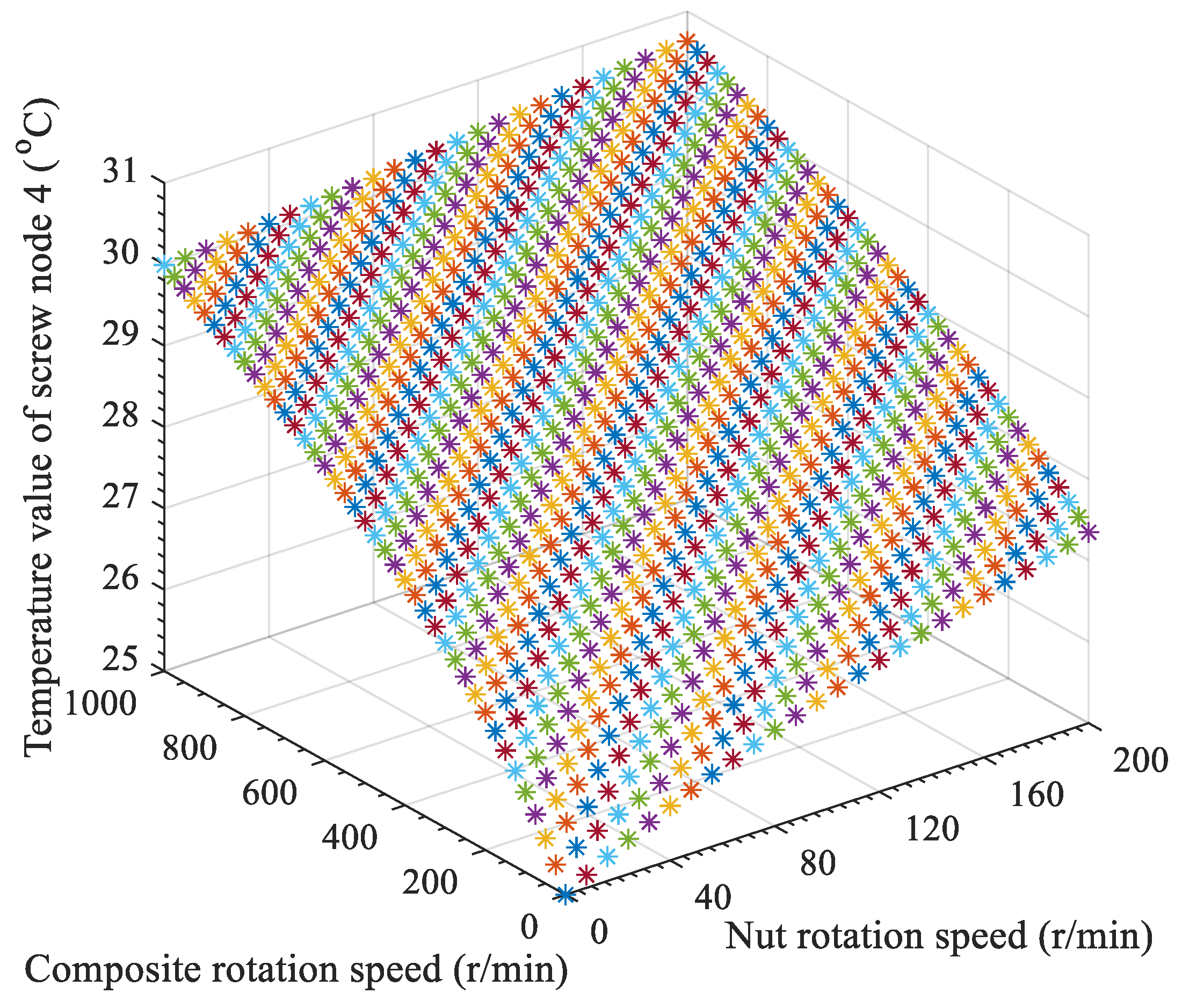

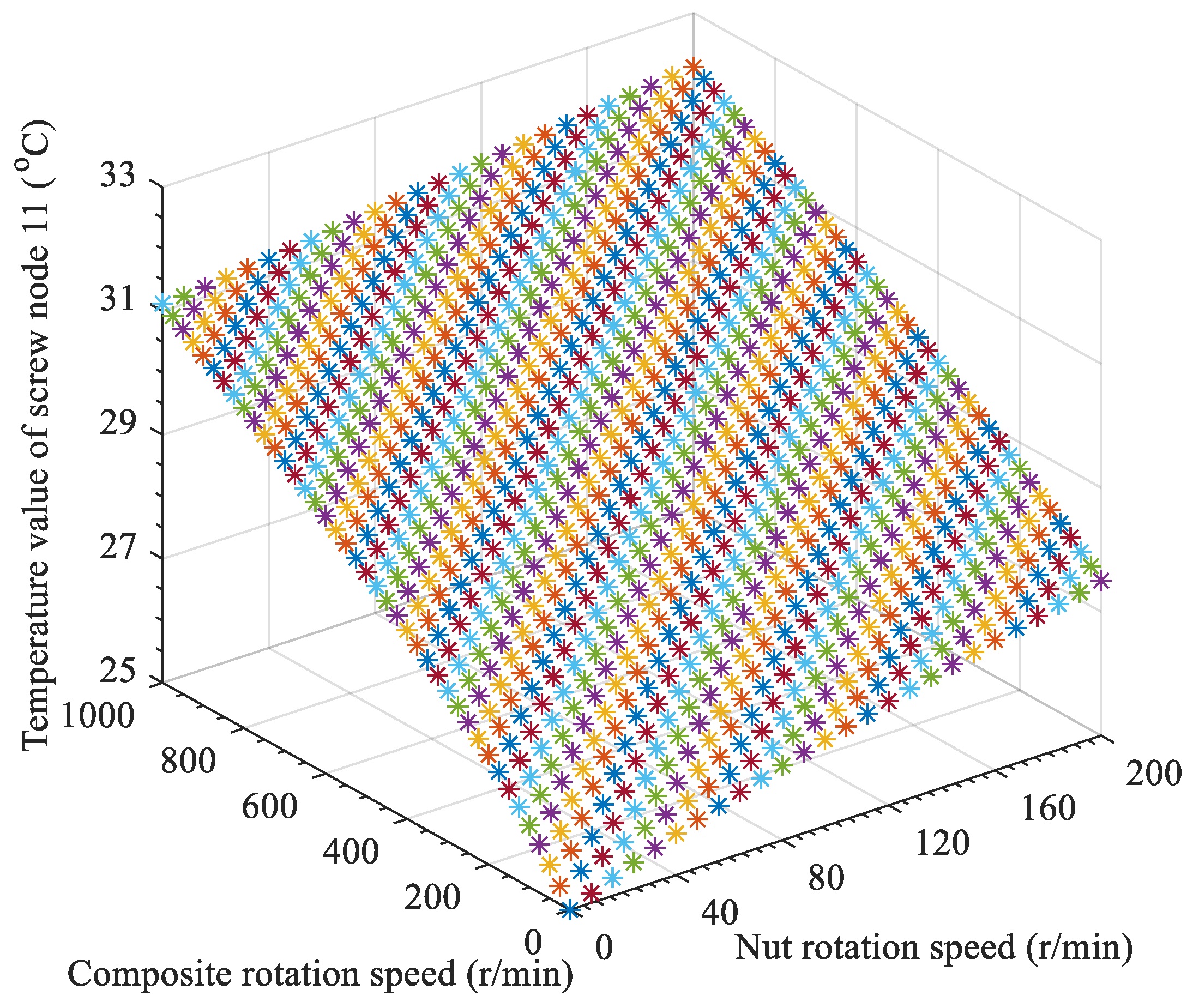

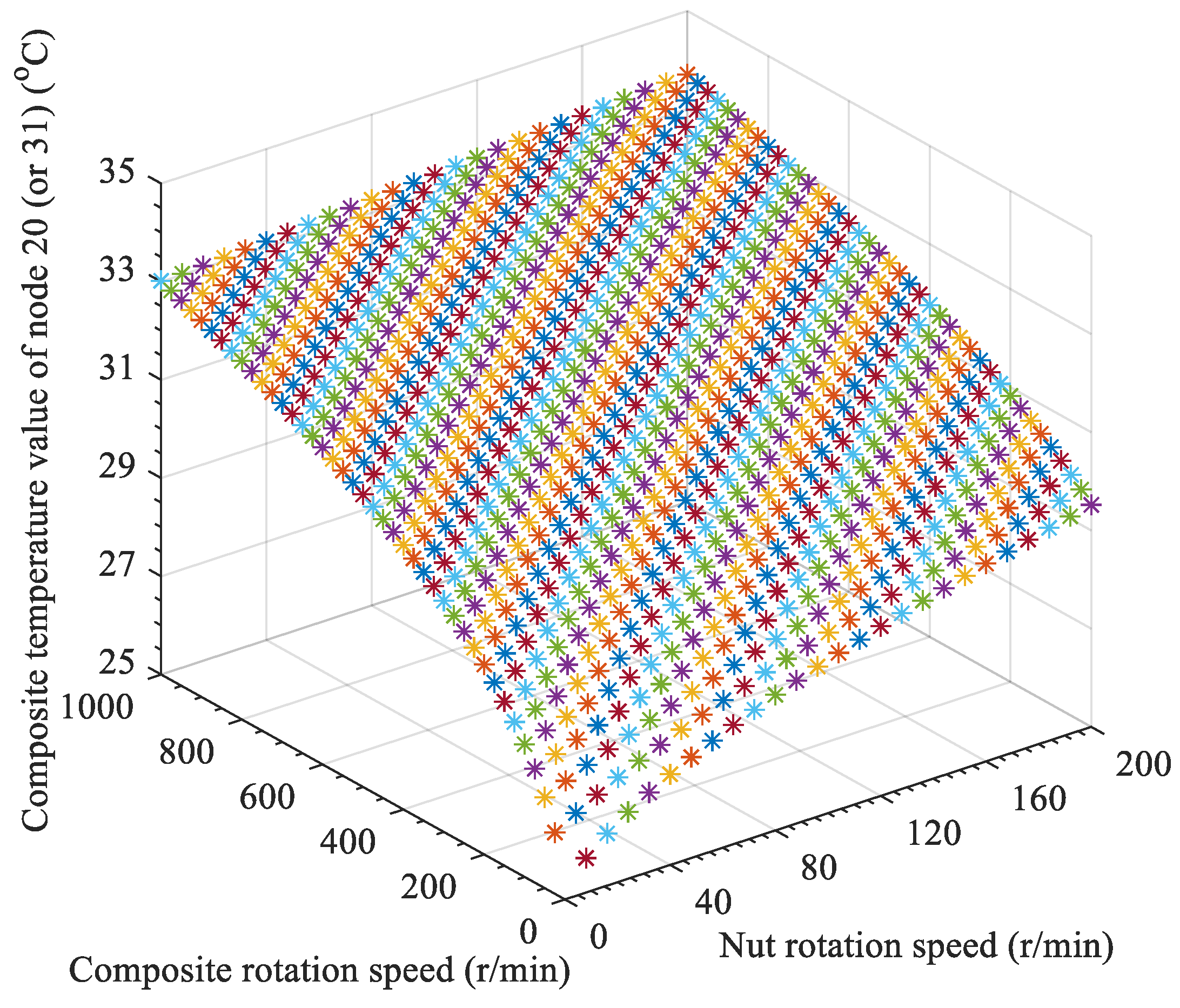

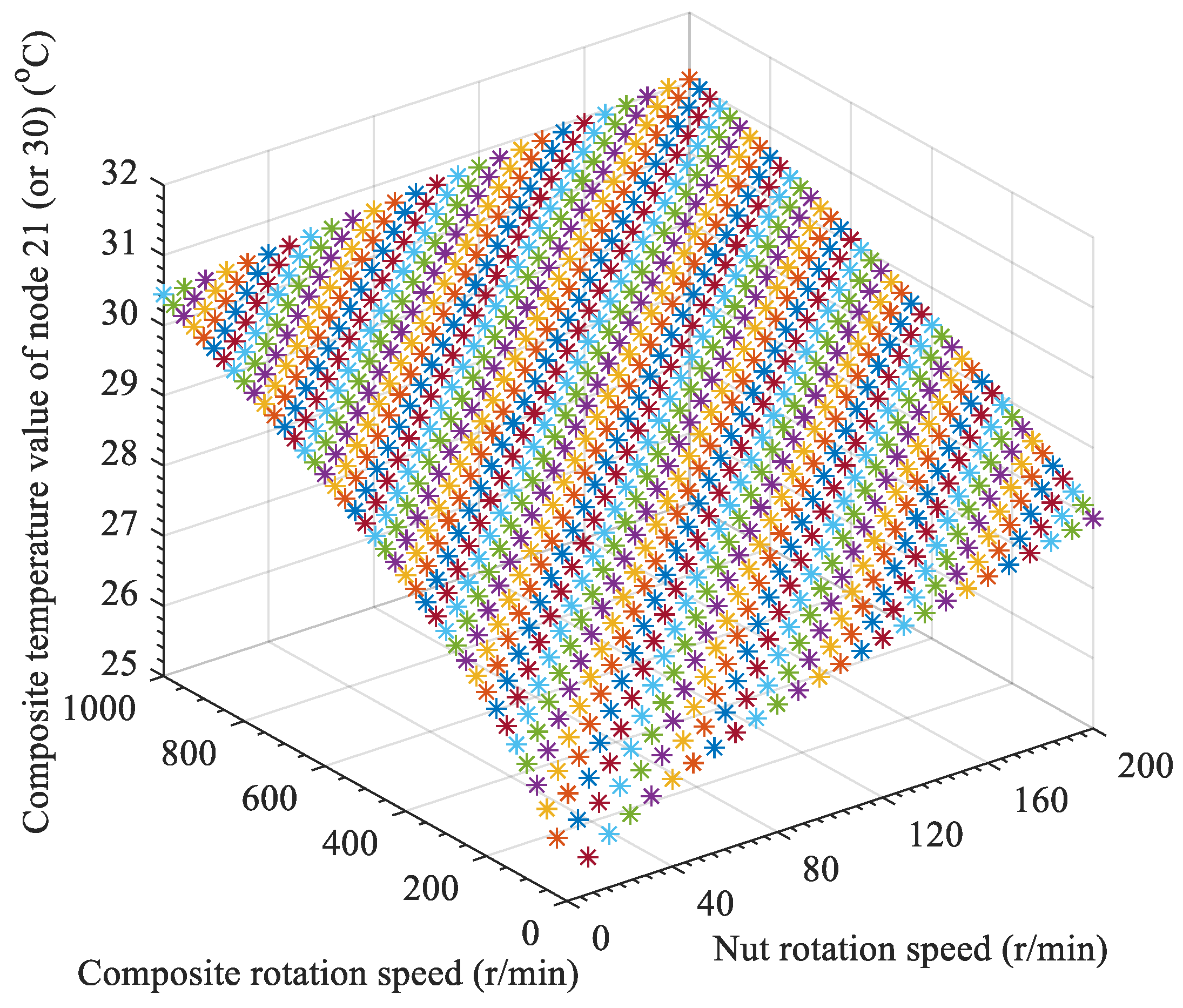

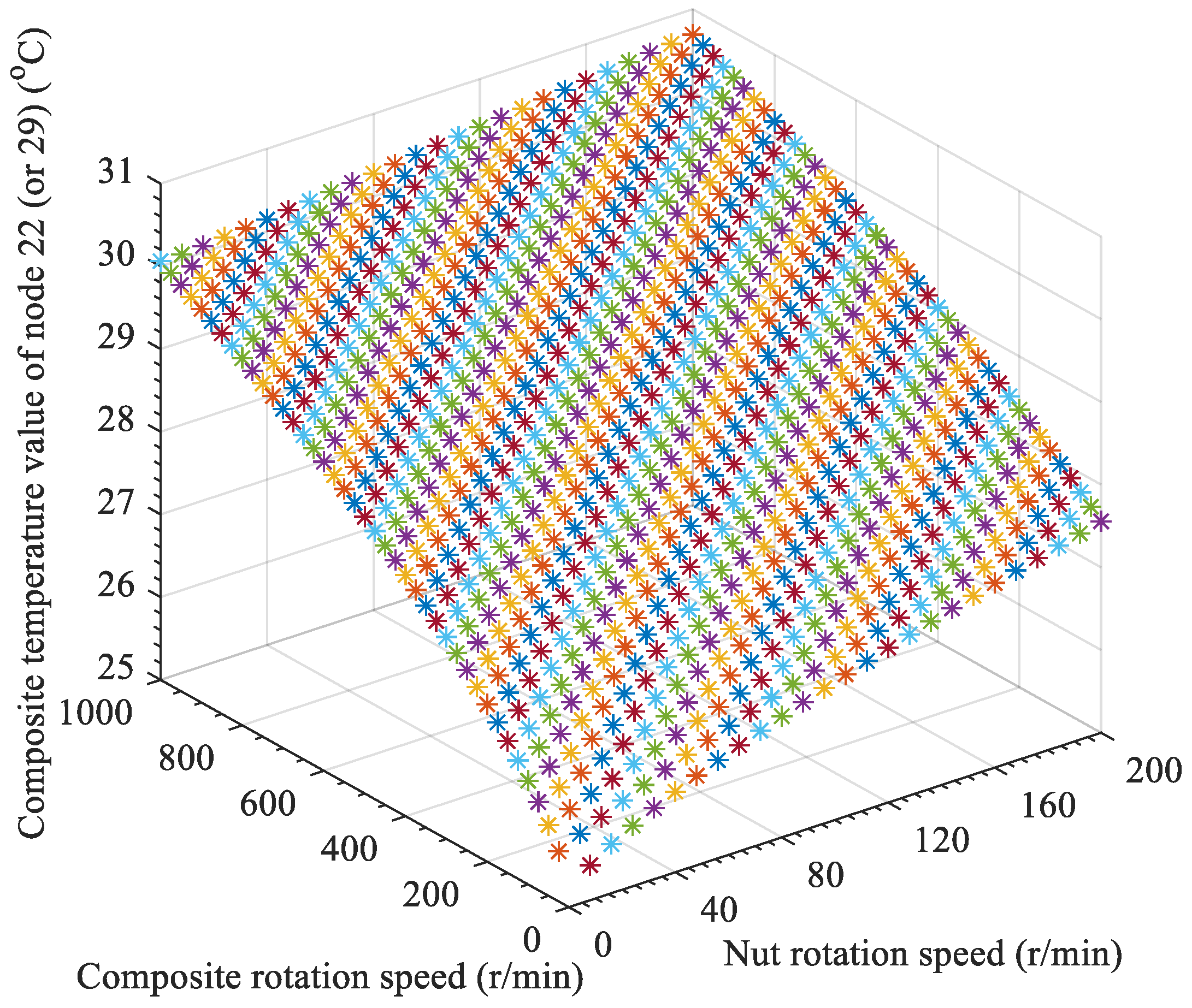

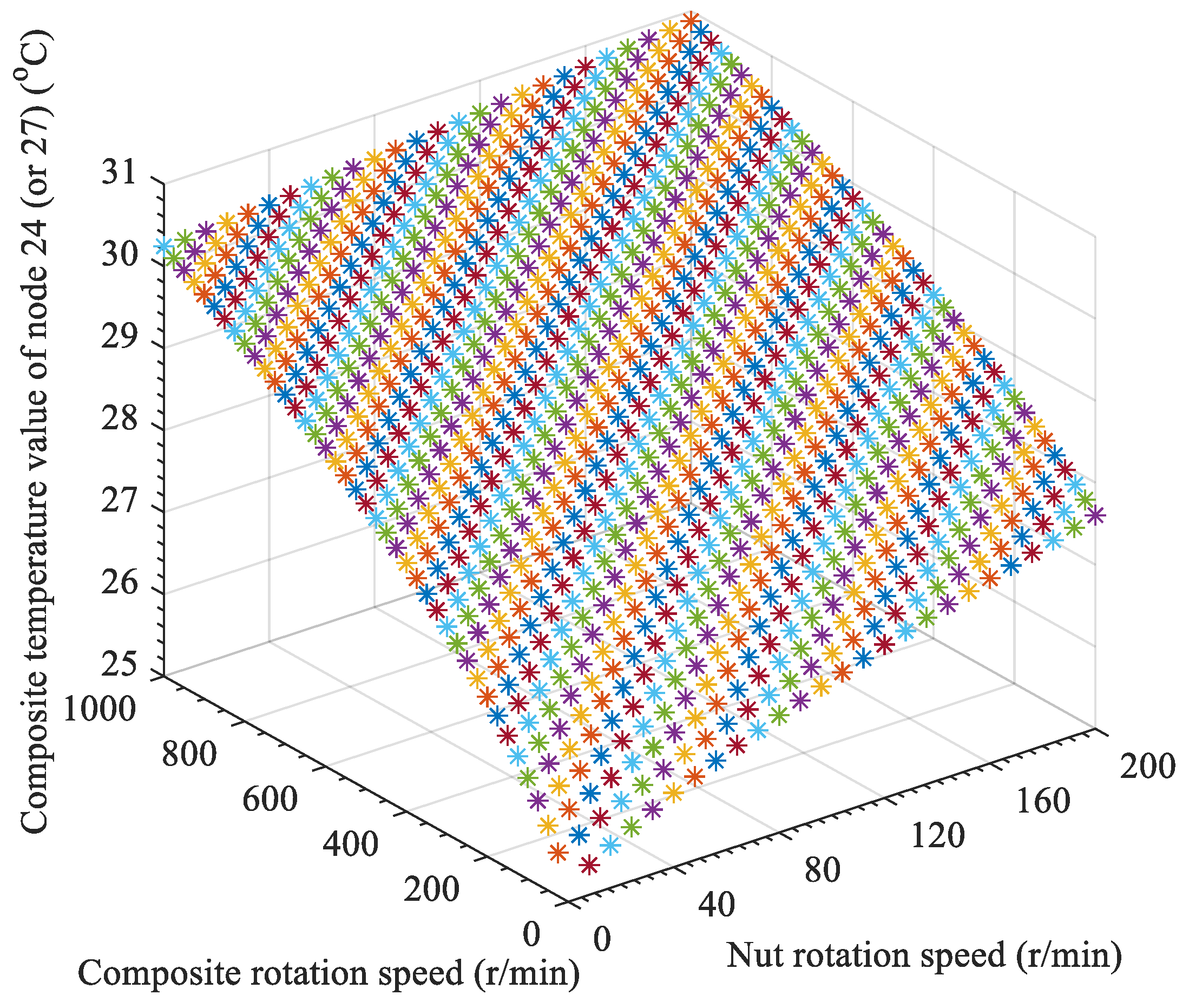

3.4. Node Synthesis Temperature of Nut-Rotating Ball Screw under Multiple Heat Source Working Conditions

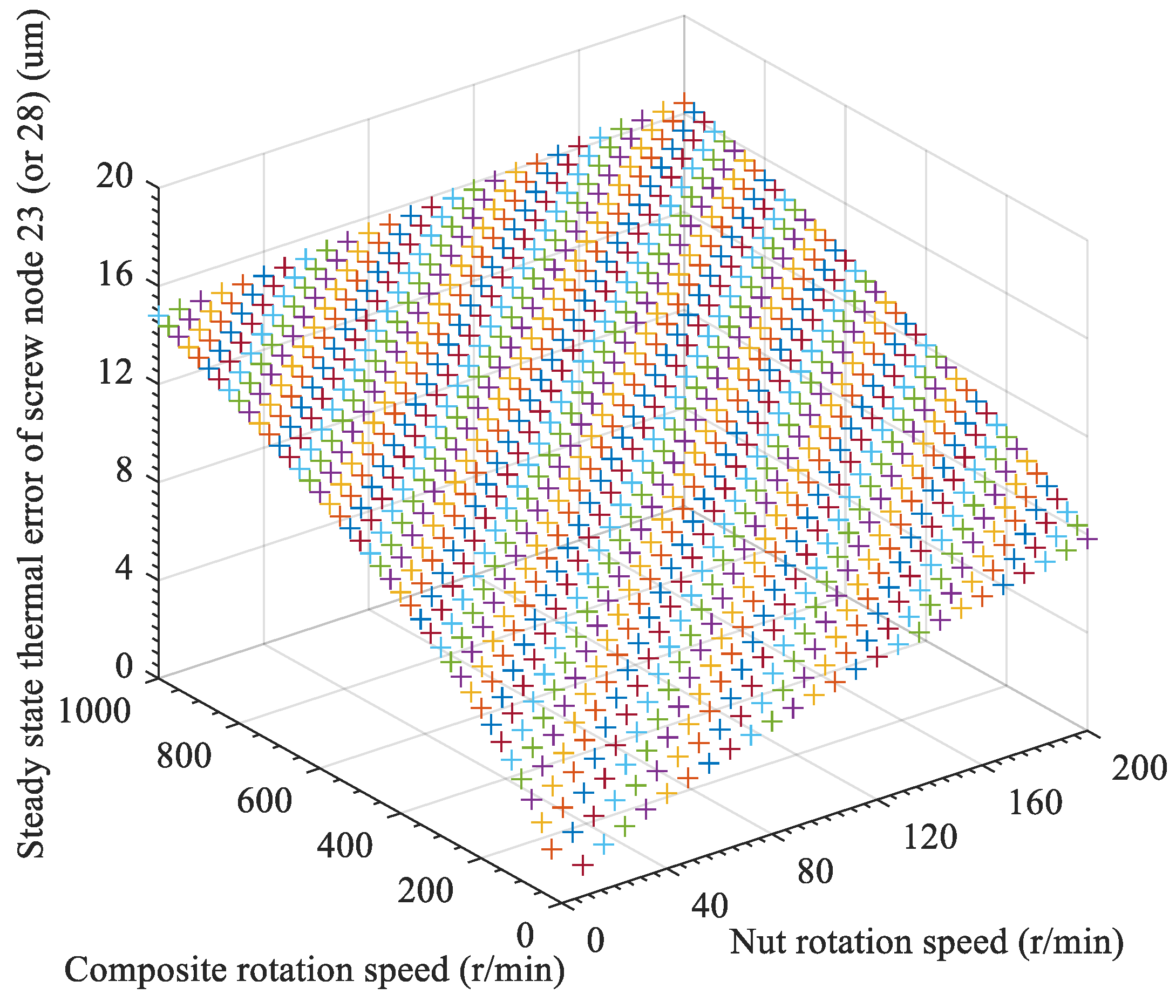

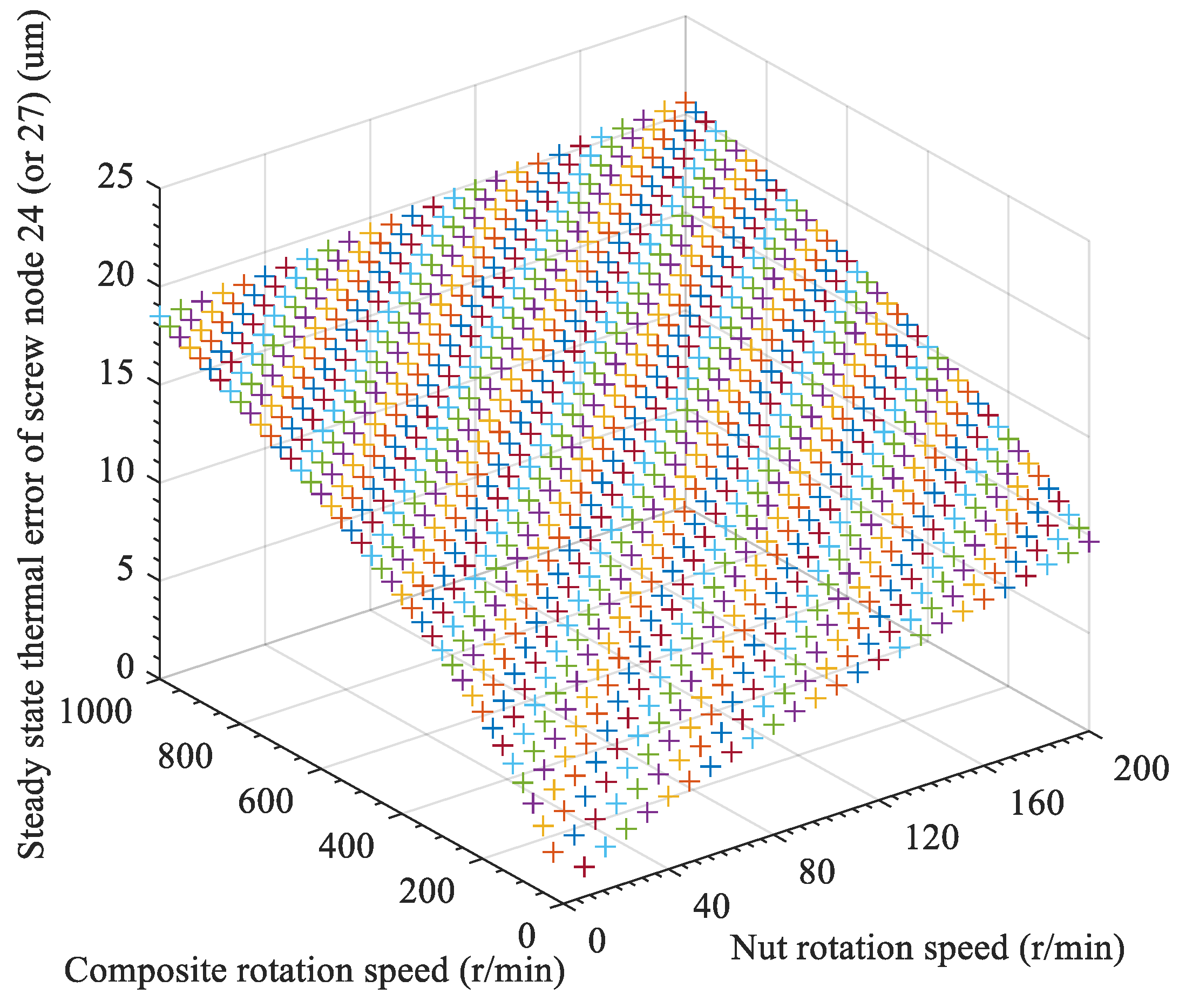

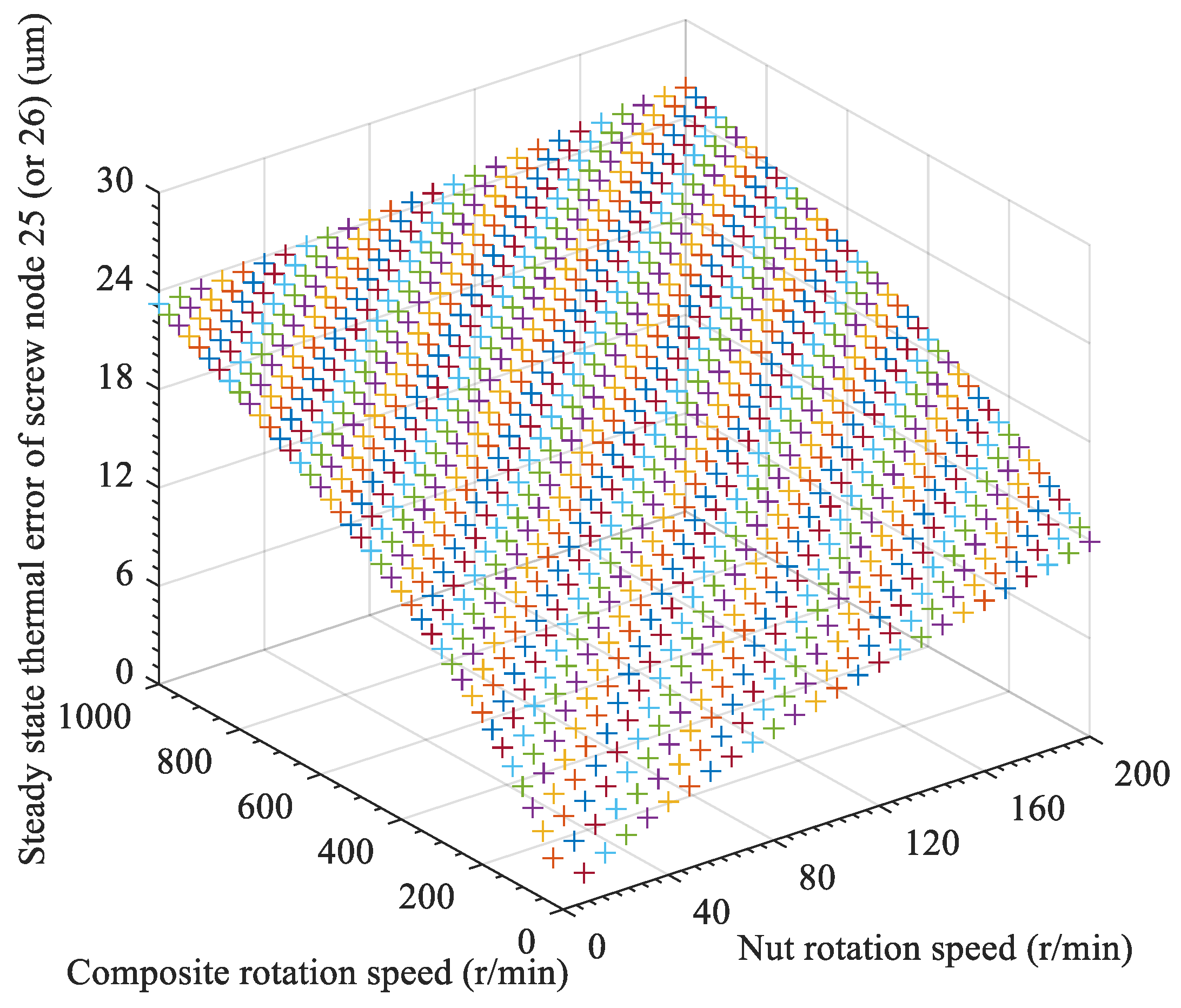

3.5. Steady State Thermal Error of Nut-Rotating Ball Screw

4. Temperature Rise and Thermal Elongation Testing Experiment for Nut-Rotating Ball Screw Transmission Mechanism

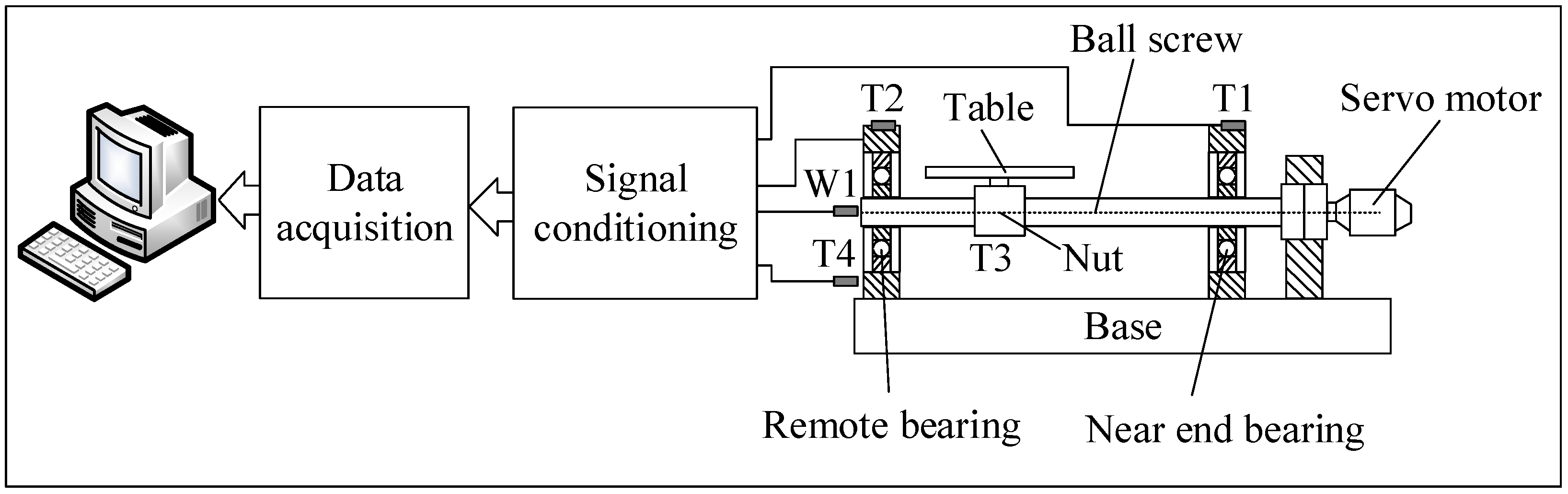

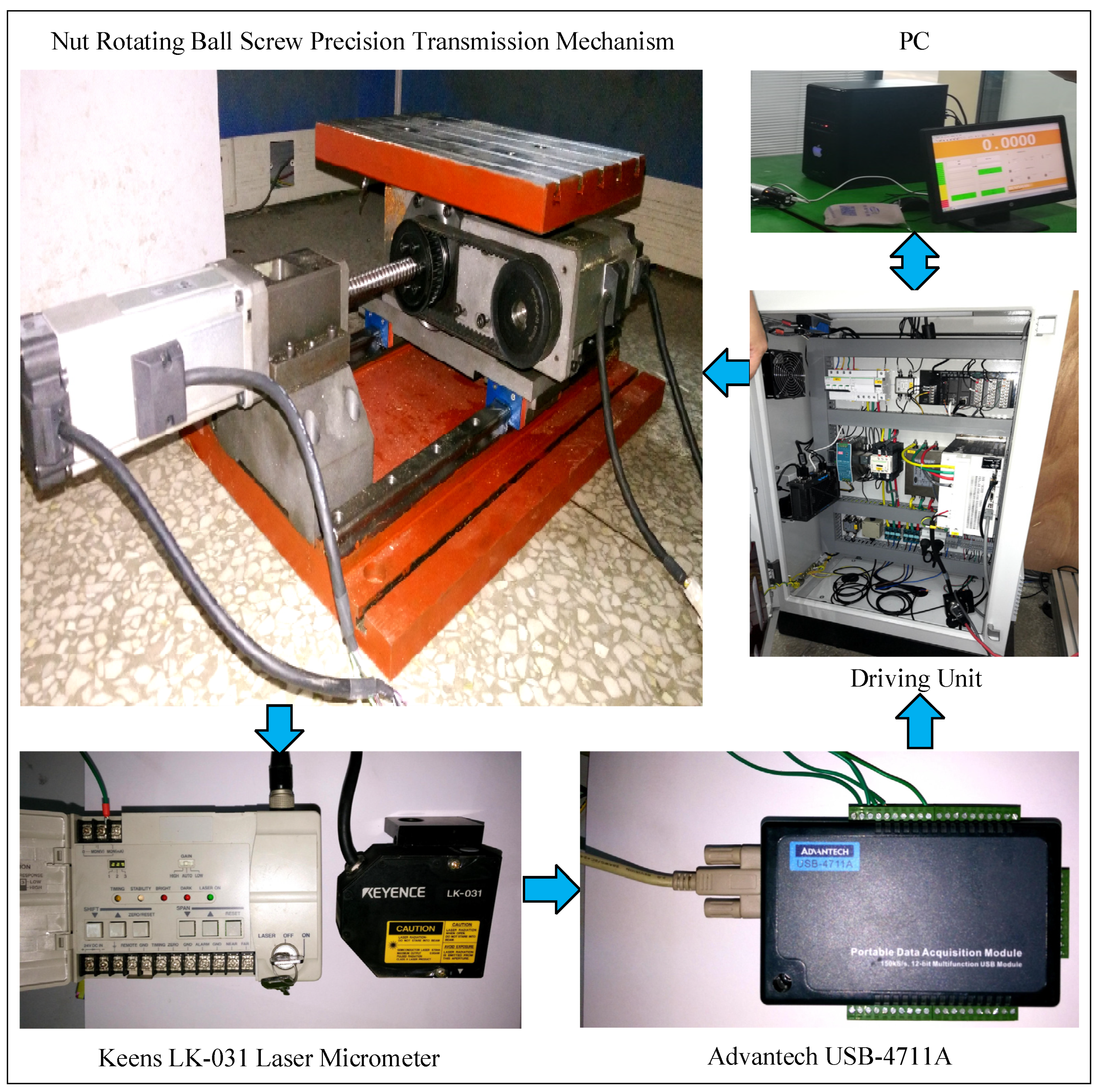

4.1. Construction of Temperature Rise and Thermal Elongation Testing System

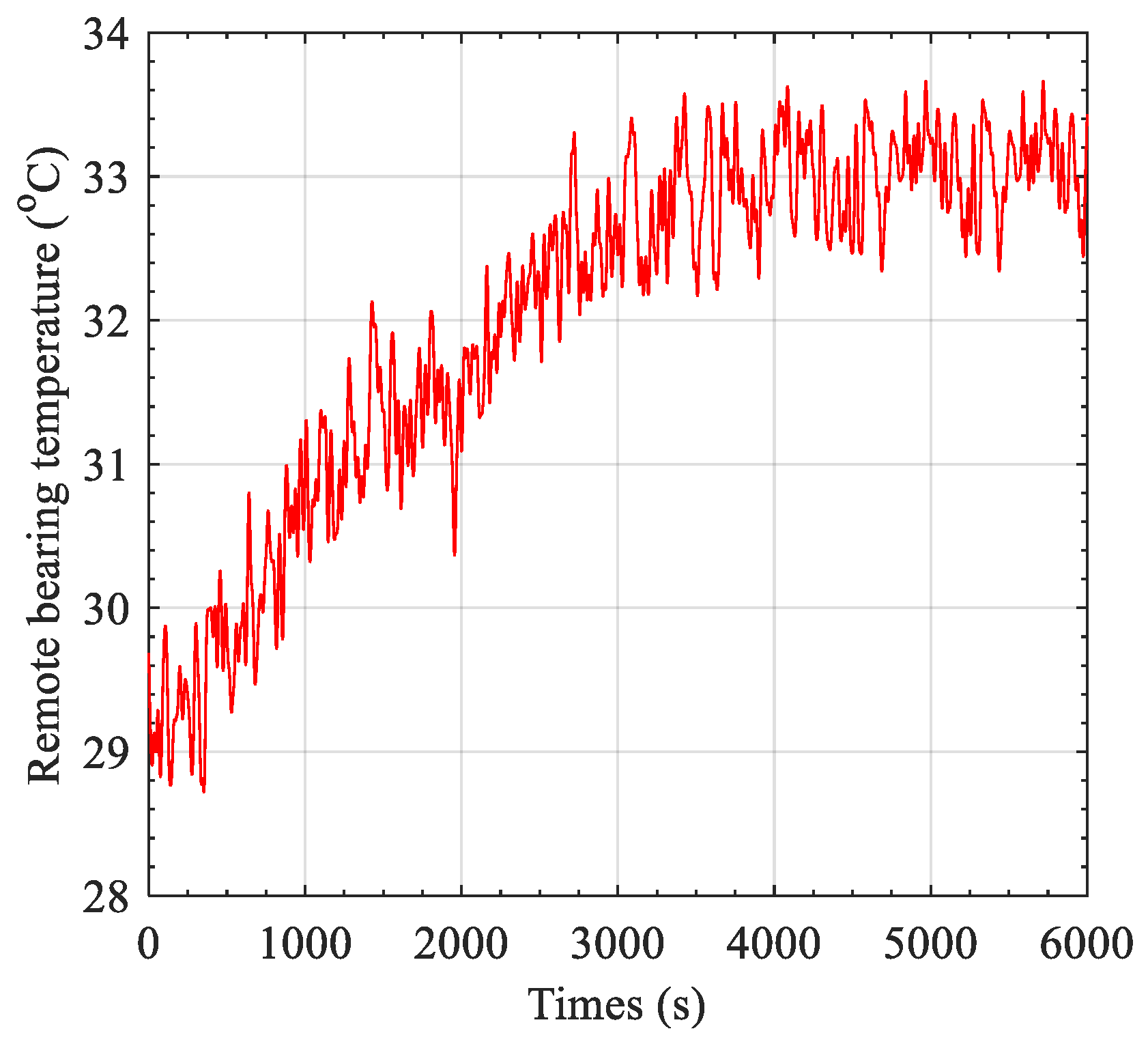

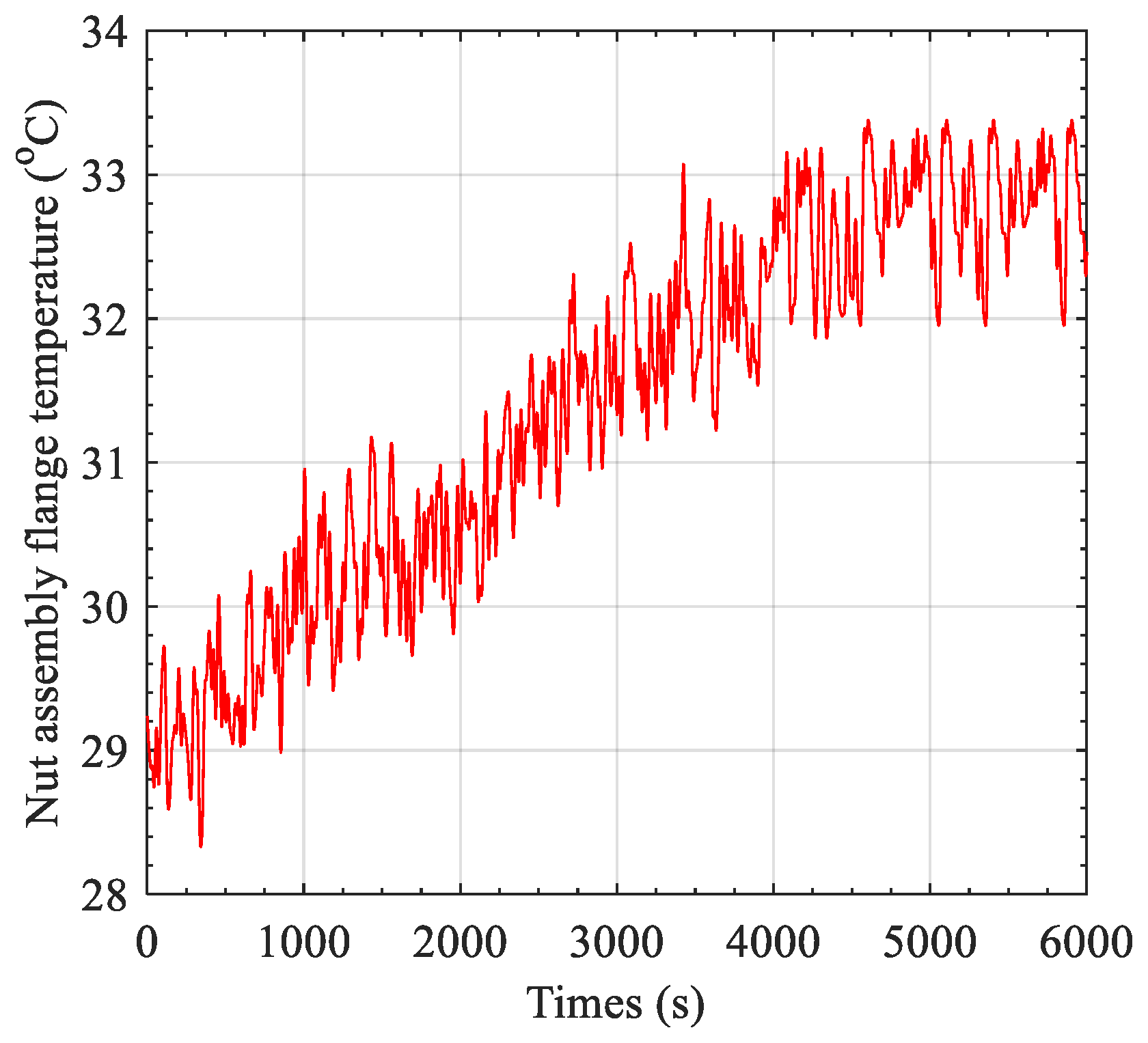

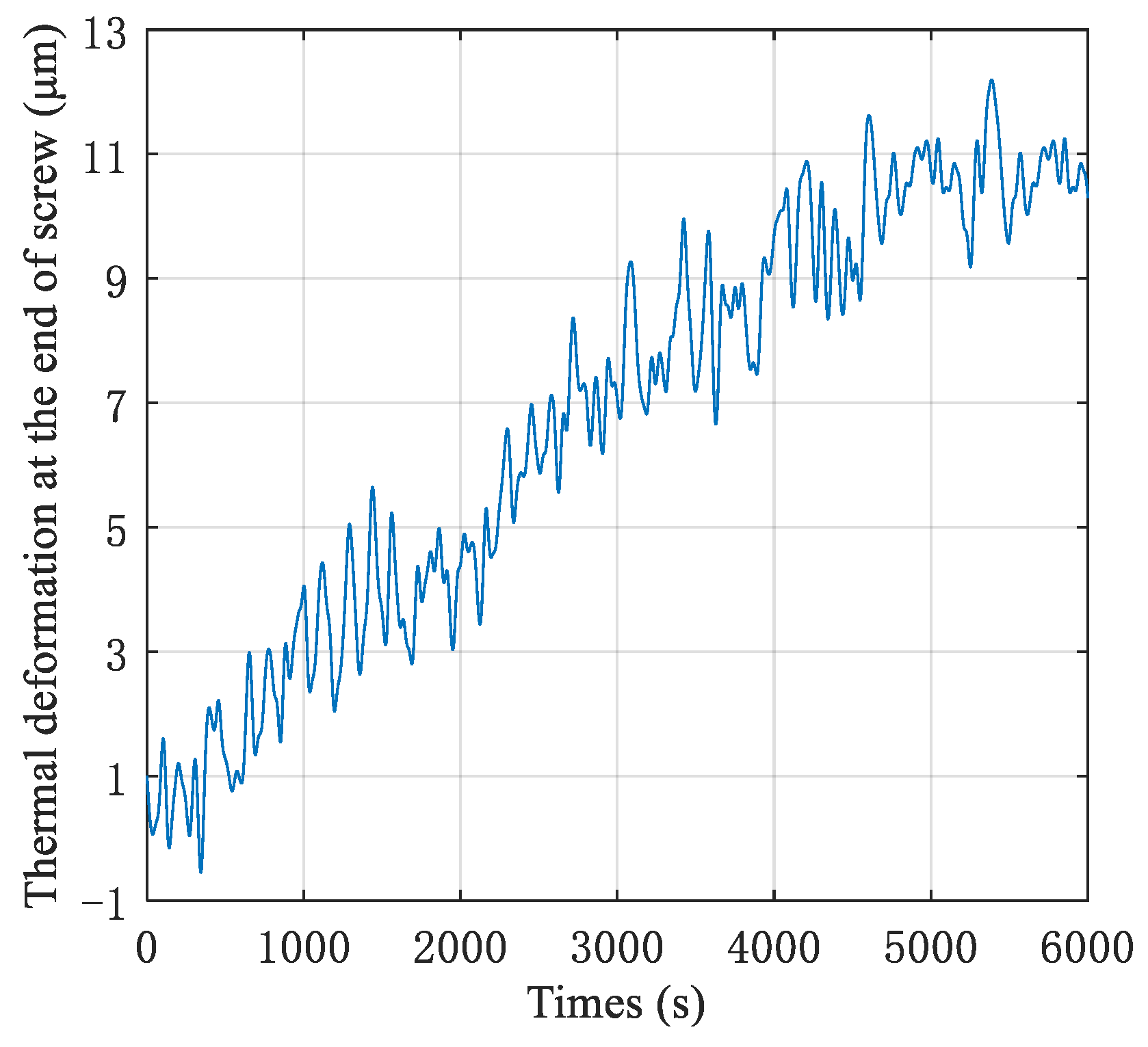

4.2. Experimental Results and Test Analysis

4.3. Thermal Effects Optimization Measures

4.3.1. Reduce the Heat Generation of the System Heat Source

- (1)

- Using fewer intermediate transmission links to reduce the number of heat sources;

- (2)

- Using non-contact bearings, guide rails, and screws (such as hydraulic bearings, hydrostatic guide rails, and hydrostatic screws) or low-friction ceramic bearings;

- (3)

- Reasonably adjusting the pre-tightening force of the bearing and screw and supplementing with appropriate lubricants;

- (4)

- Improving the structure of the ball screw pair, such as by increasing the number of threaded heads, reducing the diameter of steel balls, using hollow balls, and improving the surface processing quality of the raceway.

4.3.2. Enhance the Cooling Capacity of the System

- (1)

- Using hollow ball screw pairs as transmission components and performing forced circulation cooling on the screw pairs and bearings;

- (2)

- Using oil–air micro-lubrication;

- (3)

- Set a constant temperature working environment.

4.3.3. Compensating for Thermal Errors in the Transmission System

- (1)

- Feedback interception method: By inserting a feedback loop into the servo system, thermal error compensation is achieved by adjusting the position of the tool holder;

- (2)

- Zero drift method: Calculating the compensation amount based on the established thermal error model and then sending it to the CNC controller. Finally, the compensation amount is added at each position as a command signal to the servo loop for feedforward compensation.

5. Conclusions

- (1)

- A thermal resistance network model of a nut-rotating ball screw transmission system was established based on heat transfer theory. By addressing the system’s thermal balance equations, the distribution of its temperature field was analyzed. The results objectively reflected the temperature distribution in the system. The temperature distribution of the entire system basically conforms to the law of heat flow, indicating that the use of the thermal resistance network method for temperature field analysis of the multi-heat source system is effective. The prediction accuracy of the model can be enhanced by arranging more temperature nodes and employing experimental data to identify and correct the model parameters.

- (2)

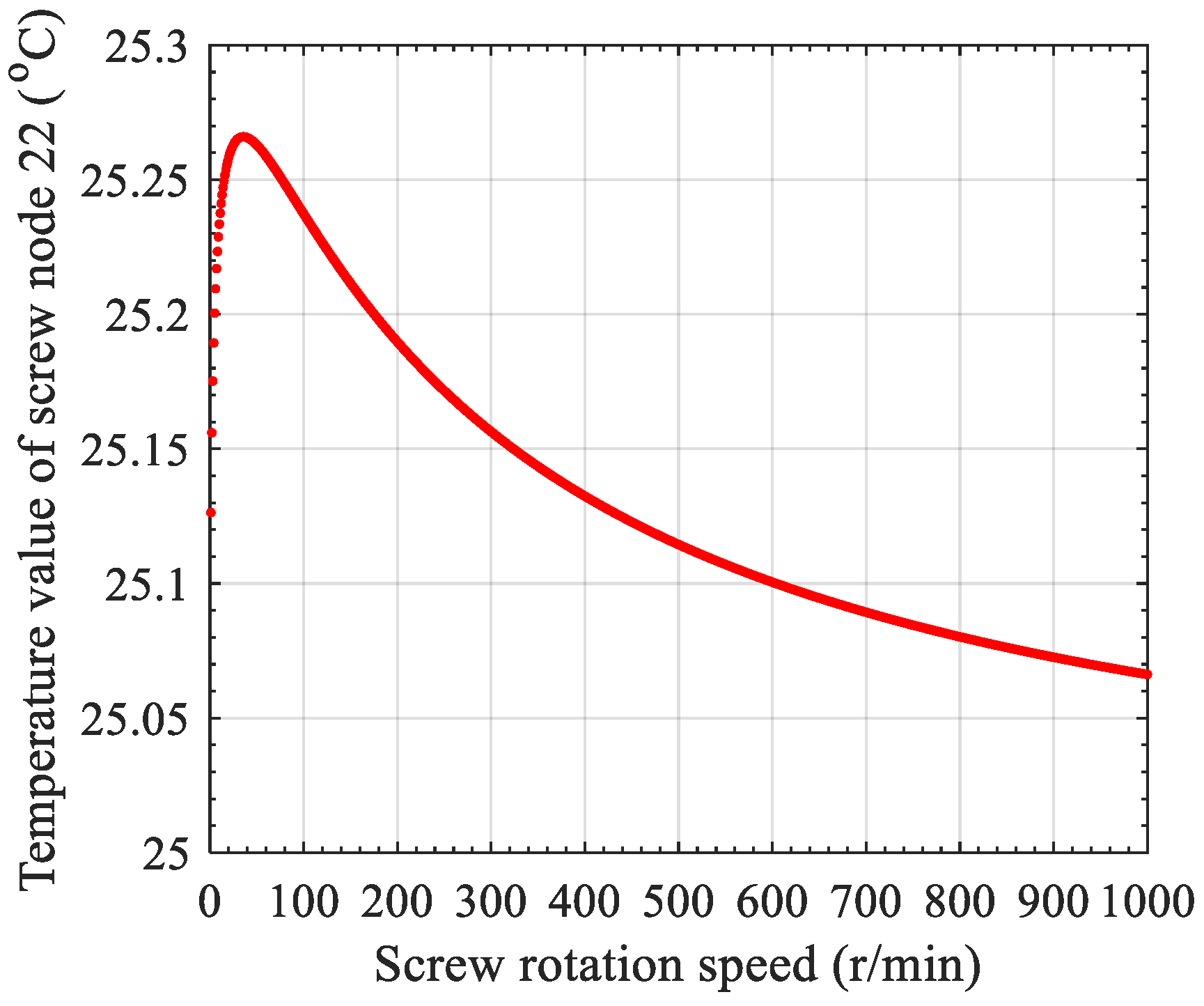

- When a unilateral heat source functions, as the distance from the heat source point increases, the steady-state temperature value of the node rapidly decays. Under the condition that the screw speed reaches a certain value, there is a point where its temperature will maintain a thermal equilibrium state and not change with the increase in screw speed. At nodes far away from the heat source, the temperature is characterized by a slight increase followed by a decrease and tends towards the ambient temperature as the screw speed increases.

- (3)

- The outer ring supporting the bearing in the nut assembly is integrated with the flange in the nut assembly, and the inner ring supporting the bearing can be integrated with the outer ring of the rotating nut. In addition, the nut and screw are driven separately. Due to the proposed structure and driving method, the dual-drive mechanism has varying heat source points from the conventional mechanism, which are also the main factors causing the different heat source distributions of the dual-drive feed mechanism.

- (4)

- Under the action of multiple heat sources and the same feed rate, the node temperature value under the dual-drive condition is higher when compared with that under the single-drive condition, and the distribution of the temperature field is much more complex than that of the single-drive mechanism under the same parameters. Considering the fact that the steady-state thermal error of the screw can be acquired by integrating temperature with the position, the value of the steady-state thermal error also tends to increase with an increase in nut rotation speed and composite rotation speed. In addition, the steady-state thermal error of each node under the dual-drive condition is greater than that under the single-drive condition.

- (5)

- The potential applications of the nut rotary ball screw transmission mechanism and the results of numerical analysis can be applied to advanced technology fields such as robotics, suspensions, powertrain, national defense, integrated electronics, optoelectronics, medicine, and genetic engineering so that the new system can have a lower stable speed limit and achieve precise micro-feed control.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delor, M.; Weaver, H.L.; Yu, Q.Q.; Ginsberg, N.S. Imaging material functionality through three-dimensional nanoscale tracking of energy flow. Nat. Mater. 2020, 19, 56–62. [Google Scholar] [CrossRef]

- Li, Z.M.; Gao, X.Y.; Yang, J.K.; Xin, X.D.; Yi, X.Y.; Bian, L.; Dong, S.X. Designing Ordered Structure with Piezoceramic Actuation Units (OSPAU) for Generating Continual Nanostep Motion. Adv. Sci. 2020, 7, 2001155. [Google Scholar] [CrossRef]

- Russo, M.; Zhang, D.; Liu, X.J.; Xie, Z.H. A review of parallel kinematic machine tools: Design, modeling, and applications. Int. J. Mach. Tools Manuf. 2024, 196, 104118. [Google Scholar] [CrossRef]

- Weng, L.T.; Gao, W.G.; Zhang, D.W.; Huang, T.; Duan, G.L.; Liu, T.; Zheng, Y.J.; Shi, K. Analytical modelling of transient thermal characteristics of precision machine tools and real-time active thermal control method. Int. J. Mach. Tools Manuf. 2023, 186, 104003. [Google Scholar] [CrossRef]

- Li, Y.; Yu, M.L.; Bai, Y.M.; Hou, Z.Y.; Wu, W.W. A review of thermal error modeling methods for machine tools. Appl. Sci. 2021, 11, 5216. [Google Scholar] [CrossRef]

- Han, L.; Tong, Z.Y. A thermal resistance network model based on three-dimensional structure. Measurement 2019, 133, 439–443. [Google Scholar] [CrossRef]

- Li, D.T.; He, Z.L.; Wang, C.; Sun, S.Z.; Ma, K.; Xing, Z.W. Simulation of dry screw vacuum pumps based on chamber model and thermal resistance network. Appl. Therm. Eng. 2022, 211, 118460. [Google Scholar] [CrossRef]

- Sun, Z.H.; Xu, Y.F.; Wang, Q.J.; Xu, J.Z.; Li, G.L.; Wen, Y. Design and identification of lumped-parameter thermal network model for real-time temperature estimation of permanent-magnet spherical motors. Therm. Sci. Eng. Prog. 2023, 44, 102047. [Google Scholar] [CrossRef]

- Meng, Q.Y.; Yan, X.X.; Sun, C.C.; Liu, Y. Research on thermal resistance network modeling of motorized spindle based on the influence of various fractal parameters. Int. Commun. Heat Mass Transf. 2020, 117, 104806. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Zhang, W.; Li, Y.B.; Guo, J. Thermal analysis of axial permanent magnet flywheel machine based on equivalent thermal network method. IEEE Access 2021, 9, 33181–33188. [Google Scholar] [CrossRef]

- Bao, Y.J.; Ma, Y.X.; Yang, Y.X.; Wang, J.L.; Cheng, D. Study on the effect of carbon fiber ply angle on thermal response of CFRP laminate based on the thermal resistance network model. Polym. Compos. 2023, 44, 8792–8804. [Google Scholar] [CrossRef]

- Zhan, Z.Q.; Fang, B.; Wan, S.K.; Bai, Y.; Hong, J.; Li, X.H. An accurate and efficient implicit thermal network method for the steady-state temperature field. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 1800–1810. [Google Scholar] [CrossRef]

- Li, T.J.; Wang, M.Z.; Zhao, C.Y. Study on real-time thermal–mechanical–frictional coupling characteristics of ball bearings based on the inverse thermal network method. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 2335–2349. [Google Scholar] [CrossRef]

- Yang, Y.B.; Zhou, X. A volumetric heat source model for thermal modeling of additive manufacturing of metals. Metals 2020, 10, 1406. [Google Scholar] [CrossRef]

- Wu, H.Y.; Guan, Q.; Xi, C.F.; Zuo, D.W. Construction of dynamic temperature field model of ball screw based on superposition of positive and negative temperature fields. Numer. Heat Transf. Part A Appl. 2023, 83, 343–360. [Google Scholar] [CrossRef]

- Liu, J.L.; Ma, C.; Wang, S.L.; Wang, S.B.; Yang, B.; Shi, H. Thermal boundary condition optimization of ball screw feed drive system based on response surface analysis. Mech. Syst. Signal Process. 2019, 121, 471–495. [Google Scholar] [CrossRef]

- Sheng, X.; Lu, X.; Zhang, J.R.; Lu, Y.Q. An analytical solution to temperature field distribution in a thick rod subjected to periodic-motion heat sources and application in ball screws. Eng. Optim. 2021, 53, 2144–2163. [Google Scholar] [CrossRef]

- Wang, L.; Jia, Z.Y.; Zhang, L. Investigation on the accurate calculation of the temperature field of permanent magnet governor and the optimization method of heat conduction. Case Stud. Therm. Eng. 2019, 13, 100360. [Google Scholar] [CrossRef]

- Liu, W.Z.; Zhang, C.; Duan, F.J.; Fu, X.; Bao, R.J.; Yu, Z.X.; Gong, X. An optimization method of temperature field distribution to improve the accuracy of laser multi-degree-of-freedom measurement system. Optik 2022, 269, 169721. [Google Scholar] [CrossRef]

- Sun, S.B.; Yan, S.H.; Cao, X.P.; Zhang, W. Distribution law of the initial temperature field in a railway tunnel with high rock temperature: A model test and numerical analysis. Appl. Sci. 2023, 13, 1638. [Google Scholar] [CrossRef]

- Gao, X.S.; Zhang, K.; Zhang, Z.T.; Wang, M.; Zan, T.; Gao, P. XGBoost-based thermal error prediction and compensation of ball screws. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 151–163. [Google Scholar] [CrossRef]

- Su, D.X.; Li, Y.; Zhao, W.H.; Zhang, H.J. Transient thermal error modeling of a ball screw feed system. Int. J. Adv. Manuf. Technol. 2023, 124, 2095–2107. [Google Scholar] [CrossRef]

- Yang, J.C.; Li, C.Y.; Xu, M.T.; Zhang, Y.M. Analysis of thermal error model of ball screw feed system based on experimental data. Int. J. Adv. Manuf. Technol. 2022, 119, 7415–7427. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.B.; Zheng, Y.N.; Gao, F.; Li, W.Q.; Hei, C.F. Thermal error compensation for a fluid-cooling ball-screw feed system. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 09544054231210963. [Google Scholar] [CrossRef]

- Liu, H.L.; Rao, Z.F.; Pang, R.D.; Zhang, Y.M. Research on thermal characteristics of ball screw feed system considering nut movement. Machines 2021, 9, 249. [Google Scholar] [CrossRef]

- Shi, H.; Ma, C.; Yang, J.; Zhao, L.; Mei, X.S.; Gong, G.F. Investigation into effect of thermal expansion on thermally induced error of ball screw feed drive system of precision machine tools. Int. J. Mach. Tools Manuf. 2015, 97, 60–71. [Google Scholar] [CrossRef]

- Rong, R.; Zhou, H.C.; Huang, Y.B.; Yang, J.Z.; Xiang, H. Novel Real-Time Compensation Method for Machine Tool’s Ball Screw Thermal Error. Appl. Sci. 2023, 13, 2833. [Google Scholar] [CrossRef]

- Cao, L.; Park, C.H.; Chung, S.C. Real-time thermal error prediction and compensation of ball screw feed systems via model order reduction and hybrid boundary condition update. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2022, 77, 227–240. [Google Scholar] [CrossRef]

- Tanaka, S.; Kizaki, T.; Tomita, K.; Tsujimura, S.; Kobayashi, H.; Sugita, N. Robust thermal error estimation for machine tools based on in-process multi-point temperature measurement of a single axis actuated by a ball screw feed drive system. J. Manuf. Process. 2023, 85, 262–271. [Google Scholar] [CrossRef]

- Liu, H.Y.; Deng, H.G.; Feng, X.Y.; Liu, Y.D.; Li, Y.F.; Yao, M. Data-driven thermal error modeling based on a novel method of temperature measuring point selection. Int. J. Adv. Manuf. Technol. 2024, 131, 1823–1848. [Google Scholar] [CrossRef]

- Peng, J.; Yin, M.; Cao, L.; Liao, Q.H.; Wang, L.; Yin, G.F. Study on the spindle axial thermal error of a five-axis machining center considering the thermal bending effect. Precis. Eng. 2022, 75, 210–226. [Google Scholar] [CrossRef]

- Yu, H.W.; Feng, X.Y.; Sun, Q. Kinematic analysis and simulation of a new type of differential micro-feed mechanism with friction. Sci. Prog. 2020, 103, 0036850419875667. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.W.; Zhang, L.G.; Wang, C.; Feng, X.Y. Dynamic characteristics analysis and experimental of differential dual drive servo feed system. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6737–6751. [Google Scholar] [CrossRef]

| Node | Location of Each Temperature Node | Node Temperature |

|---|---|---|

| 1 | The temperature of the screw section at a distance of 25 mm from the right end of the rotating nut | |

| 2 | The temperature of the screw section at the right support ball section in the nut assembly | |

| 3 | The temperature of the screw section at the left support ball section in the nut assembly | |

| 4 | The temperature of the screw section at a distance of 4 mm from the left end of the rotating nut | |

| 5 | Surface temperature of the nut inner ring at a distance of 25 mm from the right end of the rotating nut | |

| 6 | The surface temperature of the nut inner ring at the right support ball section in the nut assembly | |

| 7 | The surface temperature of the nut inner ring at the left support ball section in the nut assembly | |

| 8 | Surface temperature of the nut inner ring at a distance of 4 mm from the left end of the rotating nut | |

| 9 | Surface temperature of the nut outer ring at a distance of 25 mm from the right end of the rotating nut | |

| 10 | The average temperature of the right support ball in the nut assembly | |

| 11 | The average temperature of the left support ball in the nut assembly | |

| 12 | Surface temperature of the nut outer ring at a distance of 4 mm from the left end of the rotating nut | |

| 13 | Surface temperature of the nut seat inner ring at a distance of 25 mm from the right end of the rotating nut | |

| 14 | The surface temperature of the nut seat inner ring at the right support ball section in the nut assembly | |

| 15 | Surface temperature of the nut seat inner ring at the flange section in the nut assembly | |

| 16 | Surface temperature of the nut seat outer ring at a distance of 25 mm from the right end of the rotating nut | |

| 17 | The surface temperature of the nut seat outer ring at the right support ball section in the nut assembly | |

| 18 | Surface temperature of the nut seat outer ring at the flange section in the nut assembly | |

| I | Air temperature between nut seat and rotating nut | |

| 19, 32 | The temperature of the screw section at the left bearing section of the screw | |

| 20, 31 | The temperature of the screw section at a distance of 40 mm from the bearing section on the left side of the screw | |

| 21, 30 | The temperature of the screw section at a distance of 100 mm from the bearing section on the left side of the screw | |

| 22, 29 | The temperature of the screw section at a distance of 160 mm from the bearing section on the left side of the screw | |

| 23, 28 | The temperature of the screw section at a distance of 220 mm from the bearing section on the left side of the screw | |

| 24, 27 | The temperature of the screw section at a distance of 280 mm from the bearing section on the left side of the screw | |

| 25, 26 | The temperature of the screw section at the bearing section on the right side of the screw | |

| A | External environmental temperature |

| Parameters | Values | Unit |

|---|---|---|

| Ball screw diameter | 16 | |

| Axial force | 500 | |

| Thermal conductivity | 50 | |

| Thermal diffusivity | ||

| Lubricant kinematic viscosity | 40 | or |

| Average linear expansion coefficient of screw |

| Scope of Application | Location of Heat Exchange Surface | Flow Pattern | ||

|---|---|---|---|---|

| 0.59 | 1/4 | Vertical flat wall | laminar flow | |

| 0.12 | 1/3 | Vertical flat wall | turbulence | |

| 0.54 | 1/4 | Horizontal wall facing downwards | laminar flow | |

| 0.14 | 1/3 | Horizontal wall facing upwards | turbulence | |

| 0.27 | 1/4 | Horizontal wall facing downwards | laminar flow |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Luan, X.; Zheng, G.; Hao, G.; Liu, Y.; Xing, H.; Liu, Y.; Fu, X.; Liu, Z. Analysis and Experiment of Thermal Field Distribution and Thermal Deformation of Nut Rotary Ball Screw Transmission Mechanism. Appl. Sci. 2024, 14, 5790. https://doi.org/10.3390/app14135790

Yu H, Luan X, Zheng G, Hao G, Liu Y, Xing H, Liu Y, Fu X, Liu Z. Analysis and Experiment of Thermal Field Distribution and Thermal Deformation of Nut Rotary Ball Screw Transmission Mechanism. Applied Sciences. 2024; 14(13):5790. https://doi.org/10.3390/app14135790

Chicago/Turabian StyleYu, Hanwen, Xuecheng Luan, Guiyuan Zheng, Guangchao Hao, Yan Liu, Hongyu Xing, Yandong Liu, Xiaokui Fu, and Zhi Liu. 2024. "Analysis and Experiment of Thermal Field Distribution and Thermal Deformation of Nut Rotary Ball Screw Transmission Mechanism" Applied Sciences 14, no. 13: 5790. https://doi.org/10.3390/app14135790

APA StyleYu, H., Luan, X., Zheng, G., Hao, G., Liu, Y., Xing, H., Liu, Y., Fu, X., & Liu, Z. (2024). Analysis and Experiment of Thermal Field Distribution and Thermal Deformation of Nut Rotary Ball Screw Transmission Mechanism. Applied Sciences, 14(13), 5790. https://doi.org/10.3390/app14135790