Numerical Simulation Study of Cavity Formation in Soil under Blast Load

Abstract

:1. Introduction

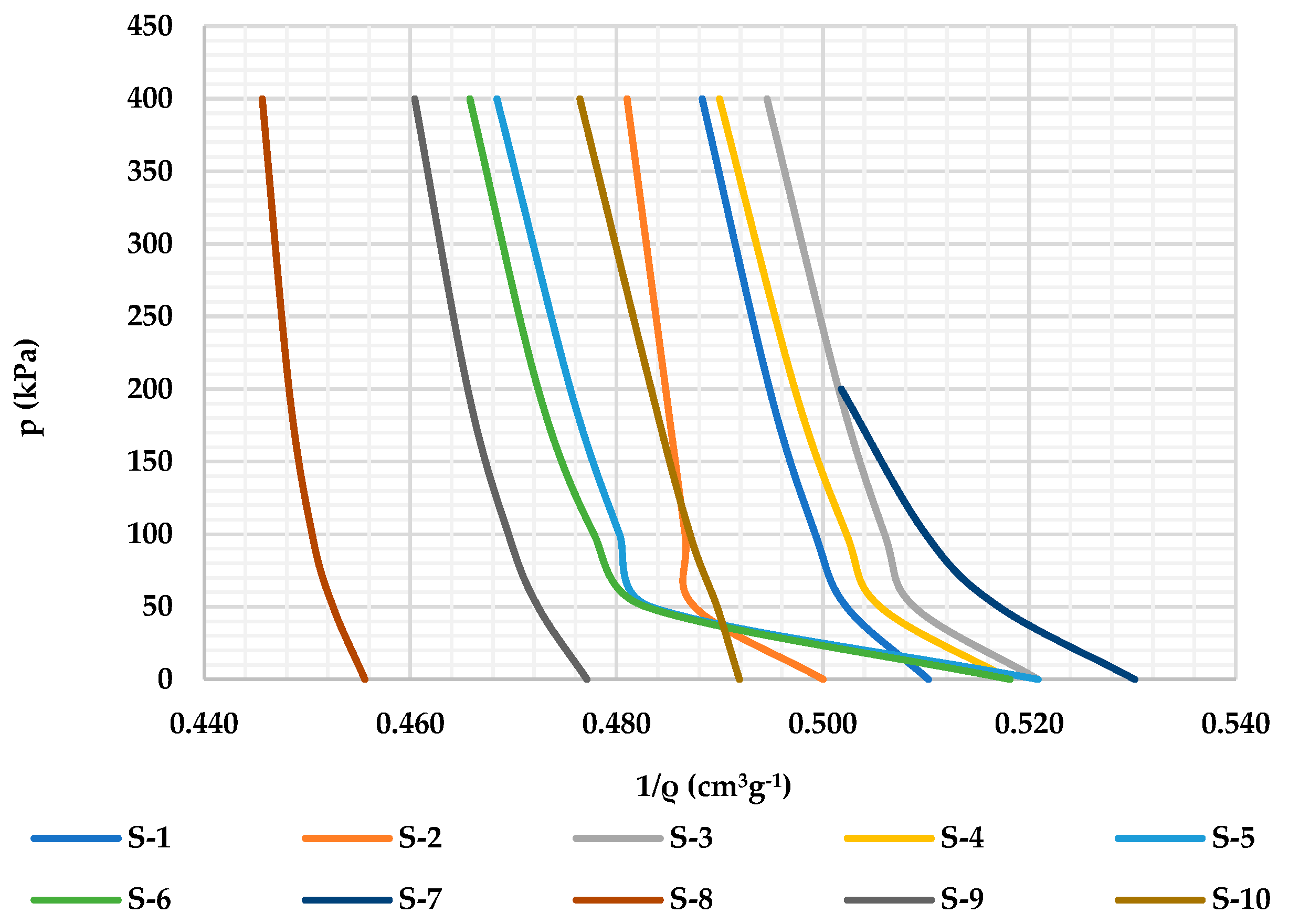

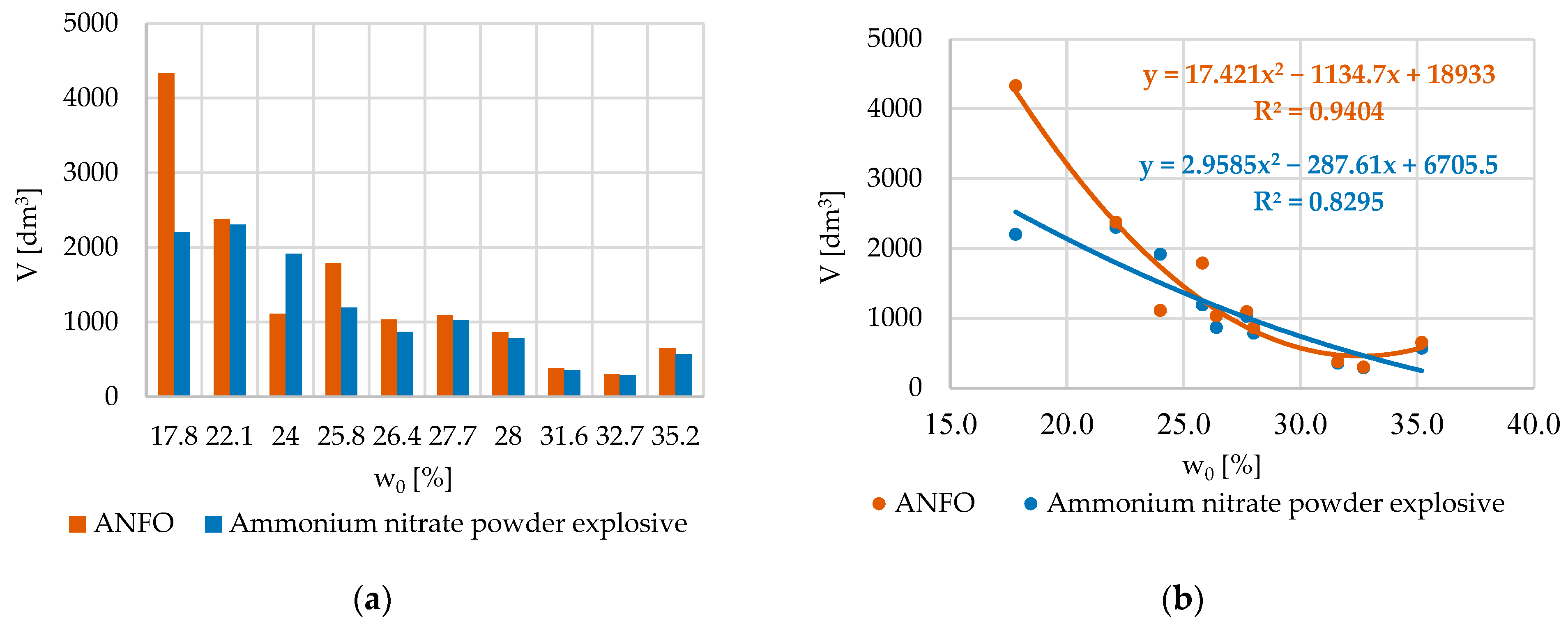

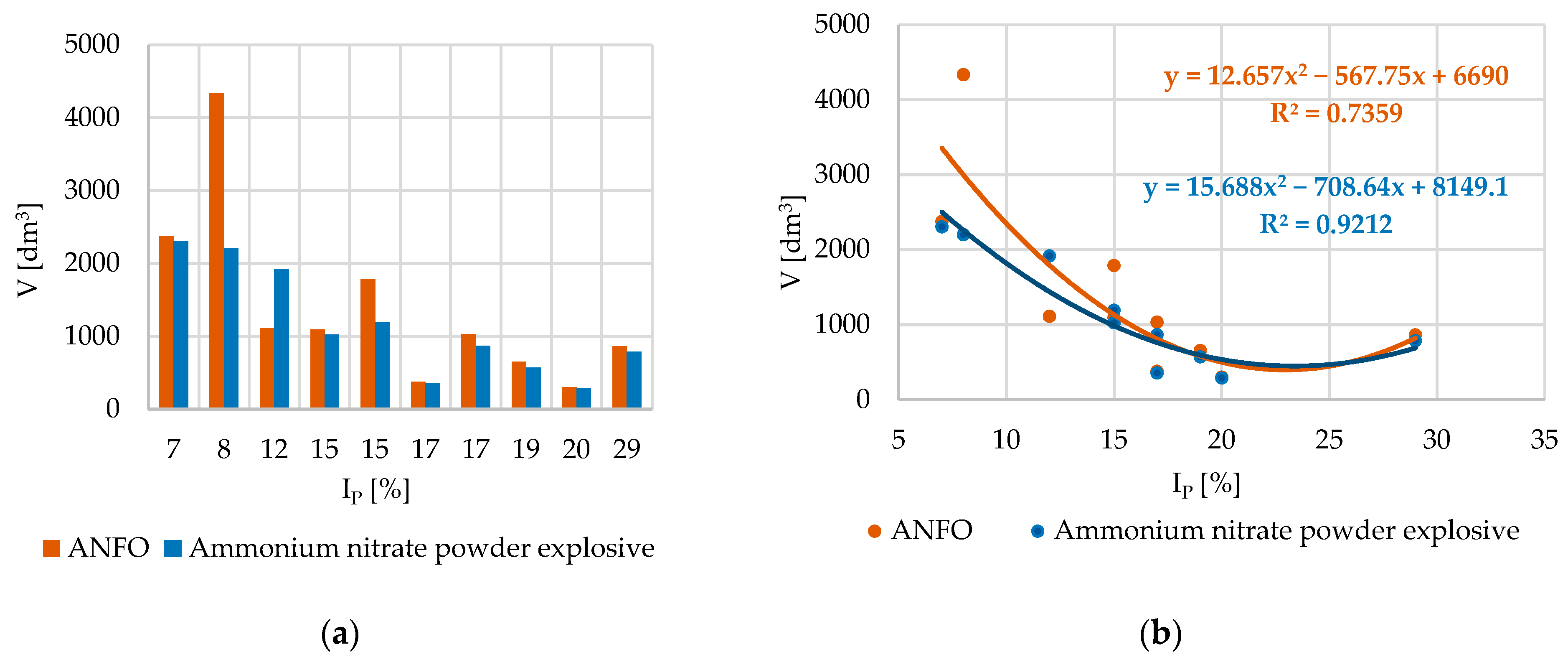

2. Materials and Methods

- -

Pakaex: NH4NO3 and mineral oil; ANFOPermonex:ammonium nitrate, trinitrotoluene, dinitrotoulene, paraffin wax, and moisture; Ammonium nitrate powder explosive- -

Riogel (:NH4NO3, MMAN, water, NaNO3, and aluminum. Watergel

3. Numerical Simulation Results and Discussion

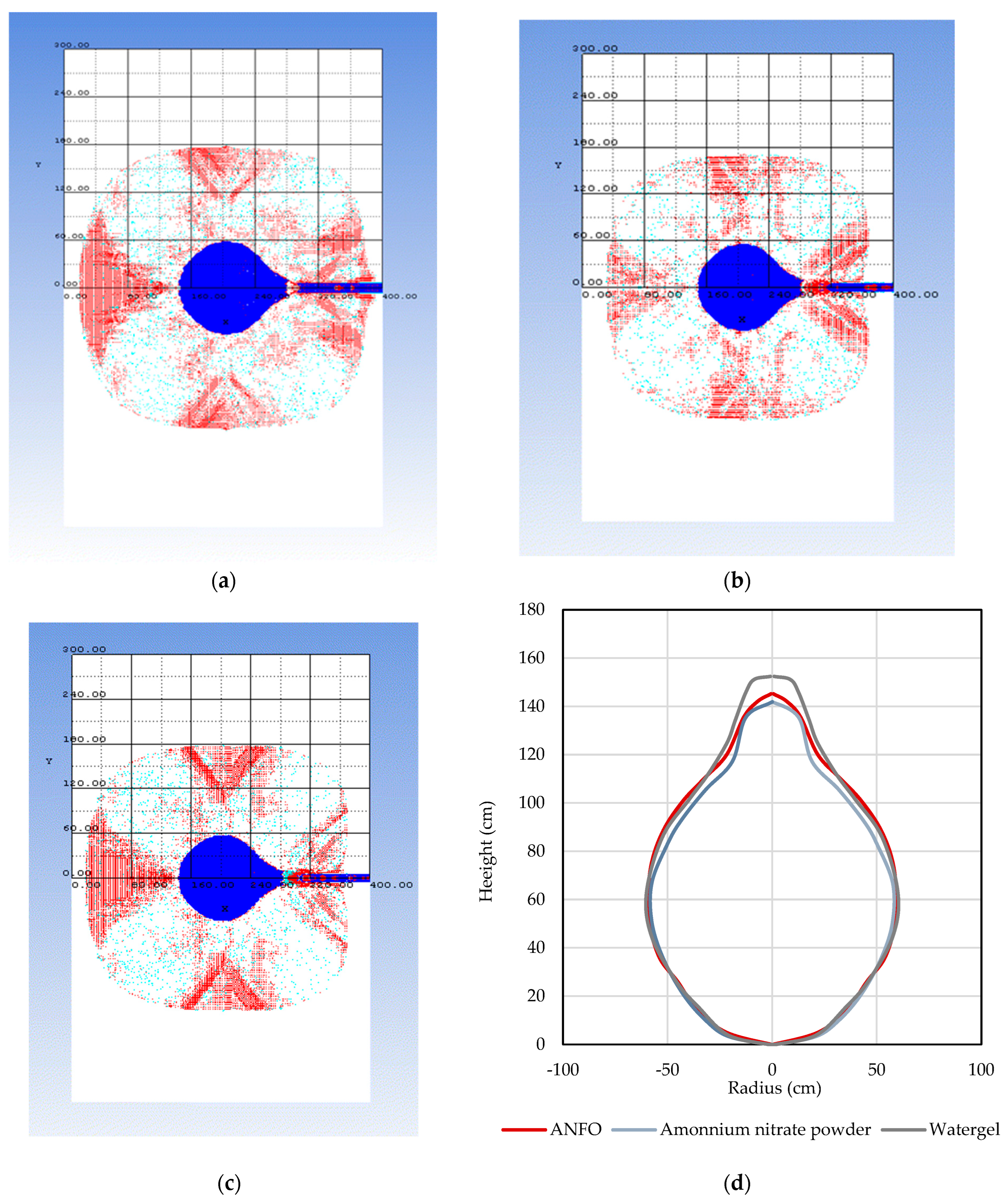

3.1. Validation of Numerical Model

3.2. Results of Numerical Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Hao, H.; Lu, Y. A three-phase soil model for simulating stress wave propagation due to blast loading. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 33–56. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Y. Numerical analysis on dynamic deformation mechanism of soil under blast loading. Soil Dyn. Earthq. Eng. 2003, 23, 705–714. [Google Scholar] [CrossRef]

- An, J.; Tuan, C.Y.; Cheeseman, B.A.; Gazonas, G.A. Simulation of Soil Behavior under Blast Loading. Int. J. Geomech. 2011, 11, 323–334. [Google Scholar] [CrossRef]

- Laine, L.; Pramm Larsen, O. Implementation of Equation of State for Dry Sand in Autodyn. In Proceedings of the 83rd Shock and Vibration Symposium, Shock and Vibration Exchange, New Orleans, LA, USA, 4–8 November 2012. [Google Scholar]

- Jayasinghe, L.B.; Thambiratnam, D.P.; Perera, N.; Jayasooriya, J.H.A.R. Computer simulation of underground blast response of pile in saturated soil. Comput. Struct. 2013, 120, 86–95. [Google Scholar] [CrossRef]

- Težak, D.; Stanković, S.; Kovač, I. Dependence Models of Borehole Expansion on Explosive Charge in Spherical Cavity Blasting. Geosciences 2019, 9, 383. [Google Scholar] [CrossRef]

- Henrych, J. The Dynamics of Explosion and Its Use, 1st ed.; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1979; pp. 259–269. [Google Scholar]

- Suceska, M. Test Methods for Explosives, 1st ed.; Springer Science & Business Media: New York, NY, USA, 2012; p. 225. [Google Scholar]

- Fickett, W.; Davis, W.C. Detonation: Theory and Experiment; reprint; Dover Publications Inc.: New York, NY, USA, 2000; p. 386. [Google Scholar]

- Cooper, P.W. Explosives Engineering, 1st ed.; Wiley-VCH: Weinheim, Germany, 2018; p. 480. [Google Scholar]

- Zukas, J.A.; Walters, W.P. Explosive Effect and Applications, 1st ed.; Springer Science & Business Media: New York, NY, USA, 1998; p. 433. [Google Scholar]

- Suceska, M. Evaluation of detonation energy from EXPLO5 computer code results. Propellants Explos. Pyrotech. 1999, 24, 280–285. [Google Scholar] [CrossRef]

- ANSYS Autodyn, version 13.0; User′s Manual Release 2010; ANSYSInc.: Canonsburg, PA, USA, 2010.

- Lee, E.L.; Horing, H.C.; Kury, J.K. Lawrence Radiation Laboratory. University of California, Livermore. UCRL-50422. 1968. Available online: https://www.osti.gov/biblio/4783904 (accessed on 26 May 2024). [CrossRef]

- Dobrilović, I.; Težak, D.; Dobrilović, M.; Sućeska, M.; Stanković, S.; Škrlec, V.; Bohanek, V. Modeling and application of civil explosives in different types of soil. In Proceedings of the 26th Seminar of New Trends in Research of Energetics Materials, Pardubice, Czech Republic, 17–19 April 2024; pp. 360–365. [Google Scholar]

- Težak, D. Influence of the Blasting Features on the Expansion in Clay Soil. Ph.D. Thesis, Faculty of Mining, Geology and Petroleum Engineering, Zagreb, Croatia, 2018. [Google Scholar]

- Nonveiller, E. Mehanika Tla I Temeljenje Građevina, 3rd ed.; Školska knjiga: Zagreb, Croatia, 1989; pp. 29–40. [Google Scholar]

- Mitchell, M.; Muftakhidinov, B.; Winchen, T.; Wilms, A.; Van Schaik, B.; Jedrzejewski-Szmek, Z. Engauge Digitizer Software. Available online: https://markummitchell.github.io/engauge-digitizer/ (accessed on 7 May 2023).

- Araya, K.; Gao, R.; Tsunematsu, S.; Ochi, K. Loosening of dense clay soils by linear blasting. J. Agric. Eng. Res. 1993, 54, 113–126. [Google Scholar] [CrossRef]

- Narsilio, G.A.; Santamarina, J.C.; Hebeler, T.; Bachus, R. Blast Densification: Multi-Instrumented Case History. J. Geotech. Geoenvironmental Eng. 2009, 135, 723–734. [Google Scholar] [CrossRef]

- Shakeran, M.; Eslami, A.; Ahmadpour, M. Geotechnical Aspects of Explosive Compaction. Shock. Vib. 2016, 14, 6719271. [Google Scholar] [CrossRef]

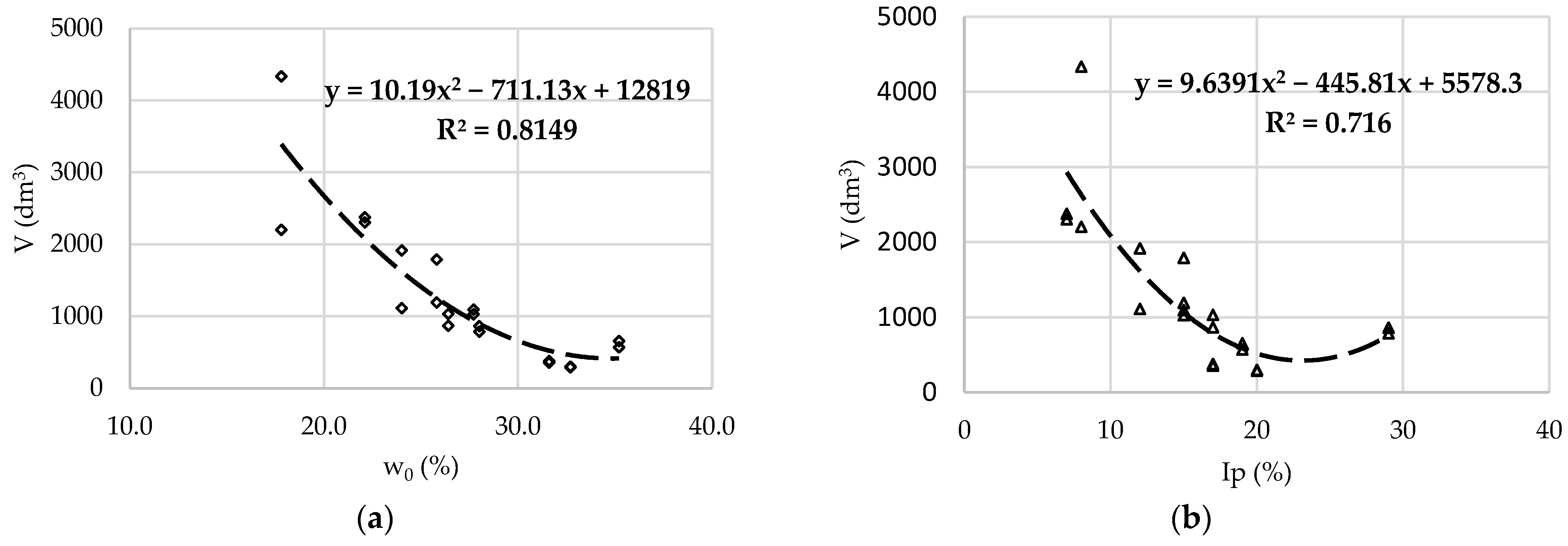

| Designation of Soil | Moisture Content [%] | Grain Size Distribution | Liquid Limit wL [%] | Plasticity Limit wp [%] | Plast. Index Ip [%] | Cons. Index Ic [-] | Solid Particle Density ρs [g/cm3] | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Gravel [%] | Sand [%] | Silt [%] | Clay [%] | |||||||

| S-1 | 28.0 | 3.5 | 3.1 | 55.6 | 37.8 | 51 | 22 | 29 | 0.79 | 2.71 |

| S-2 | 24.0 | 0.0 | 6.2 | 77.1 | 16.7 | 34 | 22 | 12 | 0.83 | 2.70 |

| S-3 | 32.7 | 0.0 | 3.9 | 68.0 | 28.1 | 44 | 24 | 20 | 0.57 | 2.75 |

| S-4 | 31.6 | 0.3 | 7.2 | 71.2 | 20.8 | 40 | 23 | 17 | 0.49 | 2.74 |

| S-5 | 26.4 | 0.0 | 4.8 | 64.5 | 30.8 | 39 | 22 | 17 | 0.78 | 2.76 |

| S-6 | 27.7 | 0.0 | 9.2 | 61.6 | 29.2 | 36 | 21 | 15 | 0.64 | 2.75 |

| S-7 | 35.2 | 0.0 | 10.4 | 71.2 | 18.5 | 48 | 29 | 19 | 0.66 | 2.66 |

| S-8 | 17.8 | 0.0 | 17.9 | 65.9 | 16.2 | 29 | 21 | 8 | 0.77 | 2.72 |

| S-9 | 22.1 | 0.0 | 49.9 | 35.9 | 14.2 | 28 | 21 | 7 | 0.63 | 2.70 |

| S-10 | 25.8 | 0.0 | 5.0 | 73.4 | 21.6 | 35 | 20 | 15 | 0.61 | 2.71 |

| Type of Explosive (Trade Name) | Density (g/cm3) | Velocity of Detonation (Measured) (m/s) | Theoretical Heat of Detonation (Literature and Producer Declaration) (KJ/kg) |

|---|---|---|---|

| ANFO ( | 0.90 | 2000 | 3597 |

| Ammonium nitrate powder explosive ( | 1.05 | 4000 | 4276 |

| Watergel ( | 1.25 | 4576 | 4591 |

| Type of Explosive | A (Mbar) | B (Mbar) | R1 (-) | R2 (-) | ω (-) | D (cm/μs) | P (Mbar) | E (Gerg/mm3) |

|---|---|---|---|---|---|---|---|---|

| ANFO (Pakaex) | 0.062805 [15] | 0.001513 [15] | 2.193732 [15] | 0.464714 [15] | 0.177879 [15] | 0.304939 [15] | 0.01933323 [15] | 0.029706 [15] |

| Ammonium nitrate Powder (Permonex) | 0.79023 | 0.01257 | 4.6797 | 0.9529 | 0.1933 | 0.4022 | 0.0379 | 0.0318 |

| Gel (Riogel) | 2.38931 | 0.022655 | 5.203369 | 1.054384 | 0.158459 | 0.4587 | 0.05828 | 0.0412 |

| Type of Explosive | Cavity Experimental [dm3] | Cavity Model [dm3] | Deviation [%] |

|---|---|---|---|

| ANFO (Pakaex) | 752 [15] | 839 [15] | 12.9 [15] |

| Ammonium nitrate powder explosive (Permonex) | 835 | 789 | 6.1 |

| Field Designation of Soil | ANFO | Ammonium Nitrate Powdered Explosive |

|---|---|---|

| Volume of Cavity [dm3] | Volume of Cavity [dm3] | |

| S-1 | 863 | 787 |

| S-2 | 1112 | 1917 |

| S-3 | 300 | 291 |

| S-4 | 378 | 356 |

| S-5 | 1033 | 868 |

| S-6 | 1095 | 1027 |

| S-7 | 655 | 572 |

| S−-8 | 4333 | 2202 |

| S-9 | 2377 | 2304 |

| S-10 | 1790 | 1193 |

| Type of Explosive | Pressure [GPa] | Volume of Gas Products [dm3/kg] | Volume of Cavity Formation [dm3] |

|---|---|---|---|

| ANFO | 0.86 | 698 | 863 |

| Ammonium nitrate powder | 3.24 | 628 | 787 |

| Water gel | 5.83 | 593 | 862 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrilović, M.; Dobrilović, I.; Sućeska, M.; Težak, D. Numerical Simulation Study of Cavity Formation in Soil under Blast Load. Appl. Sci. 2024, 14, 6790. https://doi.org/10.3390/app14156790

Dobrilović M, Dobrilović I, Sućeska M, Težak D. Numerical Simulation Study of Cavity Formation in Soil under Blast Load. Applied Sciences. 2024; 14(15):6790. https://doi.org/10.3390/app14156790

Chicago/Turabian StyleDobrilović, Mario, Ivana Dobrilović, Muhamed Sućeska, and Denis Težak. 2024. "Numerical Simulation Study of Cavity Formation in Soil under Blast Load" Applied Sciences 14, no. 15: 6790. https://doi.org/10.3390/app14156790