Experimental Investigation on a Water Diversion Shield Segment Using a Newly Developed Model Test Chamber

Abstract

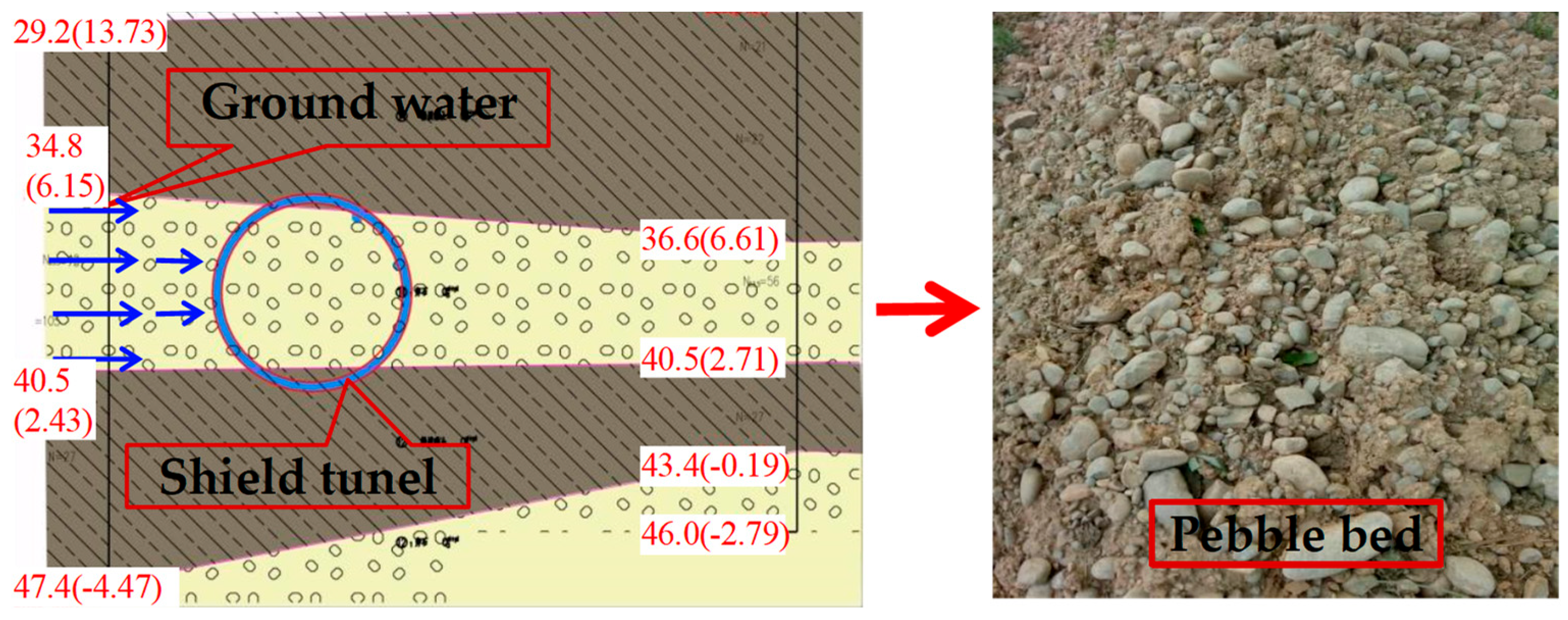

:1. Introduction

2. Materials and Methods

3. Design and Fabrication of Diversion Function Pipe Segment Model Test Box

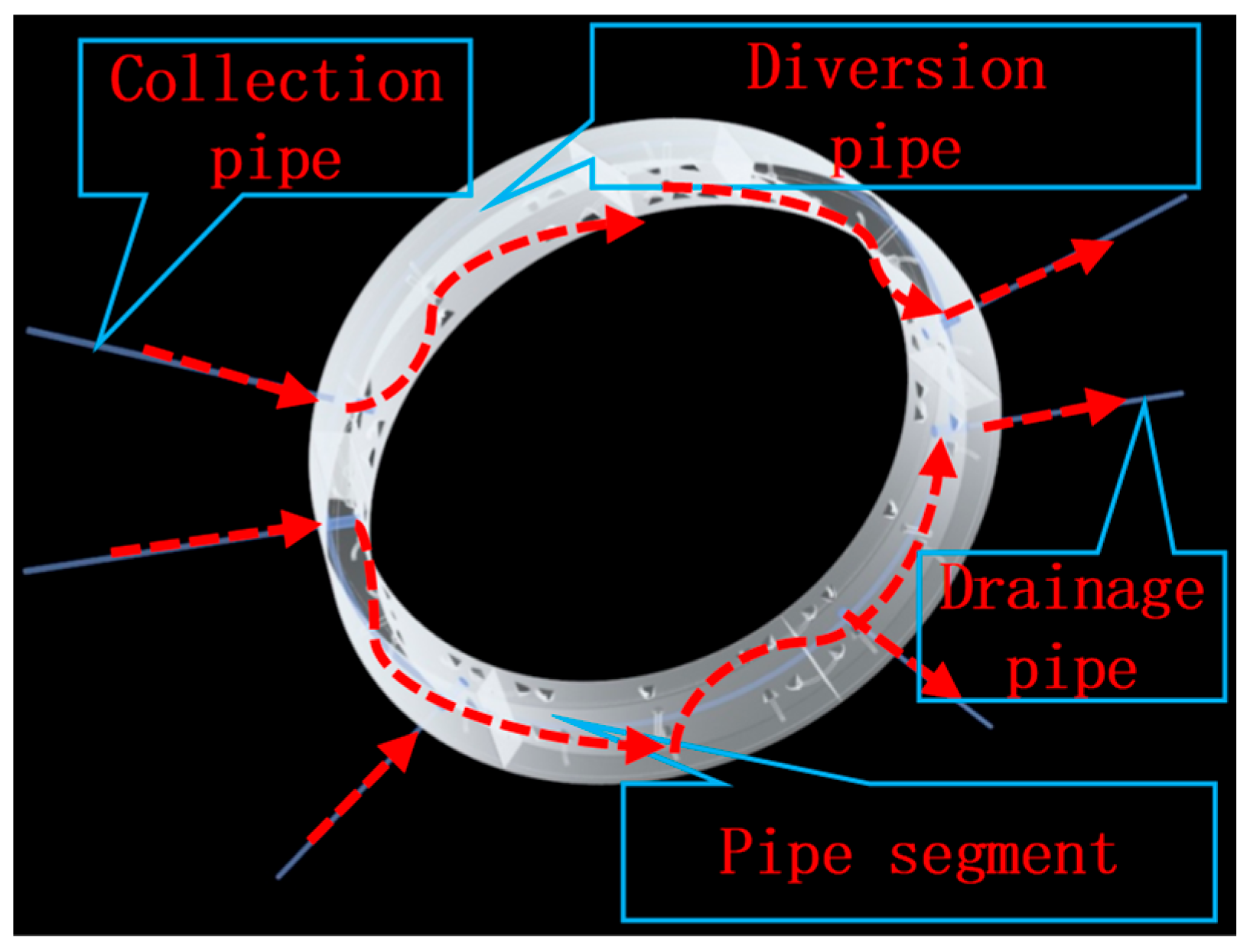

3.1. Working Principle of Diversion Function Pipe Segment

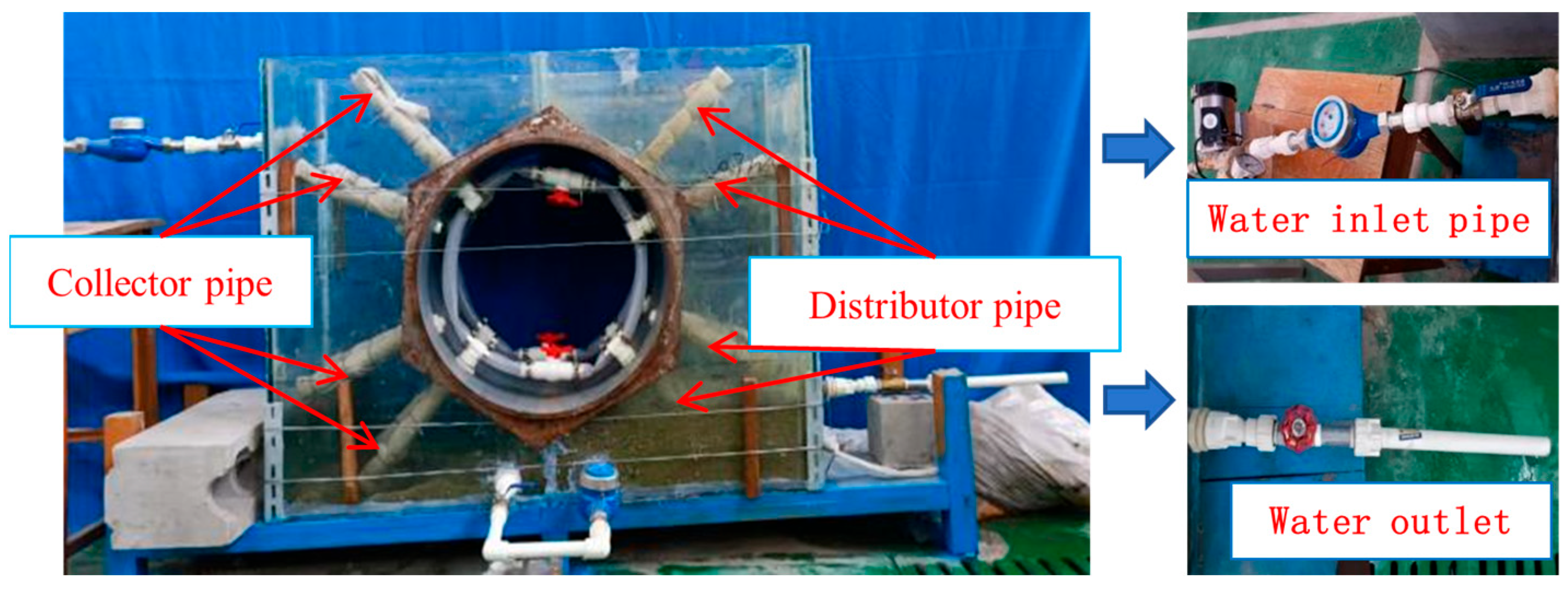

3.2. Design of the Diversion Function Pipe Model Test Box

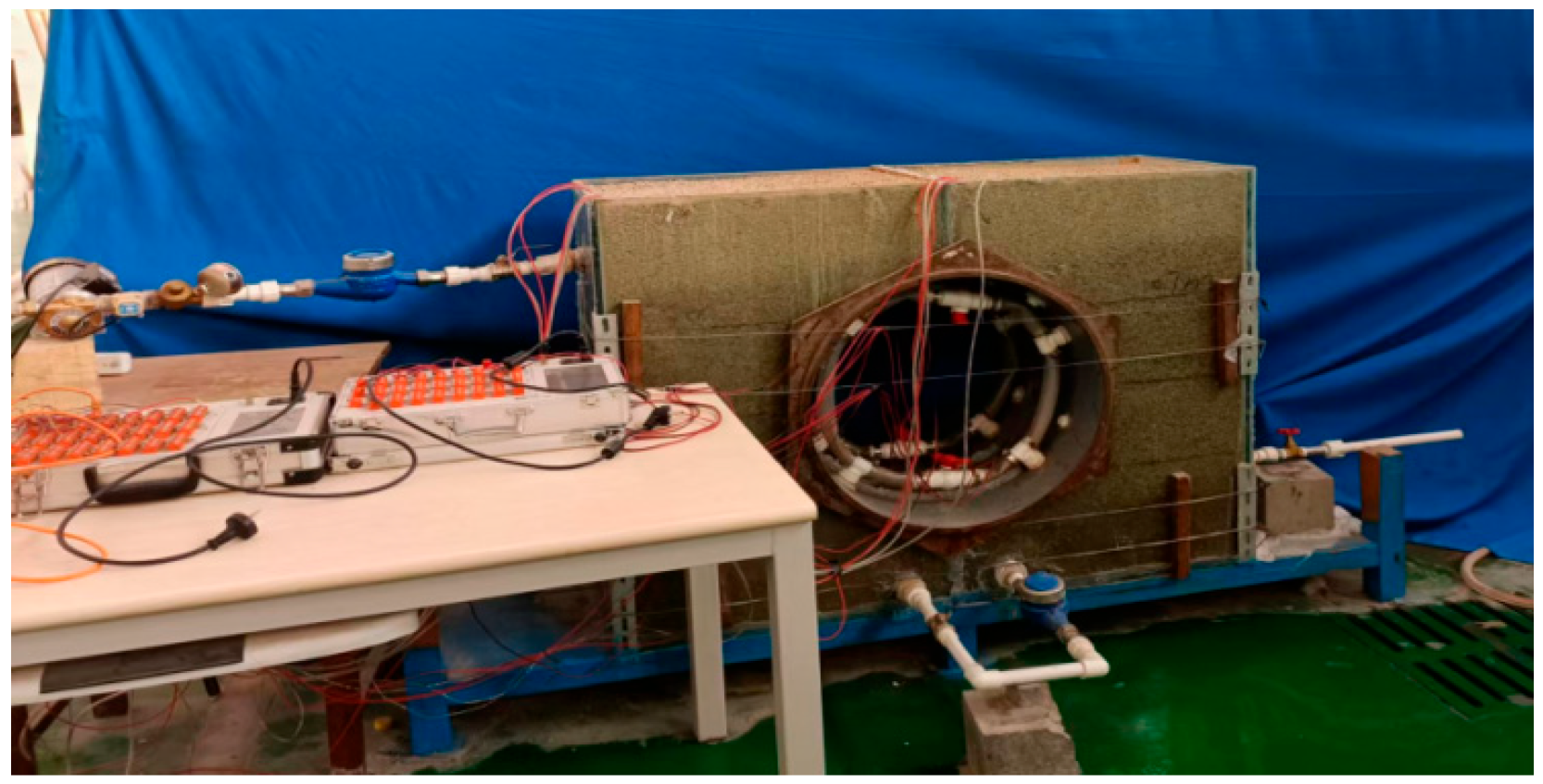

3.3. Fabrication of the Model Box

3.4. Layered Sand Filling of the Test Box and Instrumentation Embedment

3.4.1. Layered Sand Filling of the Test Box

3.4.2. Instrumentation Embedment in the Test Box

3.4.3. Strain Gauge Application

4. Analysis of Test Results for Diversion Function Pipe Segment Models

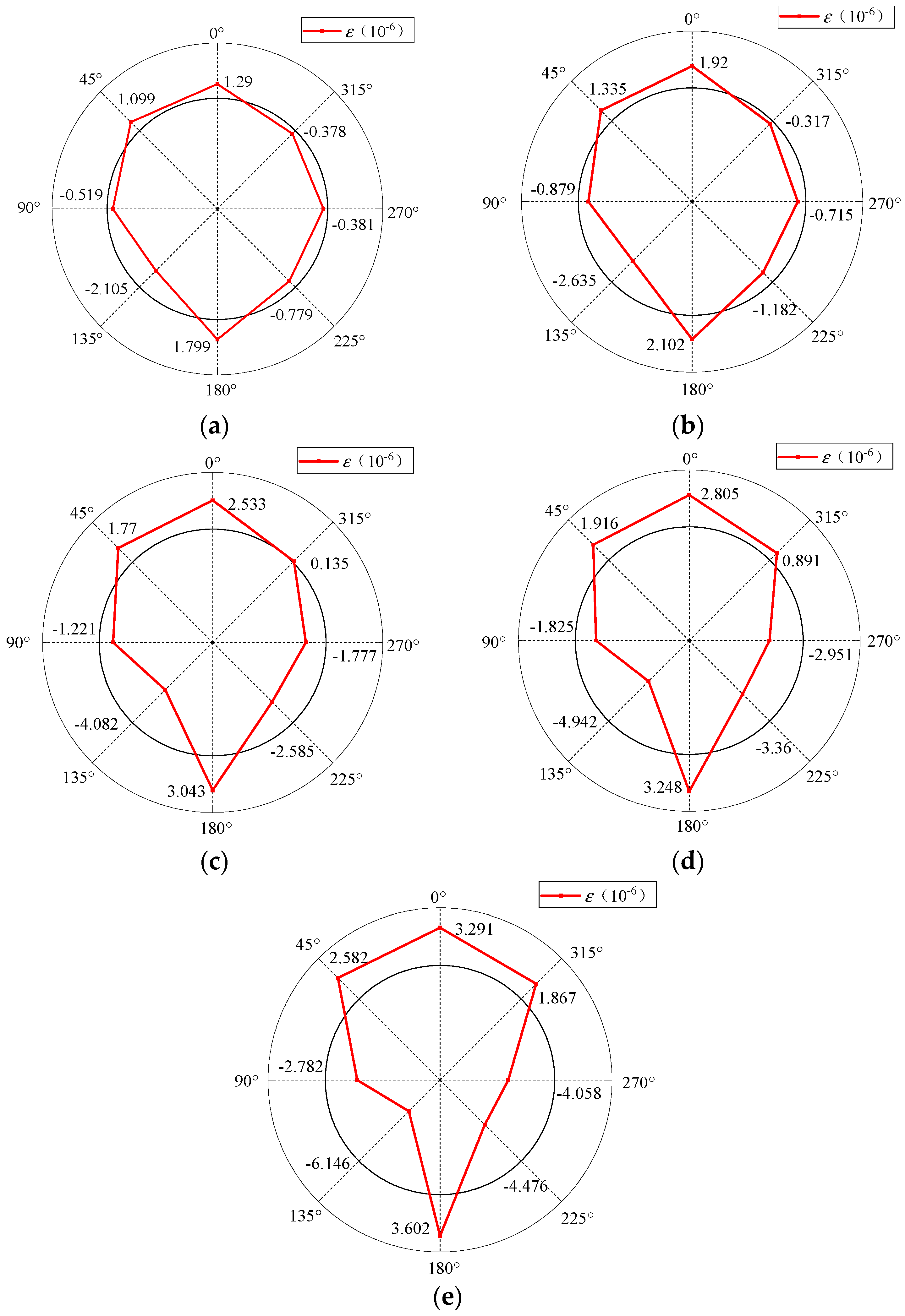

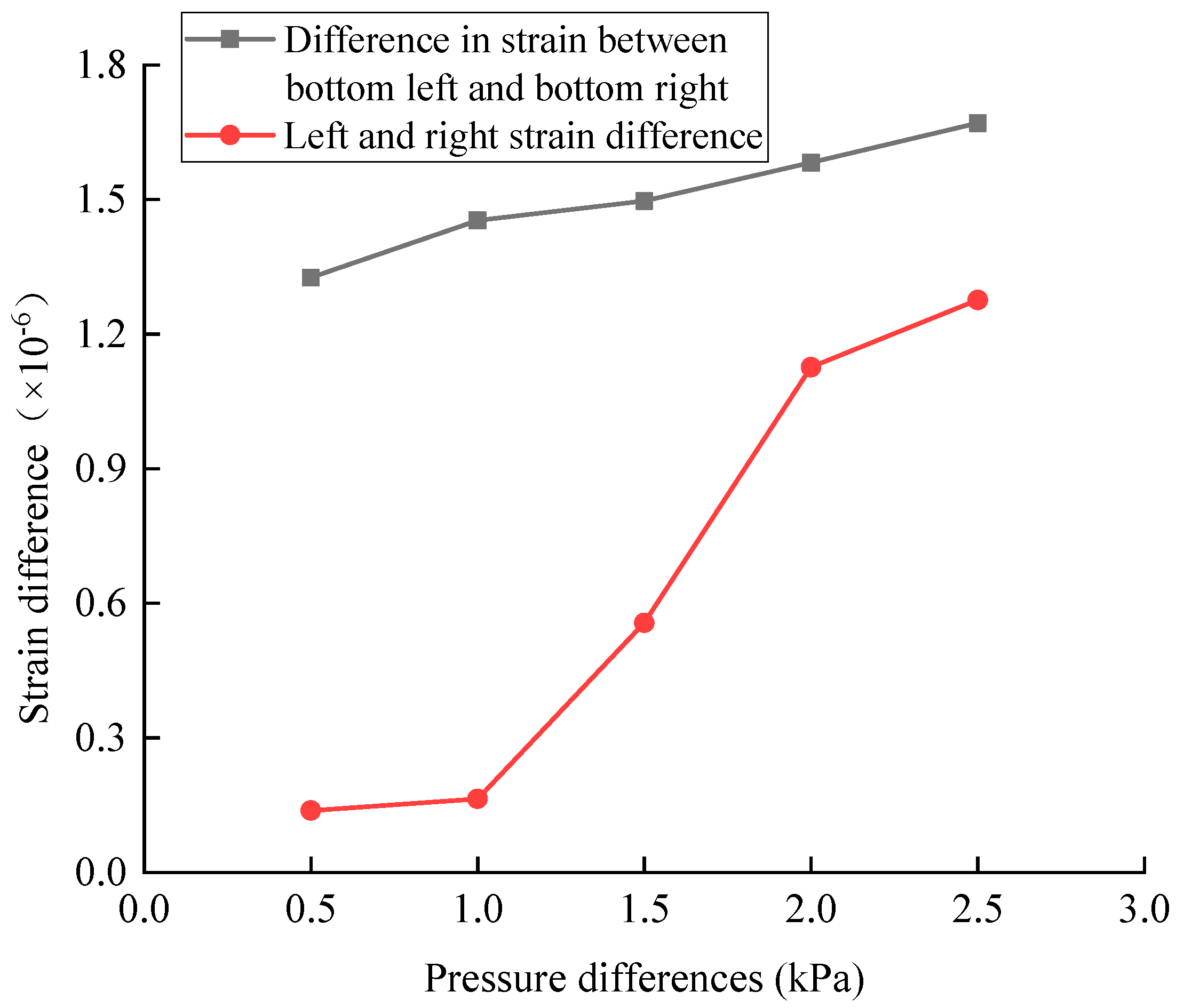

4.1. Analysis of Strain in the Pipe Segment under Different Pressures

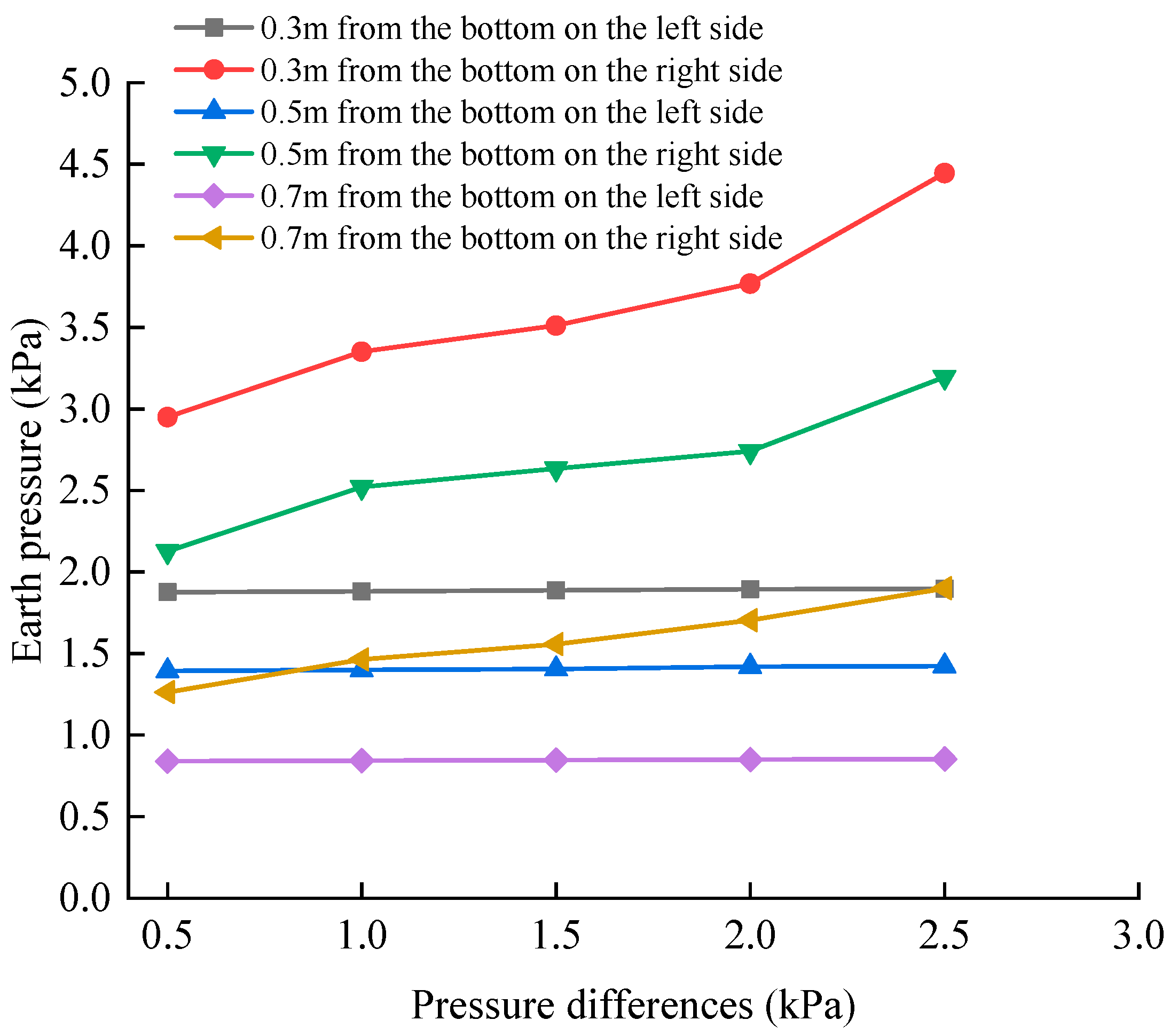

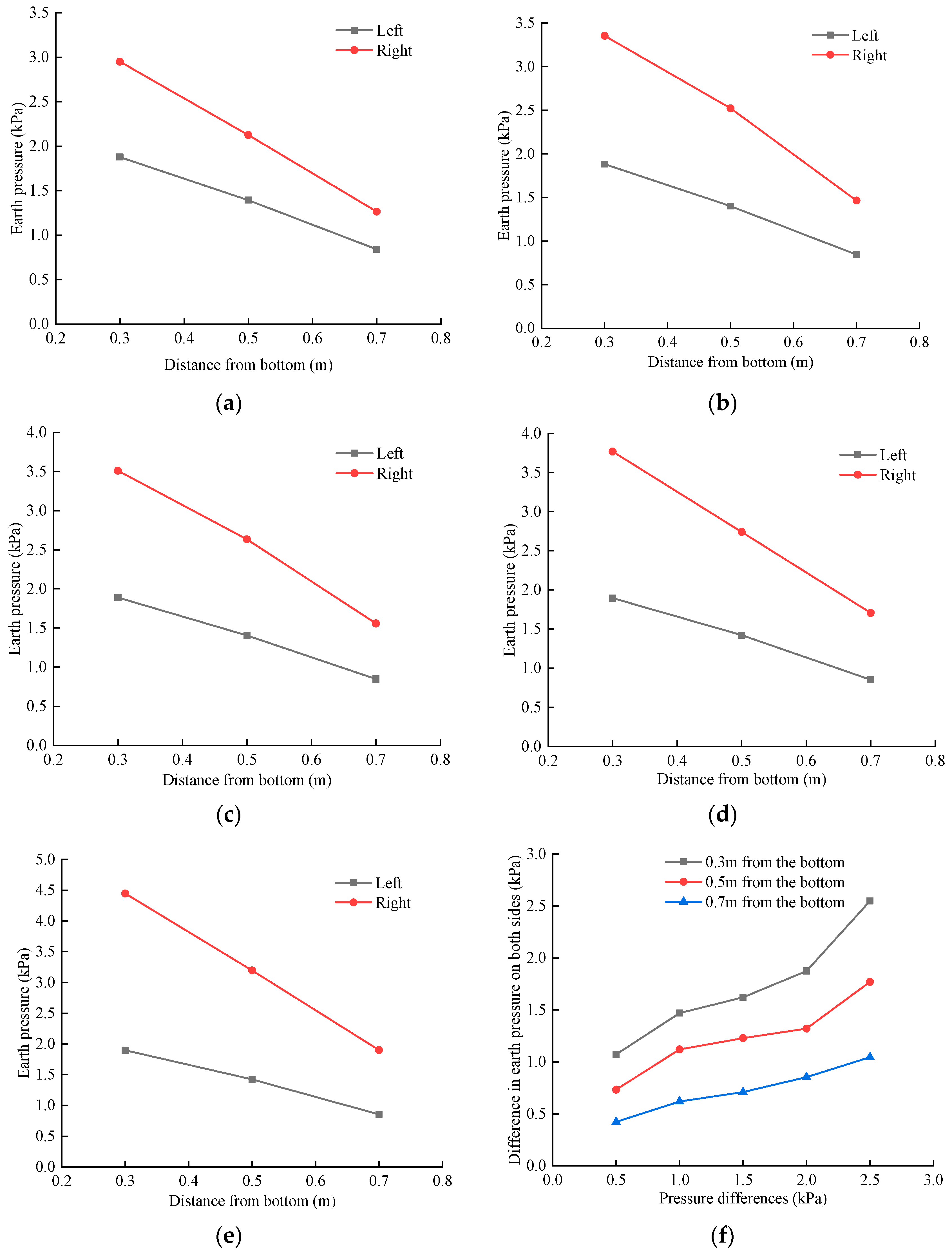

4.2. Analysis of Earth Pressure Distribution on Both Sides of the Pipe Segment under Different Pressures

4.2.1. Distribution and Variation in Earth Pressure on Both Sides of the Pipe Segment

4.2.2. Variation in Earth Pressure on Both Sides of the Pipe Segment at Different Depths

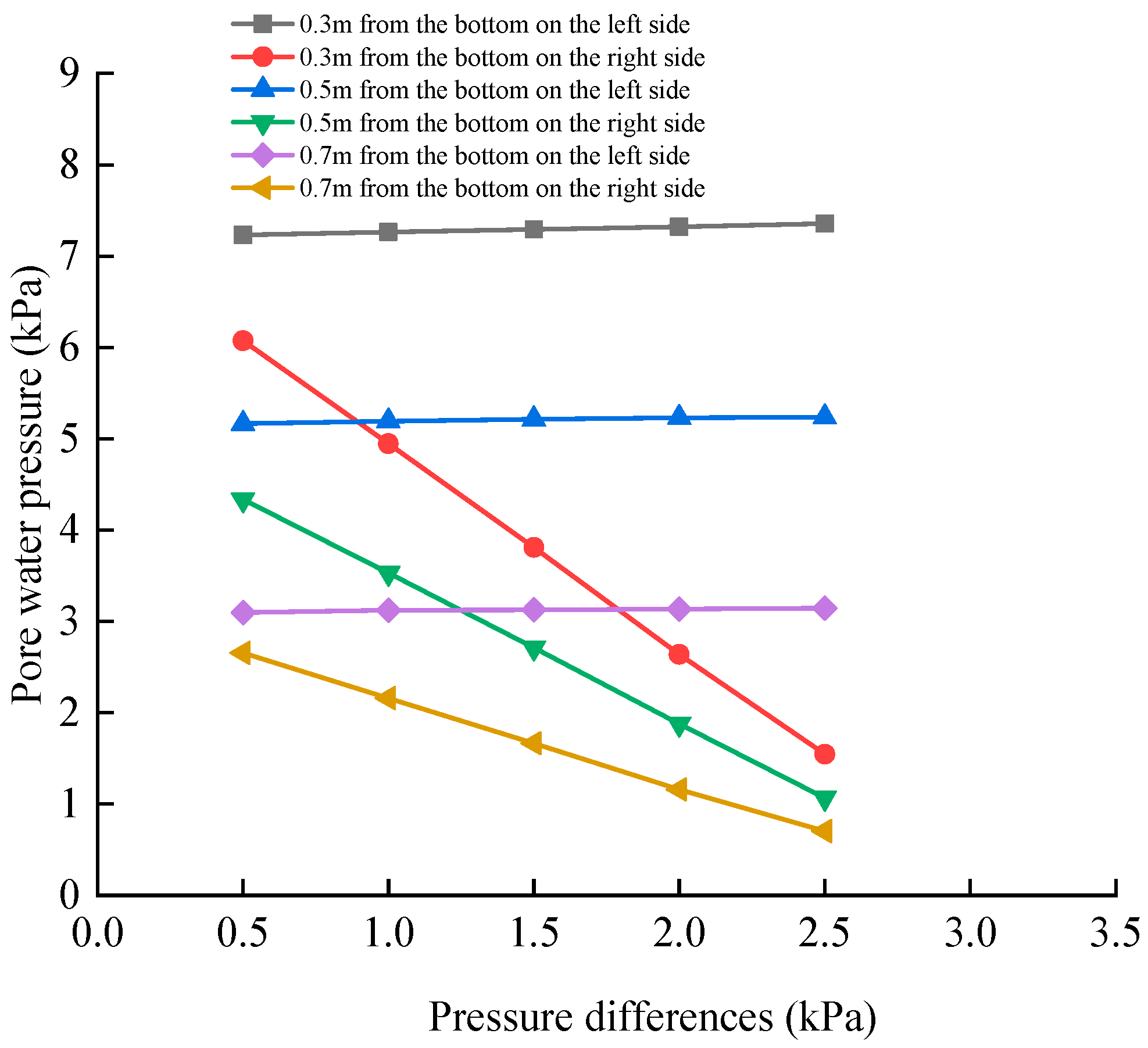

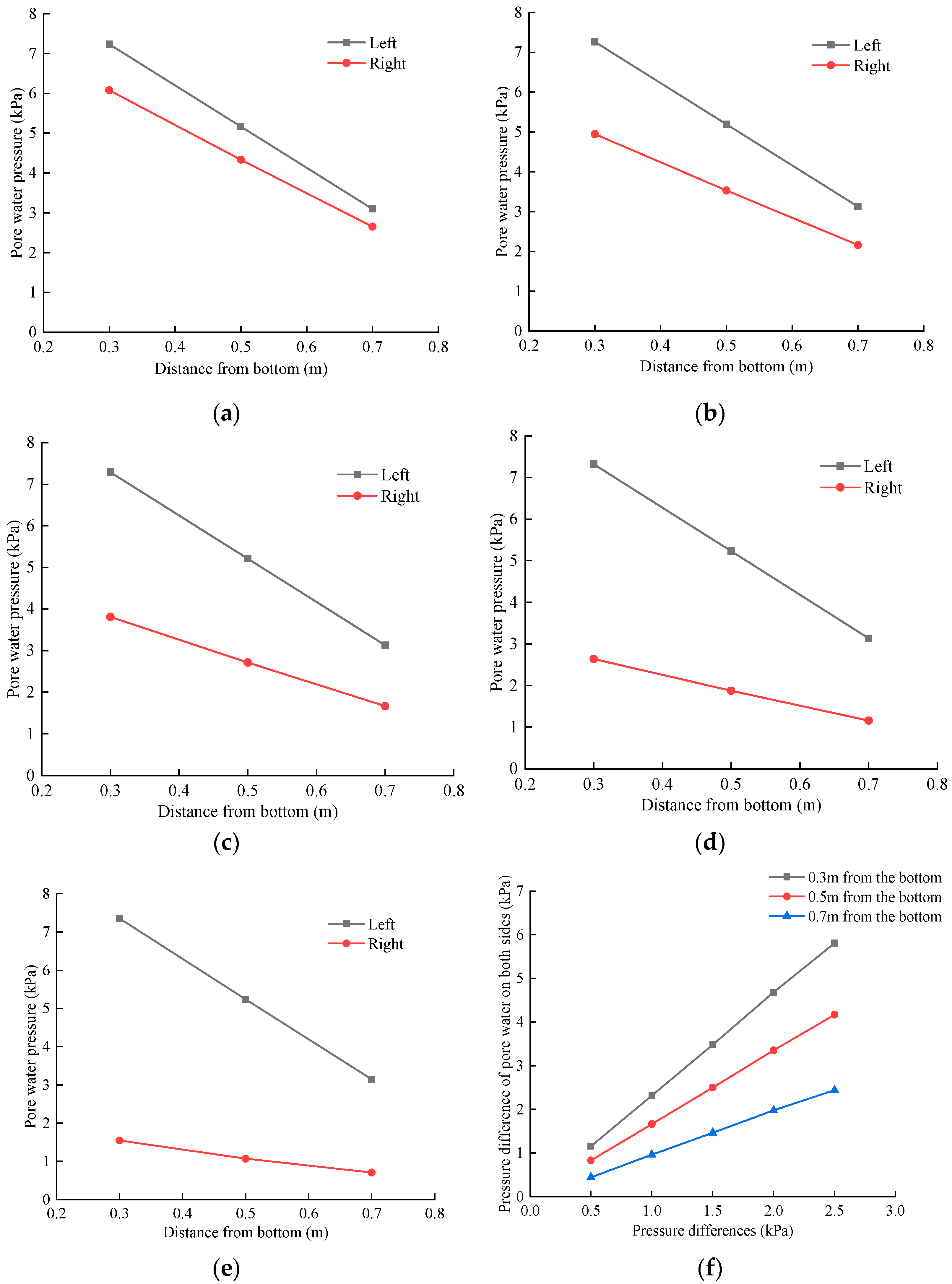

4.3. Analysis of Pore Water Pressure on Both Sides of the Pipe Segment under Different Pressures

4.3.1. Distribution and Change in Pore Water Pressure on Both Sides of the Pipe Segment

4.3.2. Changes in Pore Water Pressure on Both Sides of the Pipe Segment at Different Depths

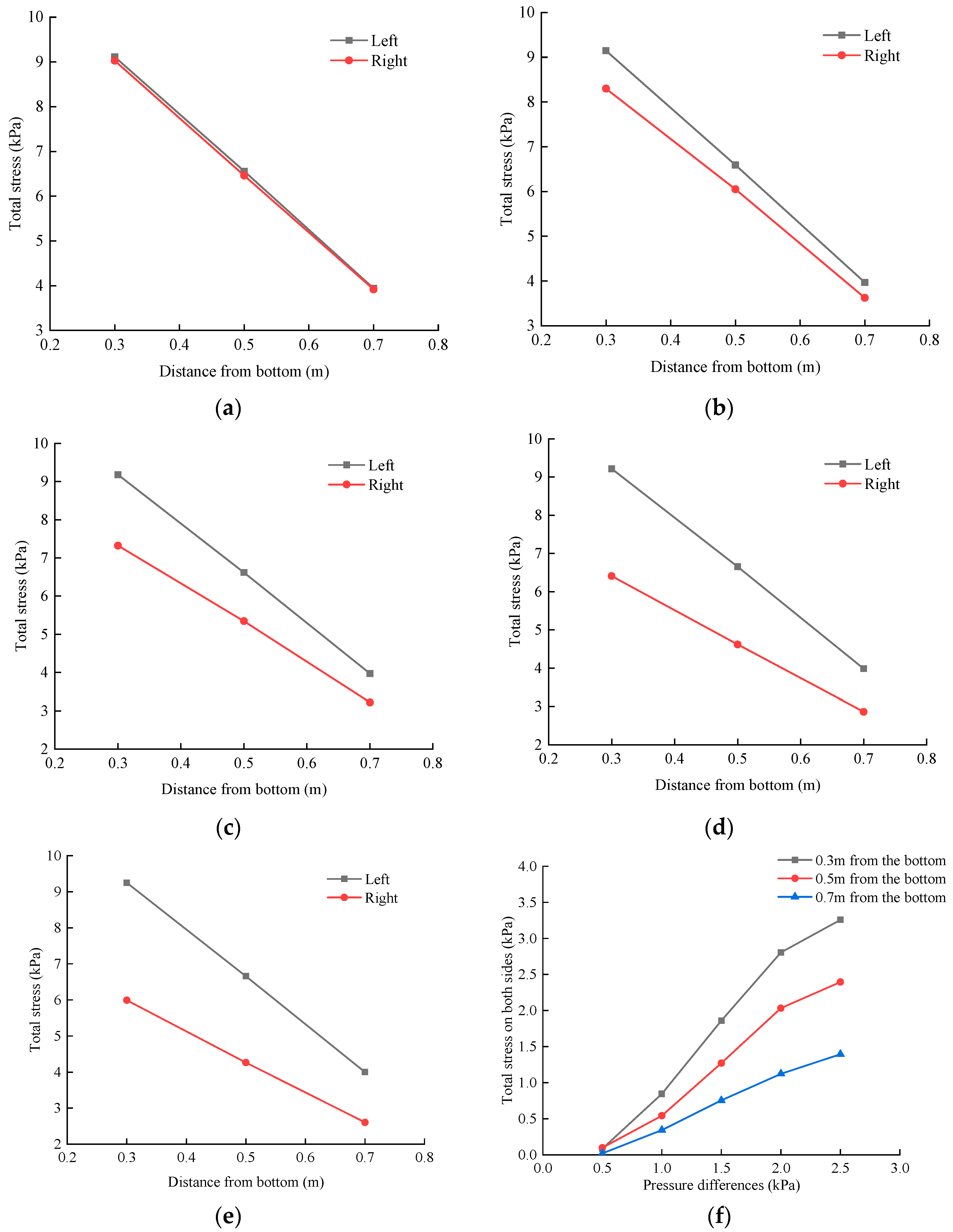

4.4. Analysis of Total Stresses on Both Sides of the Pipe Segment under Different Differential Pressures

4.4.1. Distribution and Variation in Total Stress on Both Sides of the Pipe Segment

4.4.2. Variation in Total Stress on Both Sides of the Pipe Segment at Different Depths

5. Conclusions

- (1)

- The action of back-water and unsymmetrical pressure in the sand and water on the left and right sides of the pipe segment exerts pressure on the pipe segment, causing it to deform. This leads to the compression of the top and bottom of the pipe segment, with a tendency to bulge outward. Meanwhile, the lower left, lower right, and left and right sides of the pipe segment are stretched, with a tendency for concave inward deformation. The lower left and lower right sides of the pipe segment are subjected to a significantly higher pressure from sand and water than that on the upper part of the pipe segment. The greater the difference in pressure is, the more pronounced the asymmetric nature of the strain value of the pipe segment is.

- (2)

- The soil pressure difference between the two sides of the pipe segment increases with the increase in differential pressure. This results in a greater impact at greater depths, which, in turn, causes greater pipe segment unsymmetrical pressure, more serious pipe segment bending deformation, and an increased risk of leakage at the pipe segment nodes. Furthermore, this also leads to greater difficulties in operation and maintenance. The diversion function of the pipe segment channeling can effectively reduce the pressure difference between the two sides.

- (3)

- The greater the pressure difference is, the more pronounced the influence of unsymmetrical pressure under pore water pressure is, and the closer the pipe segment is to the bottom of the position, the greater the likelihood of deformation is. Consequently, the pressure difference also increases the total stress difference between the two sides of the pipe segment. The lower part of the pipe segment is more susceptible to the bias effect, which renders it more prone to deformation.

- (4)

- The pipe segment can facilitate the circulation of confined water on both the sides and reduce the unsymmetrical pressure between the two sides through the inflow function. This can effectively address the bias pressure problem on both the sides of the pipe segment, protect the spring system and the ecology of the groundwater, mitigate the influence of bias pressure on the pipe segment, and alleviate the difficulties in the operation and maintenance of the pipe segment.

- (5)

- The industrial production, on-site experimentation, and research of water diversion shield segments that can adapt to different geology conditions will be the study focus in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hua, F.C. Application of FLAC3D to seepage field of Qingdao metro. Rock Soil Mech. 2013, 34, 299–304. [Google Scholar]

- Gong, C.J.; Wang, Y.Y.; Peng, Y.C.; Ding, W.; Lei, M.; Da, Z.; Shi, C. Three-dimensional Coupled Hydromechanical Analysis of Localized Joint Leakage in Segmental Tunnel Linings. Tunn. Undergr. Space Technol. 2022, 130, 104726. [Google Scholar] [CrossRef]

- Qiu, H.S.; Qiu, R.H.; Luo, G.; Ayasrah, M.M.; Wang, Z. Study on the Mechanical Behavior of Fluid–Solid Coupling in Shallow Buried Tunnels Under Different Biased Terrain. Symmetry 2022, 14, 1339. [Google Scholar] [CrossRef]

- Rong, C.X.; Cheng, H. Stability Analysis of Rocks around Tunnel with Ground Water Permeation. Chin. J. Rock Mech. Eng. 2004, 23, 741–744. [Google Scholar]

- Wang, K.Z.; Li, Z.K. Study on 3d physical model test of seepage of deep-buried long and large diversion tunnel. Chin. J. Rock Mech. Eng. 2009, 28, 725–731. [Google Scholar]

- Zou, J.F.; Li, S.S.; Zhang, Y.; Yuan, Z. Solution and Analysis of Circular Tunnel for the Strain-Softening Rock Masses Considering the Axial in Situ Stress and Seepage Force. Chin. J. Theor. Appl. Mech. 2014, 46, 747–755. [Google Scholar]

- Zhang, B.Q.; Wang, Q.Y.; Lu, X.Y. Analytical Solution for non-Darcian Seepage Field of a Shallow Circular Tunnel in Soft Soil. Rock Soil Mech. 2018, 39, 4377–4384. [Google Scholar]

- Zhu, C.W.; Ying, H.W.; Gong, X.N. Analytical Solutions for Seepage Fields of Underwater Tunnels with Arbitrary Burial Depth. Chin. J. Geotech. Eng. 2017, 39, 1984–1991. [Google Scholar]

- Zhu, C.W.; Ying, H.W.; Gong, X.N.; Shen, H.W.; Wang, X. Analytical Solutions to Seepage Field of Underwater Twin Parallel Tunnels. Chin. J. Geotech. Eng. 2019, 41, 355–360. [Google Scholar]

- Guo, Y.F.; Wang, H.N.; Jiang, M.J. Analytical Solutions of Seepage Field for Underwater Shallow-Buried Parallel Twin Tunnels. Chin. J. Geotech. Eng. 2021, 43, 1088–1096. [Google Scholar]

- Chen, F.B.; Yang, Z.; Huang, D.Y. Tunnel Stability Analysis of Influence Factors under the Action of Seepage Field of Rich Water. J. Transp. Sci. Eng. 2013, 29, 34–39. [Google Scholar]

- Wang, Z.L.; Ahen, L.F.; Wu, Z. Influence of Local Water Leakage of Shield Tunnels on the Pore Water Pressure of Soil Masses. Mod. Tunn. Technol. 2017, 54, 89–95. [Google Scholar]

- Wang, Q.S.; Feng, K.; Li, D.B.; He, C.; Peng, Z.; Guo, H. Ground Pore Water Pressure Disturbed by Slurry Balanced Shield Tunneling. Tunn. Constr. 2019, 39, 266–273. [Google Scholar]

- Yu, L.; Lyu, C.; Wang, M.; Xu, T. Three-dimensional Upper Bound Limit Analysis of a Deep Soil-tunnel Subjected to Pore Pressure Based on the Nonlinear Mohr-Coulomb Criterion. Comput. Geotech. 2019, 112, 293–301. [Google Scholar] [CrossRef]

- Lu, K.D. Study on Distribution Characteristics of Pore Water Pressure in The Cross-River of Shield Tunnel. Build. Tructure 2020, 50, 759–763. [Google Scholar]

- Liu, Y.; Zhao, C.P.; Lai, X.L. Research on Groundwater Inflow and Distribution of Pore Water Pressure of Shallow Tunnel in Water-Rich Region. J. Shenyang Univ. (Nat. Sci.) 2013, 29, 23–29. [Google Scholar]

- Zhang, D.M.; Liu, Y.; Huang, H.W. Leakage-induced Settlement of Ground and Shield Tunnel in Soft Clay. J. Tongji Univ. (Nat. Sci.) 2013, 41, 1185–1190. [Google Scholar]

- Li, X.Y.; Liu, G.B.; Liu, M.; Feng, Q.G. Analytical Study on Dissipation of Excess Pore Water Pressure around Tunnels with Semi-Permeable Boundary Conditions. Chin. J. Geotech. Eng. 2014, 36, 75–82. [Google Scholar]

- Xu, T.; Adam, B.; Wout, B. Analytical Solutions for Excess Pore Water Pressures Generated by TBM Tunnelling in a Semi-confined Aquifer. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2021, 118, 104162. [Google Scholar] [CrossRef]

- Huang, F.; Yang, X.L. Upper Bound Limit Analysis of Collapse Shape for Circular Tunnel Subjected to Pore Pressure Based on the Hoek–Brown Failure Criterion. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2011, 26, 614–618. [Google Scholar] [CrossRef]

- Zhang, D.M.; Ran, L.Z.; Yan, J.Y. Effect of Grouting on Tunnel Leakage-Induced Pore Pressure Change in Saturated Soft Soils. Rock Soil Mech. 2017, 38, 3427–3435+3444. [Google Scholar]

- Tang, Y.Q.; Cui, Z.D.; Zhang, X. Dynamic Response and Pore Pressure Model of the Saturated Soft Clay around the Tunnel Under Vibration Loading of Shanghai Subway. Eng. Geol. 2008, 98, 126–132. [Google Scholar] [CrossRef]

- Lina MG, C.; Siavash, G.; Jean, S. Effect of Anisotropy and Hydro-mechanical Couplings on Pore Pressure Evolution During Tunnel Excavation in Low-permeability Ground. Int. J. Rock Mech. Min. Sci. 2017, 97, 1–14. [Google Scholar]

- Huang, H.W.; Liu, Y.; Zhang, D.M. Influence of Long-Term Seepage of Shield Tunnel on Inner Force of Segments and Ground Surface Settlement. China Railw. Sci. 2012, 33, 36–43. [Google Scholar]

- Liu, Y.; Jiang, M.M. Long-term influence of leakage at shield tunnel joint on its deformation and inner force. Yangtze River 2017, 48, 96–102. [Google Scholar]

- Ye, Z.; Fu, A.R.; Liu, H.B. Effect of seepage erosion of tunnel crown on ground settlement and structural deformation in shield tunnelling. J. Hohai Univ. (Nat. Sci.) 2021, 49, 279–287. [Google Scholar]

- Liang, Z.Y.; Chen, H.; Liang, Z. Research on Mechanical Characteristics of Underwater Shield Tunnel Segment. Munic. Eng. Technol. 2020, 38, 146–148. [Google Scholar]

- Lin, R.A.; Liu, B.Y. Mechanical Characteristic Investigation of Shield Tunnel Segment in Water-rich Mucky Stratum. China J. Highw. Transp. 2018, 1, 112–118. [Google Scholar]

- Li, X.; Zhang, Y.S.; Geng, A.P.; Geng, F.J.; Wu, J.Q. Measurement and Analysis of Structure Behavior of Cross-river Shield Tunnel with Large Diameter. Chin. J. Undergr. Space Eng. 2022, 18, 297–304. [Google Scholar]

- Zhang, D.W.; Liu, Z.X.; Shen, G.G.; E, J. Measurement of earth pressure of Shallow Buried Tunnel with Super Large Diameter and Applicability Evaluation of Calculation Method. Rock Soil Mech. 2019, 40, 91–98. [Google Scholar]

- Li, X.; Zhou, S.H.; Gong, Q.M.; Chen, C.J. Evaluation of earth pressure around a Deeply Buried Metro Shield Tunnel with a Large Cross-Section under High Water Pressure Conditions. Rock Soil Mech. 2015, 36, 1415–1420+1427. [Google Scholar]

- Zhou, S.H.; Liu, C.; Li, X.; Jin, H. Reverse Calculation and Analysis of Measured Internal Force of Deeply Buried Shield Tunnels with Large Cross-section Under High Water Pressure Conditions. J. Tongji Univ. (Nat. Sci.) 2017, 45, 970–977. [Google Scholar]

- Du, C.W.; Wang, M.S.; Tan, Z.S. Analytic Solution for Seepage Field of Subsea Tunnel and Its Application. Chin. J. Geotech. Eng. 2011, 30, 3567–3573. [Google Scholar]

- Xie, J.C.; Huang, X.; Jin, G.L.; Zhang, Z.X. Seepage Characteristics and Mechanical Response of Shield Tunnels under Localized Leakage and Exosmosis. Rock Soil Mech. 2023, 44, 1179–1189. [Google Scholar]

| Main Parameter | Parameter Value | |

|---|---|---|

| Earth Pressure Cell | Pore Water Pressure Cell | |

| Overall dimension (mm) | Diameter = 28 Thickness = 6.5 | Diameter = 13 Thickness = 12 |

| range (MPa) | 0.1 | 0.05 |

| Accuracy level (level) | 0.2 | 0.2 |

| Bridge connection method | Full bridge | Full bridge |

| Supply bridge voltage (V) | - | ≤10 |

| Bridge resistance (Ω) | - | 350.0 |

| Full-scale output (με) | 400–800 | - |

| Overload capacity (%) | ≤120 | ≤120 |

| Insulation level (MΩ) | >500 | >500 |

| Lead length (m) | 3 | 3 |

| Water and moisture proof performance | Operation in saturated water media | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Xing, S.; Tian, Z.; Zhang, B.; Liu, W. Experimental Investigation on a Water Diversion Shield Segment Using a Newly Developed Model Test Chamber. Appl. Sci. 2024, 14, 6647. https://doi.org/10.3390/app14156647

Sun Y, Xing S, Tian Z, Zhang B, Liu W. Experimental Investigation on a Water Diversion Shield Segment Using a Newly Developed Model Test Chamber. Applied Sciences. 2024; 14(15):6647. https://doi.org/10.3390/app14156647

Chicago/Turabian StyleSun, Yuxuan, Shuai Xing, Zhongxi Tian, Boliang Zhang, and Wanrong Liu. 2024. "Experimental Investigation on a Water Diversion Shield Segment Using a Newly Developed Model Test Chamber" Applied Sciences 14, no. 15: 6647. https://doi.org/10.3390/app14156647

APA StyleSun, Y., Xing, S., Tian, Z., Zhang, B., & Liu, W. (2024). Experimental Investigation on a Water Diversion Shield Segment Using a Newly Developed Model Test Chamber. Applied Sciences, 14(15), 6647. https://doi.org/10.3390/app14156647