Enhancing Manufacturing Excellence with Digital-Twin-Enabled Operational Monitoring and Intelligent Scheduling

Abstract

1. Introduction

2. Materials and Methods

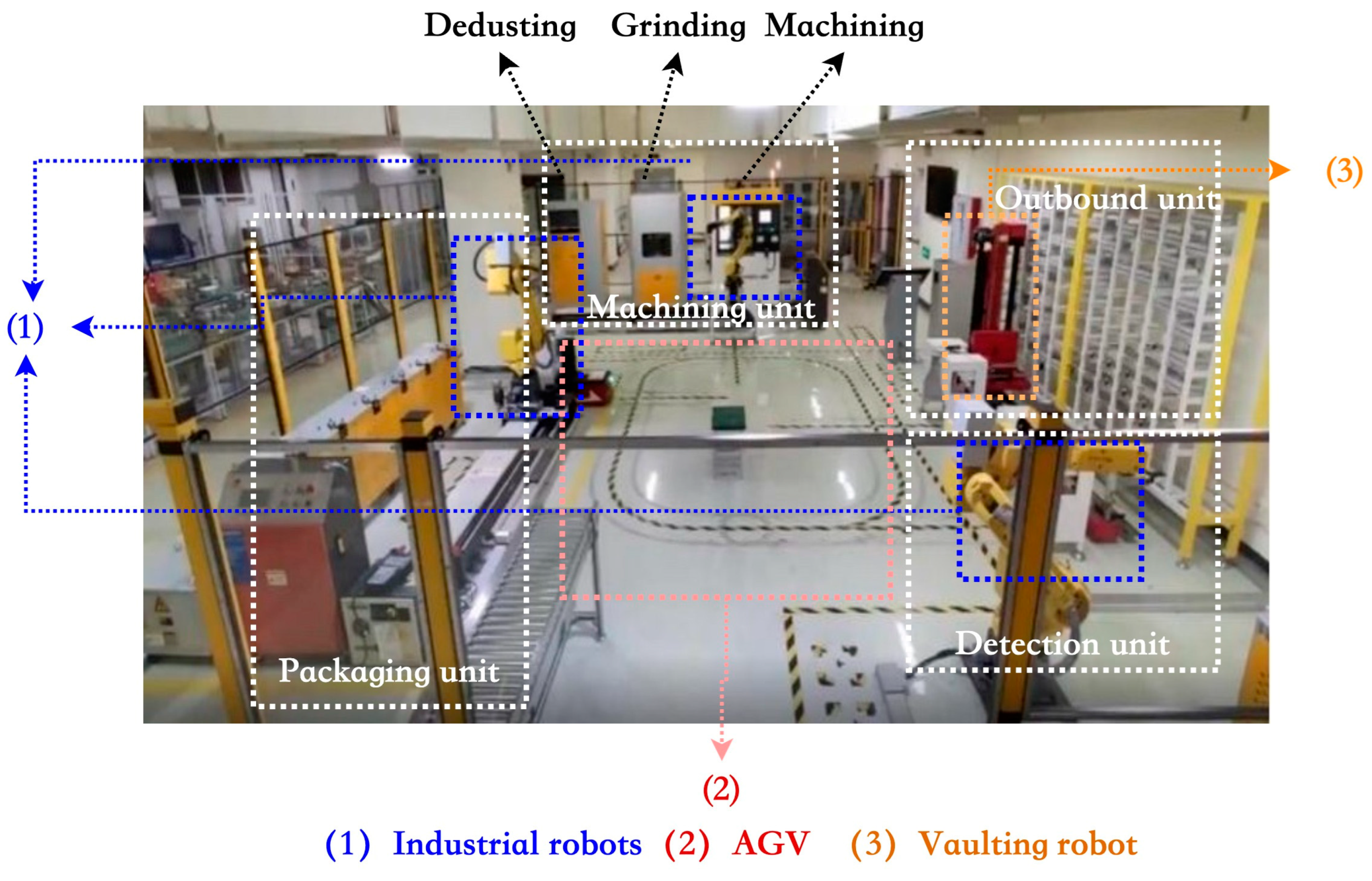

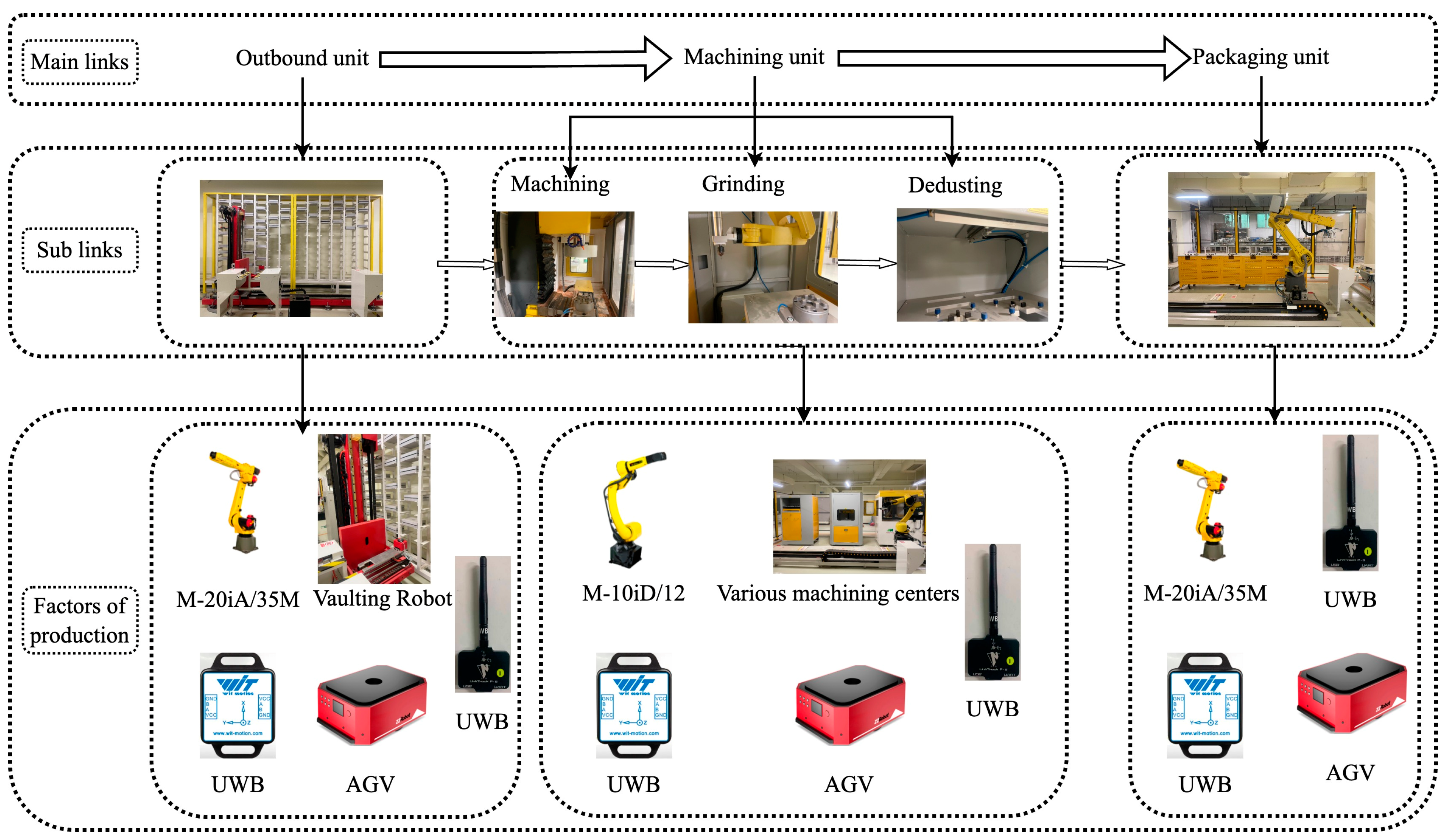

2.1. Detailed Analysis of Solid-Wood-Panel Processing: Workflow and Key Technologies

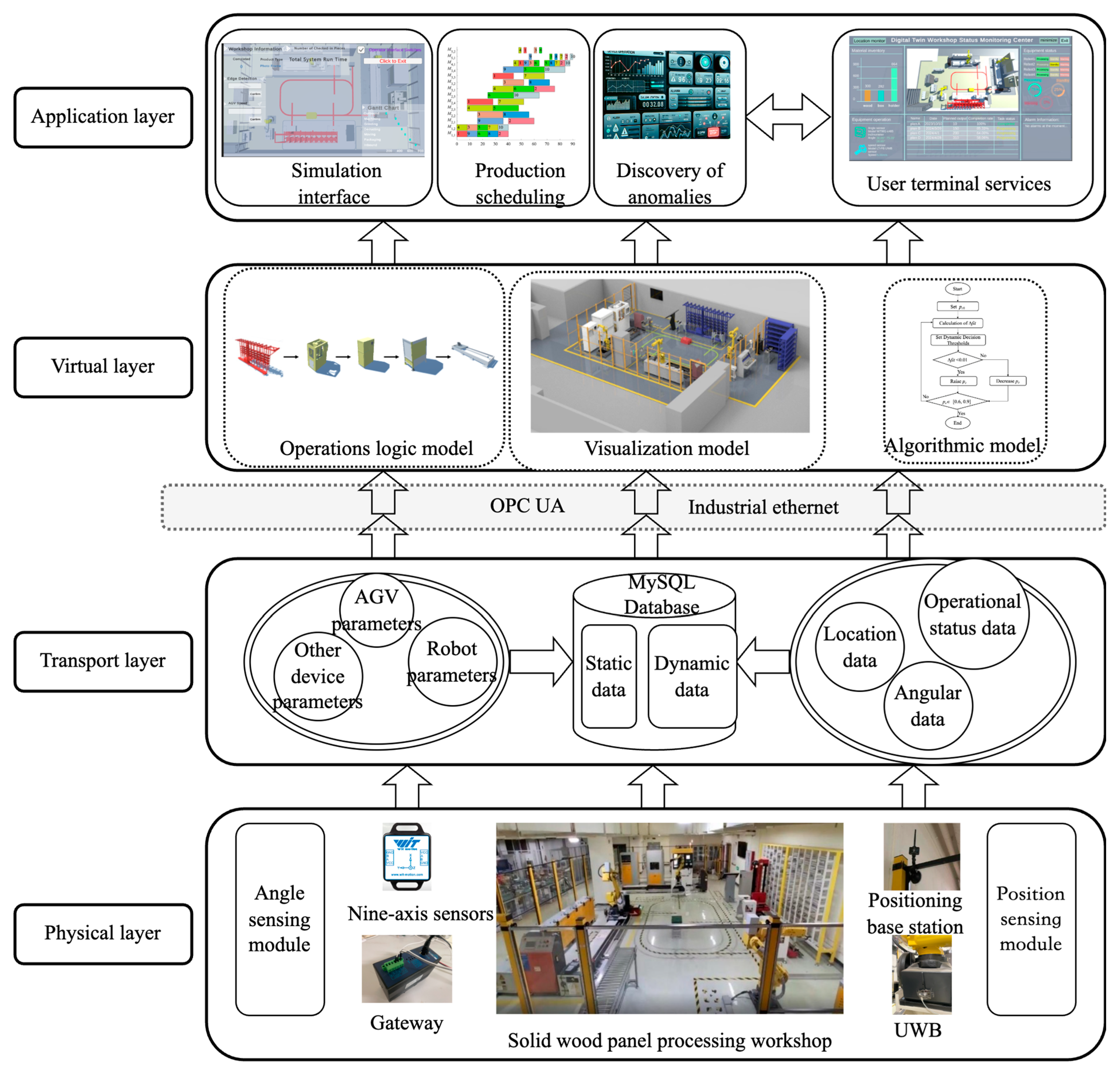

2.2. Framework of Digital Twin System for Solid-Wood-Panel Processing

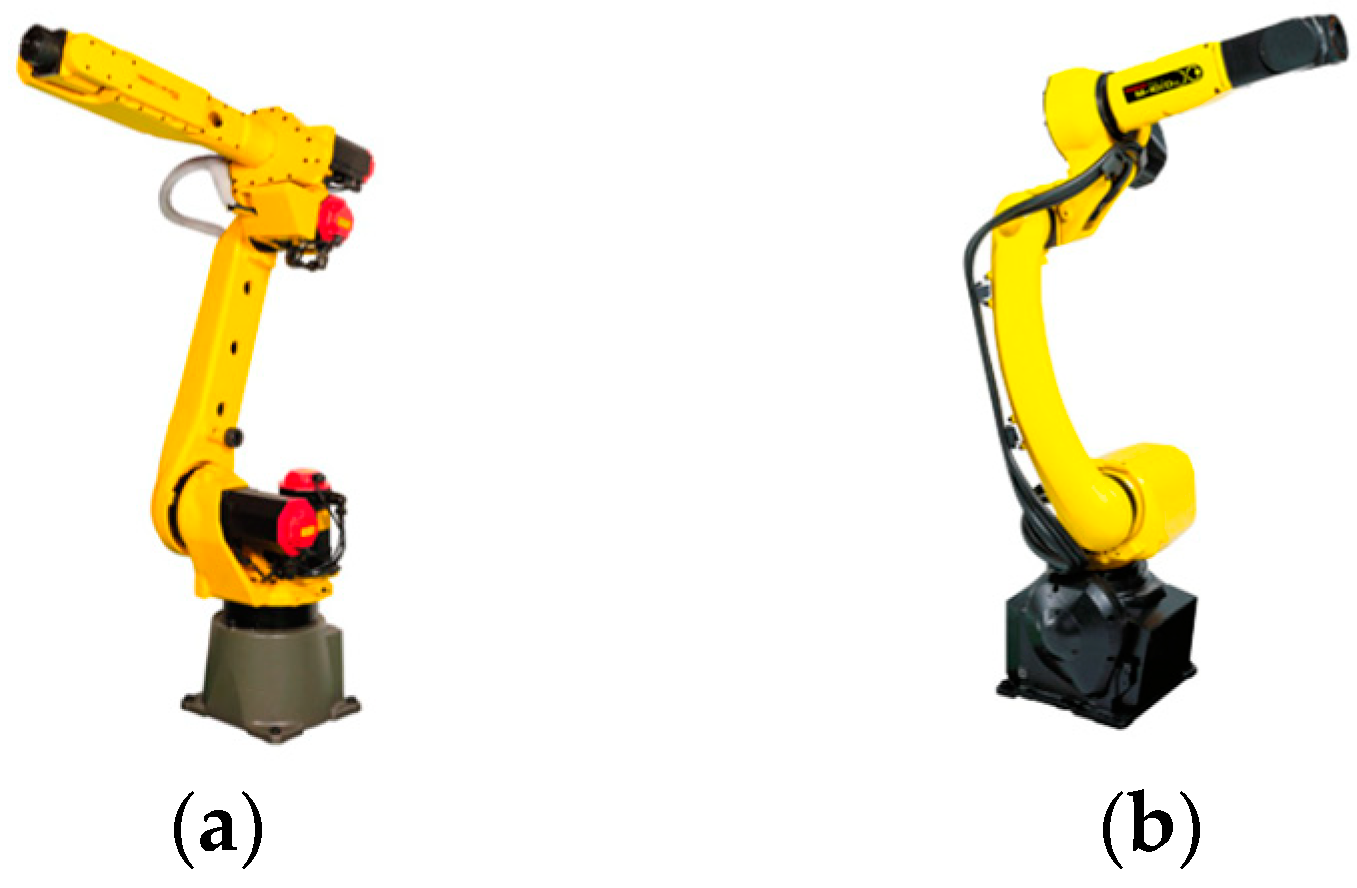

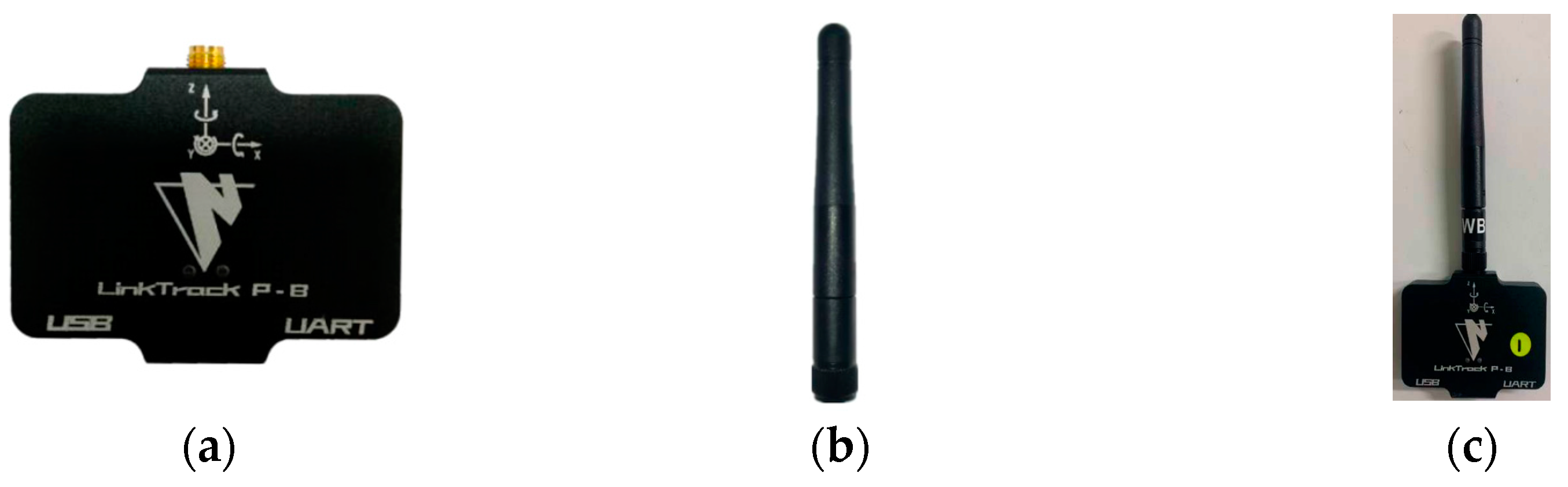

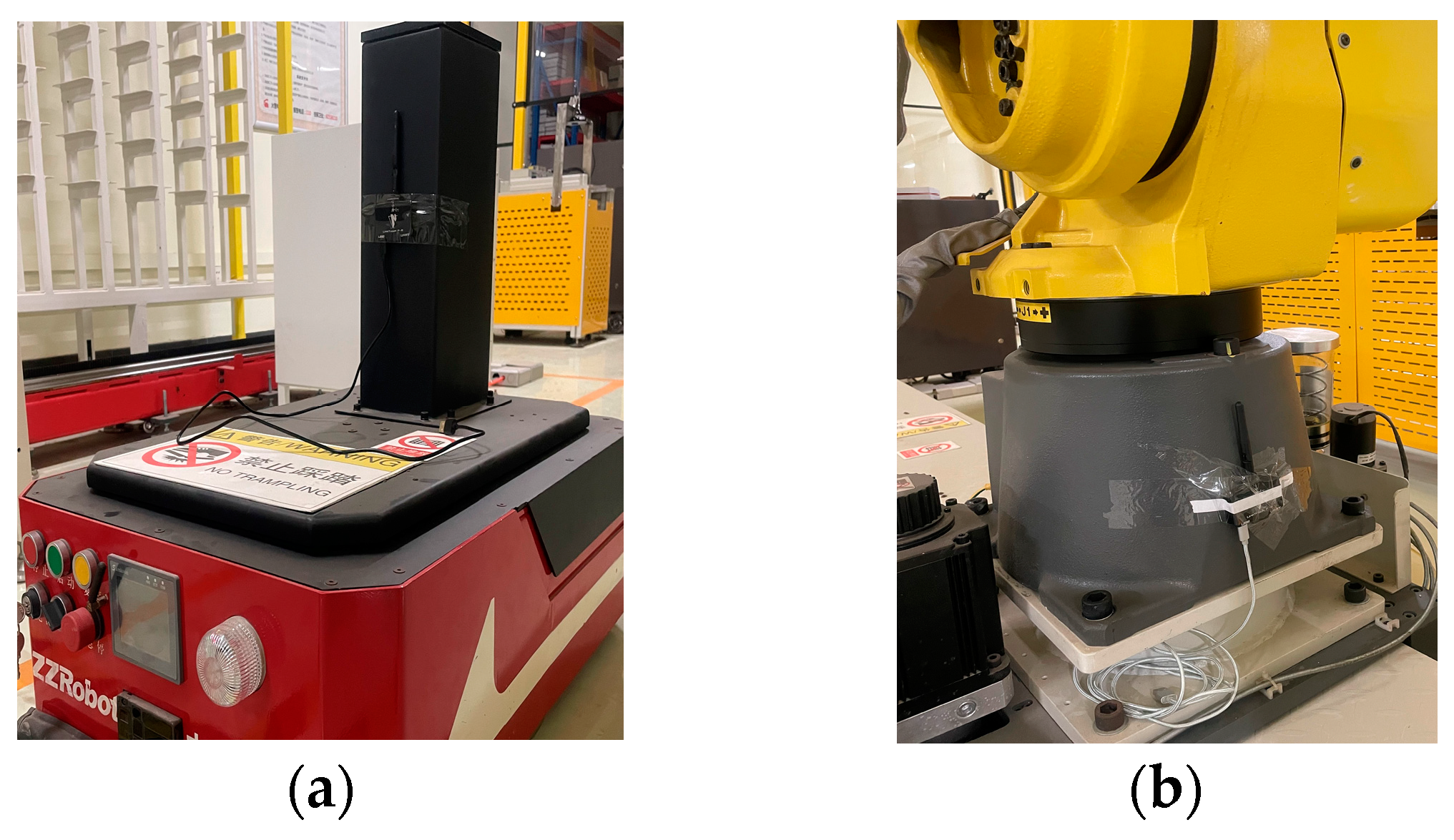

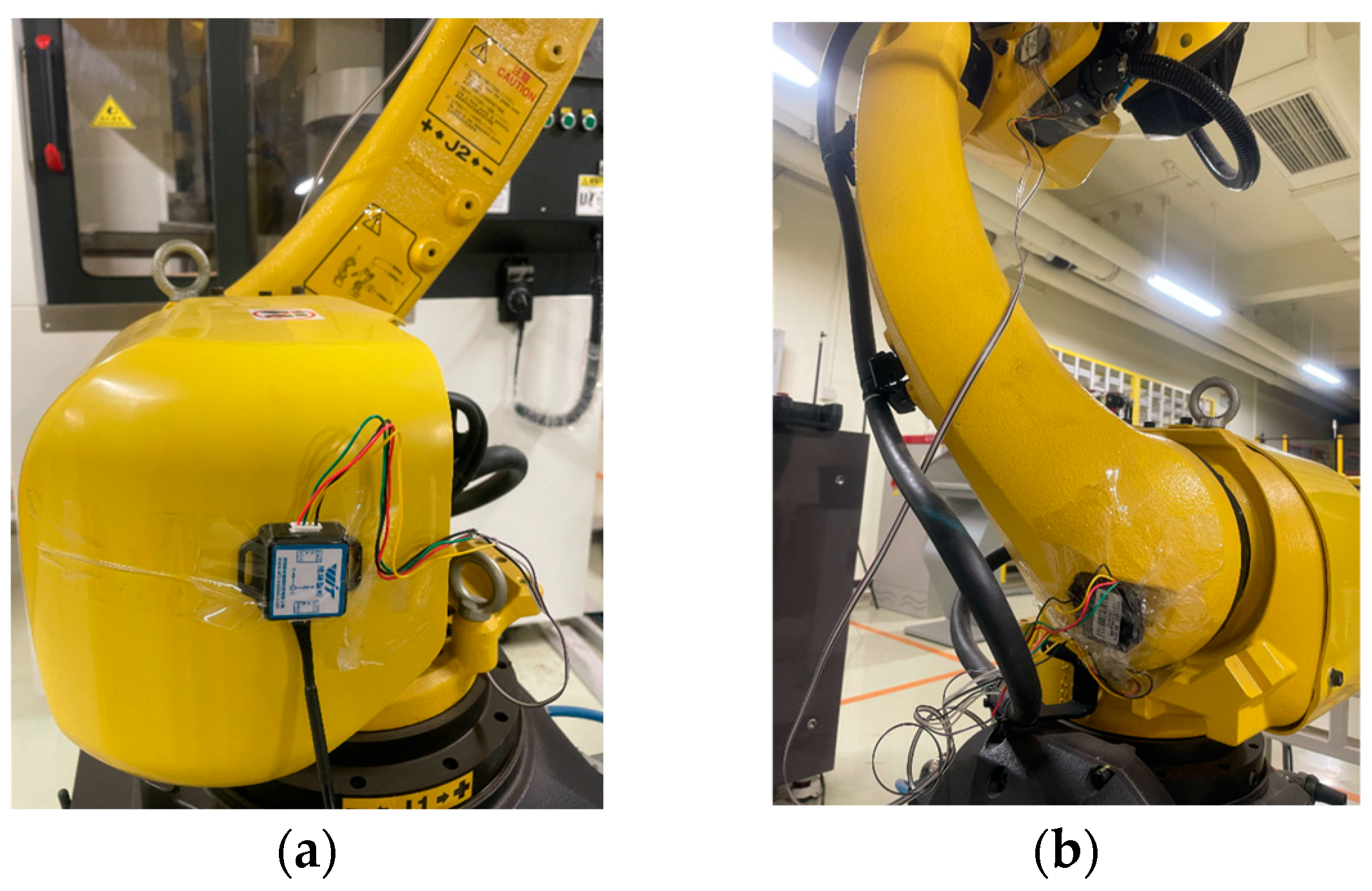

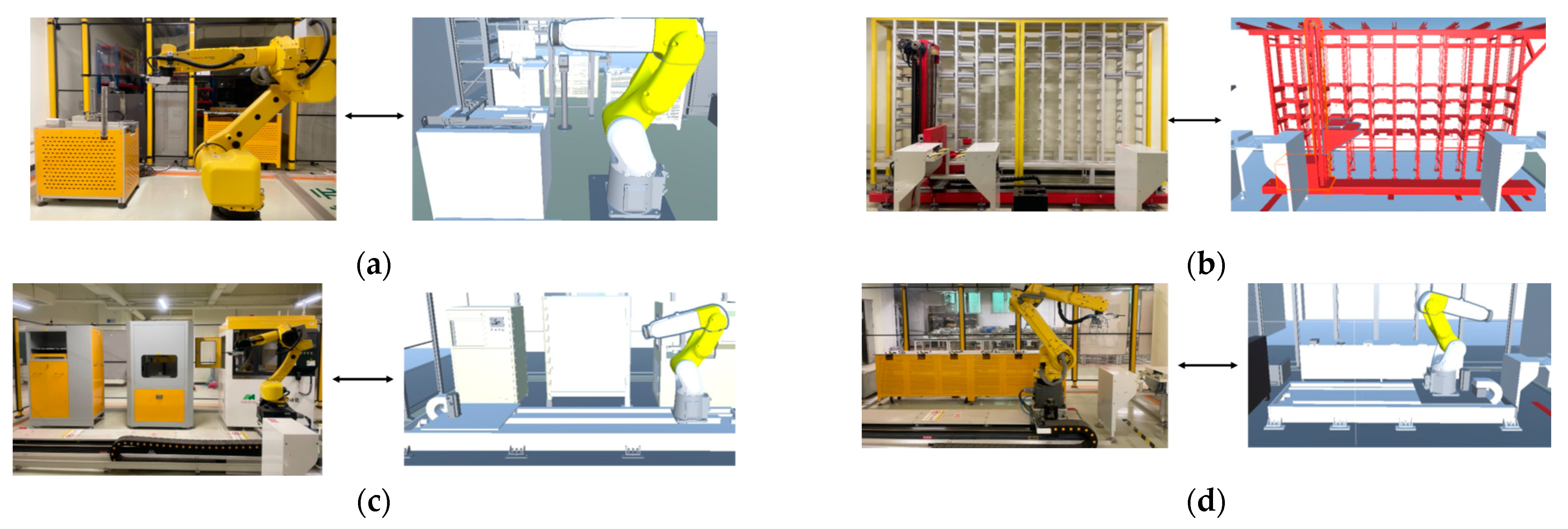

2.2.1. Physical Layer

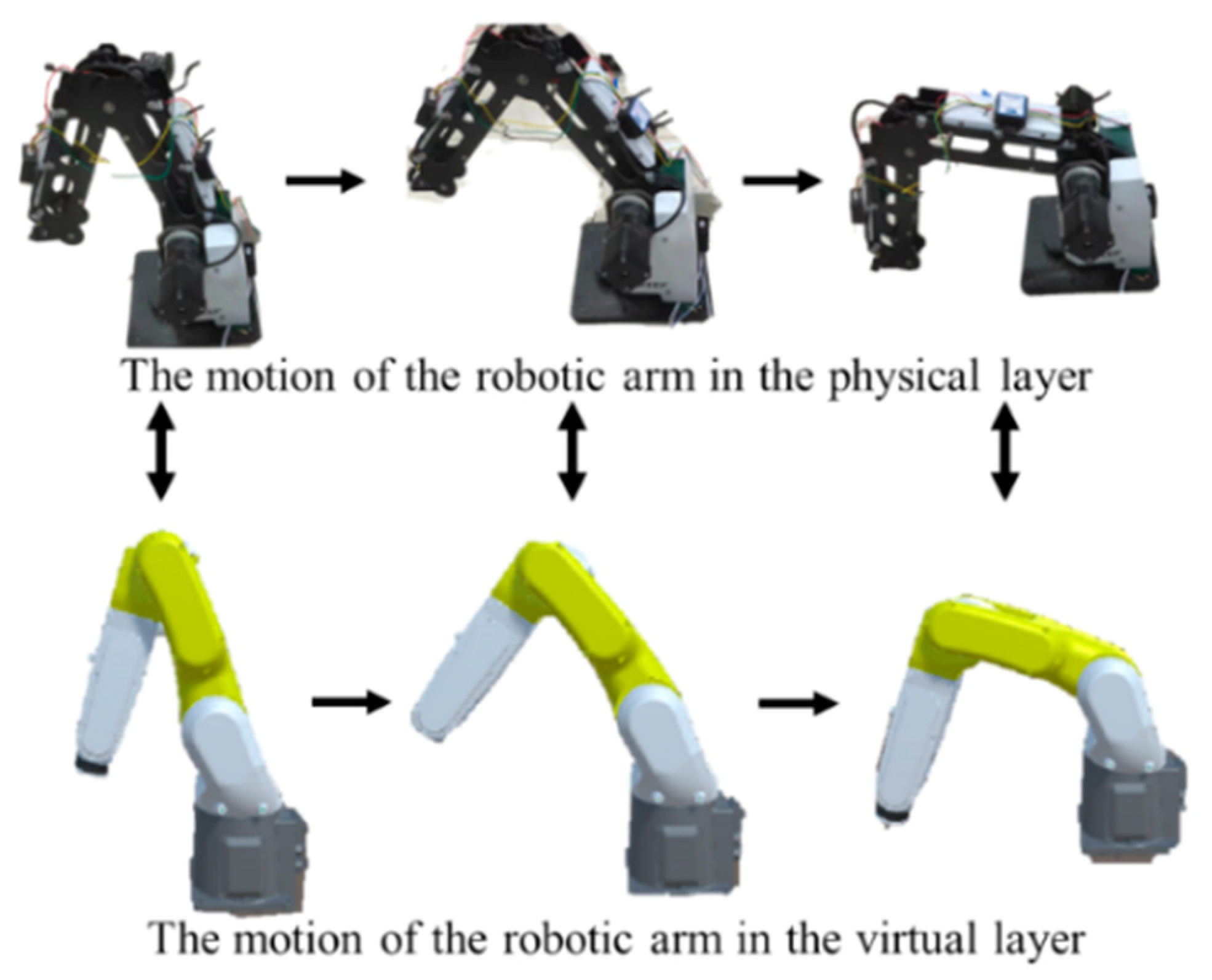

2.2.2. Virtual Layer

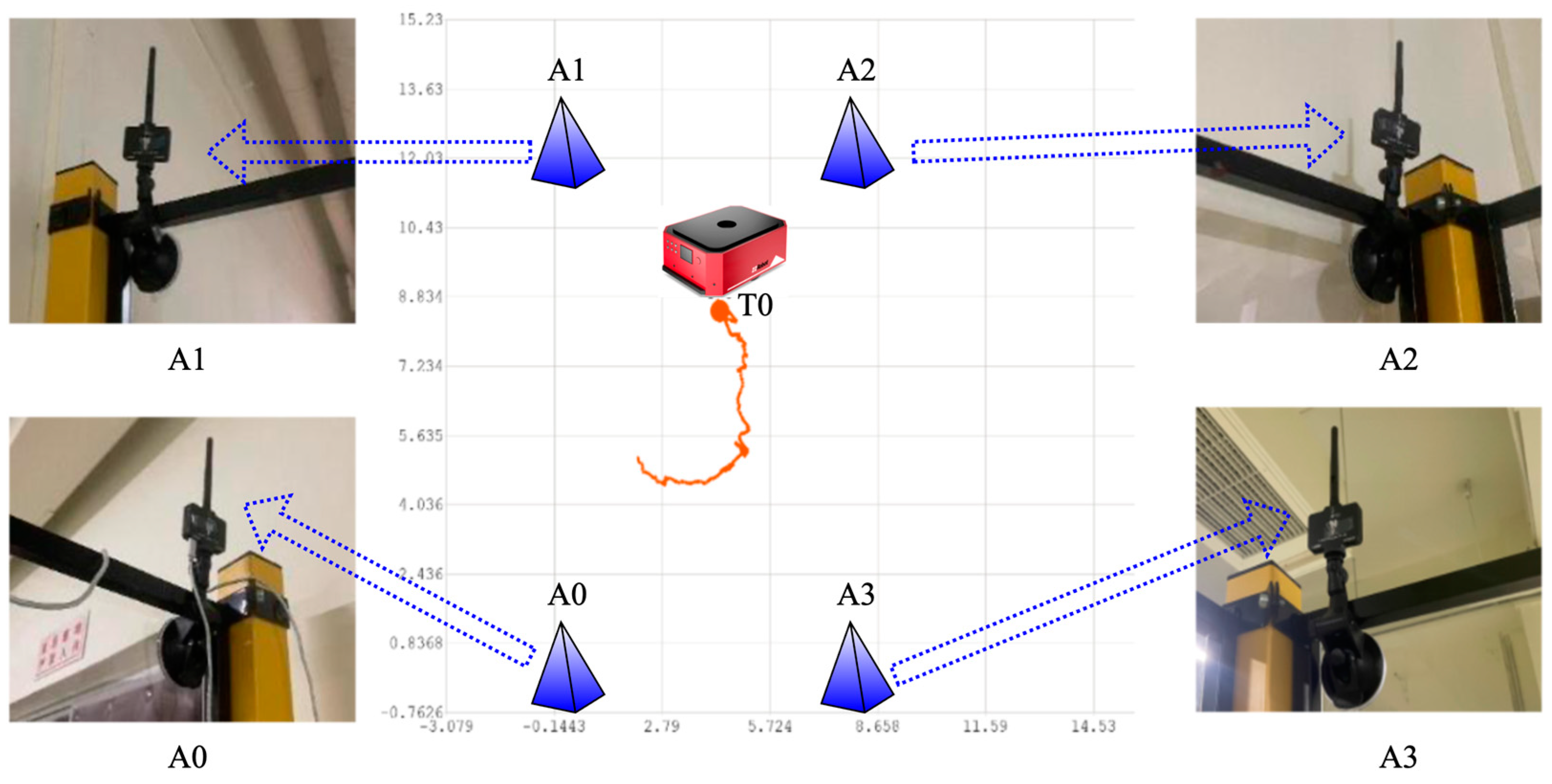

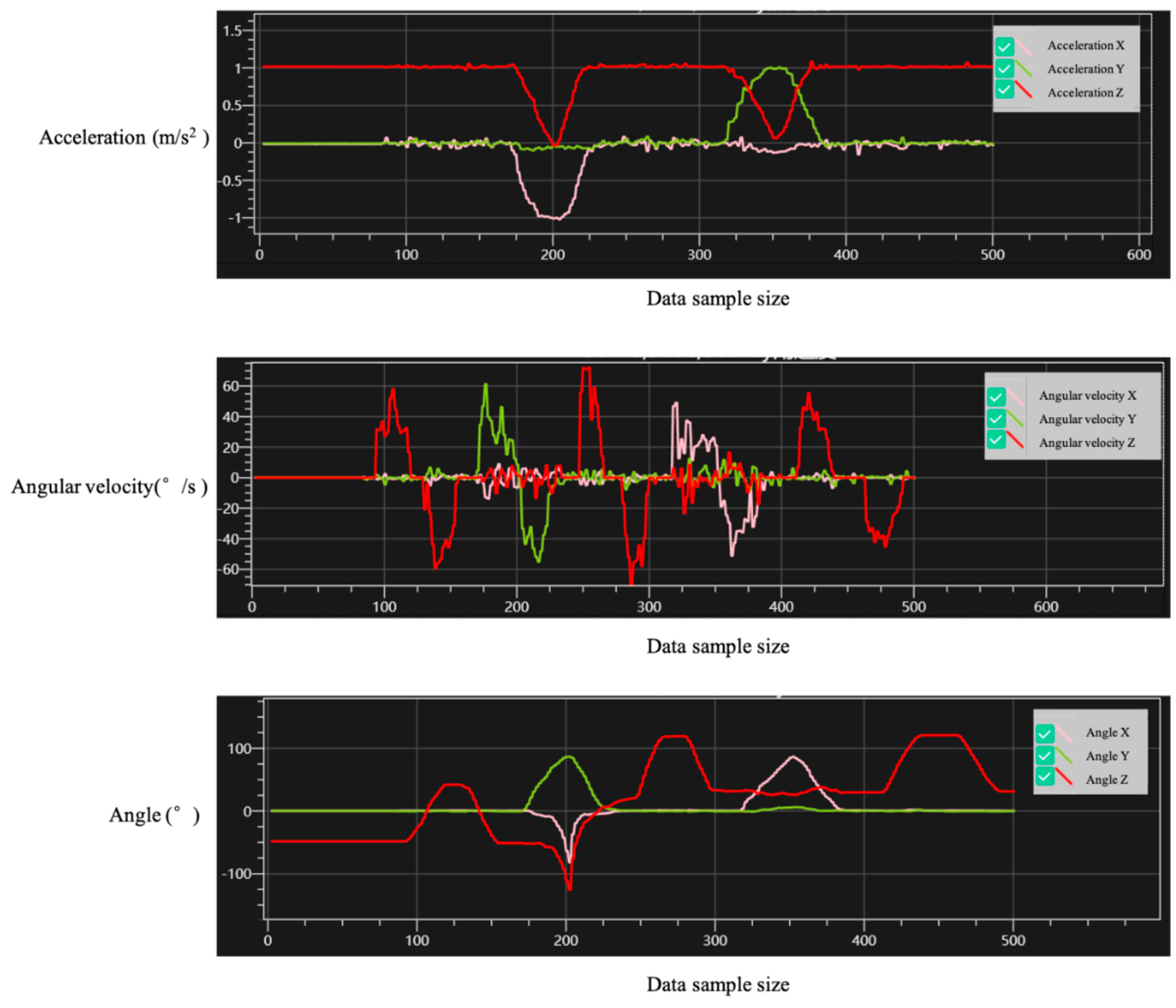

2.2.3. Transport Layer

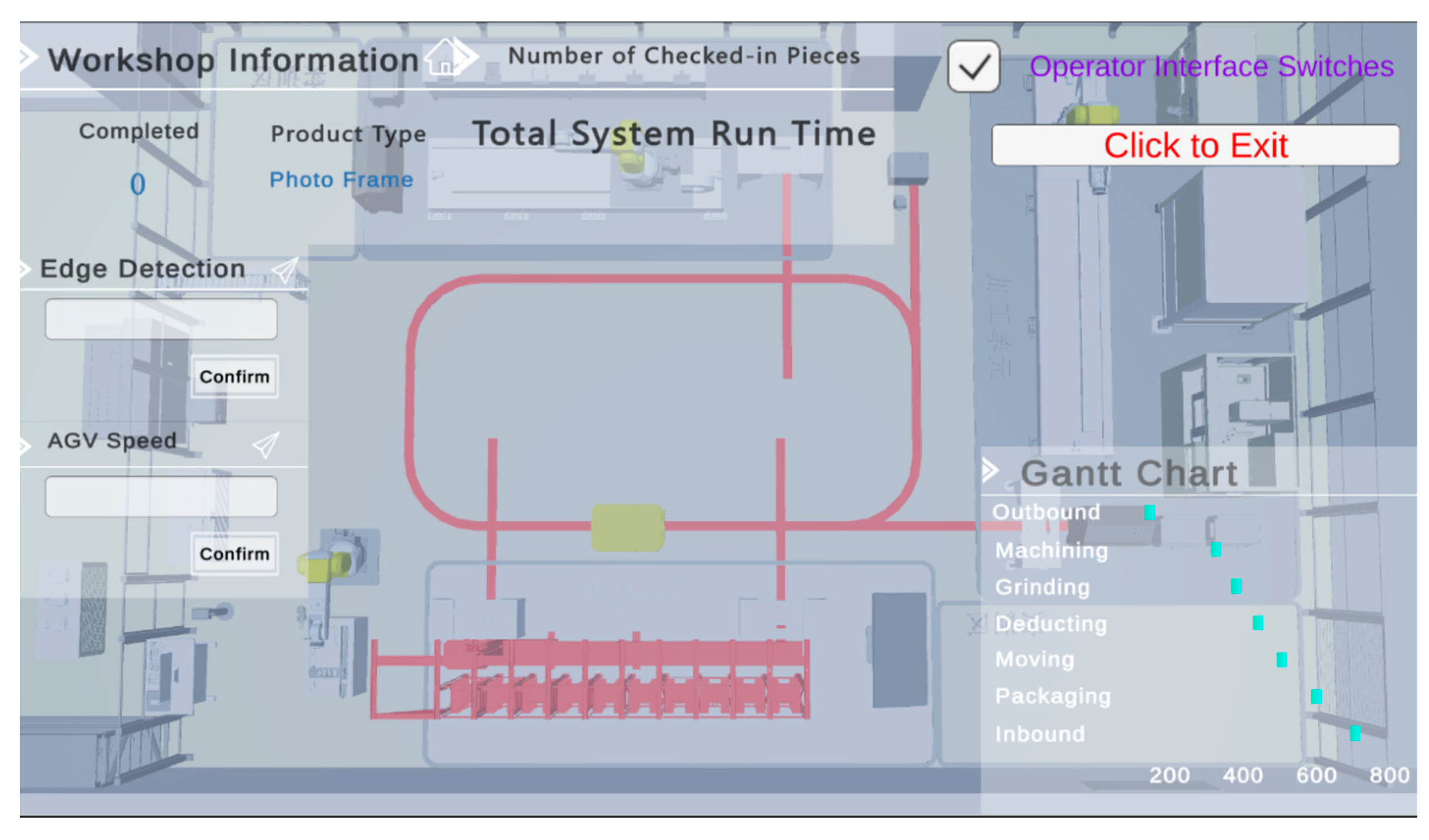

2.2.4. Application Layer

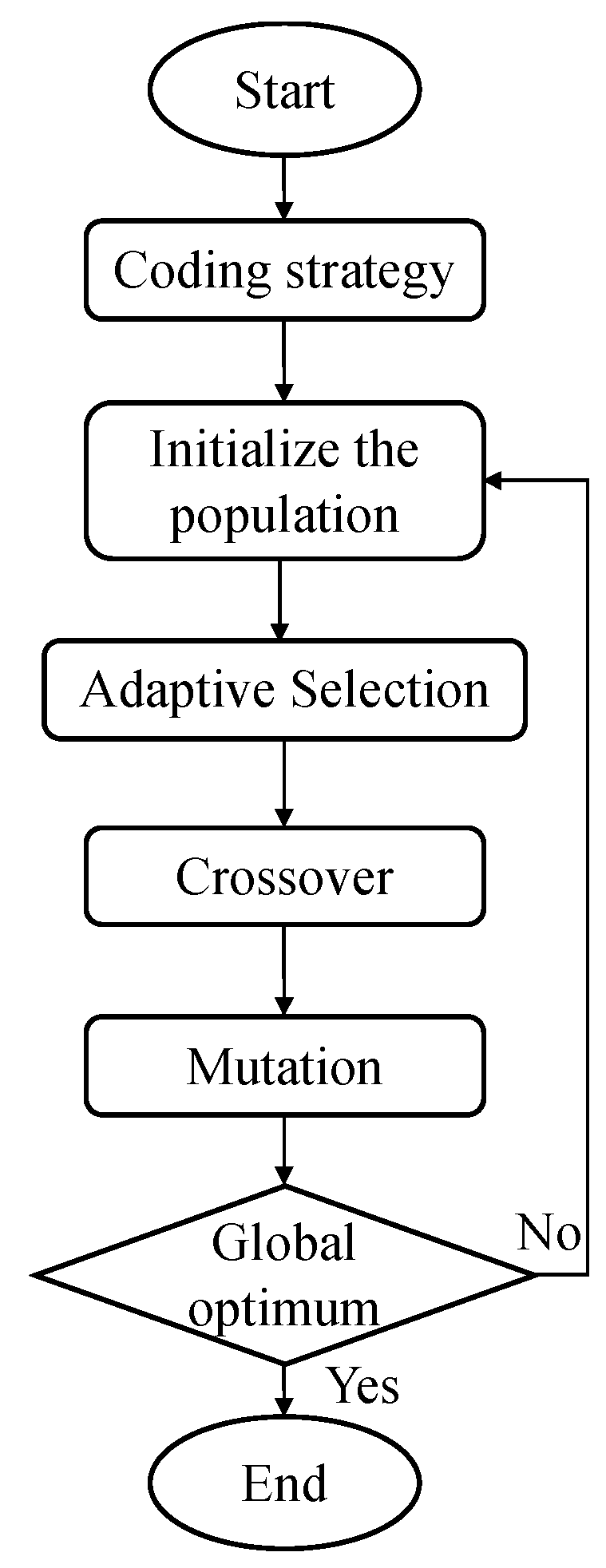

2.3. Dynamic Selection Adaptive Genetic Algorithm (DSAGA)

2.3.1. Coding Strategy and Initialize the Population

2.3.2. Objective Function

2.3.3. Adaptive Selection Operation

2.3.4. Crossover Operation

2.3.5. Mutation Operation

3. Results

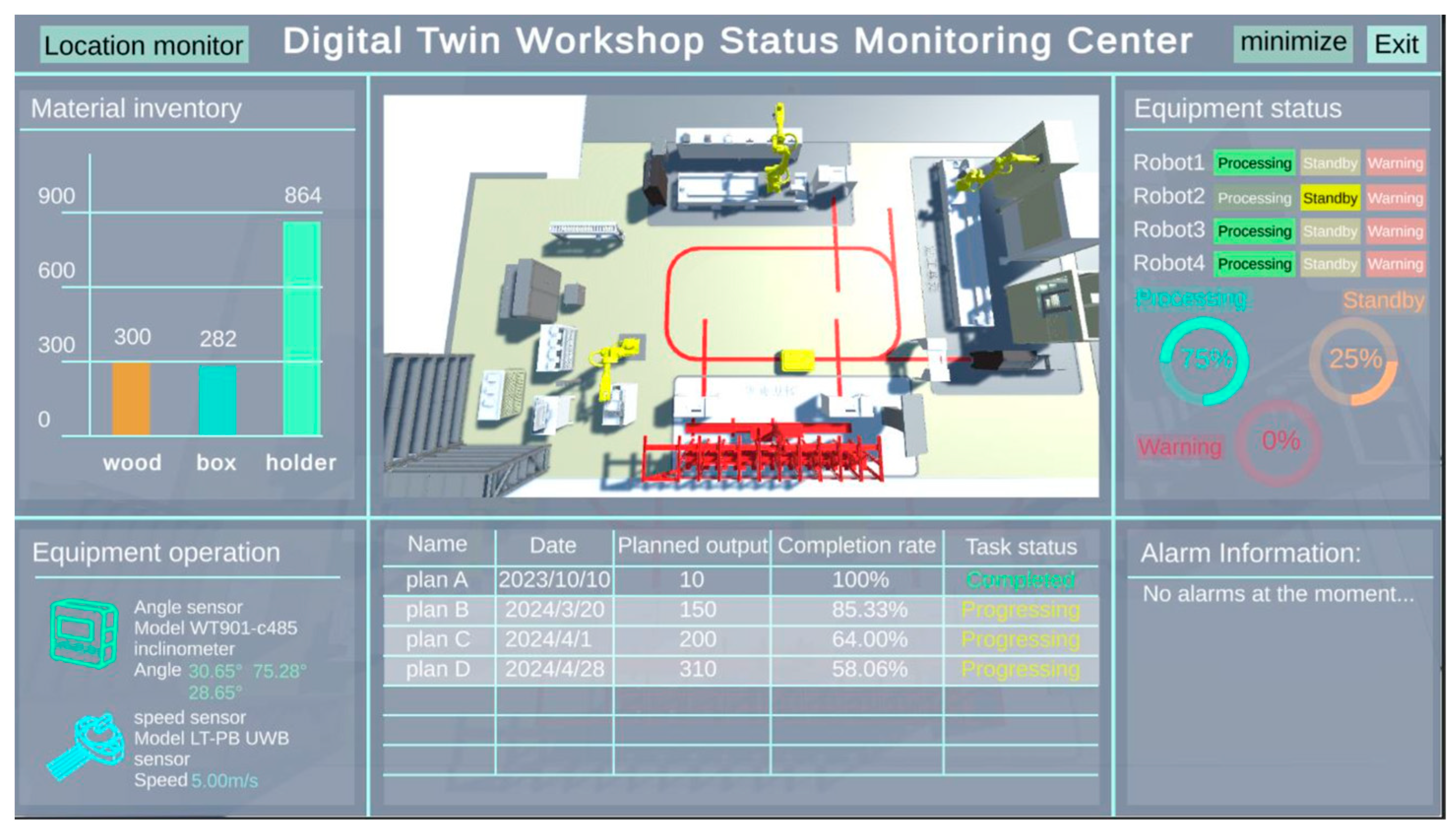

3.1. Results of Digital Twin Model Construction

3.1.1. Construction Results of the Virtual and Transmission Layers

3.1.2. Construction Results of the Application Layer

3.2. Application and DSAGA in Solid-Wood-Panel Production

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The Use of Digital Twin for Predictive Maintenance in Manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z. Digital Twin-Based Production Scheduling System for Heavy Truck Frame Shop. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 1931–1942. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Qi, Q.; Zhang, M.; Liu, W.; Cheng, J. Ten questions about digital twins: Analysis and thinking. Comput. Integr. Manuf. Syst. 2020, 26, 1–17. [Google Scholar] [CrossRef]

- Make More Digital Twins. Available online: https://www.nature.com/articles/d41586-019-02849-1 (accessed on 9 January 2024).

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y.C. Digital Twin Driven Prognostics and Health Management for Complex Equipment. CIRP Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital Twin for Smart Manufacturing, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J. Discussion on digital twin model of intelligent workshop for panel custom furniture. Wood Sci. Technol. 2023, 37, 25–32. [Google Scholar]

- Ouyang, Z.; Wu, Y.; Tao, T.; Dai, X.; Huang, Y.; Chen, X.; Wang, X.; Hao, S.; Zhan, X. Construction of furniture digital twin workshop and key technology prospects for “Made in China 2025”. Furnit. Inter. Decor. 2022, 29, 1–7. [Google Scholar] [CrossRef]

- Hopfield, J.J.; Tank, D.W. “Neural” Computation of Decisions in Optimization Problems. Biol. Cybern. 1985, 52, 141–152. [Google Scholar] [CrossRef]

- Wu, P.; He, Y.; Li, Y.; He, J.; Liu, X.; Wang, Y. Multi-Objective Optimisation of Machining Process Parameters Using Deep Learning-Based Data-Driven Genetic Algorithm and TOPSIS. J. Manuf. Syst. 2022, 64, 40–52. [Google Scholar] [CrossRef]

- Bhoskar, T.; Kulkarni, O.K.; Kulkarni, N.K.; Patekar, S.L.; Kakandikar, G.; Nandedkar, V. Genetic Algorithm and Its Applications to Mechanical Engineering: A Review. Mater. Today Proc. 2015, 2, 2624–2630. [Google Scholar] [CrossRef]

- Goldberg, D.E.; Lingle, R. Alleles, Loci, and the Traveling Salesman Problem. In Proceedings of the First International Conference on Genetic Algorithms and Their Applications; Psychology Press: London, UK, 1985; ISBN 978-1-315-79967-4. [Google Scholar]

- Tao, F.; Zhang, M.; Cheng, J.; Qi, Q. Digital Twin Workshop: A New Paradigm for Future Workshop. Comput. Integr. Manuf. Syst. 2017, 23, 1–9. [Google Scholar]

- Tao, F.; Cheng, Y.; Cheng, J.; Zhang, M.; Xu, W.; Qi, Q. Theory and Technologies for Cyber-Physical Fusion in Digital Twin Shop-Floor. Comput. Integr. Manuf. Syst. 2017, 23, 1603–1611. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 85–113. ISBN 978-3-319-38756-7. [Google Scholar]

- Xu, J.; Kong, D.; Wang, Z.; Zhao, Z.; Yu, C. Construction of Digital Twin System of Rice Supply Chain Based on Industrial Internet. Trans. Chin. Soc. Agric. Mach. 2023, 3, 372–381. [Google Scholar]

- Zhang, Q.; Liu, Z.; Duan, J.; Qin, J. A Novel Method of Digital Twin-Based Manufacturing Process State Modeling and Incremental Anomaly Detection. Machines 2023, 11, 151. [Google Scholar] [CrossRef]

- Yan, B.; Yang, F.; Qiu, S.; Wang, J.; Cai, B.; Wang, S.; Zaheer, Q.; Wang, W.; Chen, Y.; Hu, W. Digital Twin in Transportation Infrastructure Management: A Systematic Review. Intell. Transp. Infrastruct. 2023, 2, liad024. [Google Scholar] [CrossRef]

- Kang, T.; Mo, Y. A Comprehensive Digital Twin Framework for Building Environment Monitoring with Emphasis on Real-Time Data Connectivity and Predictability. Dev. Built Environ. 2024, 17, 100309. [Google Scholar] [CrossRef]

- Duru, A.; Şehirli, E.; Kabalcı, İ. Ultra-Wideband Positioning System Using TWR and Lateration Methods. In Proceedings of the Fourth International Conference on Engineering & MIS 2018, Istanbul, Turkey, 19–20 June 2018; Association for Computing Machinery: New York, NY, USA; pp. 1–4. [Google Scholar]

- Benouakta, A.; Ferrero, F.; Lizzi, L.; Staraj, R. Advancements in Industrial RTLSs: A Technical Review of UWB Localization Devices Emphasizing Antennas for Enhanced Accuracy and Range. Electronics 2024, 13, 751. [Google Scholar] [CrossRef]

- Luo, J.; Zhou, X.; Zeng, C.; Jiang, Y.; Qi, W.; Xiang, K.; Pang, M.; Tang, B. Robotics Perception and Control: Key Technologies and Applications. Micromachines 2024, 15, 531. [Google Scholar] [CrossRef]

- Grieves, M. Deep Reinforcement Learning for Inventory Optimization with Non-Stationary Uncertain Demand. Eur. J. Oper. Res. 2024, 314, 433–445. [Google Scholar]

- Haupt, R.L.; Haupt, S.E. Practical Genetic Algorithms; John Wiley & Sons: Hoboken, NJ, USA, 2023; Volume 7. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley Pub. Co.: Boston, MA, USA, 1989. [Google Scholar] [CrossRef]

- Zhang, G.; Gao, L.; Shi, Y. An Effective Genetic Algorithm for the Flexible Job-Shop Scheduling Problem. Expert. Syst. Appl. 2011, 38, 3563–3573. [Google Scholar] [CrossRef]

- Dong, W.; Li, Y.; Zheng, B.; Zen, S.; Zhang, J. A New Evolutionary Algorithm Based on the Decimal Coding. Wuhan Univ. J. Nat. Sci. 2002, 7, 150–156. [Google Scholar]

- Jenkins, W.M. A Decimal-Coded Evolutionary Algorithm for Constrained Optimization. Comput. Struct. 2002, 80, 471–480. [Google Scholar] [CrossRef]

- Yong-Kui, L. Algorithm for Circle Approximation and Generation. Comput.-Aided Des. 1993, 25, 169–171. [Google Scholar] [CrossRef]

- Si, S. Mathematical Modeling Algorithms and Applications; National Defense Industry Press: Arlington, VA, USA, 2011; ISBN 978-7-118-07647-9. [Google Scholar]

- Allahverdi, A. The Third Comprehensive Survey on Scheduling Problems with Setup Times/Costs. Eur. J. Oper. Res. 2015, 246, 345–378. [Google Scholar] [CrossRef]

- Pinedo, M.L. Scheduling: Theory, Algorithms, and Systems; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Fogel, D.B. Evolutionary Computation: Toward a New Philosophy of Machine Intelligence; Wiley-IEEE Press: Hoboken, NJ, USA, 2011. [Google Scholar]

- Goldberg, D.E.; Deb, K. A Comparative Analysis of Selection Schemes Used in Genetic Algorithms. In Foundations of Genetic Algorithms; Elsevier: Amsterdam, The Netherlands, 1991; Volume 1, pp. 69–93. ISBN 978-0-08-050684-5. [Google Scholar]

- Shannon, C.E. A Mathematical Theory of Communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Deb, K.; Goldberg, D. An Investigation of Niche and Species Formation in Genetic Function Optimization. Comput. Sci. Math. 1989, 6, 42–50. [Google Scholar]

- Back, T. Selective Pressure in Evolutionary Algorithms: A Characterization of Selection Mechanisms. In Proceedings of the First IEEE Conference on Evolutionary Computation. IEEE World Congress on Computational Intelligence, Orlando, FL, USA, 27–29 June 1994. [Google Scholar]

- Adaptive Probabilities of Crossover and Mutation in Genetic Algorithms|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/286385 (accessed on 4 April 2024).

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A Fast Elitist Non-Dominated Sorting Genetic Algorithm for Multi-Objective Optimization: NSGA-II. In Proceedings of the Parallel Problem Solving from Nature PPSN VI; Schoenauer, M., Deb, K., Rudolph, G., Yao, X., Lutton, E., Merelo, J.J., Schwefel, H.-P., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 849–858. [Google Scholar]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-Objective Optimization Using Genetic Algorithms: A Tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Crossover in Genetic Algorithm. Available online: https://www.geeksforgeeks.org/crossover-in-genetic-algorithm/ (accessed on 26 April 2024).

- Katoch, S.; Chauhan, S.S.; Kumar, V. A Review on Genetic Algorithm: Past, Present, and Future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- De Jong, K.A.; Spears, W.M. A Formal Analysis of the Role of Multi-Point Crossover in Genetic Algorithms. Ann. Math. Artif. Intell. 1992, 5, 1–26. [Google Scholar] [CrossRef]

- Hassanat, A.; Almohammadi, K.; Alkafaween, E.; Abunawas, E.; Hammouri, A.; Prasath, V.B.S. Choosing Mutation and Crossover Ratios for Genetic Algorithms—A Review with a New Dynamic Approach. Information 2019, 10, 390. [Google Scholar] [CrossRef]

- De Jong, K.A. An Analysis of the Behavior of a Class of Genetic Adaptive Systems. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 1975. [Google Scholar]

- Wang, L.; Zheng, D. An Effective Hybrid Optimization Strategy for Job-Shop Scheduling Problems. Comput. Oper. Res. 2024, 6, 585–596. [Google Scholar] [CrossRef]

- Bäck, T. Optimal Mutation Rates in Genetic Search. In Proceedings of the 5th International Conference on Genetic Algorithms, Urbana-Champaign, IL, USA, 1 June 1993; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA; pp. 2–8. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Wang, J. Solution method for scheduling of mixed flow shop for panel furniture with buffer constraints. J. For. Eng. 2023, 8, 198–204. [Google Scholar]

| Positioning Technology | Precision | Security | Anti-Interference | Cost |

|---|---|---|---|---|

| Bluetooth | 2–10 m | High | Low | Low |

| RFID | Regional targeting | Low | Lower | Lower |

| Wi-Fi | 5–10 m | Lower | High | Low |

| UWB | 6–15 m | Higher | Higher | High |

| Process | Duration Time | Number |

|---|---|---|

| Outbound | 478 s | 2 |

| Machining | 1196 s | 5 |

| Grinding | 966 s | 4 |

| Dedusting | 241 s | 1 |

| Packaging | 118 s | 2 |

| Method | Maximum Completion Time |

|---|---|

| DSAGA | 5403 s |

| GA | 5933 s |

| Method | GA |

|---|---|

| P/% | 8.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Zheng, Y.; Wu, J.; Wang, Y.; He, J.; Tang, L. Enhancing Manufacturing Excellence with Digital-Twin-Enabled Operational Monitoring and Intelligent Scheduling. Appl. Sci. 2024, 14, 6622. https://doi.org/10.3390/app14156622

Yang J, Zheng Y, Wu J, Wang Y, He J, Tang L. Enhancing Manufacturing Excellence with Digital-Twin-Enabled Operational Monitoring and Intelligent Scheduling. Applied Sciences. 2024; 14(15):6622. https://doi.org/10.3390/app14156622

Chicago/Turabian StyleYang, Jingzhe, Yili Zheng, Jian Wu, Yuejia Wang, Jinyang He, and Lingxiao Tang. 2024. "Enhancing Manufacturing Excellence with Digital-Twin-Enabled Operational Monitoring and Intelligent Scheduling" Applied Sciences 14, no. 15: 6622. https://doi.org/10.3390/app14156622

APA StyleYang, J., Zheng, Y., Wu, J., Wang, Y., He, J., & Tang, L. (2024). Enhancing Manufacturing Excellence with Digital-Twin-Enabled Operational Monitoring and Intelligent Scheduling. Applied Sciences, 14(15), 6622. https://doi.org/10.3390/app14156622