Fuelling a Clean Future: A Systematic Review of Techno-Economic and Life Cycle Assessments in E-Fuel Development

Abstract

1. Introduction

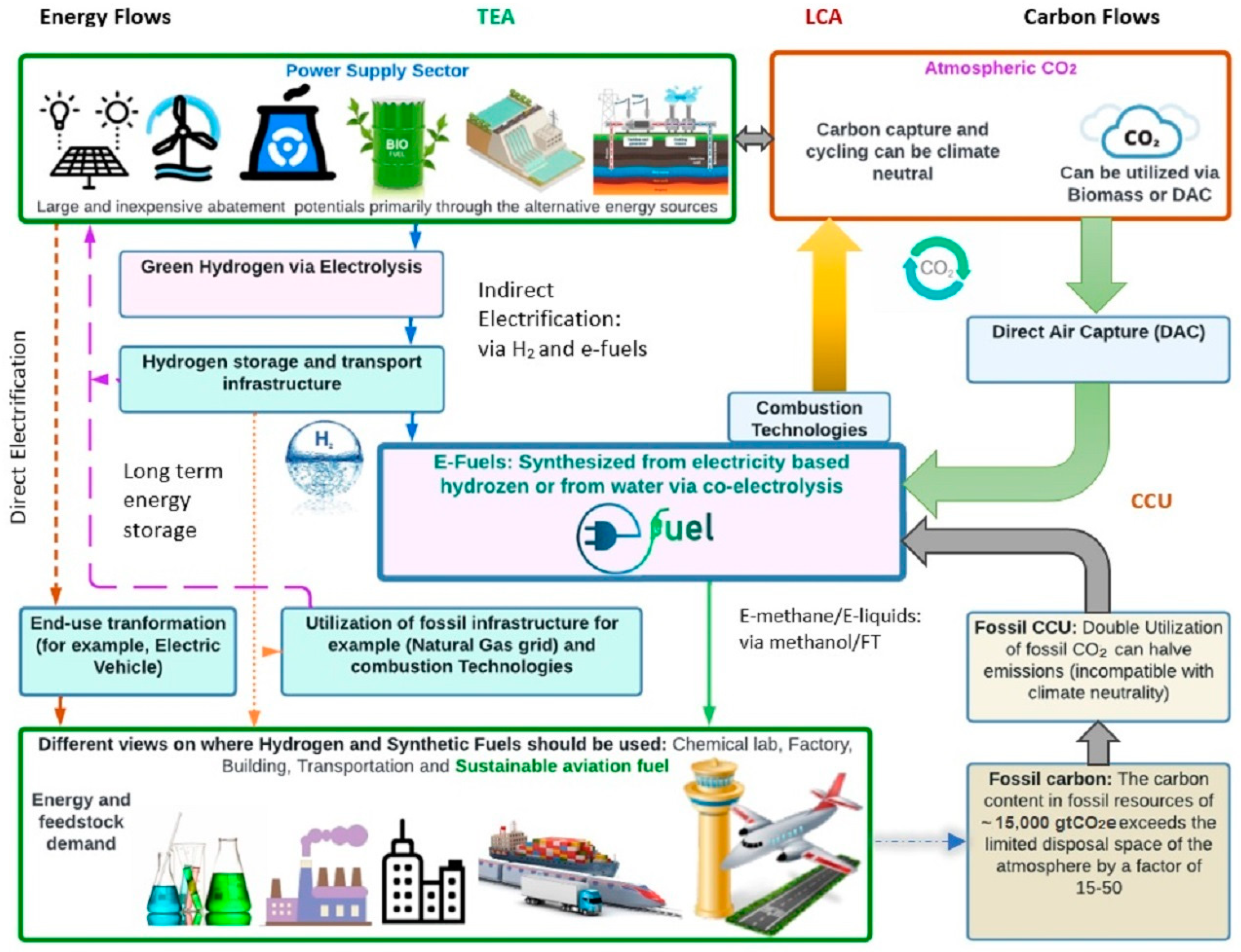

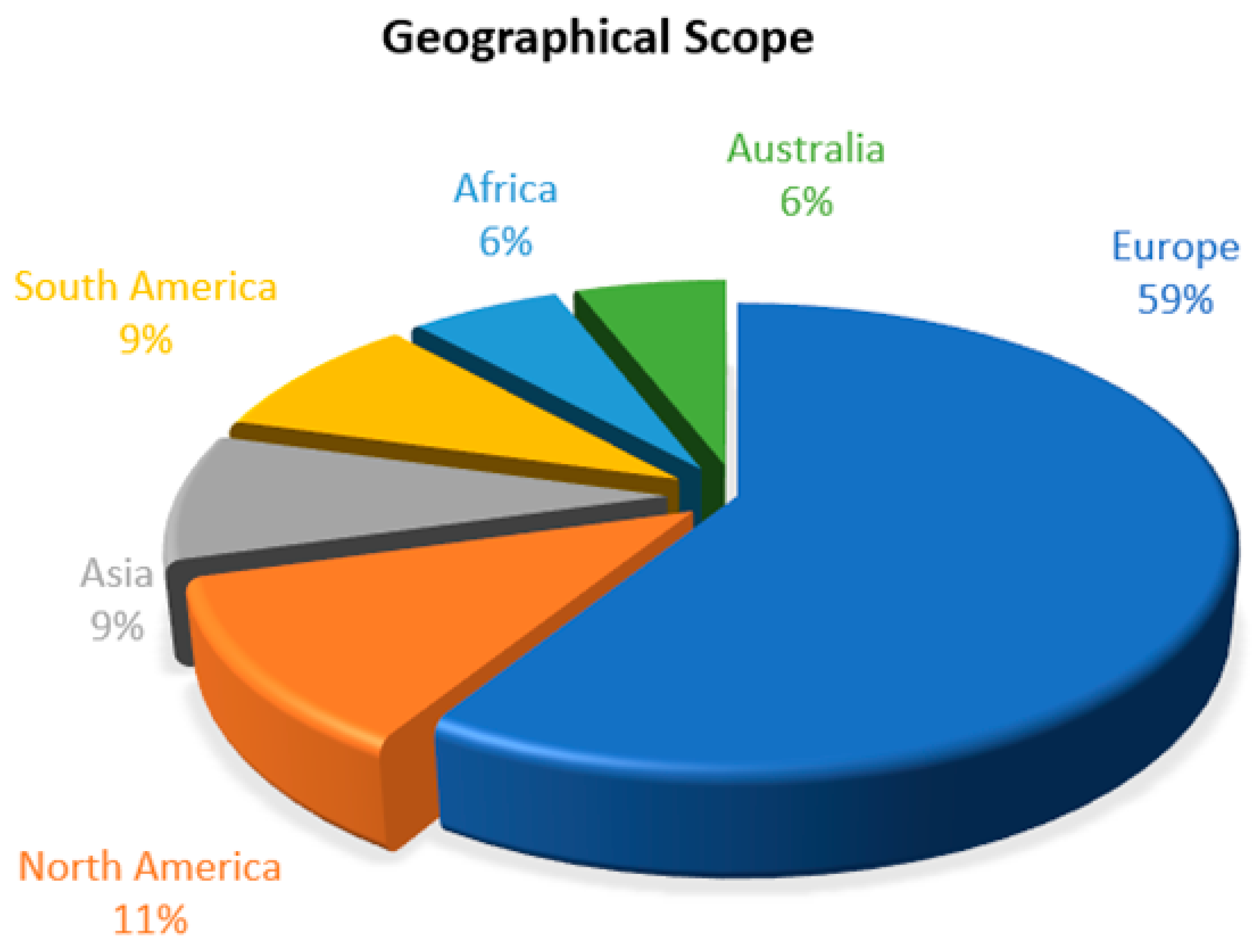

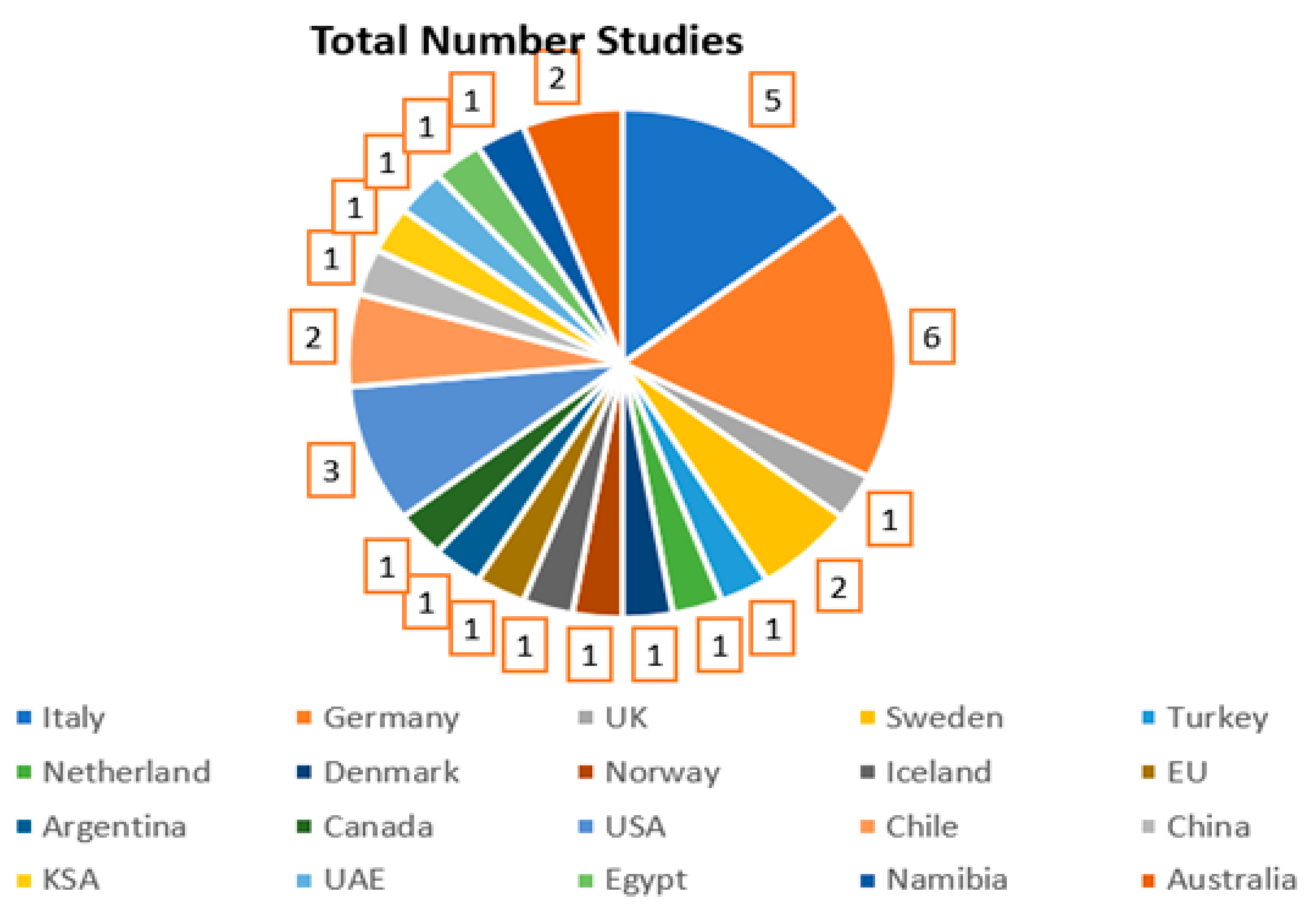

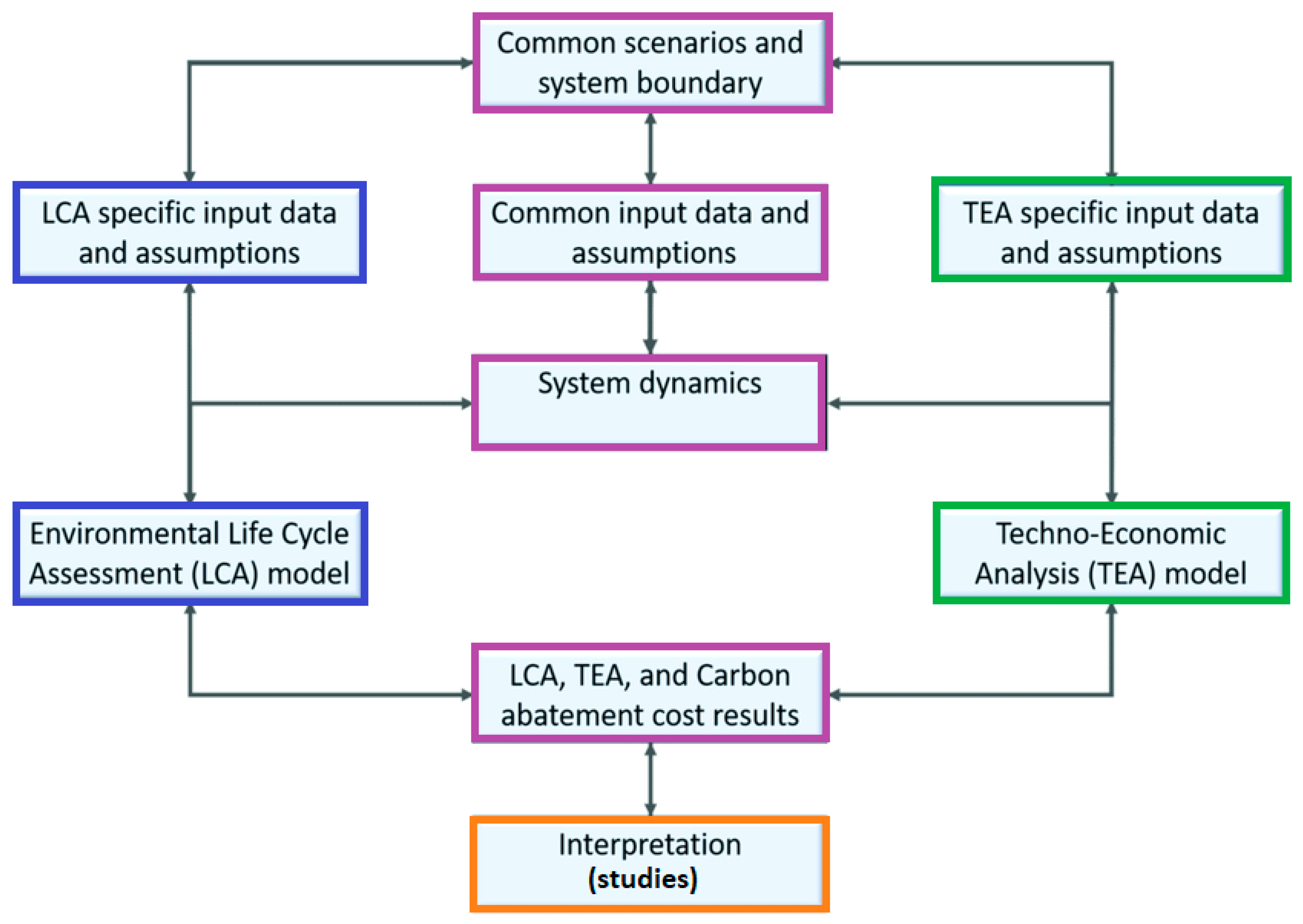

2. Methodology

2.1. Search Strategy

2.2. Inclusion and Exclusion Criteria

- Articles that specifically explored e-fuel production utilising H2 and atmospheric CO2.

- Studies offering a TEA or an LCA of the e-fuel production process.

- In addition, studies that were published in English during the years 2013 to 2024.

- Articles that mainly focused on alternative renewable fuels without specifically addressing e-fuels.

- Publications that were deficient in substantial data or lacked clarity in their methodology.

2.3. Data Analysis

3. Results and Findings from the Existing Literature

3.1. Techno-Economic Analysis (TEA)

3.2. Life Cycle Analysis (LCA)

3.3. Charting Data: Exploring Optimal Methods Both Economically and Environmentally

| Country | Year | Study Parameter | Method and Simulation | Primary Energy Sources | Feedstock | Obtained Process | Highlight | Result | Others | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|

| China | 2023 | Life cycle assessment (LCA): energy consumption, GHG, sensitivity and uncertainty analysis. | Direct fermentation, gasification, fermentation (Aspen Plus V11). | Crude coal, crude oil, and natural gas | Corn, cassava, corn cob | Ethanol-to-jet fuel (ETJ). | Few LCAs of ETJs in China; study assists policymakers for China’s SAF evolution. | Least energy and GHG emission: 370.05 KJ/MJ jet fuel and 31.66 gCO2eq/MJ jet fuel. | GHG emissions reduced up to 21.55% with cleaner electricity and heat. | [69] |

| USA | 2023 | Techno-economic and life cycle analyses: exergy, economic evaluation. | Integrated catalytic deoxygenation and hydrothermal gasification. | Fossil fuel, renewable energy sources | Esters, fatty acids (TOFA) | Hydrogen (H2) gas. | Both scenarios are economically feasible for SAF: DCFA, GWP, acidification, eutrophication, smog, ozone depletion. | Scenario 2’s MFSP (0.39 USD/L) < scenario 1 (0.62 USD/L). | Focus on process optimisation and model improvement; include experimental and kinetics data. | [51] |

| Abu Dhabi and Benevento (Italy) | 2023 | Techno-economic: DAC, methanation, TPC, LCCR, LCOM. | Hydrogenation of CO2 from DAC, H2 from water electrolysis, and renewable PV source. | Solar PV | CO2, H2 | Synthetic methane (CH4). | Cities with uneven solar energy distribution might need high H2 storage tank investments. | Electrolyser is most expensive, followed by PV field, H2 storage, reactors. LCOM: 4.9–8.2 EUR kgCH4−1 with DAC, 3.1–3.9 EUR kgCH4−1 with point-source capture. | LCOM > current methane price; need improvements/economic incentives. | [52] |

| UK | 2023 | Techno-economic and life cycle assessments focusing on carbon conversion, hydrogen conversion. | DAC unit, offshore wind farm, alkaline electrolyser, and a refinery plant. | An offshore wind farm | DAC unit, water electrolysis, and refinery plant for jet fuel hydrocarbons | Power-to-liquid (PtL). | LCA shows GWP of 21.43 gCO2eq/MJSAF. Dependent on offshore wind electricity. | Carbon conversion of 88%, hydrogen conversion of 39.16%, power-to-liquids efficiency of 25.6%. MJSP of 5.16 GBP/kg. | GWP below UK mandate of 50% emission reduction vs. fossil jet fuel. WtWa water footprint is 0.480 l/MJSAF. | [53] |

| KSA | 2023 | Techno-economic assessment focusing on fuel consumption, solar energy potential, etc. | MTO-MOGD process, electrolysis, and DAC. | Solar PV | CO2 and green hydrogen | Production of synthetic hydrocarbon. | Economic implications for decarbonising road transport. | MFSP of 3.24 USD/litre for e-gasoline and 2.89 USD/litre for e-diesel with solar power. LCOe from 379 to 564 USD/MWh. | E-fuels can become a carbon-neutral option with fossil CO2 taxation. | [54] |

| Italy | 2023 | Technical, economic, and environmental feasibility. | Hydrogenation, electrolysis, aqueous-phase reforming (APR). | Renewable energy | Palm oil, H2 | Bio-oil to naphtha, kerosene, glycerol, and diesel. | Carbon footprint of advanced scenario is 12 g CO2/MJSAF, 54% lower than conventional. | APR led to a 6.6% increase in fixed capital investment, but 22% decrease in direct manufacturing costs. Minimum fuel selling price is 1.84 USD/kg. | Limitation: waste oils may contain higher fatty acids and lower triglycerides. | [55] |

| EU | 2023 | Technical process evaluation, mass and energy balances, production cost estimation, LCA, sensitivity analysis, European SAF production potential. | Fischer–Tropsch, electrolysis by Aspen Plus® (V10). | PV and onshore wind, nuclear and electricity from national grid | Forest residue | Power- and biomass-to-liquid (PBtL). | Only Norway and Sweden suitable as PBtL production sites in 2020 based on grid mix. Economic feasibility and environmental impact. | 25 Mt a−1 fuel output achievable with direct renewable electricity sources, using 33% forest residue. | EU goal: 32% of total aviation fuel demand by SAF in 2040 can be met. | [56] |

| USA | 2021 | LCA: WTW GHG emissions of FT fuels from electrolytic H2 pathways and CO2 sources. | H2 and waste CO2 using Aspen Plus. Different process designs and system boundaries considered. | Nuclear/solar/wind electricity | H2 and waste CO2 | Electrofuels from renewable H2 and waste CO2. | FT fuels have 57–65% lower WTW GHG emissions when integrated with corn ethanol production. | A total of 45% carbon in CO2 fixed in FT fuel with 58% energy efficiency. | Using nuclear/solar/wind electricity, WTW GHG emissions reduced by 90–108% vs. petroleum fuels. | [70] |

| USA | 2023 | Techno-economic and LCA: utilities, carbon conversion and energy efficiency, hydrocracking, plant construction and operation, capital and operating expenses, GHG LCA using GREET model. | Reverse water–gas shift and Fischer–Tropsch (FT) synthesis process with nuclear energy. High-temperature electrolysis, reactants compression. | Nuclear | CO2 and low-carbon H2 | Electrofuels from CO2 and low-carbon H2. | Modelled FT process: 99% carbon conversion by recycling CO2 and oxycombustion. A total of 70% process energy efficiency. | MFSP: 0.95 USD/L, 0.74 USD/L, and 0.70 USD/L of FT fuel mix for 100, 400, and 1000 MWe nuclear power plant capacities, respectively. GHG emissions: 7 and −25 gCO2e/MJ. | WTW GHG emissions reduction of at least 92%. Potential to significantly reduce GHG emissions and ensure energy security. | [57] |

| Turkey | 2022 | Techno-economic assessment: thermodynamic and economic analysis. | Hydrogenation, PEM electrolyser, biogas purification, CO2 and hydrogen compressor. Analyses in Engineering Equation Solver program. | PV | CO2 from biogas in a wastewater treatment plant | Biogas-to-methanol: Biogas purification by water washing. Hydrogen from PEM electrolyser and solar PV. Methanol from hybrid system. | Required power for methanol production is 2923 kW, mainly from the PEM system. | Daily methanol production: 1674 kg. Electricity, hydrogen, and methanol costs: 0.043 USD kWh−1, 3.156 USD kg−1, and 0.693 USD kg−1, respectively. | Feasible methanol production costs with reasonable investments. Increased cogeneration plant efficiency and reduced emissions by enriching biogas. | [58] |

| Italy | 2023 | Techno-economic assessment, including detailed economic analysis, cost estimation, financial assumptions. | Water electrolysis, amine-based CO2 absorption, Aspen Plus. | Wind or solar electricity | Hydrogen and captured CO2 | e-methanol from green hydrogen and captured CO2. | Pre-feasibility study for a power-to-fuel plant for producing 500 kg/h renewable methanol. | Levelised cost of methanol (LCoM) calculated to be 960 EUR/t (about 175 EUR/MWh). Technology not currently economically competitive. | Process expected to become competitive in the mid-term future due to new European policies. LCoM affected by electricity price and electrolyser capital cost. | [59] |

| Netherlands | 2021 | PESTEL analysis focusing on critical uncertainties, economic factors, technological innovation, environmental concerns, legal factors, etc. | Electrolysis, DAC. | Renewable energy sources (wind or solar) | CO2 and H2 | e-Fuel. | The relevance of blue hydrogen versus green hydrogen in terms of costs and environmental benefits. | The impact of certain factors on synthetic fuel pricing and their interdependencies. | Technological advancements for essential processes will be important in the future. Local production combined with imported fuels/hydrogen may be the best combination. | [60] |

| Italy | 2020 | Technical and economic assessment focusing on waste and power-to-methanol, CO2 emission, sensitivity analysis, etc. | Syngas from waste gasification, enriched with hydrogen via water electrolysis. | Natural gas, fossil power | Waste and water | Waste-to-methanol, hybrid waste-to-methanol with hydrogen integration; power-to-methanol. | Feasibility of power-to-methanol combined with MSW gasification, aligning with energy transition and circular economy concepts. | Renewable power increase in coming years could make the hybrid case more attractive. | The hybrid scheme may become a more attractive solution in the near future considering renewable energy increases and power cost reductions. | [61] |

| Germany | 2020 | Techno-economic indicators: CO2 demand, electricity demand, avg. fuel production costs. | DAC, electrolysis. | Renewable: solar/wind electricity and nuclear energy | CO2, Water | Power-to-liquid (PtL) kerosene. | Impact of local CO2 sources on PtL. | Need for 48–745 TWh additional renewable electricity for 2030–2050 cases. Fuel production costs: 2.3–3.3 EUR/kg in 2030 drops to 1.8–3.1 EUR/kg in 2050. | Importance of sustainable CO2 sources and renewable electricity development targets. | [62] |

| Italy | 2023 | Technical and economic analysis. | Hydrogen from water electrolysis, CO2 capture, RWGS, FT synthesis. | Renewable energy (solar/wind electricity) | H2 and CO2 | Synthetic kerosene from green H2 and DAC CO2. | Sensitivity analysis and process evaluations. | Indirect and direct processes produce 66.18 bbl/d and 38.46 bbl/d respectively. Product cost varies: 460–1435 EUR/bbl and 752–2364 EUR/bbl. | Dependency on power energy and hydrogen prices. | [63] |

| Germany | 2021 | Life cycle assessment: fleet emissions and climate impact. | Hydrogen via water electrolysis followed by Fischer–Tropsch synthesis. | Wind | Water | Power-to-liquid. | Potential of PtL for aviation considering environmental impacts. | PtL from wind energy reduces impact by up to 42%. | Reduction in warming impact due to contrail-induced cloudiness. | [71] |

| Sweden | 2021 | Techno-economic assessment for 2020–2050. | Fischer–Tropsch (FT), HTL, PTL (Python 3.9 MILP model). | Fossil and biomass and renewable | Biomass, CO2 | RJF from lignocellulosic biomass and captured CO2. | Total RJF production increase due to the blending ratio. | RJF production: 3.85–16.87 TJ for 2030–2050. HTL and PTL jet fuel production cost varies: 24.2–25.4 SEK/litre and 16.7–22.0 SEK/litre. | Revenue from by-products could make HTL and PTL price-competitive. | [64] |

| Germany | 2018 | TEA and LCA: carbon capture and utilisation option for the industry. | Carbon capture and utilisation (CCU) on e-fuels generated through the anhydrous trioxane and OME1 pathway. | Renewable electricity: PV and wind | Flue gas, water, electricity, and steam | e-fuels. | OME3-5 is considered a potential solution for decarbonising heavy-duty transportation in the future. However, there is uncertainty surrounding both its cost and the resulting market potential. | OME3-5 e-fuels exhibit a notably elevated cost of production per gigajoule (GJ) compared to conventional diesel fuel available at German gas stations, and they can store less than 38.4% of electricity based on their lower heating value. | The most significant economic obstacles are associated with electricity consumption and the cost of electrolyser stacks rather than the conversion cost of OME. Nevertheless, even a substantial decrease in electricity or electrolyser prices alone would not render the OME3-5 anhydrous pathway economically competitive given the existing circumstances. Significant advancements in reaction and process efficiency are imperative to achieve competitiveness. | [65] |

| Chile, Denmark, Australia | 2019 | Costs and life cycle GHGs emissions. | Electrolytic. | Renewable: solar/wind | Hydrogen and nitrogen or carbon | e-ammonia. | In South Australia, the current energy mix relies heavily on fossil electricity, with 55% of it being produced or imported, primarily sourced from natural gas. Despite having 47% renewable power, the production of fuel under these conditions results in the lowest greenhouse gas (GHG) intensity for e-fuels when utilising the grid. Nevertheless, the life cycle emissions are only marginally lower, approximately 25%, than those of grey methanol. | When focusing on e-ammonia production, our analysis revealed that in North Chile, with its abundant solar potential and 2019 hourly grid emissions and prices, the most cost-effective solution involves using 58% of grid electricity and results in emissions of 183 gCO2e/MJNH3. In contrast, in Denmark, the least expensive option necessitates utilising 100% grid electricity, yielding emissions of 109 gCO2e/MJNH3. | It is important to note that the GHG footprint of e-fuels is often higher compared to the same fuels produced from natural gas (grey fuels). This disparity is especially pronounced in Chile, where 60% of the grid electricity originates from fossil sources such as gas, coal, and oil. In Denmark, only 20% of the electricity in 2019 came from coal, gas, or oil, which explains the relatively lower GHG footprint, even when exclusively relying on grid electricity. | [66] |

| Germany | 2021 | TEA: total costs of electrofuels and direct air capture and carbon storage. | DSACCS. | Renewable energy sources | CO2 | e-fuel. | Meeting the CO2 storage requirements outlined in the IPCC scenarios could potentially strain the availability of cost-effective and readily accessible CO2 storage sites. | Considering that the variation in costs between e-fuels and direct air capture and carbon storage (DACCS) options by 2050 falls within the range of 1.0% to 2.5% of ticket prices, a manageable expense for passengers, it prompts an evaluation of whether pursuing the e-fuels option aligns better with the precautionary principle, a fundamental tenet of environmental policy. | Given the potential limitations in CO2 storage sites and the relatively modest cost differences between e-fuels and DACCS, the choice to invest in e-fuels may be more in line with the precautionary principle, underscoring the importance of cautious and proactive environmental decision making. | [67] |

| Germany | 2015 | EEA, LCA: economic and environmental assessment of current (2015) and future (2030). | Different electrolysis technologies and Fischer–Tropsch synthesis. | Renewable energy sources: unspecified | Current alkaline and future solid oxide | e-fuel. | Using a set of optimistic estimates for these parameters resulted in a production cost of 1.17 V/leq diesel (equivalent to 3.12 V ct/MJ). Notably, abatement costs within the range of 544 to 6424 V/tCO2-eq were projected for e-fuels, signifying a substantially higher cost compared to alternative vehicle fuel technologies. | In terms of e-fuel production costs and life cycle emissions, the estimates indicated values of 4.97 V/leq diesel and 64.07 gCO2-eq/MJ in 2015. Looking ahead to 2030, the projections anticipate a reduction in costs, with figures of 3.24 V/leq diesel and 6.63 gCO2-eq/MJ. | It is essential to highlight that these estimates provide insights into the economic and environmental aspects of e-fuel production and its associated costs and emissions, underlining the challenges and potential improvements that lie ahead in this field. | [68] |

| Argentina, Namibia, Egypt, Australia, Canada, Iceland, Chile | 2020 | Economic comparison. | Fischer–Tropsch, electrolytic water splitting. | Patagonia in Argentina: wind energy Karas in Namibia: solar Egypt scenario on the Gulf of Suez: combines high wind speeds and good solar radiation Labrador in Canada: very good wind conditions and hydropower Iceland: wind, hydropower, geothermal Atacama Desert, Chile: geothermal West Australia: wind and solar | CO2, H2O | Four e-fuels: Fischer–Tropsch diesel (FTD), methanol (MeOH), dibenzyltoluene/perhydrodibenzyltoluene (H0-DBT/H18-DBT), and liquid hydrogen (LH2) −253 °C. | Particularly in the case of diesel, the levelised cost of electricity, as determined by the full load hours of the renewable energy source in use, exerts a substantial influence. | An LOHC-based system demonstrates reduced dependence on the electricity source in comparison to other technologies, primarily due to its lower electricity consumption. However, it is worth noting that factors such as the length of the transportation route and the cost of filling station infrastructure can elevate the mobility cost associated with LOHC and LH2. | Based on the established boundary conditions and assumptions, it becomes evident that methanol, cryogenic hydrogen, and liquid organic hydrogen carriers emerge as the most advantageous choices across all seven examined locations. | [72] |

| Norway | 2021 | Institutional economics theory for examining the framework of the environmental governance system concerning the adoption of CCU and e-fuels. | Carbon capture and utilisation (CCU), electrolysis, and Norwegian renewable energy. | Norwegian renewable energy: hydropower is the primary source of renewable energy, with thermal and wind power | From CO2 and water | Hydrogen-based e-fuel. | The discussions revealed a dynamic, ongoing effort within both national and international governance structures to establish more defined policy tools for the adoption or rejection of CCU and e-fuels. | Findings indicate that Norway boasts a resilient environmental governance framework that wields significant influence in conjunction with international guidelines, particularly in shaping the implementation of e-fuels and the CCU value chain. | Nevertheless, the research has pinpointed a range of challenges and uncertainties surrounding the development and integration of these technologies. These obstacles have been subject to active deliberations among key stakeholders involved in the process. | [28] |

| China | 2024 | Techno-economic analysis, and environmental impact assessment. | Gasification–Fischer–Tropsch conversion pathway. | Bioenergy | Six conventional crop straws (rice, wheat, corn, peanut, cotton, beans) | Biomass-to-liquid FT fuel. | Showing the huge decarbonisation potential of sustainable aviation fuel. | When the blending ratio of sustainable aviation fuel reaches 50%, about 60 Mt CO2e emission can be reduced, which accounts for 43% of the emission for China’s aviation sector in 2023. | Corn straw can support future large-scale sustainable aviation fuel application. | [73] |

| USA | 2024 | Techno-economic and life cycle analysis. | Electrolysis, DAC, condensation, and triethylene glycol (TEG) absorption. | Wind, solar, nuclear, hydro | Low-carbon H2 and point-source or atmospheric CO2 | Synthetic natural gas (SNG). | SNG cost can be reduced with a tax credit in the US for low-carbon H2 production. | SNG can reduce life cycle GHG emissions by 52–88% compared to fossil NG. | With a lower electricity price of 0.03 USD/kWh for water electrolysis and accounting for a 45 V tax credit, the SNG cost reaches parity with the cost of fossil NG. | [74] |

4. Discussion

4.1. Techno-Economic Analysis Research on e-Fuel Production

- Production technologies and their efficiencies.

- 2.

- Capital and operational expenditures.

- 3.

- Break-even points and return-on-investment calculations.

- 4.

- Quantitative economic analysis.

- 5.

- Technical parameters.

4.2. Life Cycle Analysis Research on e-Fuel Production

- Raw material acquisition.

- 2.

- Production process.

- 3.

- Use-phase emissions.

- 4.

- End-of-life considerations.

4.3. Economic Feasibility and Technological Challenges

4.4. Gap Analysis

4.5. Strategic Actions and Policy Implications

4.5.1. In the Context of Techno-Economic Analysis

4.5.2. In the Context of Life Cycle Analysis

4.6. Future Outlook and Research Directions

4.6.1. In the Context of Techno-Economic Analysis Research

4.6.2. In the Context of Life Cycle Analysis Research

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| List of symbols | |

| α0 | Coefficient |

| k | Number of factors |

| kg | Kilogram |

| L | Litre |

| MJ | Megajoule |

| mL | Millilitre |

| mm | Millimetre |

| µL | Microlitre |

| mf | Mass of feedstock |

| m0 | Mass of oil |

| N | Total number |

| R2 | Correlation coefficient |

| rpm | Revolution per minute |

| X1 X2 X3 | Coded independent factors |

| Y | Yield |

| ° | Degree sign |

| MWh | Megawatt hour |

| List of acronyms | |

| GHG | Greenhouse gas |

| ASPEN | Advanced system for process engineering |

| CH4 | Methane |

| E-Fuel | Electrofuel |

| Syn-Fuel | Synthetic fuel |

| CO2 | Carbon di oxide |

| H2 | Hydrogen |

| AUD | Australian dollar |

| USD | United States dollar |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| UK | United Kingdom |

| GWP | Global warming potential |

| IAEA | International Atomic Energy Agency |

| GDP | Gross domestic product |

| DOE | Department of Energy |

| ECD | Energy Citation Database |

| TEA | Techno-economic analysis |

| INIS | International Nuclear Information System |

| DAC | Direct air capture |

| EUR | European Euro |

| LCOM | Levelised cost of methane |

| PtL | Power-to-liquids |

| LCA | Life cycle analysis |

| FT | Fischer–Tropsch |

| SAF | Sustainable aviation fuel |

| UNSDGs | United Nations Sustainable Development Goals |

| APR | Aqueous-phase reforming |

| MTO | methanol-to-olefin |

| MOGD | Methanol-to-gasoline and diesel |

| LCCR | Levelised cost of CO2 removal |

| TOFA | Tall oil fatty acid |

| MFSP | Minimum fuel selling price |

| LCOe | Levelised cost of electricity |

| EU | European Union |

| CCU | Carbon capture and utilisation |

| USA | United States of America |

| MENA | Middle East and North Africa |

| OME3-5 | e-polyoxymethylene dimethyl ethers oil |

References

- Shayan, N.F.; Mohabbati-Kalejahi, N.; Alavi, S.; Zahed, M.A. SustSustainable development goals (SDGs) as a framework for corporate social responsibility (CSR). Sustainability 2022, 14, 1222. [Google Scholar] [CrossRef]

- Chu, E.; Karr, J. Environmental impact: Concept, consequences, measurement. In Reference Module in the Life Sciences; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Varghese, S. Future of Climate Change. In Future Intelligence; Springer: Cham, Switzerland, 2023; pp. 69–85. [Google Scholar] [CrossRef]

- Rifkin, J. The Green New Deal: Why the Fossil Fuel Civilization Will Collapse by 2028, and the Bold Economic Plan to Save Life on Earth; St. Martin’s Press: New York, NY, USA, 2019. [Google Scholar]

- Rashid, M.N.U.M.; Mostafa, M.G.; Belayet, H.; Salam, S.M.; Nithe, N.A. Global Energy: Need, Present Status, Future Trend and key Issues. Glob. J. Res. Eng. Elec. Eletro. Eng. 2016, 16, 36–50. [Google Scholar]

- Uddin, M.N.; Nithe, N.A. A Comprehensive Exploration of Biomass Gasification Technologies Advancing United Nations Sustainable Development Goals. Johns. Matthey Technol. Rev. 2024, 69. [Google Scholar] [CrossRef]

- Soeder, D.J.; Soeder, D.J. Fossil fuels and climate change. In Fracking and the Environment: A Scientific Assessment of the Environmental Risks from Hydraulic Fracturing and Fossil Fuels; Springer: Cham, Switzerland, 2021; pp. 155–185. [Google Scholar] [CrossRef]

- Uddin, M.N.; Rashid, M.M.; Mostafa, M.G.; Belayet, H.; Salam, S.M.; Nithe, N.A. New Energy Sources: Technological Status and Economic Potentialities. Glob. J. Sci. Front. Res. 2016, 16, 24–37. [Google Scholar]

- Xiao, Z.; Li, P.; Zhang, H.; Zhang, S.; Tan, X.; Ye, F.; Gu, J.; Zou, J.-J.; Wang, D. A comprehensive review on photo-thermal co-catalytic reduction of CO2 to value-added chemicals. Fuel 2024, 362, 130906. [Google Scholar] [CrossRef]

- Burge, C.A.; Hershberger, P.K. Climate change can drive marine diseases. In Marine Disease Ecology; Behringer, D.C., Silliman, B.R., Lafferty, K.D., Eds.; Oxford University Press: New York, NY, USA, 2020; pp. 83–94. [Google Scholar]

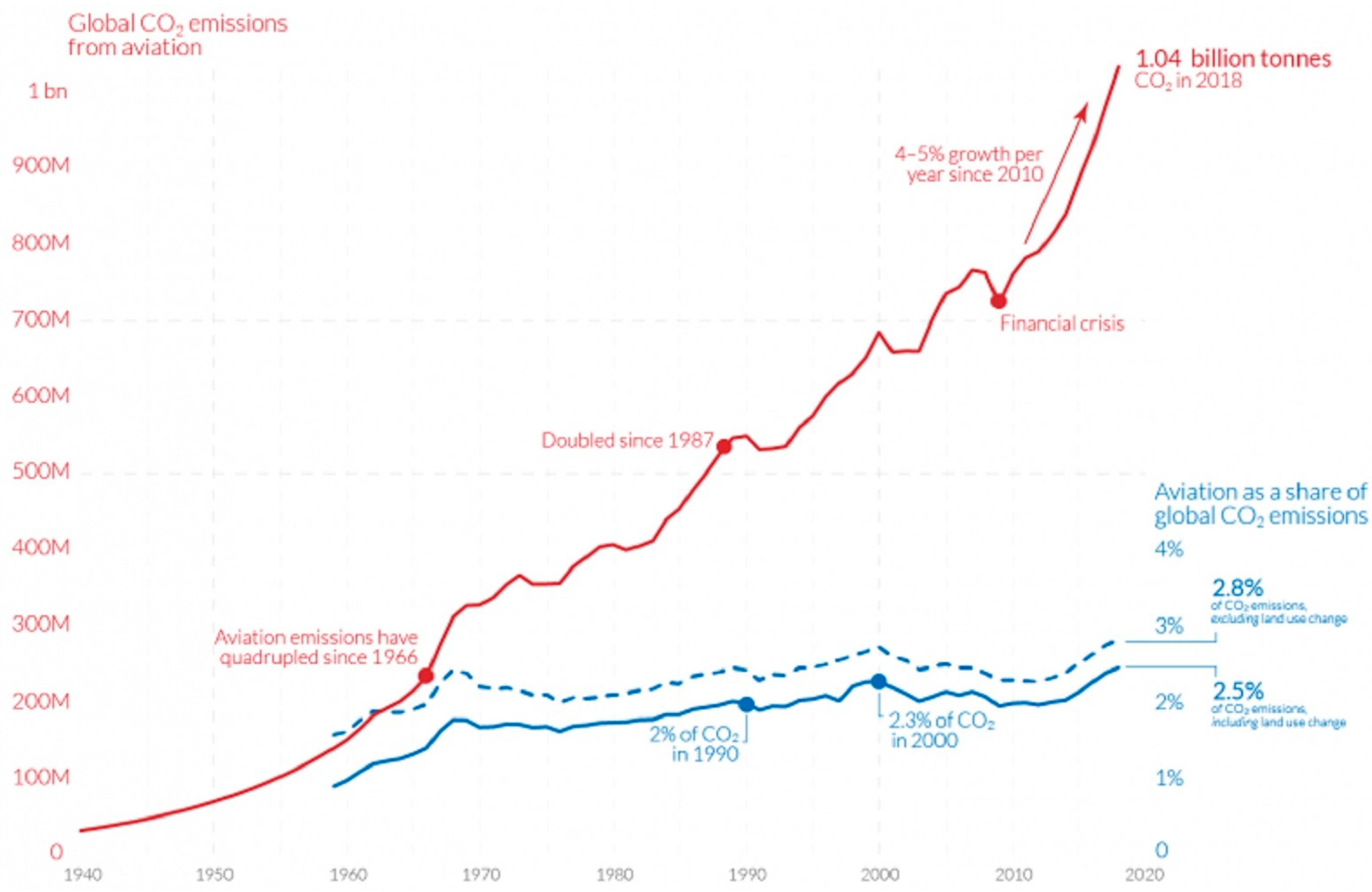

- Hannah Ritchie (2024)—What share of global CO2 emissions come from aviation?” Published online at OurWorldInData.org. Available online: https://ourworldindata.org/global-aviation-emissions (accessed on 17 August 2024).

- Gielen, D.; Gorini, R.; Wagner, N.; Leme, R.; Gutierrez, L.; Prakash, G.; Asmelash, E.; Janeiro, L.; Gallina, G.; Vale, G.; et al. Global Energy Transformation: A Roadmap to 2050; International Renewable Energy Agency: Masdar, Abu Dhabi, 2019. [Google Scholar]

- Mofijur, M.; Rasul, M.; Hassan, N.; Uddin, M. Investigation of exhaust emissions from a stationary diesel engine fuelled with biodiesel. Energy Procedia 2019, 160, 791–797. [Google Scholar] [CrossRef]

- Kamal-Chaoui, L.; Robert, A. Competitive Cities and Climate Change; OECD Publishing: Paris, UK, 2009. [Google Scholar]

- Uddin, M.; Rahman, M.; Mofijur, M.; Taweekun, J.; Techato, K.; Rasul, M. Renewable energy in Bangladesh: Status and prospects. Energy Procedia 2019, 160, 655–661. [Google Scholar] [CrossRef]

- Banister, D.; Anderton, K.; Bonilla, D.; Givoni, M.; Schwanen, T. Transportation and the environment. Annu. Rev. Environ. Resour. 2011, 36, 247–270. [Google Scholar] [CrossRef]

- Uddin, M.; Rahman, M.; Taweekun, J.; Techato, K.; Mofijur, M.; Rasul, M. Enhancement of biogas generation in up-flow sludge blanket (UASB) bioreactor from palm oil mill effluent (POME). Energy Procedia 2019, 160, 670–676. [Google Scholar] [CrossRef]

- Khalili, S.; Rantanen, E.; Bogdanov, D.; Breyer, C. Global transportation demand development with impacts on the energy demand and greenhouse gas emissions in a climate-constrained world. Energies 2019, 12, 3870. [Google Scholar] [CrossRef]

- Uddin, M.; Techato, K.; Rasul, M.; Hassan, N.; Mofijur, M. Waste coffee oil: A promising source for biodiesel production. Energy Procedia 2019, 160, 677–682. [Google Scholar] [CrossRef]

- Jiang, P.; Van Fan, Y.; Klemeš, J.J. Impacts of COVID-19 on energy demand and consumption: Challenges, lessons and emerging opportunities. Appl. Energy 2021, 285, 116441. [Google Scholar] [CrossRef]

- Rony, Z.I.; Rasul, M.G.; Jahirul, M.I.; Hasan, M.M. Optimizing Seaweed (Ascophyllum nodosum) Thermal Pyrolysis for Environmental Sustainability: A Response Surface Methodology Approach and Analysis of Bio-Oil Properties. Energies 2024, 17, 863. [Google Scholar] [CrossRef]

- Kumar, A. Global warming, climate change and greenhouse gas mitigation. In Biofuels: Greenhouse Gas Mitigation and Global Warming: Next Generation Biofuels and Role of Biotechnology; Springer: New Delhi, India, 2018; pp. 1–16. [Google Scholar] [CrossRef]

- Rahman, M.; Rasul, M.G.; Hassan, N.M.S.; Azad, A.K.; Uddin, N. Effect of small proportion of butanol additive on the performance, emission, and combustion of Australian native first- and second-generation biodiesel in a diesel engine. Environ. Sci. Pollut. Res. 2017, 24, 22402–22413. [Google Scholar] [CrossRef] [PubMed]

- Teller, E. The Element at the End of the World: Chile’s Green Hydrogen Strategy and the Global Energy Transition. Master’s Thesis, Lund University, Lund, Sweden, 2023. [Google Scholar]

- Uddin, M.; Taweekun, J.; Techato, K.; Rahman, M.; Mofijur, M.; Rasul, M. Sustainable biomass as an alternative energy source: Bangladesh perspective. Energy Procedia 2019, 160, 648–654. [Google Scholar] [CrossRef]

- Wang, F.; Rijal, D. Sustainable Aviation Fuels for Clean Skies: Exploring the Potential and Perspectives of Strained Hydrocarbons. Energy Fuels 2024, 38, 4904–4920. [Google Scholar] [CrossRef]

- Possible, M.N.Z.S. An Industry-Backed, 1.5 °C-Aligned Transition Strategy; Mission Possible Partnership: Washington, DC, USA, 2022. [Google Scholar]

- Romo Martínez, A.C. The Environmental Governance System around the Implementation of Sustainable Aviation Fuels in Norway: A Case Study on E-Fuels and Carbon Capture and Utilization Value Chain. Master’s Thesis, Norwegian University of Life Sciences, Ås, Norway, 2021. [Google Scholar]

- Siddiki, S.Y.A.; Uddin, M.; Mofijur, M.; Fattah, I.; Ong, H.C.; Lam, S.S.; Kumar, P.S.; Ahmed, S. Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J. Environ. Chem. Eng. 2021, 9, 105204. [Google Scholar] [CrossRef]

- Stančin, H.; Mikulčić, H.; Wang, X.; Duić, N. A review on alternative fuels in future energy system. Renew. Sustain. Energy Rev. 2020, 128, 109927. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An overview of recent developments in biomass pyrolysis technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Henderson, J.; Sen, A. The Energy Transition: Key Challenges for Incumbent and New Players in the Global Energy System; The Oxford Institute for Energy Studies: Oxford, UK, 2021. [Google Scholar]

- Jorschick, H.; Preuster, P.; Bösmann, A.; Wasserscheid, P. Hydrogenation of aromatic and heteroaromatic compounds—A key process for future logistics of green hydrogen using liquid organic hydrogen carrier systems. Sustain. Energy Fuels 2021, 5, 1311–1346. [Google Scholar] [CrossRef]

- Salvi, B.; Subramanian, K.; Panwar, N. Alternative fuels for transportation vehicles: A technical review. Renew. Sustain. Energy Rev. 2013, 25, 404–419. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, X.; Shen, D. Review and Perspectives of Novel Flue-Gas Internal Recirculation Combustion Technology for Low Nitrogen Emission: Fundamentals, Performance, Method, and Applications for Conventional Fossil Fuels and Sustainable e-Fuels. Energy Fuels 2023, 37, 8765–8780. [Google Scholar] [CrossRef]

- Salbrechter, K.; Schubert, T. Combination of b-fuels and e-fuels—a technological feasibility study. Energies 2021, 14, 5250. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors determining the potential of biochar as a carbon capturing and sequestering construction material: Critical review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Viscardi, R.; Bassano, C.; Nigliaccio, G.; Deiana, P. The potential of E-fuels as future fuels. ENEA Energ. Ambiente Innov. 2021, 1, 112–116. [Google Scholar]

- Becker, W.L.; Penev, M.; Braun, R.J. Production of synthetic natural gas from carbon dioxide and renewably generated hydrogen: A techno-economic analysis of a power-to-gas strategy. J. Energy Resour. Technol. 2018, 141, 021901. [Google Scholar] [CrossRef]

- Grubler, A.; Aguayo, F.; Gallagher, K.S.; Hekkert, M.; Jiang, K.; Mytelka, L.; Neij, L.; Nemet, G.F.; Wilson, C. Policies for the Energy Technology Innovation System (ETIS); Cambridge University Press: Cambridge, UK, 2012. [Google Scholar] [CrossRef]

- Hetherington, A.C.; Borrion, A.L.; Griffiths, O.G.; McManus, M.C. Use of LCA as a development tool within early research: Challenges and issues across different sectors. Int. J. Life Cycle Assess. 2013, 19, 130–143. [Google Scholar] [CrossRef]

- Yang, H.; Huang, X.; Hu, J.; Thompson, J.R.; Flower, R.J. Achievements, challenges and global implications of China’s carbon neutral pledge. Front. Environ. Sci. Eng. 2022, 16, 111. [Google Scholar] [CrossRef]

- Linzenich, A.; Bongartz, D.; Arning, K.; Ziefle, M. What’s in my fuel tank? Insights into beliefs and preferences for e-fuels and biofuels. Energy, Sustain. Soc. 2023, 13, 35. [Google Scholar] [CrossRef]

- Prussi, M.; Lee, U.; Wang, M.; Malina, R.; Valin, H.; Taheripour, F.; Velarde, C.; Staples, M.D.; Lonza, L.; Hileman, J.I. CORSIA: The first internationally adopted approach to calculate life-cycle GHG emissions for aviation fuels. Renew. Sustain. Energy Rev. 2021, 150, 111398. [Google Scholar] [CrossRef]

- Budsberg, E.; Crawford, J.T.; Morgan, H.; Chin, W.S.; Bura, R.; Gustafson, R. Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: Life cycle assessment. Biotechnol. Biofuels 2016, 9, 170. [Google Scholar] [CrossRef]

- Ukaew, S.; Shi, R.; Lee, J.H.; Archer, D.W.; Pearlson, M.; Lewis, K.C.; Bregni, L.; Shonnard, D.R. Full Chain Life Cycle Assessment of Greenhouse Gases and Energy Demand for Canola-Derived Jet Fuel in North Dakota, United States. ACS Sustain. Chem. Eng. 2016, 4, 2771–2779. [Google Scholar] [CrossRef]

- Pati, D.; Lorusso, L.N. How to write a systematic review of the literature. HERD Health Environ. Herd 2018, 11, 15–30. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 explanation and elaboration: Updated guidance and exemplars for reporting systematic reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- PRISMA-P Group; Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Michaga, M.F.; Michailos, S.; Cardozo, E.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Sustainable aviation fuel (SAF) production through power-to-liquid (PtL): A combined techno-economic and life cycle assessment. Energy Convers. Manag. 2023, 292, 117427. [Google Scholar] [CrossRef]

- Ravi, S.S.; Mazumder, J.; Sun, J.; Brace, C.; Turner, J.W. Techno-Economic assessment of synthetic E-Fuels derived from atmospheric CO2 and green hydrogen. Energy Convers. Manag. 2023, 291, 117271. [Google Scholar] [CrossRef]

- Pipitone, G.; Zoppi, G.; Pirone, R.; Bensaid, S. Sustainable aviation fuel production using in-situ hydrogen supply via aqueous phase reforming: A techno-economic and life-cycle greenhouse gas emissions assessment. J. Clean. Prod. 2023, 418, 138141. [Google Scholar] [CrossRef]

- Habermeyer, F.; Papantoni, V.; Brand-Daniels, U.; Dietrich, R.-U. Sustainable aviation fuel from forestry residue and hydrogen—A techno-economic and environmental analysis for an immediate deployment of the PBtL process in Europe. Sustain. Energy Fuels 2023, 7, 4229–4246. [Google Scholar] [CrossRef]

- Delgado, H.E.; Cappello, V.; Zang, G.; Sun, P.; Ng, C.; Vyawahare, P.; Elgowainy, A.A.; Wendt, D.S.; Boardman, R.D.; Marcinkoski, J. Techno-economic analysis and life cycle analysis of e-fuel production using nuclear energy. J. CO2 Util. 2023, 72, 102481. [Google Scholar] [CrossRef]

- Tozlu, A. Techno-economic assessment of a synthetic fuel production facility by hydrogenation of CO2 captured from biogas. Int. J. Hydrogen Energy 2022, 47, 3306–3315. [Google Scholar] [CrossRef]

- Sollai, S.; Porcu, A.; Tola, V.; Ferrara, F.; Pettinau, A. Renewable methanol production from green hydrogen and captured CO2: A techno-economic assessment. J. CO2 Util. 2023, 68, 102345. [Google Scholar] [CrossRef]

- Van de Graaff, B. Exploring the Potential of Synthetic Fuels from CO2 And H2. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 5 August 2021. [Google Scholar]

- Salladini, A.; Borgognga, A.; Agostini, E.; Annesini, M.C.; Iaquaniello, G. Power to liquid through waste as a carbon source: A technical and economic assessment. Int. J. Hydrogen Energy 2020, 45, 24467–24476. [Google Scholar] [CrossRef]

- Drünert, S.; Neuling, U.; Zitscher, T.; Kaltschmitt, M. Power-to-Liquid fuels for aviation—Processes, resources and supply potential under German conditions. Appl. Energy 2020, 277, 115578. [Google Scholar] [CrossRef]

- Colelli, L.; Segneri, V.; Bassano, C.; Vilardi, G. E-fuels, technical and economic analysis of the production of synthetic kerosene precursor as sustainable aviation fuel. Energy Convers. Manag. 2023, 288, 117165. [Google Scholar] [CrossRef]

- Trinh, J. Techno-Economic Assessment for Optimised Renewable Jet Fuel Production in Sweden. Master’s Thesis, Department of Energy Technology KTH, Stockholm, Sweden, 2021. [Google Scholar]

- Zimmermann, A.; Gençer, E.; O’Sullivan, F.; Schomäcker, R. E-Fuels as Carbon Capture and Utilization Option for the Industry? A Standardized Techno-Economic Assessment of Methanol and OME. In Proceedings of the 14th Greenhouse Gas Control Technologies Conference, Melbourne, Australia, 21–25 October 2018. [Google Scholar] [CrossRef]

- Campion, N.J.B.; Shapiro-Bengtsen, S.; Franz, S.M.; Münster, M. Quantification of costs and greenhouse gases emissions related to e-fuels production. In Proceedings of the 35th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Copenhagen, Denmark, 3–7 July 2022. [Google Scholar]

- Cames, M.; Chaudry, S.; Göckeler, K.; Kasten, P.; Kurth, S. E-Fuels Versus DACCS. Total Costs of Electro-Fuels and Direct Air Capture and Carbon Storage while Taking into Account Direct and Upstream Emissions and Environmental Risks; Study on behalf of Transport & Environment (T&E); Institute for applied ecology: Berlin, Germany, 2021. [Google Scholar]

- Hombach, L.E.; Doré, L.; Heidgen, K.; Maas, H.; Wallington, T.J.; Walther, G. Economic and environmental assessment of current (2015) and future (2030) use of E-fuels in light-duty vehicles in Germany. J. Clean. Prod. 2018, 207, 153–162. [Google Scholar] [CrossRef]

- Wang, X.; Guo, L.; Lv, J.; Li, M.; Huang, S.; Wang, Y.; Ma, X. Process design, modeling and life cycle analysis of energy consumption and GHG emission for jet fuel production from bioethanol in China. J. Clean. Prod. 2023, 389, 136027. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Bafana, A.; Wang, M. Life cycle analysis of electrofuels: Fischer–tropsch fuel production from hydrogen and corn ethanol byproduct CO2. Environ. Sci. Technol. 2021, 55, 3888–3897. [Google Scholar] [CrossRef]

- Papantoni, V.; Linke, F.; Dahlmann, K.; Kühlen, M.; Silberhorn, D.; Brand, U.; Vogt, T. Life Cycle Assessment of Power-to-Liquid for Aviation: A Case Study of a Passenger Aircraft. E3S Web Conf. 2022, 349, 02003. [Google Scholar] [CrossRef]

- Umenweke, G.C.; Pace, R.B.; Santillan-Jimenez, E.; Okolie, J.A. Techno-economic and life-cycle analyses of sustainable aviation fuel production via integrated catalytic deoxygenation and hydrothermal gasification. Chem. Eng. J. 2023, 452, 139215. [Google Scholar] [CrossRef]

- Tregambi, C.; Bareschino, P.; Hanak, D.P.; Mancusi, E.; Montagnaro, F.; Pepe, F. Techno-economic assessment of a synthetic methane production process by hydrogenation of carbon dioxide from direct air capture. Int. J. Hydrogen Energy 2023, 48, 37594–37606. [Google Scholar] [CrossRef]

- Runge, P.; Sölch, C.; Albert, J.; Wasserscheid, P.; Zöttl, G.; Grimm, V. Economic comparison of electric fuels for heavy duty mobility produced at excellent global sites—A 2035 scenario. Appl. Energy 2023, 347, 121379. [Google Scholar] [CrossRef]

- Rony, Z.I.; Rasul, M.G.; Jahirul, M.I.; Hasan, M.M. Characterisation of Pyrolysis Oil Produced from Seaweed and Plastic Wastes for Engine Applications. In Proceedings of the 2023 International Conference on Sustainable Technology and Engineering (i-COSTE), Nadi, Fiji, 4–6 December 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Yuan, H.; Yamamoto, H.; Nishino, J.; Shibata, G.; Ogawa, H. Optical Analysis on Diesel Combustion Processes of Ome Blended Ft Fuels by Rapid Compression-Expansion Machine. Available at SSRN 4748371. 5 March 2024. Hokkaido University. Available online: https://ssrn.com/abstract=4748371 (accessed on 17 August 2024).

- Havukainen, J.; Sillman, J. E-fuels: Pathway toward cleaner future. In Decarbonization Strategies and Drivers to Achieve Carbon Neutrality for Sustainability; Elsevier: Amsterdam, The Netherlands, 2024; pp. 283–297. [Google Scholar] [CrossRef]

- Veltman, M.; Laiminger, S.; Url, M.; Payrhuber, K. E-Fuels as a Key Technology for Decarbonization. MTZ Worldw. 2024, 85, 52–57. [Google Scholar] [CrossRef]

- Guzmán Mendoza, M.G. Impact of Different e-Fuels Types on Light Duty Compression Ignition Engine Performance, Emissions and CO2 Life Cycle Analysis. Doctoral Dissertation, Universitat Politècnica de València, Valencia, Spain, 2024. [Google Scholar]

- Labunski, F.; Schnurr, B.; Pössinger, J.; Götz, T. Environmental Impact of e-Fuels via the Solid Oxide Electrolyzer Cell (SOEC) and Fischer–Tropsch Synthesis (FTS) Route for Use in Germany. Energies 2024, 17, 1078. [Google Scholar] [CrossRef]

- Nagaraja, S.S.; Sarathy, S.M. Green hydrogen and e-fuels: A Saudi Arabian perspective. In The Clean Hydrogen Economy and Saudi Arabia; Routledge: England, UK, 2024; pp. 568–583. [Google Scholar] [CrossRef]

- Birel, T.; Breeman, G.; van Buitenen, A.; Vijver, M. Defueling the impasse: EU political discourse on e-fuels. Energy Policy 2024, 187, 114022. [Google Scholar] [CrossRef]

- Oke, D.; Dunn, J.B.; Hawkins, T.R. Reducing Economy-Wide Greenhouse Gas Emissions with Electrofuels and Biofuels as the Grid Decarbonizes. Energy Fuels 2024, 38, 6048–6061. [Google Scholar] [CrossRef]

- Galimova, T.; Satymov, R.; Keiner, D.; Breyer, C. Sustainable energy transition of Greenland and its prospects as a potential Arctic e-fuel and e-chemical export hub for Europe and East Asia. Energy 2024, 286, 129605. [Google Scholar] [CrossRef]

- Peters, R.; Decker, M.; Breuer, J.L.; Samsun, R.C.; Stolten, D. Ramping-Up Electro-Fuel Production. Energies 2024, 17, 1928. [Google Scholar] [CrossRef]

- Yan, W.; Cheng, F.; Wang, X.; Zhang, C. Estimating the potential of sustainable aviation fuel enabled aviation decarbonization in China: An integrated resource-technology-economy-environment analysis framework. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 2371–2376. [Google Scholar] [CrossRef]

- Lee, K.; Sun, P.; Elgowainy, A.; Baek, K.H.; Bobba, P.; Lee, K.; Sun, P.; Elgowainy, A.; Baek, K.H.; Bobba, P. Techno-economic and life cycle analysis of synthetic natural gas production from low-carbon H2 and point-source or atmospheric CO2 in the United States. J. CO2 Util. 2024, 83, 102791. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.N.; Wang, F. Fuelling a Clean Future: A Systematic Review of Techno-Economic and Life Cycle Assessments in E-Fuel Development. Appl. Sci. 2024, 14, 7321. https://doi.org/10.3390/app14167321

Uddin MN, Wang F. Fuelling a Clean Future: A Systematic Review of Techno-Economic and Life Cycle Assessments in E-Fuel Development. Applied Sciences. 2024; 14(16):7321. https://doi.org/10.3390/app14167321

Chicago/Turabian StyleUddin, M. N., and Feng Wang. 2024. "Fuelling a Clean Future: A Systematic Review of Techno-Economic and Life Cycle Assessments in E-Fuel Development" Applied Sciences 14, no. 16: 7321. https://doi.org/10.3390/app14167321

APA StyleUddin, M. N., & Wang, F. (2024). Fuelling a Clean Future: A Systematic Review of Techno-Economic and Life Cycle Assessments in E-Fuel Development. Applied Sciences, 14(16), 7321. https://doi.org/10.3390/app14167321