Studying the Freezing Law of Reinforcement by Using the Artificial Ground Freezing Method in Shallow Buried Tunnels

Abstract

:1. Introduction

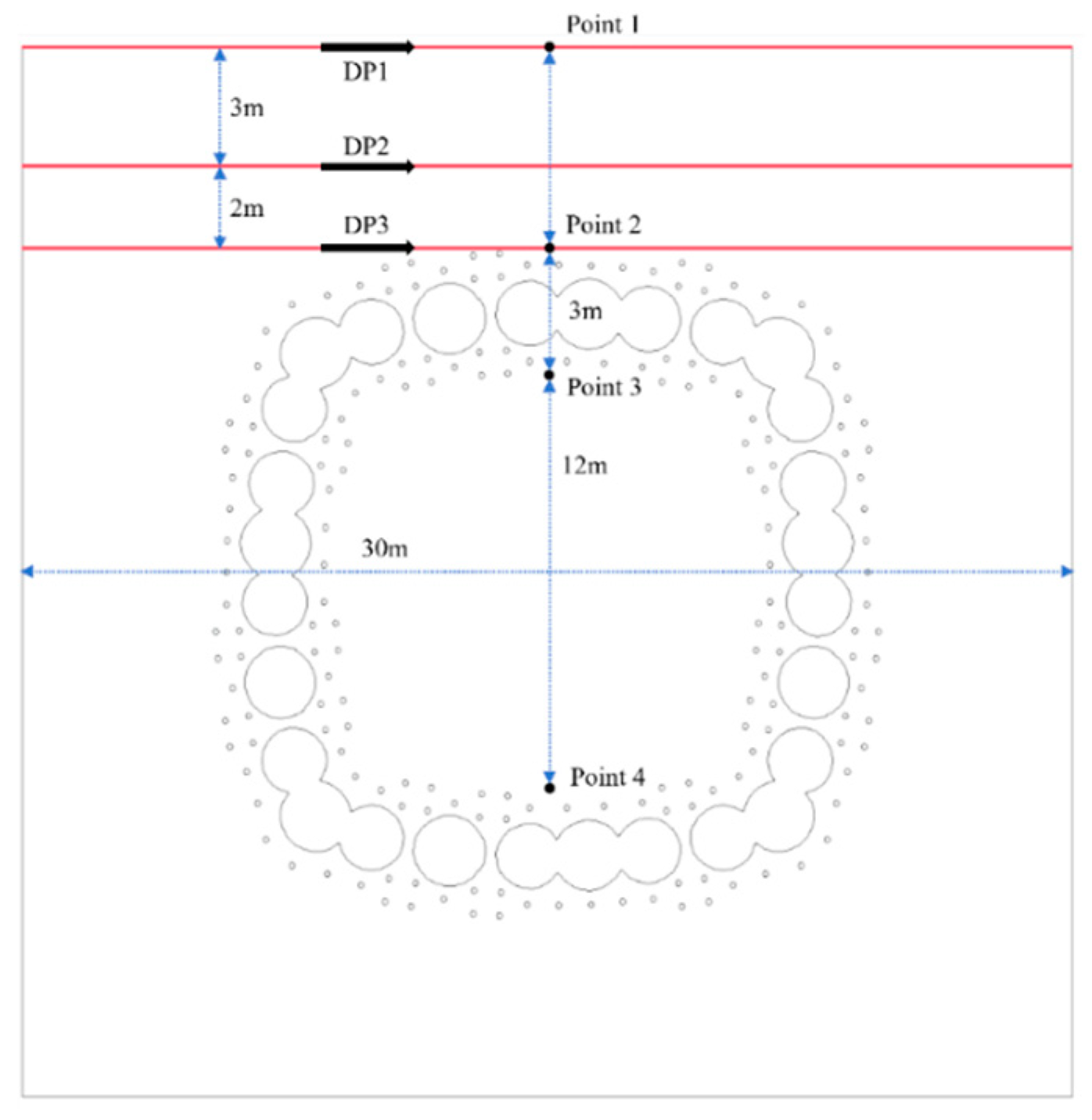

2. Project Overview

2.1. Project Profile

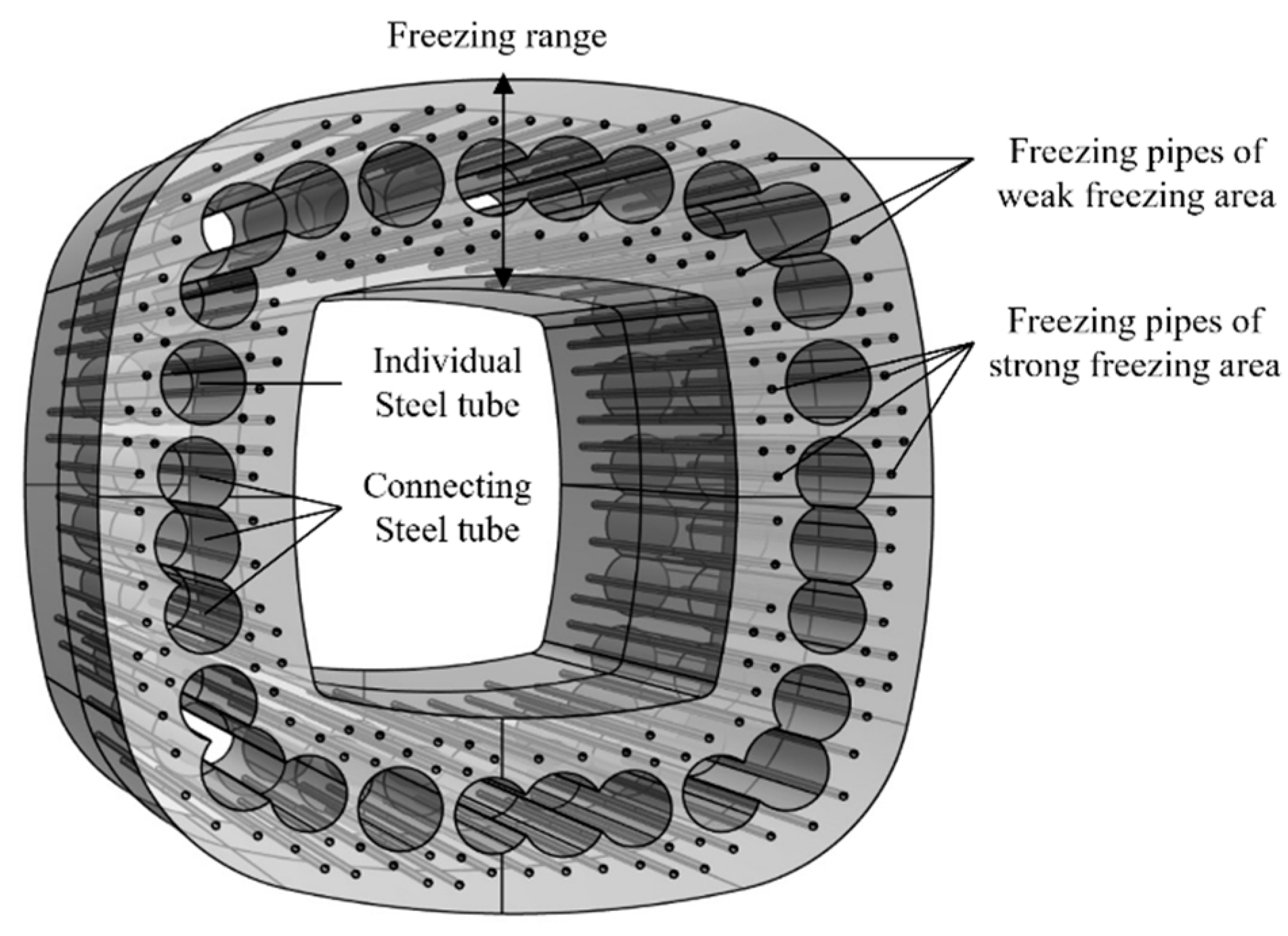

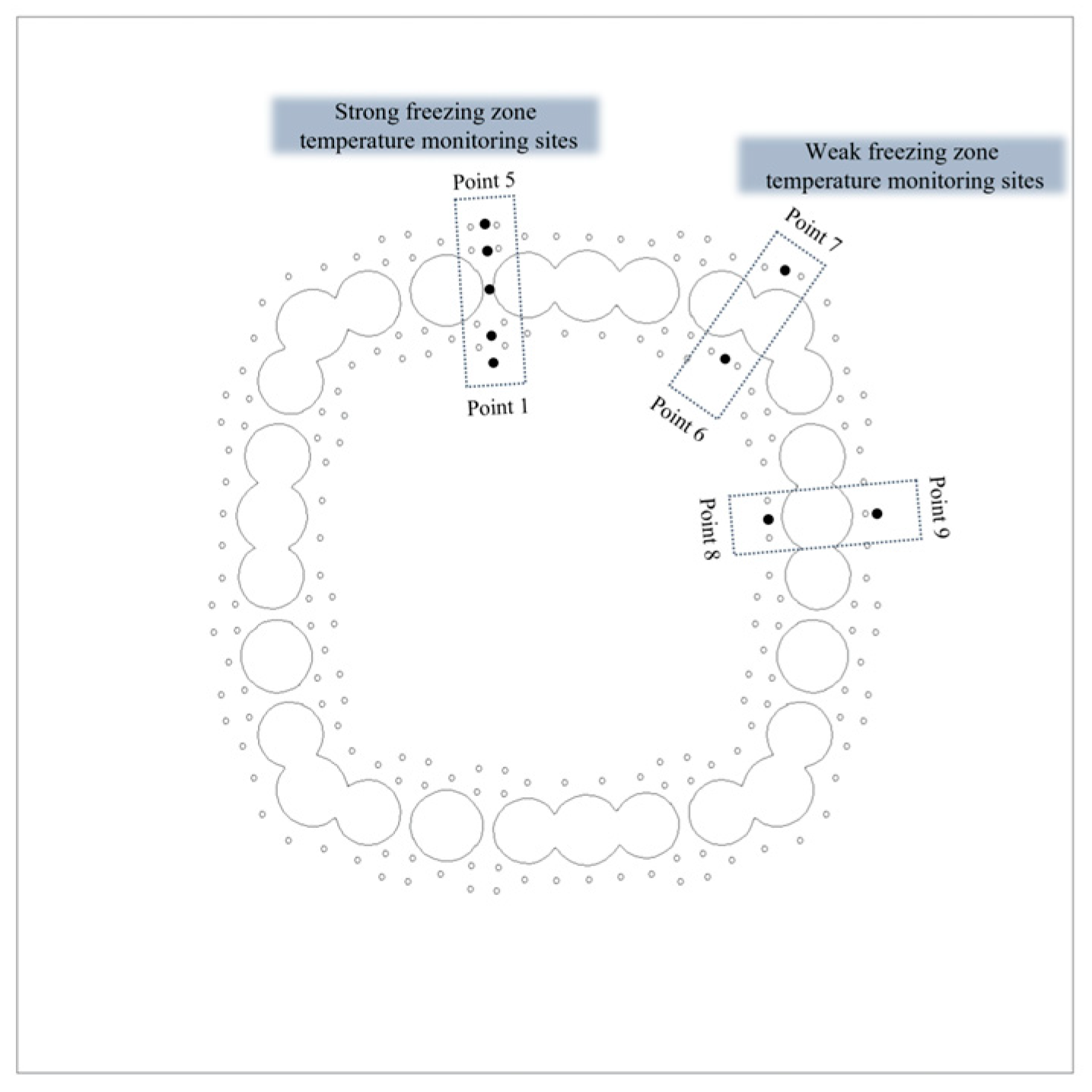

2.2. Freeze Pipe Arrangement

3. Numerical Simulation

3.1. Governing Equation

3.1.1. Temperature Field Control Equation

3.1.2. Moisture Field Control Equation

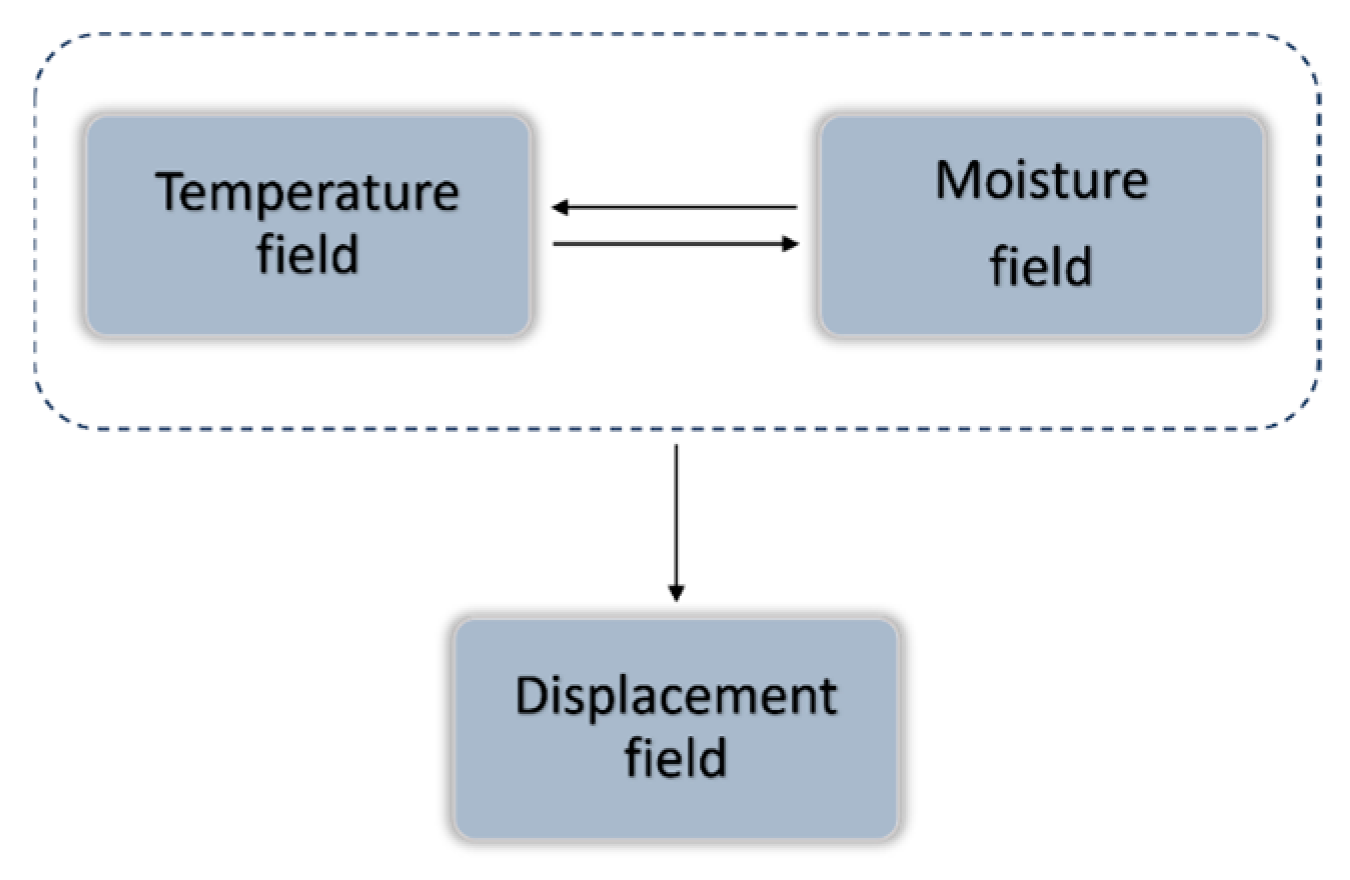

3.1.3. Hydrothermal Coupling PDE Secondary Development Module

3.1.4. Displacement Field Control Equation

3.2. Numerical Modeling Assumptions

- (1)

- The investigation report for this project indicates that powdery clay with high water content produces a large freezing rate during the freezing process. Therefore, this study simplifies the soil body to a homogeneous, continuous, isotropic, and linearly elastic soil layer with the most unfavorable soil parameters. Each parameter is derived from weighted values based on the investigation report, and the soil body has an initial temperature of 18 °C.

- (2)

- Based on existing research [35], it is assumed that the soil body begins to freeze at −1 °C and forms a stable permafrost structure at −10 °C.

- (3)

- Neglecting the loss of cold during the brine circulation process and the influence of heat convection and radiation during heat transfer, the brine temperature is directly applied to the wall of the freezing pipe as a temperature load with heat transferred solely by conduction.

- (4)

- It is assumed that moisture migration in the soil conforms to Darcy’s law.

- (5)

- The migration of salts and other solutes in the soil is not considered. Water migration is assumed to occur primarily in liquid form, ignoring the movement of gaseous water. The soil is considered saturated, containing only liquid water and solid ice in the pore space, with the saturated water content equating to the soil’s porosity.

- (6)

- It is assumed that ice crystals and the solid phase of the soil are incompressible.

3.3. Numerical Modeling

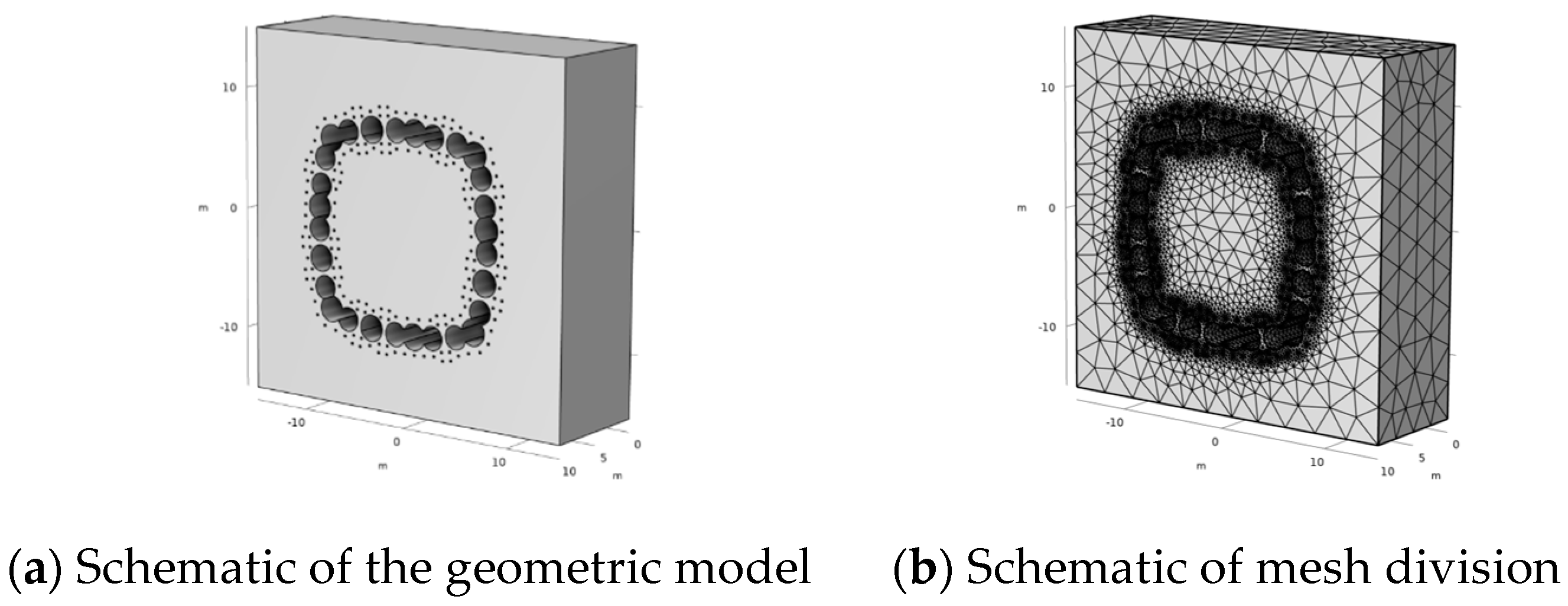

3.3.1. Geometric Modeling, Meshing and Boundary Conditions

3.3.2. Selection of Relevant Parameters

4. Analysis of Simulation Results

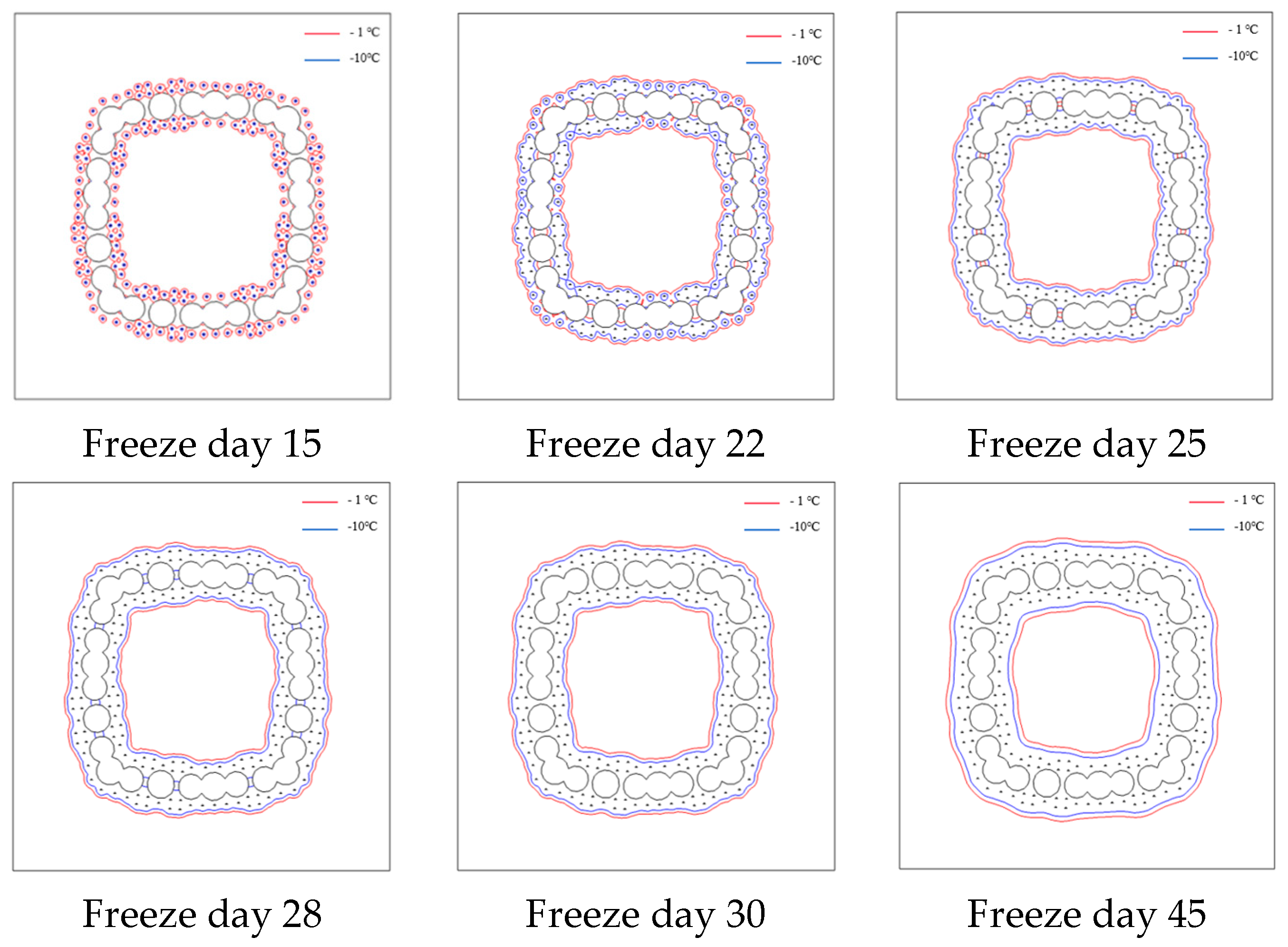

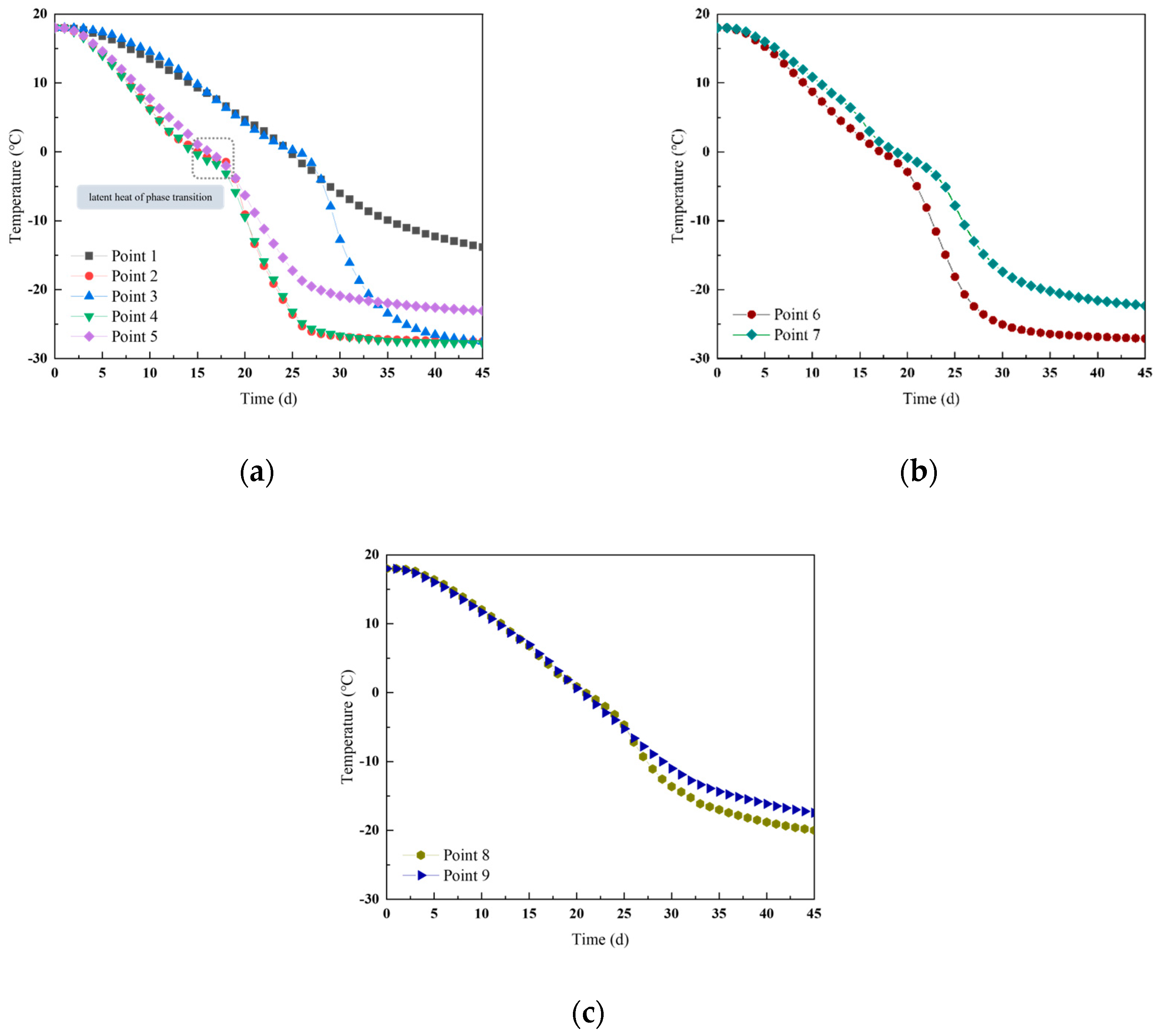

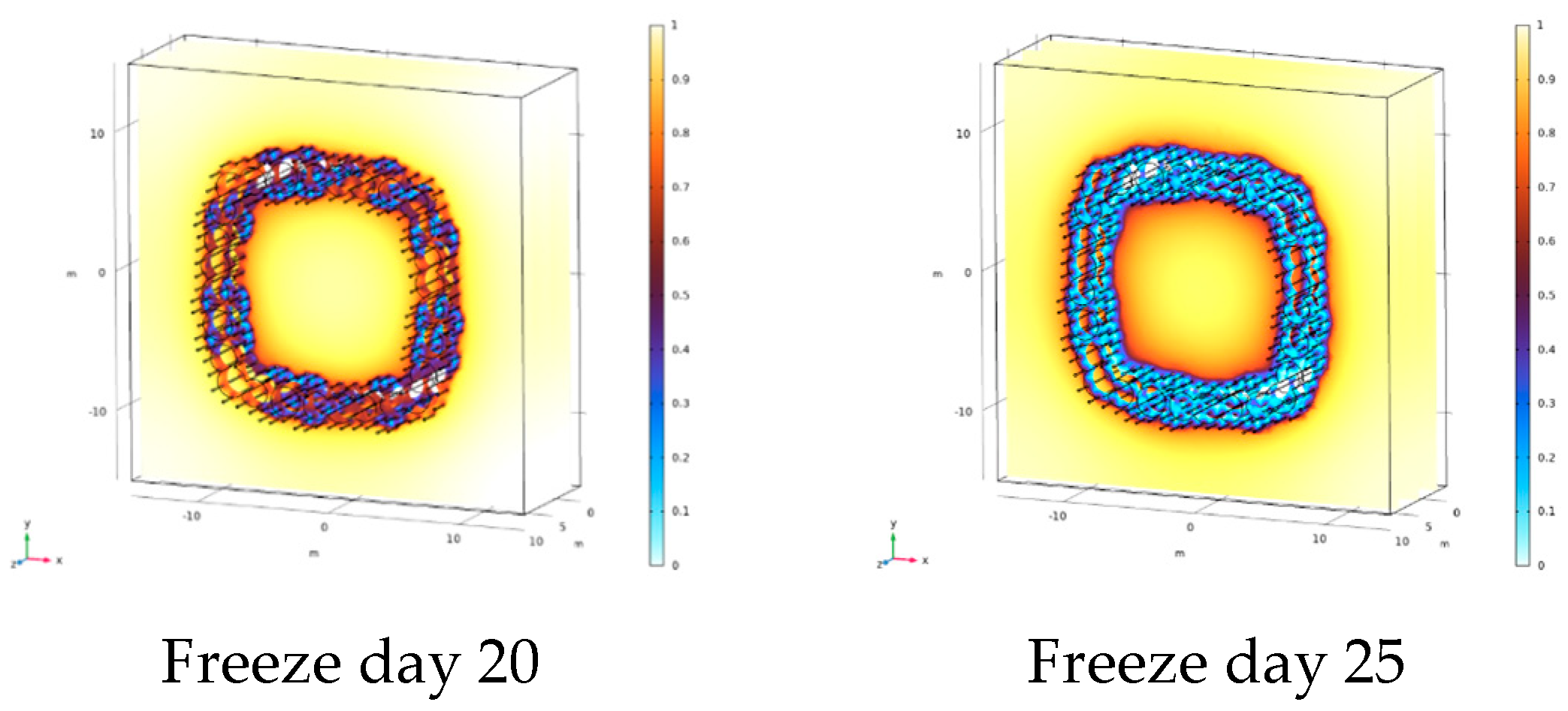

4.1. Temperature Field Calculation Results

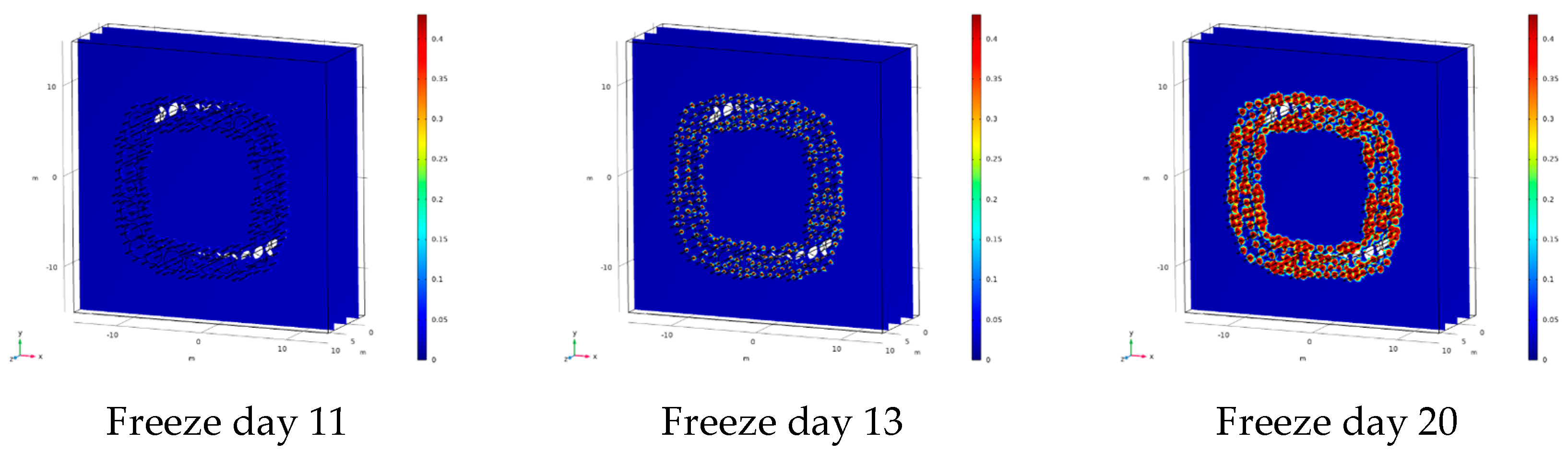

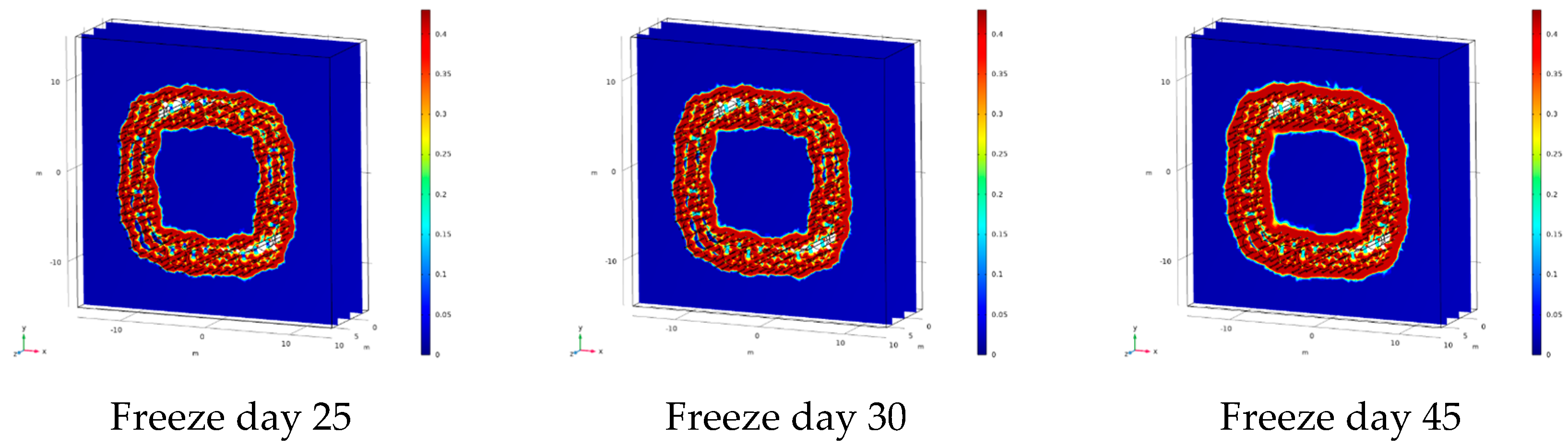

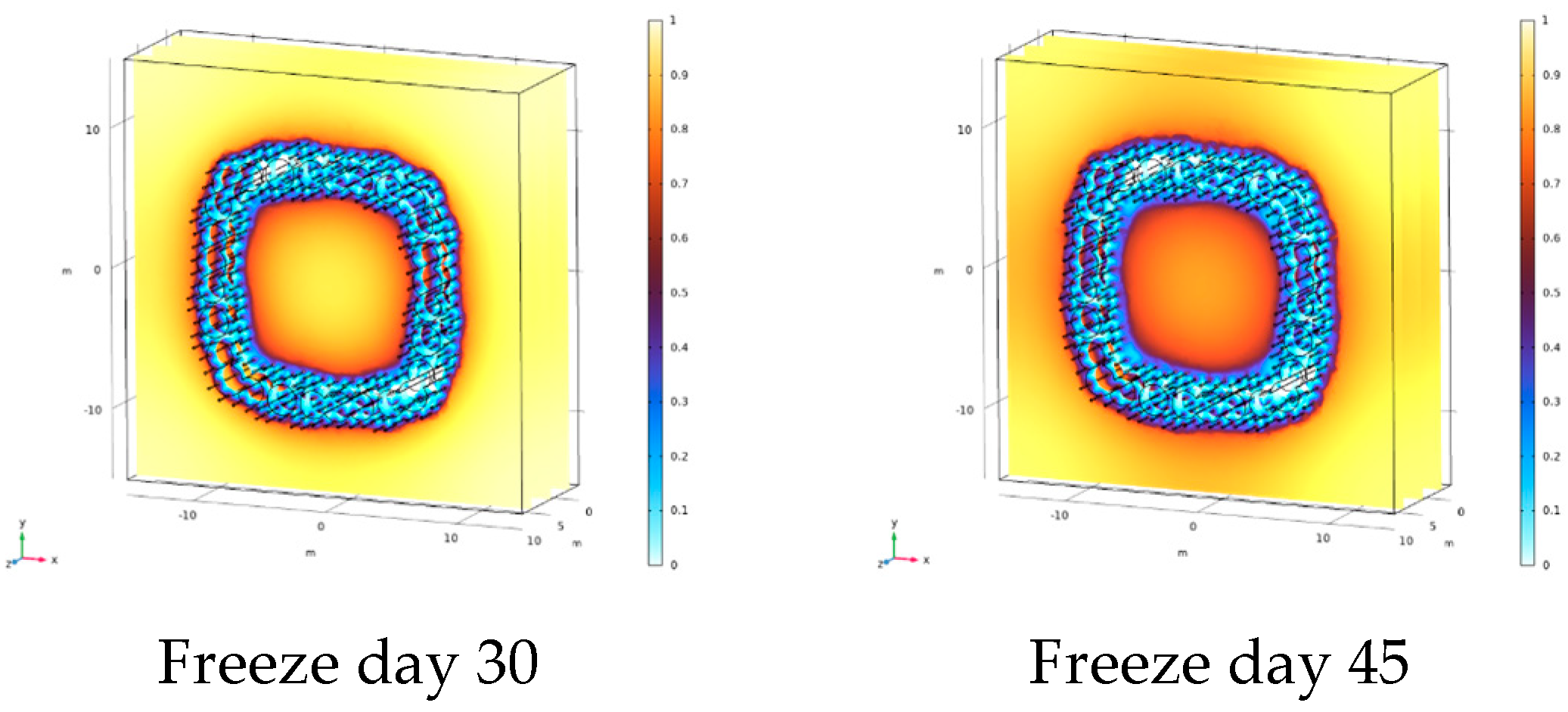

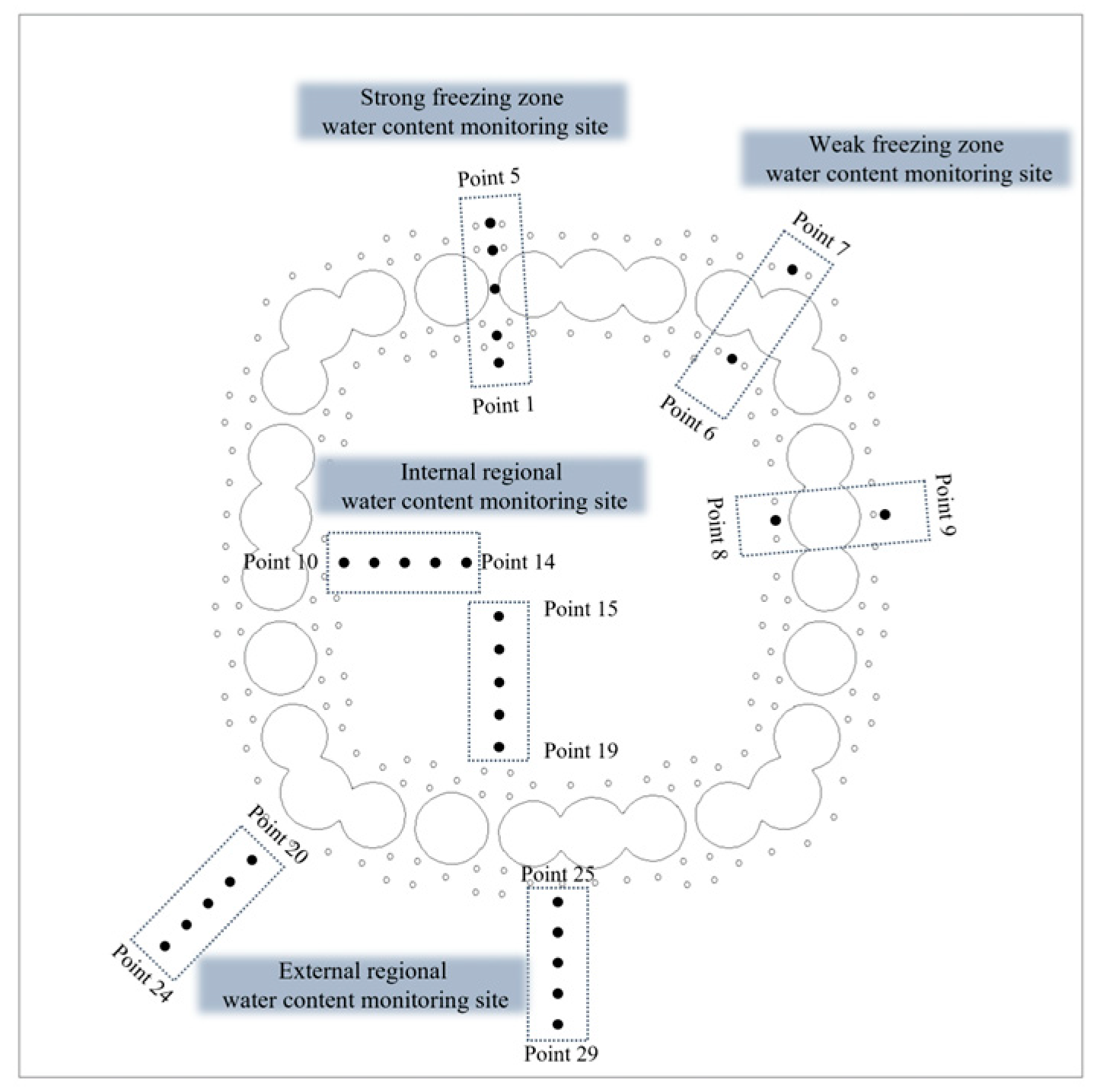

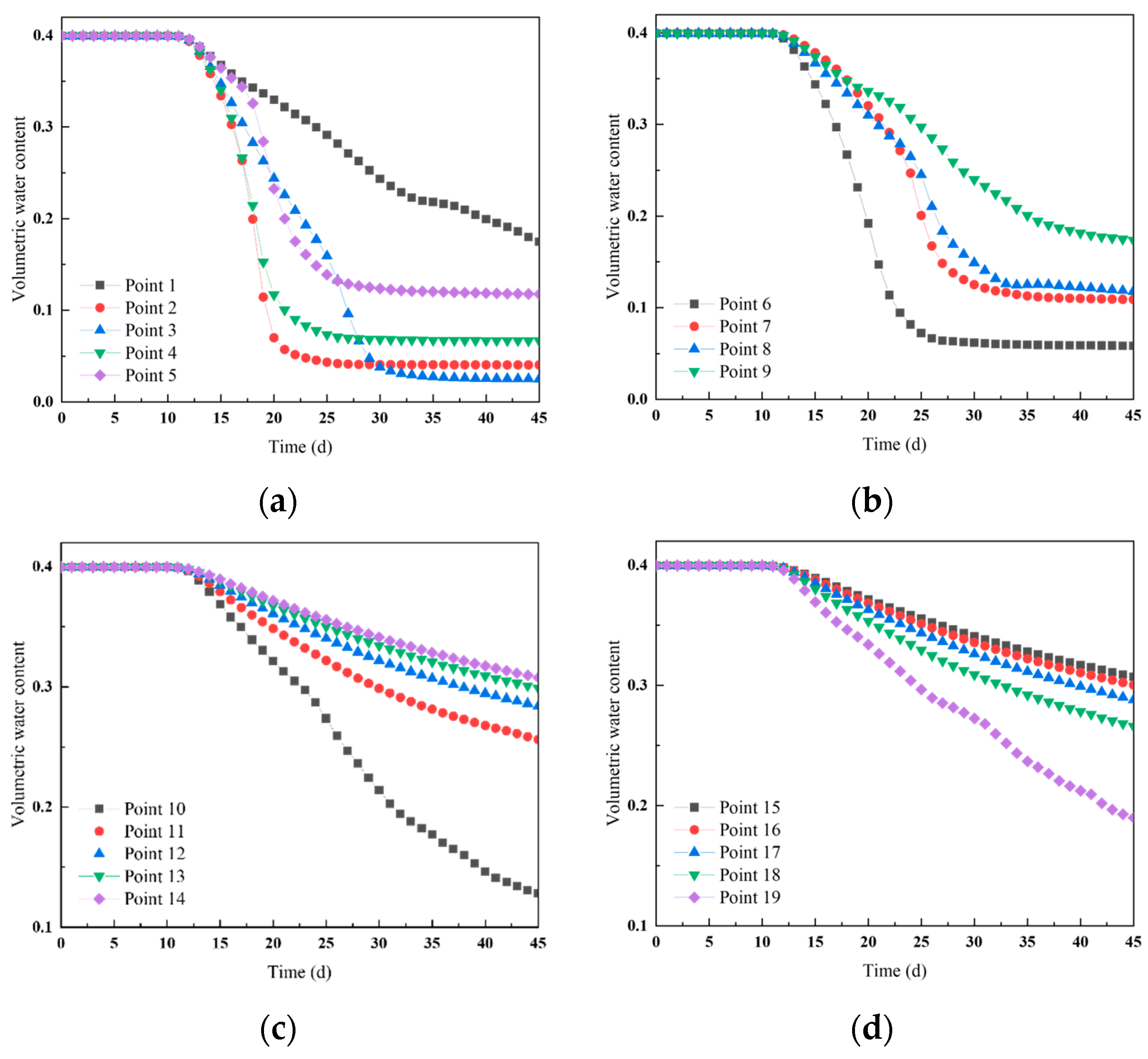

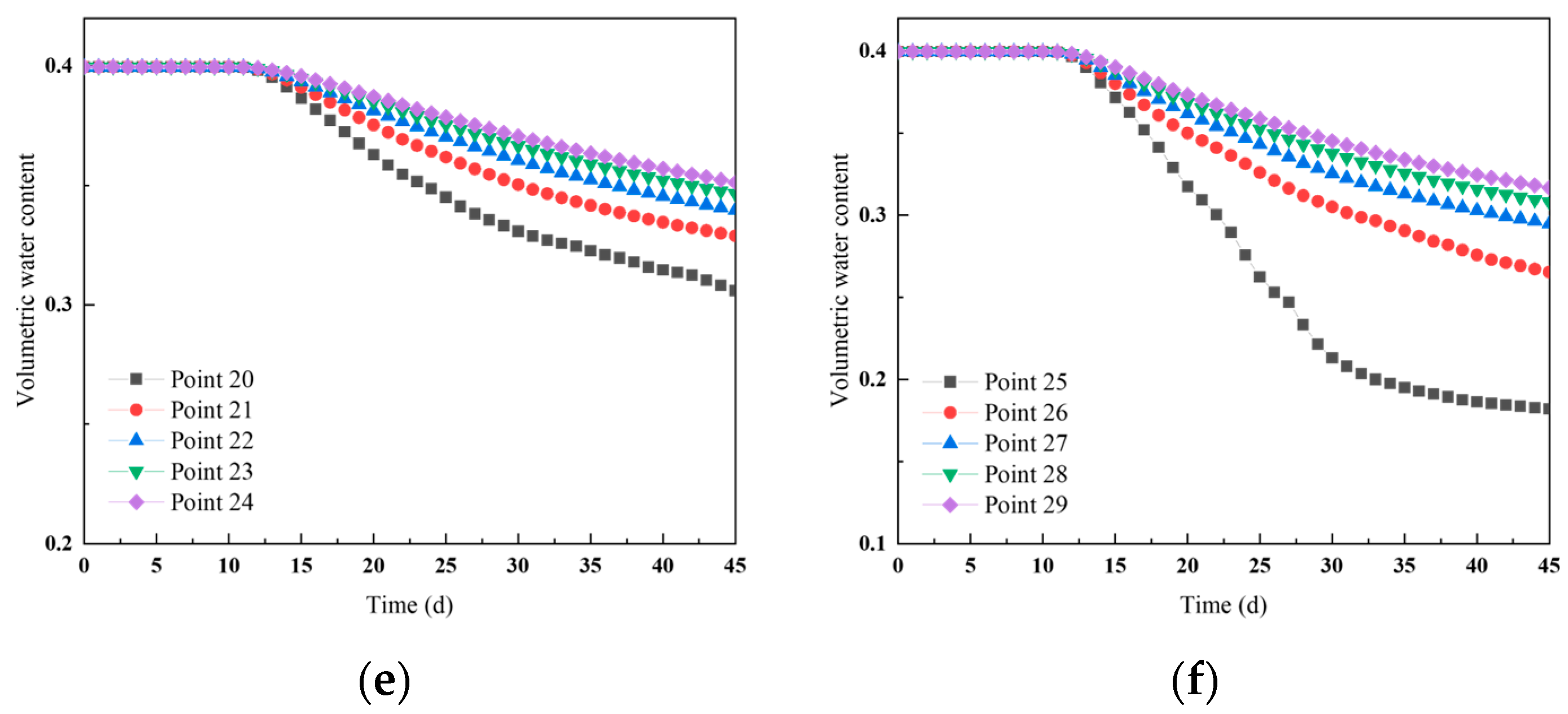

4.2. Moisture Field Calculation Results

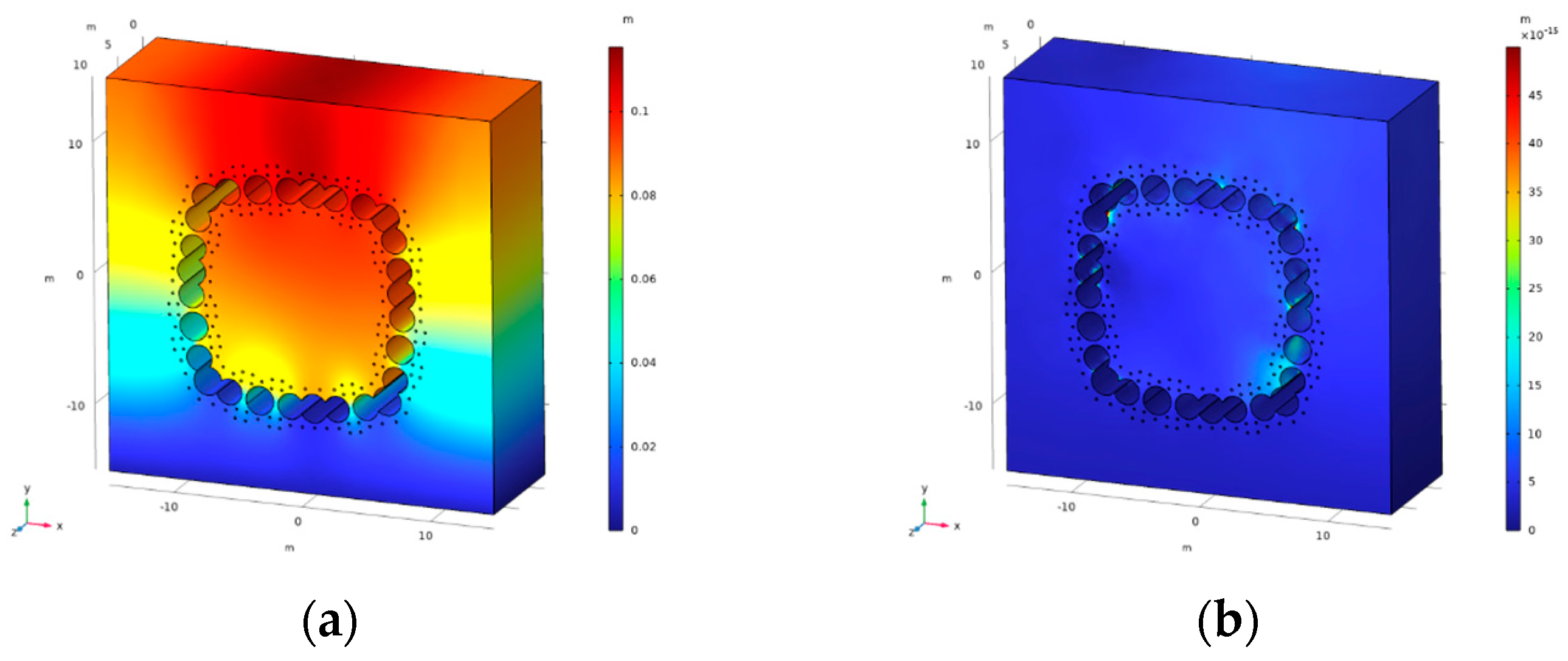

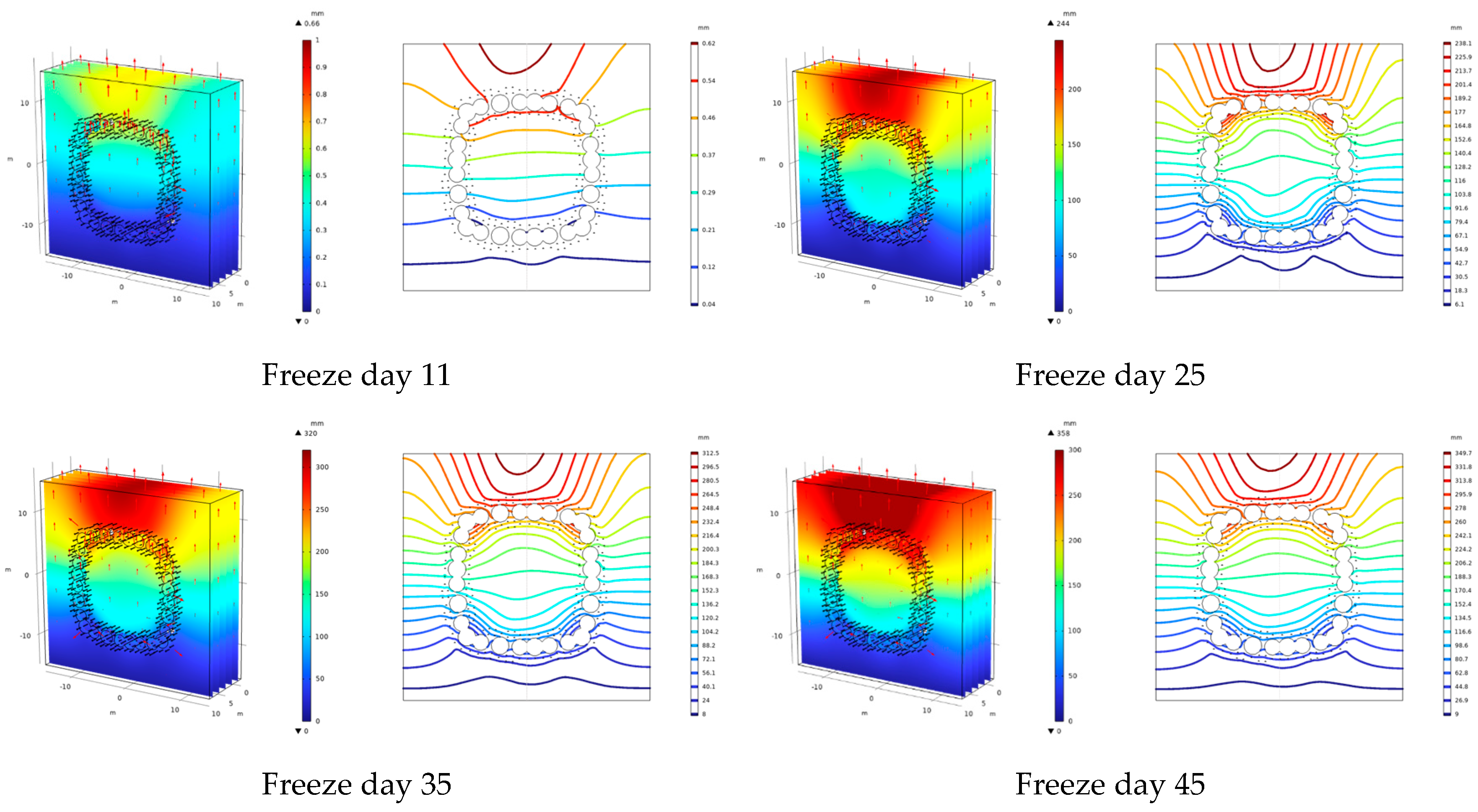

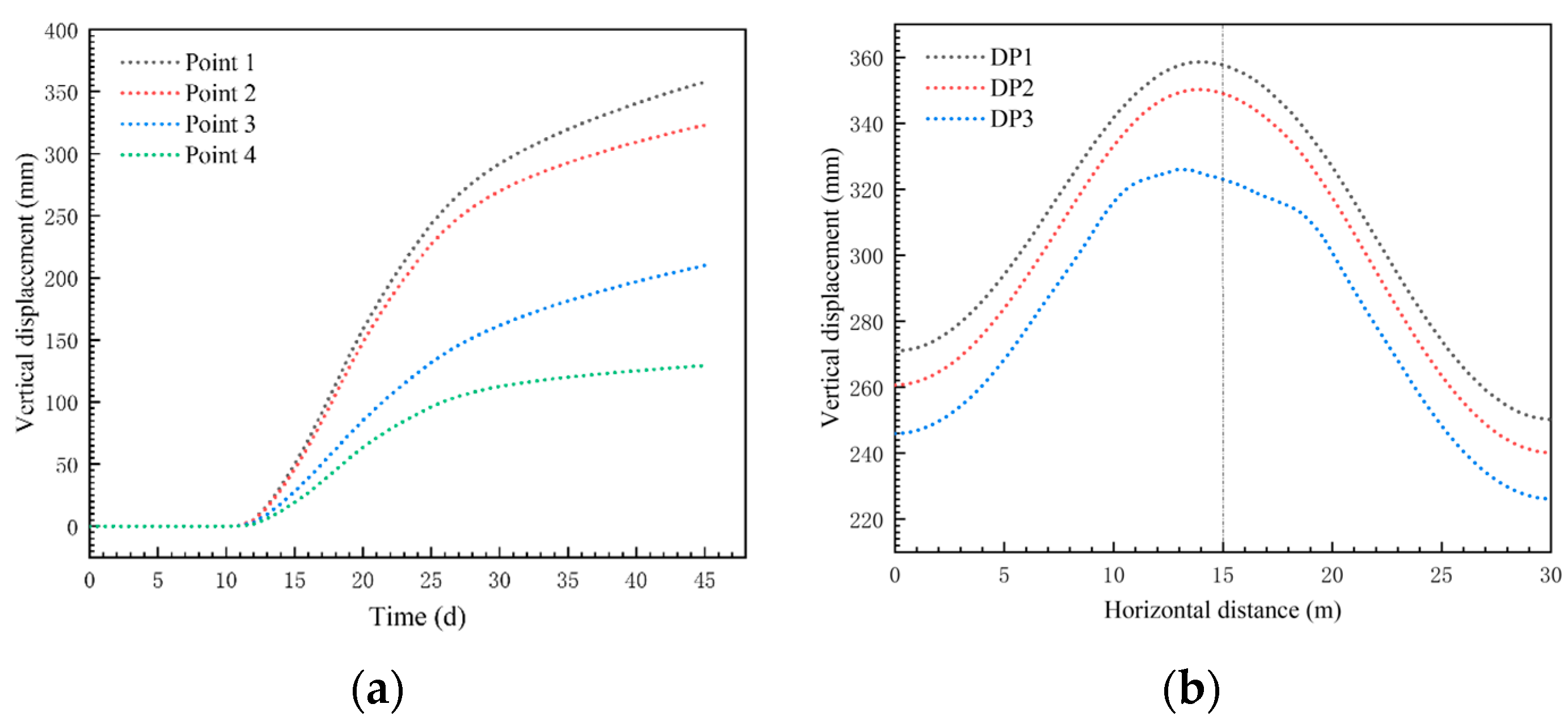

4.3. Displacement Field Calculation Results

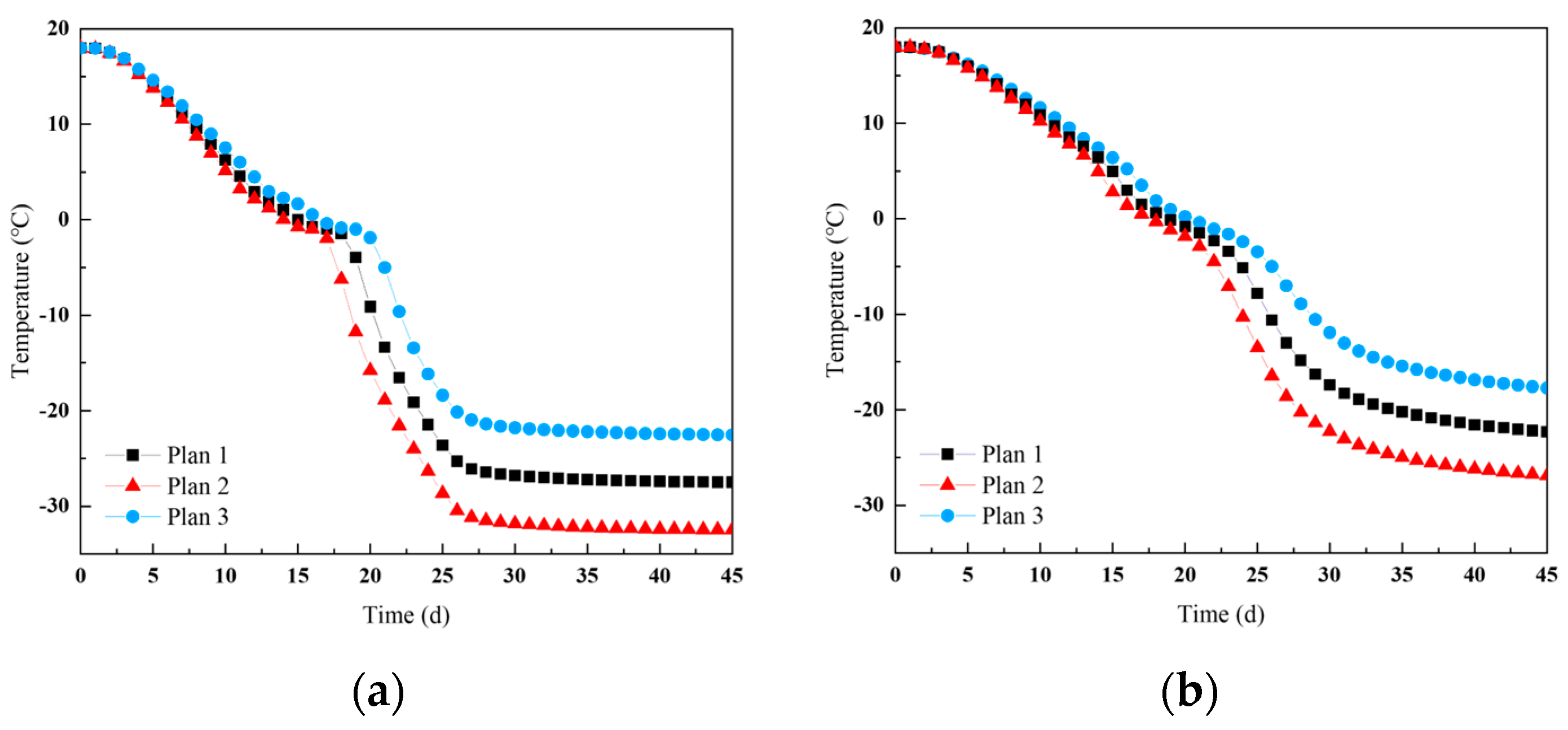

4.4. Sensitivity Analysis

5. Conclusions

- (1)

- On the 25th day of freezing, temperature variation cycles from −1 to −10 °C were completed. By the 30th day, a fully frozen curtain had formed, meeting the design requirements for thickness. This indicates that the original cooling plan for the project was relatively conservative. Future optimizations could consider shortening the freezing period and reducing costs, referring to the temperature field analysis for improvements. The soil in the strong freezing zone exhibited a faster cooling rate and greater permafrost thickness than the weak freezing zone. The intervals between the pipe curtains in the strong freezing zone enhance the stability of the gaps and the water-stopping capability, aligning with the project’s requirements.

- (2)

- The influence of the freezing pipes on the soil area resulted in changes in the cooling rate at specific time nodes during the freezing process. Different monitoring points showed varying cooling rates due to differences in the influence of the cold source. Based on monitoring data, specific areas can be targeted for freezing control measures, allowing for adjustments to the freezing program in this project or similar ones.

- (3)

- The ice content in the strong freezing area was higher than that in the weak freezing area. Due to the temperature gradient, moisture in the soil migrated toward the cold area, causing the saturation and water content of the surrounding soil to decline. Near the freezing pipe, moisture migration led to temporary water accumulation and increased saturation. By the 30th day of freezing, saturation within the curtain became uniform and approached zero with higher ice content marking the primary area of freezing and expansion effects. The saturation along the inner and outer edges of the curtain was slightly higher than inside the curtain due to moisture migration. Analyzing the saturation changes during freezing effectively elucidates the relationship between moisture migration and freeze-up.

- (4)

- The soil closer to the freezing pipe experienced a faster rate of water content reduction, eventually reaching a stable water content stage. The soil farther from the freezing pipe initially showed a slight decrease in water content. If later affected by the freezing front’s cold source, a change in the water content reduction rate can be observed; otherwise, only a slight decrease due to water migration occurs. Our analysis of moisture field changes suggests that regions with a rapidly increasing water content decrease, indicating significant moisture phase change to ice, corresponding to strong freezing effects.

- (5)

- In the early-phase change phase, frost heave was observed only near the freezing pipe, with the soil near the surface experiencing a vertical displacement of 0.66 mm. By the 35th day of freezing, upward freezing displacement continued accumulating after forming a stable freezing curtain with the maximum vertical displacement near the surface reaching 320 mm. On the 45th day, maximum freezing displacement reached 358 mm, indicating a decreased freezing heave effect in the later stages. Therefore, in actual projects, the focus should be on controlling the freezing effect before the 35th day. Additionally, dense contour lines near the freezing pipe indicated strong freezing displacement in that area, causing significant surface uplift. The maximum displacement was not centered in the construction soil but in the X-negative direction. The high water content in the powdery clay-based layer resulted in a pronounced frost expansion effect. The analysis in this paper provides a clear understanding of areas with significant frost expansion effects, offering a reference for assessing freezing programs and developing frost expansion control measures in this project or similar ones.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alzoubi, M.A.; Xu, M.; Hassani, F.P.; Poncet, S.; Sasmito, A.P. Artificial ground freezing: A review of thermal and hydraulic aspects. Tunn. Undergr. Space Technol. 2020, 104, 103534. [Google Scholar] [CrossRef]

- Hu, X.D.; Zhang, L.Y. Artificial ground freezing for rehabilitation of tunneling shield in subsea environment. Adv. Mater. Res. 2013, 734, 517–521. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Z.-Y.; Wan, P.; Tang, Y.-Q.; Zhao, W.-Q. Effects of seepage in clay-sand composite strata on artificial ground freezing and surrounding engineering environment. Chin. J. Geotech. Eng. 2021, 43, 471–480. [Google Scholar]

- Hu, J.; Liu, Y.; Li, Y.; Yao, K. Artificial ground freezing in tunnelling through aquifer soil layers: A case study in Nanjing Metro Line 2. KSCE J. Civ. Eng. 2018, 22, 4136–4142. [Google Scholar] [CrossRef]

- Huang, S.; Guo, Y.; Liu, Y.; Ke, L.; Liu, G. Study on the influence of water flow on temperature around freeze pipes and its distribution optimization during artificial ground freezing. Appl. Therm. Eng. 2018, 135, 435–445. [Google Scholar] [CrossRef]

- Mauro, A.; Normino, G.; Cavuoto, F.; Marotta, P.; Massarotti, N. Modeling artificial ground freezing for construction of two tunnels of a metro station in Napoli (Italy). Energies 2020, 13, 1272. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Y.; Wang, T.; Hu, J.; Wei, K.; Guo, Y. Numerical Analysis of the Effect of Groundwater Seepage on the Active Freezing and Forced Thawing Temperature Fields of a New Tube–Screen Freezing Method. Sustainability 2023, 15, 9367. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, W.; Qi, J.; Zhang, T. Analytic computation on the forcible thawing temperature field formed by a single heat transfer pipe with unsteady outer surface temperature. J. Coal Sci. Eng. 2012, 18, 18–24. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, G.; Li, F.; Gao, W.; Han, Y.; Wu, T.; Ma, W. Comprehensive review of artificial ground freezing applications to urban tunnel and underground space engineering in China in the last 20 years. J. Cold Reg. Eng. 2022, 36, 04022002. [Google Scholar] [CrossRef]

- Hu, J.; Li, K.; Wu, Y.; Zeng, D.; Wang, Z. Optimization of the Cooling Scheme of Artificial Ground Freezing Based on Finite Element Analysis: A Case Study. Appl. Sci. 2022, 12, 8618. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Sasmito, A.P.; Madiseh, A.; Hassani, F.P. Intermittent freezing concept for energy saving in artificial ground freezing systems. Energy Procedia 2017, 142, 3920–3925. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Sasmito, A.P.; Madiseh, A.; Hassani, F.P. Freezing on demand (FoD): An energy saving technique for artificial ground freezing. Energy Procedia 2019, 158, 4992–4997. [Google Scholar] [CrossRef]

- Tounsi, H.; Rouabhi, A.; Jahangir, E. Thermo-hydro-mechanical modeling of artificial ground freezing taking into account the salinity of the saturating fluid. Comput. Geotech. 2020, 119, 103382. [Google Scholar] [CrossRef]

- Tounsi, H.; Rouabhi, A.; Tijani, M.; Guérin, F. Thermo-hydro-mechanical modeling of artificial ground freezing: Application in mining engineering. Rock Mech. Rock Eng. 2019, 52, 3889–3907. [Google Scholar] [CrossRef]

- Auld, F.A.; Belton, J.; Allenby, D. Application of Artificial Ground Freezing. 2015. Available online: https://www.icevirtuallibrary.com/doi/abs/10.1680/ecsmge.60678.vol3.121 (accessed on 31 July 2024).

- Joudieh, Z.; Cuisinier, O.; Abdallah, A.; Masrouri, F. Artificial Ground Freezing—On the Soil Deformations during Freeze–Thaw Cycles. Geotechnics 2024, 4, 718–741. [Google Scholar] [CrossRef]

- Moriuchi, K.; Ueda, Y.; Ohrai, T. Study on the ad freeze between frozen soil and steel pipes for cutoff of water. Doboku Gakkai Ronbunshuu C 2008, 64, 294–306. [Google Scholar] [CrossRef]

- Cheng, Y.; Ma, B.; Liu, J. Scheme designing of gongbei tunnel. Highw. Tunn. 2012, 3, 34–38. [Google Scholar]

- Hu, X.; Fang, T. Numerical simulation of temperature field at the active freeze period in tunnel construction using freeze-sealing pipe roof method. Tunneling and underground construction. In Proceedings of the Geo-Shanghai 2014, Shanghai, China, 26–28 May 2014; pp. 731–741. [Google Scholar]

- Hu, X.; Wu, Y.; Li, X. A field study on the freezing characteristics of freeze-sealing pipe roof used in ultra-shallow buried tunnel. Appl. Sci. 2019, 9, 1532. [Google Scholar] [CrossRef]

- Hong, Z.; Hu, X.; Fang, T. Analytical solution to steady-state temperature field of Freeze-Sealing Pipe Roof applied to Gongbei tunnel considering operation of limiting tubes. Tunn. Undergr. Space Technol. 2020, 105, 103571. [Google Scholar] [CrossRef]

- Niu, Y.; Hong, Z.Q.; Zhang, J.; Han, L. Frozen curtain characteristics during excavation of submerged shallow tunnel using Freeze-Sealing Pipe-Roof method. Res. Cold Arid Reg. 2022, 14, 267–273. [Google Scholar] [CrossRef]

- Hong, Z.; Zhang, J.; Han, L.; Wu, Y. Numerical Study on Water Sealing Effect of Freeze-Sealing Pipe-Roof Method Applied in Underwater Shallow-Buried Tunnel. Front. Phys. 2022, 9, 794374. [Google Scholar] [CrossRef]

- Duan, Y.; Rong, C.; Long, W. Numerical Simulation Study on Frost Heave during the Freezing Phase of Shallow-Buried and Undercut Tunnel Using the Freeze-Sealing Pipe Roof Method. Appl. Sci. 2023, 13, 10344. [Google Scholar] [CrossRef]

- Cui, Z.D.; Zhang, L.J.; Xu, C. Numerical simulation of freezing temperature field and frost heave deformation for deep foundation pit by AGF. Cold Reg. Sci. Technol. 2023, 213, 103908. [Google Scholar] [CrossRef]

- Russo, G.; Corbo, A.; Cavuoto, F.; Autuori, S. Artificial ground freezing to excavate a tunnel in sandy soil. Meas. Back Anal. Tunn. Undergr. Space Technol. 2015, 50, 226–238. [Google Scholar] [CrossRef]

- Li, M.; Cai, H.; Liu, Z.; Pang, C.; Hong, R. Research on Frost Heaving Distribution of Seepage Stratum in Tunnel Construction Using Horizontal Freezing Technique. Appl. Sci. 2022, 12, 11696. [Google Scholar] [CrossRef]

- Nishimura, S.; Gens, A.; Olivella, S.; Jardine, R.J. THM-coupled finite element analysis of frozen soil: Formulation and application. Géotechnique 2009, 59, 159–171. [Google Scholar] [CrossRef]

- Taylor, G.S.; Luthin, J.N. A model for coupled heat and moisture transfer during soil freezing. Can. Geotech. J. 1978, 15, 548–555. [Google Scholar] [CrossRef]

- Bai, Q.; Li, X.; Tian, Y.-H.; Fang, J. Equations and numerical simulation for coupled water and heat transfer in frozen soil. Chin. J. Geotech. Eng. 2015, 37, 131–136. [Google Scholar]

- Tan, X.; Chen, W.; Tian, H.; Cao, J. Water flow and heat transport including ice/water phase change in porous media: Numerical simulation and application. Cold Reg. Sci. Technol. 2011, 68, 74–84. [Google Scholar] [CrossRef]

- Tang, L.; Yang, L.; Wang, X.; Yang, G.; Ren, X.; Li, Z.; Li, G. Numerical analysis of frost heave and thawing settlement of the pile–soil system in degraded permafrost region. Environ. Earth Sci. 2021, 80, 1–19. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, J.; Qi, J.; Sun, L.; Yang, K.; Tian, L.; Lin, Y.; Liu, W.; Shrestha, M.; Xue, Y.; et al. Development of a land surface model with coupled snow and frozen soil physics. Water Resour. Res. 2017, 53, 5085–5103. [Google Scholar] [CrossRef]

- Wu, J.; Han, T. Numerical research on the coupled process of the moisture-heat-stress fields in saturated soil during freezing. Eng. Mech. 2009, 26, 246–251. [Google Scholar]

- Fu, Y.; Hu, J.; Wu, Y. Finite element study on temperature field of subway connection aisle construction via artificial ground freezing method. Cold Reg. Sci. Technol. 2021, 189, 103327. [Google Scholar] [CrossRef]

- Hu, J.; Yang, P.; Dong, Z.; Cai, R. Study on numerical simulation of cup-shaped horizontal freezing reinforcement project near shield launching. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 5522–5525. [Google Scholar]

| Type of Parameter | Parameter | Value |

|---|---|---|

| Soil thermophysical parameters | Soil density (kg/m3) | 1930 |

| Water density (kg/m3) | 1000 | |

| Ice density (kg/m3) | 920 | |

| Thermal conductivity of soil (W/(m·°C)) | 1.22 | |

| Thermal conductivity of water (W/(m·°C)) | 0.63 | |

| Thermal conductivity of ice (W/(m·°C)) | 2.31 | |

| Specific heat capacity of soil (J/(kg·°C)) | 1530 | |

| Specific heat capacity of water (J/(kg·°C)) | 4200 | |

| Specific heat capacity of ice (J/(kg·°C)) | 2100 | |

| Latent heat of phase transition (J/kg) | 334,720 | |

| Soil mechanical parameters | Elastic modulus of unfrozen soil (MPa) | 40 |

| Elastic modulus of frozen soil (MPa) | 120 | |

| Unfrozen ground cohesion (kPa) | 30 | |

| Angle of internal friction in unfrozen soil (°) | 22 | |

| Poisson’s ratio for unfrozen soil | 0.31 | |

| Poisson’s ratio for frozen soil | 0.23 |

| Time/d | 0 | 10 | 20 | 30 | 45 |

| Temperature/°C | 18 | 0 | −20 | −28 | −28 |

| Time/d | 0 | 20 | 30 | 45 |

| Plan 1/°C | 18 | −20 | −28 | −28 |

| Plan 2/°C | 18 | −25 | −33 | −33 |

| Plan 3/°C | 18 | −15 | −23 | −23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Hu, J.; Dong, Q.; Chen, Y. Studying the Freezing Law of Reinforcement by Using the Artificial Ground Freezing Method in Shallow Buried Tunnels. Appl. Sci. 2024, 14, 7106. https://doi.org/10.3390/app14167106

Liu P, Hu J, Dong Q, Chen Y. Studying the Freezing Law of Reinforcement by Using the Artificial Ground Freezing Method in Shallow Buried Tunnels. Applied Sciences. 2024; 14(16):7106. https://doi.org/10.3390/app14167106

Chicago/Turabian StyleLiu, Peng, Jun Hu, Qinxi Dong, and Yongzhan Chen. 2024. "Studying the Freezing Law of Reinforcement by Using the Artificial Ground Freezing Method in Shallow Buried Tunnels" Applied Sciences 14, no. 16: 7106. https://doi.org/10.3390/app14167106