Comparison of Embankment Properties with Clay Core and Asphaltic Concrete Core

Abstract

1. Introduction

2. Materials and Methods

2.1. Significant Factors Affect the Stability of an Embankment

2.1.1. Seepage Analysis through an Embankment

- h = Hydraulic head.

- kx = Permeability coefficient in the x direction.

- ky = Permeability coefficient in the y direction.

2.1.2. Displacement Analysis of Embankments

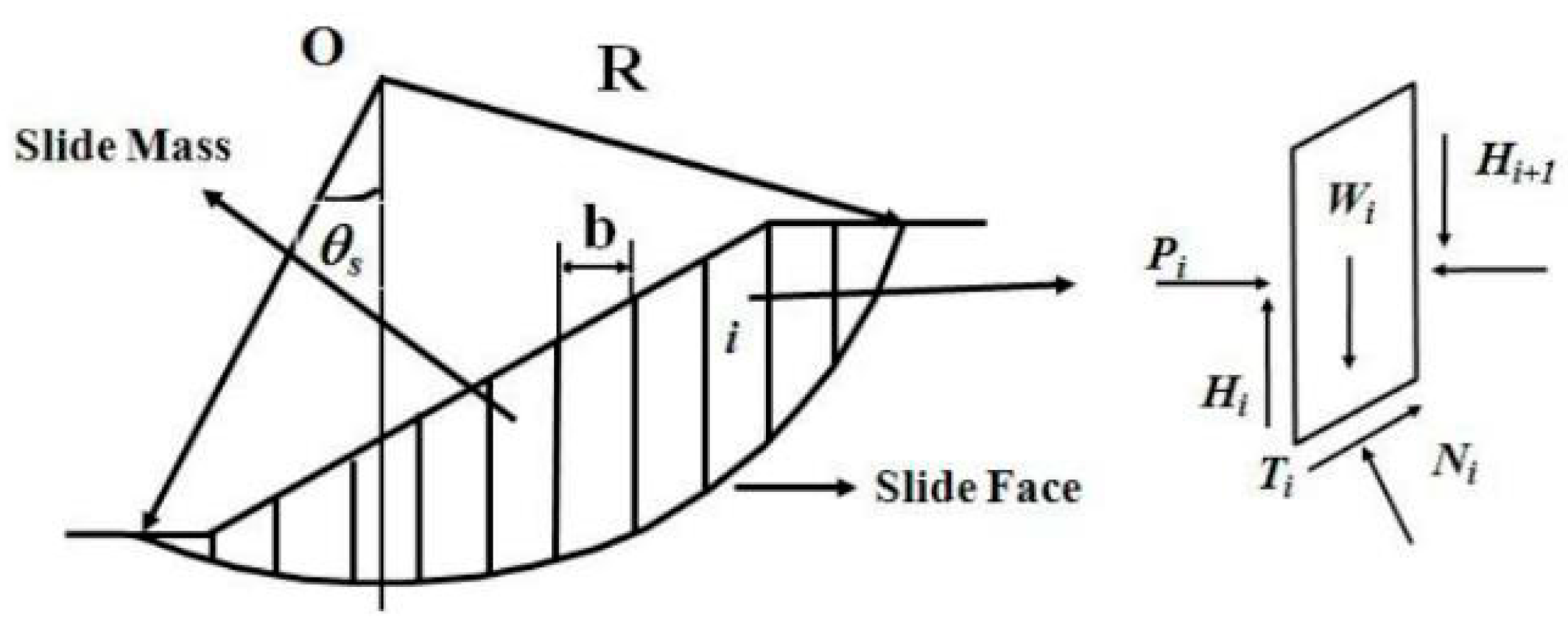

2.1.3. Slope Stability Analysis of an Embankment

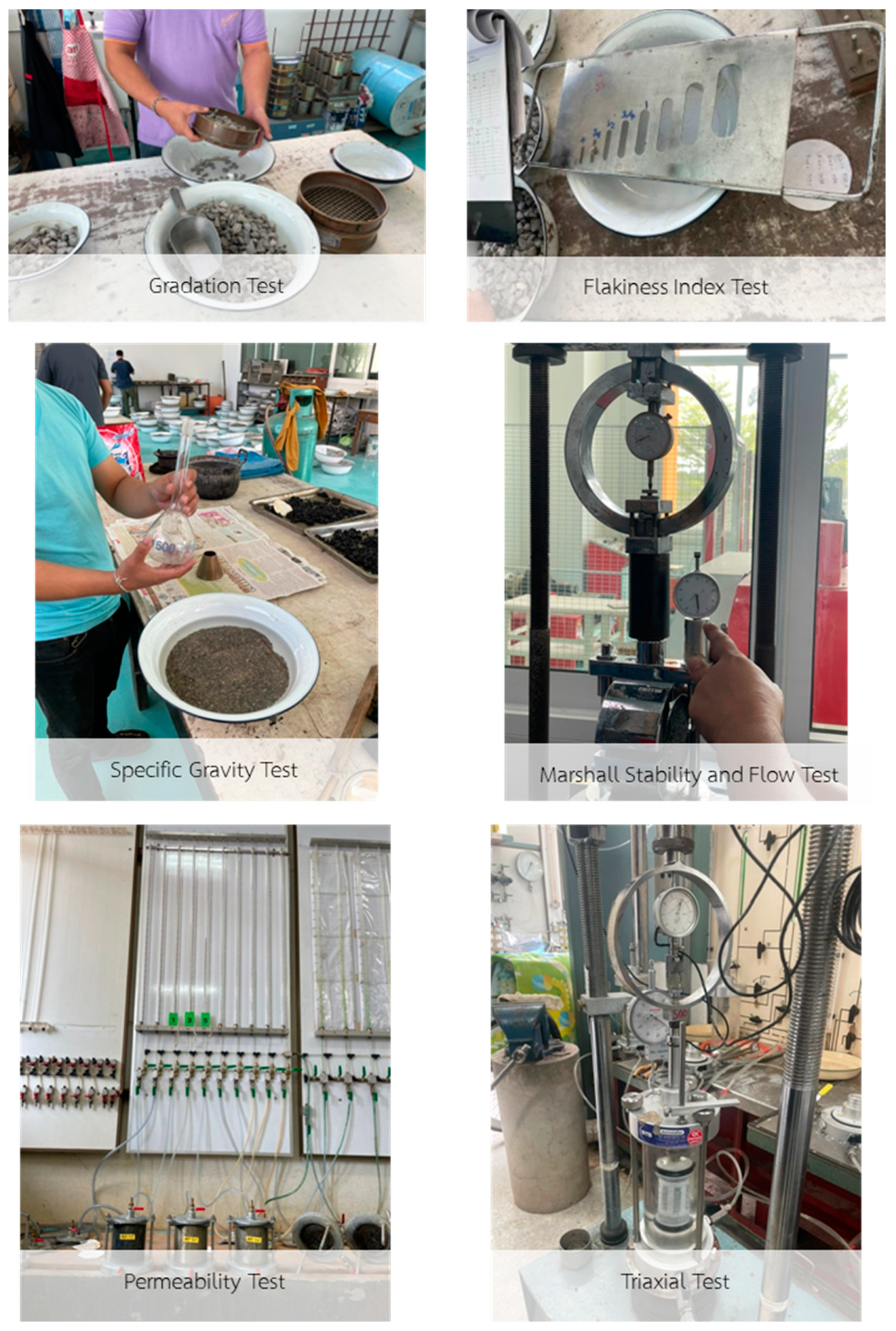

2.2. Testing of Asphaltic Concrete in the Laboratory

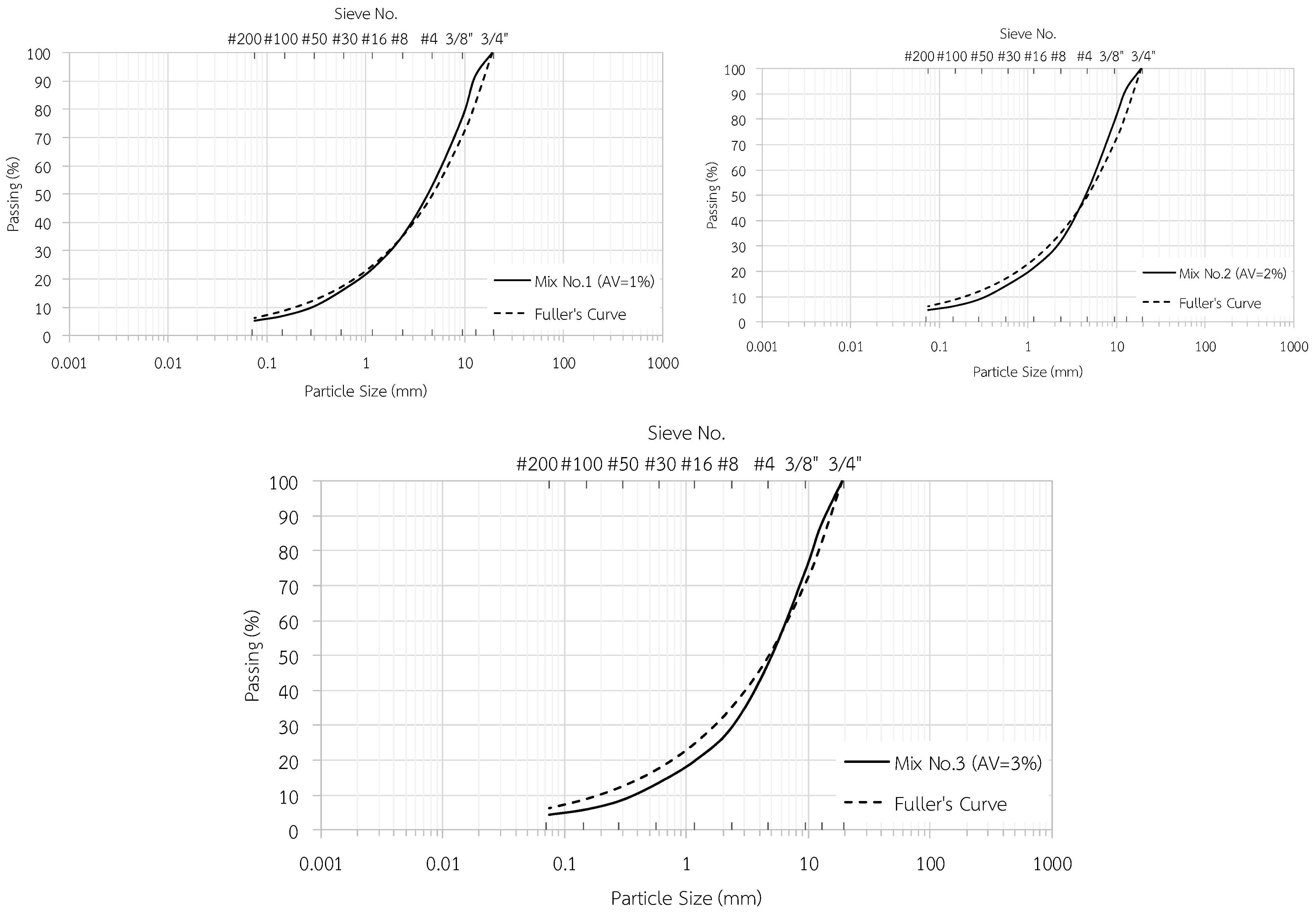

2.2.1. Analysis of Asphaltic Concrete Mixture Design Results

- 1.

- Aggregate Material Proportions.

- 2.

- Aggregate material size gradation.

- 3.

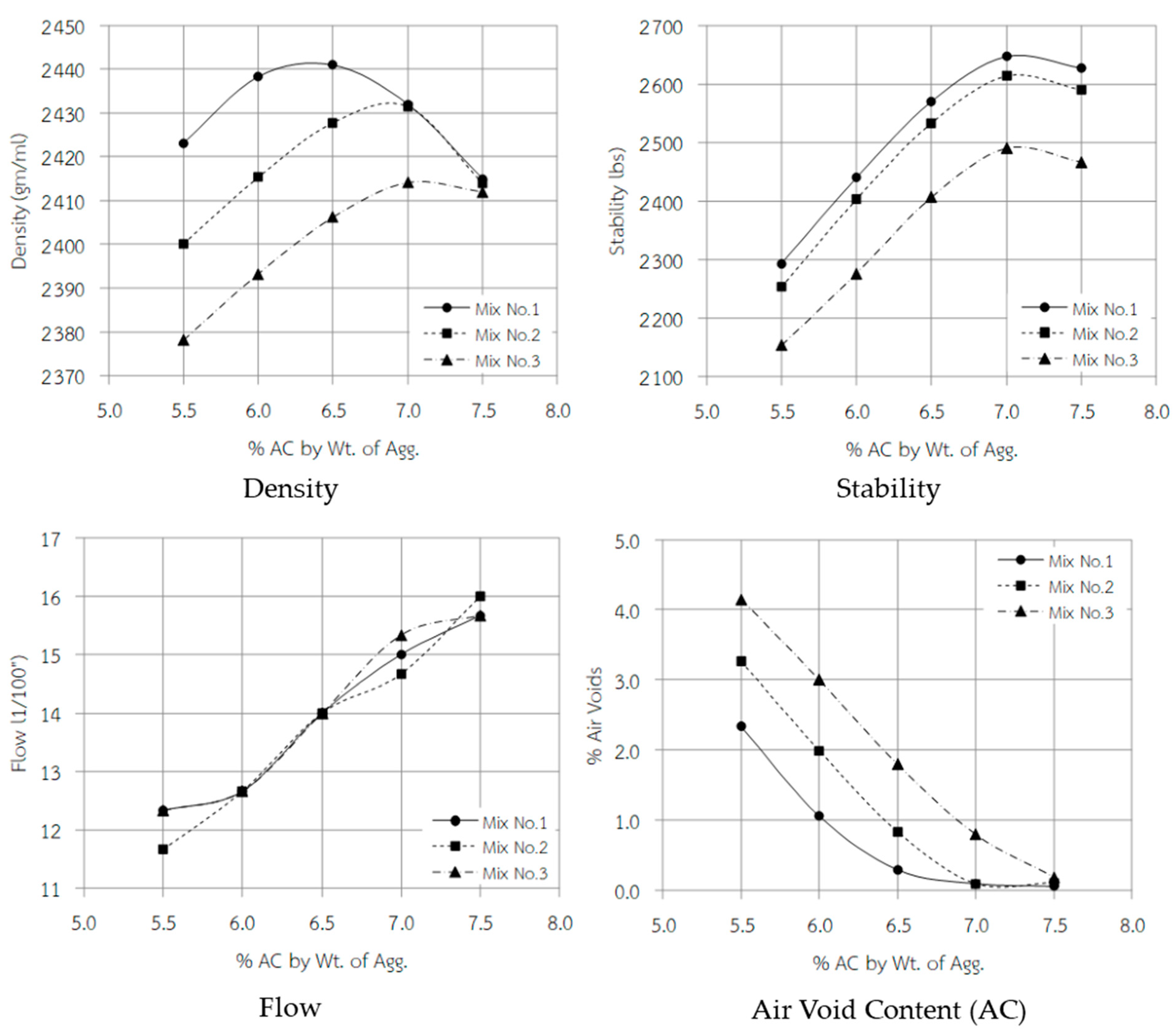

- The density, stability, and flow characteristics.

- The density of Mix No. 1 increases until it reaches its peak at 6.5% AC, and then de-creases as AC increases. However, Mix Nos. 2 and 3 exhibit an increase in density until reaching their maximum at 7% AC, and then a decrease as AC increases. When comparing the three mix proportions, Mix No. 1 provides the highest density at each AC level, followed by Mix No. 2 and then No. 3. Notably, at 7.5% AC, the density values of all three mix proportions are nearly identical. Overall, this study suggests that the appropriate AC leads to the highest density value, depending on the aggregate mix proportions.

- Stability values obtained from the experiments reveal that as AC increases, stability also increases until reaching its peak at 7.0% AC. Then, it decreases as AC further in-creases. This trend is observed across all three mix proportions. When comparing the three mix proportions, Mix No. 1 provides the highest stability at each AC level, followed by Mix No. 2 and then No. 3.

- Flow values indicate the mobility or compactness of a mixture. The flow values obtained from the experiments for all three mix proportions are relatively similar at each AC level. High flow values indicate a low resistance to deformation, making asphalt concrete more susceptible to shape distortion.

- The void content values of the three mix proportions decrease as AC increases. How-ever, when AC increases to 7.5%, the AV values of the three mix proportions are equal.

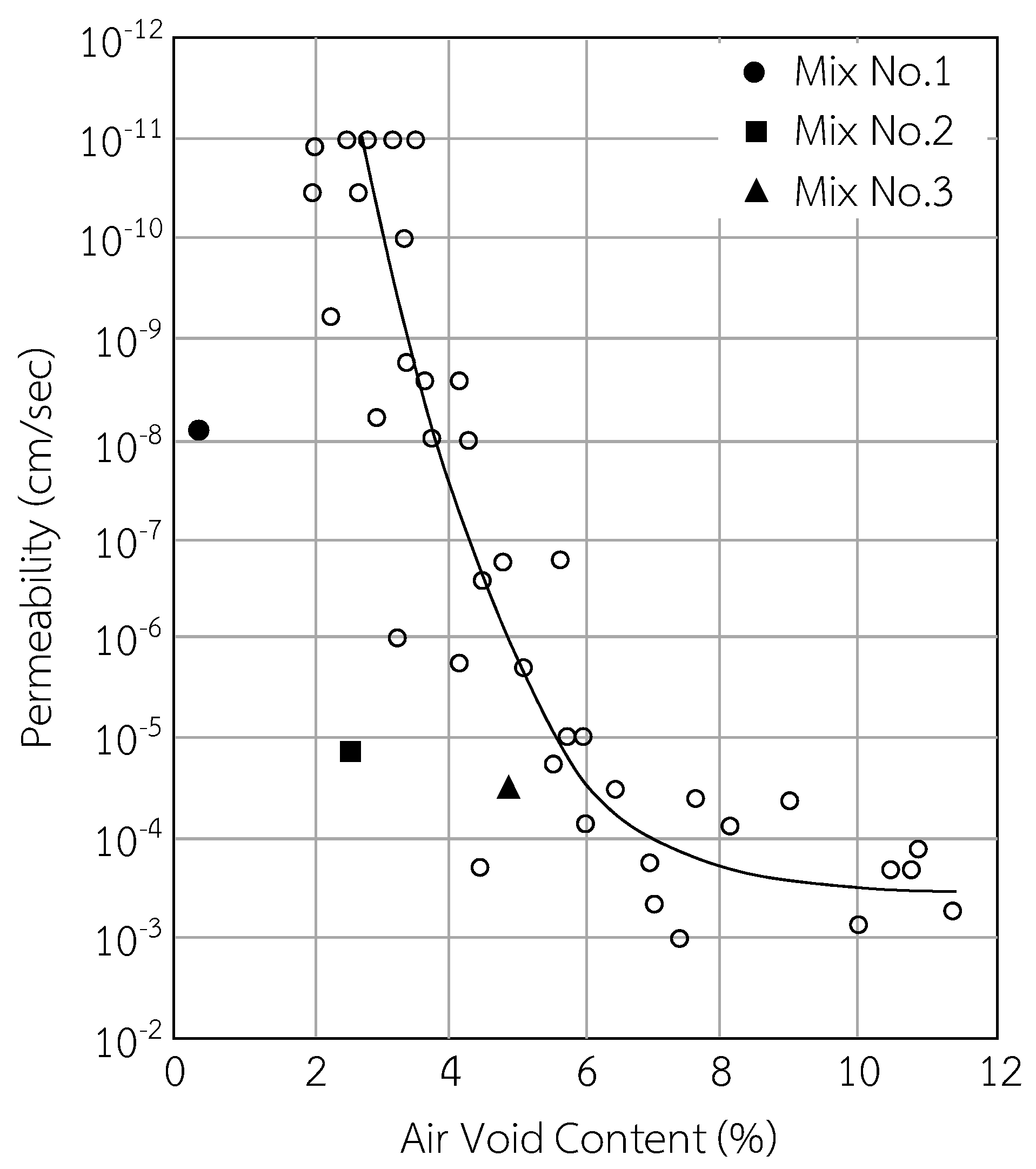

2.2.2. Analysis of Permeability Test Results

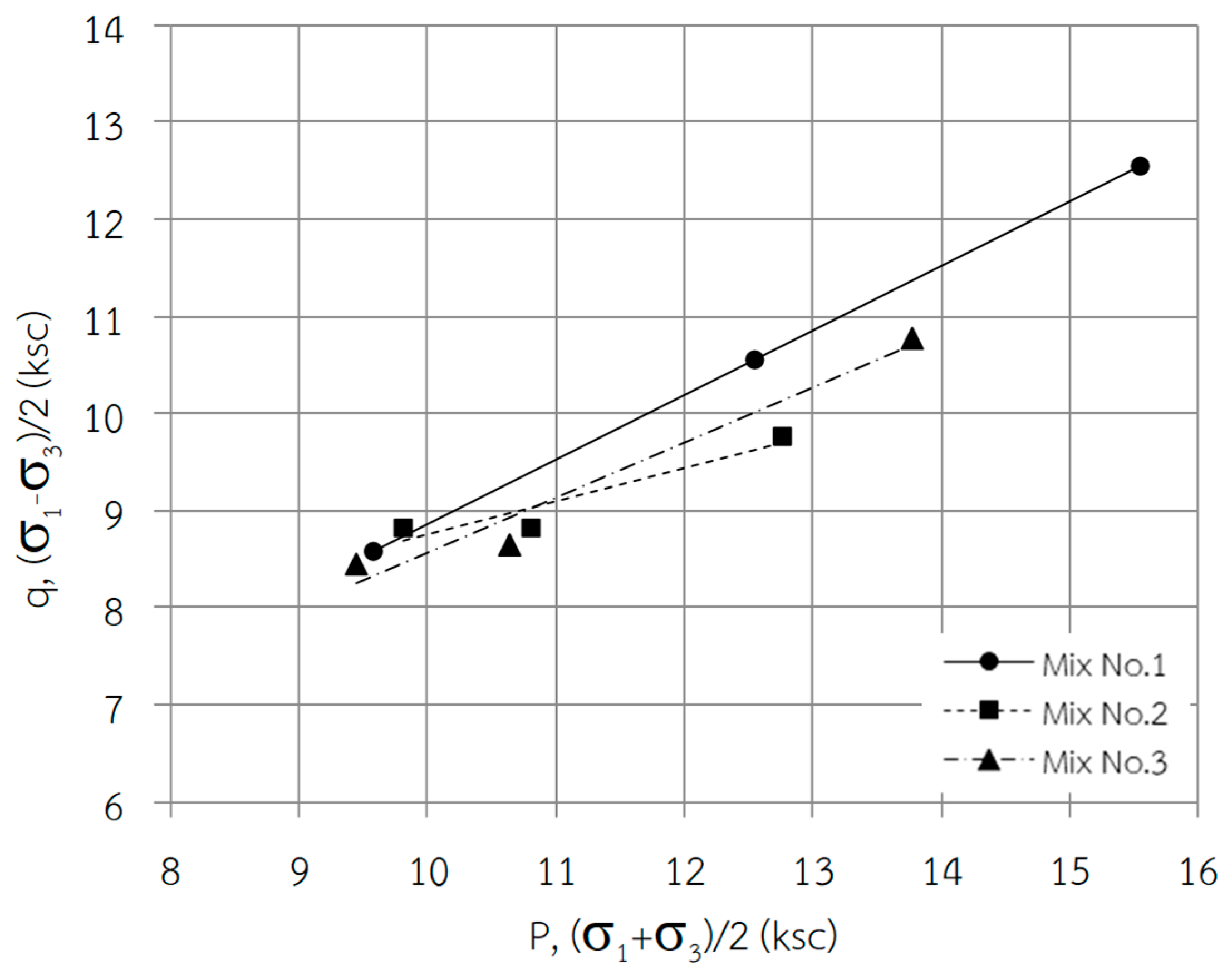

2.2.3. Analysis of Triaxial Compressive Strength Test Results

2.3. Advantages of an Asphalt Concrete Core Embankment

- Selecting asphalt concrete materials for constructing embankment cores can significantly improve construction efficiency and address specific challenges and conditions encountered during construction.

- Asphalt concrete’s ductile and viscous behavior makes it a suitable material for embankments in earthquake zones. This enables it to effectively support the strength of the embankment and accommodate differential foundation settlements without cracking, even at low temperatures.

- It has been proven that asphalt concrete exhibits self-recovery (self-sealing) properties, allowing it to quickly repair any cracks that may occur due to accidental loading.

- The core can be constructed in rainy and cold weather without delaying the construction of other sections of the embankment.

- An asphalt concrete core embankment can be successfully constructed with lower-grade compacted rockfill than what is typically required in earlier dams of this type.

2.4. Determining the Geometry and Material Engineering Properties

2.5. Case Study Determination

- Cases of different slope ratios: 1:2, 1:1.5, 1:1.5, and 1:1.

- Cases of clay core embankment and asphaltic concrete core embankment with thicknesses of 0.30, 0.50, 0.80, and 1.00 m.

- Cases of upstream assumption in the normal water level state and rapid drawdown state.

- Cases of soil embankments with a surcharge load from transportation on the soil embankment.

3. Results

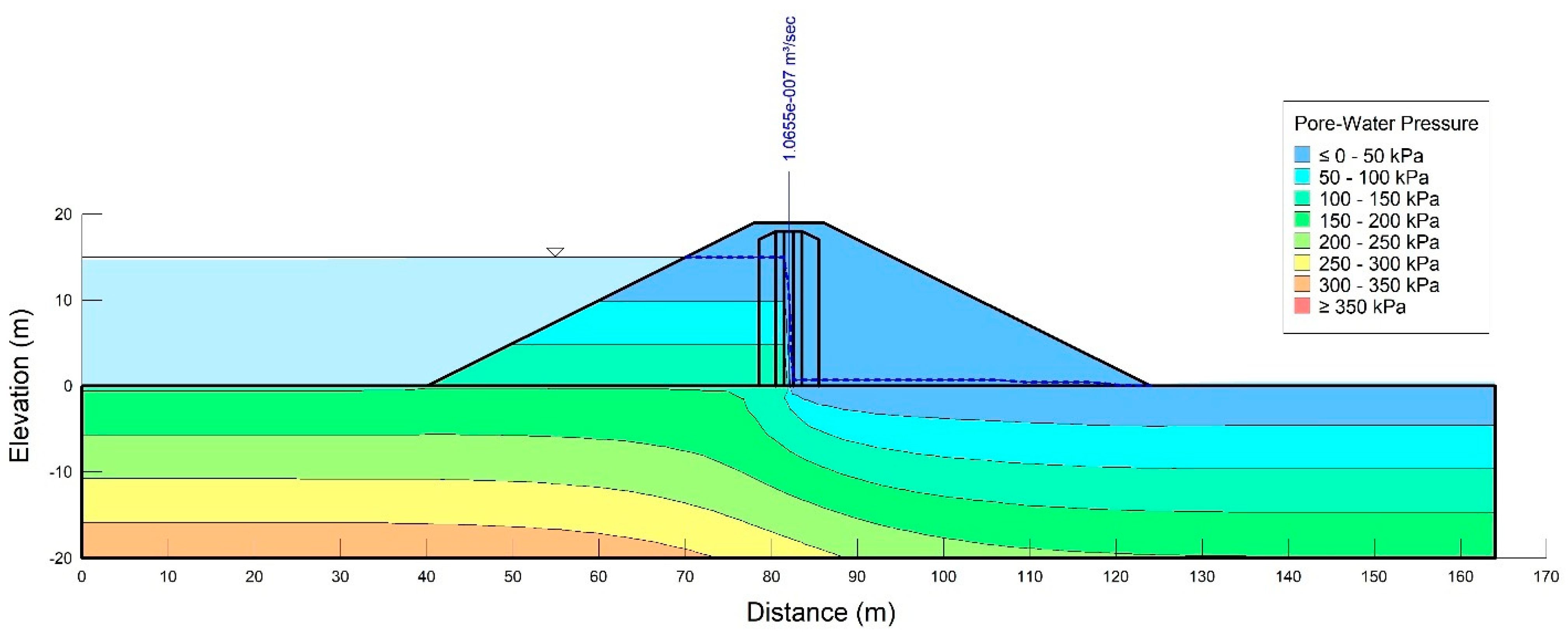

3.1. Results of Seepage Analysis through an Embankment

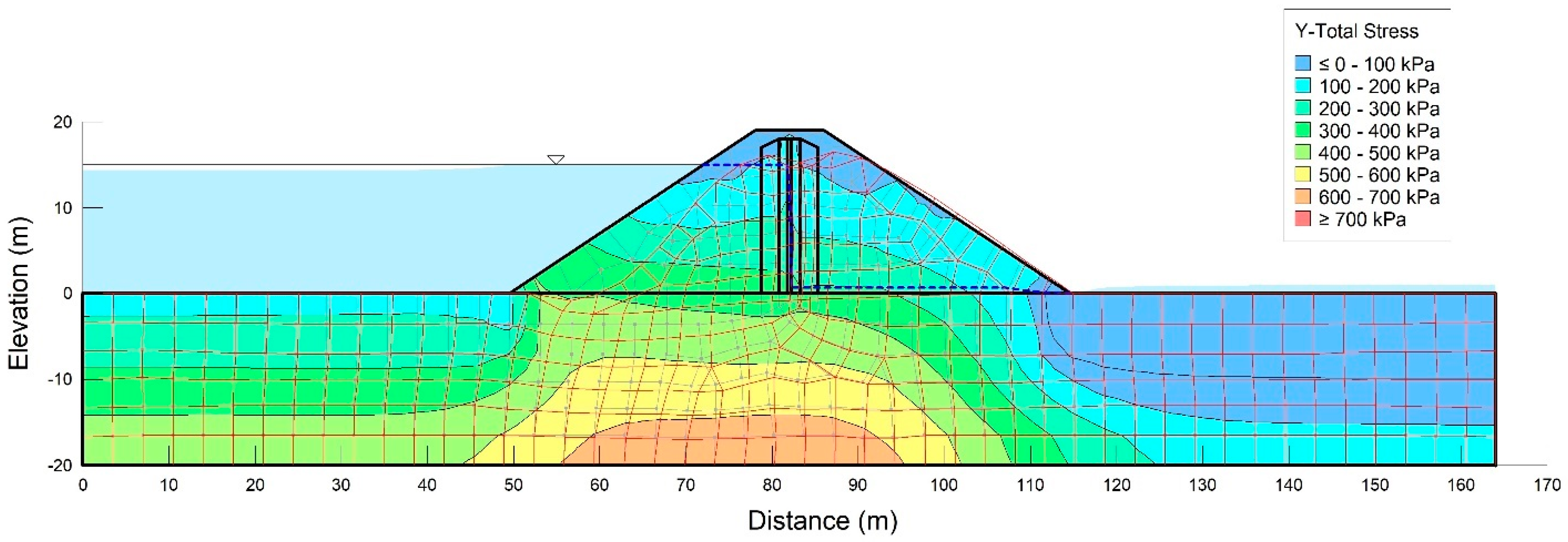

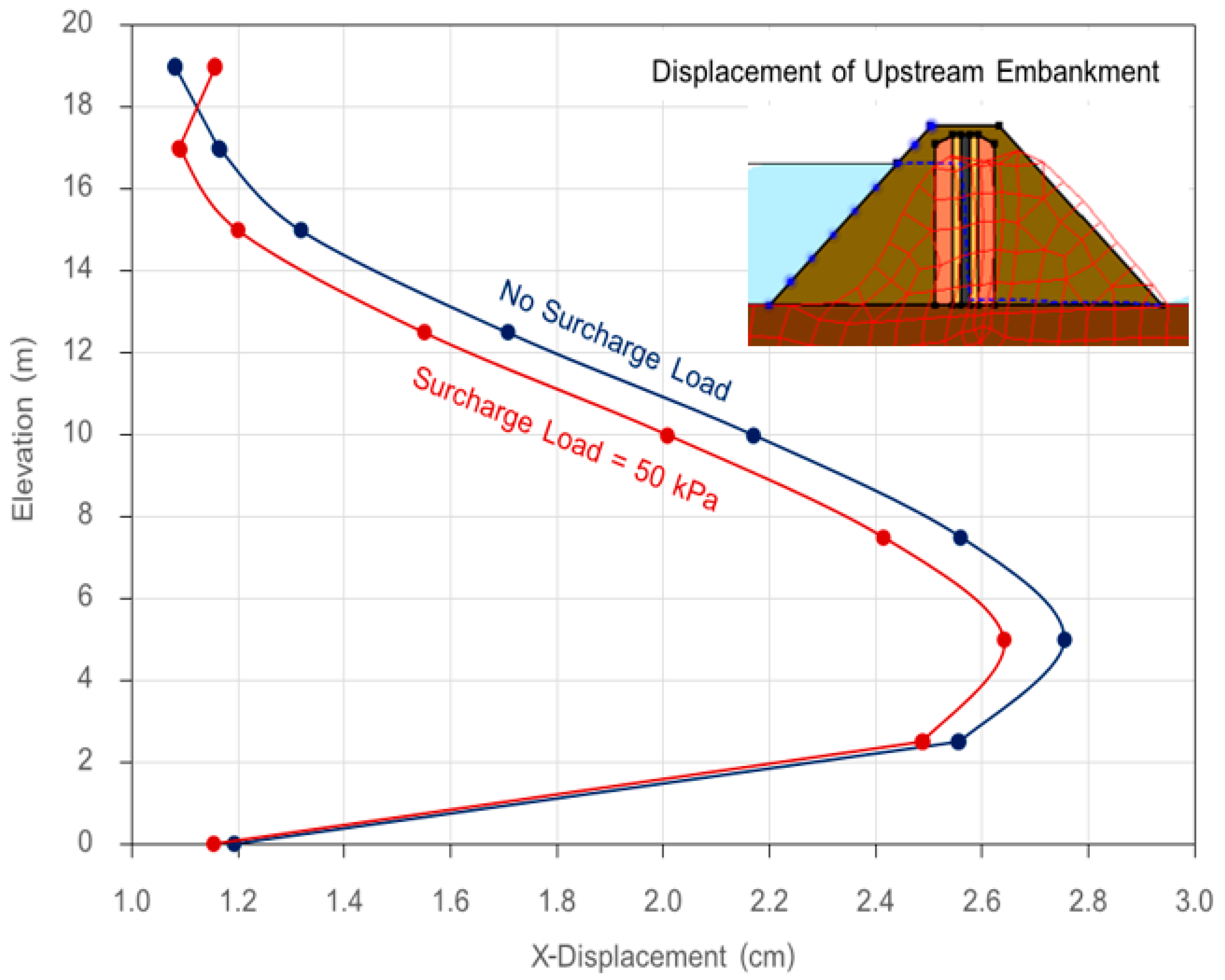

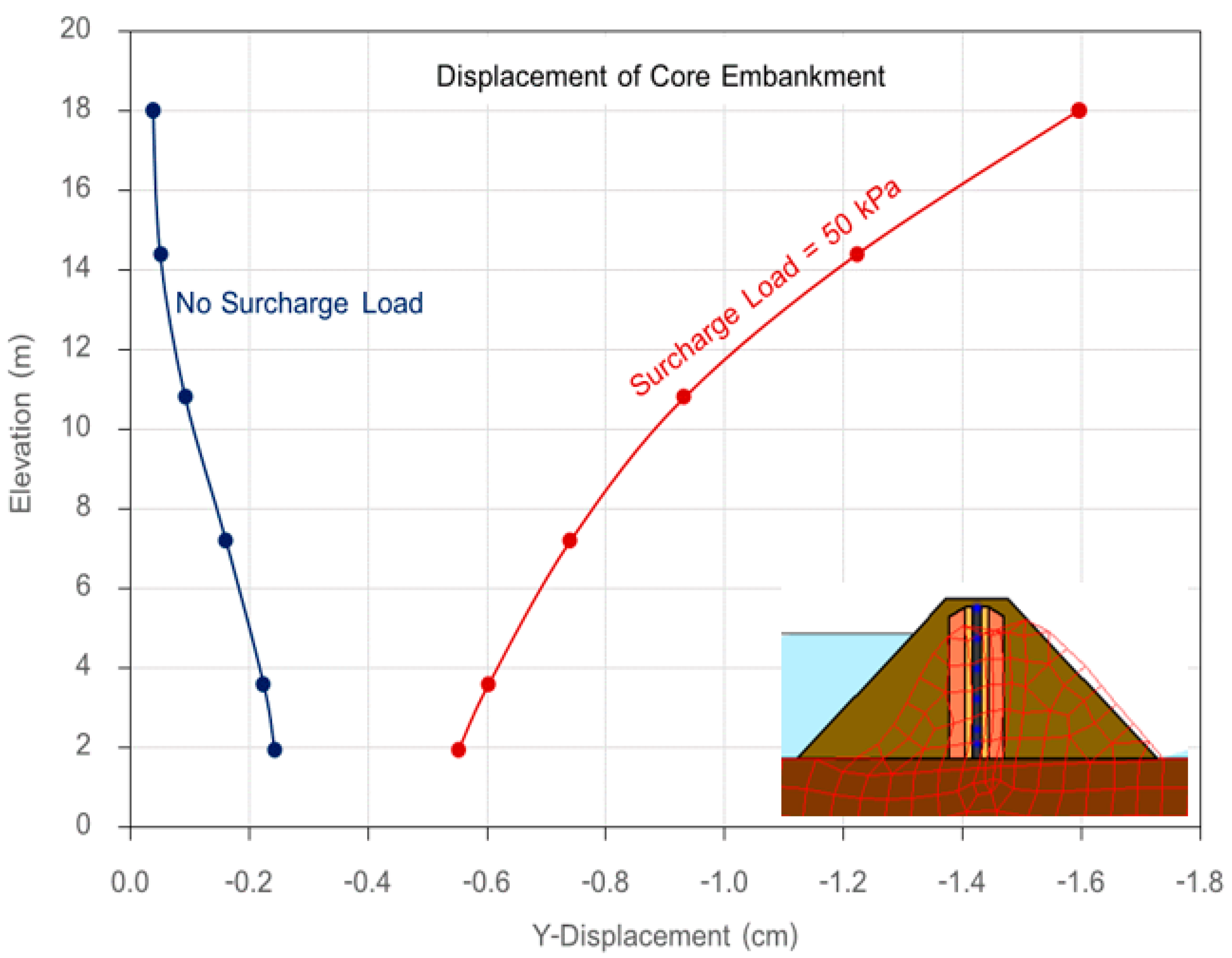

3.2. Displacement Analysis of Embankments

3.3. Result of the Slope Stability Analysis of the Embankment

4. Discussion

4.1. Seepage through an Embankment

4.2. Displacement of Embankment

4.3. Stability of the Embankment

5. Conclusions

- Water seepage through the concrete core axis: When the asphalt concrete core axis is 0.3 m-thick, the highest seepage rate observed is 15.1 × 10−4 m3/day. Compared with a clay core, the seepage rate through the asphalt concrete core is approximately 10-times lower.

- Movement of the core axis: For a slope of 1:1, asphalt concrete and clay cores exhibit the highest movement. In this scenario, the vertical movement is 1.6 cm with a load of 50 kPa, while the horizontal movement is 2.7 cm.

- Stability of dam slope: Under rapid drawdown conditions with a loading of 50 kPa and a slope of 1:1, asphalt concrete and clay cores have similar safety factors above water, with values of 0.8 and 0.7, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ps, M.A.; Balan, T.A. Numerical Analysis of Seepage in Embankment Dams. IOSR J. Mech. Civ. Eng. 2014, 4, 13–23. [Google Scholar]

- Zamanizadeh, A.; Heidarnejad, M.; Bordbar, A. Investigating the Effect of Seepage on Earth Dam Using Geostudio (Case Study “Jereh” Dam Reservoir. J. Water Sci. Environ. Technol. 2017, 2, 125–129. [Google Scholar]

- Gopal, P.; Kiran, K.T. Slope Stability and Seepage Analysis of Earthen Dam of a Summer Storage Tank: A Case Study by Using Different Approaches. Int. J. Innov. Res. Adv. Eng. 2014, 1, 130–134. [Google Scholar]

- Singh, D.; Jha, J.N.; Gill, K.S. Effect of canal water level on stability of its embankment and side slopes. Int. J. Eng. Sci. Technol. 2017, 9, 645–651. [Google Scholar]

- Pinyol, N.M.; Alonso, E.E.; Olivella, S. Rapid drawdown in slopes and embankments. Water Resour. Res. 2008, 44, W00D03. [Google Scholar] [CrossRef]

- Vaughan, P.R.; Kovacevic, N.; Ridley, A.M. The influence of climate and climate change on the stability of embankment dam slopes. Reservoirs in a Changing World. In Proceedings of the 12th Conference of the BDS, Trinity College, Dublin, Ireland, 4–8 September 2002. [Google Scholar]

- Johnston, I.; Murphy, W.; Holden, J. A review of floodwater impacts on the stability of transportation embankments. Earth-Sci. Rev. 2021, 215, 103553. [Google Scholar] [CrossRef]

- Baziar, M.H.; Salemi, S.H.; Heydari, T. Analysis of Earthquake Response of an Asphalt Concrete Core Embankment Dam. Int. J. Civ. Eng. 2006, 4, 192–211. [Google Scholar]

- Shafiei, H.; Eskandari, M.S. A Review of the Embankment Dam with Asphalt Concrete Core. Sci. Eng. Investig. 2016, 5, 111–114. [Google Scholar]

- Akhtarpour, A.; Khodaii, A. Experimental study of asphaltic concrete dynamic properties as an impervious core in embankment dams. Constr. Build. Mater. 2013, 41, 319–334. [Google Scholar] [CrossRef]

- Alim, M.A.; Ahmed, F.; Islam, M.S. Seepage Analysis of Mahananda Earthen Embankment at Chapai Nawabganj in Bangladesh. Am. J. Eng. Technol. Manag. 2017, 2, 1–6. [Google Scholar] [CrossRef]

- Devi DD, L.; Anbalagan, R. Study on Slope Stability of Earthen Dams by using GEOSTUDIO Software. Int. J. Adv. Res. Ideas Innov. Technol. 2017, 3, 408–414. [Google Scholar]

- Bayisa, N.M. Relative performance evaluation of asphaltic concrete core embankment dam and clay core embankment dam: By Plaxis software application. J. Sci. Eng. Technol. 2019, 4, 18–29. [Google Scholar]

- Mairaing, W. Earth Dam Engineering; Library Nine: Bangkok, Thailand, 2003. [Google Scholar]

- Fredlund, D.G. Slope Stability Analysis Incorporating the Effect of Soil Suction. In Slope Stability, Chapter 4; Andersen, M.G., Richards, K.S., Eds.; Wiley: New York, NY, USA, 1987; pp. 113–144. [Google Scholar]

- Abramson, L.W.; Lee, T.S.; Sharma, S.; Boyce, G.M. Slope Stability Concepts. In Slope Stabilisation and Stabilisation Methods, 2nd ed.; John Willey & Sons, Inc.: Hoboken, NJ, USA, 2002; pp. 329–461. [Google Scholar]

- Nash, D. Comprehensive Review of Limit Equilibrium Methods of Stability Analysis. In Slope Stability, Chapter 2; Andersen, M.G., Richards, K.S., Eds.; Wiley: New York, NY, USA, 1987; pp. 11–75. [Google Scholar]

- Janbu, N. Stability analysis of Slopes with Dimensionless Parameters. Ph.D. Thesis, Harvard University, Cambridge, MA, USA, 1954. [Google Scholar]

- Janbu, N. Application of Composite Slip Surface for Stability Analysis. In Proceedings of the European Conference on Stability of Earth Slopes, Stockholm, Sweden, 20–25 September 1954. [Google Scholar]

- Janbu, N. Slope Stability Computations. (Geoteknikk, NTH). Soil Mechanics and Foundation Engineering; Technical University of Norway: Trondheim, Norway, 1968. [Google Scholar]

- Morgenstern, N.R.; Price, V.E. The Analysis of the Stability of General Slip Surfaces. Geotechnique 1965, 15, 77–93. [Google Scholar] [CrossRef]

- Spencer, E. A method of Analysis of the Stability of Embankments, Assuming Parallel Interslice Forces. Geotechnique 1967, 17, 11–26. [Google Scholar] [CrossRef]

- ASCE. Stability and Performance of Slopes and Embankments; Conference Proceeding; ASCE: Berkeley, CA, USA, 1966. [Google Scholar]

- EM 1110-2-1902; Engineering and Design Stability of Earth and Rock Fill Dams. Corps of Engineers: Washington, DC, USA, 1970.

- Tanaka, T.; Tatsuoka, F.; Mohri, Y. Earthquake Induced Failure of Fujinuma Dam. In Proceedings of the International Symposium on Dams for a Changing World, Kyoto, Japan, 5 June 2012. [Google Scholar]

- Pare, J.J.; Verma, N.S. Geotechnical Practice in Hydro Electric Projects in Canada. In Proceedings of the Canadian Engineering Centennial Convention, Montreal, QC, Canada, 18–22 May 1987. [Google Scholar]

- Kjaernsli, B.; Moum, J.; Torblaa, I. Laboratory Tests on Asphaltic Concrete for an Impervious Membrane on the Venemo Rockfill Dam; Norwegian Geotechnical Institute Publication: Oslo, Norway, 1966; pp. 17–26. [Google Scholar]

- Weibiao, W.; Kaare, H. The asphalt core embankment dam: A very competitive alternative. In Proceedings of the 1st International Symposium on Rockfill Dams, Chengdu, China, 18–20 October 2009. [Google Scholar]

- Mathias, S.; Selami, G. Asphalt core embankment dams in Turkey—Dam design, core material and construction. In Proceedings of the 11th ICOLD European Club Symposium, Crete, Greece, 2–4 October 2019. [Google Scholar]

- Geo-Slope International Ltd. Seepage Modeling with SEEP/W; Geo-Slope International Ltd.: Calgary, AB, Canada, 2012. [Google Scholar]

- Gemeda, D. The Alternative Design of Gidabo Embankment Dam by Introducing Asphalt Concrete Core: Southern Ethiopia. Int. J. Sci. Eng. Res. 2020, 11, 1158–1175. [Google Scholar]

- Babak, A.; Ramez, H.; Imad, L. Asphalt concrete dynamic modulus prediction: Bayesian neural network approach. Int. J. Pavement Eng. 2023, 24, 2270569. [Google Scholar]

- Xu, W.; Huang, X.; Yang, Z.; Zhou, M.; Huang, J. Developing Hybrid Machine Learning Models to Determine the Dynamic Modulus (E*) of Asphalt Mixtures Using Parameters in Witczak 1-40D Model: A Comparative Study. Materials 2022, 15, 1791. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Zhang, J.; Li, X.; Qiao, Y.; Zhang, R.; Kumar, G.S. Investigating the effects of ensemble and weight optimization approaches on neural networks’ performance to estimate the dynamic modulus of asphalt concrete. Road Mater. Pavement Des. 2022, 24, 1939–1959. [Google Scholar] [CrossRef]

| Case | Design | Condition | Japan | ICOLD | Crop. of Eng. | SCDWR | US. Federal Register | Canada |

|---|---|---|---|---|---|---|---|---|

| 1 | Normal Water Level | Static | - | - | 1.5 | 1.5 | 1.5 | 1.5 |

| Earthquake | 1.2 | - | - | 1.1 | 1 | 1.1 | ||

| 2 | Rapid Drawdown | Static | - | 1.2 | 1.2 | 1.2 | - | 1.3 |

| Earthquake | 1.2 | - | - | - | - | 1.3 |

| Order | Testing Sequence | Proportion | Number of Samples |

|---|---|---|---|

| 1 | Testing for the particle size of materials by using a wash sieve method. | - | 2 |

| 2 | Testing for the particle size of materials by using a non-wash sieve method | - | 2 |

| 3 | Testing aggregate toughness and abrasion resistance by using the Los Angeles abrasion machine | - | 1 |

| 4 | Testing for aggregate soundness by using sodium sulfate or magnesium sulfate | - | 2 |

| 5 | Testing for the flatness index | - | 2 |

| 6 | Testing for the specific gravity of coarse aggregate | - | 3 |

| 7 | Testing for the specific gravity and water permeability of fine aggregate | - | 3 |

| 8 | Testing for the asphalt permeability of aggregate | - | 6 |

| 9 | Testing asphaltic concrete by using the Marshall method | 1 | 3 |

| 2 | 3 | ||

| 3 | 3 | ||

| 10 | Testing to determine the strength index of asphaltic concrete mixtures | 1 | 4 |

| 2 | 4 | ||

| 3 | 4 | ||

| 11 | Testing the permeability of asphaltic concrete | 1 | 1 |

| 2 | 1 | ||

| 3 | 1 | ||

| 12 | Triaxial compression testing of asphaltic concrete | 1 | 3 |

| 2 | 3 | ||

| 3 | 3 |

| Hot Bin | Standard Sieve Analysis | Aperture Size (mm) |

|---|---|---|

| 1 | No.4 | 4.75 |

| 2 | 3/8 | 9.53 |

| 3 | ½″ | 12.70 |

| 4 | ¾″ | 19.05 |

| Order | Aggregate Property Testing | Results |

|---|---|---|

| 1 | Testing for particle size distribution by using the wet sieve method | The particle size distribution is well-graded, following Fuller’s curve. Further details are provided in the next section |

| 2 | Testing for particle size distribution by using the dry sieve method | The particle size distribution is well-graded, conforming to Fuller’s curve. Further details will be elaborated in the subsequent section. |

| 3 | Testing aggregate abrasion resistance by using the Los Angeles Abrasion machine | The abrasion value using the Los Angeles machine for 3/4 inch stone is 22.30%. |

| 4 | Testing soundness of the aggregate by using sodium sulfate or magnesium sulfate | The soundness value for 3/4 inch stone is 0.70%, and for stone dust is 2.20%. |

| 5 | Testing for the flatness index | Flatness index: Hot Bin 2 (9.53 mm): 22% Hot Bin 3 (12.70 mm): 24% Hot Bin 4 (19.05 mm): 12% Length index: Hot Bin 2 (9.53 mm): 18% Hot Bin 3 (12.70 mm): 17% Hot Bin 4 (19.05 mm): 18% |

| 6 | Testing for the specific gravity of coarse aggregate material | Specific gravity of coarse aggregate: Hot Bin 2 (9.53 mm): 2.682 Hot Bin 3 (12.70 mm): 2.691 Hot Bin 4 (19.05 mm): 2.697 Water absorption: Hot Bin 2 (9.53 mm): 0.50% Hot Bin 3 (12.70 mm): 0.41% Hot Bin 4 (19.05 mm): 0.30% |

| 7 | Testing for specific gravity | Specific gravity of fine aggregate: Hot Bin 1 (size < 4.75 mm): 2.660 Water absorption: Hot Bin 1 (size < 4.75 mm): 0.81% |

| 8 | Testing for the asphalt permeability of the aggregate | Asphalt permeability value = 0.20%. |

| 9 | Testing asphaltic concrete by using the Marshall method | Design to achieve an air void content (AV) of 1% and asphalt cement content (AC 60/70) of 6%: Mix No. 1: Hot Bin 1:2:3:4 = 42:30:18:10 Design to achieve AV of 2% and AC 60/70 of 6%: Mix No. 2: Hot Bin 1:2:3:4 = 38:37:15:10 Design to achieve AV of 3% and AC 60/70 of 6%: Mix No. 3: Hot Bin 1:2:3:4 = 35:35:15:15 Further details will be provided in the next section. |

| 10 | Testing to determine the Strength Index of the asphaltic concrete mixture | Strength index: Mix No. 1 = 76.1% Mix No. 2 = 75.1% Mix No. 3 = 75.6% |

| 11 | Testing for water permeability | Water permeability (k): Mix No. 1 (*AV = 0.30%) = 8.56 × 10−9 cm/s Mix No. 2 (*AV = 2.65%) = 2.71 × 10−5 cm/s Mix No. 3 (*AV = 4.71%) = 4.56 × 10−5 cm/s Note: * In the sample preparation for testing, the AV values deviate from the designed AV of 1%, 2%, and 3% for Mix Nos. 1, 2, and 3, respectively. |

| 12 | Triaxial compression testing | Cohesion (c): Mix No. 1 = 2.70 kg/cm2 Mix No. 2 = 4.66 kg/cm2 Mix No. 3 = 3.15 kg/cm2 Internal friction angle (f): Mix No. 1 = 45.80° Mix No. 2 = 30.23° Mix No. 3 = 39.83° Further details are provided in the next section. |

| Air Void Content (%) | Aggregate Material Proportions (% by Weight) | Remark | |||

|---|---|---|---|---|---|

| Hot Bin 1 (Size < 4.75 mm) | Hot Bin 2 (Size 9.53 mm) | Hot Bin 3 (Size 12.70 mm) | Hot Bin 4 (Size 19.05 mm) | ||

| 1 | 42 | 30 | 18 | 10 | Asphalt Cement Content 6% |

| 2 | 38 | 37 | 15 | 10 | |

| 3 | 35 | 35 | 15 | 15 | |

| AV (%) | Properties of Asphalt Concrete | Remark | ||

|---|---|---|---|---|

| Density (g/mL) | Stability (lbs) | Flow (1/100 inch) | ||

| 1 | 2438 | 2440 | 1267 | Asphalt Cement (AC) 6% |

| 2 | 2415 | 2400 | 1267 | |

| 3 | 2393 | 2280 | 1267 | |

| Mix No. | AV (%) | Density (g/cm3) | Permeability (cm/s) |

|---|---|---|---|

| 1 | 0.30 | 2.395 | 8.50 × 10−9 |

| 2 | 2.65 | 2.334 | 2.71 × 10−5 |

| 3 | 4.71 | 2.309 | 4.56 × 10−5 |

| Mix No. | Test No. | Effective Confining Pressure, σ3 (ksc) | Axial Stress at Failure, σ1 (ksc) | σ1/σ3 at Failure | Young/s Modulus, ES (ksc) | Cohesion, c (ksc) | Friction Angle, ϕ (degree) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 18.16 | 18.16 | 305 | 2.7 | 45.8 |

| 2 | 2 | 23.11 | 11.55 | 269 | |||

| 3 | 3 | 28.10 | 9.37 | 319 | |||

| 2 | 4 | 1 | 18.63 | 18.63 | 342 | 4.66 | 30.23 |

| 5 | 2 | 19.62 | 9.81 | 257 | |||

| 6 | 3 | 22.53 | 7.51 | 349 | |||

| 3 | 7 | 1 | 17.90 | 17.9 | 297 | 3.15 | 39.83 |

| 8 | 2 | 19.27 | 9.63 | 295 | |||

| 9 | 3 | 24.54 | 8.18 | 317 |

| Material | Parameter | References | |||||

|---|---|---|---|---|---|---|---|

| Permeability, k (m/s) | Unit Weight, γ (kN/m3) | Cohesion, c (kPa) | Friction Angle, ϕ (deg.) | Young’s Modulus, Es (kPa) | Poisson’s Ratio | ||

| Asphaltic Concrete Core | 8.50 × 10−11 | 23 | 264 | 45 | 26,400 | 0.49 | Testing |

| Clay Core | 1.00 × 10−9 | 16 | 50 | - | 21,000 | 0.49 | WWDSE, 2008 [30] |

| Filter | 7.50 × 10−6 | 18 | - | 35 | 29,000 | 0.30 | WWDSE, 2008 |

| Transition | 5.00 × 10−4 | 18 | - | 35 | 32,000 | 0.30 | [30] |

| Rock Fill | 5.00 × 10−3 | 22 | - | 40 | 34,000 | 0.28 | WWDSE, 2008 |

| Foundation | 1.00 × 10−12 | 18 | - | 45 | 90,000 | 0.25 | [30] |

| Thickness of Core (m) | Discharge Passing through the Core (m3/Day) | |

|---|---|---|

| Asphaltic Concrete | Clay | |

| 0.30 | 15.1 × 10−4 | 3.52 × 10−2 |

| 0.50 | 9.16 × 10−4 | 2.00 × 10−2 |

| 0.80 | 5.78 × 10−4 | 1.17 × 10−2 |

| 1.00 | 4.66 × 10−4 | 0.92 × 10−2 |

| Slope Ratio | Maximum Displacement (cm) | |||||||

|---|---|---|---|---|---|---|---|---|

| No Surcharge Load | Surcharge Load = 50 kPa | |||||||

| Upstream Slope | Core | Upstream Slope | Core | |||||

| Vertical | Horizontal | Vertical | Horizontal | Vertical | Horizontal | Vertical | Horizontal | |

| 1:2 | 4.6 | 3.9 | 0.0 | 1.2 | 4.6 | 3.9 | 1.5 | 1.2 |

| 1:1.5 | 4.0 | 4.6 | 0.0 | 1.7 | 4.1 | 4.5 | 1.6 | 1.7 |

| 1:1 | 3.0 | 5.5 | 0.0 | 2.7 | 3.2 | 5.4 | 1.6 | 2.7 |

| Slope Ratio | Asphaltic Concrete Core | Clay Core | ||||||

|---|---|---|---|---|---|---|---|---|

| Normal Water Level | Rapid Drawdown | Normal Water Level | Rapid Drawdown | |||||

| U/S | D/S | U/S | D/S | U/S | D/S | U/S | D/S | |

| 1:2 | 2.1 | 2.1 | 1.2 | 2.1 | 2.0 | 2.0 | 1.1 | 2.0 |

| 1:1.5 | 1.8 | 1.7 | 1.0 | 1.7 | 1.5 | 1.6 | 0.9 | 1.6 |

| 1:1 | 1.4 | 1.3 | 0.9 | 1.3 | 1.4 | 1.2 | 0.7 | 1.2 |

| Slope Ratio | Asphaltic Concrete Core | Clay Core | ||||||

|---|---|---|---|---|---|---|---|---|

| Normal Water Level | Rapid Drawdown | Normal Water Level | Rapid Drawdown | |||||

| U/S | D/S | U/S | D/S | U/S | D/S | U/S | D/S | |

| 1:2 | 1.9 | 2.0 | 1.2 | 2.0 | 1.8 | 1.9 | 1.1 | 1.9 |

| 1:1.5 | 1.6 | 1.6 | 1.0 | 1.6 | 1.4 | 1.5 | 0.9 | 1.5 |

| 1:1 | 1.3 | 1.2 | 0.8 | 1.2 | 1.1 | 1.1 | 0.7 | 1.1 |

| Analysis of Soil Embankment Behavior | Type of Core Embankment Material | Embankment Slope | Thickness of Core Embankment | Water Level | Surcharge Load |

|---|---|---|---|---|---|

| Seepage through an embankment | ✓ | ✓ | |||

| Displacement | ✓ | ✓ | ✓ | ||

| Slope Stability | ✓ | ✓ | ✓ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rewtragulapaibul, C.; Jaritngam, S.; Wannawong, T.; Somchainuek, O. Comparison of Embankment Properties with Clay Core and Asphaltic Concrete Core. Appl. Sci. 2024, 14, 6555. https://doi.org/10.3390/app14156555

Rewtragulapaibul C, Jaritngam S, Wannawong T, Somchainuek O. Comparison of Embankment Properties with Clay Core and Asphaltic Concrete Core. Applied Sciences. 2024; 14(15):6555. https://doi.org/10.3390/app14156555

Chicago/Turabian StyleRewtragulapaibul, Chawakorn, Saravut Jaritngam, Tanawan Wannawong, and Opas Somchainuek. 2024. "Comparison of Embankment Properties with Clay Core and Asphaltic Concrete Core" Applied Sciences 14, no. 15: 6555. https://doi.org/10.3390/app14156555

APA StyleRewtragulapaibul, C., Jaritngam, S., Wannawong, T., & Somchainuek, O. (2024). Comparison of Embankment Properties with Clay Core and Asphaltic Concrete Core. Applied Sciences, 14(15), 6555. https://doi.org/10.3390/app14156555