Hydraulic Expansion Techniques for Fracture-Cavity Carbonate Rock with Field Applications

Abstract

:1. Introduction

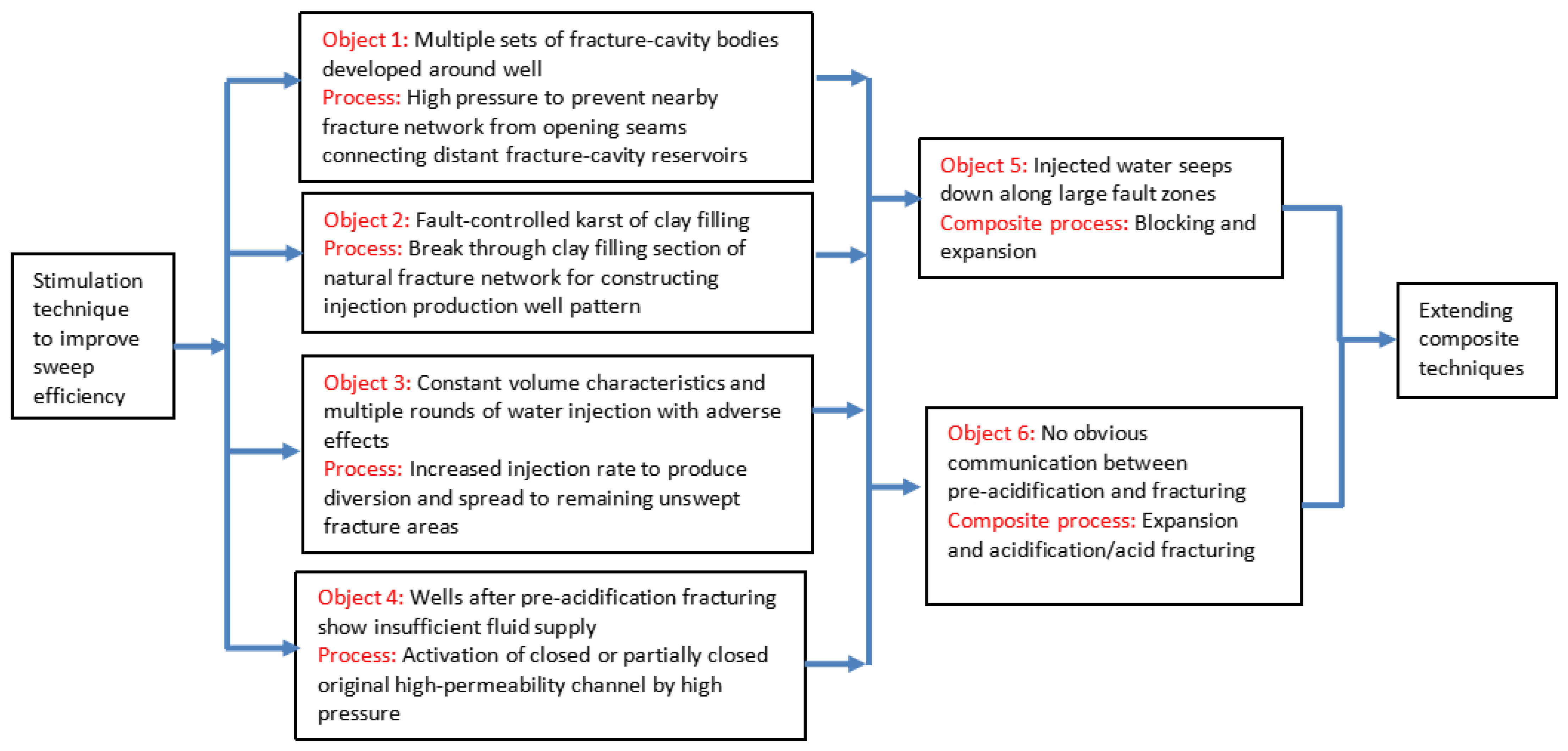

2. Proposed Method for Increased Production Using Hydraulic Expansion

2.1. High Pressure to Prevent Nearby Fracture Network from Opening Seams Connecting Distant Fracture-Cavity Reservoirs

2.2. Break through the Clay Filling Section of the Natural Fracture Network to Construct the Injection Production Well Pattern

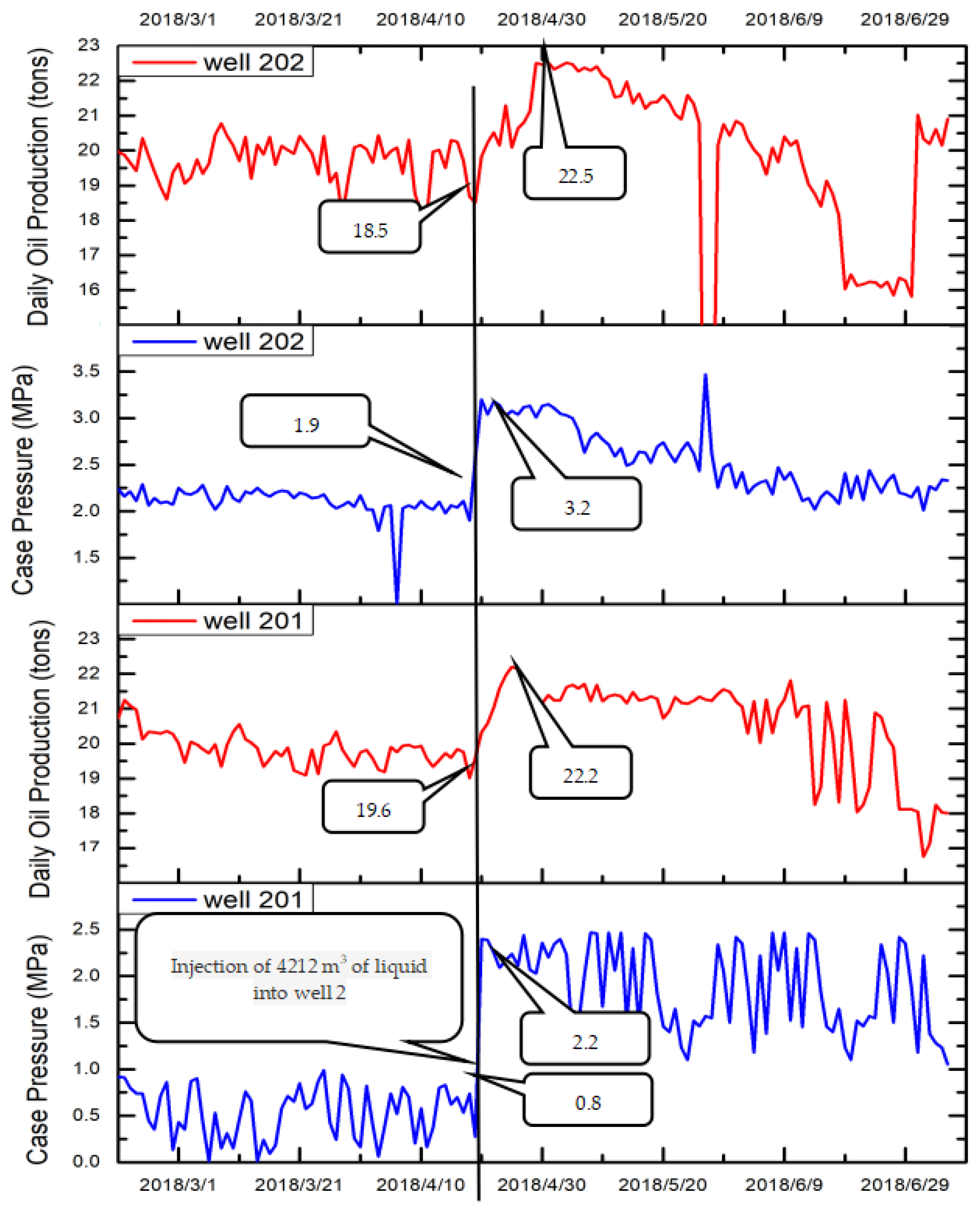

2.3. Increased Injection Rate to Produce Diversion and Spread to Remaining Unswept Fracture Areas

2.4. Activation of Closed or Partially Closed Original High-Permeability Channel by High Pressure

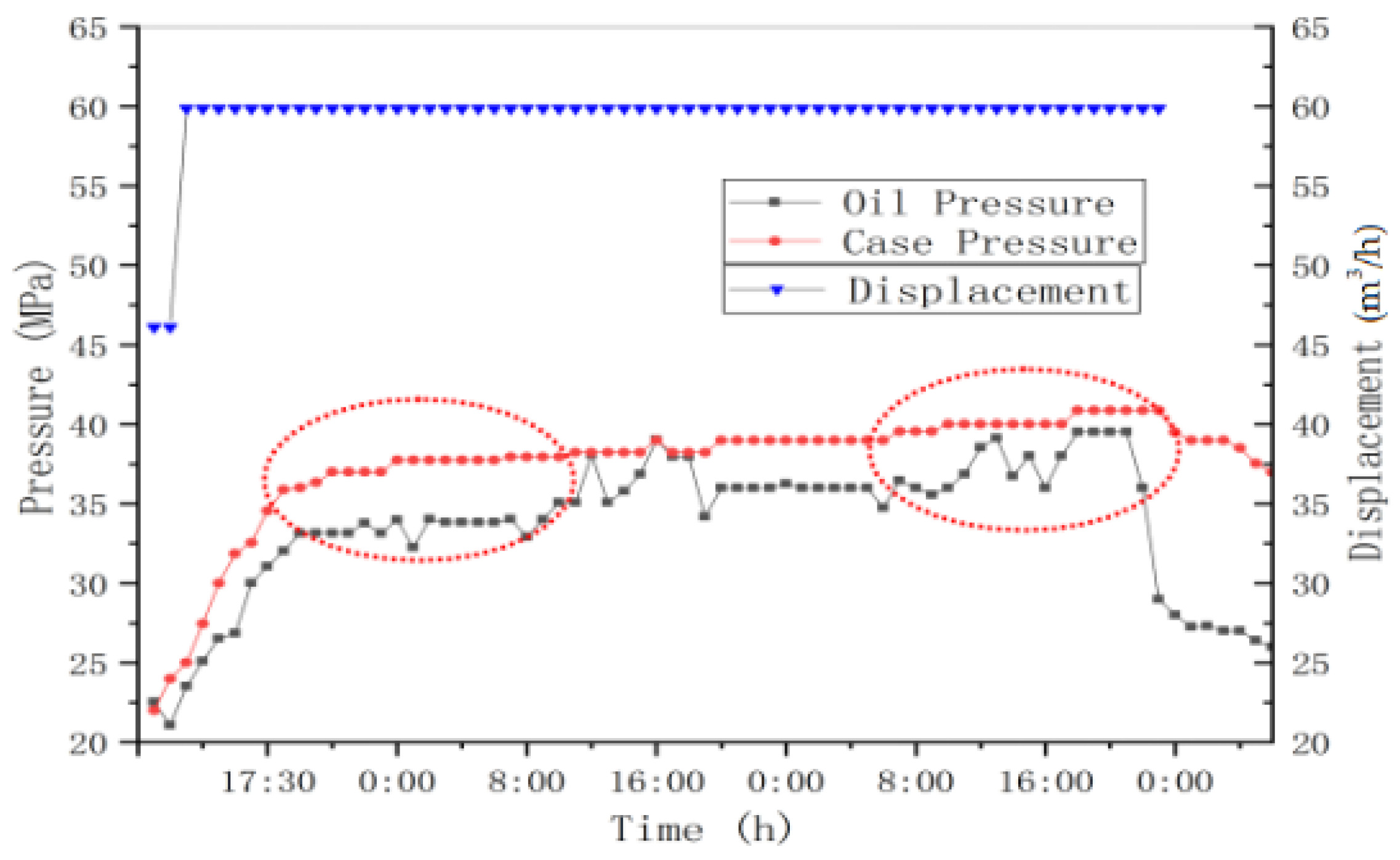

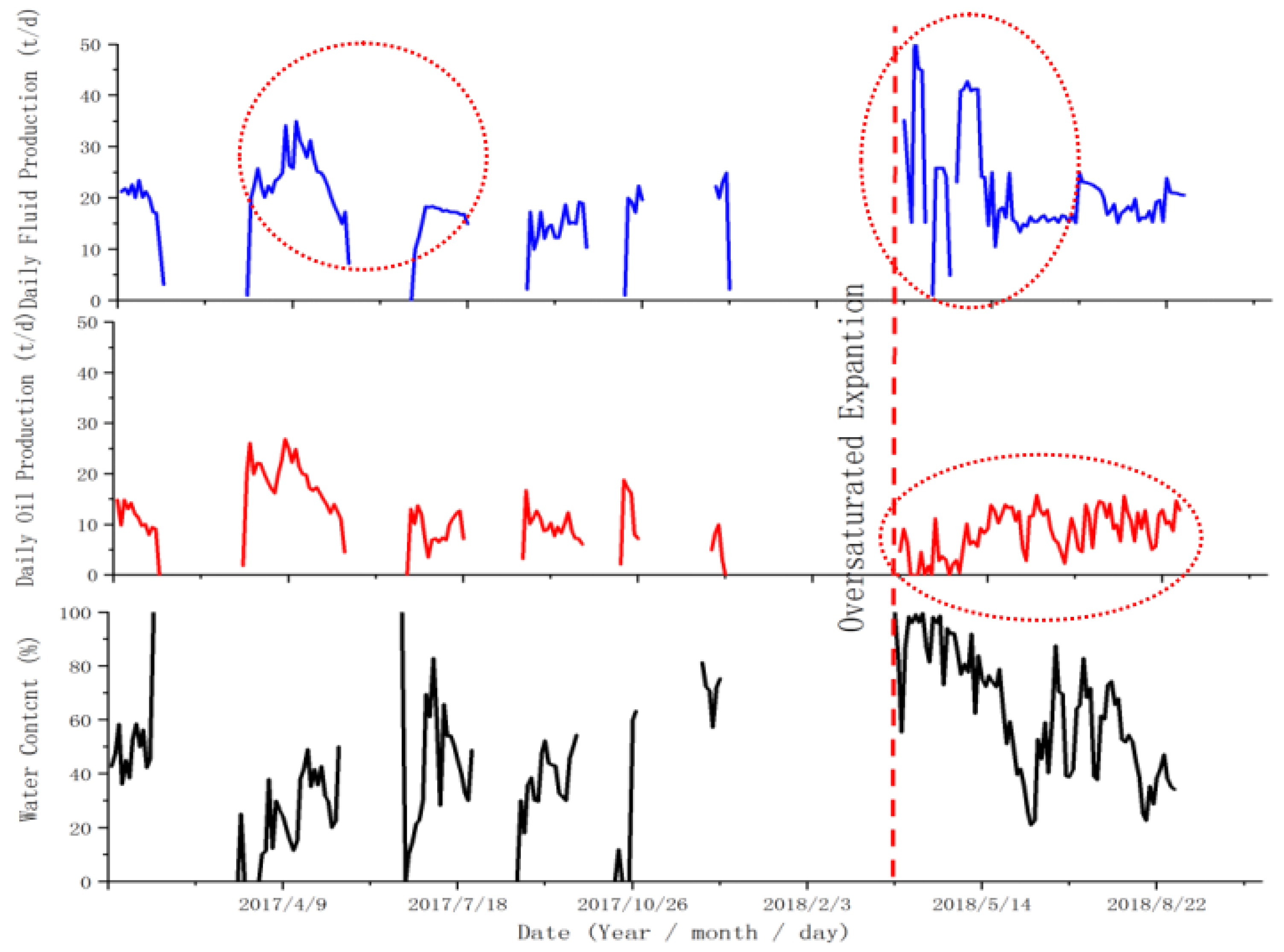

2.5. Blocking and Expansion Composite Process

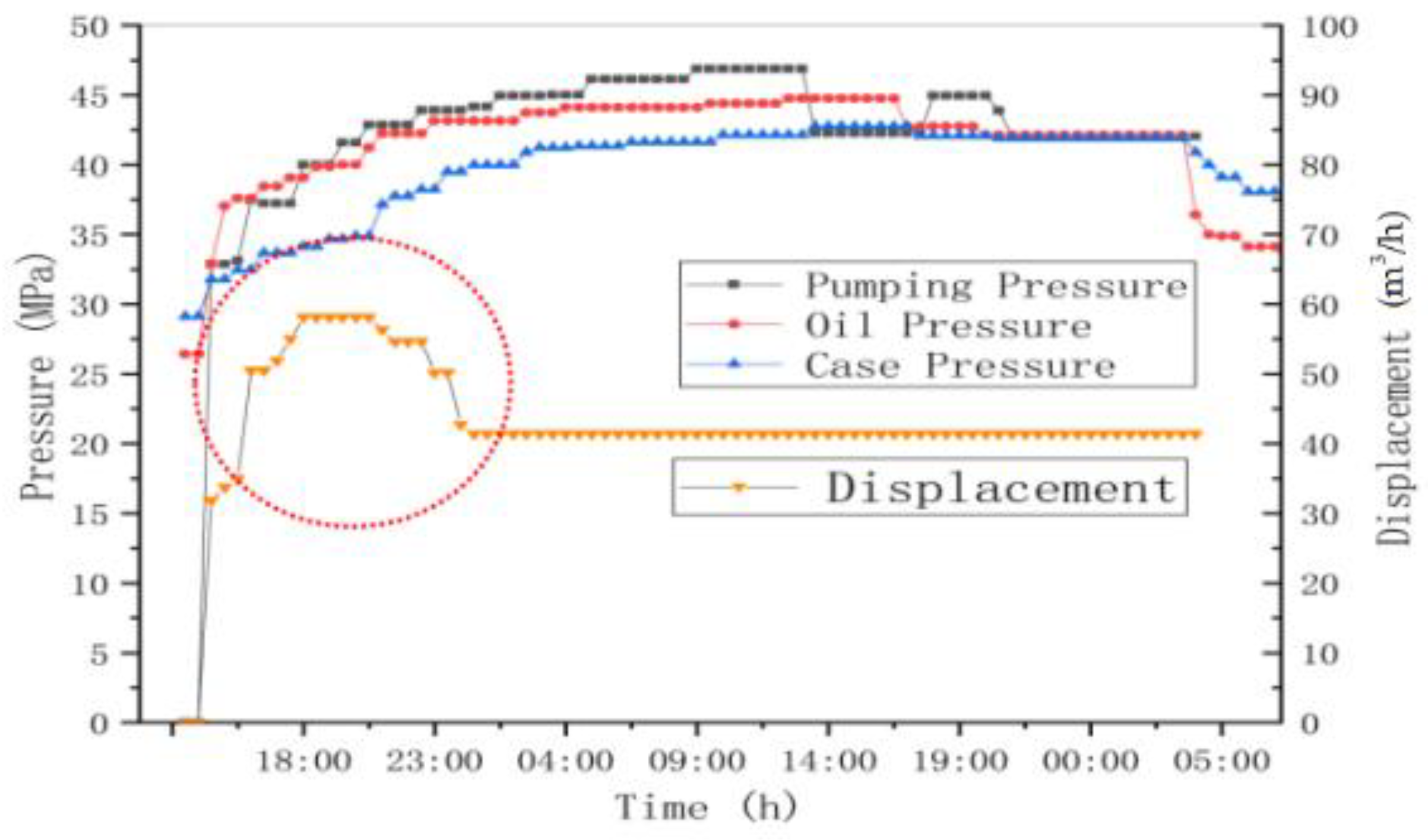

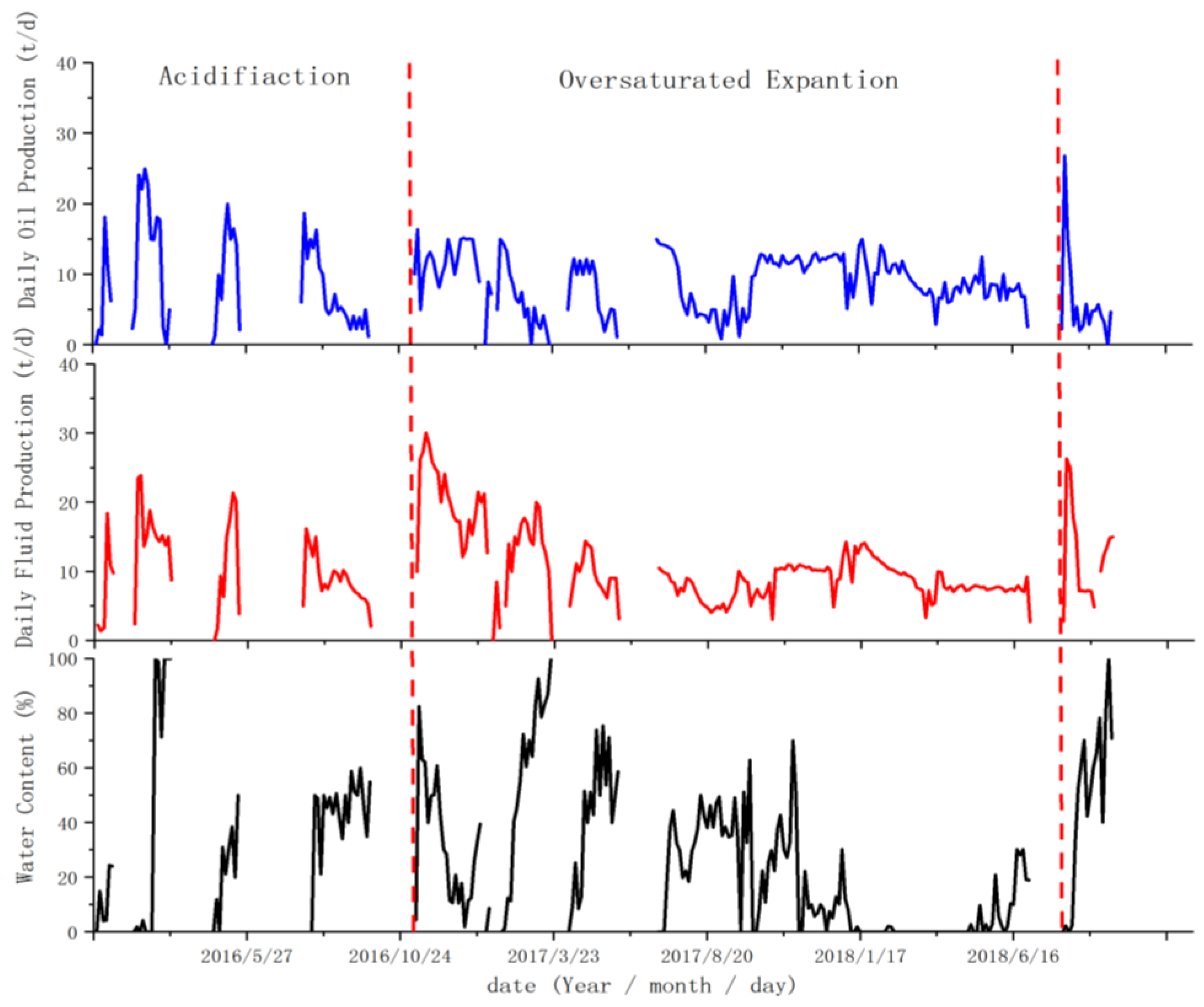

2.6. Expansion and Acidification/Acid Fracturing Composite Process

3. Analysis of Hydraulic Expansion

4. Conclusions

- After long-term exploitation of wells, the insufficient energy in the formation of fractured carbonate reservoirs leads to a rapid decrease in production, and the water content of crude oil steadily increases. Hydraulic expansion of the fractured carbonate rock may connect fractures and pores that were not affected by the original production, allowing the internal raw oil to enter the production fractures and replenish energy.

- For wells with multiple sets of well-developed fractures and cavities in the surrounding area, we apply high pressure to prevent nearby fracture networks from opening and connecting to distant fracture and cavity reservoirs. When controlling karst with clay-filled faults, we increase the injection rate to generate diversion and spread to the remaining non-eroded fracture areas. For wells with insufficient fluid supply after pre-acidification fracturing, we activate sealed or partially sealed original high-permeability channels by applying high pressure.

- Considering temporary plugging and acid fracturing, we also propose (1) temporary plugging of the main deep fractures, followed by hydraulic expansion, and (2) composite expansion and acidification/compression processes.

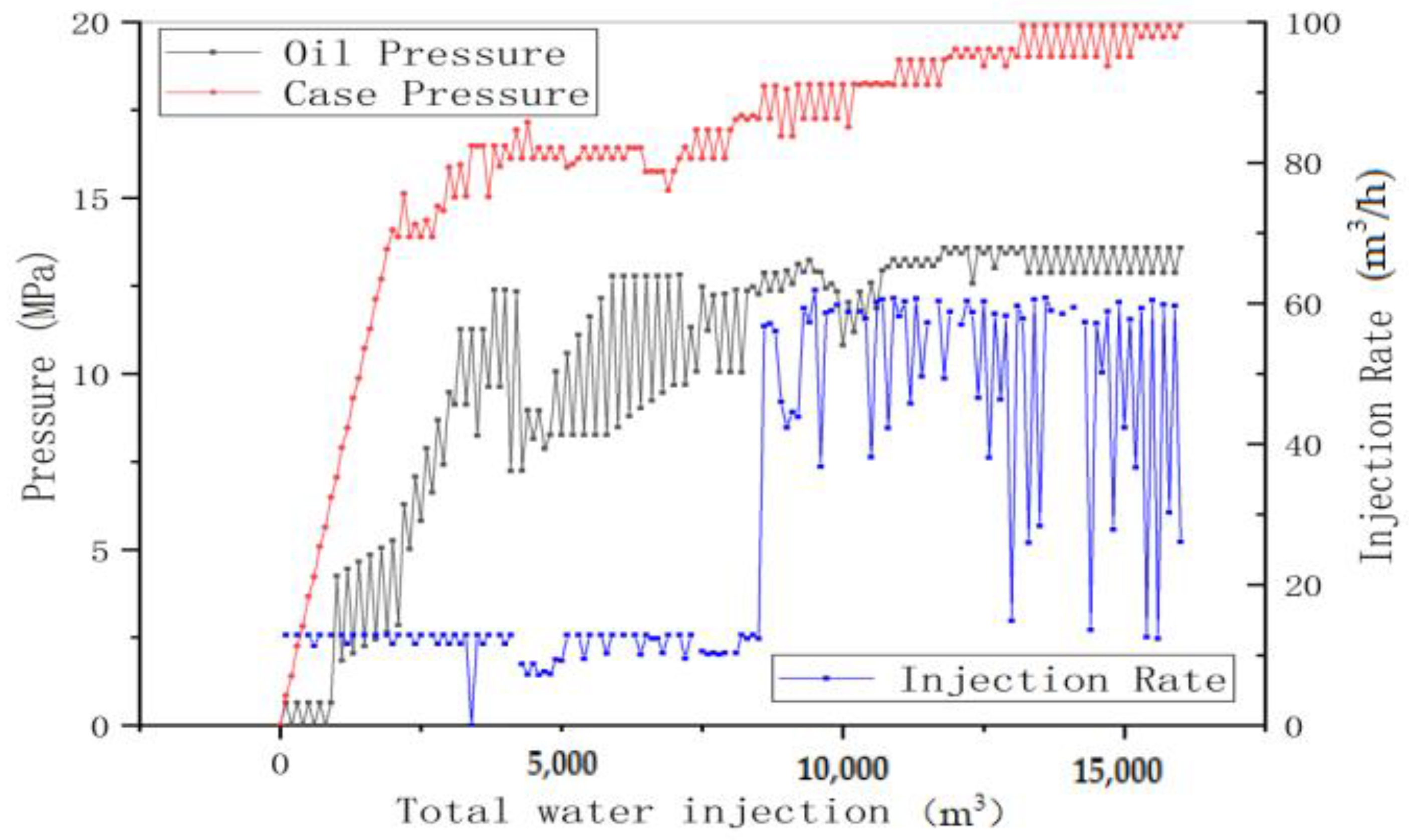

- Hydraulic expansion allows us to recover and supplement the formation energy and efficiently increase production. We tested various wells, achieving an effective hydraulic expansion rate of up to 85%. In addition, the productivity of conventional water injection and hydraulic expansion after on-site construction was evaluated for one well, clearly indicating the effectiveness of water injection and the remarkable increase in crude oil production after hydraulic expansion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martyushev, D.A.; Davoodi, S.; Kadkhodaie, A.; Riazi, M.; Kazemzadeh, Y.; Ma, T. Multiscale and diverse spatial heterogeneity analysis of void structures in reef carbonate reservoirs. Geoenergy Sci. Eng. 2024, 233, 212569. [Google Scholar] [CrossRef]

- Mohammed-Sajed, O.K.; Glover, P.W.; Al-Khatony, F.H.; Collier, R.E. Qualitative and quantitative diagenetic modelling in a tight carbonatereservoir in north-western Iraq. Geoenergy Sci. Eng. 2024, 232, 212450. [Google Scholar] [CrossRef]

- Xiao, S.; Ge, Z.; Lu, Y.; Zhou, Z.; Li, Q.; Wang, L. Investigation on coal fragmentation by high-velocity water jet in drilling: Size distributions and fractal characteristics. Appl. Sci. 2018, 8, 1988. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, Z.; Tang, X.; Li, X.; Geng, Y.; Zhang, J. Fracturing technology of searching for vugs along fractures in fractured-vuggy carbonate reservoirs. Petrol. Drilling Prod. Technol. 2021, 43, 89–96. [Google Scholar]

- Lu, Z.; Xu, S.; Aini, M.; Wang, C.; Gao, L.; Yang, Z.; Yan, C.; Huo, J. Analysis of reservoir characteristics and their effect on productivity of overseas carbonate reservoirs. Spec. Oil Gas Reserv. 2021, 28, 47–53. [Google Scholar]

- Ding, X.; Liu, X.; Qi, Z.; Zhang, W.; Liu, S. Reservoir space characterization of vuggy carbonate reservoirs with multiple scales: A case study of Ma 5–7 interval, Middle Ordovician Majiagou Fornation, Daniudi area, Ordos Basin. Petrol. Geol. Exp. 2021, 43, 689–696. [Google Scholar]

- Li, Y.; Zhao, L.; Wang, S.; Sun, L.; Zhang, W.; Yang, Y.; Hu, D.; Chen, Y. Using cyclic alternating water injection to enhance oil recovery for carbonate reservoirs developed by linear horizontal well pattern. Petrol. Explor. Dev. 2021, 48, 1139–1151. [Google Scholar] [CrossRef]

- Markova, I.; Markov, M. Secondary porosity classification in heterogeneous carbonate reservoirs based on the sonic log data. J. Appl. Geophys. 2023, 218, 105215. [Google Scholar] [CrossRef]

- Chen, L.; Jia, C.; Zhang, R.; Yue, P.; Jiang, X.; Wang, J.; Su, Z.; Xiao, Y.; Lv, Y. High-pressure capacity expansion and water injection mechanism andindicator curve model for fractured-vuggy carbonate reservoirs. Petroleum 2024, in press. [Google Scholar] [CrossRef]

- Li, X.; Lei, T.; Yang, Z.; Zhang, X.; Su, Z. Acid fracturing process progress and prospect. Oil Gas Well Test 2014, 23, 43–47. [Google Scholar]

- He, J.; Li, X. Overview of hydraulic expansion technology. In Proceedings of the 2019 International Conference on Oil and Gas Field Exploration and Development; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Azad, M.; Ghaedi, M.; Farasat, A.; Parvizi, H.; Aghaei, H. Case study of hydraulic fracturing in an offshore carbonate oil reservoir. Petrol. Res. 2022, 7, 419–429. [Google Scholar] [CrossRef]

- Saberhosseini, S.E.; Ahangari, K.; Mohammadrezaei, H. Optimization of the horizontal-well multiple hydraulic fracturing operation in a low-permeability carbonate reservoir using fully coupled XFEM model. Int. J. Rock Mech. Min. Sci. 2019, 114, 33–45. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y. Study on remaining oil distribution of fractured vuggy carbonate reservoir in Tahe 4 area. Petrochem. Technol. 2019, 26, 302–303. [Google Scholar]

- Rashid, F.; Hussein, D.; Lorinczi, P.; Glover, P.W. The effect of fracturing on permeability in carbonate reservoir rocks. Mar. Petrol. Geol. 2023, 152, 106240. [Google Scholar] [CrossRef]

- Qiu, Z.; Xu, J.; Yang, P.; Zhao, X.; Mou, T.; Zhong, H.; Huang, W. Effect of amphiphilic polymer/nano-silica composite on shale stability for water-based muds. Appl. Sci. 2018, 8, 1839. [Google Scholar] [CrossRef]

- Hu, W.G. Development technology and research direction of fractured-vuggy carbonate reservoirs in Tahe Oilfield. Reserv. Eval. Dev. 2020, 10, 1–10. [Google Scholar]

- Al-Shargabi, M.; Davoodi, S.; Wood, D.A.; Ali, M.; Rukavishnikov, V.S.; Minaev, K.M. A critical review of self-diverting acid treatments applied to carbonate oil and gas reservoirs. Petrol. Sci. 2023, 20, 922–950. [Google Scholar] [CrossRef]

- Rong, J.; Tan, M. Effectiveness analysis of Ordovician carbonate reservoirs in zones 6 and 7 of Tahe Oilfield. In Proceedings of the 2019 Academic Annual Meeting of Oil and Gas Geophysics, Nanjing, China, 28–29 November 2019. [Google Scholar]

- Chen, Y. Screening and Research on a Series of Plugging Agents for Carbonate Reservoirs in Tahe Oilfield. Ph.D. Thesis, Xi’an University of Petroleum, Xi’an, China, 2019. [Google Scholar]

| Process | Water Injection Displacement (L/min) | Injection Type | Injected Water (m3) | Particle Displacement (L/min) | Injection Approach | Injection (m3) | Elastic Particles (t) | Description |

|---|---|---|---|---|---|---|---|---|

| Seal deep cracks in lower part | 300 | Positive | 200 | 300–500 | Inverted | 250 | 5 (1–2 mm elastic particles) | Medium density ρ = 1.19 rubber particles injected and concentration gradually increasing from small to large |

| 300 | Positive | 100 | 300–500 | Inverted | 150 | 5 (1–2 mm elastic particles) | ||

| Plane advantage temporarily blocks steering | 300–500 | Positive | 100 | 300–500 | Inverted | 100 | Iso-density ρ = 1.14 rubber particles injected and concentration gradually increasing from small to large | |

| 300 | Positive | 200 | 300–500 | Inverted | 250 | 5 (2–3 mm elastic particles) | ||

| 300 | Positive | 100 | 300–500 | Inverted | 150 | 3 (2–3 mm elastic particles) | ||

| 300–500 | Positive | 100 | 300–500 | Inverted | 100 | |||

| Expansion | ≥900 | Positive | 500 | Pressure drop test and pressure measurements every half-hour for 48 h | Use thousand-type pump to increase displacement and achieve high-pressure injection. Objective: achieve expansion of reservoir around well (Q = 60 m3/h) | |||

| ≥900 | Positive | 1000 | ||||||

| ≥1500 | Positive | 500 | ||||||

| Key requirements: (1) Control pressure does not exceed 30 MPa. If the pressure increases, particle injection stops. For large-displacement replacement of salt water, if the pressure remains below 30 MPa, 20 m3 of frozen glue is deployed, and anti-injection is performed. (2) Expansion depends on the actual situation for on-site adjustment. The set pressure should not exceed 55 MPa, and the oil pressure should not exceed 60 MPa. If the construction displacement is large, pipe the network and reverse transport to ensure adequate water supply while increasing the stock of medium-density particles to 10 t for process adjustment in advance and preparation. Do not operate the pump during smooth starting and stopping of equipment, maintenance, or other activities. | ||||||||

| No. | Water Injection Displacement (L/min) | Injection Type | Injected Water (m3) | Pump Pressure (MPa) | Sleeve (MPa) | Description |

|---|---|---|---|---|---|---|

| 1 | 200–300–400 | Positive | 30 | <50 | <15 | Monitor amount of injected water |

| 2 | 800–1000 | Positive | 4000 | <50 | <15 | If positive injection pressure exceeds 3–5 MPa, casing begins to achieve balanced pressure and is gradually repressurized to 5–10–15 MPa |

| 3 | Pressure drop | Positive | – | – | – | Immediately after water injection, the pipeline is removed, and the pressure drop is measured while the well site is quickly evacuated |

| 4 | Acidification | Positive | Based on acidification design, the fracking team performs this step | |||

| Key requirements: (1) If the sealer release is sealed, the pressure is controlled at 24 MPa, and water filling proceeds or the construction is stopped depending on the situation to determine the next step. (2) If the initial pressure is very high (displacement below 30 m3/h and pressure above 30 MPa) and acidic conditions occur, small-scale acidification is considered after water injection or construction is stopped, which should be decided through discussions. (3) According to the situation of on-site adjustment, the whole process pressure should not exceed 30 MPa, and oil pressure should not exceed 50 MPa. If the construction displacement is large, it is necessary to pipe the network and reverse transport to ensure adequate water supply for the processes performed in advance and during preparation. Do not operate the pump during smooth starting and stopping of equipment, maintenance, or other activities. | ||||||

| Water Injection Type | Injected Water (m3) | Water Pressure (MPa) | Cycle Fluid Production (t) | Cycle Oil Production (t) | Cycle Water Content (%) | Production Pressure Drop (MPa) | Fluid Produced per Unit of Pressure Drop (m3/MPa) |

|---|---|---|---|---|---|---|---|

| Round three of regular water injection | 3887 | 15 | 5863 | 3221 | 45 | 29 | 201 |

| First round of high-pressure hydraulic expansion | 9361 | 23 | 2084 | 917 | 56 | 32 | 66 |

| Second round of high-pressure hydraulic expansion | 20,404 | 19 | 14,429 | 13,804 | 4 | 26 | 547 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Lu, W.; Sun, J. Hydraulic Expansion Techniques for Fracture-Cavity Carbonate Rock with Field Applications. Appl. Sci. 2024, 14, 5851. https://doi.org/10.3390/app14135851

Li J, Lu W, Sun J. Hydraulic Expansion Techniques for Fracture-Cavity Carbonate Rock with Field Applications. Applied Sciences. 2024; 14(13):5851. https://doi.org/10.3390/app14135851

Chicago/Turabian StyleLi, Jiaxue, Wenjun Lu, and Jie Sun. 2024. "Hydraulic Expansion Techniques for Fracture-Cavity Carbonate Rock with Field Applications" Applied Sciences 14, no. 13: 5851. https://doi.org/10.3390/app14135851

APA StyleLi, J., Lu, W., & Sun, J. (2024). Hydraulic Expansion Techniques for Fracture-Cavity Carbonate Rock with Field Applications. Applied Sciences, 14(13), 5851. https://doi.org/10.3390/app14135851