Construction 4.0: A Systematic Review of Its Application in Developing Countries

Abstract

:1. Introduction

1.1. Research Rationale

1.2. Research Questions

- What is the universal definition for Construction 4.0 (Section 4.1)?

- What are the technologies associated with Construction 4.0 (Section 4.2)?

- What are the research gaps recently considered in Construction 4.0 in developing countries (Section 4.3)?

- What is the level of awareness and understanding of Construction 4.0 in developing countries (Section 5.1)?

- What are the applications of Construction 4.0 in developing countries (Section 5.2)?

- What are the challenges to adoption of Construction 4.0 (Section 5.3)?

2. Research Methodology

2.1. Search Strategies (Keywords and Strings)

2.2. Period

2.3. Inclusion/Exclusion Criteria

2.4. Research Databases and Tools

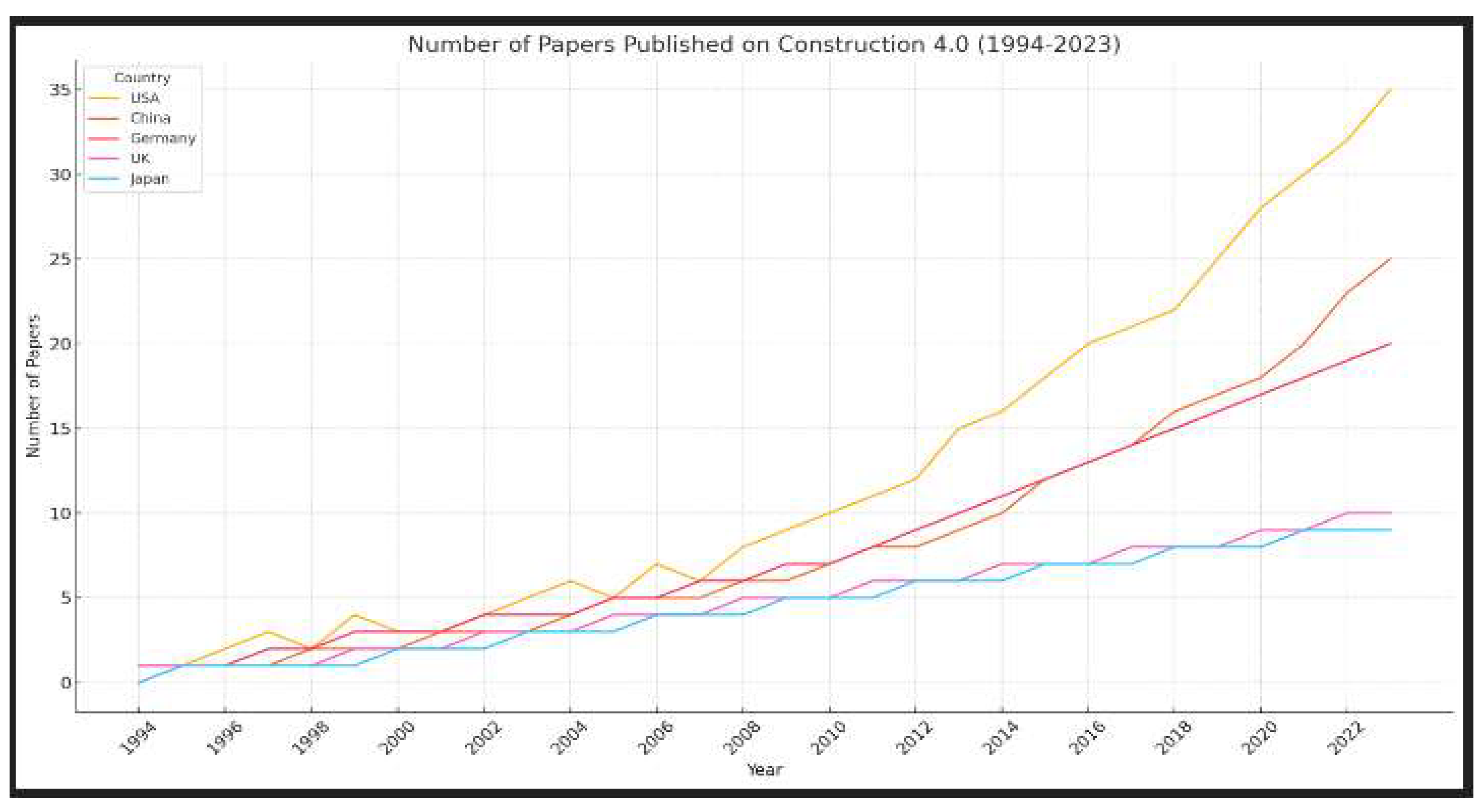

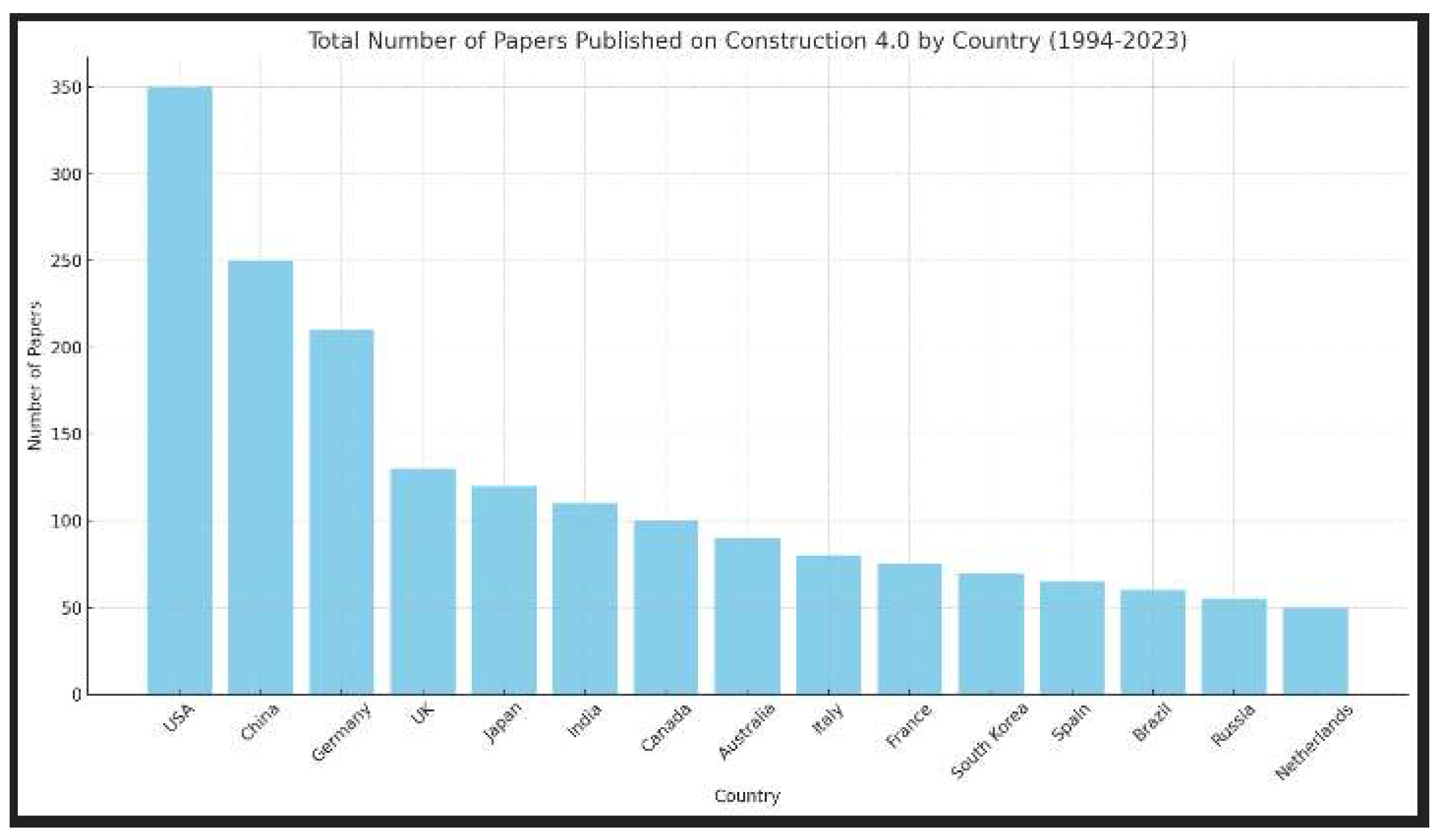

3. Bibliometric Analysis

4. Literature Review

4.1. The Concept of Construction 4.0—Finding a Universal Definition

“to establish a digitalized construction site that utilises various methodologies to monitor the progress of a project from inception to completion”.

4.2. The Various Technologies Associated with Construction 4.0

- Building in a virtual world. AI systems and autonomous construction replace manual construction.

- Factories run the world. Construction activities move to lean principles and prefabrication.

- A green reboot. Sustainable technologies and new materials meet tough environmental regulations.

- Attract new talent and build up required skills. Upskilling processes are embraced.

- Integrate and collaborate across the construction industry’s value chain. Movement to an integrated and unfragmented value chain, which facilitates seamless data flows and integrated systems.

- Adopt advanced technologies at scale. Construction industry becomes quick to adopt new technologies at scale and shows less reliance on manual labour and mechanical technologies, resulting in improved productivity.

4.3. Research Gaps Considered within Recent Construction 4.0 Publications in Developing Countries

5. Awareness, Understanding, Application, and Challenges of Construction 4.0

5.1. Awareness and Understanding of Industry/Construction 4.0

5.2. Awareness and Understanding of Construction 4.0 in Developing Countries

5.3. Application of Construction 4.0 in Developing Countries

- As per the Indian Brand Equity Foundation (IBEF), the Government of India has established an ambitious objective of augmenting the proportion of manufacturing output to 25 percent of the gross domestic product (GDP) by the year 2025, in contrast to the current level of 16 percent [55].

- The Internet of Things (IoT) is anticipated to acquire approximately 20 percent of the global IoT market within the next five years, making it a significant component of Industry 4.0 in India. Based on the forecast provided by the India Brand Equity Foundation (IBEF), it was anticipated that the Internet of Things (IoT) market in India would experience a compound annual growth rate (CAGR) exceeding 28 percent within the period of 2015 to 2020. By 2025, it is suggested that IoT devices will exceed 2 billion in India.

5.4. Challenges to Implementing Construction 4.0

6. Research Gaps to Be Filled

7. Conclusions

8. Limitations of the Study

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gildow, C. Architecture and the Industrial Revolution. Module 9. Architecture 2012. Available online: https://resources.saylor.org/wwwresources/archived/site/wp-content/uploads/2011/12/Module-9.pdf (accessed on 9 February 2024).

- Wang, Y.; Li, X.; Li, X. Eco-Topia: Design 4.0 and the Construction of E-Image City. In Proceedings of the 1st International Conference on Arts, Design and Contemporary Education (ICADCE 2015), Moscow, Russia, 22–24 April 2015; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 414–417. [Google Scholar]

- Sreekanth, P.S. Impact of Industrial Revolution on Architecture. The Archi Blog Not Just another Architecture Blog. 2011. Available online: https://thearchiblog.wordpress.com/2011/06/02/impact-of-industrial-revolution-on-architecture/ (accessed on 15 February 2024).

- Tornincasa, S.; Di Monaco, F. The future and the evolution of CAD. In Proceedings of the 14th International Research/Expert Conference: Trends in the Development of Machinery and Associated Technology, Mediterranean Cruise, 11–18 September 2010; pp. 11–18. [Google Scholar]

- Kolarevic, B. Digital fabrication: Manufacturing architecture in the information age. In Proceedings of the Twenty First Annual Conference of the Association for Computer-Aided Design in Architecture, Buffalo, NY, USA, 11–14 October 2001; pp. 268–278. [Google Scholar]

- Naboni, R.; Paoletti, I. Advanced Customization in Architectural Design and Construction; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Ashta, G.; Finco, S.; Battini, D.; Persona, A. Passive Exoskeletons to Enhance Workforce Sustainability: Literature Review and Future Research Agenda. Sustainability 2023, 15, 7339. [Google Scholar] [CrossRef]

- Gilchrist, A. Industry 4.0: The Industrial Internet of Things; Apress: Berkeley, CA, USA, 2016. [Google Scholar]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Zhang, S.; Perez, E. Case study of BIM and cloud–enabled real-time RFID indoor localization for construction management applications. J. Constr. Eng. Manag. 2016, 142, 05016003. [Google Scholar] [CrossRef]

- Toca Pérez, C.; Costa, D.B.; Farraghe, M. Construction 4.0: Case Studies. In Construction 4.0: An Innovation Platform for the Built Environment; Sawhney, A., Riley, M., Javier, I., Eds.; Routledge; Taylor and Francis: London, UK, 2020; pp. 421–440. ISBN 9781032653600. [Google Scholar]

- Boton, C.; Rivest, L.; Ghnaya, O.; Chouchen, M. What is at the Root of Construction 4.0: A Systematic Review of the Recent Research Effort. Arch. Comput. Methods Eng. 2021, 28, 2331–2350. [Google Scholar] [CrossRef]

- Shafei, H.; Radzi, A.R.; Algahtany, M.; Rahman, R.A. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings 2022, 12, 2206. [Google Scholar] [CrossRef]

- Begić, H.; Galić, M. A Systematic Review of Construction 4.0 in the Context of the BIM 4.0 Premise. Buildings 2021, 11, 337. [Google Scholar] [CrossRef]

- Ottoni, A.L.C.; Novo, M.S.; Costa, D.B. Deep Learning for vision systems in Construction 4.0: A systematic review. SIViP 2023, 17, 1821–1829. [Google Scholar] [CrossRef]

- Wang, K.; Guo, F. Towards sustainable development through the perspective of construction 4.0: Systematic literature review and bibliometric analysis. Buildings 2022, 12, 1708. [Google Scholar] [CrossRef]

- van der Heijden, J. Construction 4.0 in a narrow and broad sense: A systematic and comprehensive literature review. Build. Environ. 2023, 244, 110788. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating major challenges for industry 4.0 adoption among construction companies. Eng. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Schwab, K.; Davis, N. Shaping the Future of the Fourth Industrial Revolution; Crown Currency: Preston, VIC, Australia, 2018. [Google Scholar]

- Klinc, R.; Turk, Ž. Construction 4.0–digital transformation of one of the oldest industries. Econ. Bus. Rev. 2019, 21, 4. [Google Scholar] [CrossRef]

- Unlocking the Potential of Industry 4.0 for Developing Countries. Regional Conference on Industrial Development—Asia Pacific. Vienna. 2018. Available online: https://hub.unido.org/sites/default/files/publications/Unlocking%20the%20Potential%20of%20Industry%204.0%20for%20Developing%20Countries.pdf (accessed on 21 January 2024).

- Singh, A.; Misra, S.C. Identifying challenges in the adoption of industry 4.0 in the Indian construction industry. In Progress in Advanced Computing and Intelligent Engineering: Proceedings of ICACIE 2019; Springer: Singapore, 2021; Volume 1, pp. 380–398. [Google Scholar]

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2020, 27, 2213–2232. [Google Scholar] [CrossRef]

- El Jazzar, M.; Schranz, C.; Urban, H.; Nassereddine, H. Integrating construction 4.0 technologies: A four-layer implementation plan. Front. Built Environ. 2021, 7, 671408. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Javier, I. Construction 4.0: An Innovation Platform for the Built Environment; Routledge; Taylor and Francis: London, UK, 2020; 526p, ISBN 9781032653600. [Google Scholar]

- Osakwe, M.M.; Iyawa, G.E.; Mutalya, A.K. Industry 4.0: University Students’ Perception Awareness and Preparedness. In Proceedings of the 2020 IST-Africa Conference (IST-Africa), Kampala, Uganda, 18–22 May 2020. [Google Scholar]

- Rastogi, S. Construction 4.0: The 4th generation revolution. In Proceedings of the Indian Lean Construction Conference–ILCC, Chennai, India, 27–29 July 2017. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitization and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industry 4.0 scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5 January 2016; pp. 3928–3937. [Google Scholar]

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040; USDOE Energy Information Administration (EIA), Office of Energy Analysis: Washington, DC, USA, 2016. [Google Scholar]

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manuf. 2018, 21, 671–678. [Google Scholar] [CrossRef]

- Moshood, T.D.; Adeleke, A.Q.; Nawanir, G.; Ajibike, W.A.; Shittu, R.A. Emerging challenges and sustainability of industry 4.0 era in the Malaysian construction industry. Emerg. Chall. Sustain. Ind. 2020, 12, 1627–1634. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Thwala, W.D.; Rillie, I. Industry 4.0 deployment in the construction industry: A bibliometric literature review and UK-based case study. Smart Sustain. Built Environ. 2021, 10, 557–580. [Google Scholar] [CrossRef]

- Economic and Social Council. Industry 4.0 for Inclusive Development; Commission on Science and Technology for Development; Economic and Social Council: New York, NY, USA, 2022. [Google Scholar]

- Tahmasebinia, F.; Sepasgozar, S.M.E.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Mansuri, K.K.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0: Theoretical and laboratory investigations. Constr. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of building information modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.; Mohammed, B.S. Industry revolution IR 4.0: Future opportunities and challenges in construction industry. MATEC Web Conf. 2018, 203, 02010. [Google Scholar] [CrossRef]

- Mansour, H.; Aminudin, E.; Mansour, T. Implementing industry 4.0 in the construction industry-strategic readiness perspective. Int. J. Constr. Manag. 2023, 23, 1457–1470. [Google Scholar] [CrossRef]

- Irizarry, J.; Costa, D.B. Exploratory study of potential applications of unmanned aerial systems for construction management tasks. J. Manag. Eng. 2016, 32, 05016001. [Google Scholar] [CrossRef]

- Sharma, R.; Asif, M.; Jha, P.C. Industry 4.0 technologies: A literature review. In Proceedings of the 10th International Conference on Management of Digital Eco Systems, Tokyo, Japan, 25–28 September 2018; pp. 215–220. [Google Scholar]

- Li, Y.; Gong, Y. Employment Impact Analysis of Industry 4.0 Technologies in Developing Countries. J. Appl. Econ. 2020, 23, 345–362. [Google Scholar]

- Khan, Z.; Awan, K.M.; AlSaif, A. Industry 4.0: A solution towards technology integration in developing countries. In Proceedings of the 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 30–31 January 2019; pp. 1–6. [Google Scholar]

- Abidin, M.I.Z.; Yusof, S.M. Skill Development in Industry 4.0 Era: A Case Study of Developing Country. J. Adv. Res. Dyn. Control Syst. 2021, 13, 355–363. [Google Scholar]

- Miao, Y.; Zhu, Y.; Wamba, S.F. Managing SMEs’ digitalization toward Industry 4.0. IEEE Trans. Eng. Manag. 2020, 65, 492–499. [Google Scholar]

- Delera, M.; Pietrobelli, C.; Calza, E.; Lavopa, A. Does value chain participation facilitate the adoption of Industry 4.0 technologies in developing countries? World Dev. 2022, 152, 105788. [Google Scholar] [CrossRef]

- Singaram, L.R.; Zakaria, R.; Munikanan, V.; Wahi, N.; Aminudin, E.; Sahamir, S.R.; Redzuan, A.A.; Gara, J.; Faizal Zulkarnaini, M.; Khalid, R. Pre-investigation on adaptation of construction 4.0 multi criteria business model by SME contractors in Malaysia. Clean. Eng. Technol. 2023, 15, 100662. [Google Scholar] [CrossRef]

- Rajbhandari, S.; Devkota, N.; Khanal, G.; Mahato, S.; Paudel, U.R. Assessing the industrial readiness for adoption of industry 4.0 in Nepal: A structural equation model analysis. Heliyon 2022, 8, e08919. [Google Scholar] [CrossRef]

- Olatunde, N.A.; Gento, A.M.; Okorie, V.N.; Oyewo, O.W.; Mewomo, M.C.; Awodele, I.A. Construction 4.0 technologies in a developing economy: Awareness, adoption readiness and challenges. Front. Eng. Built Environ. 2023, 3, 108–121. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution. Crown Business. World Economic Forum. 2016. Available online: https://www.weforum.org/about/the-fourth-industrial-revolution-by-klaus-schwab/ (accessed on 15 March 2024).

- Cheng, M.Y.; Lu, Y.C.; Le, N.H. Application of Construction 4.0: A Systematic Literature Review. Sustainability 2020, 12, 1856. [Google Scholar]

- Camarinha-Matos, L.M.; Afsarmanesh, H. Industry 4.0 and Smart Manufacturing—A Review of Research Trends and Industrial Cases. IFIP Adv. Inf. Commun. Technol. 2016, 380, 1–12. [Google Scholar]

- Fernandes, L.G.; Jabbour CJ, C.; Filho, M.G. Understanding the Industry 4.0 adoption barriers in developing countries: Insights from Brazilian companies. Technol. Forecast. Soc. Change 2020, 151, 119812. [Google Scholar]

- Khan, S.; Ahmad, F.; Kumar, A. Understanding Industry 4.0: A comprehensive review on technological advancement and its applications. Mater. Today Proc. 2021, 46, 10707–10711. [Google Scholar]

- Zavadskas, E.K.; Antuchevičienė, J.; Turskis, Z. Industry 4.0 and Its Impact on Sustainable Development: Evidence from European and Asian Countries. Sustainability 2021, 13, 3381. [Google Scholar]

- Marzouk, M.; El-kholy, M.S.; Ragab, A. Workforce 4.0 Skills in Engineering Education and the Need for Lifelong Learning. Procedia Comput. Sci. 2020, 170, 1132–1139. [Google Scholar]

- Teisserenc, B.; Sepasgozar, S. Adoption of blockchain technology through digital twins in the construction industry 4.0: A PESTELS approach. Buildings 2021, 11, 670. [Google Scholar] [CrossRef]

- Ribeiro, D.B.; Coutinho, A.D.; Satyro, W.C.; Campos, F.C.; Lima, C.R.; Contador, J.C.; Gonçalves, R.F. The DAWN readiness model to assess the level of use of Industry 4.0 technologies in the construction industry in Brazil. Constr. Innov. 2024, 24, 515–536. [Google Scholar] [CrossRef]

- Sajjad, M.; Hu, A.; Waqar, A.; Falqi, I.I.; Alsulamy, S.H.; Bageis, A.S.; Alshehri, A.M. Evaluation of the success of industry 4.0 digitalization practices for sustainable construction management: Chinese construction industry. Buildings 2023, 13, 1668. [Google Scholar] [CrossRef]

- Siau, K.; Xi, Y.; Zou, C. Industry 4.0: Challenges and opportunities in different countries. Cut. Bus. Technol. J. 2019, 32, 6–14. [Google Scholar]

- Islam, M.A.; Jantan, A.H.; Hashim, H.; Chong, C.W.; Abdullah, M.M.; Abdul Hamid, A.B. Fourth industrial revolution in developing countries: A case on Bangladesh. J. Manag. Inf. Decis. Sci. 2018, 21, 1–9. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Topal, H.F.; Hunt, D.V.; Rogers, C.D. Urban Sustainability and Smartness Understanding (USSU)—Identifying influencing factors: A systematic review. Sustainability 2020, 12, 4682. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, V.; Verma, P.; Kandasamy, J. Identification and severity assessment of challenges in the adoption of industry 4.0 in Indian construction industry. Asia Pac. Manag. Rev. 2023, 28, 299–315. [Google Scholar] [CrossRef]

- Jadhav, V.V.; Mahadeokar, R.; Bhoite, D.S. The fourth industrial revolution (I4. 0) in India: Challenges & opportunities. Management 2014, 6, 105–109. [Google Scholar]

- Susilo, D. Industry 4.0: Is Indonesia Ready? Manag. Anal. J. 2020, 9, 262–270. [Google Scholar] [CrossRef]

- Nguyen, X.T.; Luu, Q.K. Factors affecting adoption of industry 4.0 by small-and medium-sized enterprises: A case in Ho Chi Minh city, Vietnam. J. AsianFinanc. Econ. Bus. 2020, 7, 255–264. [Google Scholar] [CrossRef]

- Kohpaiboon, A. Industry 4.0 policies in Thailand. Working Paper 2020, Yusof Ishak Institute. Available online: https://www.iseas.edu.sg/wp-content/uploads/pdfs/ISEAS_EWP_2020-2_Archanun.pdf (accessed on 24 February 2024).

- Allioui, H.; Mourdi, Y. Exploring the full potentials of IoT for better financial growth and stability: A comprehensive survey. Sensors 2023, 23, 8015. [Google Scholar] [CrossRef]

- Singh, A.; Misra, S.C. Safety performance & evaluation framework in Indian construction industry. Saf. Sci. 2021, 134, 105023. [Google Scholar]

- Hizam-Hanafiah, M.; Soomro, M.A.; Abdullah, N.L. Industry 4.0 readiness models: A systematic literature review of model dimensions. Information 2020, 11, 364. [Google Scholar] [CrossRef]

- Bajpai, A.; Misra, S.C. Barriers to implementing digitalization in the Indian construction industry. Int. J. Qual. Reliab. Manag. 2022, 39, 2438–2464. [Google Scholar] [CrossRef]

- Topal, H.F.; Hunt, D.V.L.; Rogers, C.D. Sustainability understanding and behaviors across urban areas: A case study on Istanbul City. Sustainability 2021, 13, 7711. [Google Scholar] [CrossRef]

- Lovell, L.J.; Davies, R.J.; Hunt, D.V. The application of historic building information modelling (HBIM) to cultural heritage: A review. Heritage 2023, 6, 6691–6717. [Google Scholar] [CrossRef]

- Mojumder, A.; Singh, A. An exploratory study of the adaptation of green supply chain management in construction industry: The case of Indian Construction Companies. J. Clean. Prod. 2021, 295, 126400. [Google Scholar] [CrossRef]

- de Almeida Barbosa Franco, J.; Domingues, A.M.; de Almeida Africano, N.; Deus, R.M.; Battistelle, R.A. Sustainability in the civil construction sector supported by industry 4.0 technologies: Challenges and opportunities. Infrastructures 2022, 7, 43. [Google Scholar] [CrossRef]

- Bhat, T.P. India and Industry 4.0. Working Paper, Institute of Studies in Industrial Development. 2022. Available online: https://isid.org.in/wp-content/uploads/2022/07/WP218.pdf (accessed on 28 April 2024).

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction industry 4.0 and sustainability: An enabling framework. IEEE Trans. Eng. Manag. 2021, 71, 1–19. [Google Scholar] [CrossRef]

| Definition of Construction 4.0 | Reference |

|---|---|

| “The overarching framework encompassing the digital transformation of the construction industry and the built environment is commonly referred to as Construction 4.0.” | [20] |

| “Construction 4.0 technology is an emerging and innovative technological advancement that has been empirically demonstrated to significantly improve project performance.” | [21] |

| “Construction 4.0 technology refers to the integration of various advanced technologies aimed at improving productivity within the construction industry”. | [22] |

| “Construction 4.0 is fuelled by the development of various technologies, the drastic change in the needs of owners, the shift toward mass customization, and the need for green construction and sustainability”. | [23] |

| “Construction 4.0 is seen as a subset of Industry 4.0, an application of Industry 4.0 (technologies and processes) to the construction industry, as well as a novel development in and of itself.” | [24] |

| “Construction 4.0 is the convergence of industrial production, CPSs, and digital technologies with the ultimate goal of creating a digital construction site”. | [17] |

| “Construction 4.0 is the combination of the “digitization of the construction industry and industrialization of construction processes””. | [14] |

| “Construction 4.0 is an adaptive of the construction industry for Industrial revolution 4.0 as it evolved from the manufacturing industry publicised by the German government”. | [25] |

| Technology Group | Description | Reference |

|---|---|---|

| Internet of Things—IoT | Through the usage of integrated sensors and wireless technologies, the Internet of Things (IoT) makes it possible to store, analyse, and disseminate data in a timelier manner. According to [1], this subject area is generally acknowledged to be an essential area of developing technology, and it has attracted substantial interest from a variety of sectors. The Internet of Things (IoT) is now used in the arena of Construction 4.0, where it is utilised to combine multiple commodities such as wireless sensor networks, middleware, cloud computing, and IoT application software. This utilisation of the IoT is currently being monitored. | [12,14,25,26,28,30,31,32,33,34,35,36] |

| Artificial intelligence—AI | The term “artificial intelligence” (AI) is used to refer to a specific category of computer programmes that are developed with the goal of imitating human cognitive skills. The construction industry makes extensive use of artificial intelligence version 4.0, notably in adaptive vision systems that make it possible to identify a variety of components present at a building site. In addition, such a device has the capability to distinguish both voices and patterns, allowing for very accurate monitoring of the actions of construction workers. The present investigation is centred on the possibility of applying the approach to the prediction of a variety of anomalies like cost overruns, concerns of safety at a site, quality issues, etc., that could occur in the fields of building architecture, building construction, and building services. In addition, Ref. [2] found that intelligent manufacturing is a strategy that has a good chance of success. | [12,14,25,28,30,31,32,33,34,35,36] |

| Building Information Modelling—BIM | Building Information Modelling (BIM) is a software tool that, according to [37], makes it easier for all parties engaged in a building project to create, transmit, share, and disseminate information with one another. Building Information Modelling, often known as BIM, has been an essential part of the digital revolution that has taken place in the construction industry. In general, Building Information Modelling (BIM), and more specifically the integration of 5D planning and budgeting, is anticipated to result in significant cost reductions (including direct costs, efficiency gains, delay avoidance, risk mitigation, and enhanced reputation) throughout the entirety of the construction value chain, which includes design, construction, operation, and decommissioning. This includes the phases of design, construction, and operation. Ref. [38] suggests that the implementation of Building Information Modelling (BIM) has the capacity to optimise operational procedures throughout the entirety of a construction project [13]. This assertion is in accordance with the discoveries made by the previously mentioned scholars. Ref. [38] asserts that Building Information Modelling (BIM) is currently regarded as the primary technological solution for the digitalisation of the building manufacturing sector. | [2,12,13,14,25,26,28,30,31,32,33,34,35,36,39] |

| Three-dimensional printing | The process of producing three-dimensional objects utilising a computer-controlled apparatus is commonly known as “3D printing”, which is a widely recognised term. Additive manufacturing, also known as 3D printing, is a technique that involves the creation of a tangible, three-dimensional object from a digital model using a layer-by-layer approach to add material. The ultimate outcome is the paramount aspect. Extensive research and development endeavours spanning a quarter of a century have been dedicated to exploring the applications of three-dimensional printing, as noted by [29]. It now has uses in a variety of fields, including healthcare, aircraft, and vehicles. That said, the technology that enables three-dimensional printing in the building industry exists and is well used, and it is mostly concentrated on projects of a small to medium size. The largest 3D-printed building currently exists in Dubai. These technologies have the potential to replace human labour with automated production, resulting in time savings but also loss of jobs. According to [40], the quality of the print, behaviour of the material (i.e., cement, water, aggregates, and polymers), speed, and length of time between layers are all key elements that influence the quality of the final build. | [12,14,25,26,28,30,31,32,33,34,35,36] |

| Unmanned aerial vehicles—UAVs | According to [19], the construction industry has found substantial use for drones, particularly for the purpose of observation, mapping, and monitoring during survey work, construction, and facility operations. According to Irizarry and Costa (2016), there has been a progressive growth in the use of unmanned aerial vehicles (UAVs), not least in the construction industry. | [12,14,25,26,28,30,31,32,33,34,35,36] |

| Augmented reality—AR—and virtual reality—VR | When compared to augmented reality (AR), virtual reality (VR) represents a more developed step along the spectrum of virtuality. Virtual reality (VR) technology provides users with an immersive experience via the use of headsets that give a 360-degree field of view. This enables users to interact with a simulated world that is unique and set apart from their actual surroundings. Since 1990, there has been a major increase in the progress and application of this phenomenon, according to [32], notably in sectors such as education and training. According to [38], the use of virtual reality (VR) in training for the construction sector has the potential to reduce the risk of possible dangers, improve operational efficiency, and make it easier to identify dangerous regions. All this allows the final build to be modified prior to construction taking place. | [12,14,25,26,28,30,31,32,33,34,35,36,38] |

| Ref. | Date | Country | Methodology Used | Research Gap Considered | Findings of Research |

|---|---|---|---|---|---|

| [39] | 2019 | India | Survey, literature review | Adoption challenges (i.e., barriers and enablers) of Construction 4.0 | Highlighted the need for policy support, infrastructure, and a skilled workforce. |

| [41] | 2020 | China | Mixed methods | Impact of Construction 4.0 on employment | Highlighted shifts in job roles and skill requirements alongside productivity gains from implementing Construction 4.0. |

| [42] | 2018 | Pakistan | Case studies, interviews | Infrastructure readiness for Construction 4.0 | Identified gaps in technological infrastructure and skills development. |

| [43] | 2021 | Malaysia | Longitudinal studies | Skill development for Construction 4.0 | Highlighted the need for continuous learning and adaptation to technological changes. |

| [44] | 2017 | Bangladesh | Action research | Integration of SMEs into Construction 4.0 | Emphasised the need for collaboration and support mechanisms for mall to medium enterprises (SMEs). |

| [45] | 2020 | Indonesia | Comparative analysis | Technological capabilities in Construction 4.0 | Identified variances in adoption rates and technological infrastructure. |

| [46] | 2022 | Ghana, Vietnam, and Thailand | Using a novel UNIDO database | Digital supply chain disruptions and Construction 4.0 | Concluded that a firm’s participation in a global value chain (GVC) is positively associated with the adoption of Construction 4.0 technologies. |

| [47] | 2023 | Malaysia | Pilot questionnaire and multicriteria business model | Adoption of Construction 4.0 by SME contractors | Identified 6 main factors (i.e., management, finance, resources, technology, personnel, and legal) that impact on SMEs adopting Construction 4.0. |

| [48] | 2022 | Nepal | Structural equation model analysis using census method | Industrial readiness for adoption of Construction 4.0 | Identified that the major problem while adopting Construction 4.0 is the lack of skilled manpower in the industrial sector. In addition, customers, culture, strategy and leadership, governance, and operations have a significant effect on technology innovation decision making. |

| [49] | 2020 | Nigeria | Cross-sectional studies | Socio-economic implications of Construction 4.0 | Identified opportunities for economic growth and job creation alongside challenges of inequality and digital divide. |

| [49] | 2023 | Osun State, Nigeria | Convenient sampling technique | Awareness, adoption, readiness, and challenges | Identified lack of standardisation as the biggest challenge, followed by a lack of investment and the cost of implementation. |

| Operational Excellence Enhance efficiency through greater automation. Product customisation at the cost of mass-produced products. | Enhanced Services Higher revenues from digitally refined products. Access to new markets. |

| Physical Elements | Virtual Elements |

| Smart Factory Digital modelling. Equipment infrastructure. Data usage. IT systems. | Strategy and Organisation Strategy. Investments. Innovation management. |

| Smart Product ICT add-on functionalities. Data analytics in usage phase. | Smart Operations Cloud usage. IT security. Autonomous processes. Information sharing. |

| Employees Skill acquisition. Employee skill sets. | Data-Driven Services Services. Shares of revenue. Shares of data used. |

| Challenges | Challenges | Ways to Overcome Challenges |

|---|---|---|

| Limited infrastructure and connectivity [42,49] | Sufficient infrastructure and connection are essential for the effective implementation of Construction 4.0 technology; however, in developing countries, these are not always available or reliable. | Access to dependable internet access, mobile networks, and digital infrastructure is essential for immediate communication, data sharing, and remote monitoring of construction projects, especially in distant or underserved regions. |

| The complexity of IoT solutions [44,49] | Fully integrating emerging technologies like Building Information Modelling (BIM), Internet of Things (IoT), drones, and augmented reality into current building procedures may be difficult. | It is essential to provide smooth interoperability and compatibility across various systems and software platforms to fully use the advantages of Construction 4.0. |

| Skill gap in IoT development [39,41,42,48,49] | Implementing Construction 4.0 technologies need a proficient staff capable of utilising and overseeing sophisticated digital tools and equipment. | Offering sufficient training and upskilling programmes for construction experts and workers is crucial to close the skills gap and guarantee the effective use of contemporary building methods. |

| Data production, protection, and management [49,53] | Construction 4.0 produces extensive data from sensors, drones, and BIM models, requiring effective data management and security measures. Construction organisations have substantial hurdles in managing, analysing, and safeguarding these data. | Securing data privacy, integrity, and cybersecurity is crucial to protect sensitive information and maintain trust with stakeholders, not least in developing countries. |

| Cost and return on investment (ROI) [49,61] | Construction 4.0 technologies provide several advantages including enhanced efficiency, productivity, and quality, but the initial expenditure is likely to be substantial. | To obtain a positive ROI, one must perform a thorough cost–benefit analysis, engage in long-term planning, and implement efficient project management to support the integration of contemporary technologies and guarantee financial gain. |

| Regulation and standardisation [47,49,61] | The regulations and laws concerning the use of new technology in building are always developing. Businesses implementing Construction 4.0 principles may have difficulty in complying with regulations, standards, and safety, quality, and liability concerns. | It is crucial to address legal and regulatory obstacles to reduce risks and guarantee adherence to industry norms. Therein, standardisation will help broker greater uptake of Construction 4.0. |

| Culture change [73] and resistance to change [49] | Developing countries may be resistant to a change in the way things have always been done. As such, implementing Construction 4.0 would require a substantial culture change in the construction industry towards a more collaborative, data-driven, and digitally enabled project delivery strategy. | Overcoming reluctance to change, cultivating an innovative culture, and encouraging cooperation among stakeholders are crucial for the effective implementation and approval of contemporary building methods. Education is key in identifying the short- and long-term benefits of Construction 4.0. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaiswal, S.V.; Hunt, D.V.L.; Davies, R.J. Construction 4.0: A Systematic Review of Its Application in Developing Countries. Appl. Sci. 2024, 14, 6197. https://doi.org/10.3390/app14146197

Jaiswal SV, Hunt DVL, Davies RJ. Construction 4.0: A Systematic Review of Its Application in Developing Countries. Applied Sciences. 2024; 14(14):6197. https://doi.org/10.3390/app14146197

Chicago/Turabian StyleJaiswal, Shubham V., Dexter V. L. Hunt, and Richard J. Davies. 2024. "Construction 4.0: A Systematic Review of Its Application in Developing Countries" Applied Sciences 14, no. 14: 6197. https://doi.org/10.3390/app14146197

APA StyleJaiswal, S. V., Hunt, D. V. L., & Davies, R. J. (2024). Construction 4.0: A Systematic Review of Its Application in Developing Countries. Applied Sciences, 14(14), 6197. https://doi.org/10.3390/app14146197