Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review

Abstract

1. Introduction

2. The Process Plant Inspection and Maintenance System

2.1. Classification of Current Plant Maintenance Strategies

2.2. Improve TAM Efficiency by Conducting a Survey Questionnaire

2.3. Improve TAM Efficiency with Assessment Tools

2.4. Improve TAM Efficiency with Software Development

2.5. Improve TAM Efficiency with the Risk-Based Inspection Method

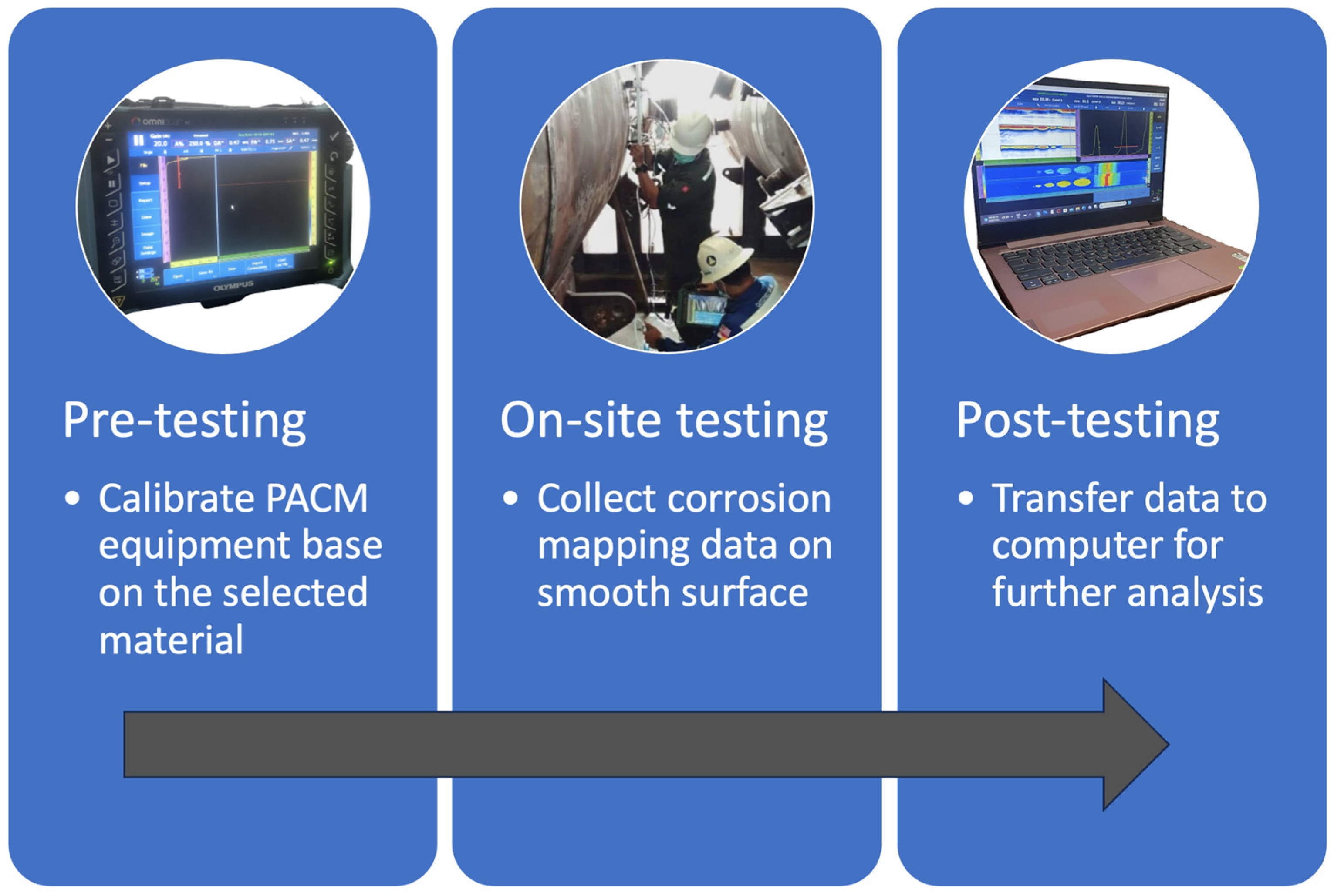

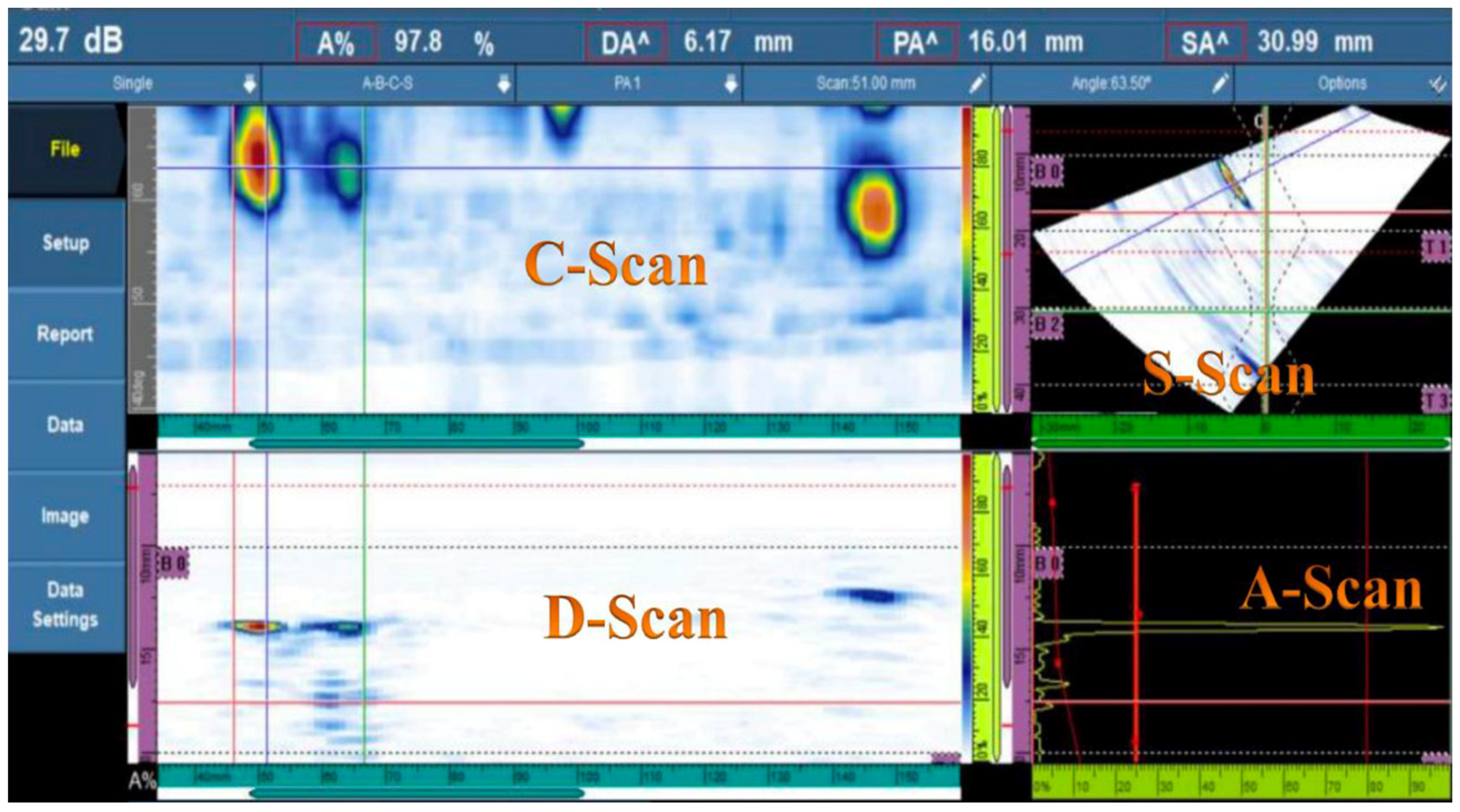

2.6. Potential Non-Destructive Testing Techniques for On-Stream Inspection

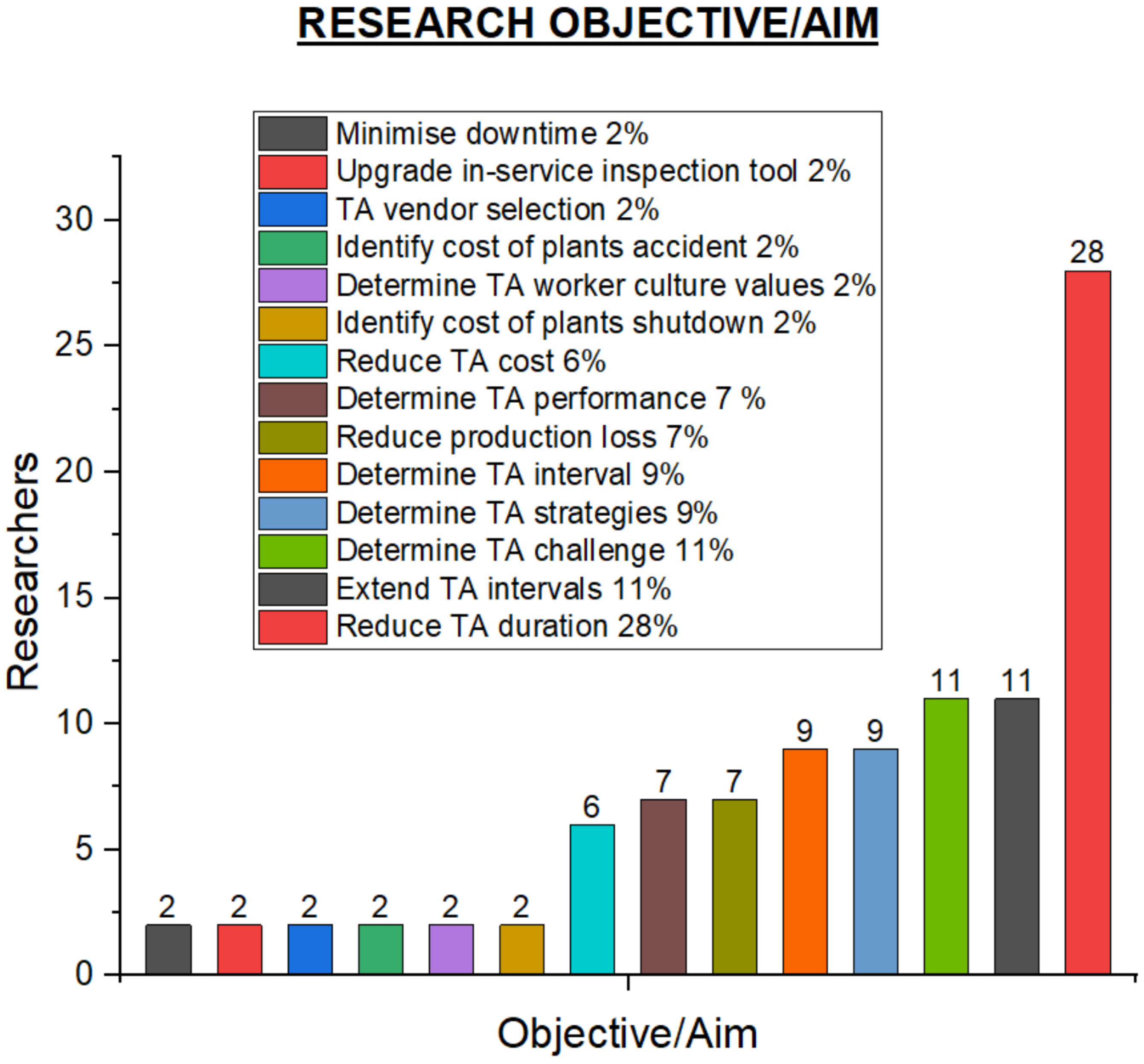

2.7. Literature Review Summary

3. Conclusions

4. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishnankutty, P.; Hwang, B.G.; Caldas, C.H.; Muralidharan, S.; de Oliveira, D.P. Assessing the Implementation of Best Productivity Practices in Maintenance Activities, Shutdowns, and Turnarounds of Petrochemical Plants. Sustainability 2019, 11, 1239. [Google Scholar] [CrossRef]

- Nageswaran, C. Maintaining the Integrity of Process Plant Susceptible to High Temperature Hydrogen Attack. Part 1: Analysis of Non-Destructive Testing Techniques; TWI Ltd.: Cambridge, UK, 2018. [Google Scholar]

- Ghazali, Z.; Lim, M.R.T.; Jamak, A.B.S.A. Maintenance Performance Improvement Analysis Using Fuzzy Delphi Method a Case of an International Lube Blending Plant in Malaysia. J. Qual. Maint. Eng. 2019, 25, 162–180. [Google Scholar] [CrossRef]

- Yin, Z.; Caldas, C.; De Oliveira, D.; Hwang, B.-G.; Shan, M. Mechanization Level Assessment and Technology Identification for Productivity Improvement in Petrochemical Facility Maintenance. J. Qual. Maint. Eng. 2019, 27, 1–20. [Google Scholar] [CrossRef]

- Čepin, M. Evaluation of the Importance Factors of the Power Plants within the Power System Reliability Evaluation. Eksploat. Niezawodn. Maint. Reliab. 2019, 21, 631–637. [Google Scholar] [CrossRef]

- Al-Marri, A.N.; Nechi, S.; Ben-Ayed, O.; Charfeddine, L. Analysis of the Performance of TAM in Oil and Gas Industry: Factors and Solutions for Improvement. Energy Rep. 2020, 6, 2276–2287. [Google Scholar] [CrossRef]

- Muralidharan, S.; Krishnankutty, P.; Hwang, B.G.; Caldas, C.; Mulva, S. Enhancing Labour Productivity in Petrochemical Construction and Maintenance Projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–22 July 2018; Volume 2, pp. 829–839. [Google Scholar] [CrossRef]

- Musah, A.A.; Ghazali, Z.; Nizam Shahrul Isha, A. Turnaround Maintenance Workers Cultural Values and Conflict Management Style Preference: Moderating Role of Temperament. SHS Web Conf. 2018, 56, 02004. [Google Scholar] [CrossRef][Green Version]

- Waratimi, E.; Wordu, A.A.; Nkoi, B. Statistical Model to Evaluate Turn-Around-Maintenance of Port Harcourt Refinery in Nigeria. Am. J. Eng. Res. 2018, 7, 166–178. [Google Scholar]

- Vianello, C.; Milazzo, M.F.; Maschio, G. The Management of Industrial Safety in Chemical and Petrochemical Industry by Comparing Costs and Benefits. Chem. Eng. Trans. 2018, 67, 379–384. [Google Scholar] [CrossRef]

- Elwerfalli, A.; Alsadaie, S.; Mujtaba, I.M. Estimation of Shutdown Schedule to Remove Fouling Layers of Heat Exchangers Using Risk-Based Inspection (RBI). Processes 2021, 9, 2177. [Google Scholar] [CrossRef]

- Jory, C. Tips for Internal Corrosion Using the Echo to Echo Technique with Compression. NDT Tech. 2019, 18, 8–11. [Google Scholar]

- Jamil, J.; Yahya, S.Y.S. Corrosion Assessment Using Advanced Ultrasonic Measurement Technique. IOP Conf. Ser. Mater. Sci. Eng. 2019, 554, 012004. [Google Scholar] [CrossRef]

- Tangadi, S.; Telidevara, N.K.S.P.; Maddi, H.K. PAUT as Tool for Corrosion Damage Monitoring. In Proceedings of the Indian National Seminar & Exhibition on Non-Destructive Evaluation NDE 2015, Hyderabad, India, 26–28 November 2015. [Google Scholar]

- Mohan, B.C.; Jeyasekhar, M.C.; Duhan, K.; Land, I.; Belait, K.; Manager, C. Oil and Gas Assets Condition Monitoring by High Sensitive PAUT Hydroform Corrosion Monitoring Technique for Integrity Assessment. In Proceedings of the NDE 2019—Conference & Exhibition, Bengaluru, India, 5–7 December 2019. [Google Scholar]

- Turcu, F.; Jedamski, T.; Treppmann, D.R.D. In-Service Corrosion Mapping—Challenges for the Chemical Industry. In Proceedings of the 12th European Conference on Non-Destructive Testing (ECNDT 2018), Gothenburg, Sweden, 11–15 June 2018; pp. 1–8. [Google Scholar]

- Grzejda, R. Modelling Nonlinear Preloaded Multi-Bolted Systems on the Operational State. Eng. Trans. 2016, 64, 525–531. [Google Scholar]

- Grzejda, R. Study of the Distribution of Bolt Forces in a Multi-Bolted System under Operational Normal Loads. AIP Conf. Proc. 2019, 2078, 020011. [Google Scholar] [CrossRef]

- Grzejda, R. Impact of Nonlinearity of the Contact Layer between Elements Joined in a Multi-Bolted System on Its Preload. Mech. Mech. Eng. 2017, 21, 541–548. [Google Scholar] [CrossRef]

- Al-turki, U.; Duffuaa, S.; Bendaya, M. Trends in Turnaround Maintenance Planning: Literature Review. J. Qual. Maint. Eng. 2019, 25, 253–271. [Google Scholar] [CrossRef]

- Aghaee, A.; Aghaee, M. A Novel Fuzzy Hybrid Multi-Criteria Decision-Making Approach for Evaluating Maintenance Strategies in Petrochemical Industry. J. Qual. Maint. Eng. 2020, 27, 351–365. [Google Scholar] [CrossRef]

- Alsyouf, I.; Hamdan, S.; Shamsuzzaman, M.; Haridy, S.; Alawaysheh, I. On Preventive Maintenance Policies: A Selection Framework. J. Qual. Maint. Eng. 2020, 27, 225–252. [Google Scholar] [CrossRef]

- Jiang, A.; Qingxia, L.; Jinyi, Y.; Leqing, H.; Haining, W. An Operating Environment-Based Preventive Maintenance Decision Model Maintenance. J. Qual. Maint. Eng. 2019, 26, 592–610. [Google Scholar] [CrossRef]

- Oleghe, O.; Salonitis, K. The Application of a Hybrid Simulation Modelling Framework as a Decision-Making Tool for TPM Improvement. J. Qual. Maint. Eng. 2019, 25, 476–498. [Google Scholar] [CrossRef]

- Bataineh, O.; Al-Hawari, T.; Alshraideh, H.; Dalalah, D. A Sequential TPM-Based Scheme for Improving Production Effectiveness Presented with a Case Study. J. Qual. Maint. Eng. 2019, 25, 144–161. [Google Scholar] [CrossRef]

- Chaabane, K.; Schutz, J.; Dellagi, S.; Trabelsi, W. Analytical Evaluation of TPM Performance Based on an Economic Criterion. J. Qual. Maint. Eng. 2020, 27, 413–429. [Google Scholar] [CrossRef]

- Sahoo, S. Assessment of TPM and TQM Practices on Business Performance: A Multi-Sector Analysis. J. Qual. Maint. Eng. 2019, 25, 412–434. [Google Scholar] [CrossRef]

- Kundu, K.; Cifone, F.; Costa, F.; Portioli-Staudacher, A. An Evaluation of Preventive Maintenance Framework in an Italian Manufacturing Company Company. J. Qual. Maint. Eng. 2020, 28, 37–57. [Google Scholar] [CrossRef]

- Salonen, A.; Gopalakrishnan, M. Practices of Preventive Maintenance Planning in Discrete Manufacturing Industry. J. Qual. Maint. Eng. 2019, 27, 331–350. [Google Scholar] [CrossRef]

- Uchida, S.; Chimi, Y.; Kasahara, S.; Hanawa, S.; Okada, H.; Naitoh, M.; Kojima, M.; Kikura, H.; Lister, D.H. Improvement of Plant Reliability Based on Combining of Prediction and Inspection of Crack Growth Due to Intergranular Stress Corrosion Cracking. Nucl. Eng. Des. 2019, 341, 112–123. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Han, X.; Lu, Z. Joint Optimal Production Planning and Proactive Maintenance Policy for a System Subject to Degradation. J. Qual. Maint. Eng. 2019, 25, 236–252. [Google Scholar] [CrossRef]

- Acernese, A.; Del Vecchio, C.; Tipaldi, M.; Battilani, N.; Glielmo, L. Condition-Based Maintenance: An Industrial Application on Rotary Machines Rotary Machines. J. Qual. Maint. Eng. 2020, 27, 565–585. [Google Scholar] [CrossRef]

- Khalid, W.; Albrechtsen, S.H.; Sigsgaard, K.V.; Mortensen, N.H.; Hansen, K.B.; Soleymani, I. Predicting Maintenance Work Hours in Maintenance Planning Work Hours. J. Qual. Maint. Eng. 2019, 27, 366–384. [Google Scholar] [CrossRef]

- Tiddens, W.; Braaksma, J. Exploring Predictive Maintenance Applications in Industry Applications. J. Qual. Maint. Eng. 2020, 28, 68–85. [Google Scholar] [CrossRef]

- Braglia, M.; Castellano, D.; Gallo, M.; Braglia, M. A Novel Operational Approach to Equipment Maintenance: TPM and RCM Jointly at Work. J. Qual. Maint. Eng. 2019, 25, 612–634. [Google Scholar] [CrossRef]

- Elwerfalli, A.; Al-Maqespi, S. Selection of Appropriate Maintenance Strategy for Oil and Gas Equipment Using Analytical Hierarchy Process (AHP). In Proceedings of the 2nd South American International Conference on Industrial Engineering and Operations Management, Sao Paulo, Brazil, 5–8 April 2021; pp. 3578–3584. [Google Scholar]

- Mhlanga, M.Z.; Munapo, E.; Mavetera, N. Investigating Causes of Delays and Cost Escalation in Project Execution during Turnarounds. Investig. Manag. Financ. Innov. 2016, 13, 334–348. [Google Scholar] [CrossRef][Green Version]

- Dhandha, K.H. Shut down Inspection Requirements in Oil and Gas Refineries. In Proceedings of the NDE 2020—Virtual Conference & Exhibition, Virtual, 10–12 December 2020. [Google Scholar]

- Laza, K. The Piping Integrity Management Challenge. Insp. J. 2017, 23, 1–11. [Google Scholar]

- Hlophe, S.C.; Visser, J.K. Risk Management during Outage Projects at Power Plants. S. Afr. J. Ind. Eng. 2018, 29, 82–91. [Google Scholar] [CrossRef]

- Iheukwumere-Esotu, L.O.; Yunusa-Kaltungo, A. Knowledge Management and Experience Transfer in Major Maintenance Activities: A Practitioner’s Perspective. Sustainability 2022, 14, 52. [Google Scholar] [CrossRef]

- Akbar, J.u.D.; Ghazali, Z. The Influence of Coordination on the Performance of Plant Turnaround Maintenance through Team Alignment in Malaysian Process-Based Industry. SHS Web Conf. 2018, 56, 02007. [Google Scholar] [CrossRef][Green Version]

- Wongthong, T.; Paoprasert, N. Factors Affecting the Petrochemical Maintenance Supplierselection in Thailand. Int. J. Mech. Eng. Technol. 2019, 10, 46–60. [Google Scholar]

- Mazumder, L.K.; Mubashar, S. A Study on Plant Shut down Process and Its Impact on Time and Cost. Int. J. Res. IT Manag. 2016, 6, 1–5. [Google Scholar]

- Wenchi, S.; Wang, J.; Wang, X.; Chong, H.Y. An Application of Value Stream Mapping for Turnaround Maintenance in Oil and Gas Industry: Case Study and Lessions Learned. In Proceedings of the 31st Annual ARCOM Conference, Lincoln, UK, 7–9 September 2015; pp. 813–822. [Google Scholar]

- Fabić, M.; Pavletić, D.; Šterpin Valić, G. Factors in Turnaround Refinery (TAR) Project Management Process. Teh. Vjesn. 2020, 27, 1367–1377. [Google Scholar] [CrossRef]

- Shou, W.C.; Wang, J.; Wang, X.Y. 4D BIM for Improving Plant Turnaround Maintenance Planning and Execution: A Case Study. In Proceedings of the ISARC 2018—35th International Symposium on Automation and Robotics in Construction and International AEC/FM Hackathon: The Future of Building Things, Berlin, Germany, 20–25 July 2018. [Google Scholar] [CrossRef]

- Khasanah, R.; Jamasri; Yuniarto, H.A. Evaluation of Turnaround Maintenance Practice Effects in the Process Industry. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012097. [Google Scholar] [CrossRef]

- Al-Turki, U.; Duffuaa, S. Performance Measures for Turnaround Maintenance. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pilsen, Czech Republic, 23–26 July 2019; pp. 534–539. [Google Scholar]

- Łukaszewicz, A. Nonlinear Numerical Model of Friction Heating during Rotary Friction Welding. J. Frict. Wear 2018, 39, 476–482. [Google Scholar] [CrossRef]

- Sidun, P.; Łukaszewicz, A. Verification of Ram-Press Pipe Bending Process Using Elasto-Plastic FEM Model. Acta Mech. Autom. 2017, 11, 47–52. [Google Scholar] [CrossRef]

- Łukaszewicz, A. Temperature Field in the Contact Zone in the Course of Rotary Friction Welding of Metals. Mater. Sci. 2019, 55, 39–45. [Google Scholar] [CrossRef]

- Altehmazi, M.M.; Suliman, S.M.A.; Alalawi, Y. An Optimization Approach to the Preventive Maintenance Planning Process. Mod. Appl. Sci. 2017, 11, 20–29. [Google Scholar] [CrossRef]

- Ostadi, B.; Saifpanahi, H. A Practical Self-Assessment Framework for Evaluation of Maintenance Management System Based on RAMS Model and Maintenance Standards. J. Ind. Syst. Eng. 2017, 10, 125–143. [Google Scholar]

- Chen, Y.H.; Li, T.; Xue, D.L. Research and Application of Nuclear Power Plant In-Service Inspection Information Management Platform. E3S Web Conf. 2021, 257, 3–6. [Google Scholar] [CrossRef]

- Tak, K.; Kim, J. A Planning Model for Inspection and Replacement of Pipes in a Refinery Plant. Chem. Eng. Trans. 2017, 57, 991–996. [Google Scholar] [CrossRef]

- Lee, J.C.; Aziz, H.A.; Osman, H.; Tan, L.S.; Manaf, N.A. In-Service Piping Inspection Work-Aid Tool for Oil & Gas Industries. Curr. Sci. Technol. 2021, 1, 32–43. [Google Scholar] [CrossRef]

- Gunawan, N. Identification of Variables Causing Delays to Turnaround Maintenance Project. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1098, 022072. [Google Scholar] [CrossRef]

- Elwerfalli, A.; Khan, M.K.; Munive-Hernandez, J.E. Developing Turnaround Maintenance (TAM) Model to Optimize TAM Performance Based on the Critical Static Equipment (CSE) of GAS Plants. Int. J. Ind. Eng. Oper. Manag. 2019, 1, 12–31. [Google Scholar] [CrossRef]

- Wagh, P.V. Risk Based Inspection Approach for Effective Monitoring Remaining Life for Integrity of Refinery Equipment. In Proceedings of the NDE 2018 Conference & Exhibition, Mumbai, India, 19–21 December 2018. [Google Scholar]

- Elwerfalli, A. A Methodology to Increase Interval between Turnarounds Maintenance for Methanol Plants Based on the Heat Exchangers. In Proceedings of the 2nd International Conference on Research in Science, Engineering and Technology, Oxford, UK, 8–10 November 2019. [Google Scholar]

- Elwerfalli, A.; Khan, M.K.; Munive, J.E. A New Methodology for Improving TAM Scheduling of Oil and Gas Plants. In Proceedings of the World Congress on Engineering, London, UK, 29 June–1 July 2016; Volume 2224, pp. 807–812. [Google Scholar]

- Hameed, A.; Khan, F.; Ahmed, S. A Risk-Based Shutdown Inspection and Maintenance Interval Estimation Considering Human Error. Process Saf. Environ. Prot. 2016, 100, 9–21. [Google Scholar] [CrossRef]

- Priyanta, D.; Zaman, M.B. Semin the Development of a Risk-Based Maintenance Flowchart to Select the Correct Methodology to Develop Maintenance Strategies of Oil and Gas Equipment. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1052, 012042. [Google Scholar] [CrossRef]

- Romanczuk-Ruszuk, E.; Krawczyńska, A.; Łukaszewicz, A.; Józwik, J.; Tofil, A.; Oksiuta, Z. Bioactivity, Cytotoxicity, and Tribological Studies of Nickel-Free Austenitic Stainless Steel Obtained via Powder Metallurgy Route. Materials 2023, 16, 7637. [Google Scholar] [CrossRef] [PubMed]

- Nisbet, R.T. Ultrasonic Thickness Measurements at High Temperature. NDT Tech. 2004, 10, 1–4. [Google Scholar]

- Cheong, Y.M.; Kim, K.M.; Kim, D.J. High-Temperature Ultrasonic Thickness Monitoring for Pipe Thinning in a Flow-Accelerated Corrosion Proof Test Facility. Nucl. Eng. Technol. 2017, 49, 1463–1471. [Google Scholar] [CrossRef]

- Njelle, V.Z.; Ikeh, O.D.; Ikpe, A.E.; Usuoyibo, A. Study of Corrosion Rate of Low and Medium Carbon Steel Pressure Vessel in Nigeria Oil and Gas Industry Using Ultrasonic Testing (UT) and Phase Array Ultrasonic Testing (PAUT) Method. J. Sci. Technol. Res. 2019, 1, 161–170. [Google Scholar]

- Choi, Y.M.; Kang, D.; Kim, Y.L.; Cho, S.; Park, T.; Park, I.K. Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities. Appl. Sci. 2022, 12, 5867. [Google Scholar] [CrossRef]

- Brizuela, J.; Camacho, J.; Cosarinsky, G.; Iriarte, J.M.; Cruza, J.F. Improving Elevation Resolution in Phased-Array Inspections for NDT. NDT E Int. 2019, 101, 1–16. [Google Scholar] [CrossRef]

- Ghose, B. Evaluation of Probability of Detection (POD) and Minimum Number of Exposures Required for Detection of Planar Flaw in Cylindrical Object by Radiographic NDE Method. In Proceedings of the Asia Pacific Conference on NDT (APCNDT—2013), Mumbai, India, 18–22 November 2013; Volume 19. [Google Scholar]

- Sengottuvelappan, E. Phased Array Ultrasonic Inspection Of 25%Cr Super Duplex Stainless Steel on Subsea Manifold Piping Girth Welds in Lieu of Radiography. E-J. Nondestruct. Test. 2015, 20, 1–8. [Google Scholar]

- Tai, J.L.; Grzejda, R.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Tarasiuk, W.; Rychlik, A. Experimental Investigation on the Corrosion Detectability of A36 Low Carbon Steel by the Method of Phased Array Corrosion Mapping. Materials 2023, 16, 5297. [Google Scholar] [CrossRef]

- Lei, X.; Wirdelius, H.; Rosell, A. Experimental Validation of a Phased Array Probe Model in Ultrasonic Inspection. Ultrasonics 2020, 108, 106217. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Tarasiuk, W.; Napiórkowski, J.; Łukaszewicz, A.; Shahar, F.S. Ultrasonic Velocity and Attenuation of Low-Carbon Steel at High Temperatures. Materials 2023, 16, 5123. [Google Scholar] [CrossRef] [PubMed]

- Weekes, B.; Almond, D.P.; Cawley, P.; Barden, T. Eddy-Current Induced Thermography—Probability of Detection Study of Small Fatigue Cracks in Steel, Titanium and Nickel-Based Superalloy. NDT E Int. 2012, 49, 47–56. [Google Scholar] [CrossRef]

- Yusa, N.; Tomizawa, T.; Song, H.; Hashizume, H. Probability of Detection Analyses of Eddy Current Data for the Detection of Corrosion. Nondestruct. Test. Diagn. 2018, 4, 3–7. [Google Scholar] [CrossRef]

- Barat, V.; Marchenkov, A.; Ivanov, V.; Bardakov, V.; Elizarov, S.; Machikhin, A. Empirical Approach to Defect Detection Probability by Acoustic Emission Testing. Appl. Sci. 2021, 11, 9429. [Google Scholar] [CrossRef]

- Pollock, A. Probability of Detection for Acoustic Emission. J. Acoust. Emiss. 2007, 25, 231–237. [Google Scholar]

- Turcotte, J.; Rioux, P.; Lavoie, J. Comparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D Scanners. In Proceedings of the 19th World Conference on Non-Destructive Testing 2016, Munich, Germany, 13–17 June 2016; pp. 1–10. [Google Scholar]

- Kurian, M.C.; Shalij, P.R.; Pramod, V.R. Maintenance Strategy Selection in a Cement Industry Using Analytic Network Process. J. Qual. Maint. Eng. 2019, 26, 509–525. [Google Scholar] [CrossRef]

- Adjoul, O.; Benfriha, K. Design for Maintenance: New Algorithmic Approach. J. Qual. Maint. Eng. 2018, 27, 129–143. [Google Scholar] [CrossRef]

- Nwadinobi, C.P.; Nwankwojike, B.N.; Abam, F.I. Improved Markov Stable State Simulation for Maintenance Planning. J. Qual. Maint. Eng. 2019, 25, 199–212. [Google Scholar] [CrossRef]

- Hatsey, N.H.; Birkie, S.E. Total Cost Optimization of Submersible Irrigation Pump Maintenance Using Simulation. J. Qual. Maint. Eng. 2018, 27, 187–202. [Google Scholar] [CrossRef]

- Elwerfalli, A. A Framework to Prolong Interval of Turnaround Maintenance (TAM) of Processing Plants: Pressure Drums Case Study. In Proceedings of the 3rd European International Conference on Industrial Engineering and Operations Management, Pilsen, Czech Republic, 23–26 July 2019; pp. 1819–1824. [Google Scholar]

- Zhang, M.; Liang, W.; Qiu, Z.; Lin, Y. Application of Risk-Based Inspection Method for Gas Compressor Station. J. Phys. Conf. Ser. 2017, 842, 012064. [Google Scholar] [CrossRef]

- Eskandari, D.; Charkhand, H.; Gholami, A. A Semi-Quantitative Approach Development for Risk-Based Inspection in a Petrochemical Plant. J. Med. Sci. 2020, 8, 425–433. [Google Scholar] [CrossRef]

- Siswantoro, N.; Priyanta, D.; Ramadhan, J. Implementation of Risk-Based Inspection (RBI) in Condensate Separator and Storage Vessel: A Case Study. Int. J. Mar. Eng. Innov. Res. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Saisandhiya, N.R. Hazard Identification and Risk Assessment in Petrochemical Industry. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 778–783. [Google Scholar] [CrossRef]

| TAM | |

|---|---|

| RCM | Integration: TAM employs Reliability-centered maintenance (RCM) principles during turnarounds to optimize maintenance strategies. RCM identifies essential assets and failure modes, which subsequently impact the planning and execution of TAM tasks. |

| CBM | Strategic Use: Condition-based maintenance (CBM) is implemented at TAM to evaluate the current status of critical assets in real time. The information derived from CBM is utilized to make informed decisions and perform maintenance actions that are precisely targeted. |

| TPM | Efficiency Goals: Total productive maintenance (TPM) principles are applied within TAM to maximize equipment efficiency during production. Turnarounds allow the implementation of TPM strategies, contributing to overall plant productivity. |

| PM | Scheduled Tasks: Preventive maintenance (PM) tasks are scheduled during TAM to prevent potential failures. The integration ensures that planned maintenance is executed efficiently, minimizing disruptions during production. |

| CM | Unplanned Maintenance: While TAM primarily focuses on planned maintenance, Corrective maintenance (CM) is included to address unforeseen issues discovered during the turnaround. CM tasks are executed efficiently to minimize downtime. |

| PdM | Predictive Insights: Predictive maintenance (PdM) techniques are employed within TAM to predict potential issues before they become critical. Predictive insights guide the planning of maintenance tasks, which optimizes resource allocation. |

| RBM | Risk Assessment: Risk-based maintenance (RBM) principles are crucial in TAM for prioritizing maintenance tasks based on risk assessments. Identifying high-risk components ensures that resources are allocated to address critical areas during turnarounds. |

| RCM | |

|---|---|

| CBM | Data Synergy: CBM data can complement RCM analyses by providing real-time condition data for assets identified as critical through RCM. This synergy enhances the precision of maintenance decision-making. |

| TPM | Optimizing Strategies: RCM principles optimize TPM strategies by identifying the most effective maintenance tasks for enhancing equipment reliability. The collaboration ensures a proactive approach to asset management. |

| PM | Task Optimization: RCM influences the optimization of PM tasks during both routine operations and turnarounds. PM tasks are selected based on RCM analyses, ensuring a targeted preventive approach. |

| CM | Reducing Unplanned Downtime: RCM aims to reduce the need for CM by proactively addressing potential failure modes. CM tasks become more focused and efficient, minimizing unplanned downtime. |

| Maintenance Strategy | Advantages | Limitation |

|---|---|---|

| PdM |

|

|

| PM |

|

|

| CBM |

|

|

| RCM |

|

|

| CM |

|

|

| TPM |

|

|

| Technique | Advantages | Limitations | Suitable for Process Plant | Suitable for High-Temperature Surfaces |

|---|---|---|---|---|

| Phased Array Corrosion Mapping (PACM) |

|

| Yes | Yes (with limitations) |

| Ultrasonic Thickness Gauging (UTG) |

|

| Yes | Yes |

| Ultrasonic Testing (UT) |

|

| Yes | No |

| Radiography Testing (RT) |

|

| Yes | No |

| Eddy Current Testing (ET) |

|

| Yes (for conductive materials) | No |

| Acoustic Emission Testing (AET) |

|

| Yes | No |

| Improving Method | Methods | Description | Research/Knowledge Gaps | Journal Articles |

|---|---|---|---|---|

| Survey Questionnaire | Questionnaire-based approach | Conducting a survey questionnaire to identify the underlying causes of maintenance issues and to collect potential solutions from stakeholders | More research is needed to determine the most effective survey design and to validate the results against other data sources. Additionally, more research is needed to investigate the impact of cultural values on ethics and conflict management during TAM. | [8,9,40,41,42,43,44] |

| Assessment Tools | Value Stream Map, Analytic Hierarchy Process (AHP) method, and logistic regression approach | Using assessment tools such as the value stream map, AHP method, and logistic regression approach to dissect intricate factors affecting success and to orchestrate efficient and productive turnaround processes | More research is needed to compare the effectiveness of different assessment tools and to determine the most appropriate tool for different types of maintenance strategies. Additionally, more research is needed to investigate the impact of new workers and transient teams on communication gaps, idling workers, and spare part shortages during TAM. | [1,4,6,7,9,36,45,46,81,82] |

| Software Development | Four-dimensional building information modeling, maintenance management system, inspection manager software, in-service inspection platform, and optimization model | Developing software tools such as four-dimensional building information modeling, maintenance management system, inspection manager software, in-service inspection platform, and optimization model to streamline processes and enhance data tracking | More research is needed to evaluate the usability and effectiveness of the software tools, and to determine their impact on maintenance outcomes. Additionally, more research is needed to investigate the use of technology-based solutions for automating tasks and increasing maintenance efficiency. | [10,47,48,49,53,54,55,56,57,83,84] |

| Risk-Based Inspection | Risk-based identification, decision-making model, risk-based failure analysis, probability failure distributions, risk-based optimization, and risk-based maintenance strategies | Employing a risk-based inspection approach to assess the risk, incident consequences, probability of failure modes, and to optimize maintenance schedules, intervals, and strategies | More research is needed to determine the most appropriate risk assessment methodology for different types of maintenance strategies, and to evaluate the accuracy and reliability of the results. Additionally, more research is needed to investigate the impact of human errors introduced during shutdowns on maintenance optimization and risk-based strategies. | [11,58,59,60,61,62,63,64,85,86,87,88,89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Oksiuta, Z.; Krishnamoorthy, R.R. Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review. Appl. Sci. 2024, 14, 6707. https://doi.org/10.3390/app14156707

Tai JL, Sultan MTH, Łukaszewicz A, Shahar FS, Oksiuta Z, Krishnamoorthy RR. Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review. Applied Sciences. 2024; 14(15):6707. https://doi.org/10.3390/app14156707

Chicago/Turabian StyleTai, Jan Lean, Mohamed Thariq Hameed Sultan, Andrzej Łukaszewicz, Farah Syazwani Shahar, Zbigniew Oksiuta, and Renga Rao Krishnamoorthy. 2024. "Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review" Applied Sciences 14, no. 15: 6707. https://doi.org/10.3390/app14156707

APA StyleTai, J. L., Sultan, M. T. H., Łukaszewicz, A., Shahar, F. S., Oksiuta, Z., & Krishnamoorthy, R. R. (2024). Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review. Applied Sciences, 14(15), 6707. https://doi.org/10.3390/app14156707