Experimental Study on Shear Creep Characteristics of Residual Soil with Different Stone Content

Abstract

:1. Introduction

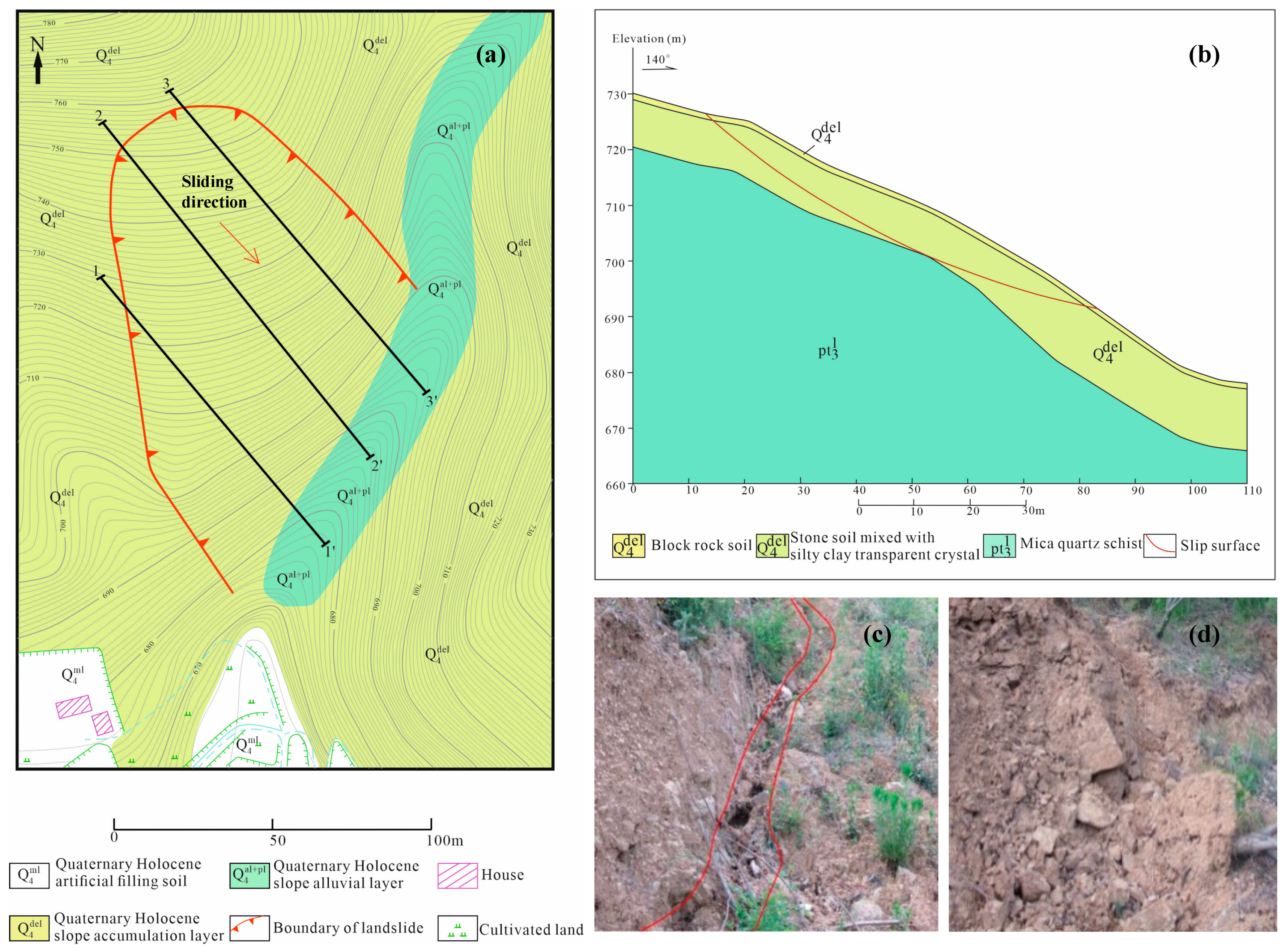

2. Residual Soil Landslide Overview

3. Test Program

3.1. Test Equipment

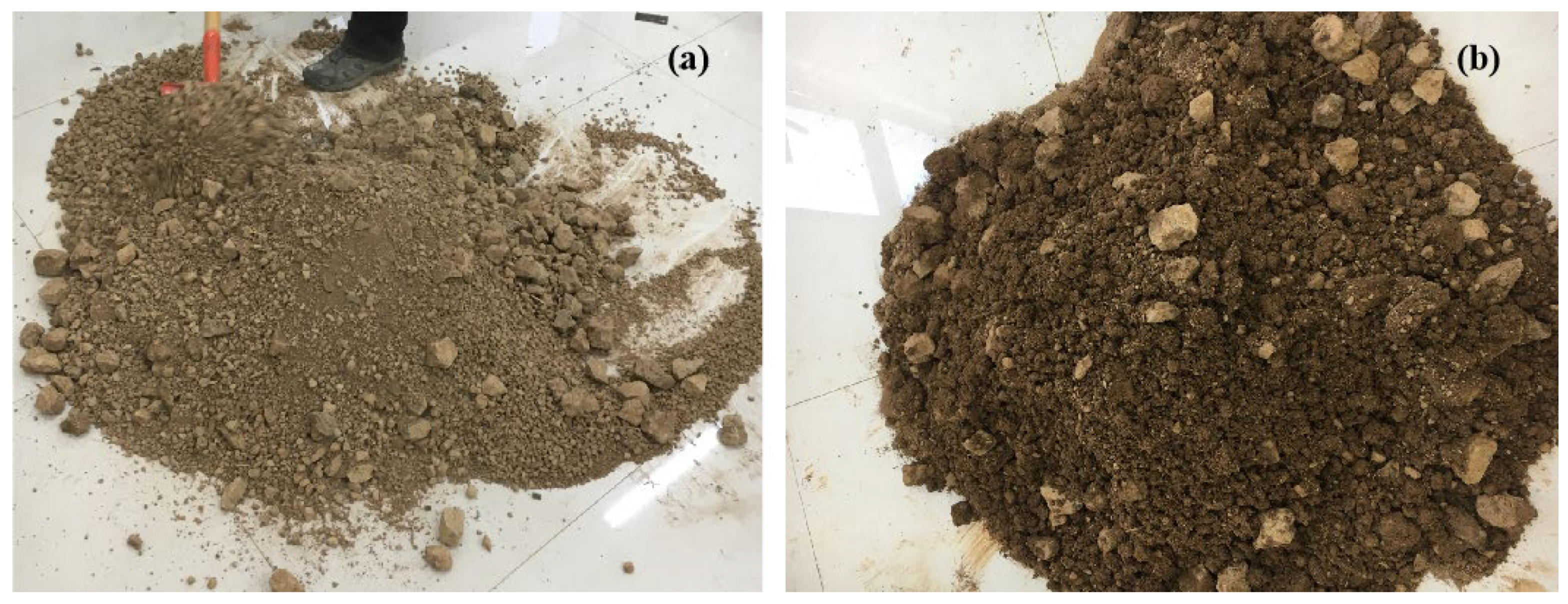

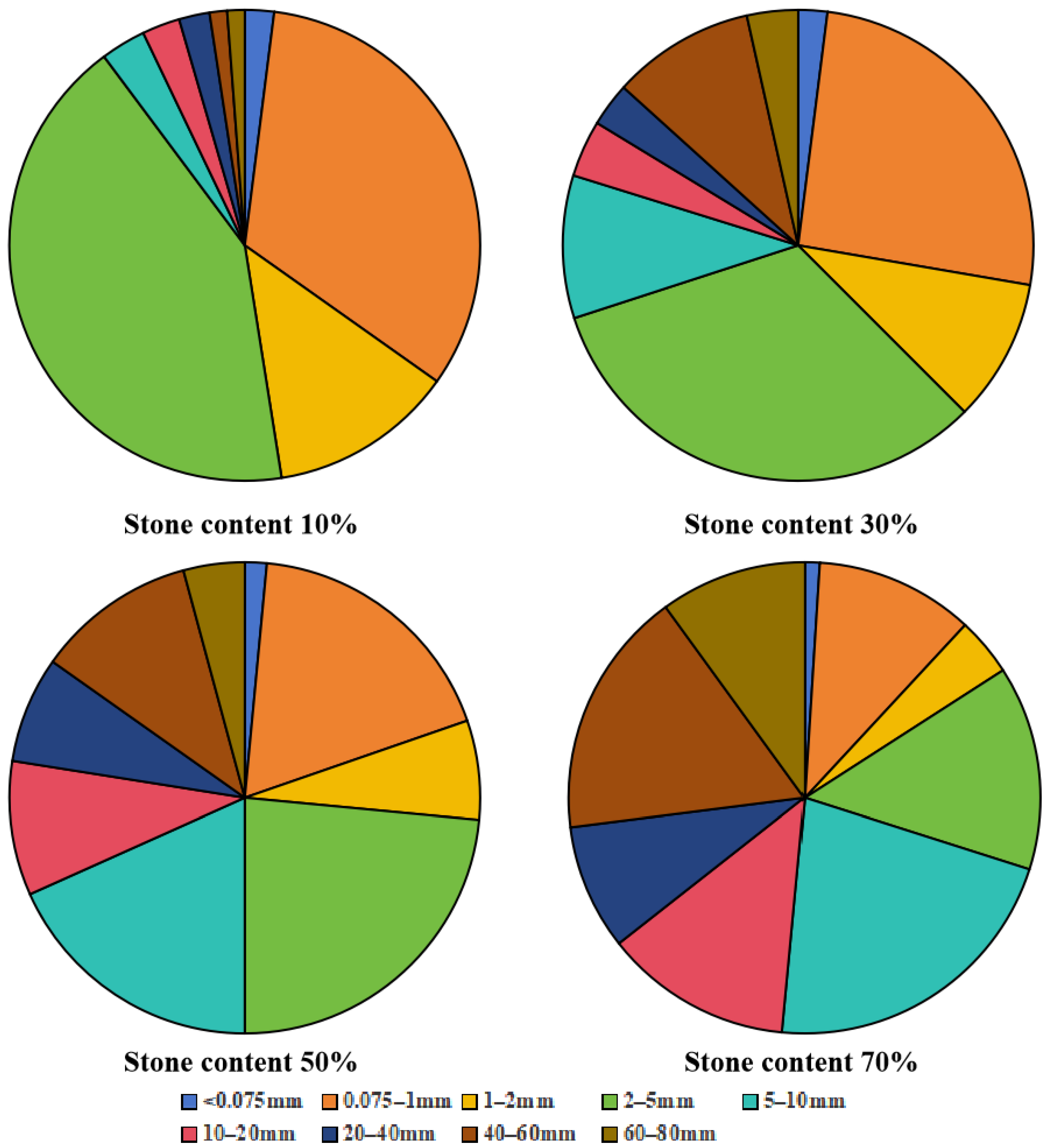

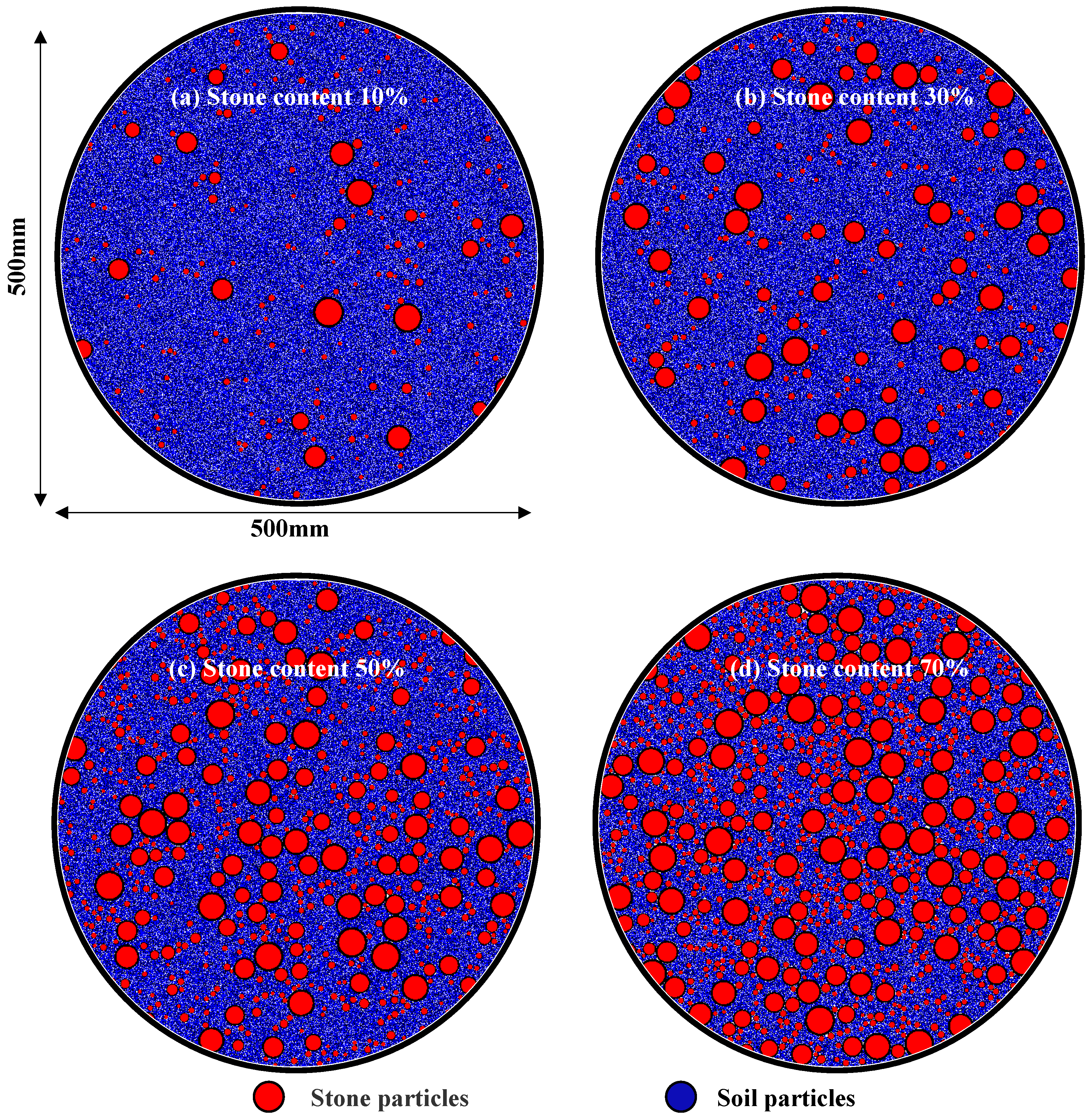

3.2. Sample Preparation

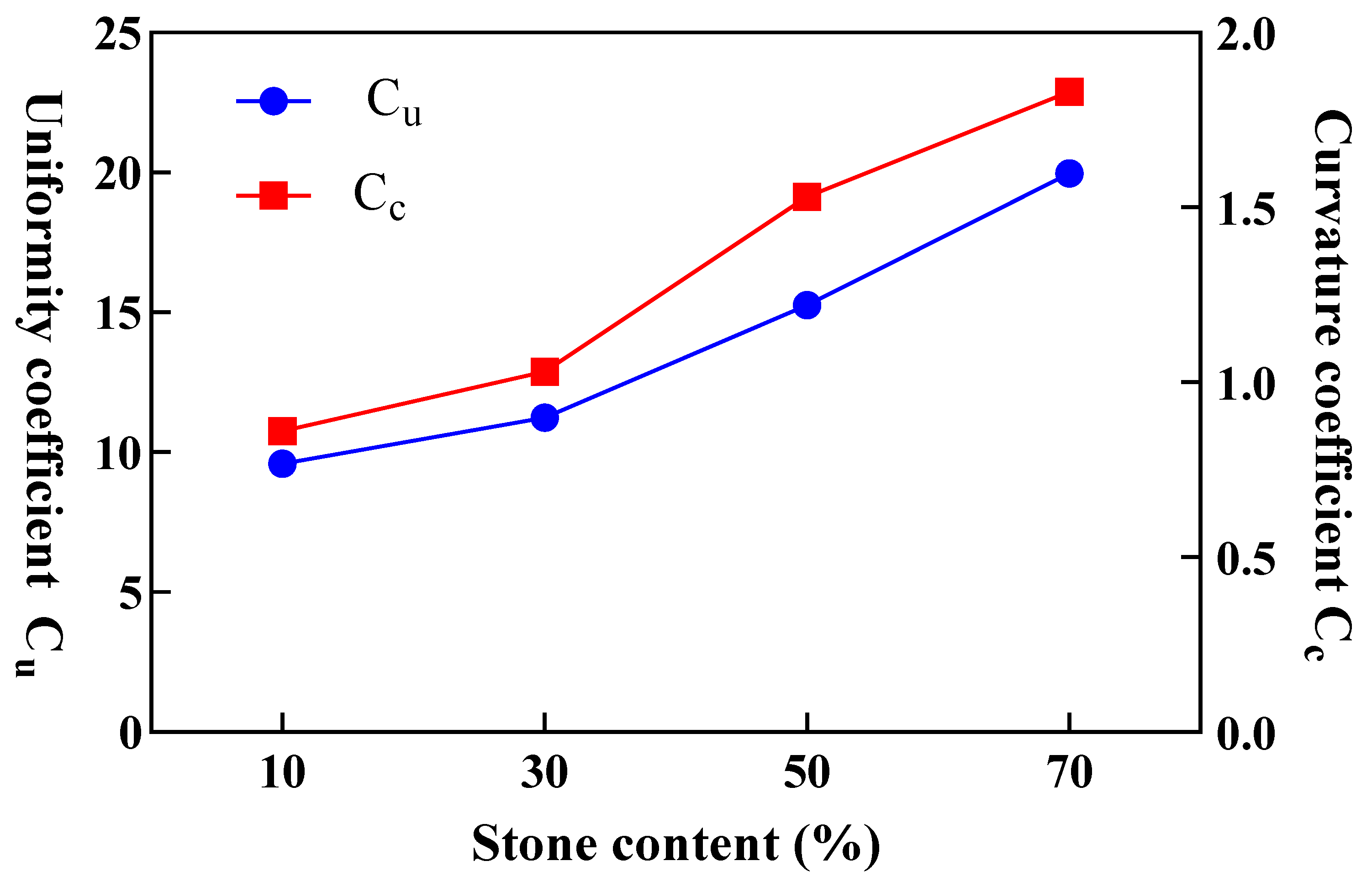

3.3. Loading Program

4. Test Results and Analysis

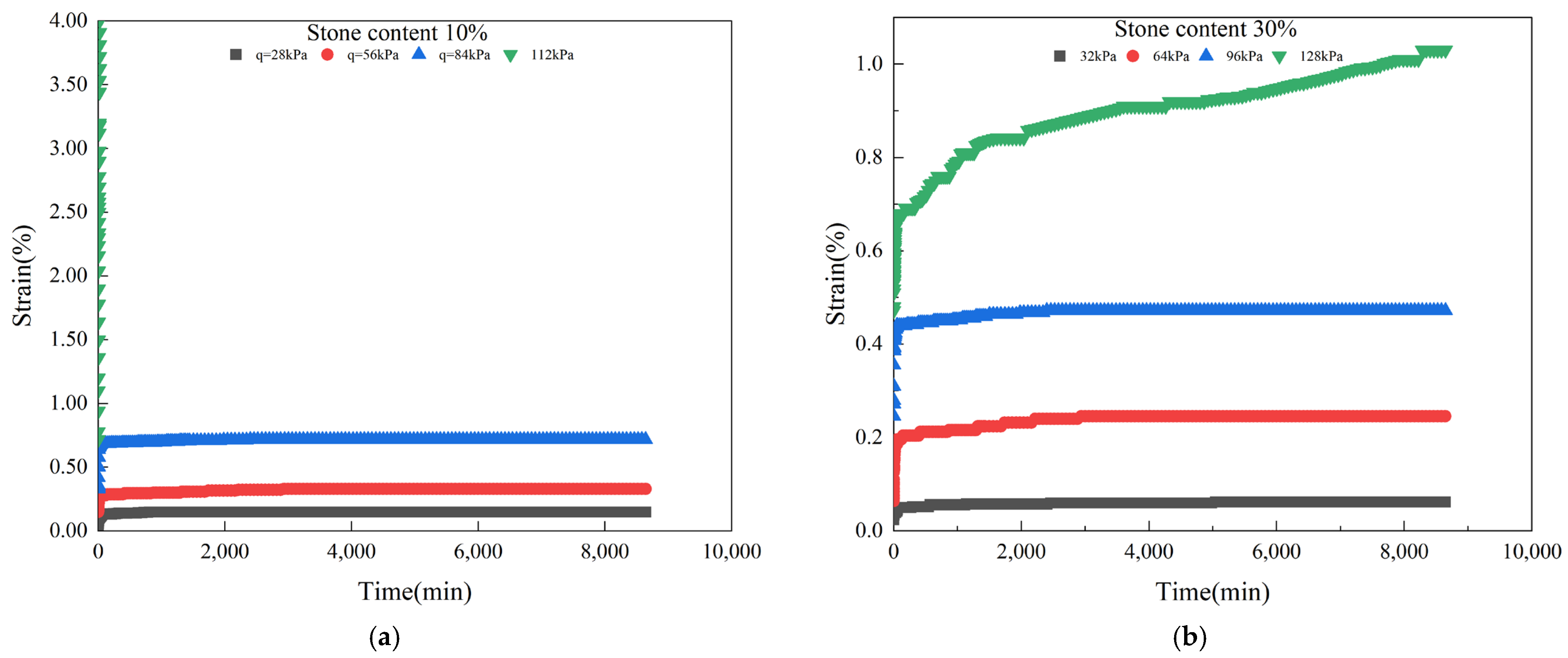

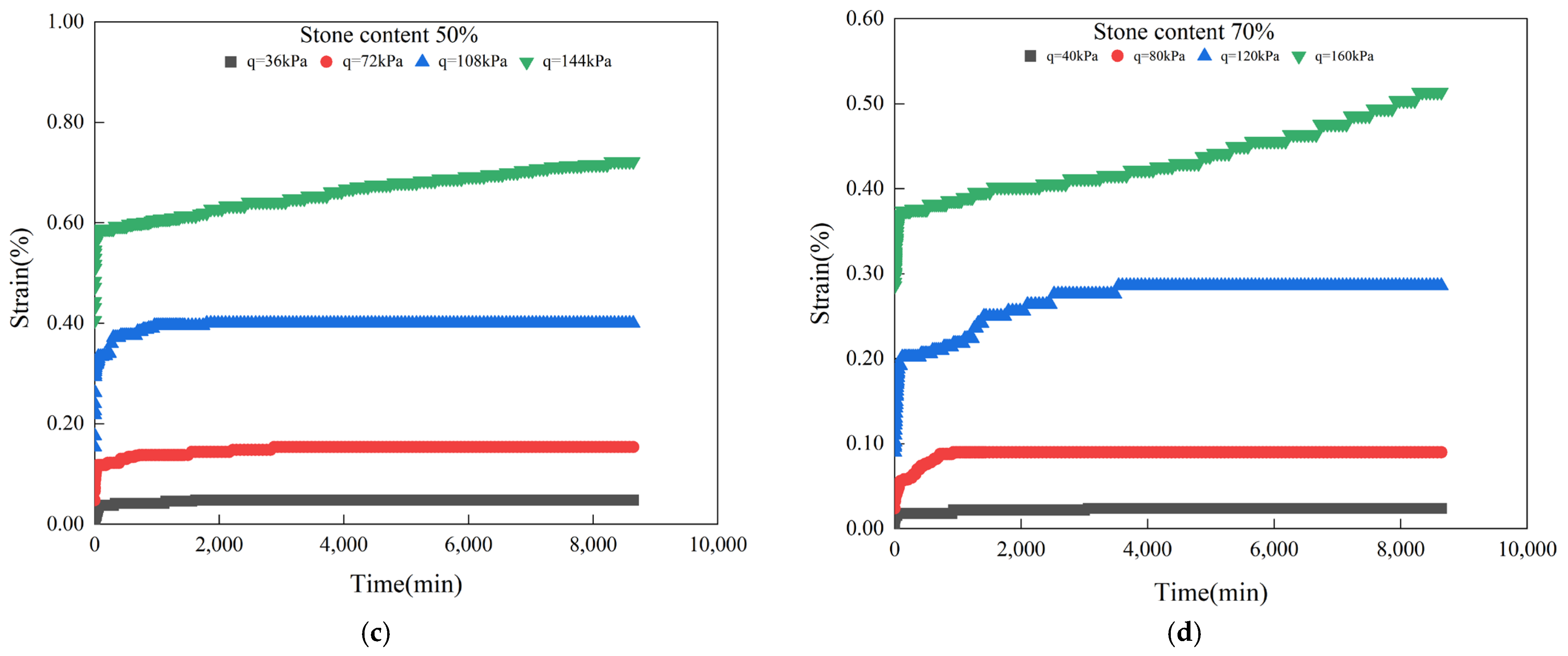

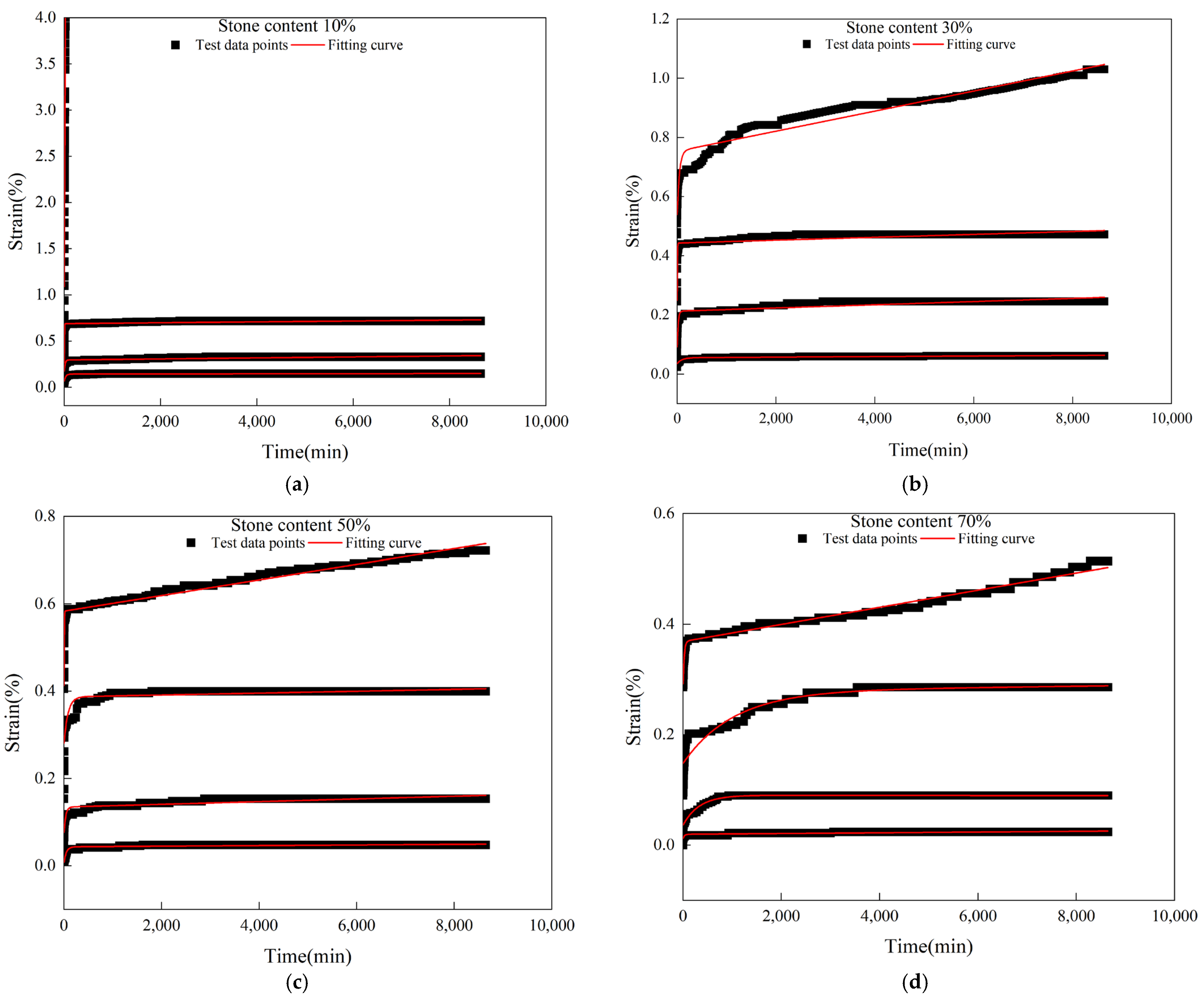

4.1. Characteristics of Creep Curve of Residual Slope Accumulation Soil

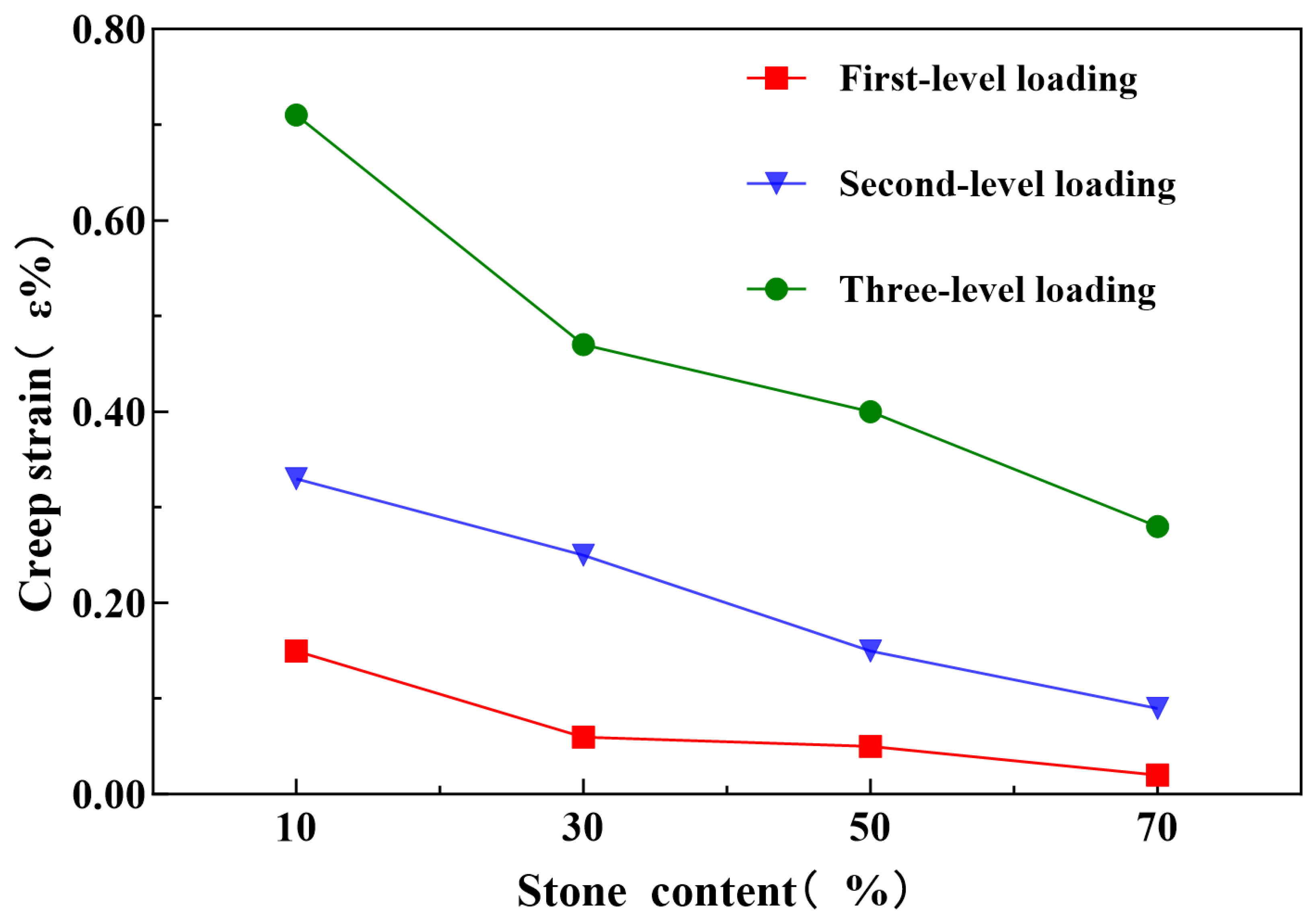

4.2. Influence of Stone Content on Creep of Residual Soil

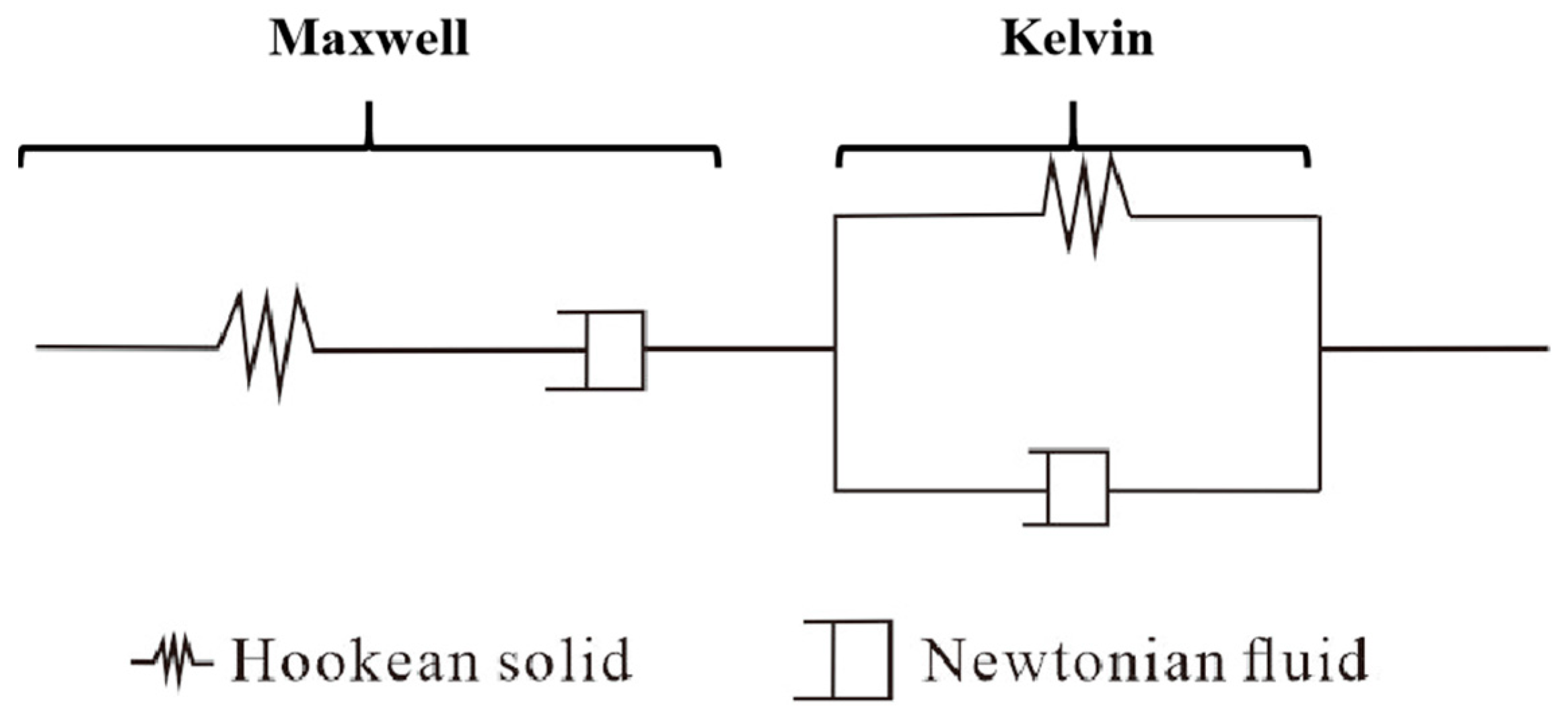

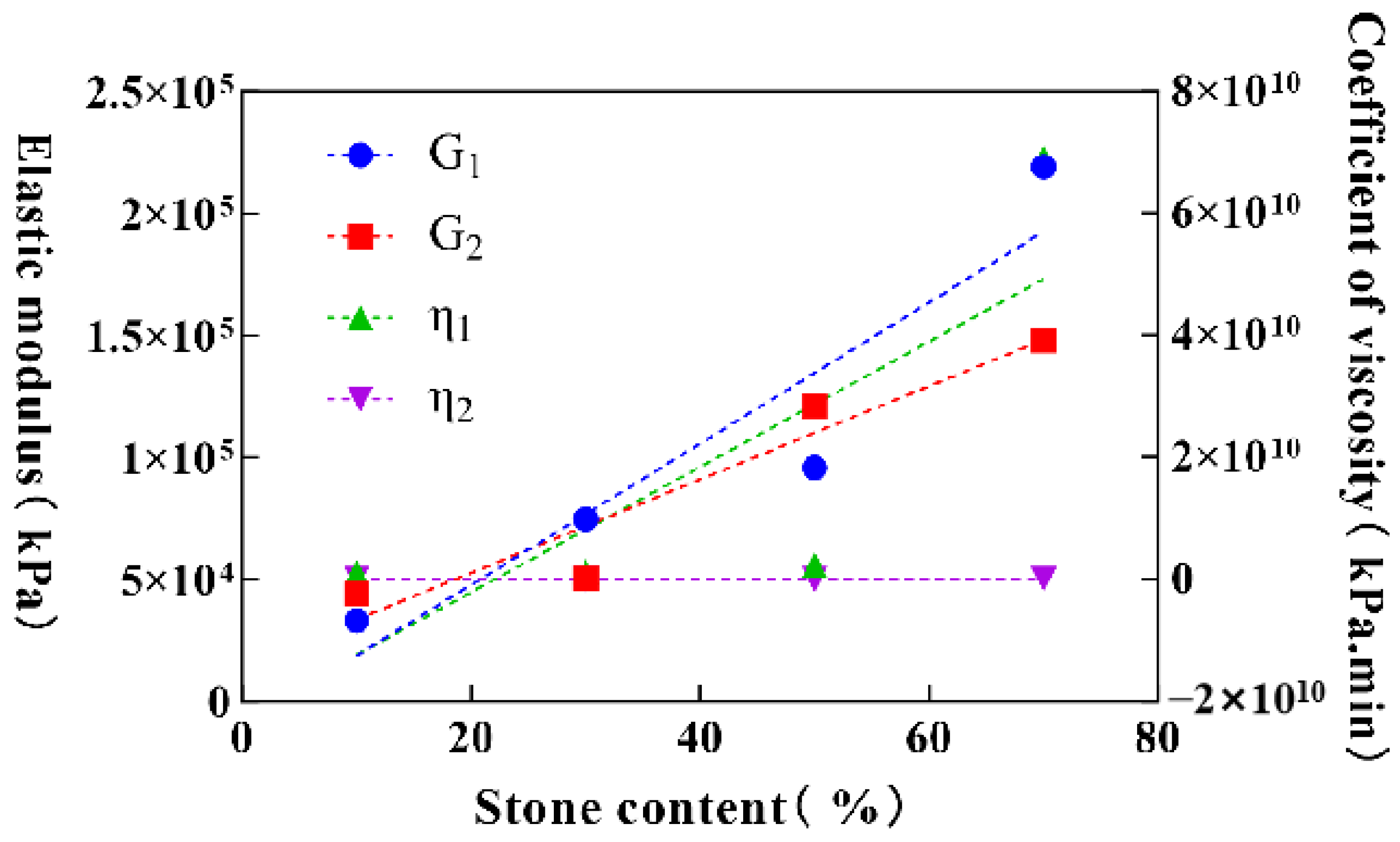

5. Creep Model and Parameterization

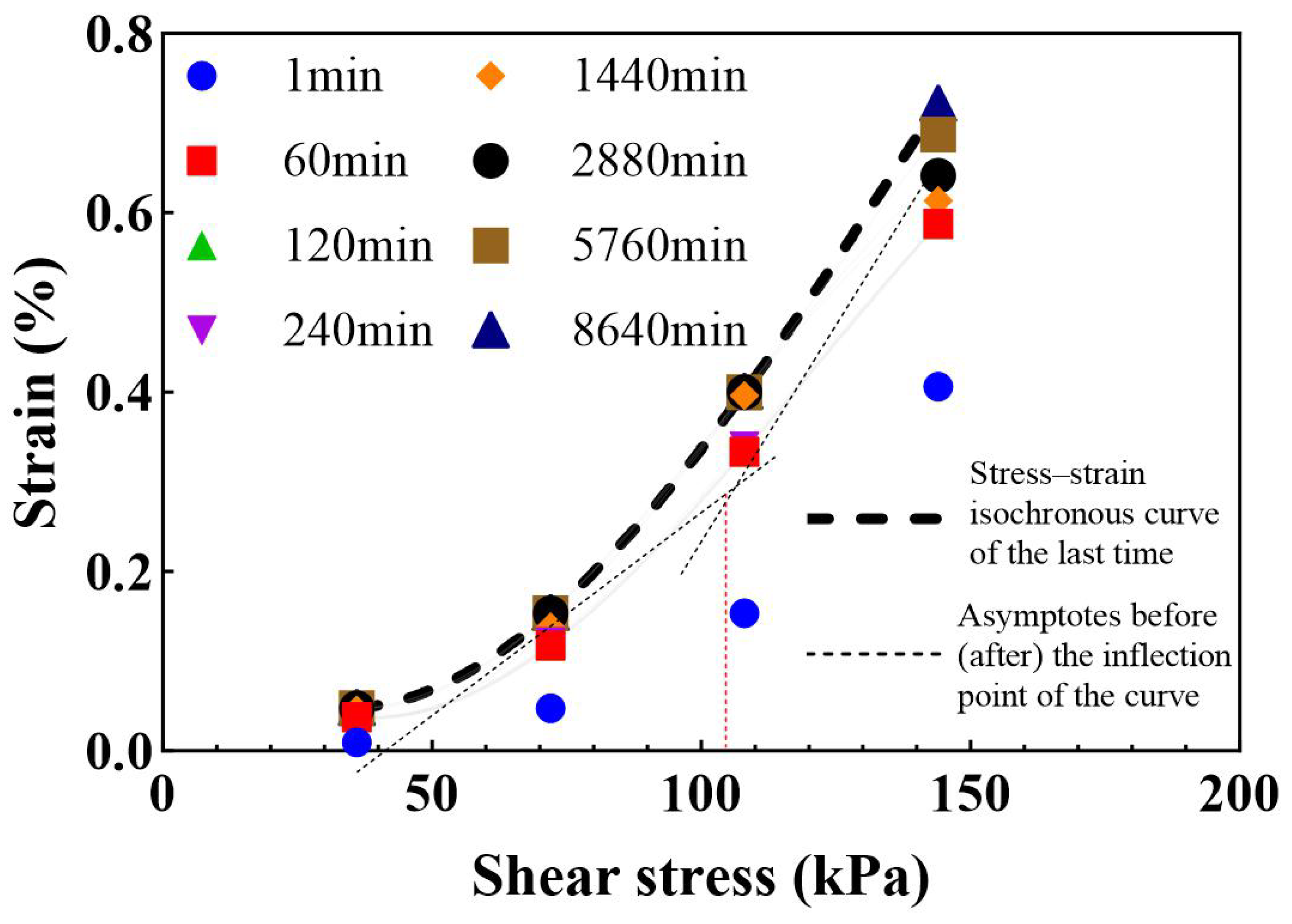

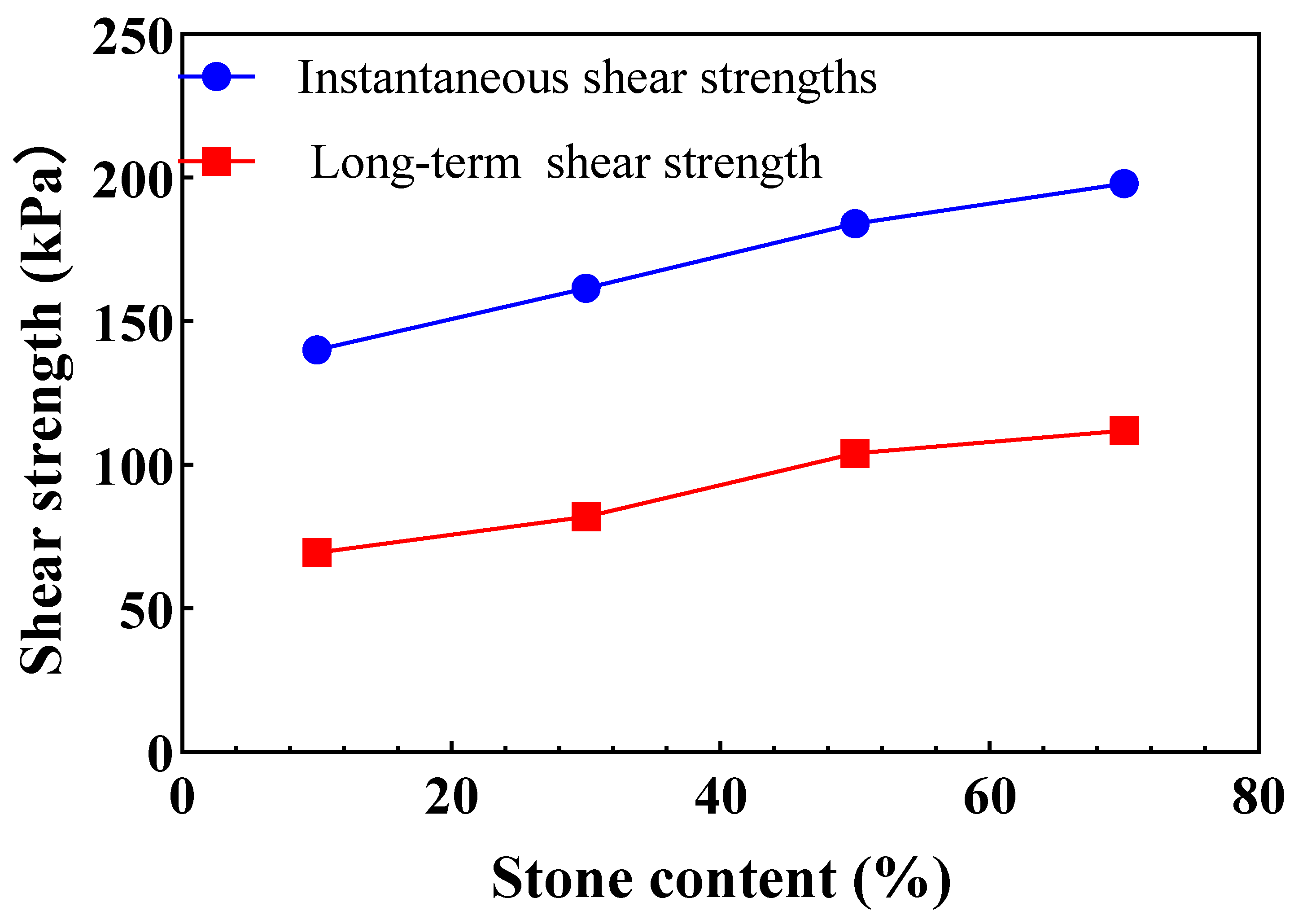

6. Long-Term Strength

7. Discussion

8. Conclusions

- (1)

- Residual slope soil with varying rock contents exhibits noticeable creep behavior. At lower stress levels, it tends to transition from attenuation creep to steady-state creep. However, under high stress, it undergoes accelerated creep. As the stone content increases, the deformation of the sample shifts from primarily displacement of fine particles to a combination of displacement of coarse and fine particles, as well as damage deformation of large particle block stones. With a higher stone content, the interlocking effect of the particle skeleton becomes more pronounced, making particle rotation more challenging, resulting in a decrease in the shear creep of the sample.

- (2)

- The Burgers model is employed to effectively fit the creep curve, particularly during the decelerated creep and steady-state creep stages. As the stone content increases, the four parameters of the Burgers model significantly increase, with the instantaneous elasticity coefficient (G1) and viscosity coefficient (η1) experiencing more pronounced changes. This indicates that, with an increase in stone content, the specimen’s ability to resist instantaneous deformation and irrecoverable deformation significantly improves, while its ability to resist slow deformation and recovery also increases.

- (3)

- The average long-term strength of specimens with different stone content is found to be approximately 54% of their instantaneous strength. As the stone content increases, the ratio of long-term strength to instantaneous strength also increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.-Y.; Li, D.-D.; Liu, H.-D.; Wang, S.-W.; Geng, Z.; Peng, B. Formation and failure mechanism of the landslide: A case study for Huaipa, Western Henan, China. Environ. Earth Sci. 2021, 80, 478. [Google Scholar] [CrossRef]

- Massey, C.I.; Petley, D.N.; Mcsaveney, M.J. Patterns of movement in reactivated landslides. Eng. Geol. 2013, 159, 1–19. [Google Scholar] [CrossRef]

- Ehrlich, M.; Da Costa, D.P.; Silva, R.C. Behavior of a colluvial slope located in Southeastern Brazil. Landslides 2018, 15, 1595–1613. [Google Scholar] [CrossRef]

- Den Ham, G.V.; Rohn, J.; Meier, T.; Czurda, K. A Method for Modeling of a Creeping Slope with a Visco-Hypoplastic Material Law. Math. Geol. 2006, 38, 711–719. [Google Scholar] [CrossRef]

- Carey, J.M.; Petley, D.N. Progressive shear-surface development in cohesive materials; implications for landslide behaviour. Eng. Geol. 2014, 177, 54–65. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, Q.; Li, S.; Wang, S. Time-Dependent Behavior of Diabase and a Nonlinear Creep Model. Rock Mech. Rock Eng. 2014, 47, 1211–1224. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, H.; Zou, Q.; Li, C.; Chen, J.; Gao, R. Viscoelastic-plastic damage creep model for salt rock based on fractional derivative theory. Mech. Mater. 2020, 150, 103600. [Google Scholar] [CrossRef]

- Li, S.-N.; Peng, Z.; Huang, Z.-H.; Liang, Q.; Liu, J.; Zhou, W.-Q. Time-Dependent Deformation and Long-Term Strength of Carbonaceous Mudstone under Dry and Wet Cycles. Sustainability 2022, 14, 12044. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, M.; Gu, L.; Zhang, F. Creep Behavior and Long-Term Strength Characteristics of Greenschist under Different Confining Pressures. Geotech. Test. J. 2018, 41, 55–71. [Google Scholar] [CrossRef]

- Jiang, X.; Wen, B. Creep behavior of slip zone of reactivated slow-moving landslide and its characteristic strength. Rock Soil Mech. 2015, 36, 495–501+549. [Google Scholar]

- Zhu, F.; Duan, Z.; Wu, Z.; Wu, Y.; Li, T.; Cai, Y. Experimental Study on Direct Shear Creep Characteristics and Long-Term Strength of Red Layer Sliding Zone Soil in Southern Hunan. Adv. Mater. Res. 2013, 842, 782–787. [Google Scholar] [CrossRef]

- Lai, X.L.; Wang, S.M.; Ye, W.M.; Cui, Y.J. Experimental investigation on the creep behavior of an unsaturated clay. Can. Geotech. J. 2014, 51, 621–628. [Google Scholar] [CrossRef]

- Zheng, H.; Feng, X.-T.; Hao, X.-J. A creep model for weakly consolidated porous sandstone including volumetric creep. Int. J. Rock Mech. Min. Sci. 2015, 78, 99–107. [Google Scholar] [CrossRef]

- Long, Z.; Cheng, Y.; Yang, G.; Yang, D.; Xu, Y. Study on Triaxial Creep Test and Constitutive Model of Compacted Red Clay. Int. J. Civ. Eng. 2020, 19, 517–531. [Google Scholar] [CrossRef]

- Sun, J. Some advances in rock rheological mechanics and its engineering applications. Chin. J. Rock Mech. Eng. 2007, 26, 1081–1106. (In Chinese) [Google Scholar]

- Jiang, Z.; Wang, H. Study on Shear Creep Characteristics and Creep Model of Soil-Rock Mixture Considering the Influence of Water Content. Front. Phys. 2022, 10, 819709. [Google Scholar] [CrossRef]

- Yin, Q.; Dai, J.; Dai, G.; Gong, W.; Zhang, F.; Zhu, M. Study on Creep Behavior of Silty Clay Based on Fractal Derivative. Appl. Sci. 2022, 12, 8327. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, X.; Lin, X.; Jin, L.; Wang, W. A Modified Plastic Burgers Model for the Non-Decaying Creep of Frozen Soils. Appl. Sci. 2024, 14, 2092. [Google Scholar] [CrossRef]

- Xiao, M.; Guo, X.; Li, C.; Ren, J.; Dong, J.; Zhuang, Y.; Li, Z. Study of fractional Burgers damage creep model and creep properties of asphalt mixtures. Mater. Struct. 2024, 57, 74. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, J.; Ren, Y.; Liang, C.; Zhang, Q. Study on long-term uniaxial compression creep mechanical behavior of rocksalt-mudstone combined body. Int. J. Damage Mech. 2022, 31, 275–293. [Google Scholar]

- Okubo, S.; Fukui, K.; Hashiba, K. Long-term creep of water-saturated tuff under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2010, 47, 839–844. [Google Scholar] [CrossRef]

- Sun, M.; Tang, H.; Wang, X.; Hu, X.; Wang, M.; Ni, W. Creep properties of sliding-zone soil from a creeping landslide. Rock Soil Mech. 2017, 38, 385–391+399. [Google Scholar]

- Liu, H.; Miao, H.; Chen, Z. Shear creep behaviors of sliding-zone soil of bedding landslide in Jurassic stratum in Three Gorges Reservoir area. Chin. J. Geotech. Eng. 2019, 41, 1573–1580. [Google Scholar]

- Hu, X.; Sun, M.; Tang, H.; Xie, N.; Guo, J. Creep tests of gravel-soil of Majiagou landslide in Three Gorges Reservoir area. Rock Soil Mech. 2014, 35, 3163–3169+3190. [Google Scholar]

- Dong, J.; Jing, M.; Zhao, Y. Study on creep characteristics of Huahuayanzu landslide deposits. J. North China Univ. Water Resour. Electr. Power (Nat. Sci. Ed.) 2024, 45, 77–84. [Google Scholar]

- Dong, J.; Zhao, Y.; Liu, H.; Zhao, J.; Zhang, Z.; Chi, Q.; Yang, J. Creep Characteristics of a Strongly Weathered Argillaceous Sandstone Sliding Zone and the Disaster Evolution Mechanism of the Huaipa Landslide, China. Appl. Sci. 2023, 13, 8579. [Google Scholar] [CrossRef]

- Wen, B.; Jiang, X. Effect of gravel content on creep behavior of clayey soil at residual state: Implication for its role in slow-moving landslides. Landslides 2017, 14, 559–576. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z.; Wulan, T.; Fan, Z.; Wang, C. Calibration method of mesoscopic parameters using BP neural network and Burgers model. Trans. Chin. Soc. Agric. Eng. 2022, 38, 152–161. [Google Scholar]

- Yang, J.; Dong, J.; Huang, Z.; Zheng, Z.; Qi, D. Large-scale direct shear tests on accumulation body with different stone contents. Chin. J. Geotech. Eng. 2016, 38, 161–166. [Google Scholar]

- Jiang, Q.; Xu, Y.; Wang, H. Research on shear deformation characteristics of soil-rock mixtures under different stone contents. J. Eng. Geol. 2020, 28, 951–958. [Google Scholar]

| Moisture Condition | Gravity (kN/m3) | Cohesion (kPa) | Friction (°) | Natural Water Content% | 2 mm Plastic Limit/% | 10 mm Liquid Limit/% |

|---|---|---|---|---|---|---|

| Nature | 26.3 | 12.5 | 24.8 | 11–17 | 20.33 | 33.34 |

| Saturation | 27.3 | 8.0 | 22.0 |

| Stone Content/% | Quality of Water/kg | Percentage of Mass of Particles/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| <0.075 mm | 0.075–1 mm | 1–2 mm | 2–5 mm | 5–10 mm | 10–20 mm | 20–40 mm | 40–60 mm | 60–80 mm | ||

| 10 | 12.7 | 2 | 32.8 | 12.7 | 42.3 | 3.1 | 2.6 | 2.1 | 1.2 | 1.2 |

| 30 | 10.7 | 2 | 25.7 | 9.8 | 32.5 | 9.8 | 3.9 | 3 | 9.8 | 3.5 |

| 50 | 8.2 | 1.5 | 18.2 | 6.8 | 23.5 | 18.3 | 9.2 | 7.3 | 11 | 4.2 |

| 70 | 5.2 | 1 | 10.9 | 4 | 14 | 21.6 | 12.9 | 8.6 | 17 | 10 |

| Consolidation Pressure/kPa | Stone Content% | Instantaneous Shear Strength/kPa | Creep Grading Loading Stress/kPa |

|---|---|---|---|

| 200 | 10 | 140 | 28, 56, 84, 112 |

| 200 | 30 | 161.5 | 32, 64, 96, 128 |

| 200 | 50 | 184 | 36, 72, 108, 144 |

| 200 | 70 | 198 | 40, 80, 120, 160 |

| Stone Content | Τ [kPa] | [kPa] | [kPa] | [kPa.min] | [kPa.min] | |

|---|---|---|---|---|---|---|

| 10% | 28 | 4.17 × 104 | 3.63 × 104 | 4.41 × 109 | 1.16 × 106 | 0.97 |

| 56 | 3.30 × 104 | 4.41 × 104 | 1.04 × 109 | 1.08 × 105 | 0.93 | |

| 84 | 1.13 × 104 | 1.37 × 104 | 1.77 × 109 | 2.27 × 104 | 0.93 | |

| 112 | 1.19 × 104 | 2.97 × 104 | 2.04 × 108 | 5.38 × 106 | 0.92 | |

| 30% | 32 | 8.95 × 104 | 1.61 × 105 | 3.39 × 109 | 1.54 × 107 | 0.97 |

| 64 | 7.46 × 104 | 5.04 × 104 | 1.18 × 109 | 1.23 × 105 | 0.93 | |

| 96 | 5.41 × 104 | 3.61 × 104 | 1.97 × 109 | 3.02 × 104 | 0.89 | |

| 128 | 2.39 × 104 | 5.85 × 104 | 3.77 × 108 | 5.74 × 105 | 0.97 | |

| 50% | 36 | 4.85 × 105 | 9.88 × 104 | 5.24 × 109 | 4.88 × 106 | 0.98 |

| 72 | 9.57 × 104 | 1.21 × 105 | 2.32 × 109 | 2.55 × 105 | 0.94 | |

| 108 | 3.86 × 104 | 1.01 × 105 | 5.00 × 109 | 8.81 × 105 | 0.86 | |

| 144 | 4.01 × 104 | 6.42 × 104 | 8.07 × 108 | 5.26 × 104 | 0.98 | |

| 70% | 40 | 3.26 × 105 | 5.28 × 105 | 5.99 × 109 | 1.57 × 107 | 0.85 |

| 80 | 2.19 × 105 | 1.48 × 105 | 6.91 × 1010 | 2.66 × 106 | 0.99 | |

| 120 | 1.28 × 105 | 9.19 × 104 | 1.22 × 109 | 5.26 × 105 | 0.94 | |

| 160 | 5.54 × 104 | 2.00 × 105 | 1.03 × 109 | 3.66 × 105 | 0.99 |

| Consolidation Pressure/kPa | Stone Content% | Instantaneous Strength/kPa | Long-Term Strength/kPa | Reduced Factor |

|---|---|---|---|---|

| 200 | 10 | 140 | 69.5 | 0.49 |

| 30 | 161.5 | 82 | 0.53 | |

| 50 | 184 | 104 | 0.57 | |

| 70 | 198 | 112 | 0.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Wang, T.; Zhao, Y. Experimental Study on Shear Creep Characteristics of Residual Soil with Different Stone Content. Appl. Sci. 2024, 14, 6829. https://doi.org/10.3390/app14156829

Dong J, Wang T, Zhao Y. Experimental Study on Shear Creep Characteristics of Residual Soil with Different Stone Content. Applied Sciences. 2024; 14(15):6829. https://doi.org/10.3390/app14156829

Chicago/Turabian StyleDong, Jinyu, Tanyu Wang, and Yawen Zhao. 2024. "Experimental Study on Shear Creep Characteristics of Residual Soil with Different Stone Content" Applied Sciences 14, no. 15: 6829. https://doi.org/10.3390/app14156829