A Review of Sustainable Pavement Aggregates

Abstract

:1. Introduction

2. Plastic Waste

Polyethylene Terephthalate (PET)

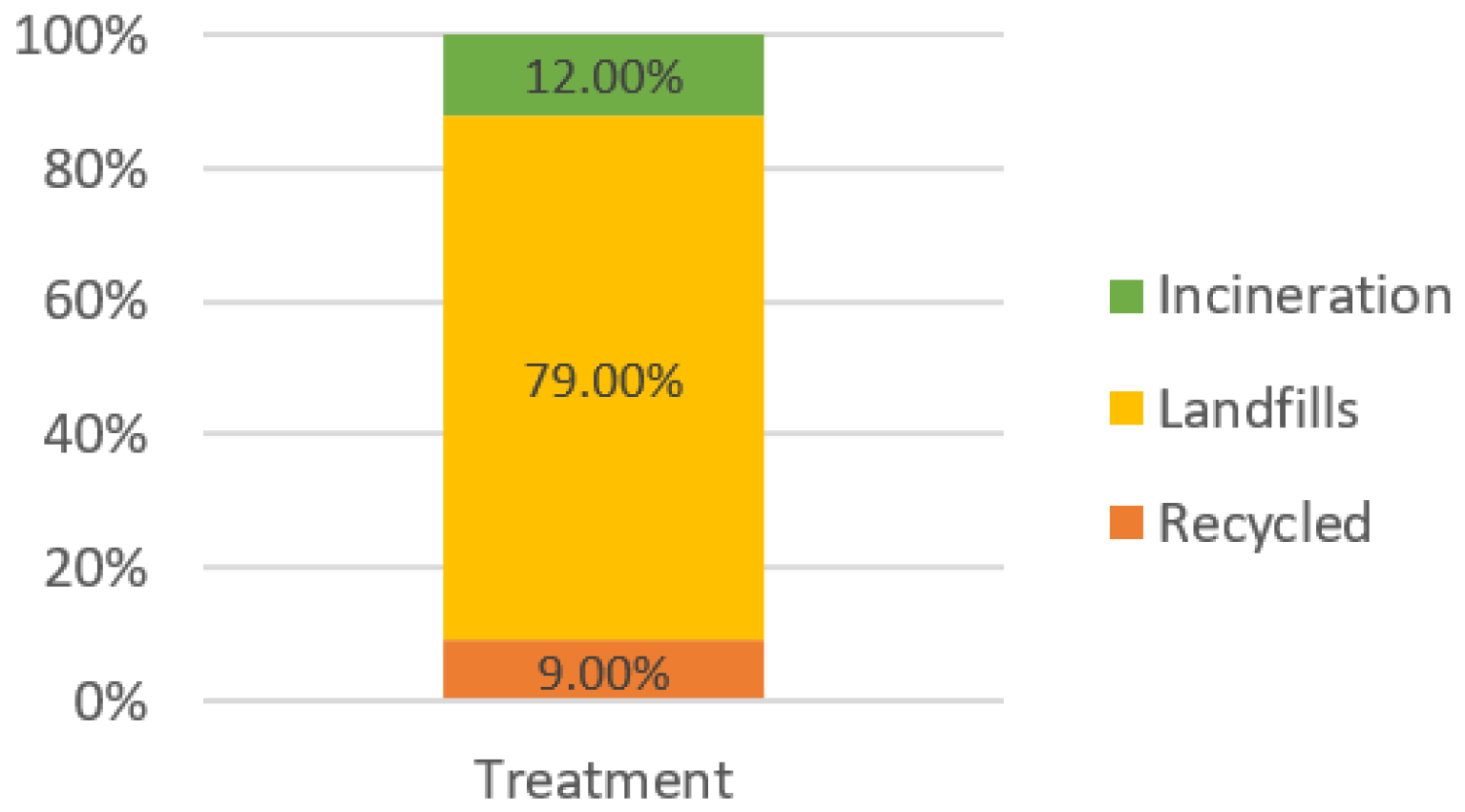

3. Waste Materials

3.1. Tire Recycling

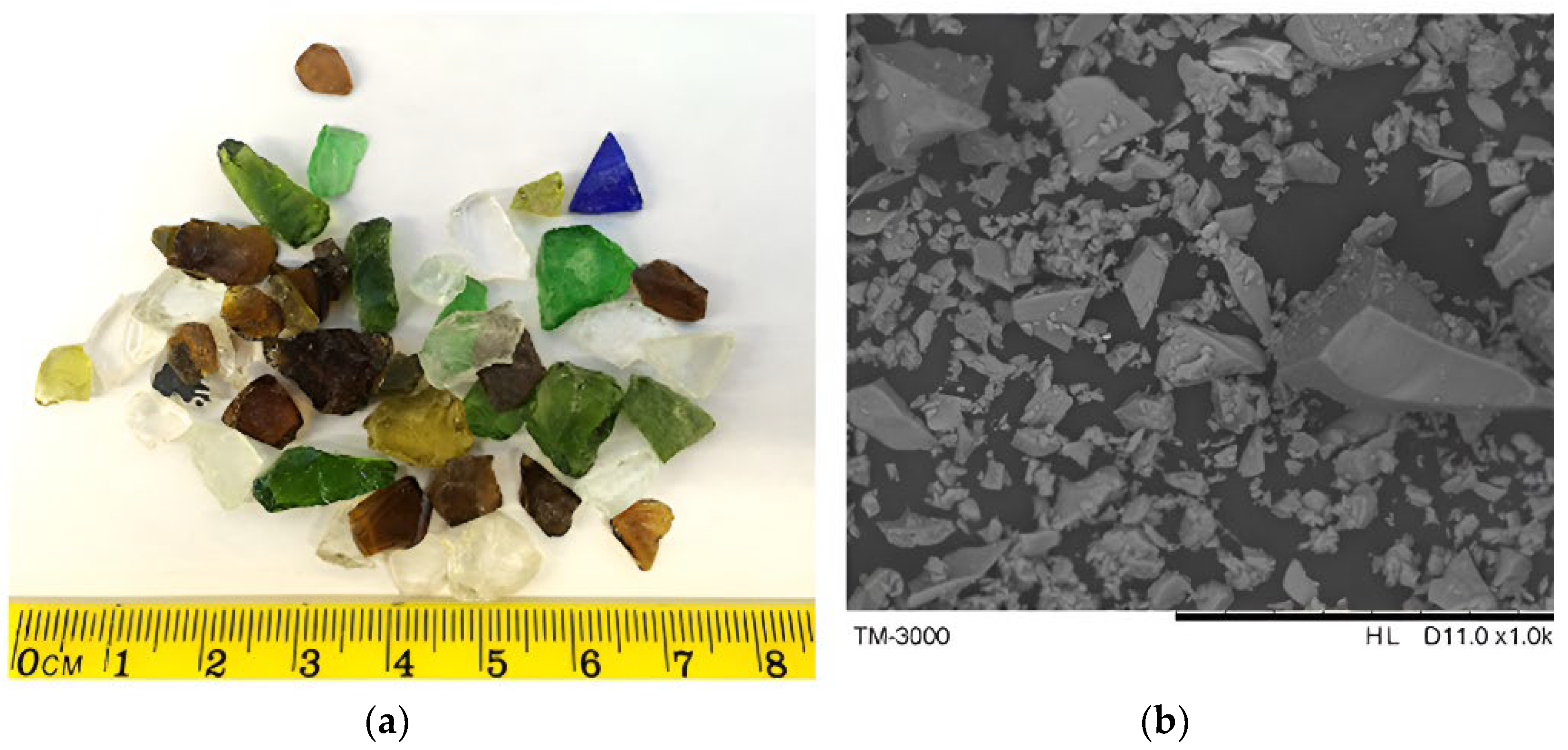

3.2. Waste Glass (WG)

4. Waste in Civil Engineering

4.1. Reclaimed Asphalt Pavement (RAP)

4.2. Recycled Concrete Aggregate (RCA)

5. Industrial and Mining Waste

5.1. Mining Waste

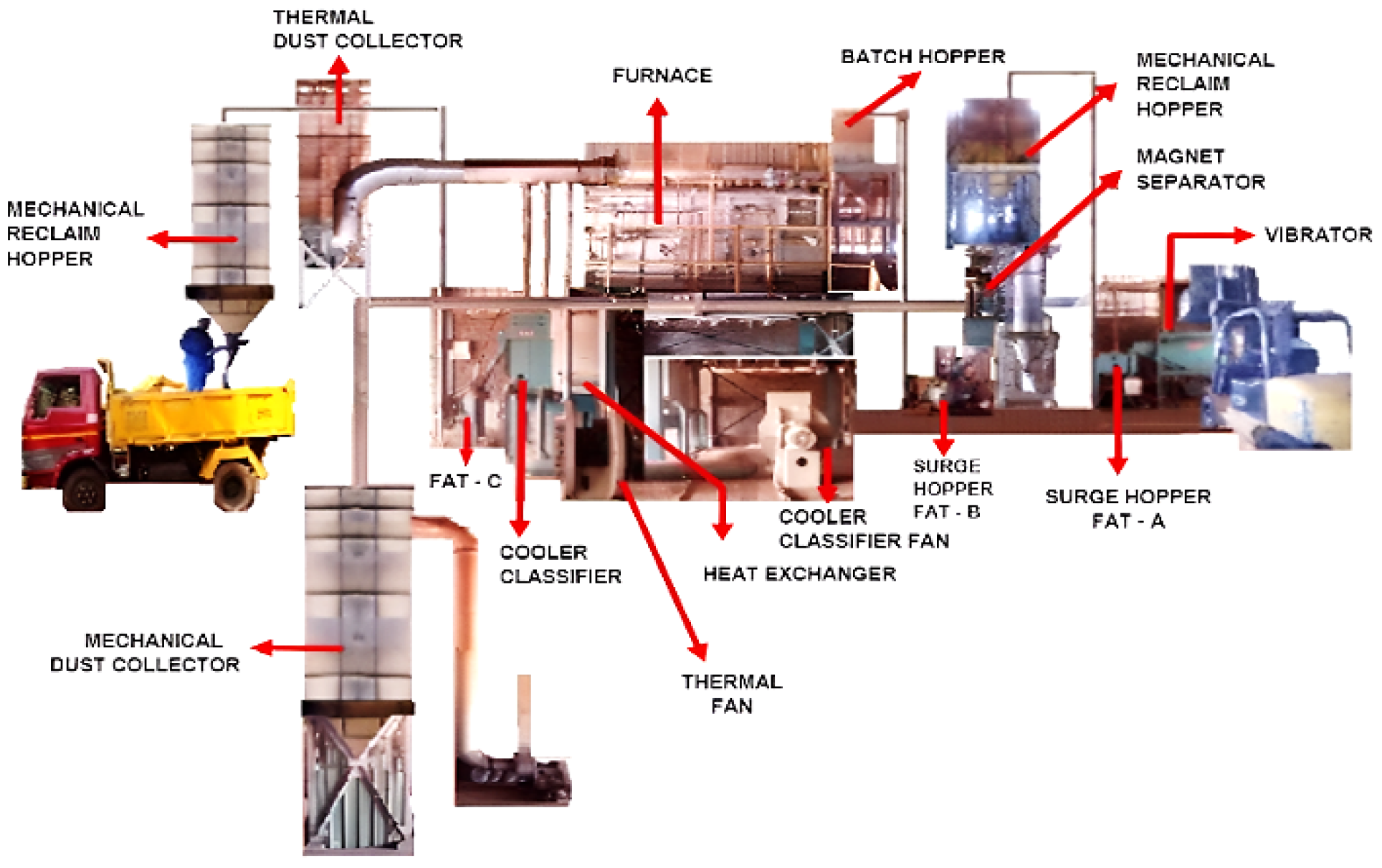

5.2. Waste Foundry Sand (WFS)

6. Analysis and Discussion

7. Recommendations

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blaauw, S.A.; Maina, J.W. Life Cycle Inventory for Pavements—A Case Study of South Africa. Transp. Eng. 2021, 3, 100049. [Google Scholar] [CrossRef]

- Barbieri, D.M.; Lou, B.; Wang, F.; Hoff, I.; Wu, S.; Li, J.; Vignisdottir, H.R.; Bohne, R.A.; Anastasio, S.; Kristensen, T. Assessment of carbon dioxide emissions during production, construction and use stages of asphalt pavements. Transp. Res. Interdiscip. Perspect. 2021, 11, 100436. [Google Scholar] [CrossRef]

- Mao, X.; Wang, J.; Yuan, C.; Yu, W.; Gan, J. A Dynamic Traffic Assignment Model for the Sustainability of Pavement Performance. Sustainability 2018, 11, 170. [Google Scholar] [CrossRef]

- Carrillo, Á.O.; Ortíz, R.S.M.; Hernández, F.M. Revisión de las tendencias innovadoras en la estructuración de pavimentos como parte del desarrollo sustentable review of innovative trends in the structuring of paving as part of sustainable development. Emerg. Trends Educ. 2018, 2, 55–76. [Google Scholar]

- Zhao, X.; Webber, R.; Kalutara, P.; Browne, W.; Pienaar, J. Construction and demolition waste management in Australia: A mini-review. Waste Manag. Res 2022, 40, 34–46. [Google Scholar] [CrossRef]

- Tiza, T.M.; Mogbo, O.; Singh, S.K.; Shaik, N.; Shettar, M.P. Bituminous pavement sustainability improvement strategies. Energy Nexus 2022, 6, 100065. [Google Scholar] [CrossRef]

- Mohd Hasan, M.R.; Chew, J.-W.; Jamshidi, A.; Yang, X.; Hamzah, M.O. Review of sustainability, pretreatment, and engineering considerations of asphalt modifiers from the industrial solid wastes. J. Traffic Transp. Eng. Engl. Ed. 2019, 6, 209–244. [Google Scholar] [CrossRef]

- Bressi, S.; Primavera, M.; Santos, J. A comparative life cycle assessment study with uncertainty analysis of cement treated base (CTB) pavement layers containing recycled asphalt pavement (RAP) materials. Resour. Conserv. Recycl. 2022, 180, 106160. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Towards very high RAP content asphalt mixes: A comprehensive performance-based study of rejuvenated binders. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 1022–1035. [Google Scholar] [CrossRef]

- Guzmán Ortiz, D.V.; Hernández Zaragoza, J.B.; López Lara, T.; Horta Rangel, J.M.; Giraldo Posada, D.A. Uso de agregado de pavimento asfáltico reciclado para un pavimento rígido. Ingeniería Investigación y Tecnología 2021, 22, 1–11. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.; De Azevedo, A.; Klyuev, S.; Vatin, N.; Karelina, M. Capacity to Develop Recycled Aggregate Concrete in South East Asia. Buildings 2021, 11, 234. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: Properties, performance, and sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Maduabuchukwu Nwakaire, C.; Poh Yap, S.; Chuen Onn, C.; Wah Yuen, C.; Adebayo Ibrahim, H. Utilisation of recycled concrete aggregates for sustainable highway pavement applications; a review. Constr. Build. Mater. 2020, 235, 117444. [Google Scholar] [CrossRef]

- Agudelo, G.; Palacio, C.A.; Neves Monteiro, S.; Colorado, H.A. Foundry Sand Waste and Residual Aggregate Evaluated as Pozzolans for Concrete. Sustainability 2022, 14, 9055. [Google Scholar] [CrossRef]

- Alfayez, S.A.; Suleiman, A.R.; Nehdi, M.L. Recycling Tire Rubber in Asphalt Pavements: State of the Art. Sustainability 2020, 12, 9076. [Google Scholar] [CrossRef]

- Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; Hu, C.; et al. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Cardoso, J.; Ferreira, A.; Almeida, A.; Santos, J. Incorporation of plastic waste into road pavements: A systematic literature review on the fatigue and rutting performances. Constr. Build. Mater. 2023, 407, 133441. [Google Scholar] [CrossRef]

- Paredes Cuba, D.E.; Paredes Cuba, N.J.; Urteaga Toro, M.R. Technical—Economic comparison of a conventional pavement and a modified pavement with incorporation of recycled pet plastic in its treading layer, cajamarca 2020. In Proceedings of the 20th LACCEI International Multi-Conference for Engineering, Education and Technology: “Education, Research and Leadership in Post-Pandemic Engineering: Resilient, Inclusive and Sustainable Actions”, Latin American and Caribbean Consortium of Engineering Institutions, Boca Raton, FL, USA, 18–22 July 2022. [Google Scholar] [CrossRef]

- Jegatheesan, N.; Rengarasu, T.M.; Bandara, W.M.K.R.T.W. Mechanical properties of modified hot mix asphalt containing polyethylene terephthalate fibers as binder additive and carbonized wood particles as fine aggregate replacement. Asian Transp. Stud. 2020, 6, 100029. [Google Scholar] [CrossRef]

- Prabhakaran, G.; Musa Patvegar, S.; Prakash Arul Jose, J.; Gouse Peera, D.; Joshi, B.; Ganeshkumar, B. Study of the impact in bituminous mix using crushed waste glass. Mater. Today Proc. 2023, In press, S2214785323039159. [Google Scholar] [CrossRef]

- Arias Torres, S.M.; Córdova Castro, J.D.; Gómez Botero, M.A. Alternativas de aprovechamiento de residuos de la industria minera de El Bajo Cauca Antioqueño en el sector de la construcción. Reveia 2021, 18, 36. [Google Scholar] [CrossRef]

- Rondón Quintana, H.A.; Muniz De Farias, M.; Reyes Lizcano, F.A. Uso de escorias de alto horno y acero en mezclas asfálticas: Revisión. Rev. Ing. Univ. Medellín 2018, 17, 71–97. [Google Scholar] [CrossRef]

- Dimulescu, C.; Burlacu, A. Industrial Waste Materials as Alternative Fillers in Asphalt Mixtures. Sustainability 2021, 13, 8068. [Google Scholar] [CrossRef]

- Chen, J.-S.; Wei, S.-H. Engineering properties and performance of asphalt mixtures incorporating steel slag. Constr. Build. Mater. 2016, 128, 148–153. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Noor, A.; Rehman, M.A.U. A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Hake, S.L.; Damgir, R.M.; Awsarmal, P.R. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. Transp. Res. Procedia 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- Martín, E. El Asfalto Ecológico Fabricado con Botellas de Plástico Llega para Quedarse: Ya Está en Reino Unido, Sudáfrica o Dubái. el 6 de Octubre de 2021. [En Línea]. Available online: https://www.motorpasion.com/futuro-movimiento/asfalto-fabricado-a-partir-plastico-carreteras-futuro (accessed on 13 June 2024).

- Li, R.; Leng, Z.; Yang, J.; Lu, G.; Huang, M.; Lan, J.; Zhang, H.; Bai, Y.; Dong, Z. Innovative application of waste polyethylene terephthalate (PET) derived additive as an antistripping agent for asphalt mixture: Experimental investigation and molecular dynamics simulation. Fuel 2021, 300, 121015. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Performance of PET and nano-silica modified stone mastic asphalt mixtures. Case Stud. Constr. Mater. 2022, 16, e01044. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, M.; Hong, J.; Lai, F.; Gao, Y. Molecular dynamics study on improvement effect of bis(2-hydroxyethyl) terephthalate on adhesive properties of asphalt-aggregate interface. Fuel 2021, 285, 119175. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Athari, S.; Mikhailenko, P.; Kakar, M.R.; Bueno, M.; Piao, Z.; Pieren, R.; Heutschi, K. Effect of waste materials on acoustical properties of semi-dense asphalt mixtures. Transp. Res. Part D Transp. Environ. 2022, 102, 103154. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Piao, Z.; Kakar, M.R.; Athari, S.; Bueno, M.; Poulikakos, L.D. Effect of waste PET and CR as sand replacement on the durability and acoustical properties of semi dense asphalt (SDA) mixtures. Sustain. Mater. Technol. 2021, 29, e00295. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.; Zoorob, S.E.; Abdulrahman, S.; Saeed, S.M. Irradiated polyethylene terephthalate fiber and binder contents optimization for fiber-reinforced asphalt mix using response surface methodology. Ain Shams Eng. J. 2021, 12, 271–282. [Google Scholar] [CrossRef]

- Harihanandh, M.; Karthik, P. Feasibility study of recycled plastic waste as fine aggregates in concrete. Mater. Today Proc. 2022, 52, 1807–1811. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Waste polyethylene terephthalate as an aggregate in concrete. Mat. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef]

- Gavela, S.; Rakanta, E.; Ntziouni, A.; Kasselouri-Rigopoulou, V. Eleven-Year Follow-Up on the Effect of Thermoplastic Aggregates’ Addition to Reinforced Concrete. Buildings 2022, 12, 1779. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Phetprapai, T.; Singsang, W.; Phetchuay, C.; Thumrongvut, J.; Tabyang, W. Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability 2022, 14, 6839. [Google Scholar] [CrossRef]

- Bocci, E.; Prosperi, E. Recycling of reclaimed fibers from end-of-life tires in hot mix asphalt. J. Traffic Transp. Eng. Engl. Ed. 2020, 7, 678–687. [Google Scholar] [CrossRef]

- Hejna, A.; Korol, J.; Przybysz-Romatowska, M.; Zedler, Ł.; Chmielnicki, B.; Formela, K. Waste tire rubber as low-cost and environmentally-friendly modifier in thermoset polymers—A review. Waste Manag. 2020, 108, 106–118. [Google Scholar] [CrossRef] [PubMed]

- Riekstins, A.; Haritonovs, V.; Straupe, V. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar] [CrossRef]

- Fathollahi, A.; Makoundou, C.; Coupe, S.J.; Sangiorgi, C. Leaching of PAHs from rubber modified asphalt pavements. Sci. Total Environ. 2022, 826, 153983. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.H.; Mazumder, M.; Lee, S.-J.; Lee, M.-S. Effect of production process on performance properties of warm rubberized binders. J. Traffic Transp. Eng. Engl. Ed. 2019, 6, 589–597. [Google Scholar] [CrossRef]

- Frolova, O.; Salaiová, B. Analysis of Road Cover Roughness on “Control” Road Section with Crumb Tire Rubber. Procedia Eng. 2017, 190, 589–596. [Google Scholar] [CrossRef]

- Sheng, Y.; Li, H.; Geng, J.; Tian, Y.; Li, Z.; Xiong, R. Production and performance of desulfurized rubber asphalt binder. Int. J. Pavement Res. Technol. 2017, 10, 262–273. [Google Scholar] [CrossRef]

- Badri, R.M.; Al Kaissi, Z.A.; Sutanto, M.; Alobaidi, M.K. Investigating the rheological properties of asphalt binder incorporating different crumb rubber contents based on a response surface methodology. J. King Saud Univ. Eng. Sci. 2022, 34, 322–328. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Xu, J.; Lin, P. Investigating the role of swelling-degradation degree of crumb rubber on CR/SBS modified porous asphalt binder and mixture. Constr. Build. Mater. 2021, 300, 124048. [Google Scholar] [CrossRef]

- Khalili, M.; Jadidi, K.; Karakouzian, M.; Amirkhanian, S. Rheological properties of modified crumb rubber asphalt binder and selecting the best modified binder using AHP method. Case Stud. Constr. Mater. 2019, 11, e00276. [Google Scholar] [CrossRef]

- Piao, Z.; Mikhailenko, P.; Kakar, M.R.; Bueno, M.; Hellweg, S.; Poulikakos, L.D. Urban mining for asphalt pavements: A review. J. Clean. Prod. 2021, 280, 124916. [Google Scholar] [CrossRef]

- Fernández-Ruiz, R.; Friedrich, K.E.J.; Redrejo, M.J.; Pérez-Aparicio, R.; Saiz-Rodríguez, L. Quantification of recycled rubber content of end-of-life tyres in asphalt bitumen by total-reflection X-ray fluorescence spectrometry. Spectrochim. Acta Part B At. Spectrosc. 2020, 166, 105803. [Google Scholar] [CrossRef]

- Noura, S.; Al-Sabaeei, A.M.; Safaeldeen, G.I.; Muniandy, R.; Carter, A. Evaluation of measured and predicted resilient modulus of rubberized Stone Mastic Asphalt (SMA) modified with truck tire rubber powder. Case Stud. Constr. Mater. 2021, 15, e00633. [Google Scholar] [CrossRef]

- Wang, S.; Huang, W.; Liu, X.; Lin, P. Influence of high content crumb rubber and different preparation methods on properties of asphalt under different aging conditions: Chemical properties, rheological properties, and fatigue performance. Constr. Build. Mater. 2022, 327, 126937. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B. Effect of recycled waste glass on the properties of high-performance concrete: A critical review. Case Stud. Constr. Mater. 2022, 17, e01149. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Elrahman, M.A. Properties of ultra-high performance geopolymer concrete incorporating recycled waste glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ghaderi, A. Experimental investigation of waste glass powder, basalt fibre, and carbon nanotube on the mechanical properties of concrete. Constr. Build. Mater. 2020, 252, 119115. [Google Scholar] [CrossRef]

- Taghipoor, M.; Tahami, A.; Forsat, M. Numerical and laboratory investigation of fatigue prediction models of asphalt containing glass wastes. Int. J. Fatigue 2020, 140, 105819. [Google Scholar] [CrossRef]

- Glosser, D.; Santykul, E.; Fagan, E.; Suraneni, P. A thermodynamic perspective on wind turbine glass fiber waste as a supplementary cementitious material. CEMENT 2022, 9, 100039. [Google Scholar] [CrossRef]

- Abdullah, G.M.S.; Alshaikh, I.M.H.; Zeyad, A.M.; Magbool, H.M.; Bakar, B.H.A. The effect of openings on the performance of self-compacting concrete with volcanic pumice powder and different steel fibers. Case Stud. Constr. Mater. 2022, 17, e01148. [Google Scholar] [CrossRef]

- Ray, S.; Haque, M.; Ahmed, T.; Nahin, T.T. Comparison of artificial neural network (ANN) and response surface methodology (RSM) in predicting the compressive and splitting tensile strength of concrete prepared with glass waste and tin (Sn) can fiber. J. King Saud Univ. Eng. Sci. 2023, 35, 185–199. [Google Scholar] [CrossRef]

- Ahmed, T.; Ray, S.; Haque, M.; Tasnim Nahin, T.; Ferdous Mita, A. Optimization of properties of concrete prepared with waste glass aggregate and condensed milk can fiber using response surface methodology. Clean. Eng. Technol. 2022, 8, 100478. [Google Scholar] [CrossRef]

- Sha, A.; Liu, Z.; Jiang, W.; Qi, L.; Hu, L.; Jiao, W.; Barbieri, D.M. Advances and development trends in eco-friendly pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Marathe, S.; Shetty, T.S.; Mithun, B.M.; Ranjith, A. Strength and durability studies on air cured alkali activated pavement quality concrete mixes incorporating recycled aggregates. Case Stud. Constr. Mater. 2021, 15, e00732. [Google Scholar] [CrossRef]

- Suddeepong, A.; Intra, A.; Horpibulsuk, S.; Suksiripattanapong, C.; Arulrajah, A.; Shen, J.S. Durability against wetting-drying cycles for cement-stabilized reclaimed asphalt pavement blended with crushed rock. Soils Found. 2018, 58, 333–343. [Google Scholar] [CrossRef]

- Spreadbury, C.J.; Clavier, K.A.; Lin, A.M.; Townsend, T.G. A critical analysis of leaching and environmental risk assessment for reclaimed asphalt pavement management. Sci. Total Environ. 2021, 775, 145741. [Google Scholar] [CrossRef]

- Zaumanis, M.; Loetscher, D.; Mazor, S.; Stöckli, F.; Poulikakos, L. Impact of milling machine parameters on the properties of reclaimed asphalt pavement. Constr. Build. Mater. 2021, 307, 125114. [Google Scholar] [CrossRef]

- Lyubarskaya, M.A.; Merkusheva, V.S.; Osian, P.A.; Ilin, A.A.; Svintsov, E.S. Integrated Approach to Using Technology of Reclaimed Asphalt Pavement (RAP). Procedia Eng. 2017, 189, 860–866. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Farias, M.M.D.; Silva, J.P.S. Fatigue analysis of hot recycled asphalt mixtures with RAP incorporation. Case Stud. Constr. Mater. 2022, 16, e01132. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Sahoo, U.C. Influence of softer binder and rejuvenator on bituminous mixtures containing reclaimed asphalt pavement (RAP) material. Int. J. Transp. Sci. Technol. 2022, 11, 46–59. [Google Scholar] [CrossRef]

- Wang, D.; Riccardi, C.; Jafari, B.; Cannone Falchetto, A.; Wistuba, M.P. Investigation on the effect of high amount of Re-recycled RAP with Warm mix asphalt (WMA) technology. Constr. Build. Mater. 2021, 312, 125395. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Xiang, Q.; Qin, W.; Yi, J. Research on the influence of RAP and aged asphalt on the performance of plant-mixed hot recycled asphalt mixture and blended asphalt. Case Stud. Constr. Mater. 2021, 15, e00722. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.; Al-shamayleh, R.A.; Ibrahim, R.; Alkhrissat, T.; Alqatamin, A. Mechanical properties evaluation of asphalt mixtures with variable contents of reclaimed asphalt pavement (RAP). Results Eng. 2022, 14, 100463. [Google Scholar] [CrossRef]

- Naser, M.; Abdel-Jaber, M.T.; Al-shamayleh, R.; Louzi, N.; Ibrahim, R. Evaluating the effects of using reclaimed asphalt pavement and recycled concrete aggregate on the behavior of hot mix asphalts. Transp. Eng. 2022, 10, 100140. [Google Scholar] [CrossRef]

- Andrew, B.; Buyondo, K.A.; Kasedde, H.; Kirabira, J.B.; Olupot, P.W.; Yusuf, A.A. Investigation on the use of reclaimed asphalt pavement along with steel fibers in concrete. Case Stud. Constr. Mater. 2022, 17, e01356. [Google Scholar] [CrossRef]

- Orosa, P.; Orozco, G.; Carret, J.C.; Carter, A.; Pérez, I.; Pasandín, A.R. Compactability and mechanical properties of cold recycled mixes prepared with different nominal maximum sizes of RAP. Constr. Build. Mater. 2022, 339, 127689. [Google Scholar] [CrossRef]

- Rathore, M.; Zaumanis, M. Impact of laboratory mixing procedure on the properties of reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 264, 120709. [Google Scholar] [CrossRef]

- Omranian, S.R.; Hamzah, M.O.; Gungat, L.; Teh, S.Y. Evaluation of asphalt mixture behavior incorporating warm mix additives and reclaimed asphalt pavement. J. Traffic Transp. Eng. Engl. Ed. 2018, 5, 181–196. [Google Scholar] [CrossRef]

- Ishaq, M.A.; Giustozzi, F. Rejuvenator effectiveness in reducing moisture and freeze/thaw damage on long-term performance of 20% RAP asphalt mixes: An Australian case study. Case Stud. Constr. Mater. 2020, 13, e00454. [Google Scholar] [CrossRef]

- Pasche, E.; Bruschi, G.J.; Specht, L.P.; Aragão, F.T.S.; Consoli, N.C. Fiber-reinforcement effect on the mechanical behavior of reclaimed asphalt pavement–powdered rock–Portland cement mixtures. Transp. Eng. 2022, 9, 100121. [Google Scholar] [CrossRef]

- Mondal, A.; Ransinchung, G. Evaluating the engineering properties of asphalt mixtures containing RAP aggregates incorporating different wastes as fillers and their effects on the ageing susceptibility. Clean. Waste Syst. 2022, 3, 100037. [Google Scholar] [CrossRef]

- Torres, P.J.L.; Paucar, J.H.M.; Córdova, E.W.A. Influencia de aditivos (polímeros y polialuminio) en las propiedades físico-mecánicas de mezclas asfálticas en caliente. FIGEMPA Investigción y Desarrollo 2020, 1, 60–71. [Google Scholar] [CrossRef]

- Wang, P.; Liu, H.; Guo, H.; Yu, Y.; Guo, Y.; Yue, G.; Li, Q.; Wang, L. Study on preparation and performance of alkali-activated low carbon recycled concrete: Corn cob biomass aggregate. J. Mater. Res. Technol. 2023, 23, 90–105. [Google Scholar] [CrossRef]

- Shmlls, M.; Abed, M.; Horvath, T.; Bozsaky, D. Multicriteria based optimization of second generation recycled aggregate concrete. Case Stud. Constr. Mater. 2022, 17, e01447. [Google Scholar] [CrossRef]

- Kox, S.; Vanroelen, G.; Van Herck, J.; De Krem, H.; Vandoren, B. Experimental evaluation of the high-grade properties of recycled concrete aggregates and their application in concrete road pavement construction. Case Stud. Constr. Mater. 2019, 11, e00282. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Rafiq Kakar, M.; Piao, Z.; Bueno, M.; Poulikakos, L. Incorporation of recycled concrete aggregate (RCA) fractions in semi-dense asphalt (SDA) pavements: Volumetrics, durability and mechanical properties. Constr. Build. Mater. 2020, 264, 120166. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Reyes-Lizcano, F.A.; Rondón-Quintana, H.A. Use of recycled concrete aggregates in asphalt mixtures for pavements: A review. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 725–741. [Google Scholar] [CrossRef]

- Jayakody, S.; Gallage, C.; Ramanujam, J. Performance characteristics of recycled concrete aggregate as an unbound pavement material. Heliyon 2019, 5, e02494. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Peñabaena-Niebles, R.; Giustozzi, F.; Martinez-Arguelles, G. Eco-friendly design of Warm mix asphalt (WMA) with recycled concrete aggregate (RCA): A case study from a developing country. Constr. Build. Mater. 2022, 326, 126890. [Google Scholar] [CrossRef]

- Vega-Araujo, D.; Martinez-Arguelles, G.; Santos, J. Comparative life cycle assessment of warm mix asphalt with recycled concrete aggregates: A Colombian case study. Procedia CIRP 2020, 90, 285–290. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Y.; Bie, Y.; Duan, P.; Wang, L. Multi-scale performance study of concrete with recycled aggregate from tannery sludge. Case Stud. Constr. Mater. 2022, 17, e01698. [Google Scholar] [CrossRef]

- Marat, M.K.; Cheynesh, B.K.-S.; Yulia, S.T.; Albert, M.K. Planetary Technology. Prerequisites for the Formation of a New Scientific Discipline. Min. Ind. 2020, 3, 113–120. [Google Scholar] [CrossRef]

- Benarchid, Y.; Taha, Y.; Argane, R.; Tagnit-Hamou, A.; Benzaazoua, M. Concrete containing low-sulphide waste rocks as fine and coarse aggregates: Preliminary assessment of materials. J. Clean. Prod. 2019, 221, 419–429. [Google Scholar] [CrossRef]

- Ivannikov, A.L.; Kongar-Syuryun, C.; Rybak, J.; Tyulyaeva, Y. The reuse of mining and construction waste for backfill as one of the sustainable activities. IOP Conf. Ser. Earth Environ. Sci. 2019, 362, 012130. [Google Scholar] [CrossRef]

- Ermolovich, E.A.; Ivannikov, A.L.; Khayrutdinov, M.M.; Kongar-Syuryun, C.B.; Tyulyaeva, Y.S. Creation of a Nanomodified Backfill Based on the Waste from Enrichment of Water-Soluble Ores. Materials 2022, 15, 3689. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Liu, S.; Hu, G.; Yang, T.; Du, C.; Oeser, M. Infiltration Capacity and Structural Analysis of Permeable Pavements for Sustainable Urban: A Full-scale Case Study. J. Clean. Prod. 2021, 288, 125111. [Google Scholar] [CrossRef]

- Cao, L.; Zhou, J.; Zhou, T.; Dong, Z.; Tian, Z. Utilization of iron tailings as aggregates in paving asphalt mixture: A sustainable and eco-friendly solution for mining waste. J. Clean. Prod. 2022, 375, 134126. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Tyulyaeva, Y.; Khairutdinov, A.M.; Kowalik, T. Industrial waste in concrete mixtures for construction of underground structures and minerals extraction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 032004. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B.; Aleksakhin, A.V.; Eliseeva, E.N.; Zhaglovskaya, A.V.; Klyuev, R.V.; Petrusevich, D.A. Modern Technologies Providing a Full Cycle of Geo-Resources Development. Resources 2023, 12, 50. [Google Scholar] [CrossRef]

- Sidorova, E.Y. Modern strategic decisions in the field of waste as a basis of development of circular economy and greening of industrial production. In Proceedings of the 19th SGEM International Multidisciplinary Scientific GeoConference EXPO Proceedings, Albena, Bulgaria, 28 June–7 July 2019. [Google Scholar]

- Hossiney, N.; Das, P.; Mohan, M.K.; George, J. In-plant production of bricks containing waste foundry sand—A study with Belgaum foundry industry. Case Stud. Constr. Mater. 2018, 9, e00170. [Google Scholar] [CrossRef]

- Zamora-Castro, S.A.; Salgado-Estrada, R.; Sandoval-Herazo, L.C.; Melendez-Armenta, R.A.; Manzano-Huerta, E.; Yelmi-Carrillo, E.; Herrera-May, A.L. Sustainable Development of Concrete through Aggregates and Innovative Materials: A Review. Appl. Sci. 2021, 11, 629. [Google Scholar] [CrossRef]

- Mushtaq, S.M.; Siddique, R.; Goyal, S.; Kaur, K. Experimental studies and drying shrinkage prediction model for concrete containing waste foundry sand. Clean. Eng. Technol. 2021, 2, 100071. [Google Scholar] [CrossRef]

- Apithanyasai, S.; Supakata, N.; Papong, S. The potential of industrial waste: Using foundry sand with fly ash and electric arc furnace slag for geopolymer brick production. Heliyon 2020, 6, e03697. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, Y.; Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef]

- Dash, M.K.; Patro, S.K.; Rath, A.K. Sustainable use of industrial-waste as partial replacement of fine aggregate for preparation of concrete—A review. Int. J. Sustain. Built Environ. 2016, 5, 484–516. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J. Understanding the performance of expansive subgrade materials treated with non-traditional stabilisers: A review. Clean. Eng. Technol. 2021, 4, 100159. [Google Scholar] [CrossRef]

- Sithole, N.T. Alternative cleaner production of sustainable concrete from waste foundry sand and slag. J. Clean. Prod. 2022, 336, 130399. [Google Scholar] [CrossRef]

- Dyer, P.P.O.L.; De Lima, M.G. Waste foundry sand in hot mix asphalt: A review. Constr. Build. Mater. 2022, 359, 129342. [Google Scholar] [CrossRef]

| Blend Type | Replacement Value | Method/Test | Effect | Author |

|---|---|---|---|---|

| HMA PG64-16 PG58-28 AC20 | 15% 10% 15% | AHP | Improves resistance to deformation | Khalili et al., (2019) [51] |

| SMA | 20% | ITS | Decreases tensile strength | Noura et al., (2021) [54] |

| HCRMA | 50% | LAS | Decreases fatigue resistance | Wang et al., (2022) [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-Vargas, J.R.; Zamora-Castro, S.A.; Herrera-May, A.L.; Sandoval-Herazo, L.C.; Salgado-Estrada, R.; Diaz-Vega, M.E. A Review of Sustainable Pavement Aggregates. Appl. Sci. 2024, 14, 7113. https://doi.org/10.3390/app14167113

Ramírez-Vargas JR, Zamora-Castro SA, Herrera-May AL, Sandoval-Herazo LC, Salgado-Estrada R, Diaz-Vega ME. A Review of Sustainable Pavement Aggregates. Applied Sciences. 2024; 14(16):7113. https://doi.org/10.3390/app14167113

Chicago/Turabian StyleRamírez-Vargas, Jaime R., Sergio A. Zamora-Castro, Agustín L. Herrera-May, Luis C. Sandoval-Herazo, Rolando Salgado-Estrada, and María E. Diaz-Vega. 2024. "A Review of Sustainable Pavement Aggregates" Applied Sciences 14, no. 16: 7113. https://doi.org/10.3390/app14167113

APA StyleRamírez-Vargas, J. R., Zamora-Castro, S. A., Herrera-May, A. L., Sandoval-Herazo, L. C., Salgado-Estrada, R., & Diaz-Vega, M. E. (2024). A Review of Sustainable Pavement Aggregates. Applied Sciences, 14(16), 7113. https://doi.org/10.3390/app14167113