Analytical Investigation of Vertical Force Control in In-Wheel Motors for Enhanced Ride Comfort

Abstract

:1. Introduction

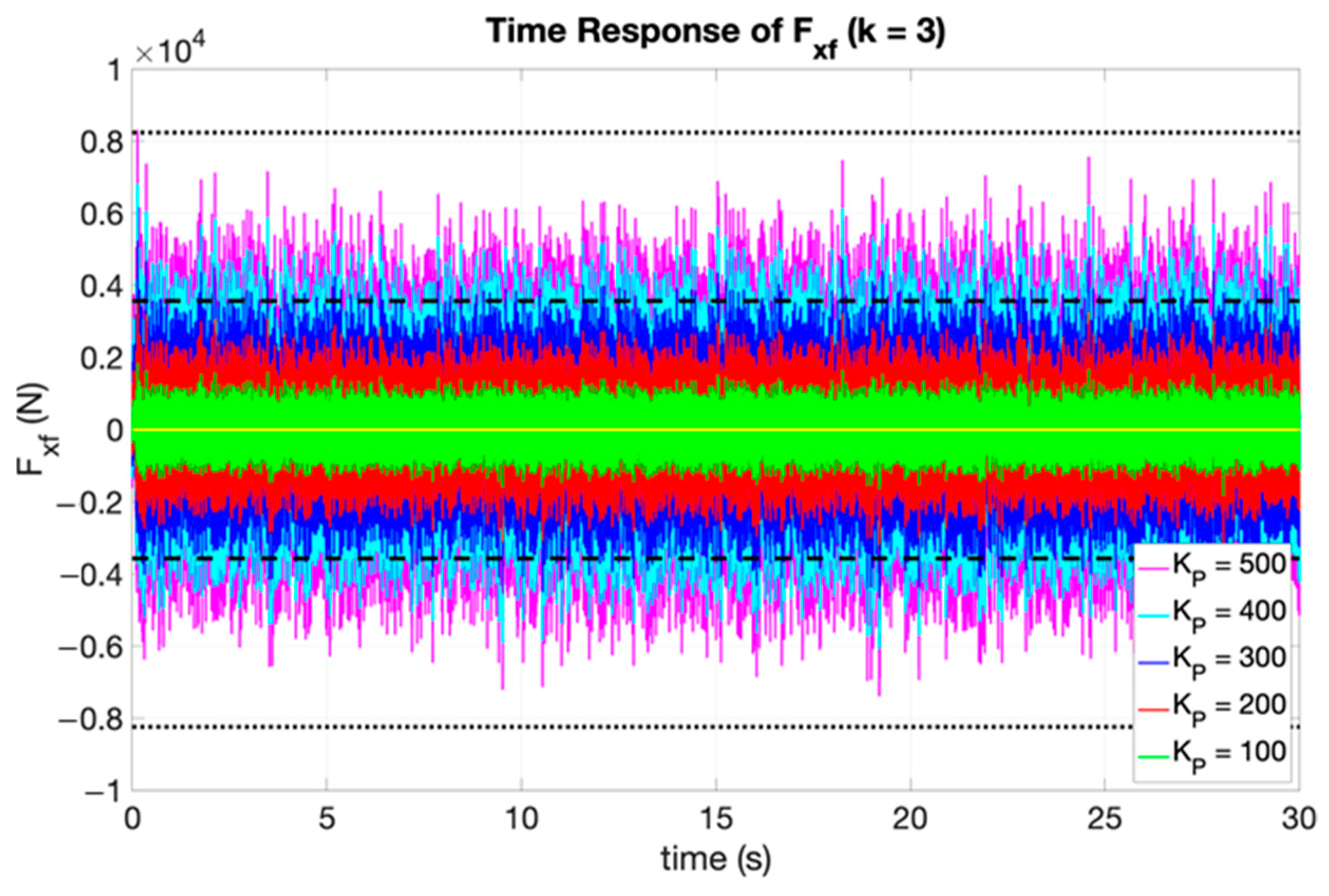

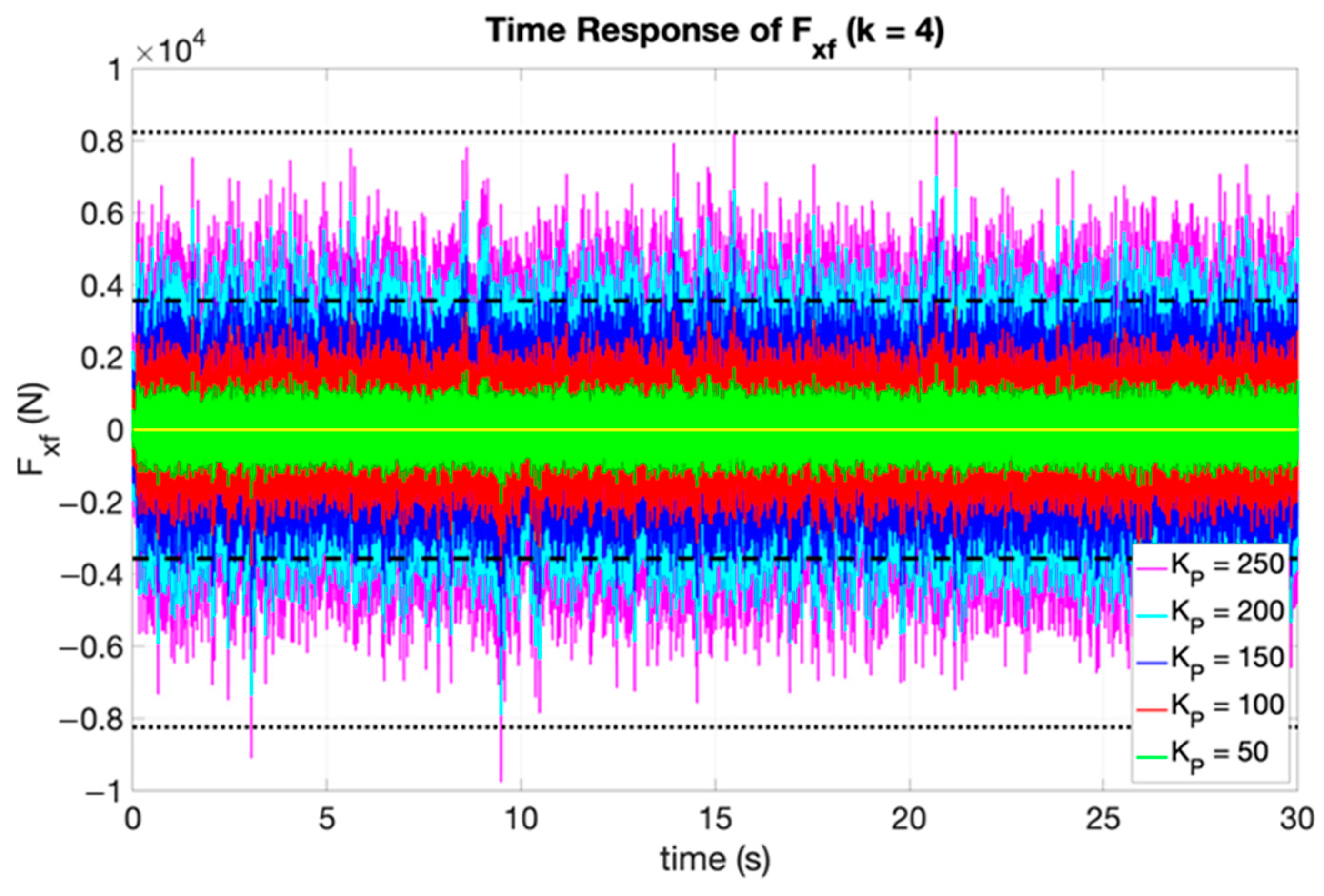

2. Dynamics Models and Methods

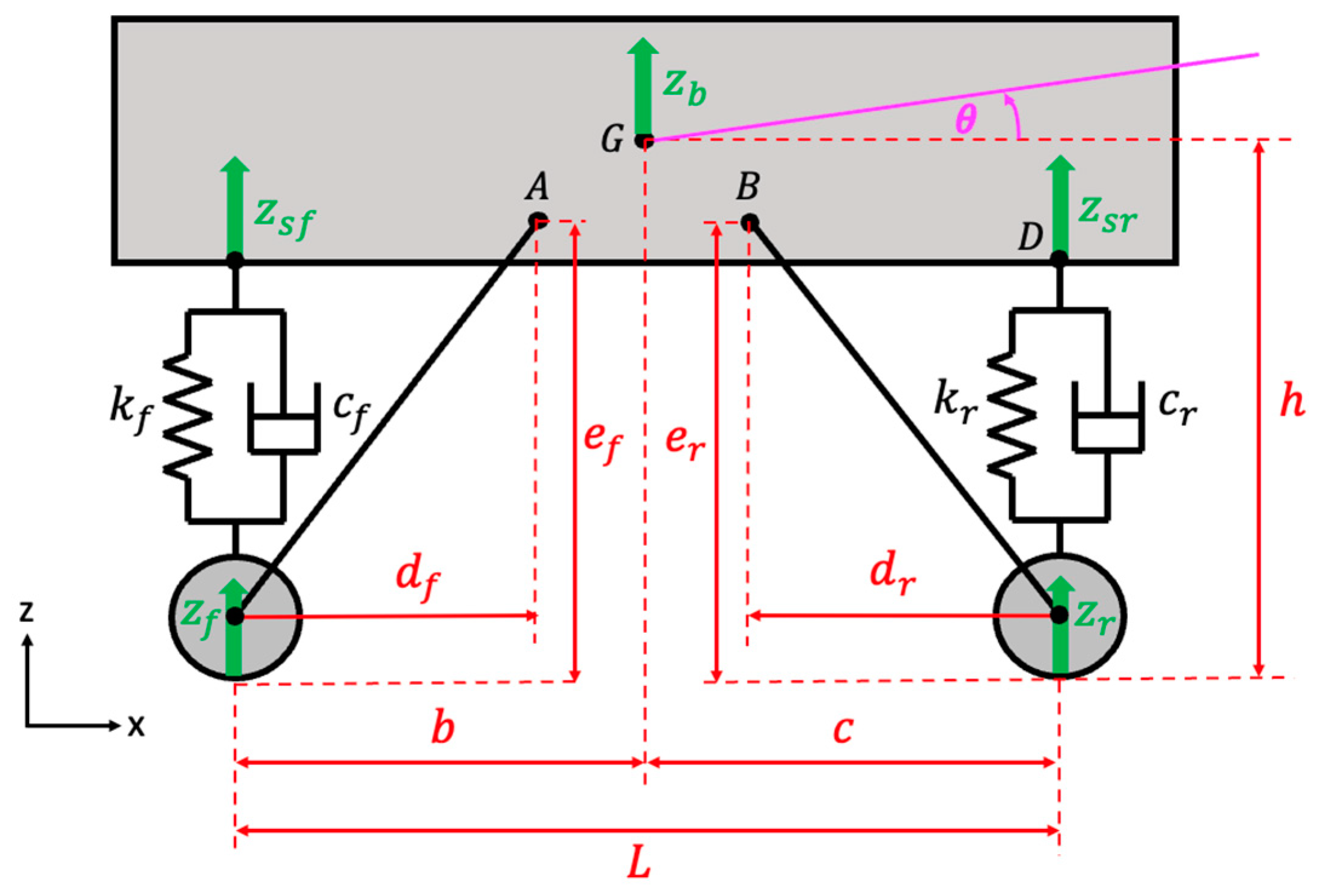

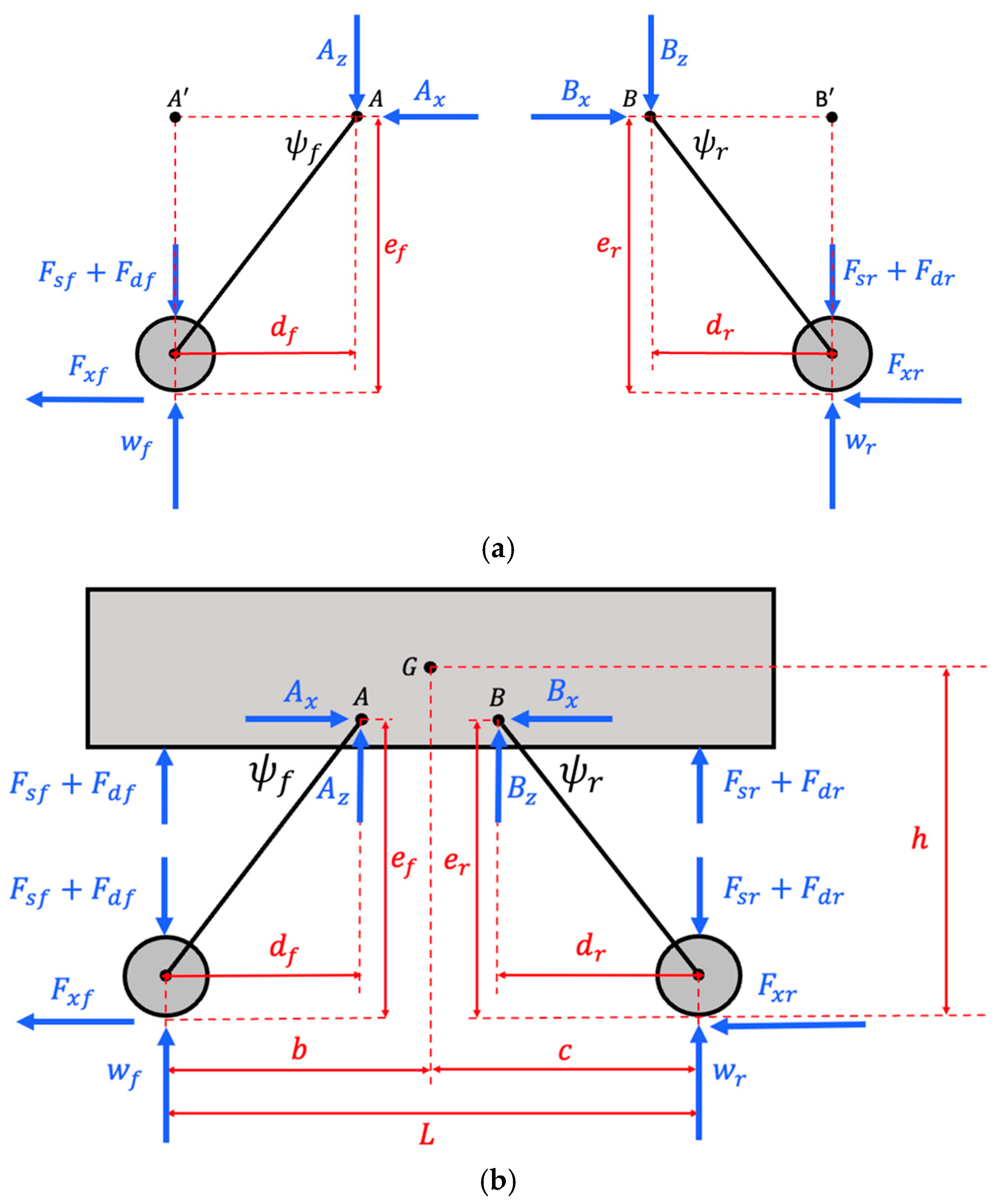

2.1. Vehicle Dynamics Model

2.2. Vehicle Dynamics Model with Proportional Ride-Blending Controller

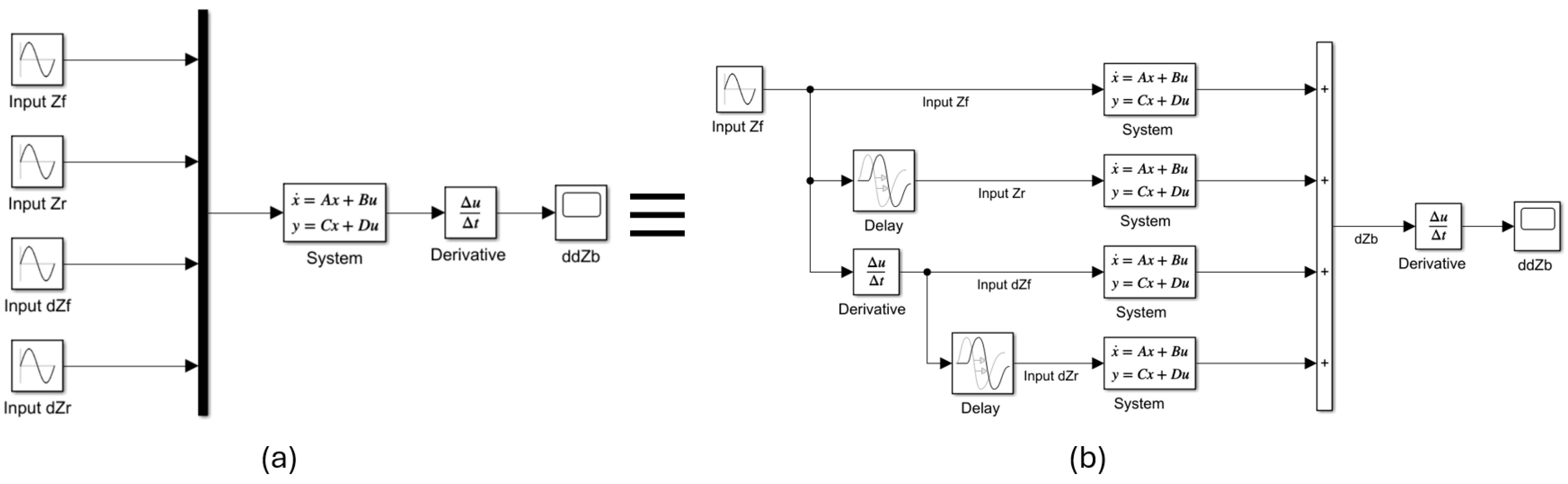

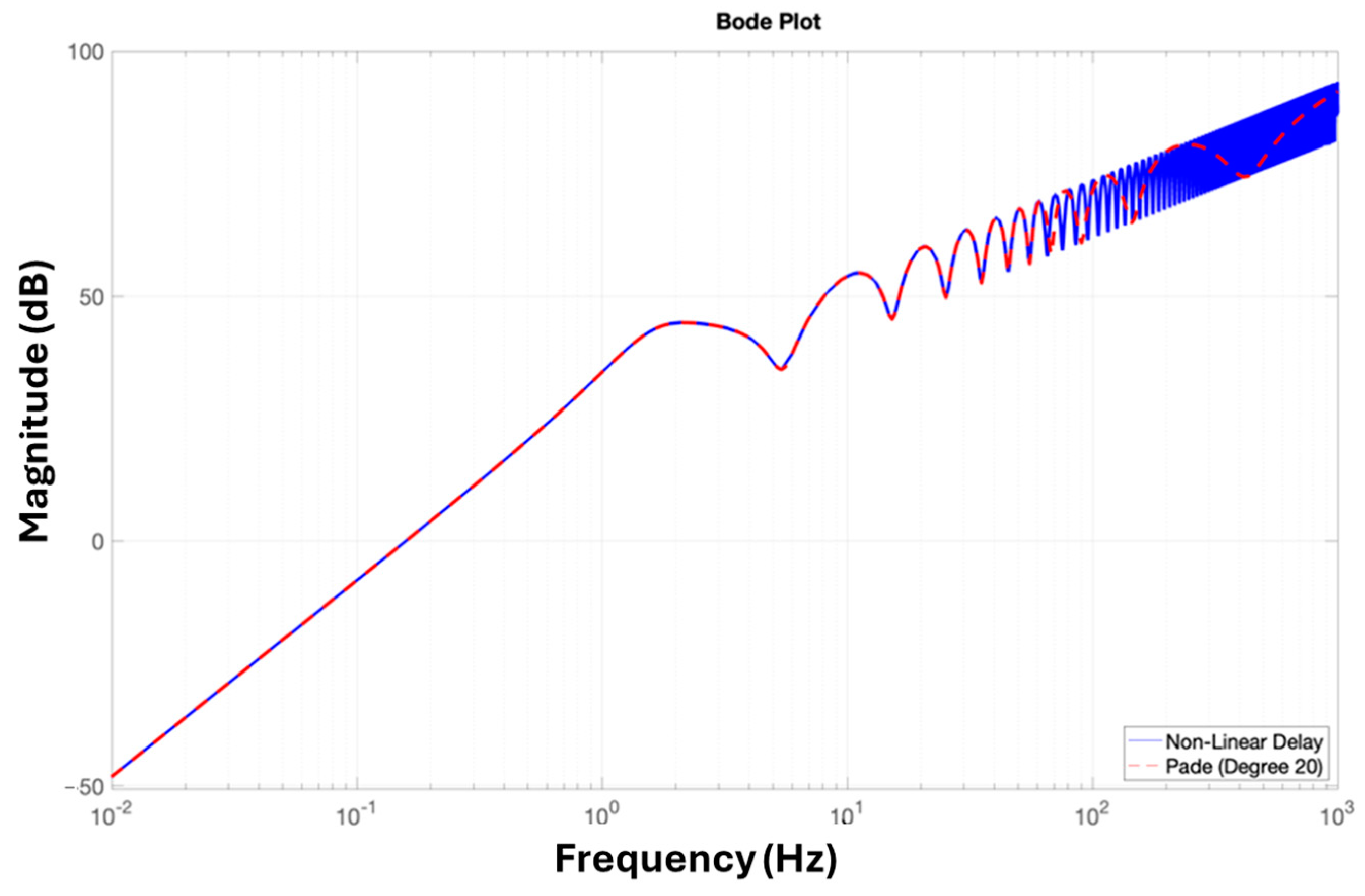

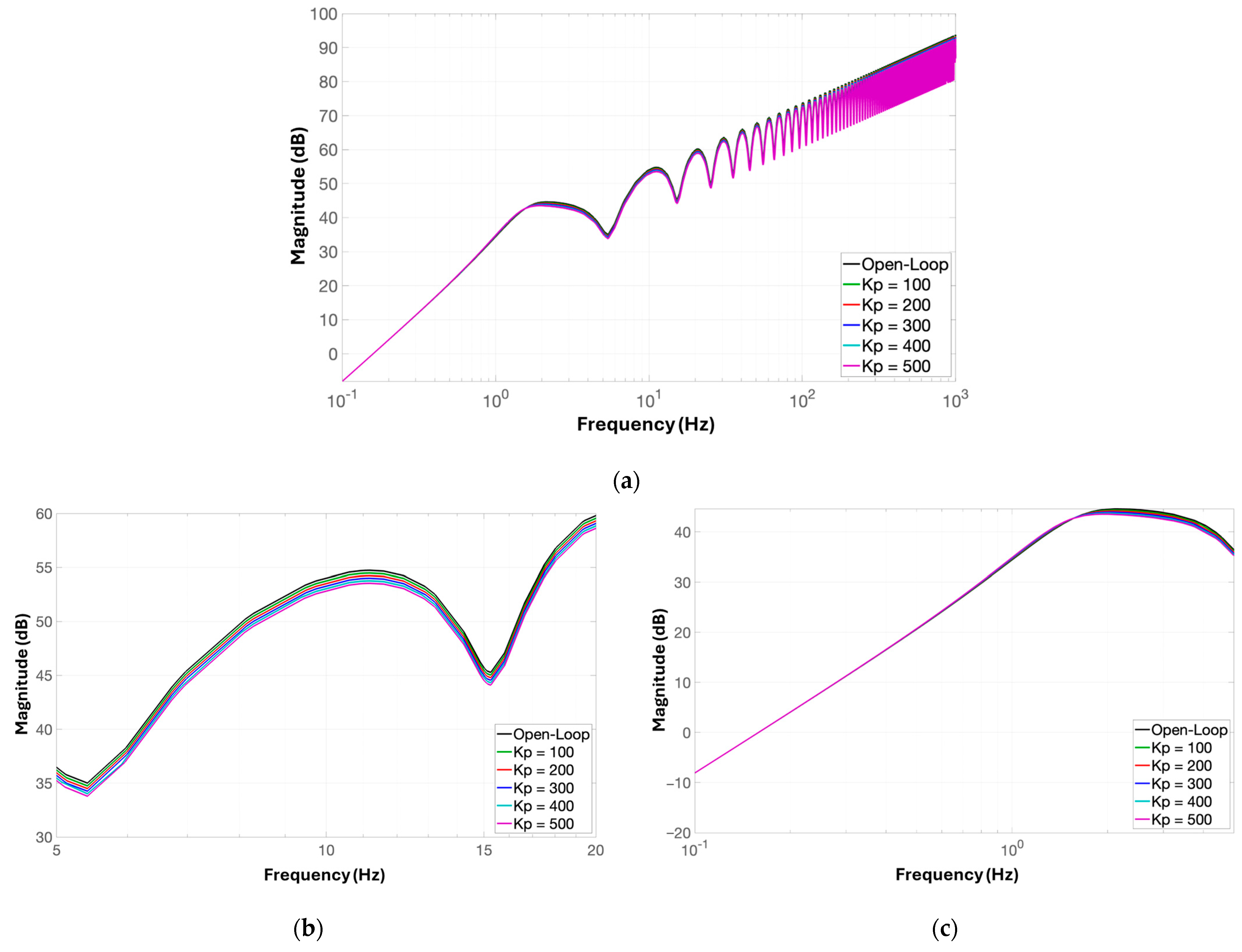

2.3. Frequency Response of the Vehicle System

2.4. Ride Comfort (ISO 2631)

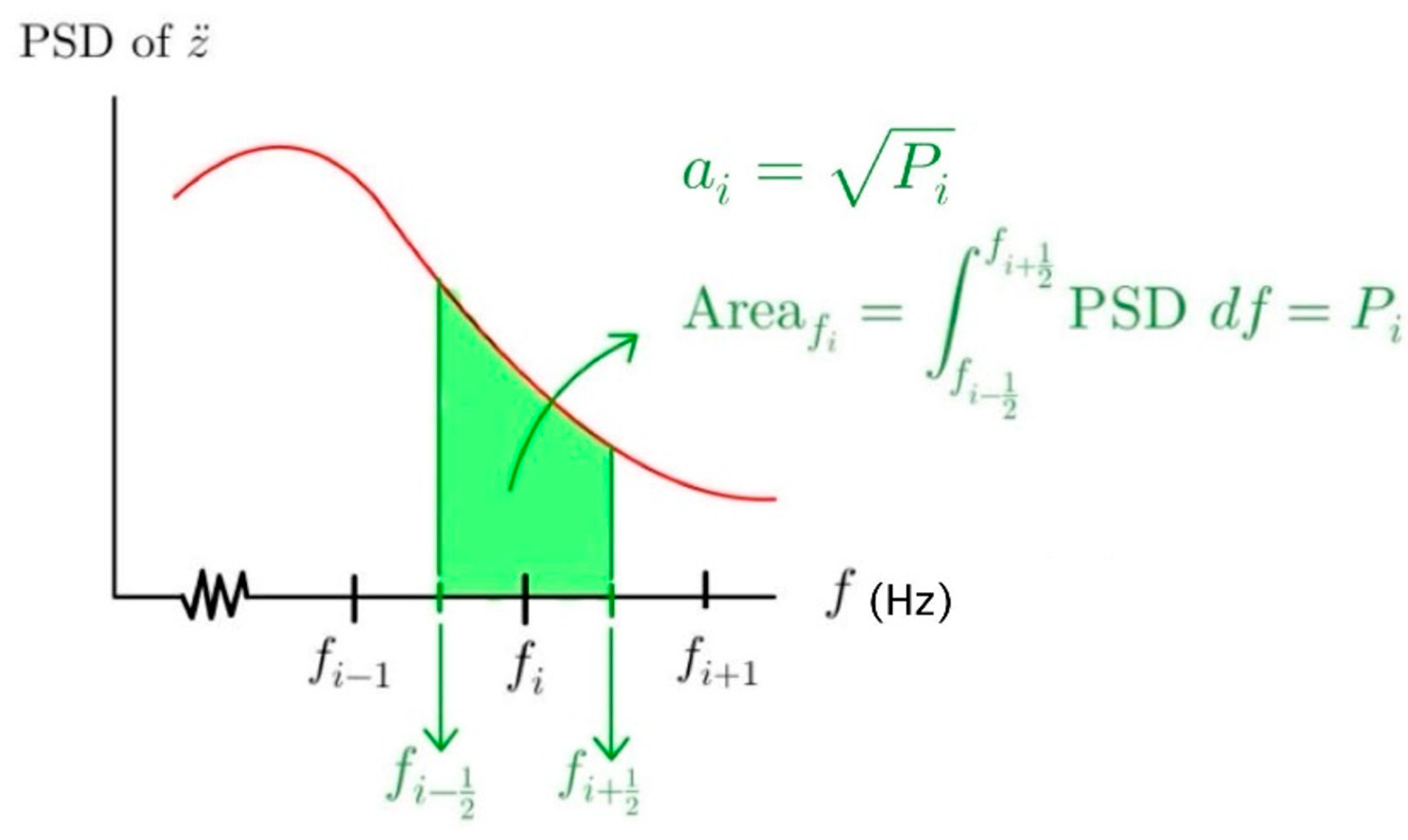

2.4.1. Power Spectral Density (PSD)

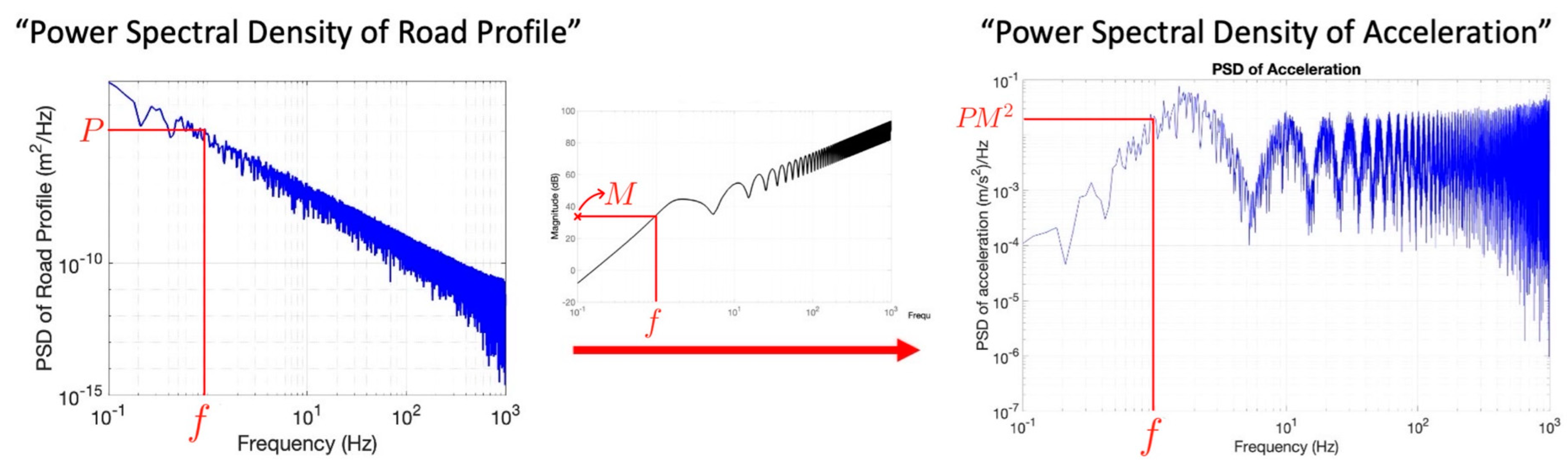

2.4.2. Classification of Roads (ISO 8608)

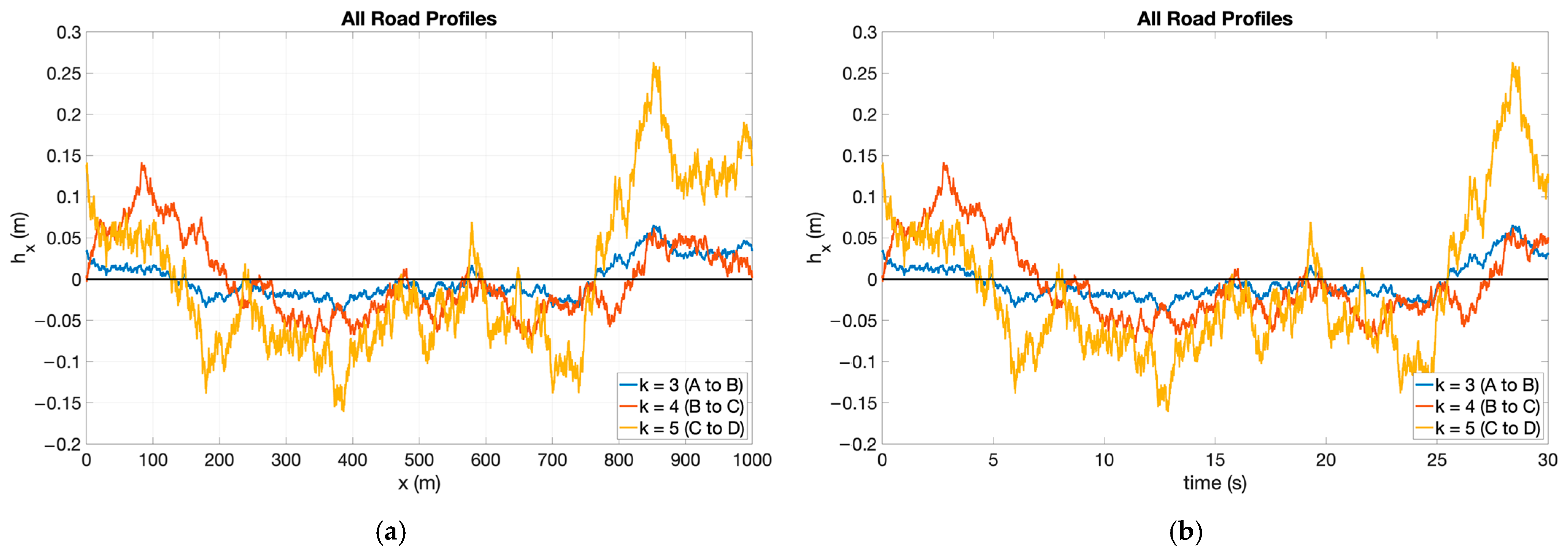

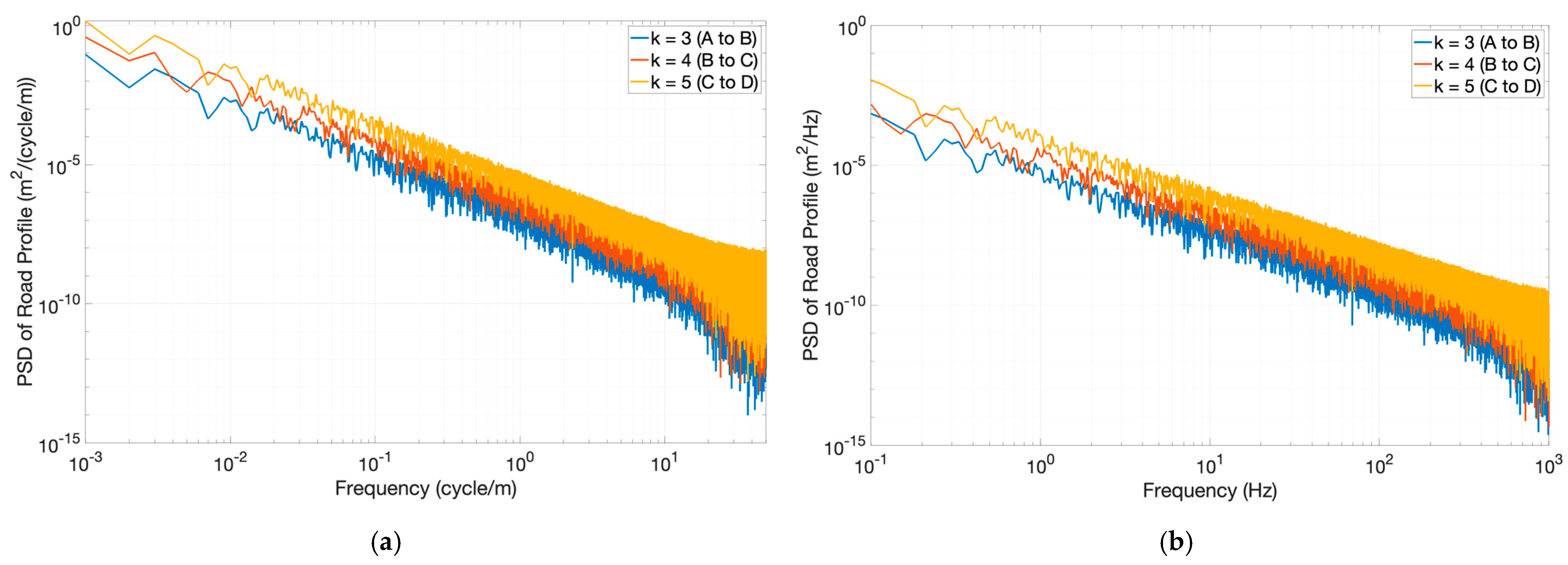

2.4.3. PSD of the Road Profiles

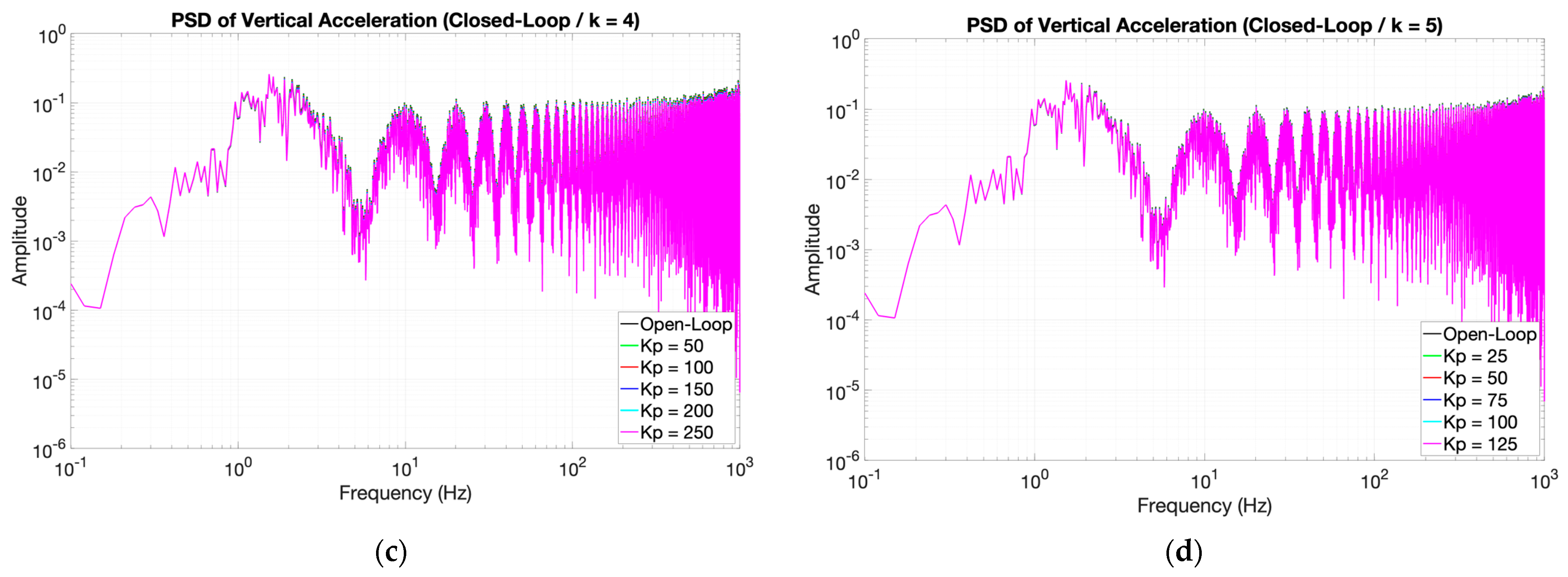

2.4.4. PSD of the Sprung Mass Vertical Acceleration

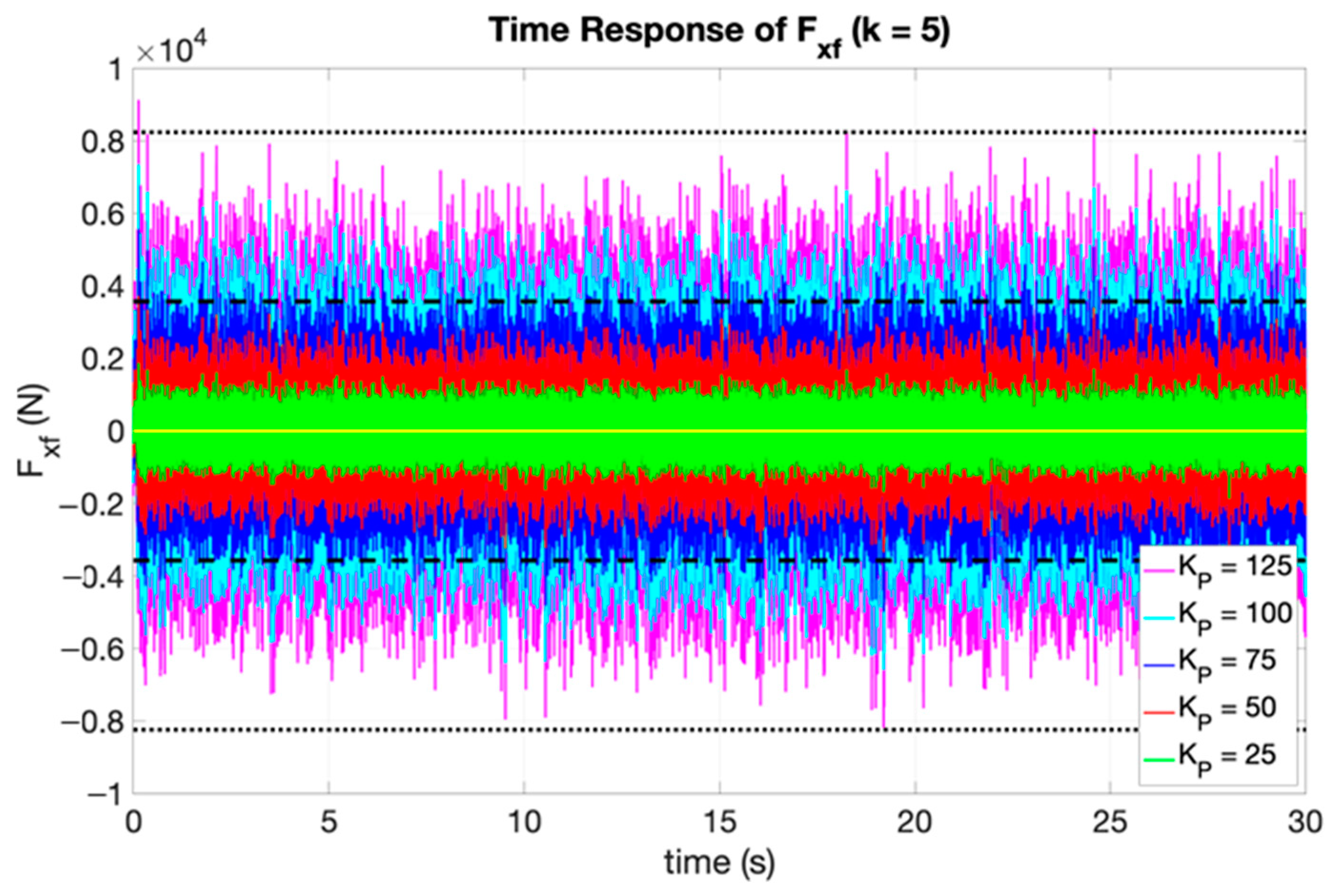

3. Results and Discussion

3.1. Frequency Response of the Open-Loop and Closed-Loop System

3.2. Frequency-Weighted Acceleration

3.3. Frequency-Weighted Acceleration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Kopylov, S.; Phanomchoeng, G.; Ambrož, M.; Petan, Ž.; Kunc, R.; Qiu, Y. Improvements to a vehicle’s ride comfort by controlling the vertical component of the driving force based on in-wheel motors. J. Vib. Control 2023, 29, 4001–4014. [Google Scholar] [CrossRef]

- Murata, S. Innovation by in-wheel-motor drive unit. Veh. Syst. Dyn. 2012, 50, 807–830. [Google Scholar] [CrossRef]

- Ricciardi, V.; Ivanov, V.; Dhaens, M.; Vandersmissen, B.; Geraerts, M.; Savitski, D.; Augsburg, K. Ride blending control for electric vehicles. World Electr. Veh. J. 2019, 10, 36. [Google Scholar] [CrossRef]

- Ma, Y.; Deng, Z.; Xie, D. Control of the active suspension for in-wheel motor. J. Adv. Mech. Des. Syst. Manuf. 2013, 7, 535–543. [Google Scholar] [CrossRef]

- Liu, M.; Gu, F.; Zhang, Y. Ride comfort optimization of in-wheel-motor electric vehicles with in-wheel vibration absorbers. Energies 2017, 10, 1647. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Poussot-Vassal, C.; Spelta, C.; Sename, O.; Dugard, L. Semi-Active Suspension Control Design for Vehicles; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Zhu, S.; Tang, H. Simulation of magneto-rheological semi-active suspension system of EV driven by in-wheel motor. In Proceedings of the 3rd International Conference on Mechatronics, Robotics and Automation, Shenzhen, China, 20–21 April 2015; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 265–271. [Google Scholar]

- Nie, S.; Zhuang, Y.; Chen, F.; Wang, Y.; Liu, S. A method to eliminate unsprung adverse effect of in-wheel motor-driven vehicles. J. Low Freq. Noise Vib. Act. Control 2018, 37, 955–976. [Google Scholar] [CrossRef]

- Anaya-Martinez, M.; Lozoya-Santos, J.D.J.; Félix-Herrán, L.C.; Tudon-Martinez, J.C.; Ramirez-Mendoza, R.A.; Morales-Menendez, R. Control of automotive semi-active MR suspensions for in-wheel electric vehicles. Appl. Sci. 2020, 10, 4522. [Google Scholar] [CrossRef]

- Liu, M.; Gu, F.; Huang, J.; Wang, C.; Cao, M. Integration design and optimization control of a dynamic vibration absorber for electric wheels with in-wheel motor. Energies 2017, 10, 2069. [Google Scholar] [CrossRef]

- Shao, X.; Naghdy, F.; Du, H. Enhanced ride performance of electric vehicle suspension system based on genetic algorithm optimization. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Ma, Y.; Lu, C.; Zhao, H.; Hao, M. Nonlinear model predictive slip control based on vertical suspension system for an in-wheel-motored electric vehicle. In Proceedings of the 2017 29th Chinese Control And Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 4967–4972. [Google Scholar]

- Liu, M.; Zhang, Y.; Huang, J.; Zhang, C. Optimization control for dynamic vibration absorbers and active suspensions of in-wheel-motor-driven electric vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 2377–2392. [Google Scholar] [CrossRef]

- Fang, Z.; Liang, J.; Tan, C.; Tian, Q.; Pi, D.; Yin, G. Enhancing robust driver assistance control in distributed drive electric vehicles through integrated AFS and DYC technology. IEEE Trans. Intell. Veh. 2024. early access. [Google Scholar] [CrossRef]

- Fang, Z.; Han, D.; Wang, J.; Wei, W.; Pi, D.; Yin, G. A Nash-equilibrium-based AFS-TVA Coordinated Control System for Distributed Drive Electric Vehicles Considering Safety and Energy. IEEE Trans. Transp. Electrif. 2024. early access. [Google Scholar] [CrossRef]

- Jastrzębski, Ł.; Sapiński, B. Experimental investigation of an automotive magnetorheological shock absorber. Acta Mech. Autom. 2017, 11, 253–259. [Google Scholar] [CrossRef]

- Zou, J.; Guo, X.; Abdelkareem, M.A.; Xu, L.; Zhang, J. Modelling and ride analysis of a hydraulic interconnected suspension based on the hydraulic energy regenerative shock absorbers. Mech. Syst. Signal Process. 2019, 127, 345–369. [Google Scholar] [CrossRef]

- Tang, X.; Lin, T.; Zuo, L. Design and optimization of a tubular linear electromagnetic vibration energy harvester. IEEE/ASME Trans. Mechatron. 2013, 19, 615–622. [Google Scholar] [CrossRef]

- Kopylov, S.; Chen, Z.B.; Abdelkareem, M.A. Acceleration based ground-hook control of an electromagnetic regenerative tuned mass damper for automotive application. Alex. Eng. J. 2020, 59, 4933–4946. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Yang, J. Development of Robust Guaranteed Cost Mixed Control System for Active Suspension of In-Wheel-Drive Electric Vehicles. Math. Probl. Eng. 2022, 4628539. [Google Scholar] [CrossRef]

- Ahmad, I.; Ge, X.; Han, Q.L. Decentralized dynamic event-triggered communication and active suspension control of in-wheel motor driven electric vehicles with dynamic damping. IEEE/CAA J. Autom. Sin. 2021, 8, 971–986. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Sun, S.; Li, S.; Yang, J.; Yan, Z. Design of Constrained Robust Controller for Active Suspension of In-Wheel-Drive Electric Vehicles. Mathematics 2021, 9, 249. [Google Scholar] [CrossRef]

- Long, G.; Ding, F.; Zhang, N.; Zhang, J.; Qin, A. Regenerative active suspension system with residual energy for in-wheel motor driven electric vehicle. Appl. Energy 2020, 260, 114180. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Fu, C.; Zhai, J. Model Predictive Control of Active Suspension for an Electric Vehicle Considering Influence of Braking Intensity. Appl. Sci. 2021, 11, 52. [Google Scholar] [CrossRef]

- Ahmad, I.; Ge, X.; Han, Q.L. Communication-constrained active suspension control for networked in-wheel motor-driven electric vehicles with dynamic dampers. IEEE Trans. Intell. Veh. 2022, 7, 590–602. [Google Scholar] [CrossRef]

- Yatak, M.Ö.; Şahin, F. Ride comfort-road holding trade-off improvement of full vehicle active suspension system by interval type-2 fuzzy control. Eng. Sci. Technol. Int. J. 2021, 24, 259–270. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, L.; Li, Y.; Zhang, Z.; Yu, Y. Robust Control for Active Suspension of Hub-Driven Electric Vehicles Subject to in-Wheel Motor Magnetic Force Oscillation. Appl. Sci. 2020, 10, 3929. [Google Scholar] [CrossRef]

- Kissai, M.; Monsuez, B.; Tapus, A. Review of integrated vehicle dynamics control architectures. In Proceedings of the 2017 European Conference on Mobile Robots (ECMR), Paris, France, 6–8 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–8. [Google Scholar]

- Múčka, P. Simulated road profiles according to ISO 8608 in vibration analysis. J. Test. Eval. 2018, 46, 405–418. [Google Scholar] [CrossRef]

- Min-Soo, P.A.R.K.; Fukuda, T.; Kim, T.G.; Maeda, S. Health risk evaluation of whole-body vibration by ISO 2631-5 and ISO 2631-1 for operators of agricultural tractors and recreational vehicles. Ind. Health 2013, 51, 364–370. [Google Scholar]

- Katsuyama, E. Decoupled 3D moment control using in-wheel motors. Veh. Syst. Dyn. 2013, 51, 18–31. [Google Scholar] [CrossRef]

- Hott, L.; Ivanov, V.; Augsburg, K.; Ricciardi, V.; Dhaens, M.; Al Sakka, M.; Praet, K.; Molina, J.V. Ride blending control for awd electric vehicle with in-wheel motors and electromagnetic suspension. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Virtual, 18 November–16 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- The MathWorks Inc. Matlab. Available online: https://www.mathworks.com (accessed on 30 June 2024).

- Andrianov, I.; Shatrov, A. Padé Approximants, Their Properties, and Applications to Hydrodynamic Problems. Symmetry 2021, 13, 1869. [Google Scholar] [CrossRef]

- Medina Santiago, A.; Orozco Torres, J.A.; Hernández Gracidas, C.A.; Garduza, S.H.; Franco, J.D. Diagnosis and Study of Mechanical Vibrations in Cargo Vehicles Using ISO 2631-1:1997. Sensors 2023, 23, 9677. [Google Scholar] [CrossRef] [PubMed]

- Múčka, P.; Stein, G.J.; Tobolka, P. Whole-body vibration and vertical road profile displacement power spectral density. Veh. Syst. Dyn. 2020, 58, 630–656. [Google Scholar] [CrossRef]

- Múčka, P. Passenger car vibration dose value prediction based on ISO 8608 road surface profiles. SAE Int. J. Veh. Dyn. Stab. NVH 2021, 5, 425–441. [Google Scholar] [CrossRef]

- Agostinacchio, M.; Ciampa, D.; Olita, S. The vibrations induced by surface irregularities in road pavements—A Matlab® approach. Eur. Transp. Res. Rev. 2014, 6, 267–275. [Google Scholar] [CrossRef]

- Kanafi, M.M. 1-Dimensional Surface Roughness Power Spectrum of a Profile or Topography. MATLAB Central File Exchange 2020. Available online: https://www.mathworks.com/matlabcentral/fileexchange/54315-1-dimensional-surface-roughness-power-spectrum-of-a-profile-or-topography (accessed on 20 July 2024).

| Parameters | Symbol | Value | Units |

|---|---|---|---|

| Sprung mass | 2055.2 | ||

| Pitch inertia | 3404.9 | ||

| Horizontal distance from front wheel to point A | 0.51 | ||

| Horizontal distance from rear wheel to point B | 0.53 | ||

| Horizontal distance from front wheel to rear wheel | 2.974 | ||

| Horizontal distance from front wheel to point G | 1.621 | ||

| Vertical distance from rear wheel to point G | 1.353 | ||

| Vertical distance from ground to point A | 0.16 | ||

| Vertical distance from ground to point B | 0.15 | ||

| Vertical distance from ground to point G | 0.418 | ||

| Spring stiffness of front suspension | 103,800 | ||

| Spring stiffness of rear suspension | 99,200 | ||

| Damping coefficient of front suspension | 6010 | ||

| Damping coefficient of rear suspension | 10,008 | ||

| Unloaded tire radius | 0.364 |

| Class of Road Profile | |

|---|---|

| A to B | 3 |

| B to C | 4 |

| C to D | 5 |

| D to E | 6 |

| E to F | 7 |

| F to G | 8 |

| G to H | 9 |

| Frequency-Weighted ) | Percentage Decrease (Compared with Open-Loop) | |

|---|---|---|

| 0 (Open-Loop) | 0.3721 | 0% |

| 100 | 0.3622 | 2.6641% |

| 200 | 0.3528 | 5.1856% |

| 300 | 0.3439 | 7.5756% |

| 400 | 0.3355 | 9.8441% |

| 500 | 0.3275 | 12.000% |

| Frequency-Weighted ) | Percentage Decrease (Compared with Open-Loop) | |

|---|---|---|

| 0 (Open-Loop) | 0.7349 | 0% |

| 50 | 0.7250 | 1.3583% |

| 100 | 0.7153 | 2.6789% |

| 150 | 0.7058 | 3.9632% |

| 200 | 0.6966 | 5.2127% |

| 250 | 0.6877 | 6.4288% |

| Frequency-Weighted ) | Percentage Decrease (Compared with Open-Loop) | |

|---|---|---|

| 0 (Open-Loop) | 1.4884 | 0% |

| 25 | 1.4783 | 0.6800% |

| 50 | 1.4683 | 1.3506% |

| 75 | 1.4585 | 2.0119% |

| 100 | 1.4488 | 2.6641% |

| 125 | 1.4392 | 3.3073% |

| 0 (Open-Loop) | 4.130 |

| 100 | 4.014 |

| 200 | 3.904 |

| 300 | 3.800 |

| 400 | 3.702 |

| 500 | 3.609 |

| 0 (Open-Loop) | 8.269 |

| 50 | 8.151 |

| 100 | 8.037 |

| 150 | 7.925 |

| 200 | 7.817 |

| 250 | 7.712 |

| 0 (Open-Loop) | 16.52 |

| 25 | 16.40 |

| 50 | 16.28 |

| 75 | 16.17 |

| 100 | 16.05 |

| 125 | 15.94 |

| Type of Road Profile | The Most Appropriate | Percentage Decrease in Frequency-Weighted Acceleration (Compared with Open-Loop) |

|---|---|---|

| k = 3 (Class A to B) | 300 | 7.5756% |

| k = 4 (Class B to C) | 150 | 3.9632% |

| k = 5 (Class C to D) | 75 | 2.0119% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bunlapyanan, C.; Chantranuwathana, S.; Phanomchoeng, G. Analytical Investigation of Vertical Force Control in In-Wheel Motors for Enhanced Ride Comfort. Appl. Sci. 2024, 14, 6582. https://doi.org/10.3390/app14156582

Bunlapyanan C, Chantranuwathana S, Phanomchoeng G. Analytical Investigation of Vertical Force Control in In-Wheel Motors for Enhanced Ride Comfort. Applied Sciences. 2024; 14(15):6582. https://doi.org/10.3390/app14156582

Chicago/Turabian StyleBunlapyanan, Chanoknan, Sunhapos Chantranuwathana, and Gridsada Phanomchoeng. 2024. "Analytical Investigation of Vertical Force Control in In-Wheel Motors for Enhanced Ride Comfort" Applied Sciences 14, no. 15: 6582. https://doi.org/10.3390/app14156582