Analysing Near-Miss Incidents in Construction: A Systematic Literature Review

Abstract

:1. Introduction

- Q1—Are near-miss events in construction industry the subject of scientific research?

- Q2—What methods have been employed thus far to obtain information on near misses and systems for recording incidents in construction companies?

- Q3—What methods have been used to analyse the information and figures obtained?

- Q4—What are the key aspects of near misses in the construction industry that have been of interest to the researchers?

2. Definition of Near-Miss Events

3. Research Methodology

- -

- methods of obtaining information on incidents, including reporting and recording incidents;

- -

- real-time monitoring of workers;

- -

- methods of data analysis;

- -

- thematic areas of research.

4. Results

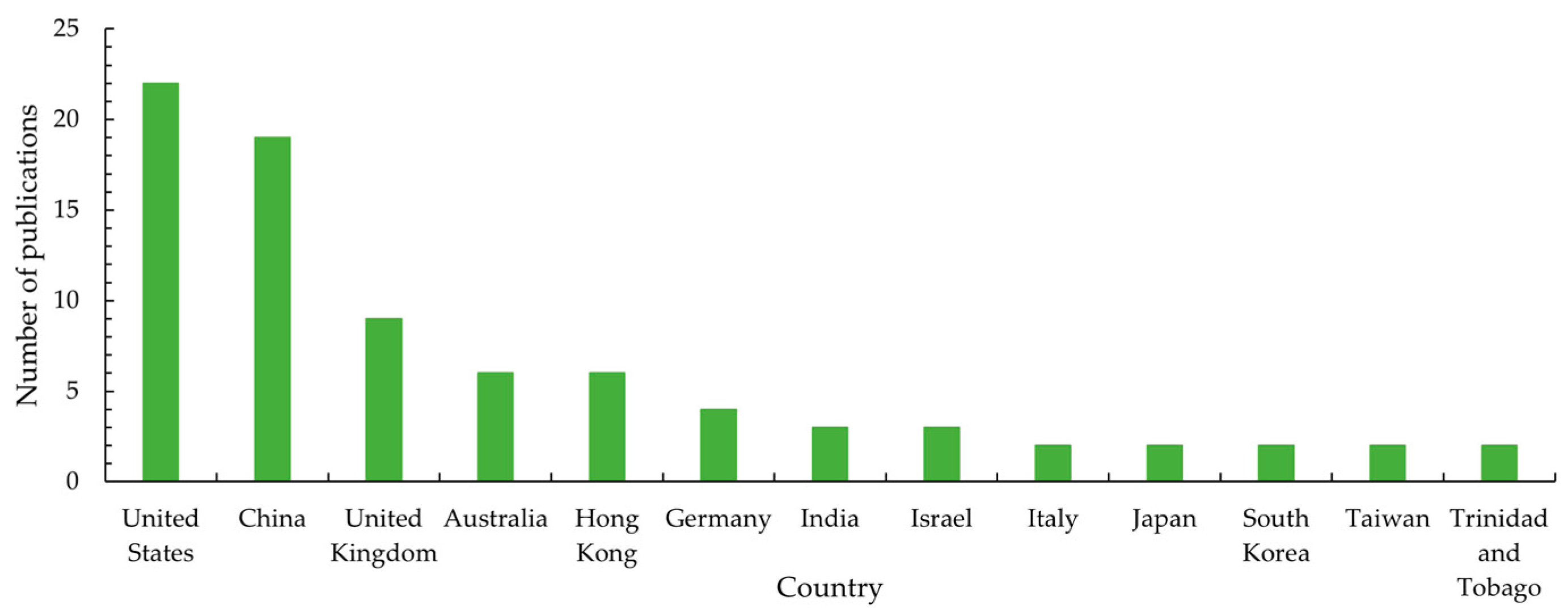

4.1. A Statistical Analysis of Publications

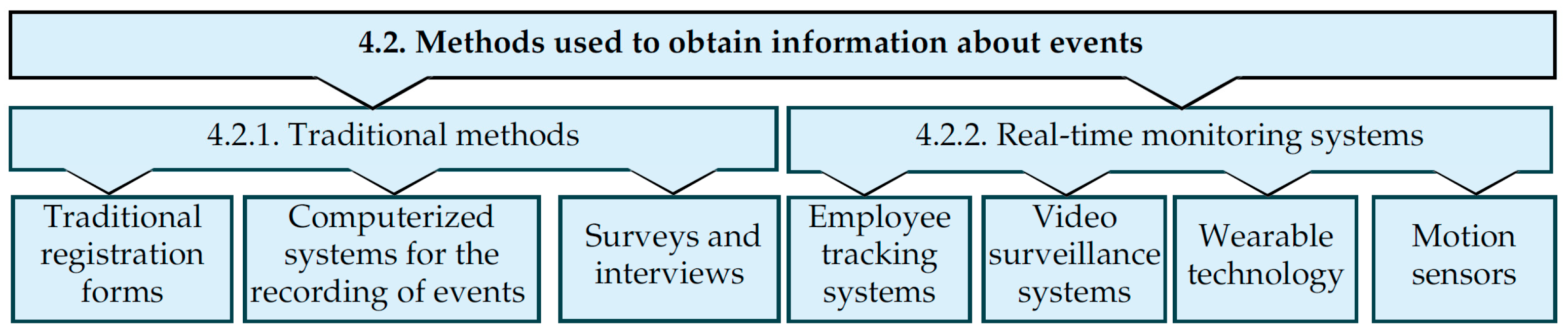

4.2. Methods Used to Obtain Information about Near Misses

4.2.1. Traditional Methods

- Traditional registration forms

- Computerized systems for the recording of events

- Surveys and interviews

4.2.2. Real-Time Monitoring Systems

- Employee-tracking systems

- Video surveillance systems

- Wearable technology

- Motion sensors

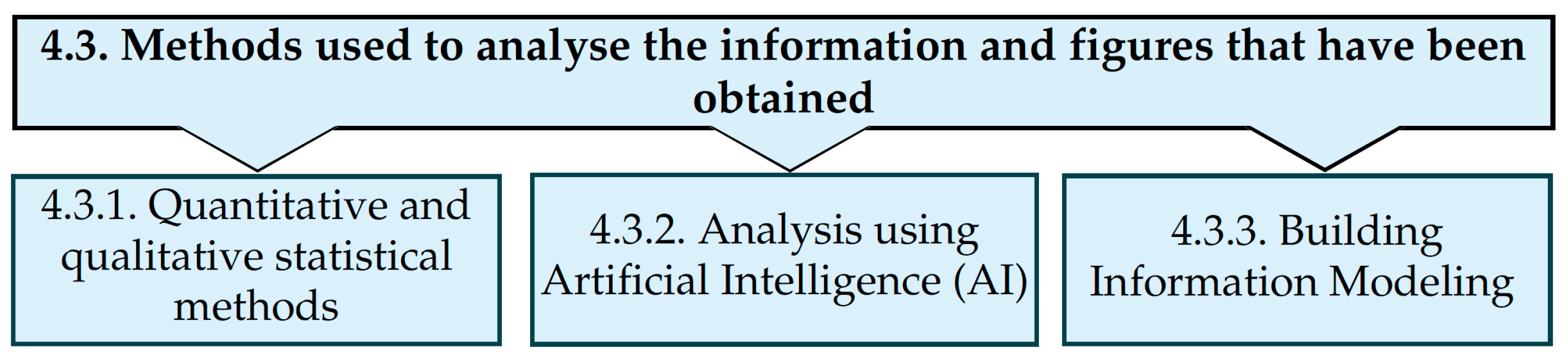

4.3. Methods Used to Analyse the Information and Figures That Have Been Obtained

4.3.1. Quantitative and Qualitative Statistical Methods

4.3.2. Analysis Using Artificial Intelligence (AI)

4.3.3. Building Information Modelling

4.4. Key Aspects of Near-Miss Investigations in the Construction Industry

4.4.1. Occupational Risk Assessment

4.4.2. Causes of Hazards in Construction

4.4.3. Time Series of Near Misses

4.4.4. Material Factors of Construction Processes

4.5. A Comprehensive Overview of the Research Questions and References on Near Misses in the Construction Industry

5. Discussion

5.1. Interest of Researchers in Near Misses in Construction (Question 1)

5.2. Methods Used to Obtain Near-Miss Information (Question 2)

5.3. Methods Used to Analyse the Information and Data Sets (Question 3)

5.4. Key Aspects of Near-Miss Investigations in the Construction Industry (Question 4)

6. Conclusions

- A quantitative analysis of the Q1 question has revealed a positive trend, namely that there is a growing interest among researchers in studying near misses in construction. The greatest interest in NM topics is observed in the United States of America, China, the United Kingdom, Australia, Hong Kong, and Germany. Additionally, there has been a recent emergence of interest in Poland. The majority of articles are mainly published in journals such as Safety Science (10), Journal of Construction Engineering and Management (8), and Automation in Construction (5);

- The analysis of question Q2 illustrates that traditional paper-based event registration systems are currently being superseded by advanced IT systems. However, both traditional and advanced systems are subject to the disadvantage of relying on employee-reported data, which introduces a significant degree of uncertainty regarding in the quality of the information provided. A substantial proportion of the data and findings presented in the studies was obtained through surveys and interviews. The implementation of real-time monitoring systems is becoming increasingly prevalent in construction sites. The objective of such systems is to provide immediate alerts in the event of potential hazards, thereby preventing a significant number of near misses. Real-time monitoring systems employ a range of technologies, including ultrasonic technology, radio frequency identification (RFID), inertial measurement units (IMUs), real-time location systems (RTLSs), industrial cameras, wearable technology, motion sensors, and advanced IT technologies, among others;

- The analysis of acquired near-miss data is primarily conducted through the utilisation of quantitative and qualitative statistical methods, as evidenced by the examination of the Q3 question. In recent years, research utilising artificial intelligence (AI) has made significant advances. The most commonly employed artificial intelligence techniques include text mining, machine learning, and artificial neural networks. The growing deployment of Building Information Modelling (BIM) technology has precipitated a profound transformation in the safety management of construction sites, with the advent of sophisticated tools for the identification and management of hazardous occurrences;

- In response to question Q4, the study of near misses in the construction industry has identified several key aspects that have attracted the attention of researchers. These include the utilisation of both quantitative and qualitative methodologies for risk assessment, the analysis of the causes of hazards, the identification of accident precursors through the creation of time series, and the examination of material factors pertaining to construction processes. Researchers are focusing on the utilisation of both databases and advanced technologies, such as real-time location tracking, for the assessment and analysis of occupational risks. Techniques such as Analytic Hierarchy Process (AHP) and clustering facilitate a comprehensive assessment and categorisation of incidents, thereby enabling the identification of patterns and susceptibility to specific types of accidents. Moreover, the impact of a company’s safety climate and organisational culture on the frequency and characteristics of near misses represents a pivotal area of investigation. The findings of this research indicate that effective safety management requires a holistic approach that integrates technology, risk management and safety culture, with the objective of reducing accidents and enhancing overall working conditions on construction sites.

7. Gaps and Future Research Directions, Limitations

- Given the diversity and variability of construction sites and the changing conditions and circumstances of work, it is essential to create homogeneous clusters of near misses and to analyse the phenomena within these clusters. The formation of such clusters may be contingent upon the direct causes of the events in question;

- Given the inherently dynamic nature of construction, it is essential to analyse time series of events that indicate trends in development and safety levels. The numerical characteristics of these trends may be used to construct predictive models for future accidents and near misses;

- The authors have identified potential avenues for future research, which could involve the development of mathematical models using techniques such as linear regression, artificial intelligence, and machine learning. The objective of these models is to predict the probable timing of occupational accidents within defined incident categories, utilising data from near misses. Moreover, efforts are being made to gain access to the hazardous incident recording systems of different construction companies, with a view to facilitating comparison of the resulting data;

- One significant limitation of near-miss research is the lack of an integrated database that encompasses a diverse range of construction sites and construction work. A data resource of this nature would be of immense value for the purpose of conducting comprehensive analyses and formulating effective risk management strategies. This issue can be attributed to two factors: firstly, the reluctance of company managers to share their databases with researchers specialising in risk assessment, and secondly, the reluctance of employees to report near-miss incidents. Such actions may result in adverse consequences for employees, including disciplinary action or negative perceptions from managers. This consequently results in the recording of only a subset of incidents, thereby distorting the true picture of safety on the site.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Year | Source Title | DOI/ISBN/ISSN | Reference |

|---|---|---|---|

| 1999 | Construction Management and Economics | 10.1080/014461999371691 | [98] |

| 2002 | Structural Engineer | 14665123 | [99] |

| 2009 | Building a Sustainable Future—Proceedings of the 2009 Construction Research Congress | 10.1061/41020(339)4 | [100] |

| 2010 | Safety Science | 10.1016/j.ssci.2010.04.009 | [14] |

| 2010 | Automation in Construction | 10.1016/j.autcon.2009.11.017 | [57] |

| 2010 | Safety Science | 10.1016/j.ssci.2009.06.006 | [12] |

| 2012 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0000518 | [90] |

| 2013 | ISARC 2013—30th International Symposium on Automation and Robotics in Construction and Mining, Held in Conjunction with the 23rd World Mining Congress | 10.22260/isarc2013/0113 | [101] |

| 2014 | Proceedings of the Institution of Civil Engineers: Civil Engineering | 10.1680/cien.14.00010 | [103] |

| 2014 | Safety Science | 10.1016/j.ssci.2013.12.012 | [55] |

| 2014 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0000795 | [102] |

| 2014 | 31st International Symposium on Automation and Robotics in Construction and Mining, ISARC 2014—Proceedings | 10.22260/isarc2014/0115 | [58] |

| 2014 | Construction Research Congress 2014: Construction in a Global Network—Proceedings of the 2014 Construction Research Congress | 10.1061/9780784413517.0181 | [54] |

| 2014 | Construction Research Congress 2014: Construction in a Global Network—Proceedings of the 2014 Construction Research Congress | 10.1061/9780784413517.0235 | [28] |

| 2014 | Construction Research Congress 2014: Construction in a Global Network—Proceedings of the 2014 Construction Research Congress | 10.1061/9780784413517.0096 | [17] |

| 2015 | Automation in Construction | 10.1016/j.autcon.2015.09.003 | [45] |

| 2015 | 32nd International Symposium on Automation and Robotics in Construction and Mining: Connected to the Future, Proceedings | 10.22260/isarc2015/0062 | [60] |

| 2015 | ASSE Professional Development Conference and Exposition 2015 | - | [104] |

| 2015 | Congress on Computing in Civil Engineering, Proceedings | 10.1061/9780784479247.019 | [66] |

| 2016 | Automation in Construction | 10.1016/j.autcon.2016.03.008 | [47] |

| 2016 | Automation in Construction | 10.1016/j.autcon.2016.04.007 | [67] |

| 2016 | IEEE IAS Electrical Safety Workshop | 10.1109/ESW.2016.7499701 | [105] |

| 2016 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0001100 | [87] |

| 2016 | Safety Science | 10.1016/j.ssci.2015.11.025 | [16] |

| 2016 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0001049 | [65] |

| 2016 | IEEE Transactions on Industry Applications | 10.1109/TIA.2015.2461180 | [109] |

| 2017 | Safety Science | 10.1016/j.ssci.2017.06.012 | [93] |

| 2017 | ENR (Engineering News-Record) | 8919526 | [108] |

| 2017 | 6th CSCE-CRC International Construction Specialty Conference 2017—Held as Part of the Canadian Society for Civil Engineering Annual Conference and General Meeting 2017 | 978-151087841-9 | [89] |

| 2017 | Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics) | 10.1007/978-3-319-72323-5_12 | [106] |

| 2017 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0001209 | [107] |

| 2017 | Safety Science | 10.1016/j.ssci.2016.08.027 | [68] |

| 2017 | Safety Science | 10.1016/j.ssci.2016.08.022 | [18] |

| 2018 | Safety Science | 10.1016/j.ssci.2018.04.004 | [110] |

| 2018 | International Journal of Construction Management | 10.1080/15623599.2017.1382067 | [111] |

| 2018 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0001420 | [86] |

| 2018 | Proceedings of SPIE—The International Society for Optical Engineering | 10.1117/12.2296548 | [19] |

| 2019 | Automation in Construction | 10.1016/j.autcon.2019.102854 | [34] |

| 2019 | Physica A: Statistical Mechanics and its Applications | 10.1016/j.physa.2019.121495 | [36] |

| 2019 | Sustainability (Switzerland) | 10.3390/su11051264 | [73] |

| 2019 | Computing in Civil Engineering 2019: Data, Sensing, and Analytics—Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2019 | 978-078448243-8 | [64] |

| 2019 | Journal of Health, Safety and Environment | 18379362 | [112] |

| 2019 | Computing in Civil Engineering 2019: Data, Sensing, and Analytics—Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2019 | 978-078448243-8 | [63] |

| 2019 | Computing in Civil Engineering 2019: Smart Cities, Sustainability, and Resilience—Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2019 | 10.1061/9780784482445.026 | [85] |

| 2019 | Journal of Construction Engineering and Management | 10.1061/(ASCE)CO.1943-7862.0001582 | [75] |

| 2019 | Advances in Intelligent Systems and Computing | 10.1007/978-3-030-02053-8_107 | [74] |

| 2020 | Accident Analysis and Prevention | 10.1016/j.aap.2020.105496 | [113] |

| 2020 | Advanced Engineering Informatics | 10.1016/j.aei.2020.101062 | [72] |

| 2020 | Advanced Engineering Informatics | 10.1016/j.aei.2020.101060 | [53] |

| 2020 | ARCOM 2020—Association of Researchers in Construction Management, 36th Annual Conference 2020—Proceedings | 978-099554633-2 | [71] |

| 2020 | International Journal of Building Pathology and Adaptation | 10.1108/IJBPA-03-2020-0018 | [114] |

| 2020 | Communications in Computer and Information Science | 10.1007/978-3-030-42852-5_8 | [88] |

| 2021 | Journal of Architectural Engineering | 10.1061/(ASCE)AE.1943-5568.0000501 | [115] |

| 2021 | Safety Science | 10.1016/j.ssci.2021.105368 | [97] |

| 2021 | ACM International Conference Proceeding Series | 10.1145/3482632.3487473 | [116] |

| 2021 | Reliability Engineering and System Safety | 10.1016/j.ress.2021.107687 | [82] |

| 2021 | Proceedings of the 37th Annual ARCOM Conference, ARCOM 2021 | - | [70] |

| 2022 | Buildings | 10.3390/buildings12111855 | [117] |

| 2022 | Safety Science | 10.1016/j.ssci.2022.105704 | [31] |

| 2022 | Sensors | 10.3390/s22093482 | [81] |

| 2022 | Proceedings of International Structural Engineering and Construction | 10.14455/ISEC.2022.9(2).CSA-03 | [56] |

| 2022 | Journal of Information Technology in Construction | 10.36680/j.itcon.2022.045 | [83] |

| 2022 | Forensic Engineering 2022: Elevating Forensic Engineering—Selected Papers from the 9th Congress on Forensic Engineering | 10.1061/9780784484555.005 | [118] |

| 2022 | Computational Intelligence and Neuroscience | 10.1155/2022/4851615 | [84] |

| 2022 | International Journal of Construction Management | 10.1080/15623599.2020.1839704 | [61] |

| 2023 | Journal of Construction Engineering and Management | 10.1061/JCEMD4.COENG-13979 | [78] |

| 2023 | Heliyon | 10.1016/j.heliyon.2023.e21607 | [119] |

| 2023 | Accident Analysis and Prevention | 10.1016/j.aap.2023.107224 | [77] |

| 2023 | Safety | 10.3390/safety9030047 | [120] |

| 2023 | Engineering, Construction and Architectural Management | 10.1108/ECAM-09-2021-0797 | [121] |

| 2023 | Advanced Engineering Informatics | 10.1016/j.aei.2023.101929 | [76] |

| 2023 | Engineering, Construction and Architectural Management | 10.1108/ECAM-05-2023-0458 | [80] |

| 2023 | Intelligent Automation and Soft Computing | 10.32604/iasc.2023.031359 | [62] |

| 2023 | International Journal of Construction Management | 10.1080/15623599.2020.1847405 | [79] |

| 2024 | Heliyon | 10.1016/j.heliyon.2024.e26410 | [3] |

References

- Occupational Risk|Safety and Health at Work EU-OSHA. Available online: https://osha.europa.eu/en/tools-and-resources/eu-osha-thesaurus/term/70194i (accessed on 28 June 2023).

- Guo, S.; Zhou, X.; Tang, B.; Gong, P. Exploring the Behavioral Risk Chains of Accidents Using Complex Network Theory in the Construction Industry. Phys. A Stat. Mech. Its Appl. 2020, 560, 125012. [Google Scholar] [CrossRef]

- Woźniak, Z.; Hoła, B. The Structure of near Misses and Occupational Accidents in the Polish Construction Industry. Heliyon 2024, 10, e26410. [Google Scholar] [CrossRef]

- Li, X.; Sun, W.; Fu, H.; Bu, Q.; Zhang, Z.; Huang, J.; Zang, D.; Sun, Y.; Ma, Y.; Wang, R.; et al. Schedule Risk Model of Water Intake Tunnel Construction Considering Mood Factors and Its Application. Sci. Rep. 2024, 14, 3857. [Google Scholar] [CrossRef]

- Li, X.; Huang, J.; Li, C.; Luo, N.; Lei, W.; Fan, H.; Sun, Y.; Chen, W. Study on Construction Resource Optimization and Uncertain Risk of Urban Sewage Pipe Network. Period. Polytech. Civ. Eng. 2022, 66, 335–343. [Google Scholar] [CrossRef]

- Central Statistical Office Central Statistical Office/Thematic Areas/Labor Market/Working Conditions/Accidents at Work/Accidents at Work in the 1st Quarter of 2024. Available online: https://stat.gov.pl/obszary-tematyczne/rynek-pracy/warunki-pracy-wypadki-przy-pracy/wypadki-przy-pracy-w-1-kwartale-2024-roku,3,55.html (accessed on 17 July 2024).

- Manzo, J. The $5 Billion Cost of Construction Fatalities in the United States: A 50 State Comparison; The Midwest Economic Policy Institute (MEPI): Saint Paul, MN, USA, 2017. [Google Scholar]

- Sousa, V.; Almeida, N.M.; Dias, L.A. Risk-Based Management of Occupational Safety and Health in the Construction Industry—Part 1: Background Knowledge. Saf. Sci. 2014, 66, 75–86. [Google Scholar] [CrossRef]

- Amirah, N.A.; Him, N.F.N.; Rashid, A.; Rasheed, R.; Zaliha, T.N.; Afthanorhan, A. Fostering a Safety Culture in Manufacturing through Safety Behavior: A Structural Equation Modelling Approach. J. Saf. Sustain. 2024; in press. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention; A Scientific Approach; McGraw-Hill: New York, NY, USA, 1931. [Google Scholar]

- Near Miss Definition Per OSHA—What Is a Near Miss? Available online: https://safetystage.com/osha-compliance/near-miss-definition-osha/ (accessed on 17 August 2024).

- Cambraia, F.B.; Saurin, T.A.; Formoso, C.T. Identification, Analysis and Dissemination of Information on near Misses: A Case Study in the Construction Industry. Saf. Sci. 2010, 48, 91–99. [Google Scholar] [CrossRef]

- Tan, J.; Li, M. How to Achieve Accurate Accountability under Current Administrative Accountability System for Work Safety Accidents in Chemical Industry in China: A Case Study on Major Work Safety Accidents during 2010–2020. J. Chin. Hum. Resour. Manag. 2022, 13, 26–40. [Google Scholar] [CrossRef]

- Wu, W.; Gibb, A.G.F.; Li, Q. Accident Precursors and near Misses on Construction Sites: An Investigative Tool to Derive Information from Accident Databases. Saf. Sci. 2010, 48, 845–858. [Google Scholar] [CrossRef]

- Janicak, C.A. Fall-Related Deaths in the Construction Industry. J. Saf. Res. 1998, 29, 35–42. [Google Scholar] [CrossRef]

- Li, H.; Yang, X.; Wang, F.; Rose, T.; Chan, G.; Dong, S. Stochastic State Sequence Model to Predict Construction Site Safety States through Real-Time Location Systems. Saf. Sci. 2016, 84, 78–87. [Google Scholar] [CrossRef]

- Yang, K.; Aria, S.; Ahn, C.R.; Stentz, T.L. Automated Detection of Near-Miss Fall Incidents in Iron Workers Using Inertial Measurement Units. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 935–944. [Google Scholar] [CrossRef]

- Raviv, G.; Fishbain, B.; Shapira, A. Analyzing Risk Factors in Crane-Related near-Miss and Accident Reports. Saf. Sci. 2017, 91, 192–205. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, M.; Cao, T. A Study of Using Smartphone to Detect and Identify Construction Workers’ near-Miss Falls Based on ANN. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XII, Denver, CO, USA, 4–8 March 2018; p. 80. [Google Scholar] [CrossRef]

- Santiago, K.; Yang, X.; Ruano-Herreria, E.C.; Chalmers, J.; Cavicchia, P.; Caban-Martinez, A.J. Characterising near Misses and Injuries in the Temporary Agency Construction Workforce: Qualitative Study Approach. Occup. Environ. Med. 2020, 77, 94–99. [Google Scholar] [CrossRef] [PubMed]

- What Is OSHA’s Definition of a Near Miss. Available online: https://www.osha.com/blog/near-miss-definition (accessed on 4 August 2023).

- Martins, I. Investigation of Occupational Accidents and Diseases a Practical Guide for Labour Inspectors; International Labour Office: Geneva, Switzerland, 2015. [Google Scholar]

- National Safety Council. Near Miss Reporting Systems; National Safety Council: Singapore, 2013. [Google Scholar]

- PKN PN-ISO 45001:2018-06; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. CRC Press: Boca Raton, FL, USA, 2019.

- PKN PN-N-18001:2004; Occupational Health and Safety Management Systems—Requirements. CRC Press: Boca Raton, FL, USA, 2004.

- World Health Organisation. WHO Draft GuiDelines for Adverse Event Reporting and Learning Systems; World Health Organisation: Geneva, Switzerland, 2005. [Google Scholar]

- International Atomic Energy Agency IAEA Satety Glossary. Terminology Used in Nuclear Safety and Radiation Protection: 2007 Edition; International Atomic Energy Agency: Vienna, Austria, 2007. [Google Scholar]

- Marks, E.; Teizer, J.; Hinze, J. Near Miss Reporting Program to Enhance Construction Worker Safety Performance. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19 May 2014; pp. 2315–2324. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Saleh, J.H. Near-Miss Management Systems and Observability-in-Depth: Handling Safety Incidents and Accident Precursors in Light of Safety Principles. Saf. Sci. 2017, 91, 154–167. [Google Scholar] [CrossRef]

- Thoroman, B.; Goode, N.; Salmon, P. System Thinking Applied to near Misses: A Review of Industry-Wide near Miss Reporting Systems. Theor. Issues Ergon. Sci. 2018, 19, 712–737. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Tornese, F.; Guglielmi, A.; Pellicci, M.; Campo, G.; De Merich, D. Near Miss Management Systems in the Industrial Sector: A Literature Review. Saf. Sci. 2022, 150, 105704. [Google Scholar] [CrossRef]

- Bird, F. Management Guide to Loss Control; Loss Control Publications: Houston, TX, USA, 1975. [Google Scholar]

- Zimmermann. Bauer International Norms and Identity; Zimmermann: Sydney, NSW, Australia, 2006; pp. 5–21. [Google Scholar]

- Arslan, M.; Cruz, C.; Ginhac, D. Semantic Trajectory Insights for Worker Safety in Dynamic Environments. Autom. Constr. 2019, 106, 102854. [Google Scholar] [CrossRef]

- Arslan, M.; Cruz, C.; Ginhac, D. Visualizing Intrusions in Dynamic Building Environments for Worker Safety. Saf. Sci. 2019, 120, 428–446. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, R.; Jiang, S.; Zhou, Y.; Ding, L.; Skibniewski, M.J.; Lin, X. Human Dynamics in Near-Miss Accidents Resulting from Unsafe Behavior of Construction Workers. Phys. A Stat. Mech. Its Appl. 2019, 530, 121495. [Google Scholar] [CrossRef]

- Chen, F.; Wang, C.; Wang, J.; Zhi, Y.; Wang, Z. Risk Assessment of Chemical Process Considering Dynamic Probability of near Misses Based on Bayesian Theory and Event Tree Analysis. J. Loss Prev. Process Ind. 2020, 68, 104280. [Google Scholar] [CrossRef]

- Wright, L.; Van Der Schaaf, T. Accident versus near Miss Causation: A Critical Review of the Literature, an Empirical Test in the UK Railway Domain, and Their Implications for Other Sectors. J. Hazard. Mater. 2004, 111, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Saleh, J.H.; Saltmarsh, E.A.; Favar, F.M.; Loı¨c Brevault, L. Accident Precursors, near Misses, and Warning Signs: Critical Review and Formal Definitions within the Framework of Discrete Event Systems. Reliab. Eng. Syst. Saf. 2013, 114, 148–154. [Google Scholar] [CrossRef]

- Fred, A. Manuele Reviewing Heinrich. Am. Soc. Saf. Prof. 2011, 56, 52–61. [Google Scholar]

- Love, P.E.D.; Tenekedjiev, K. Understanding Near-Miss Count Data on Construction Sites Using Greedy D-Vine Copula Marginal Regression: A Comment. Reliab. Eng. Syst. Saf. 2022, 217, 108021. [Google Scholar] [CrossRef]

- Jan van Eck, N.; Waltman, L. VOSviewer Manual; Universiteit Leiden: Leiden, The Netherlands, 2015. [Google Scholar]

- Scopus. Content Coverage Guide; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–24. [Google Scholar]

- Lukic, D.; Littlejohn, A.; Margaryan, A. A Framework for Learning from Incidents in the Workplace. Saf. Sci. 2012, 50, 950–957. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T. Proximity Hazard Indicator for Workers-on-Foot near Miss Interactions with Construction Equipment and Geo-Referenced Hazard Area. Autom. Constr. 2015, 60, 58–73. [Google Scholar] [CrossRef]

- Zong, L.; Fu, G. A Study on Designing No-Penalty Reporting System about Enterprise Staff’s near Miss. Adv. Mater. Res. 2011, 255–260, 3846–3851. [Google Scholar] [CrossRef]

- Golovina, O.; Teizer, J.; Pradhananga, N. Heat Map Generation for Predictive Safety Planning: Preventing Struck-by and near Miss Interactions between Workers-on-Foot and Construction Equipment. Autom. Constr. 2016, 71, 99–115. [Google Scholar] [CrossRef]

- Zou, P.X.W.; Lun, P.; Cipolla, D.; Mohamed, S. Cloud-Based Safety Information and Communication System in Infrastructure Construction. Saf. Sci. 2017, 98, 50–69. [Google Scholar] [CrossRef]

- Hinze, J.; Godfrey, R. An Evaluation of Safety Performance Measures for Construction Projects. J. Constr. Res. 2011, 4, 5–15. [Google Scholar] [CrossRef]

- Construction Inspection Software|IAuditor by SafetyCulture. Available online: https://safetyculture.com/construction/ (accessed on 25 August 2023).

- Incident Reporting Made Easy|Safety Compliance|Mobile EHS Solutions. Available online: https://www.safety-reports.com/lp/safety/incident/ (accessed on 25 August 2023).

- Wu, F.; Wu, T.; Yuce, M.R. An Internet-of-Things (IoT) Network System for Connected Safety and Health Monitoring Applications. Sensors 2019, 19, 21. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Luo, H.; Xu, S.; Love, P.E.D.; Lu, Z.; Ye, C. Automated Text Classification of Near-Misses from Safety Reports: An Improved Deep Learning Approach. Adv. Eng. Inform. 2020, 44, 101060. [Google Scholar] [CrossRef]

- Gatti, U.C.; Lin, K.-Y.; Caldera, C.; Chiang, R. Exploring the Relationship between Chronic Sleep Deprivation and Safety on Construction Sites. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–24 May 2014; pp. 1772–1781. [Google Scholar] [CrossRef]

- Hon, C.K.H.; Chan, A.P.C.; Yam, M.C.H. Relationships between Safety Climate and Safety Performance of Building Repair, Maintenance, Minor Alteration, and Addition (RMAA) Works. Saf. Sci. 2014, 65, 10–19. [Google Scholar] [CrossRef]

- Oni, O.; Olanrewaju, A.; Cheen, K.S. Accidents at construction sites and near-misses: A constant problem. Int. Struct. Eng. Constr. 2022, 9, 2022. [Google Scholar] [CrossRef]

- Wu, W.; Yang, H.; Chew, D.A.S.; Yang, S.-H.; Gibb, A.G.F.; Li, Q. Towards an Autonomous Real-Time Tracking System of near-Miss Accidents on Construction Sites. Autom. Constr. 2010, 19, 134–141. [Google Scholar] [CrossRef]

- Aria, S.S.; Yang, K.; Ahn, C.R.; Vuran, M.C. Near-Miss Accident Detection for Ironworkers Using Inertial Measurement Unit Sensors. In Proceedings of the International Symposium on Automation and Robotics in Construction, ISARC 2014, Sydney, Australia, 9–11 July 2014; Volume 31, pp. 854–859. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Garza, J.M. de la Productivity-Safety Model: Debunking the Myth of the Productivity-Safety Divide through a Mixed-Reality Residential Roofing Task. J. Constr. Eng. Manag. 2020, 146, 04020124. [Google Scholar] [CrossRef]

- Teizer, J. Magnetic Field Proximity Detection and Alert Technology for Safe Heavy Construction Equipment Operation. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction, Oulu, Finland, 15–18 June 2015. [Google Scholar] [CrossRef]

- Mohajeri, M.; Ardeshir, A.; Banki, M.T.; Malekitabar, H. Discovering Causality Patterns of Unsafe Behavior Leading to Fall Hazards on Construction Sites. Int. J. Constr. Manag. 2022, 22, 3034–3044. [Google Scholar] [CrossRef]

- Kisaezehra; Farooq, M.U.; Bhutto, M.A.; Kazi, A.K. Real-Time Safety Helmet Detection Using Yolov5 at Construction Sites. Intell. Autom. Soft Comput. 2023, 36, 911–927. [Google Scholar] [CrossRef]

- Li, C.; Ding, L. Falling Objects Detection for near Miss Incidents Identification on Construction Site. In Proceedings of the ASCE International Conference on Computing in Civil Engineering, Atlanta, GA, USA, 17–19 June 2019; pp. 138–145. [Google Scholar] [CrossRef]

- Jeelani, I.; Ramshankar, H.; Han, K.; Albert, A.; Asadi, K. Real-Time Hazard Proximity Detection—Localization of Workers Using Visual Data. In Proceedings of the ASCE International Conference on Computing in Civil Engineering, Atlanta, GA, USA, 17–19 June 2019; pp. 281–289. [Google Scholar] [CrossRef]

- Lim, T.-K.; Park, S.-M.; Lee, H.-C.; Lee, D.-E. Artificial Neural Network–Based Slip-Trip Classifier Using Smart Sensor for Construction Workplace. J. Constr. Eng. Manag. 2015, 142, 04015065. [Google Scholar] [CrossRef]

- Yang, K.; Jebelli, H.; Ahn, C.R.; Vuran, M.C. Threshold-Based Approach to Detect Near-Miss Falls of Iron Workers Using Inertial Measurement Units. In Proceedings of the 2015 International Workshop on Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015; 2015; 2015, pp. 148–155. [Google Scholar] [CrossRef]

- Yang, K.; Ahn, C.R.; Vuran, M.C.; Aria, S.S. Semi-Supervised near-Miss Fall Detection for Ironworkers with a Wearable Inertial Measurement Unit. Autom. Constr. 2016, 68, 194–202. [Google Scholar] [CrossRef]

- Raviv, G.; Shapira, A.; Fishbain, B. AHP-Based Analysis of the Risk Potential of Safety Incidents: Case Study of Cranes in the Construction Industry. Saf. Sci. 2017, 91, 298–309. [Google Scholar] [CrossRef]

- Saurin, T.A.; Formoso, C.T.; Reck, R.; Beck da Silva Etges, B.M.; Ribeiro JL, D. Findings from the Analysis of Incident-Reporting Systems of Construction Companies. J. Constr. Eng. Manag. 2015, 141, 05015007. [Google Scholar] [CrossRef]

- Williams, E.; Sherratt, F.; Norton, E. Exploring the Value in near Miss Reporting for Construction Safety. In Proceedings of the 37th Annual Conference, Virtual Event, 6–10 December 2021; pp. 319–328. [Google Scholar]

- Baker, H.; Smith, S.; Masterton, G.; Hewlett, B. Data-Led Learning: Using Natural Language Processing (NLP) and Machine Learning to Learn from Construction Site Safety Failures. In Proceedings of the 36th Annual ARCOM Conference, Online, 7–8 September 2020; pp. 356–365. [Google Scholar]

- Jin, R.; Wang, F.; Liu, D. Dynamic Probabilistic Analysis of Accidents in Construction Projects by Combining Precursor Data and Expert Judgments. Adv. Eng. Inform. 2020, 44, 101062. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, C.; Mi, C.; Qian, L. Exploring the Potential Use of Near-Miss Information to Improve Construction Safety Performance. Sustainability 2019, 11, 1264. [Google Scholar] [CrossRef]

- Boateng, E.B.; Pillay, M.; Davis, P. Predicting the Level of Safety Performance Using an Artificial Neural Network. Adv. Intell. Syst. Comput. 2019, 876, 705–710. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, T.; Zhao, X. Using Smartphones to Detect and Identify Construction Workers’ Near-Miss Falls Based on ANN. J. Constr. Eng. Manag. 2018, 145, 04018120. [Google Scholar] [CrossRef]

- Gadekar, H.; Bugalia, N. Automatic Classification of Construction Safety Reports Using Semi-Supervised YAKE-Guided LDA Approach. Adv. Eng. Inform. 2023, 56, 101929. [Google Scholar] [CrossRef]

- Zhu, Y.; Liao, H.; Huang, D. Using Text Mining and Multilevel Association Rules to Process and Analyze Incident Reports in China. Accid. Anal. Prev. 2023, 191, 107224. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Lin, Q.; Jin, H. Research on Near-Miss Incidents Monitoring and Early Warning System for Building Construction Sites Based on Blockchain Technology. J. Constr. Eng. Manag. 2023, 149, 04023124. [Google Scholar] [CrossRef]

- Chung, W.W.S.; Tariq, S.; Mohandes, S.R.; Zayed, T. IoT-Based Application for Construction Site Safety Monitoring. Int. J. Constr. Manag. 2020, 23, 58–74. [Google Scholar] [CrossRef]

- Liu, X.; Xu, F.; Zhang, Z.; Sun, K. Fall-Portent Detection for Construction Sites Based on Computer Vision and Machine Learning. Eng. Constr. Archit. Manag. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Abbasi, H.; Guerrieri, A.; Lee, J.; Yang, K. Mobile Device-Based Struck-By Hazard Recognition in Construction Using a High-Frequency Sound. Sensors 2022, 22, 3482. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Li, H.; Dong, C. Understanding Near-Miss Count Data on Construction Sites Using Greedy D-Vine Copula Marginal Regression. Reliab. Eng. Syst. Saf. 2021, 213, 107687. [Google Scholar] [CrossRef]

- Bugalia, N.; Tarani, V.; Student, G.; Kedia, J.; Gadekar, H. Machine Learning-Based Automated Classification Of Worker-Reported Safety Reports In Construction. J. Inf. Technol. Constr. 2022, 27, 926–950. [Google Scholar] [CrossRef]

- Chen, S.; Xi, J.; Chen, Y.; Zhao, J. Association Mining of Near Misses in Hydropower Engineering Construction Based on Convolutional Neural Network Text Classification. Comput. Intell. Neurosci. 2022, 2022, 4851615. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Golparvar-Fard, M.; Naphade, M.; Gopalakrishna, M.M. Video-Based Activity Forecasting for Construction Safety Monitoring Use Cases. In Proceedings of the ASCE International Conference on Computing in Civil Engineering, Atlanta, GA, USA, 17–19 June 2019; pp. 204–210. [Google Scholar] [CrossRef]

- Rashid, K.M.; Behzadan, A.H. Risk Behavior-Based Trajectory Prediction for Construction Site Safety Monitoring. J. Constr. Eng. Manag. 2018, 144, 04017106. [Google Scholar] [CrossRef]

- Shen, X.; Marks, E. Near-Miss Information Visualization Tool in BIM for Construction Safety. J. Constr. Eng. Manag. 2016, 142, 04015100. [Google Scholar] [CrossRef]

- Erusta, N.E.; Sertyesilisik, B. An Investigation into Improving Occupational Health and Safety Performance of Construction Projects through Usage of BIM for Lean Management. In Communications in Computer and Information Science (CCIS); Springer: Berlin/Heidelberg, Germany, 2020; Volume 1188, pp. 91–100. [Google Scholar] [CrossRef]

- Coffland, M.M.; Kim, A.; Sadatsafavi, H.; Uber, M.M. Improved Data Storage for Better Safety Analysis and Decision Making in Large Construction Management Firms. Available online: https://www.researchgate.net/publication/320474383_Improved_Data_Storage_for_Better_Safety_Analysis_and_Decision_Making_in_Large_Construction_Management_Firms (accessed on 12 June 2024).

- Zhou, Z.; Li, Q.; Wu, W. Developing a Versatile Subway Construction Incident Database for Safety Management. J. Constr. Eng. Manag. 2011, 138, 1169–1180. [Google Scholar] [CrossRef]

- Wu, W.; Yang, H.; Li, Q.; Chew, D. An Integrated Information Management Model for Proactive Prevention of Struck-by-Falling-Object Accidents on Construction Sites. Autom. Constr. 2013, 34, 67–74. [Google Scholar] [CrossRef]

- Hoła, B. Identification and Evaluation of Processes in a Construction Enterprise. Arch. Civ. Mech. Eng. 2015, 15, 419–426. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L.; Skibniewski, M.J.; Luo, H.; Jiang, S. Characterizing Time Series of Near-Miss Accidents in Metro Construction via Complex Network Theory. Saf. Sci. 2017, 98, 145–158. [Google Scholar] [CrossRef]

- Woźniak, Z.; Hoła, B. Time Series Analysis of Hazardous Events Based on Data Recorded in a Polish Construction Company. Arch. Civ. Eng. 2024; in process. [Google Scholar]

- Drozd, W. Characteristics of Construction Site in Terms of Occupational Safety. J. Civ. Eng. Environ. Archit. 2016, 63, 165–172. [Google Scholar]

- Meliá, J.L.; Mearns, K.; Silva, S.A.; Lima, M.L. Safety Climate Responses and the Perceived Risk of Accidents in the Construction Industry. Saf. Sci. 2008, 46, 949–958. [Google Scholar] [CrossRef]

- Bugalia, N.; Maemura, Y.; Ozawa, K. A System Dynamics Model for Near-Miss Reporting in Complex Systems. Saf. Sci. 2021, 142, 105368. [Google Scholar] [CrossRef]

- Gyi, D.E.; Gibb, A.G.F.; Haslam, R.A. The Quality of Accident and Health Data in the Construction Industry: Interviews with Senior Managers. Constr. Manag. Econ. 1999, 17, 197–204. [Google Scholar] [CrossRef]

- Menzies, J. Structural Safety: Learning and Warnings. Struct. Eng. 2002, 80, 15–16. [Google Scholar]

- Fullerton, C.E.; Allread, B.S.; Teizer, J. Pro-Active-Real-Time Personnel Warning System. In Proceedings of the Construction Research Congress 2009: Building a Sustainable Future, Seattle, WA, USA, 5–7 April 2009; pp. 31–40. [Google Scholar] [CrossRef]

- Marks, E.D.; Wetherford, J.E.; Teizer, J.; Yabuki, N. Potential of Leading Indicator Data Collection and Analysis for Proximity Detection and Alert Technology in Construction. In Proceedings of the 30th ISARC—International Symposium on Automation and Robotics in Construction Conference, Montreal, QC, Canada, 11–15 August 2013; pp. 1029–1036. [Google Scholar] [CrossRef]

- Martin, H.; Lewis, T.M. Pinpointing Safety Leadership Factors for Safe Construction Sites in Trinidad and Tobago. J. Constr. Eng. Manag. 2014, 140, 04013046. [Google Scholar] [CrossRef]

- Hobson, P.; Emery, D.; Brown, L.; Bashford, R.; Gill, J. People–Plant Interface Training: Targeting an Industry Fatal Risk. Proc. Inst. Civ. Eng. Civ. Eng. 2014, 167, 138–144. [Google Scholar] [CrossRef]

- Marks, E.; Mckay, B.; Awolusi, I. Using near Misses to Enhance Safety Performance in Construction. In Proceedings of the ASSE Professional Development Conference and Exposition, Dallas, TX, USA, 7–10 June 2015. [Google Scholar]

- Popp, J.D.; Scarborough, M.S. Investigations of near Miss Incidents—New Facility Construction and Commissioning Activities. IEEE Trans. Ind. Appl. 2016, 53, 615–621. [Google Scholar] [CrossRef]

- Nickel, P.; Lungfiel, A.; Trabold, R.J. Reconstruction of near Misses and Accidents for Analyses from Virtual Reality Usability Study. In Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2017; Volume 10700, pp. 182–191. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Pestana, C.; Lee, H.W. Alignment between Lean Principles and Practices and Worker Safety Behavior. J. Constr. Eng. Manag. 2017, 143, 04016083. [Google Scholar] [CrossRef]

- Van Voorhis, S.; Korman, R. Reading Signs of Trouble. Eng. News-Rec. 2017, 278, 14–17. [Google Scholar]

- Doan, D.R. Investigation of a near-miss shock incident. IEEE Trans. Ind. Appl. 2016, 52, 560–561. [Google Scholar] [CrossRef]

- Oswald, D.; Sherratt, F.; Smith, S. Problems with safety observation reporting: A construction industry case study. Saf. Sci. 2018, 107, 35–45. [Google Scholar] [CrossRef]

- Raviv, G.; Shapira, A. Systematic approach to crane-related near-miss analysis in the construction industry. Int. J. Constr. Manag. 2018, 18, 310–320. [Google Scholar] [CrossRef]

- Whiteoak, J.; Appleby, J. Mate, that was bloody close! A case history of a nearmiss program in the Australian construction industry. J. Health Saf. Environ. 2019, 35, 31–43. [Google Scholar]

- Duryan, M.; Smyth, H.; Roberts, A.; Rowlinson, S.; Sherratt, F. Knowledge transfer for occupational health and safety: Cultivating health and safety learning culture in construction firms. Accid. Anal. Prev. 2020, 139, 105496. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, A.Y.; Osei-Kyei, R.; Hardie, M. A critical analysis of safety performance indicators in construction. Int. J. Build. Pathol. Adapt. 2020, 39, 547–580. [Google Scholar] [CrossRef]

- Martin, H.; Mohan, N.; Ellis, L.; Dunne, S. Exploring the Role of PPE Knowledge, Attitude, and Correct Practices in Safety Outcomes on Construction Sites. J. Archit. Eng. 2021, 27, 05021011. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, S. A simulation model of engineering construction near-miss event disclosure strategy based on evolutionary game theory. In Proceedings of the 2021 4th International Conference on Information Systems and Computer Aided Education, Dalian, China, 24–26 September 2021; pp. 2572–2577. [Google Scholar] [CrossRef]

- Alamoudi, M. The Integration of NOSACQ-50 with Importance-Performance Analysis Technique to Evaluate and Analyze Safety Climate Dimensions in the Construction Sector in Saudi Arabia. Buildings 2022, 12, 1855. [Google Scholar] [CrossRef]

- Herrmann, A.W. Development of CROSS in the United States. In Proceedings of the Forensic Engineering 2022: Elevating Forensic Engineering—Selected Papers from the 9th Congress on Forensic Engineering, Denver, Colorado, 4–7 November 2022; Volume 2, pp. 40–43. [Google Scholar] [CrossRef]

- Al Shaaili, M.; Al Alawi, M.; Ekyalimpa, R.; Al Mawli, B.; Al-Mamun, A.; Al Shahri, M. Near-miss accidents data analysis and knowledge dissemination in water construction projects in Oman. Heliyon 2023, 9, e21607. [Google Scholar] [CrossRef] [PubMed]

- Agnusdei, G.P.; Gnoni, M.G.; Tornese, F.; De Merich, D.; Guglielmi, A.; Pellicci, M. Application of Near-Miss Management Systems: An Exploratory Field Analysis in the Italian Industrial Sector. Safety 2023, 9, 47. [Google Scholar] [CrossRef]

- Duan, P.; Zhou, J. A science mapping approach-based review of near-miss research in construction. Eng. Constr. Archit. Manag. 2023, 30, 2582–2601. [Google Scholar] [CrossRef]

| No. | Name of Institution/Organization | Definition |

|---|---|---|

| 1 | Occupational Safety and Health Administration (OSHA) [21] | “A near-miss is a potential hazard or incident in which no property was damaged and no personal injury was sustained, but where, given a slight shift in time or position, damage or injury easily could have occurred. Near misses also may be referred to as close calls, near accidents, or injury-free events.” |

| 2 | International Labour Organization (ILO) [22] | “An event, not necessarily defined under national laws and regulations, that could have caused harm to persons at work or to the public, e.g., a brick that falls off scaffolding but does not hit anyone” |

| 3 | American National Safety Council (NSC) [23] | “A Near Miss is an unplanned event that did not result in injury, illness, or damage—but had the potential to do so” |

| 4 | PN-ISO 45001:2018-06 [24] | A near-miss incident is described as an event that does not result in injury or health issues. |

| 5 | PN-N-18001:2004 [25] | A near-miss incident is an accident event without injury. |

| 6 | World Health Organization (WHO) [26] | Near misses have been defined as a serious error that has the potential to cause harm but are not due to chance or interception. |

| 7 | International Atomic Energy Agency (IAEA) [27] | Near misses have been defined as potentially significant events that could have consequences but did not due to the conditions at the time. |

| No. | Journal | Number of Publications |

|---|---|---|

| 1 | Safety Science | 10 |

| 2 | Journal of Construction Engineering and Management | 8 |

| 3 | Automation in Construction | 5 |

| 4 | Advanced Engineering Informatics | 3 |

| 5 | Construction Research Congress 2014 Construction in a Global Network Proceedings of the 2014 Construction Research Congress | 3 |

| 6 | International Journal of Construction Management | 3 |

| 7 | Accident Analysis and Prevention | 2 |

| 8 | Computing in Civil Engineering 2019 Data Sensing and Analytics Selected Papers From The ASCE International Conference | 2 |

| 9 | Engineering Construction and Architectural Management | 2 |

| 10 | Heliyon | 2 |

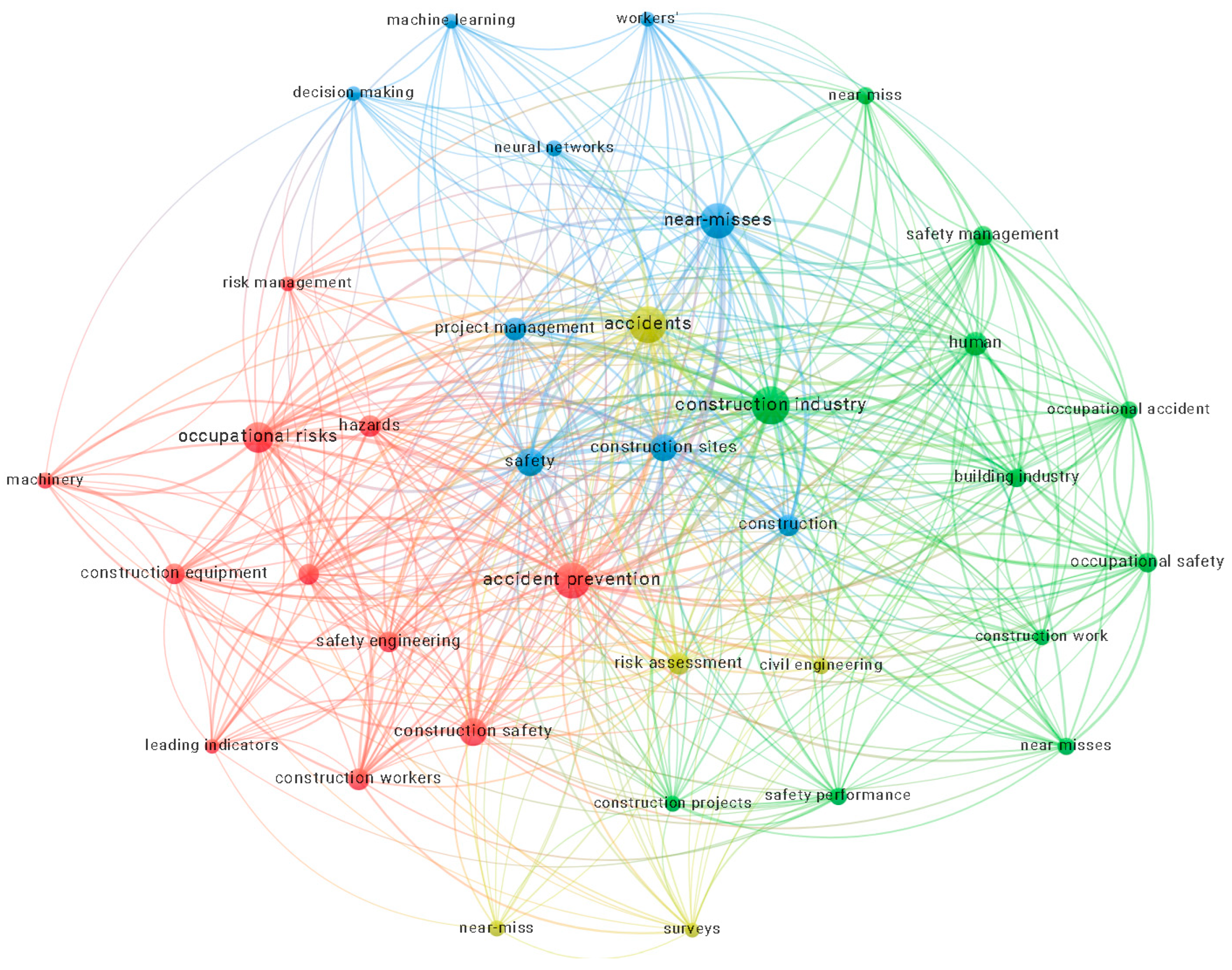

| Cluster Number | Colour | Basic Keywords |

|---|---|---|

| 1 | blue | construction, construction sites, decision making, machine learning, near misses, neural networks, project management, safety, workers |

| 2 | green | building industry, construction industry, construction projects, construction work, human, near miss, near misses, occupational accident, occupational safety, safety, management, safety performance |

| 3 | red | accident prevention, construction equipment, construction, safety, construction workers, hazards, human resource management, leading indicators, machinery, occupational risks, risk management, safety engineering |

| 4 | yellow | accidents, risk assessment, civil engineering, near miss, surveys |

| Number of Question | Question | References |

|---|---|---|

| Q1 | Are near misses in the construction industry studied scientifically? | [3,12,14,16,17,18,19,28,31,34,36,45,47,53,54,55,56,57,58,60,61,62,63,64,65,66,67,68,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,93,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121] |

| Q2 | What methods have been used to obtain information on near misses and systems for recording incidents in construction companies? | [14,16,17,18,19,34,45,47,53,54,55,56,57,58,60,61,62,63,65,66,67] |

| Q3 | What methods have been used to analyse the information and figures that have been obtained? | [14,18,19,34,47,53,60,61,62,63,67,68,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89] |

| Q4 | What are the key aspects of near misses in the construction industry that have been of interest to the researchers? | [3,12,17,18,45,55,60,62,73,81,90,93,97] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, Z.; Hoła, B. Analysing Near-Miss Incidents in Construction: A Systematic Literature Review. Appl. Sci. 2024, 14, 7260. https://doi.org/10.3390/app14167260

Woźniak Z, Hoła B. Analysing Near-Miss Incidents in Construction: A Systematic Literature Review. Applied Sciences. 2024; 14(16):7260. https://doi.org/10.3390/app14167260

Chicago/Turabian StyleWoźniak, Zuzanna, and Bożena Hoła. 2024. "Analysing Near-Miss Incidents in Construction: A Systematic Literature Review" Applied Sciences 14, no. 16: 7260. https://doi.org/10.3390/app14167260