Thermodynamic Analysis and Performance Evaluation of Microjet Engines in Gas Turbine Education

Abstract

:1. Introduction

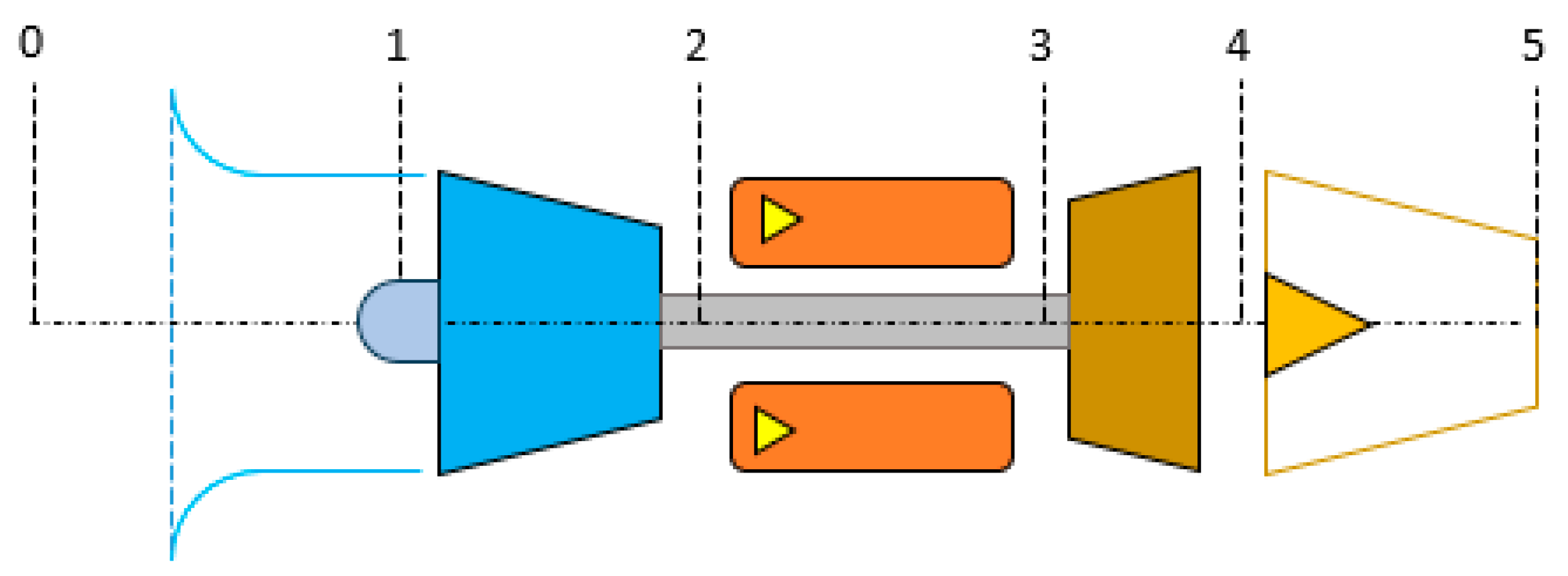

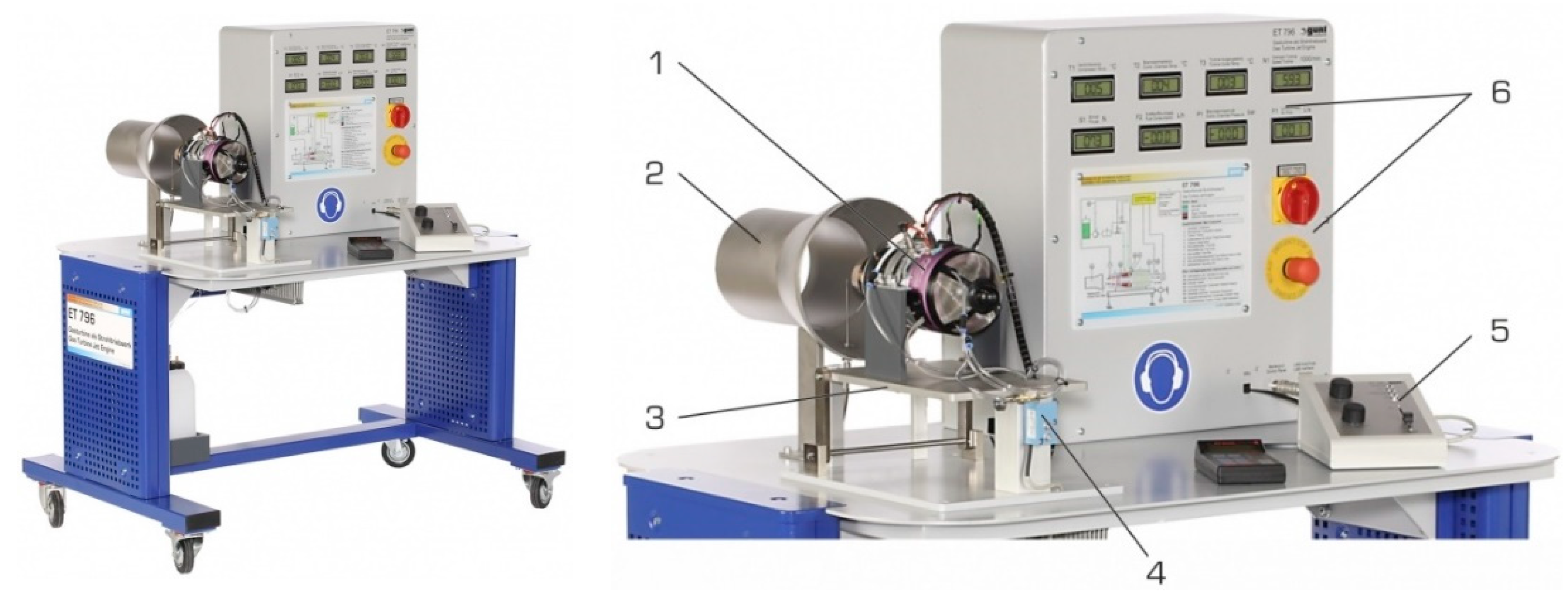

2. The Basis of Study

3. The Particular Engine Data Library

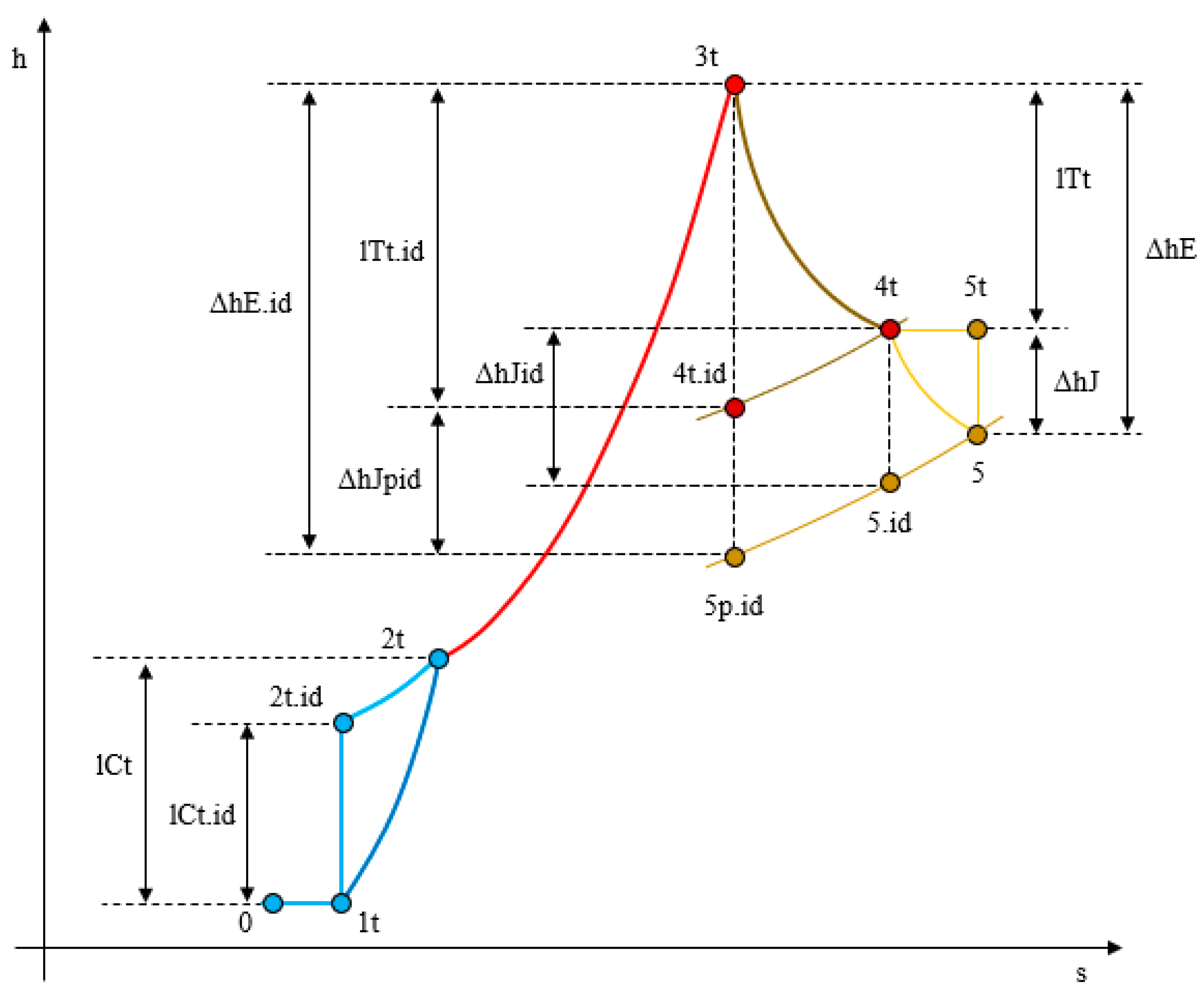

4. Calculation Model

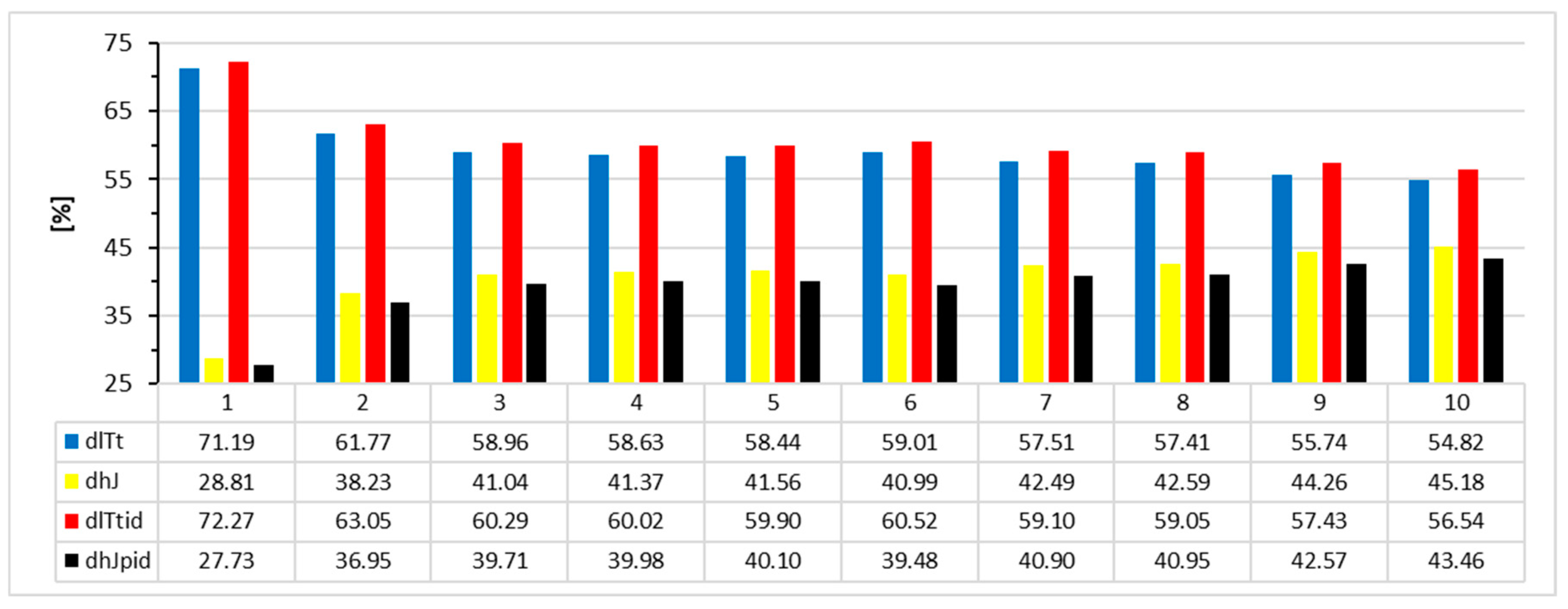

5. Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Engine thrust | |

| Specific fuel consumption | |

| Engine shaft speed | |

| Fuel flow | |

| Fuel flow coefficient | |

| Air excess | |

| Mass air flow | |

| Gases flow | |

| Overall total pressure ratio | |

| Turbine total pressure ratio | |

| Compressor total adiabatic efficiency | |

| Turbine total adiabatic efficiency | |

| Combustion efficiency | |

| Mechanical efficiency | |

| Intake total pressure loss | |

| Combustor chamber total pressure loss | |

| Total temperature | |

| Total pressure | |

| Air enthalpy polynomial function | |

| Air entropy polynomial function | |

| Ideal gases enthalpy polynomial function | |

| Ideal gases entropy polynomial function | |

| Ideal gases mass participations | |

| Air excess mass participations | |

| Gases enthalpy and entropy polynomial coefficients | |

| Compressor total specific ideal work | |

| Compressor total specific actual work | |

| Turbine total specific ideal work | |

| Turbine total specific actual work | |

| Turbine total specific ideal work | |

| Total specific enthalpy of station “i” | |

| Total specific ideal f entropy of station “i” | |

| Jet nozzle power | |

| Fuel power | |

| Fuel lower heating value | |

| Thermal efficiency | |

| Jet nozzle outlet actual velocity | |

| Jet nozzle outlet ideal velocity | |

| Heat capacity at constant pressure | |

| Gases adiabatic coefficient | |

| Jet nozzle outlet Mach number | |

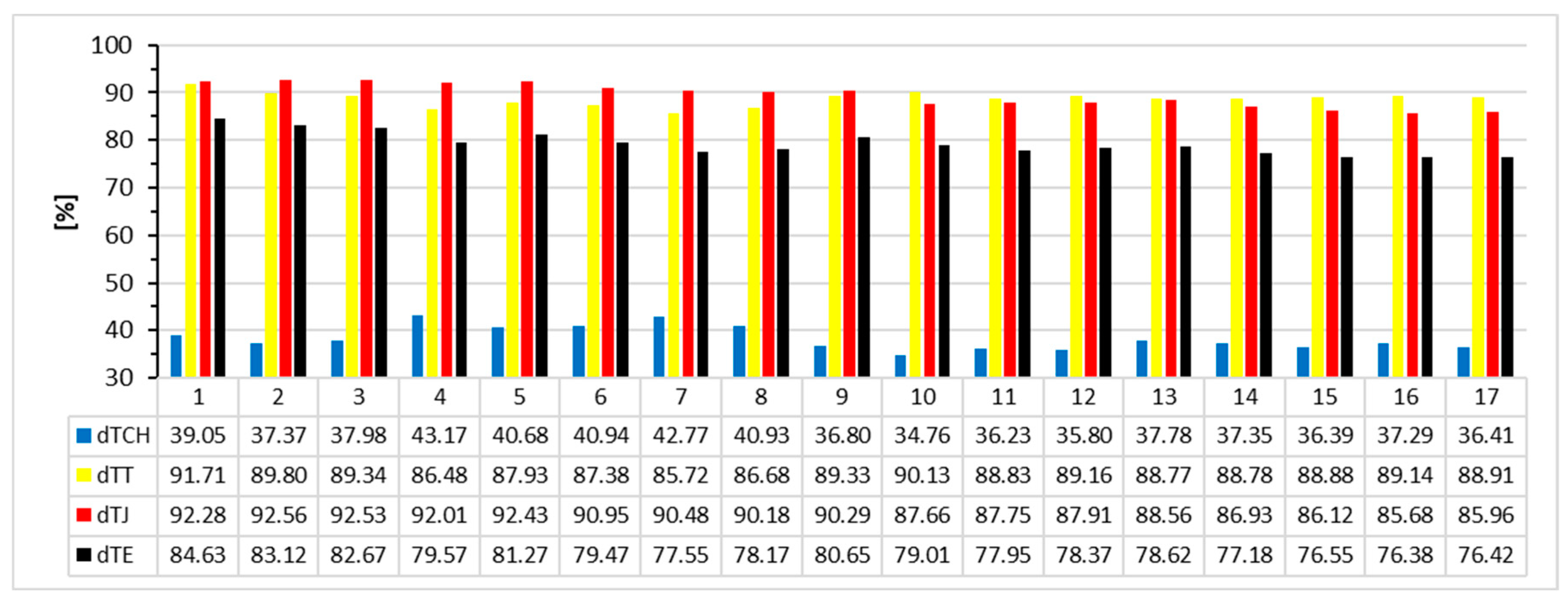

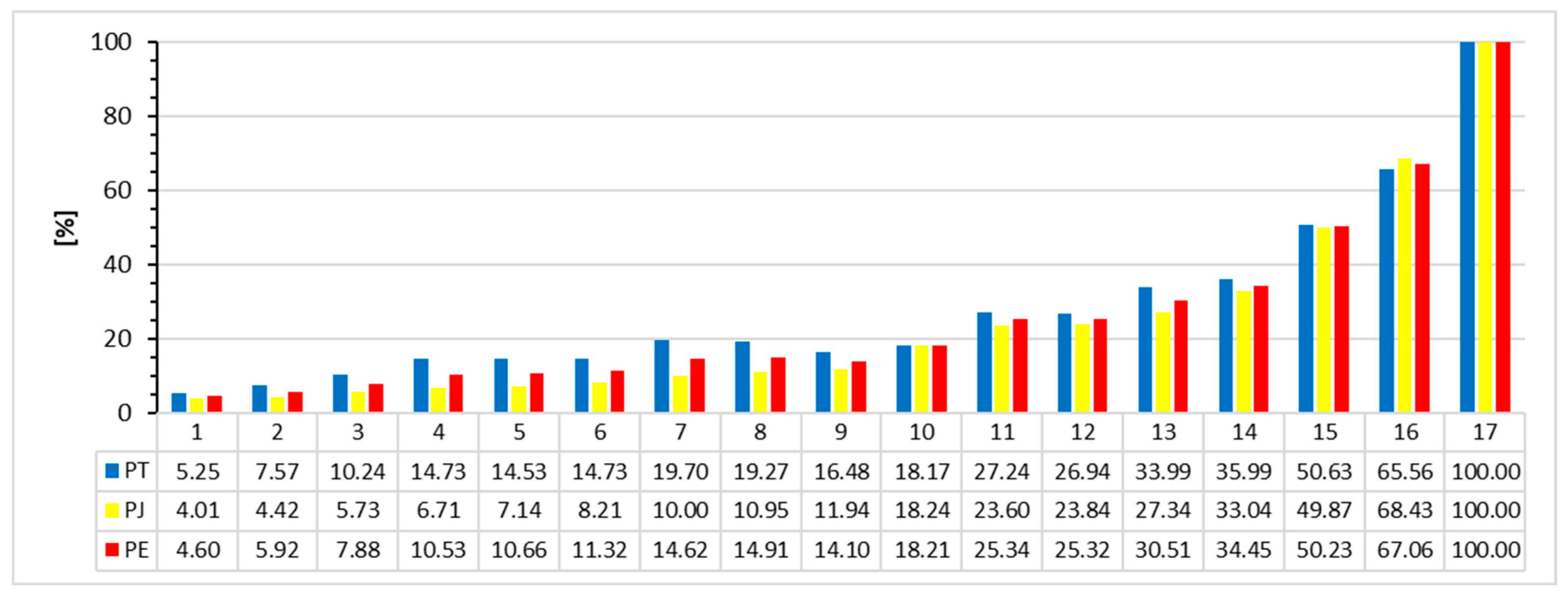

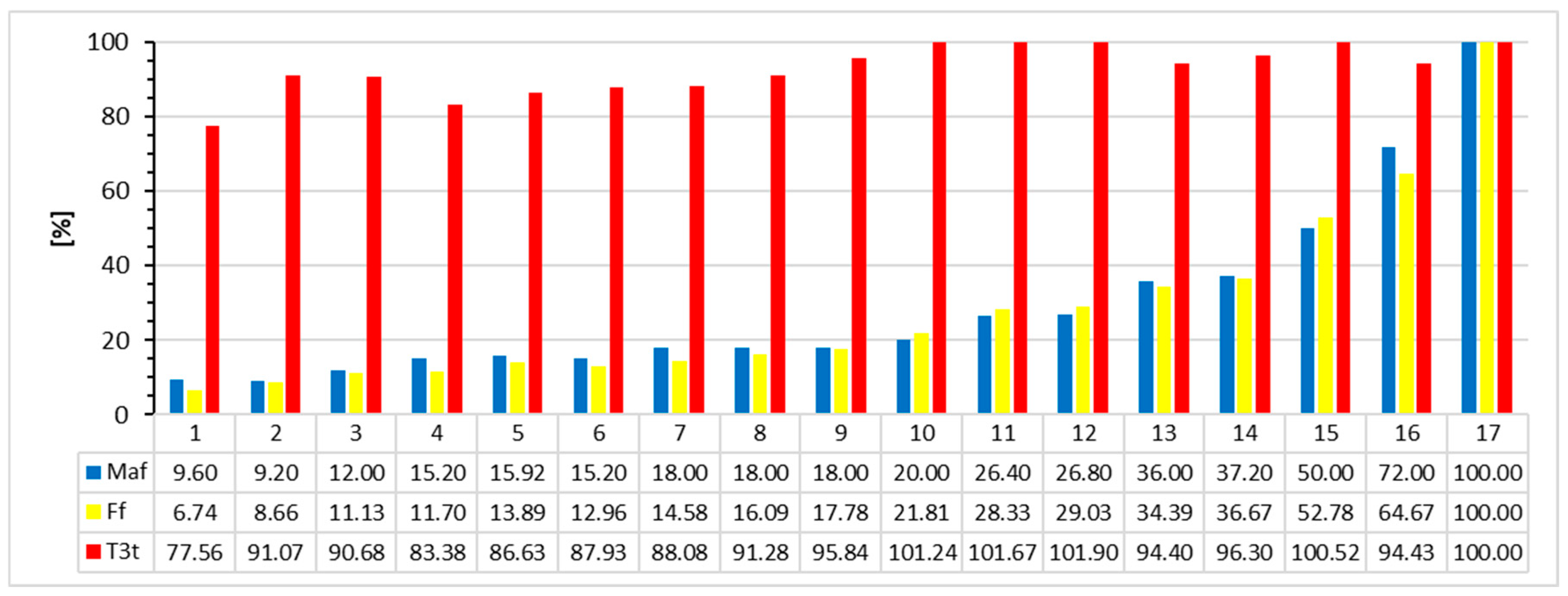

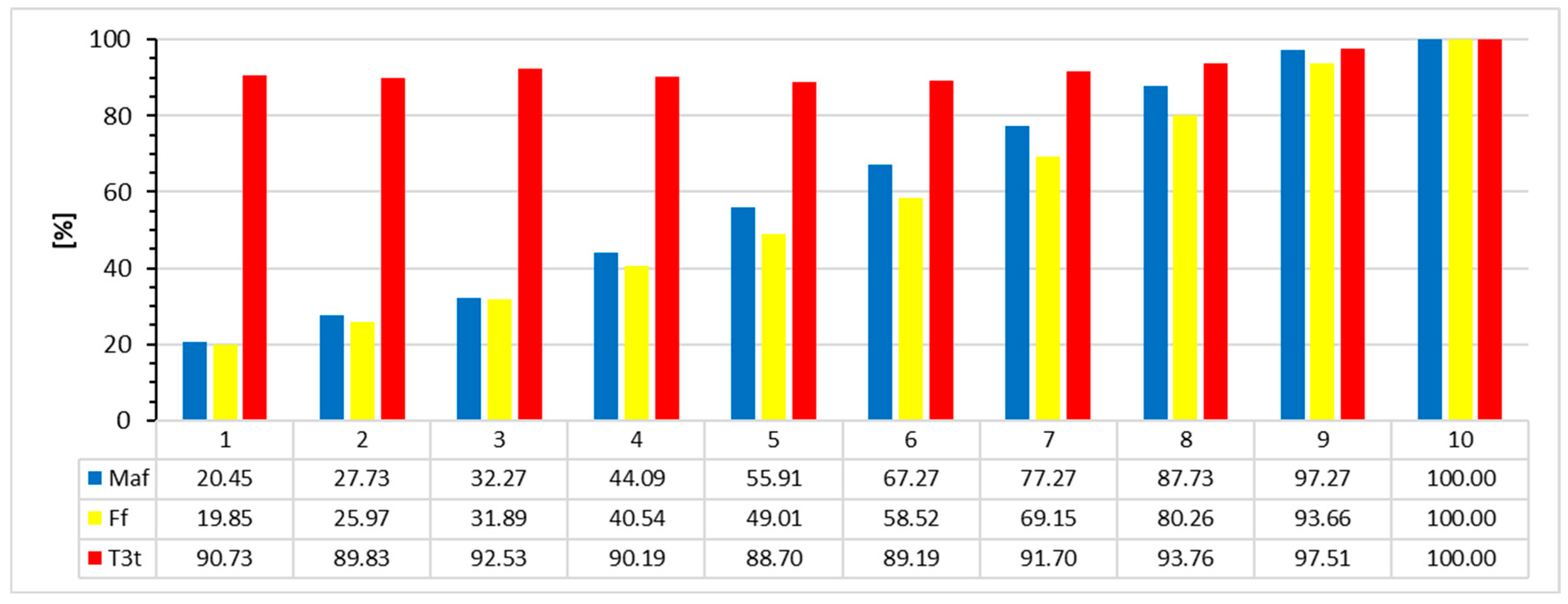

| Percentage parameters for JetCat and AMT micro jets | |

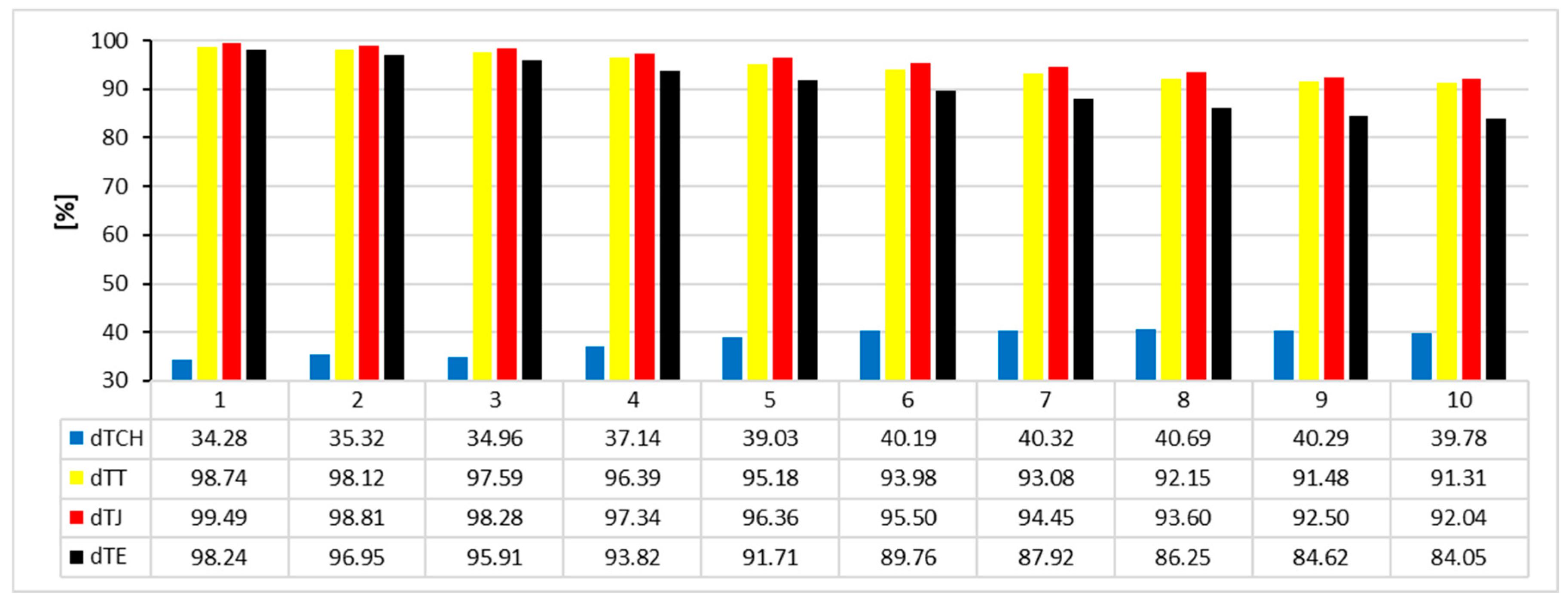

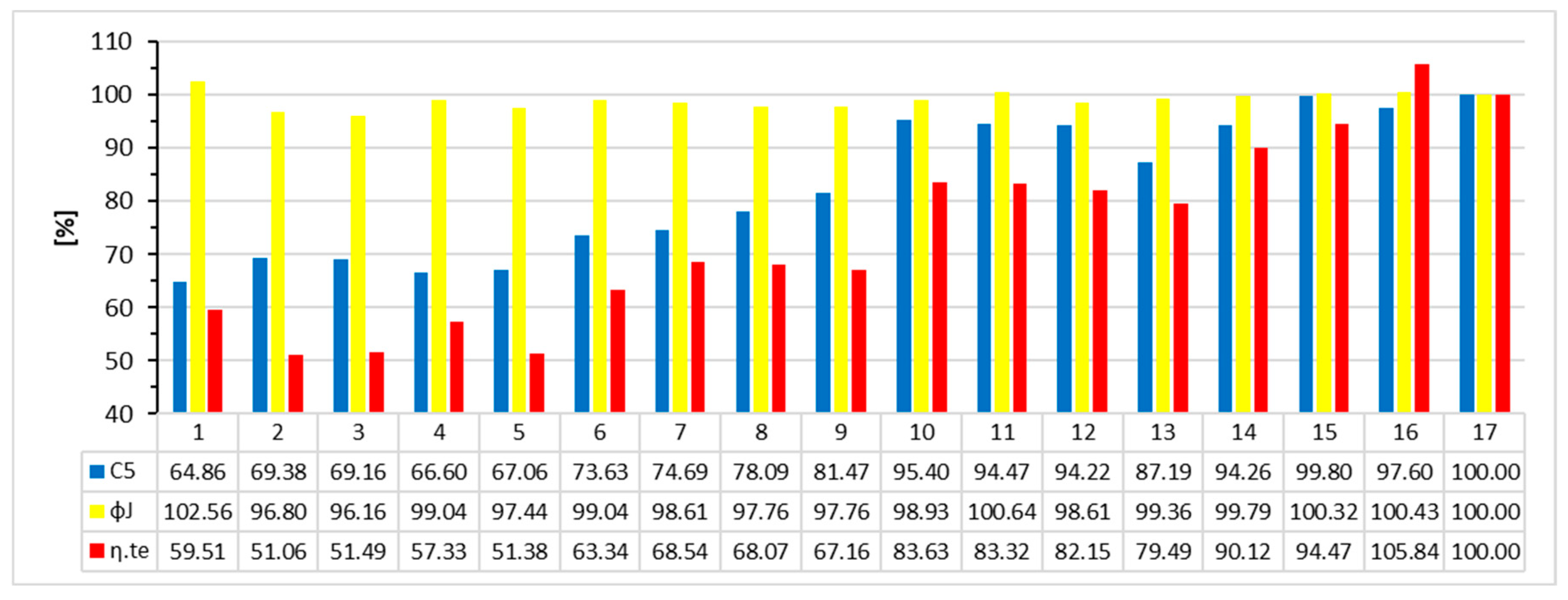

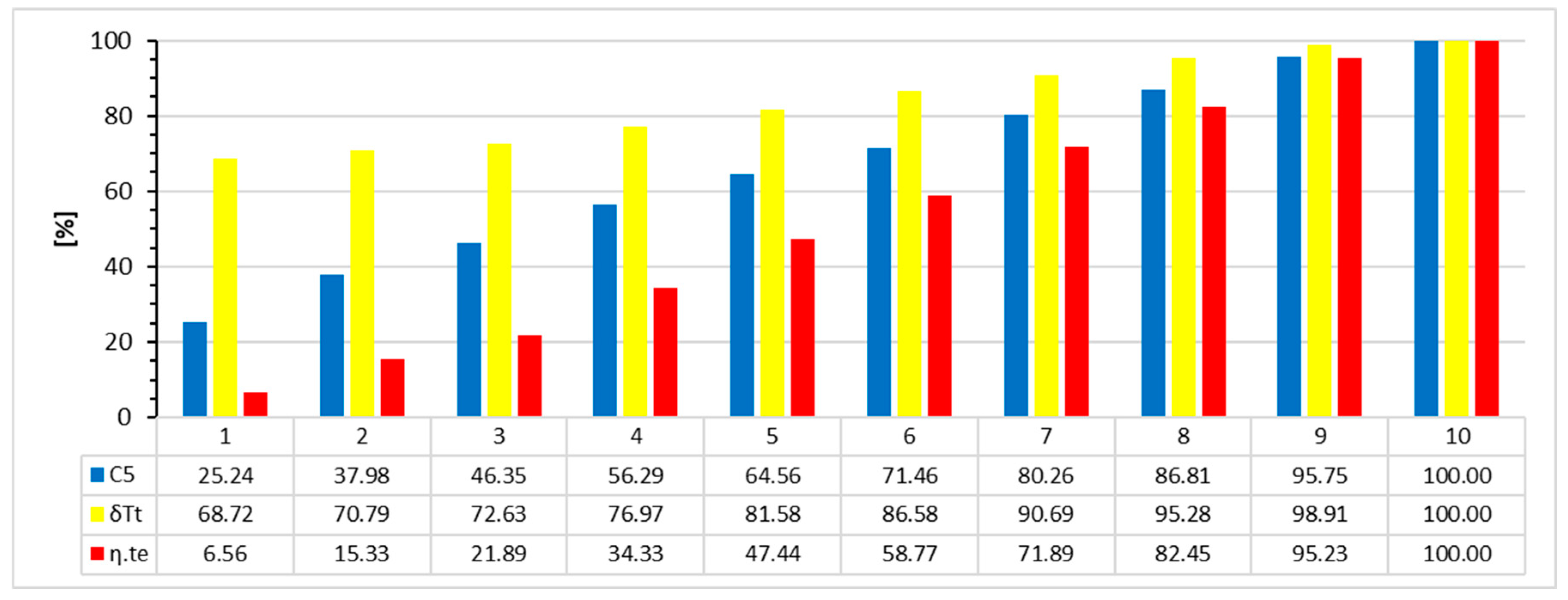

| Percentage parameters for JetCat P80 model |

References

- Ren, L.; Zhu, R.; Liao, L.; Zhou, Y. Analysis on the development of micro gas turbine generation technology. J. Phys. Conf. Ser. 2021, 1983, 012006. [Google Scholar] [CrossRef]

- Elzahaby, A.M.; Khalil, M.K.; Khalil, H.E. Theoretical and Experimental Analysis of a Micro Turbojet Engine’s Performance. Int. J. Sci. Eng. Res. 2016, 7, 404–410. [Google Scholar]

- Oppong, F. Micro Gas Turbine Performance Evaluation. Master’s Thesis, Department of Mechanical and Mechatronics Engineering, University of Stellenbosch, Stellenbosch, South Africa, December 2016. [Google Scholar]

- Van den Braembussche, R.A. Micro Gas Turbines—A Short Survey of Design Problems. In Micro Gas Turbines; Educational Notes RTO-EN-AVT-131, Paper 1; RTO: Neuilly-sur-Seine, France, 2002; pp. 1–18. [Google Scholar]

- Leong, C.H.; Jacob, J.; Liou, W.W. Development of a Turbojet Engine Lab for Propulsion Education. In Proceedings of the 40th AIAA/ASME/SAE/ASME Joint Propulsion Conference and Exhibit, AIAA Paper 2004-4085, Fort Lauderdale, FL, USA, 11–14 July 2004. [Google Scholar]

- Liou, W.; Leong, C.H. Gas Turbine Engine Testing Education at Western Michigan University. Collection of Technical Papers. In Proceedings of the 45th AIAA Aerospace Sciences Meeting, Reno, NV, USA, 8 January 2007; Volume 13, pp. 8716–8724. [Google Scholar]

- Available online: https://www.dlr.de/en/at/about-us/departments (accessed on 25 March 2024).

- Available online: https://www.testdevices.com/blog/the-testing-capabilities-of-subscale-jet-engine-rigs-part-1/ (accessed on 25 March 2024).

- Available online: https://www.turbinetechnologies.com/educational-lab-products/turbojet-engine-lab (accessed on 25 March 2024).

- Available online: https://www.gunt.de/en/products/thermal-engineering/thermal-fluid-energy-machines/gas-turbines/gas-turbine-jet-engine/061.79600/et796/glct-1:pa-148:ca-107:pr-261 (accessed on 25 March 2024).

- Sajesh, M.; Jyothi Sankar, P.R.; Vishnu Prakash, K.; Nikhil Das, K. Performance Analysis of a Micro Turbojet Engine. Trans. Eng. Sci. 2014, 2, 27–37. [Google Scholar]

- Juste, G.L.; Montañés, J.L.; Velazquez, A. Micro-Jet Test Facility for Aerospace Propulsión Engineering Education. Int. J. Eng. Educ. 2009, 25, 11–16. [Google Scholar]

- Wu, X.; Hu, X.; Xiang, X.; Lin, S.; You, J.; Tian, F. An analysis approach for micro gas turbine engine’s performance by experiment and numerical simulation. Case Stud. Therm. Eng. 2023, 49, 103305. [Google Scholar] [CrossRef]

- Cican, G. Experimental Transient Process Analysis of Micro-Turbojet Aviation Engines: Comparing the Effects of Diesel and Kerosene Fuels at Different Ambient Temperatures. Energies 2024, 17, 1366. [Google Scholar] [CrossRef]

- Cican, G.; Frigioescu, T.-F.; Crunteanu, D.-E.; Cristea, L. Micro Turbojet Engine Nozzle Ejector Impact on the Acoustic Emission, Thrust Force and Fuel Consumption Analysis. Aerospace 2023, 10, 162. [Google Scholar] [CrossRef]

- Andoga, R.; Főző, L.; Schrötter, M.; Szabo, S. The Use of Ethanol as an Alternative Fuel for Small Turbojet Engines. Sustainability 2021, 13, 2541. [Google Scholar] [CrossRef]

- Przysowa, R.; Gawron, B.; Białecki, T.; Łęgowik, A.; Merkisz, J.; Jasiński, R. Performance and Emissions of a Microturbine and Turbofan Powered by Alternative Fuels. Aerospace 2021, 8, 25. [Google Scholar] [CrossRef]

- Kulczycki, A.; Przysowa, R.; Białecki, T.; Gawron, B.; Jasiński, R.; Merkisz, J.; Pielecha, I. Empirical Modeling of Synthetic Fuel Combustion in a Small Turbofan. Energies 2024, 17, 2622. [Google Scholar] [CrossRef]

- Grzeszczyk, R.; Merkisz, J.; Górecki, M.; van de Goor, B.; Kamińska, E. The Laboratory Test Bench for a Small Turbojet Engine, PTNSS–2011–SC–125. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-LOD6-0030-0041/c/grzeszczyk_merkisz_gorecki_goor_kaminska_the_laboratory_ss_3_2011.pdf (accessed on 25 March 2024).

- Available online: https://www.jetcat.de/en/products/ (accessed on 25 March 2024).

- Available online: https://www.jetmodelproducts.com/amt.htm (accessed on 25 March 2024).

- Available online: https://jetcentral.com.mx/turbines/ (accessed on 25 March 2024).

- Available online: https://www.pbs.cz/en/Aerospace/Aircraft-Engines (accessed on 25 March 2024).

- Available online: https://www.hyblturbines.cz/h16bl/ (accessed on 25 March 2024).

- Chauhan, S.; Wessley, G.J.J. Thermodynamic Performance Analysis of a Micro Turbojet Engine for UAV and Drone Propulsion. Int. J. Recent Technol. Eng. 2019, 7, 1–6. [Google Scholar]

- Talib, A.R.A.; Gires, E.; Ahmad, M.T. Performance Evaluation of a Small-Scale Turbojet Engine Running on Palm Oil Biodiesel Blends, Hindawi Publishing Corporation. J. Fuels 2014, 2014, 946485. [Google Scholar] [CrossRef]

- Cican, G.; Toma, A.; Puscasu, C.; Catana, R.M. Jet CAT P80 Thermal Analyses and Performance Assessment Using Different Fuels Types. J. Therm. Sci. 2018, 27, 389–393. [Google Scholar] [CrossRef]

- Available online: https://www.amtjets.com/pdf/lynx_manual_rev.20190919.pdf (accessed on 25 March 2024).

- Available online: https://www.jetcat.de/jetcat/Kataloge/JetCat%20Lieferprogramm%202018.pdf (accessed on 25 March 2024).

- Available online: http://www.amtjets.com/specs.php (accessed on 25 March 2024).

- Catană, R.M.; Dediu, G.; Tărăbîc, C.M.; Șerbescu, H.M. Performance Calculations of Gas Turbine Engine Components Based on Particular Instrumentation Methods. Appl. Sci. 2021, 11, 4492. [Google Scholar] [CrossRef]

- Catana, R.M.; Badea, G.P. Experimental Analysis on the Operating Line of Two Gas Turbine Engines by Testing with Different Exhaust Nozzle Geometries. Energies 2023, 16, 5627. [Google Scholar] [CrossRef]

- Available online: https://www.jetcat.de/en/products/produkte/jetcat/kategorien/Zubehoer/Kraftstoffzusaetze (accessed on 25 March 2024).

- Available online: http://plone.ufpb.br/labrads/contents/documentos/until-2013-11-21-et796e-gas-turbine-as-jet-duplex.pdf (accessed on 25 March 2024).

- Bathie, W.W. Fundamentals of Gas Turbines; Iowa State University of Science and Technology: Ames, IA, USA, 1984. [Google Scholar]

- Japikse, D.; Baines, N.C. Introduction to Turbomachinery; Concepts ETI, Inc.: Norwich, VT, USA; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

- Stanciu, D.; Marinescu, M. Technical Thermodynamics; Politehnica University of Bucharest: Bucharest, Romania; Printech Publishing House: Columbus, OH, USA, 2002; ISSN 973-652-577-5. [Google Scholar]

- Catana, R.M. Studies and Experimental Research in the Evaluation of Gas Turbine Engines Operating Regimes by Testing on the Test Bench after a Supplementary Instrumentation and Processing of the Measured Data. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 2019. [Google Scholar]

- Bakalis, D.P.; Stamatis, A.G. Data analysis and performance model calibration of a small turbojet engine. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2011, 226, 1523–1533. [Google Scholar] [CrossRef]

- Tuccillo, R.; Cameretti, M.C. Combustion and Combustors for MGT Applications. In Micro Gas Turbines; Educational Notes RTO-EN-AVT-131, Paper 5; RTO: Neuilly-sur-Seine, France, 2005; pp. 1–56. [Google Scholar]

- Catana, R.M.; Dediu, G. Analytical Calculation Model of the TV3-117 Turboshaft Working Regimes Based on Experimental Data. Appl. Sci. 2023, 13, 10720. [Google Scholar] [CrossRef]

- Catană, R.M.; Dediu, G.; Tărăbîc, C.M. Studies and Experimental Research in the Evaluation of TV2-117A Turboshaft Engine Working Regimes. Appl. Sci. 2022, 12, 3703. [Google Scholar] [CrossRef]

| Engine Model | NE | TR | πCt | Maf | SFC |

|---|---|---|---|---|---|

| rpm | N | - | kg/s | kg/(N∙h) | |

| P80-SE | 125,000 | 97 | 2.3 | 0.240 | 0.1500 |

| P100-RX | 154,000 | 100 | 2.9 | 0.230 | 0.1870 |

| P130-RX | 127,000 | 130 | 3.0 | 0.300 | 0.1850 |

| P160-RXi-B | 122,000 | 158 | 3.5 | 0.380 | 0.1600 |

| P180-NX | 126,000 | 175 | 3.5 | 0.380 | 0.1600 |

| P200-RX | 112,000 | 210 | 4.0 | 0.450 | 0.1500 |

| P220-RXi | 117,000 | 220 | 3.9 | 0.450 | 0.1580 |

| P300-PRO | 106,000 | 300 | 3.55 | 0.500 | 0.1570 |

| P400-PRO | 98,000 | 397 | 3.80 | 0.670 | 0.1579 |

| P500-PRO GL | 80,000 | 492 | 3.60 | 0.900 | 0.1510 |

| P550-PRO GL | 83,000 | 550 | 3.80 | 0.930 | 0.1440 |

| P1000-PRO | 61,500 | 1100 | 3.80 | 1.800 | 0.1270 |

| Engine Model | NE | TR | πCt | Maf | SFC |

|---|---|---|---|---|---|

| rpm | N | - | kg/s | kg/(N∙h) | |

| Pegasus HP | 117,000 | 167 | 3.0 | 0.398 | 0.1796 |

| Olympus HP | 108,500 | 230 | 3.3 | 0.450 | 0.1670 |

| Titan | 96,000 | 392 | 3.8 | 0.660 | 0.1561 |

| Nike | 61,500 | 784 | 4.0 | 1.250 | 0.1454 |

| Lynx | 46,000 | 1569 | 4.0 | 2.500 | 0.1377 |

| NE | TR | T3t | T2t | p3t |

|---|---|---|---|---|

| rpm | N | °C | °C | bar a |

| 34,951 | 4.6 | 608.8 | 21.1 | 1.100 |

| 47,160 | 9.3 | 592.2 | 30.0 | 1.168 |

| 55,320 | 13.4 | 618.3 | 36.5 | 1.228 |

| 68,295 | 22.0 | 595.8 | 48.6 | 1.357 |

| 79,369 | 32.0 | 581.4 | 60.4 | 1.502 |

| 88,787 | 42.8 | 586.1 | 72.2 | 1.658 |

| 97,786 | 55.1 | 610.2 | 86.0 | 1.825 |

| 105,423 | 67.8 | 630.1 | 99.0 | 1.997 |

| 112,706 | 82.8 | 666.3 | 108.4 | 2.189 |

| 115,675 | 88.9 | 690.3 | 114.4 | 2.266 |

| σdat | σcat | ηca | ηTt | φJ | Ra [J/kg∙K] | Rg [J/kg∙K] |

|---|---|---|---|---|---|---|

| 0.98 | 0.96 | 0.85/0.88/0.90/ 0.94/0.96 | see Table 10 | see Table 10 | 287.15 | 288.25 |

| σdat | σcat | ηca | ηTt | φJ | Ra [J/kg∙K] | Rg [J/kg∙K] |

|---|---|---|---|---|---|---|

| 0.995 | 0.96 | 0.95 | 0.84 | 0.94 | 287.15 | 288.26 |

| Engine Model | PT | PJ | PE | h3t | lTt | ΔhJ | ΔhE | lTt.id | ΔhJ.p.id | ΔhE.id | ΔhJ.id |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | kW | kW | kW | kW | kW | kW | kW | kW | kW | kW | |

| P80-SE | 22.912 | 19.277 | 42.190 | 1039.296 | 93.887 | 78.993 | 172.880 | 114.497 | 83.605 | 198.102 | 64.734 |

| P100-RX | 33.076 | 21.259 | 54.335 | 1248.755 | 140.631 | 90.389 | 231.020 | 190.042 | 105.248 | 295.290 | 60.303 |

| P130-RX | 44.742 | 27.553 | 72.295 | 1242.569 | 145.890 | 89.843 | 235.733 | 197.149 | 105.608 | 302.757 | 59.068 |

| P160-RXi-B | 64.353 | 32.251 | 96.605 | 1127.453 | 166.278 | 83.332 | 249.610 | 221.704 | 91.371 | 313.075 | 41.155 |

| Pegasus HP | 63.455 | 34.318 | 97.773 | 1179.208 | 156.164 | 84.458 | 240.622 | 208.219 | 96.288 | 304.507 | 48.994 |

| P180-NX | 64.353 | 39.488 | 103.841 | 1198.369 | 165.954 | 101.830 | 267.784 | 218.360 | 112.414 | 330.774 | 65.557 |

| P200-RX | 86.063 | 48.065 | 134.128 | 1199.415 | 187.603 | 104.774 | 292.377 | 246.846 | 115.783 | 362.629 | 63.217 |

| P220-RXi | 84.165 | 52.648 | 136.813 | 1250.528 | 183.103 | 114.539 | 297.642 | 240.926 | 129.283 | 370.209 | 78.269 |

| Olympus HP | 71.986 | 57.417 | 129.402 | 1323.616 | 156.264 | 124.639 | 280.903 | 202.940 | 142.946 | 345.886 | 101.657 |

| P300-PRO | 79.382 | 87.705 | 167.087 | 1411.256 | 154.715 | 170.938 | 325.653 | 193.394 | 192.821 | 386.215 | 159.647 |

| Titan | 118.998 | 113.489 | 232.487 | 1417.321 | 175.773 | 167.635 | 343.408 | 225.350 | 181.238 | 406.588 | 138.442 |

| P400-PRO | 117.664 | 114.639 | 232.302 | 1421.344 | 171.168 | 166.768 | 337.936 | 219.446 | 188.112 | 407.558 | 146.629 |

| P500-PRO GL | 148.484 | 131.466 | 279.950 | 1300.337 | 161.284 | 142.800 | 304.084 | 204.158 | 158.878 | 363.036 | 121.665 |

| P550-PRO GL | 157.199 | 158.876 | 316.076 | 1330.654 | 165.125 | 166.887 | 332.012 | 198.946 | 185.605 | 384.551 | 156.829 |

| Nike | 221.134 | 239.788 | 460.921 | 1398.775 | 172.536 | 187.091 | 359.627 | 210.410 | 205.232 | 415.642 | 173.269 |

| P1000-PRO | 286.36 | 329.019 | 615.379 | 1298.871 | 155.732 | 178.931 | 334.663 | 179.002 | 197.771 | 376.773 | 178.260 |

| Lynx | 436.807 | 480.813 | 917.620 | 1388.505 | 170.628 | 187.817 | 358.445 | 205.576 | 207.728 | 413.304 | 178.337 |

| NE rpm | PT | PJ | PE | h3t | lTt | ΔhJ | ΔhE | lTt.id | ΔhJ.p.id | ΔhE.id | ΔhJ.id |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | kW | kW | kW | kW | kW | kW | kW | kW | kW | kW | |

| 34,951 | 0.571 | 0.231 | 0.802 | 916.009 | 12.476 | 5.049 | 17.525 | 14.853 | 5.699 | 20.552 | 5.714 |

| 47,160 | 1.136 | 0.703 | 1.839 | 905.688 | 18.475 | 11.432 | 29.907 | 21.994 | 12.890 | 34.884 | 12.938 |

| 55,320 | 1.776 | 1.236 | 3.012 | 935.891 | 24.456 | 17.026 | 41.482 | 29.114 | 19.177 | 48.291 | 19.268 |

| 68,295 | 3.493 | 2.465 | 5.958 | 909.517 | 35.580 | 25.108 | 60.688 | 42.357 | 28.209 | 70.566 | 28.416 |

| 79,369 | 5.781 | 4.111 | 9.892 | 892.662 | 46.420 | 33.012 | 79.432 | 55.262 | 36.994 | 92.256 | 37.361 |

| 88,787 | 8.764 | 6.089 | 14.853 | 897.855 | 58.259 | 40.475 | 98.734 | 69.356 | 45.236 | 114.592 | 45.806 |

| 97,786 | 11.913 | 8.801 | 20.714 | 925.544 | 69.068 | 51.025 | 120.093 | 82.224 | 56.912 | 139.136 | 57.747 |

| 105,423 | 15.793 | 11.714 | 27.507 | 948.480 | 80.493 | 59.705 | 140.198 | 95.824 | 66.447 | 162.271 | 67.570 |

| 112,706 | 19.872 | 15.78 | 35.652 | 990.703 | 91.476 | 72.638 | 164.114 | 108.900 | 80.710 | 189.610 | 82.207 |

| 115,675 | 21.472 | 17.694 | 39.166 | 1018.969 | 96.143 | 79.226 | 175.369 | 114.456 | 87.994 | 202.450 | 89.663 |

| Engine Model | T2t | α.ex | Ff | T3t | ΔTT | ΔTJ | ΔTE | ΔTT.id | ΔTJ.p.id | ΔTE.id | ΔTJ.id |

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | - | g/min | °C | °C | °C | °C | °C | °C | °C | °C | |

| P80-SE | 108.9 | 4.182 | 242.5 | 705.2 | 81.1 | 69.3 | 150.4 | 99.1 | 73.6 | 172.7 | 74.9 |

| P100-RX | 156.1 | 3.118 | 311.7 | 875.5 | 117.2 | 76.7 | 193.9 | 159.0 | 90.0 | 249.0 | 93.2 |

| P130-RX | 161.3 | 3.163 | 400.8 | 870.8 | 121.9 | 76.3 | 198.2 | 165.3 | 90.6 | 255.9 | 93.9 |

| P160-RXi-B | 180.9 | 3.811 | 421.3 | 778.6 | 142.2 | 72.7 | 214.9 | 190.4 | 80.6 | 271.0 | 84.4 |

| Pegasus HP | 171.3 | 3.363 | 500.0 | 819.5 | 131.9 | 72.7 | 204.6 | 176.6 | 83.7 | 260.3 | 87.1 |

| P180-NX | 180.9 | 3.44 | 466.7 | 836.0 | 140.0 | 87.7 | 227.7 | 184.9 | 97.8 | 282.7 | 101.7 |

| P200-RX | 202.1 | 3.622 | 525.0 | 838.0 | 158.7 | 90.7 | 249.4 | 209.8 | 101.4 | 311.2 | 106.2 |

| P220-RXi | 198.1 | 3.282 | 579.3 | 878.3 | 153.4 | 98.0 | 251.4 | 202.6 | 111.9 | 314.5 | 116.7 |

| Olympus HP | 171.8 | 2.971 | 640.0 | 935.8 | 129.0 | 104.9 | 233.9 | 168.1 | 121.2 | 289.3 | 125.0 |

| P300-PRO | 170.7 | 2.691 | 785.0 | 1003.9 | 126.0 | 142.0 | 268.0 | 157.8 | 161.3 | 319.1 | 165.0 |

| Titan | 191.5 | 2.734 | 1020.0 | 1009.3 | 143.2 | 139.6 | 282.8 | 184.2 | 152.1 | 336.3 | 156.8 |

| P400-PRO | 187.0 | 2.709 | 1045.0 | 1012.3 | 139.4 | 138.6 | 278.0 | 179.2 | 157.7 | 336.9 | 162.4 |

| P500-PRO GL | 176.7 | 3.072 | 1238.0 | 917.6 | 133.7 | 120.9 | 254.6 | 169.7 | 135.6 | 305.3 | 139.6 |

| P550-PRO GL | 180.6 | 2.977 | 1320.0 | 941.6 | 136.3 | 140.9 | 277.2 | 164.6 | 157.7 | 322.3 | 161.2 |

| Nike | 188.3 | 2.780 | 1900.0 | 994.9 | 141.0 | 156.4 | 297.4 | 172.3 | 172.8 | 345.1 | 176.8 |

| P1000-PRO | 171.0 | 3.267 | 2328.0 | 918.0 | 129.3 | 152.1 | 281.4 | 148.9 | 169.0 | 317.9 | 171.7 |

| Lynx | 186.1 | 2.934 | 3600.0 | 988.3 | 139.9 | 157.5 | 297.4 | 168.9 | 175.3 | 344.2 | 179.2 |

| NE rpm | T2t | α.ex | Ff | T3t | ΔTtT | ΔTJ | ΔTE | ΔTtT.id | ΔTJ.p.id | ΔTE.id | ΔTJ.id |

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | - | g/min | °C | °C | °C | °C | °C | °C | °C | °C | |

| 34,951 | 26.5 | 5.221 | 42.155 | 601.0 | 11.0 | 4.4 | 15.4 | 13.1 | 5.0 | 18.1 | 5.0 |

| 47,160 | 32.5 | 5.366 | 55.144 | 592.2 | 16.3 | 10.1 | 26.4 | 19.4 | 11.4 | 30.8 | 11.5 |

| 55,320 | 38.5 | 5.154 | 67.739 | 618.3 | 21.5 | 15.0 | 36.5 | 25.6 | 16.9 | 42.5 | 16.9 |

| 68,295 | 49.6 | 5.490 | 86.097 | 595.8 | 31.4 | 22.3 | 53.7 | 37.4 | 25.2 | 62.6 | 25.3 |

| 79,369 | 60.4 | 5.767 | 104.084 | 581.4 | 41.2 | 29.6 | 70.8 | 49.1 | 33.2 | 82.3 | 33.5 |

| 88,787 | 72.2 | 5.837 | 124.259 | 586.1 | 51.7 | 36.3 | 88.0 | 61.7 | 40.6 | 102.3 | 41.1 |

| 97,786 | 83.0 | 5.660 | 146.851 | 610.2 | 61.1 | 45.6 | 106.7 | 72.8 | 51.0 | 123.8 | 51.6 |

| 105,423 | 94.4 | 5.545 | 170.455 | 630.1 | 70.9 | 53.3 | 124.2 | 84.5 | 59.6 | 144.1 | 60.4 |

| 112,706 | 105.4 | 5.256 | 198.901 | 666.3 | 80.0 | 64.5 | 144.5 | 95.4 | 71.9 | 167.3 | 73.0 |

| 115,675 | 110.1 | 5.057 | 212.371 | 690.3 | 83.7 | 70.0 | 153.7 | 99.7 | 78.1 | 177.8 | 79.3 |

| Engine Model | ηCt | ηTt | i2t | p2t | δT | p4t | Gf | C5 | ϕJ | M5 | η.te |

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | - | kW | bar a | - | bar a | kg/s | m/s | - | - | - | |

| P80-SE | 0.82 | 0.82 | 382.763 | 2.2839 | 1.5335 | 1.4297 | 0.2440 | 397.5 | 0.962 | 0.663 | 11.20 |

| P100-RX | 0.72 | 0.74 | 430.619 | 2.8797 | 1.8541 | 1.4910 | 0.2352 | 425.2 | 0.908 | 0.658 | 9.61 |

| P130-RX | 0.72 | 0.74 | 435.896 | 2.979 | 1.9065 | 1.5000 | 0.3067 | 423.9 | 0.902 | 0.659 | 9.69 |

| P160-RXi-B | 0.74 | 0.75 | 455.906 | 3.4754 | 2.2378 | 1.4909 | 0.3870 | 408.2 | 0.929 | 0.677 | 10.79 |

| Pegasus HP | 0.72 | 0.75 | 446.089 | 3.1776 | 2.0547 | 1.4846 | 0.4063 | 411.0 | 0.914 | 0.661 | 9.67 |

| P180-NX | 0.74 | 0.76 | 455.906 | 3.4754 | 2.1090 | 1.5820 | 0.3878 | 451.3 | 0.929 | 0.728 | 11.92 |

| P200-RX | 0.74 | 0.76 | 477.587 | 3.9719 | 2.3464 | 1.6250 | 0.4588 | 457.8 | 0.925 | 0.747 | 12.90 |

| P220-RXi | 0.74 | 0.76 | 473.411 | 3.8726 | 2.2202 | 1.6745 | 0.4597 | 478.6 | 0.917 | 0.763 | 12.81 |

| Olympus HP | 0.74 | 0.77 | 446.617 | 3.2769 | 1.8720 | 1.6804 | 0.4607 | 499.3 | 0.917 | 0.763 | 12.64 |

| P300-PRO | 0.80 | 0.80 | 445.425 | 3.5251 | 1.7527 | 1.9308 | 0.5131 | 584.7 | 0.928 | 0.877 | 15.74 |

| Titan | 0.75 | 0.78 | 466.746 | 3.7733 | 1.9317 | 1.8752 | 0.6770 | 579.0 | 0.944 | 0.873 | 15.68 |

| P400-PRO | 0.77 | 0.78 | 462.11 | 3.7733 | 1.8931 | 1.9135 | 0.6874 | 577.5 | 0.925 | 0.867 | 15.46 |

| P500-PRO GL | 0.78 | 0.79 | 451.581 | 3.5747 | 1.8994 | 1.8068 | 0.9206 | 534.4 | 0.932 | 0.834 | 14.96 |

| P550-PRO GL | 0.80 | 0.83 | 455.59 | 3.7733 | 1.8415 | 1.9671 | 0.9520 | 577.7 | 0.936 | 0.900 | 16.96 |

| Nike | 0.80 | 0.82 | 463.387 | 3.9719 | 1.8571 | 2.0532 | 1.2817 | 611.7 | 0.941 | 0.935 | 17.78 |

| P1000-PRO | 0.85 | 0.87 | 445.747 | 3.7733 | 1.7452 | 2.0757 | 1.8388 | 598.2 | 0.942 | 0.946 | 19.92 |

| Lynx | 0.81 | 0.83 | 461.225 | 3.9719 | 1.8354 | 2.0775 | 2.5600 | 612.9 | 0.938 | 0.940 | 18.82 |

| NE rpm | Maf | Gf | πCt | i2t | ηCt | δTt | p4t | C5 | M5 | η.te | ηCt∙ηTt |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/s | kg/s | - | kW | - | - | bar a | m/s | - | - | ||

| 34,951 | 0.045 | 0.0458 | 1.1368 | 299.790 | 0.860 | 1.0612 | 1.0368 | 100.5 | 0.165 | 0.77 | 0.722 |

| 47,160 | 0.061 | 0.0615 | 1.2070 | 305.813 | 0.859 | 1.0932 | 1.0686 | 151.2 | 0.251 | 1.80 | 0.722 |

| 55,320 | 0.071 | 0.0726 | 1.2690 | 311.839 | 0.827 | 1.1217 | 1.095 | 184.5 | 0.304 | 2.57 | 0.694 |

| 68,295 | 0.097 | 0.0982 | 1.4023 | 322.992 | 0.818 | 1.1886 | 1.1419 | 224.1 | 0.378 | 4.03 | 0.687 |

| 79,369 | 0.123 | 0.1245 | 1.5521 | 333.851 | 0.827 | 1.2599 | 1.1924 | 257.0 | 0.443 | 5.57 | 0.695 |

| 88,787 | 0.148 | 0.1504 | 1.7133 | 345.727 | 0.819 | 1.3371 | 1.2401 | 284.5 | 0.494 | 6.90 | 0.688 |

| 97,786 | 0.170 | 0.1725 | 1.8859 | 356.607 | 0.824 | 1.4005 | 1.3032 | 319.5 | 0.552 | 8.44 | 0.692 |

| 105,423 | 0.193 | 0.1962 | 2.0636 | 368.104 | 0.818 | 1.4714 | 1.3574 | 345.6 | 0.596 | 9.68 | 0.687 |

| 112,706 | 0.214 | 0.2172 | 2.2620 | 379.210 | 0.821 | 1.5275 | 1.4332 | 381.2 | 0.650 | 11.18 | 0.690 |

| 115,675 | 0.220 | 0.2233 | 2.3415 | 383.960 | 0.818 | 1.5443 | 1.4675 | 398.1 | 0.672 | 11.74 | 0.687 |

| Engine Model | ΔdlTt | ΔdhJ | ΔdTT | ΔdTE | ΔdTJ.id | ΔdTJ |

|---|---|---|---|---|---|---|

| % | % | % | % | % | % | |

| P80-SE | 0.17 | −0.17 | 1.50 | 2.91 | 0.03 | 1.65 |

| P100-RX | −0.57 | 0.57 | 3.42 | 5.54 | 0.07 | 2.64 |

| P130-RX | −1.14 | 1.14 | 3.77 | 5.79 | 0.07 | 2.58 |

| P160-RXi-B | −2.57 | 2.57 | 4.64 | 6.05 | 0.08 | 2.06 |

| Pegasus HP | −1.06 | 1.06 | 4.23 | 6.18 | 0.08 | 2.58 |

| P180-NX | −2.43 | 2.43 | 4.09 | 5.70 | 0.08 | 2.26 |

| P200-RX | −3.16 | 3.16 | 4.72 | 6.09 | 0.11 | 2.11 |

| P220-RXi | −1.96 | 1.96 | 4.32 | 6.27 | 0.09 | 2.74 |

| Olympus HP | −2.30 | 2.30 | 3.45 | 5.31 | 0.09 | 2.43 |

| P300-PRO | −0.80 | 0.80 | 2.41 | 4.73 | 0.07 | 2.89 |

| Titan | −3.88 | 3.88 | 3.56 | 5.13 | 0.11 | 2.20 |

| P400-PRO | −0.79 | 0.79 | 2.92 | 5.53 | 0.08 | 3.30 |

| P500-PRO GL | −0.07 | 0.07 | 2.68 | 5.18 | 0.08 | 3.14 |

| P550-PRO GL | 0.25 | −0.25 | 2.20 | 4.70 | 0.06 | 3.12 |

| Nike | −2.89 | 2.89 | 3.00 | 4.78 | 0.08 | 2.43 |

| P1000-PRO | −1.68 | 1.68 | 1.93 | 3.27 | 0.07 | 1.78 |

| Lynx | −2.08 | 2.08 | 2.42 | 4.02 | 0.08 | 2.15 |

| NE | ΔdlTt | ΔdhJ | ΔdTT | ΔdTE | ΔdTJ.id | ΔdTJ |

|---|---|---|---|---|---|---|

| rpm | % | % | % | % | % | % |

| 34,951 | −1.15 | 1.15 | 0.23 | 0.30 | 0.00 | 0.07 |

| 47,160 | −1.30 | 1.30 | 0.35 | 0.51 | −0.01 | 0.18 |

| 55,320 | −1.34 | 1.34 | 0.46 | 0.67 | 0.00 | 0.23 |

| 68,295 | −1.40 | 1.40 | 0.69 | 1.01 | 0.00 | 0.36 |

| 79,369 | −1.47 | 1.47 | 0.91 | 1.35 | 0.02 | 0.48 |

| 88,787 | −1.52 | 1.52 | 1.14 | 1.65 | 0.01 | 0.59 |

| 97,786 | −1.59 | 1.59 | 1.32 | 1.94 | −0.01 | 0.75 |

| 105,423 | −1.64 | 1.64 | 1.49 | 2.19 | 0.02 | 0.85 |

| 112,706 | −1.69 | 1.69 | 1.62 | 2.43 | 0.02 | 1.01 |

| 115,675 | −1.71 | 1.71 | 1.65 | 2.50 | 0.03 | 1.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Catana, R.M.; Cican, G.; Badea, G.-P. Thermodynamic Analysis and Performance Evaluation of Microjet Engines in Gas Turbine Education. Appl. Sci. 2024, 14, 6754. https://doi.org/10.3390/app14156754

Catana RM, Cican G, Badea G-P. Thermodynamic Analysis and Performance Evaluation of Microjet Engines in Gas Turbine Education. Applied Sciences. 2024; 14(15):6754. https://doi.org/10.3390/app14156754

Chicago/Turabian StyleCatana, Razvan Marius, Grigore Cican, and Gabriel-Petre Badea. 2024. "Thermodynamic Analysis and Performance Evaluation of Microjet Engines in Gas Turbine Education" Applied Sciences 14, no. 15: 6754. https://doi.org/10.3390/app14156754