The Effect of Pre-Treatment and the Drying Method on the Nutritional and Bioactive Composition of Sea Cucumbers—A Review

Abstract

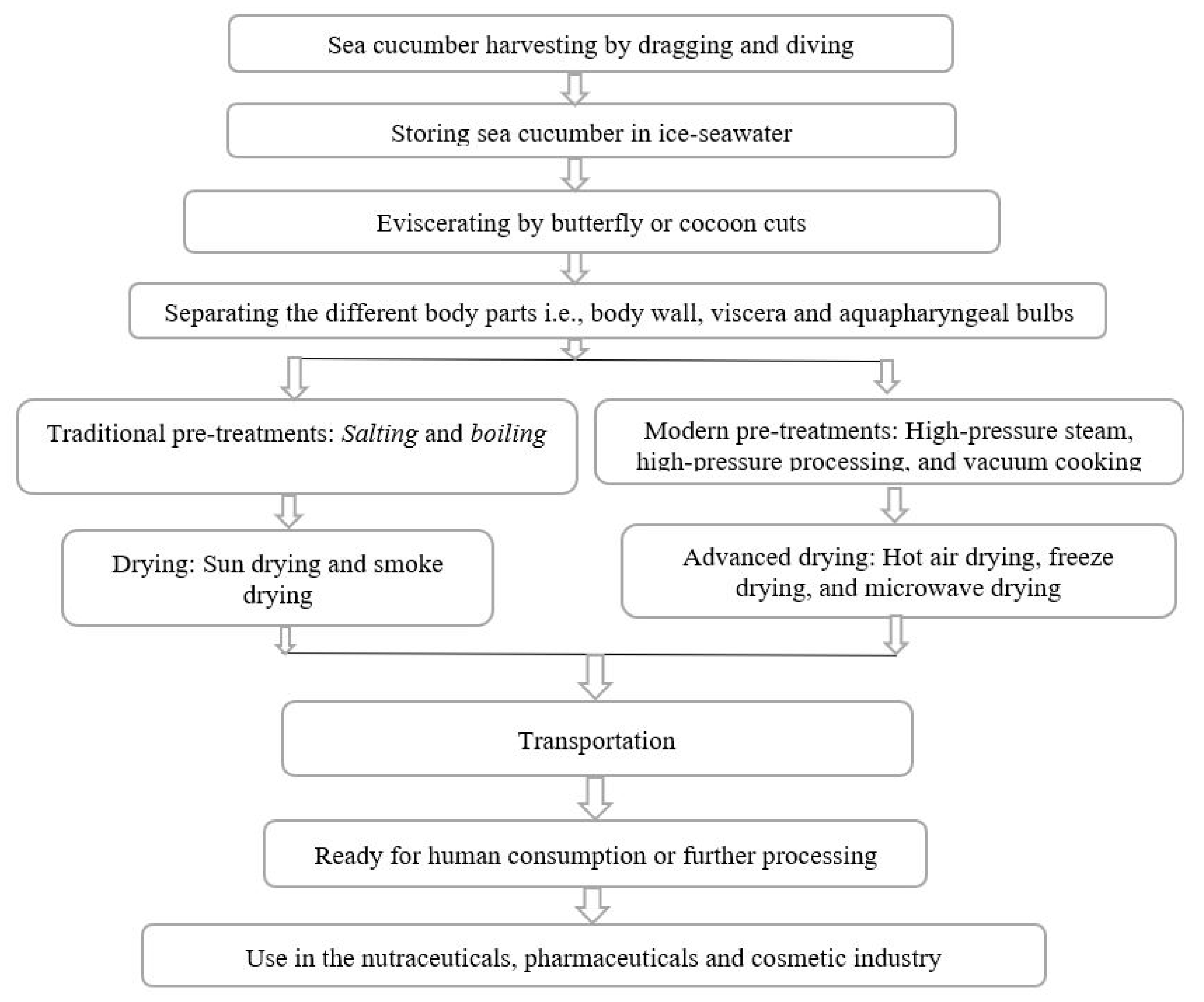

:1. Introduction

2. Proximate Composition of Sea Cucumber

3. Major Pre-Treatments for Sea Cucumber Processing

3.1. Boiling/Heating

| Species | Pre-Treatment | Texture | References | |||||

|---|---|---|---|---|---|---|---|---|

| Hardness/g | Adhesiveness | Springiness | Cohesiveness | Chewiness/g | Resilience | |||

| Cucumaria frondosa | Blanch at 40 °C, 60 °C, and 80 °C for 45 min | 5955.04–12,532.65 | (−668.44)–(−30) | 0.54–0.86 | 0.28–0.78 | 2020.45–4453.01 | 0.15–0.44 | [58] |

| Boiling at 100 °C for 15, 30, 45, 60, and 120 min | 3693.17–6504.57 | (−41.72)–(−27.89) | 0.84–0.90 | 0.81–0.83 | 2788.71–4176.96 | 0.47–0.55 | ||

| Steaming at 100 °C for 15, 30, 45, 60, and 120 min | 3090.1–5162.88 | (−72.37)–(−20.27) | 0.86–0.89 | 0.77–0.82 | 2260.60–3415.58 | 0.43–0.52 | ||

| Stichopus japonicus | Heat at 40 °C for 0, 15,30, 60, 90, and 120 min | 15,825.2–37,173.3 | NA | 0.48–0.71 | 0.31–0.43 | 2933.11–10,655.06 | 0.32–0.41 | [8] |

| Stichopus japonicus | Boiling at 100 °C for 30, 60, 90, 120, 150, and 180 min | 552.26–2837.57 | 0.99–1.68 | 376.3–4700.2 | 0.69–0.90 | 0.64–0.77 | [26] | |

| Apostichopus japonicus | Heat at 80 °C for 10, 20, 40, and 80 min | 121–948 | 0.78–0.95 | 0.59–0.84 | 111.43–410.87 | 0.39–0.65 | [57] | |

| Heat at 90 °C for 10, 20, 40, and 80 min | 356.5–570.6 | 0.82–0.97 | 0.70–0.84 | 257.75–458.64 | 0.50–0.63 | |||

| Heat at 100 °C for 10, 20, 40, and 80 min | 96–266 | 0.89–0.96 | 0.78–0.89 | 81.60–177.13 | 0.57–0.71 | |||

| Heat at 110 °C for 10, 20, 40, and 80 min | 16.2–303.5 | 0.42–1.00 | 0.25–0.90 | 0.97–257.65 | 0.44–0.73 | |||

| Heat at 120 °C for 10, 20, 40, and 80 min | 27.6–298 | 0.64–0.94 | 0.23–0.86 | 3.43–151.87 | 0.31–0.68 | |||

| Apostichopus japonicus | Heat steam sterilization at 121 °C for 15 min under 0.15 MPa then store for 0, 15, 30, 45, 60, 75, 90, and 160 days | 15.67–295.85 | 0.68–1.03 | 0.35–0.76 | 9.18–236.11 | 0.31–0.54 | [53] | |

| Species | Pre-Treatments | Proximate Compounds | Bioactive Compounds | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|

| Protein | Lipid | Carb. | Phenolics | Saponin | Polysac. | Collagen | |||

| Cucumaria frondose (BW) | Boiling at 100 °C for 30 min vs. steaming | 11.8% I | - | - | - | - | - | - | [58] |

| Apostichopus japonicus (BW) | Boiling at 100 °C for 10 min, then vacuum cooking at 95 °C −0.04 MPa for 4 hr | 9.95% I | 0.59% I | 1.64% I | - | - | 1.5% I | - | [37] |

| Stichopus japonicus (BW) | Infrared radiation (10,000 W/m2) with FD | 51.8% I | - | - | - | 0.07% I | 6.25% I | - | [60] |

| Apostichopus japonicus (BW) | Boiling at 100 °C for 10 min | 11.5% D | - | 33% D | - | 41% D | - | - | [47] |

| Cucumaria frondosa (IO) | HPP (200, 400, and 600 MPa for 5, 10, and 15 min) | - | - | - | 32.59% I | - | - | - | [7] |

| Cucumaria frondosa (BW) | HPP (200, 400, and 600 MPa for 5, 10, and 15 min) | 29.21% I | [7] | ||||||

| Cucumaria frondosa Flower | HPP (600 MPa for 10 min) | 241.38 mg GAE/100 g | [61] | ||||||

| Holothuria scabra (BW) | Brining with 15 g/100 mL of saline | - | - | - | - | - | - | 14.28% D | [23] |

| Holothuria scabra (BW) | Kenching for 24 h | - | - | - | - | - | - | 18.49% D | [23] |

| Holothuria scabra (BW) | Smoking | - | - | - | - | - | - | 12.50% D | [23] |

| Holothuria scabra (BW) | Boiling at 80–90 °C | - | - | - | - | - | - | 69.81% D | [23] |

| Holothuria scabra (BW) | Boiling at 80–90 °C and salted for 48 h | - | - | - | - | - | - | 38.41% D | [23] |

| Sticopus japonicus (BW) | Atmospheric pressure boiling at 100 °C for 1 h | 14.8% D | - | - | - | - | - | - | [62] |

| Sticopus japonicus (BW) | Atmospheric pressure steaming at 100 °C for 1 h | 13.0% D | - | - | - | - | - | - | [62] |

| Sticopus japonicus (BW) | High-pressure steaming at 121 °C for 10 min under 0.21 MPa | 11.6% D | - | - | - | - | - | - | [62] |

| Apostichopus japonicus (BW) | Vacuum cooking at 95 °C for 3 h under −0.04 MPa | 9.95% I | 0.59% I | 1.64% I | - | - | 1.5% I | - | [37] |

| Apostichopus japonicus (BW) | Vacuum cooking at 95 °C for 3 h under −0.04 MPa then soaking at 4 °C water for 12 h | 1.33% I | 0.04% D | 0.28% D | - | - | 0.33% I | - | [37] |

3.2. Salting

3.3. Vacuum Cooking

3.4. High-Pressure Steam

3.5. High-Pressure Processing (HPP)

4. Effect of Drying on the Nutritional, Biochemical, and Physiochemical Properties of Sea Cucumbers

4.1. Sun Drying

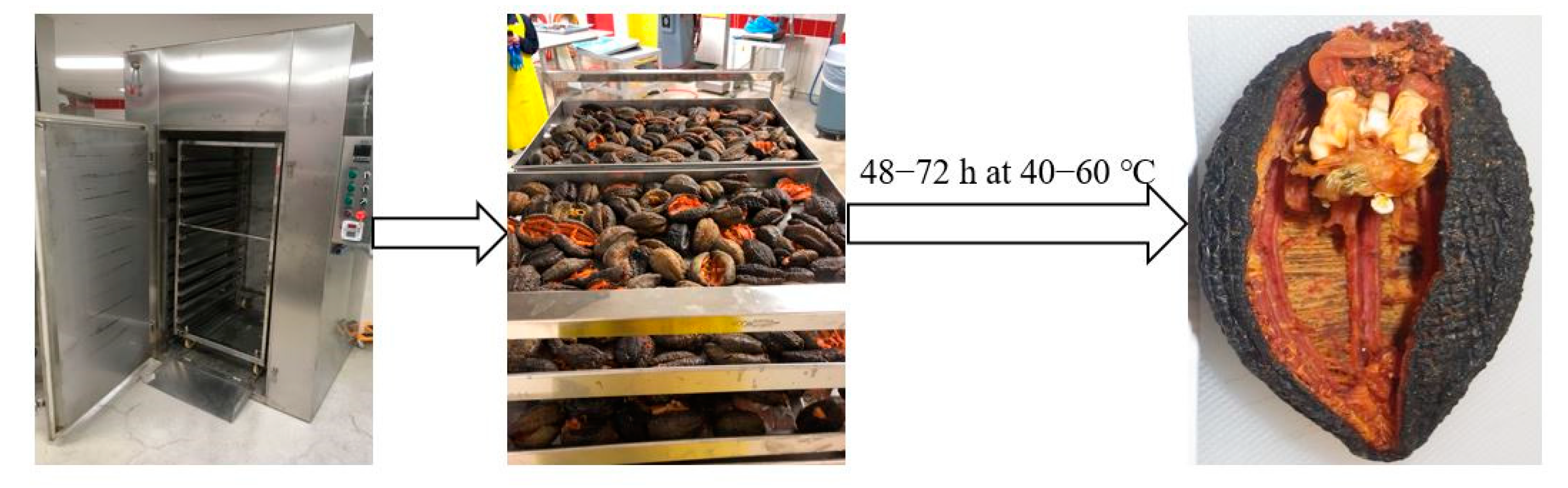

4.2. Hot Air Drying

4.3. Vacuum Drying

4.4. Microwave Vacuum Drying

4.5. Cabinet Drying

4.6. Freeze Drying

5. Challenges and Future Perspectives of Sea Cucumber Processing

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Dave, D.; Trenholm, S.; Ramakrishnan, V.V.; Murphy, W. Effect of drying on nutritional composition of atlantic sea cucumber (Cucumaria frondosa) viscera derived from Newfoundland fisheries. Processes 2021, 9, 703. [Google Scholar] [CrossRef]

- Hossain, A.; Dave, D.; Shahidi, F. Northern Sea cucumber (Cucumaria frondosa): A potential candidate for functional food, nutraceutical, and pharmaceutical sector. Mar. Drugs 2020, 18, 274. [Google Scholar] [CrossRef] [PubMed]

- Öztürk, F.; Gündüz, H. The effect of different drying methods on chemical composition, fatty acid, and amino acid profiles of sea cucumber (Holothuria tubulosa Gmelin, 1791). J. Food Process. Preserv. 2018, 42, e13723. [Google Scholar] [CrossRef]

- Hossain, A.; Dave, D.; Shahidi, F. Sulfated polysaccharides in sea cucumbers and their biological properties: A review. Int. J. Biol. Macromol. 2023, 253, 127329. [Google Scholar] [CrossRef] [PubMed]

- Senadheera, T.R.; Hossain, A.; Dave, D.; Shahidi, F. Functional and physiochemical properties of protein isolates from different body parts of North Atlantic Sea cucumber (Cucumaria frondosa). Food Biosci. 2023, 52, 102511. [Google Scholar] [CrossRef]

- Senadheera, T.R.L.; Hossain, A.; Dave, D.; Shahidi, F. Antioxidant and ACE-Inhibitory Activity of Protein Hydrolysates Produced from Atlantic Sea Cucumber (Cucumaria frondosa). Molecules 2023, 28, 5263. [Google Scholar] [CrossRef]

- Hossain, A.; Yeo, J.; Dave, D.; Shahidi, F. Phenolic compounds and antioxidant capacity of sea cucumber (Cucumaria frondosa) processing discards as affected by high-pressure processing (HPP). Antioxidants 2022, 11, 337. [Google Scholar] [CrossRef] [PubMed]

- Bi, J.; Li, Y.; Cheng, S.; Dong, X.; Kamal, T.; Zhou, D.; Li, D.; Jiang, P.; Zhu, B.W.; Tan, M. Changes in body wall of sea cucumber (Stichopus japonicus) during a two-step heating process assessed by rheology, LF-NMR, and texture profile analysis. Food Biophys. 2016, 11, 257–265. [Google Scholar] [CrossRef]

- Amir, N.; Aprianto, R.; Tuwo, A.; Tresnati, J. Processing and quality characteristics sea cucumber Bohadschia vitiensis at Kambuno Island in Sembilan Islands, Bone Gulf, South Sulawesi, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 564, 012047. [Google Scholar] [CrossRef]

- Senadheera, T.R.L.; Hossain, A.; Dave, D.; Shahidi, F. In Silico Analysis of Bioactive Peptides Produced from Underutilized Sea Cucumber By-Products—A Bioinformatics Approach. Mar. Drugs 2022, 20, 610. [Google Scholar] [CrossRef]

- Purcell, S.W.; Ngaluafe, P.; Aram, K.T.; Lalavanua, W. Variation in postharvest processing of sea cucumbers by fishers and commercial processors among three Pacific Island countries. SPC Bêche-De-Mer Inf. Bull 2016, 36, 58–66. [Google Scholar]

- Purcell, S.W. Processing Sea Cucumbers into Beche-De-Mer: A Manual for Pacific Island Fishers; Southern Cross University: Lismore, Australia, 2014; ISBN 978-982-00-0711-6. [Google Scholar]

- Lavitra, T.; Rachelle, D.; Rasolofonirina, R.; Jangoux, M.; Eeckhaut, I. Processing and marketing of holothurians in the Toliara region, southwestern Madagascar. SPC Beche-De-Mer Inf. Bull. 2008, 28, 24–33. [Google Scholar]

- Ram, R.; Chand, R.V.; Zeng, C.; Southgate, P.C. Recovery rates for eight commercial sea cucumber species from the Fiji Islands. Reg. Stud. Mar. Sci. 2016, 8, 59–64. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Zhou, D.Y.; Liu, Y.X.; Yu, M.M.; Liu, B.; Song, L.; Dong, X.P.; Qi, H.; Shahidi, F. Inhibitory effect of natural metal ion chelators on the autolysis of sea cucumber (Stichopus japonicus) and its mechanism. Food Res. Int. 2020, 133, 109205. [Google Scholar] [CrossRef]

- Mangubhai, S.; Nand, Y.; Ram, R.; Fox, M.; Tabunakawai-Vakalalabure, M.; Vodivodi, T.; Lalavanuam, W.; Purcell, S. Value-chain analysis of the wild-caught sea cucumber fishery. Fiji’s Sea Cucumber Fishery: Advances in Science for Improved Management. Wildl. Conserv. Soc. 2017, 01/17, 23–29. [Google Scholar]

- Available online: https://www.sealifebase.se/summary/Bohadschia-vitiensis.html (accessed on 22 June 2024).

- Available online: https://www.sealifebase.se/summary/Bohadschia-similis.html (accessed on 22 June 2024).

- Available online: https://www.sealifebase.se/summary/Holothuria-edulis.html (accessed on 22 June 2024).

- Available online: https://www.sealifebase.se/summary/Actinopyga-miliaris.html (accessed on 22 June 2024).

- Aprianto, R.; Amir, N.; Tresnati, J.; Tuwo, A.; Nakajima, M. Economically important sea cucumber processing techniques in South Sulawesi, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2019, 370, 012082. [Google Scholar] [CrossRef]

- Wu, H.T.; Li, D.M.; Zhu, B.W.; Sun, J.J.; Zheng, J.; Wang, F.L.; Konno, K.; Jiang, X. Proteolysis of noncollagenous proteins in sea cucumber, Stichopus japonicus, body wall: Characterisation and the effects of cysteine protease inhibitors. Food Chem. 2013, 141, 1287–1294. [Google Scholar] [CrossRef]

- Ram, R.; Chand, R.V.; Forrest, A.; Southgate, P.C. Effect of processing method on quality, texture, collagen and amino acid composition of sandfish (Holothuria scabra). LWT 2017, 86, 261–269. [Google Scholar] [CrossRef]

- Fan, X.; Ma, Y.; Li, M.; Li, Y.; Sang, X.; Zhao, Q. Thermal treatments and their influence on physicochemical properties of sea cucumbers: A comprehensive review. Int. J. Food Sci. Technol. 2022, 57, 5790–5800. [Google Scholar] [CrossRef]

- Peng, Z.; Hou, H.; Bu, L.; Li, B.; Zhang, Z.; Xue, C. Nonenzymatic softening mechanism of collagen gel of sea cucumber (A postichopus japonicus). J. Food Process. Preserv. 2015, 39, 2322–2331. [Google Scholar] [CrossRef]

- Dong, X.; Qi, H.; Feng, D.; He, B.; Nakamura, Y.; Yu, C.; Zhu, B. Oxidative stress involved in textural changes of sea cucumber Stichopus japonicus body wall during low-temperature treatment. Int. J. Food Prop. 2018, 21, 2646–2659. [Google Scholar] [CrossRef]

- Moon, J.H.; Chung, D.H.; Pan, C.H.; Yoon, W.B. Determination of principal components for characterizing the drying of sea cucumbers (Stichopus japonicus selenka) using far infrared radiation drying and hot air drying. J. Aquat. Food Prod. Technol. 2017, 26, 1221–1232. [Google Scholar] [CrossRef]

- Yu, W.; Wang, Z.; Pan, Y.; Jiang, P.; Pan, J.; Yu, C.; Dong, X. Effect of κ-carrageenan on quality improvement of 3D printed Hypophthalmichthys molitrix-sea cucumber compound surimi product. LWT 2022, 154, 112279. [Google Scholar] [CrossRef]

- Chong, N.V.W.; Pindi, W.; Chye, F.Y.; Shaarani, S.M.; Lee, J.S. Effects of drying methods on the quality of dried sea cucumbers from Sabah–a review. Int. J. Nov. Res. Life Sci. 2015, 2, 49–64. [Google Scholar]

- Nursid, M.; Patantis, G.; Oktavia, D.A.; Legistari, N. Comparison of metabolite profiles and cytotoxicity of the black sea cucumber (Holothuria atra) dried with different drying techniques. Int. Food Res. J. 2022, 29, 1179–1187. [Google Scholar] [CrossRef]

- Rasyid, A.; Yasman, Y.; Putra, M.Y. Current prospects of nutraceutical and pharmaceutical use of sea cucumbers. Pharmacia 2021, 68, 561–572. [Google Scholar]

- Haider, M.S.; Sultana, R.; Jamil, K.; Tarar, O.M.; Afzal, W. A study on proximate composition, amino acid profile, fatty acid profile and some mineral contents in two species of sea cucumber. JAPS J. Anim. Plant Sci. 2015, 25, 168. [Google Scholar]

- González-Wangüemert, M.; Roggatz, C.C.; Rodrigues, M.J.; Barreira, L.; da Silva, M.M.; Custódio, L. A new insight into the influence of habitat on the biochemical properties of three commercial sea cucumber species. Int. Aquat. Res. 2018, 10, 361–373. [Google Scholar] [CrossRef]

- Bechtel, P.J.; Oliveira, A.C.; Demir, N.; Smiley, S. Chemical composition of the giant red sea cucumber, P arastichopus californicus, commercially harvested in Alaska. Food Sci. Nutr. 2013, 1, 63–73. [Google Scholar] [CrossRef]

- Barzkar, N.; Attaran Fariman, G.; Taheri, A. Proximate composition and mineral contents in the body wall of two species of sea cucumber from Oman Sea. Environ. Sci. Pollut. Res. 2017, 24, 18907–18911. [Google Scholar] [CrossRef]

- Göçer, M.; Olgunoglu, I.A.; Olgunoglu, M.P. A study on fatty acid profile and some major mineral contents of sea cucumber (Holothuria (platyperona) sanctori) from Mediterranean Sea (Turkey). Food Sci. Qual. Manag. 2018, 72, 1–5. [Google Scholar]

- Li, C.; Li, H.; Guo, S.; Li, X.; Zhu, X. Evaluation of processing methods on the nutritional quality of sea cucumber (Apostichopus japonicus Selenka). J. Aquat. Food Prod. Technol. 2018, 27, 406–417. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, L.; Tang, X.; Xia, X.; Hu, W.; Zhou, P. Season and geography induced variation in sea cucumber (Stichopus japonicus) nutritional composition and gut microbiota. J. Food Compos. Anal. 2021, 101, 103838. [Google Scholar] [CrossRef]

- Andriamanamisata, V.L.R.; Telesphore, A.F. The nutritional values of two species of sea cucumbers (Holothuria scabra and Holothuria lessoni) from Madagascar. Afr. J. Food Sci. 2019, 13, 281286. [Google Scholar]

- Wen, J.; Hu, C.; Fan, S. Chemical composition and nutritional quality of sea cucumbers. J. Sci. Food Agric. 2010, 90, 2469–2474. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.Y.; Elamin, S.M.; Gideiri, Y.B.A.; Ali, S.M. The proximate composition and the nutritional value of some sea cucumber species inhabiting the Sudanese Red Sea. Food Sci. Qual. Manag. 2015, 41, 11–16. [Google Scholar]

- Nishanthan, G.; Kumara, P.A.D.A.; De Croos, M.D.S.T.; Prasada, D.V.P.; Dissanayake, D.C.T. Effects of processing on proximate and fatty acid compositions of six commercial sea cucumber species of Sri Lanka. J. Food Sci. Technol. 2018, 55, 1933–1941. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Forero, A.; Medina-Lambraño, K.; and Acosta-Ortíz, E. Variations in the proximate composition of the sea cucumber, Isostichopus sp. aff badionotus. Int. Aquat. Res. 2021, 13, 241–252. [Google Scholar]

- Zhong, Y.; Khan, M.A.; Shahidi, F. Compositional characteristics and antioxidant properties of fresh and processed sea cucumber (Cucumaria frondosa). J. Agric. Food Chem. 2007, 55, 1188–1192. [Google Scholar] [CrossRef]

- Aydın, M.; Sevgili, H.; Tufan, B.; Emre, Y.; Köse, S. Proximate composition and fatty acid profile of three different fresh and dried commercial sea cucumbers from Turkey. Int. J. Food Sci. Technol. 2011, 46, 500–508. [Google Scholar] [CrossRef]

- Omran, N.E.S.E.S. Nutritional value of some Egyptian sea cucumbers. Afr. J. Biotechnol. 2013; 12, 5466–5472. [Google Scholar] [CrossRef]

- Yin, P.; Jia, A.; Heimann, K.; Zhang, M.; Liu, X.; Zhang, W.; Liu, C. Hot water pretreatment-induced significant metabolite changes in the sea cucumber Apostichopus japonicus. Food Chem. 2020, 314, 126211. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Zhang, M.; Mujumdar, A.S.; Wang, S. Microwave freeze drying of sea cucumber (Stichopus japonicus). J. Food Eng. 2010, 96, 491–497. [Google Scholar] [CrossRef]

- Tamilmani, P.; Pandey, M.C. Thermal analysis of meat and meat products: A review. J. Therm. Anal. Calorim. 2016, 123, 1899–1917. [Google Scholar] [CrossRef]

- Singh, A.; Benjakul, S. Proteolysis and its control using protease inhibitors in fish and fish products: A review. Compr. Rev. Food Sci. Food Saf. 2018, 17, 496–509. [Google Scholar] [CrossRef] [PubMed]

- Laopoolkit, P.; Suwannaporn, P. Effect of pretreatments and vacuum drying on instant dried pork process optimization. Meat Sci. 2011, 88, 553–558. [Google Scholar] [CrossRef] [PubMed]

- Palka, K.; Daun, H. Changes in texture, cooking losses, and myofibrillar structure of bovine M. semitendinosus during heating. Meat Sci. 1999, 51, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Peng, Z.; Lu, J.; Li, B.; Hou, H.U. Self-Degradation of Sea Cucumber Body Wall Under 4C Storage Condition. J. Food Process. Preserv. 2016, 41, 715–723. [Google Scholar] [CrossRef]

- Zhong, M.; Chen, T.; Hu, C.; Ren, C. Isolation and characterization of collagen from the body wall of sea cucumber Stichopus monotuberculatus. J. Food Sci. 2015, 80, C671–C679. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Zhu, B.; Sun, L.; Zheng, J.; Jiang, D.; Zhou, D.; Wu, H.; Murata, Y. Changes of collagen in sea cucumber (Stichopus japonicas) during cooking. Food Sci. Biotechnol. 2011, 20, 1137–1141. [Google Scholar] [CrossRef]

- Wang, J.; Lin, L.; Sun, X.; Hou, H. Mechanism of sea cucumbers (Apostichopus japonicus) body wall changes under different thermal treatment at micro-scale. LWT 2020, 130, 109461. [Google Scholar] [CrossRef]

- Zhang, K.; Hou, H.; Bu, L.; Li, B.; Xue, C.; Peng, Z.; Su, S. Effects of heat treatment on the gel properties of the body wall of sea cucumber (Apostichopus japonicus). J. Food Sci. Technol. 2017, 54, 707–717. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Liu, R.; Geirsdóttir, M.; Li, S.; Tomasson, T.; Xiong, S.; Li, X.; Gudjónsdóttir, M. Thermal-Induced Autolysis Enzymes Inactivation, Protein Degradation and Physical Properties of Sea Cucumber, Cucumaria frondosa. Processes 2022, 10, 847. [Google Scholar] [CrossRef]

- Obuz, E.; Dikeman, M.E.; Loughin, T.M. Effects of cooking method, reheating, holding time, and holding temperature on beef longissimus lumborum and biceps femoris tenderness. Meat Sci. 2003, 65, 841–851. [Google Scholar] [CrossRef] [PubMed]

- Mamatov, S.; Zhang, M.; Jia, A.; Liu, X.; Liu, C. Effect of infrared radiation (IR) pre-treatment on the freeze-drying of sea cucumber. Int J Innov Technol Explor Eng 2019, 8, 475–478. [Google Scholar]

- Hossain, A.; Senadheera, T.R.; Dave, D.; Shahidi, F. Phenolic profiles of Atlantic Sea cucumber (Cucumaria frondosa) tentacles and their biological properties. Food Res. Int. 2023, 163, 112262. [Google Scholar] [CrossRef]

- Gu, P.; Qi, S.; Zhai, Z.; Liu, J.; Liu, Z.; Jin, Y.; Qi, Y.; Zhao, Q.; Wang, F. Comprehensive proteomic analysis of sea cucumbers (Stichopus japonicus) in thermal processing by HPLC-MS/MS. Food Chem. 2022, 373, 131368. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, R.B. Application of osmo-air dehydration for processing of tropical frepical fruits in rural areas. Indian Food Ind. 2005, 24, 62–69. [Google Scholar]

- Yadav, A.K.; Singh, S.V. Osmotic dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2014, 51, 1654–1673. [Google Scholar] [CrossRef]

- Schellekens, M. New research issues in sous-vide cooking. Trends Food Sci. Technol. 1996, 7, 256–262. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chen, S.D. Application of High-Pressure Processing on Ultrasonically Treated Extract from Wild Bitter Gourd. Processes 2022, 10, 1926. [Google Scholar] [CrossRef]

- Yu, Q.; Fan, L. Improving the bioactive ingredients and functions of asparagus from efficient to emerging processing technologies: A review. Food Chem. 2021, 358, 129903. [Google Scholar] [CrossRef] [PubMed]

- Knorr, D. Effects of high-hydrostatic-pressure processes on food safety and quality. Food Technol. 1993, 47, 156–161. [Google Scholar]

- Barba, F.J.; Esteve, M.J.; Frígola, A. High pressure treatment effect on physicochemical and nutritional properties of fluid foods during storage: A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 307–322. [Google Scholar] [CrossRef]

- Da Silveira, T.F.F.; Cristianini, M.; Kuhnle, G.G.; Ribeiro, A.B.; Teixeira Filho, J.; Godoy, H.T. Anthocyanins, non-anthocyanin phenolics, tocopherols and antioxidant capacity of açaí juice (Euterpe oleracea) as affected by high pressure processing and thermal pasteurization. Innov. Food Sci. Emerg. Technol. 2019, 55, 88–96. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, R.; Zhang, M. Effects of high hydrostatic pressure processing and subsequent storage on phenolic contents and antioxidant activity in fruit and vegetable products. Int. J. Food Sci. Technol. 2017, 52, 3–12. [Google Scholar] [CrossRef]

- Hossain, A.; Dave, D.; Shahidi, F. Effect of high-pressure processing (HPP) on phenolics of North Atlantic Sea cucumber (Cucumaria frondosa). J. Agric. Food Chem. 2022, 70, 3489–3501. [Google Scholar] [CrossRef] [PubMed]

- Hossain, A.; Dave, D.; Shahidi, F. Antioxidant potential of sea cucumbers and their beneficial effects on human health. Mar. Drugs 2022, 20, 521. [Google Scholar] [CrossRef] [PubMed]

- Coroneo, V.; Corrias, F.; Brutti, A.; Addis, P.; Scano, E.; Angioni, A. Effect of High-Pressure Processing on Fresh Sea Urchin Gonads in Terms of Shelf Life, Chemical Composition, and Microbiological Properties. Foods 2022, 11, 260. [Google Scholar] [CrossRef]

- Lee, Y.C.; Kung, H.F.; Cheng, Q.L.; Lin, C.S.; Tseng, C.H.; Chiu, K.; Tsai, Y.H. Effects of high-hydrostatic-pressure processing on the chemical and microbiological quality of raw ready-to-eat hard clam marinated in soy sauce during cold storage. LWT 2022, 159, 113229. [Google Scholar] [CrossRef]

- Gupta, S.; Farid, M.M.; Fletcher, G.C.; Melton, L.D. Color, yield, and texture of heat and high pressure processed mussels during ice storage. J. Aquat. Food Prod. Technol. 2015, 24, 68–78. [Google Scholar] [CrossRef]

- Kingsley, D.H. High pressure processing of bivalve shellfish and HPP’s use as a virus intervention. Foods 2014, 3, 336–350. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Zhang, M.; Mujumdar, A.S. Study on a combination drying technique of sea cucumber. Dry. Technol. 2007, 25, 2011–2019. [Google Scholar] [CrossRef]

- Ridhowati, S.; Chasanah, E.; Syah, D.; Zakaria, F. A study on the nutrient substances of sea cucumber Stichopus variegatus flour using vacuum oven. Int. Food Res. J. 2018, 25, 1419. [Google Scholar]

- Shamsuddeen, M.M.; Cha, D.A.; Kim, S.C.; Kim, J.H. Effects of decompression condition and temperature on drying rate in a hybrid heat pump decompression type dryer used for seafood drying. Dry. Technol. 2021, 39, 2130–2144. [Google Scholar] [CrossRef]

- He, X.; Lin, R.; Cheng, S.; Wang, S.; Yuan, L.; Wang, H.; Wang, H.; Tan, M. Effects of microwave vacuum drying on the moisture migration, microstructure, and rehydration of sea cucumber. J. Food Sci. 2021, 86, 2499–2512. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Luan, Z. The effect of high-pulsed electric field pretreatment on vacuum freeze drying of sea cucumber. Int. J. Appl. Electromagn. Mech. 2018, 57, 247–256. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, L.; Liu, S.; Ru, X.; Xing, L.; Cao, X.; Zhang, T.; Yang, H. The effect of salinity on the growth, energy budget and physiological performance of green, white and purple color morphs of sea cucumber, Apostichopus japonicus. Aquaculture 2015, 437, 297–303. [Google Scholar] [CrossRef]

- Tamarit-Pino, Y.; Batías-Montes, J.M.; Segura-Ponce, L.A.; Díaz-Álvarez, R.E.; Guzmán-Meza, M.F.; Quevedo-León, R.A. Effect of electrohydrodynamic pretreatment on drying rate and rehydration properties of Chilean sea cucumber (Athyonidium chilensis). Food Bioprod. Process. 2020, 123, 284–295. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Vega-Mercado, H. Dehydration of Foods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Janjai, S.; Bala, B.K. Solar drying technology. Food Eng. Rev. 2012, 4, 16–54. [Google Scholar] [CrossRef]

- Duan, X.; Liu, L.L.; Ren, G.Y.; Zhu, W.X. Microwave freeze drying of type I collagen from bovine bone. Dry. Technol. 2013, 31, 1701–1706. [Google Scholar] [CrossRef]

- Greensmith, M. Practical Dehydration; Woodhead Publishing: Cambridge, UK, 1998. [Google Scholar]

- Li, M.; Qi, Y.; Mu, L.; Li, Z.; Zhao, Q.; Sun, J.; Jiang, Q. Effects of processing method on chemical compositions and nutritional quality of ready-to-eat sea cucumber (Apostichopus japonicus). Food Sci. Nutr. 2019, 7, 755–763. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, M.J.; Do, H.V.; Mun, S.; Jun, H.J.; Lee, J.H.; Kim, Y.R.; Lee, S.J. Hypocholesterolemic and hypoglycemic effects of enzymatically modified carbohydrates from rice in high-fat-fed C57BL/6J mice. Mol. Nutr. Food Res. 2011, 55 (Suppl. S2), S214–S226. [Google Scholar] [CrossRef] [PubMed]

- Senadheera, T.R.L.; Hossain, A.; Shahidi, F. Marine Bioactives and Their Application in the Food Industry: A Review. Appl. Sci. 2023, 13, 12088. [Google Scholar] [CrossRef]

- Hou, H.; Chen, T.; Peng, Z.; Zhang, Z.; Xue, C.; Li, B. Stability and degradation regulation of body wall gel of sea cucumber treated by high hydrostatic pressure. Trans. Chin. Soc. Agric. Eng. 2014, 30, 316–322. [Google Scholar]

- Ding, L.; Zhang, T.T.; Che, H.X.; Zhang, L.Y.; Xue, C.H.; Chang, Y.G.; Wang, Y.M. Saponins of sea cucumber attenuate atherosclerosis in ApoE−/− mice via lipid-lowering and anti-inflammatory properties. J. Funct. Foods 2018, 48, 490–497. [Google Scholar] [CrossRef]

- Song, F.; Su, H.; Yang, N.; Zhu, L.; Cheng, J.; Wang, L.; Cheng, X. Myo-inositol content determined by myo-inositol biosynthesis and oxidation in blueberry fruit. Food Chem. 2016, 210, 381–387. [Google Scholar] [CrossRef]

- Venegas-Calerón, M.; Ruíz-Méndez, M.V.; Martínez-Force, E.; Garcés, R.; Salas, J.J. Characterization of Xanthoceras sorbifolium Bunge seeds: Lipids, proteins and saponins content. Ind. Crops Prod. 2017, 109, 192–198. [Google Scholar] [CrossRef]

| Species | Moisture (%) | Ash (%) | Protein (%) | Lipid (%) | References |

|---|---|---|---|---|---|

| Bohadschia vitiensis (DB) | - | 30.78 | 17.69 | - | [9] |

| Apostichopus japonicus Selenka (DB) | 5.10 | 34.90 | 52 | 5.11 | [37] |

| Cucumaria frondosa Viscera (DB) | - | 11.95 | 48.26 | 26.12 | [1] |

| Stichopus japonicus (DB) | - | 34.15 | 52.4 | 12.4 | [38] |

| Holothuria lessoni (DB) | 13.47 | 34.51 | 41.18 | 3.02 | [39] |

| Holothuria atra (DB) | 4.5 | 7.3 | 82.9 | 2.4 | [30] |

| Stichopus herrmanni (DB) | 10.2 | 37.9 | 47.0 | 0.8 | [40] |

| Thelenota ananas (DB) | 15.1 | 25.1 | 55.2 | 1.9 | [40] |

| Thelenota anax (DB) | 1.2 | 39.2 | 40.7 | 9.9 | [40] |

| Holothuria fuscogilva (DB) | 11.6 | 26.4 | 57.8 | 0.3 | [40] |

| Holothuria fuscopunctata (DB) | 7.0 | 39.6 | 50.1 | 0.3 | [40] |

| Actinopyga mauritiana (DB) | 11.6 | 15.4 | 63.3 | 1.4 | [40] |

| Actinopyga caerulea (DB) | 0.81 | 28.4 | 56.9 | 10.1 | [40] |

| Bohadschia argus (DB) | 13.0 | 17.7 | 62.1 | 1.1 | [40] |

| Actinopyga echinites (DB) | 9.30 | 29.25 | 60.20 | 1.25 | [41] |

| Parastichopus californicus (DB) | 4.03 | 25.73 | 47.03 | 8.19 | [30] |

| Stichopus chloronotus (DB) | - | 27.7 | 57.93 | 3.94 | [42] |

| Holothuria spinifera (DB) | - | 48.14 | 47.16 | 1.03 | [42] |

| Apostichpous japonicas (WB) | 91.71 | 2.97 | 3.35 | 0.29 | [37] |

| Holothuria tubulosa (WB) | 84.04 | 6.63 | 10.33 | 0.20 | [3] |

| Cucumaria frondosa Viscera (WB) | 82.07 | 2.14 | 8.65 | 4.68 | [1] |

| Isostichopus sp. aff badionotus (WB) | 93.26 | 3.97 | 7.21 | 0.07 | [43] |

| Cucumaria frondosa (WB) | 90.5 | 3.5 | 5.5 | 0.8 | [44] |

| Holothuria scabra (WB) | 87.12 | 6.82 | 5.10 | 0.37 | [31] |

| Holothuria mammata (WB) | 85.24 | 5.13 | 11.1 | 0.55 | [45] |

| Holothuria polii (WB) | 81.24 | 7.85 | 8.66 | 0.33 | [45] |

| Stichopus horrens (WB) | 92.83 | 3.4 | 3.63 | 0.42 | [35] |

| Holothuria Arenicola (WB) | 93.02 | 2.01 | 4.47 | 0.65 | [35] |

| Actinopyga mauritiana (WB) | 84.71 | 2.12 | 7.00 | 4.99 | [46] |

| Bohadschia marmorata (WB) | 83.17 | 6.03 | 6.96 | 4.83 | [46] |

| Holothuria leucospilota (WB) | 81.41 | 4.3 | 7.02 | 4.60 | [46] |

| Species | Cr | Ni | Mn | Cu | Pb | Cd | Zn | Fe | Na | K | Ca | Mg | References |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Holothuria Arenicola | - | 0.19 | 5.23 | 0.95 | - | - | 4.28 | - | 4750 | 520 | 5700 | 4750 | [32] |

| Actinopyga mauritiana | - | 0.25 | 5.85 | 5.11 | - | - | 5.23 | - | 6220 | 620 | 2610 | 1870 | [32] |

| Holothuria mammata | 0.09 | 0.05 | 0.45 | - | - | - | 1.05 | 3.37 | 6650 | 386 | 4110 | 1270 | [33] |

| Holothuria polii | 0.08 | - | 4.62 | - | 0.31 | 0.009 | 0.89 | 4.06 | 5690 | 327 | 14,500 | 2140 | [33] |

| Holothuria tubulosa | 1.52 | 0.25 | 8.66 | - | 0.65 | - | 22.77 | 440 | 7520 | 558 | 9580 | 1660 | [33] |

| Parastichopus californicus | 0.67 | 0.4 | 4.36 | 0.35 | - | - | 4.04 | 18.42 | 8800 | 400 | 2500 | 1400 | [34] |

| Stichopus horrens | - | - | - | - | - | - | 0.096 | 521.78 | - | - | 106.3 | 92.5 | [35] |

| Holothuria sanctori | - | - | - | - | - | - | - | - | 552.4 | - | 656.7 | 155.77 | [36] |

| Holothuria scabra | - | - | - | - | - | - | - | 2.84 | 666.2 | 61.42 | 1812.32 | 304.61 | [31] |

| Apostichopus japonicus | 0.67 | - | 0.65 | 1.14 | - | - | 5.02 | 26.54 | 18,271.3 | 1660.15 | 1506.92 | 1480.44 | [37] |

| Apostichopus japonicus selenka | 0.20 | - | 0.19 | 0.85 | - | - | 0.97 | 4.12 | 234 | 20 | 25 | 33 | [37] |

| Species | Drying Methods | Moisture (%) | Ash (%) | Protein (%) | Lipid (%) | References |

|---|---|---|---|---|---|---|

| Holothuria tubulosa (BW) | HAD | 6.86 | 38.16 | 56.12 | 1.36 | [3] |

| FD | 6.00 | 30.39 | 62.70 | 1.93 | ||

| MD | 6.04 | 32.78 | 59.79 | 1.65 | ||

| Cucumaria frondosa Viscera | HAD | 7.84 | 12.49 | 45.79 | 25.69 | [1] |

| FD | 1.79 | 12.53 | 46.96 | 23.19 | ||

| Apostichopus japonicus selenka (BW) | HAD | 5.15 | 32.99 | 51 | 5.2 | [37] |

| SD | 5.3 | 37.18 | 46.50 | 5.10 | ||

| VFD | 3.99 | 31.89 | 48 | 5.22 | ||

| Holothuria atra (BW) | SD | 7.5 | 8.8 | 78.6 | 2.7 | [30] |

| Oven-Dried at 40 °C | 7.2 | 8.8 | 78.8 | 2.6 | ||

| Oven-Dried at 40 °C | 8.4 | 8.5 | 80.6 | 2.4 | ||

| Oven-Dried at 40 °C | 4.5 | 7.3 | 82.9 | 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, A.; Hossain, A.; Dave, D. The Effect of Pre-Treatment and the Drying Method on the Nutritional and Bioactive Composition of Sea Cucumbers—A Review. Appl. Sci. 2024, 14, 6475. https://doi.org/10.3390/app14156475

Das A, Hossain A, Dave D. The Effect of Pre-Treatment and the Drying Method on the Nutritional and Bioactive Composition of Sea Cucumbers—A Review. Applied Sciences. 2024; 14(15):6475. https://doi.org/10.3390/app14156475

Chicago/Turabian StyleDas, Amit, Abul Hossain, and Deepika Dave. 2024. "The Effect of Pre-Treatment and the Drying Method on the Nutritional and Bioactive Composition of Sea Cucumbers—A Review" Applied Sciences 14, no. 15: 6475. https://doi.org/10.3390/app14156475