Experimental Flow Performance Investigation of Francis Turbines from Model to Prototype

Abstract

1. Introduction

2. Methodology and Experimental Measurements Techniques

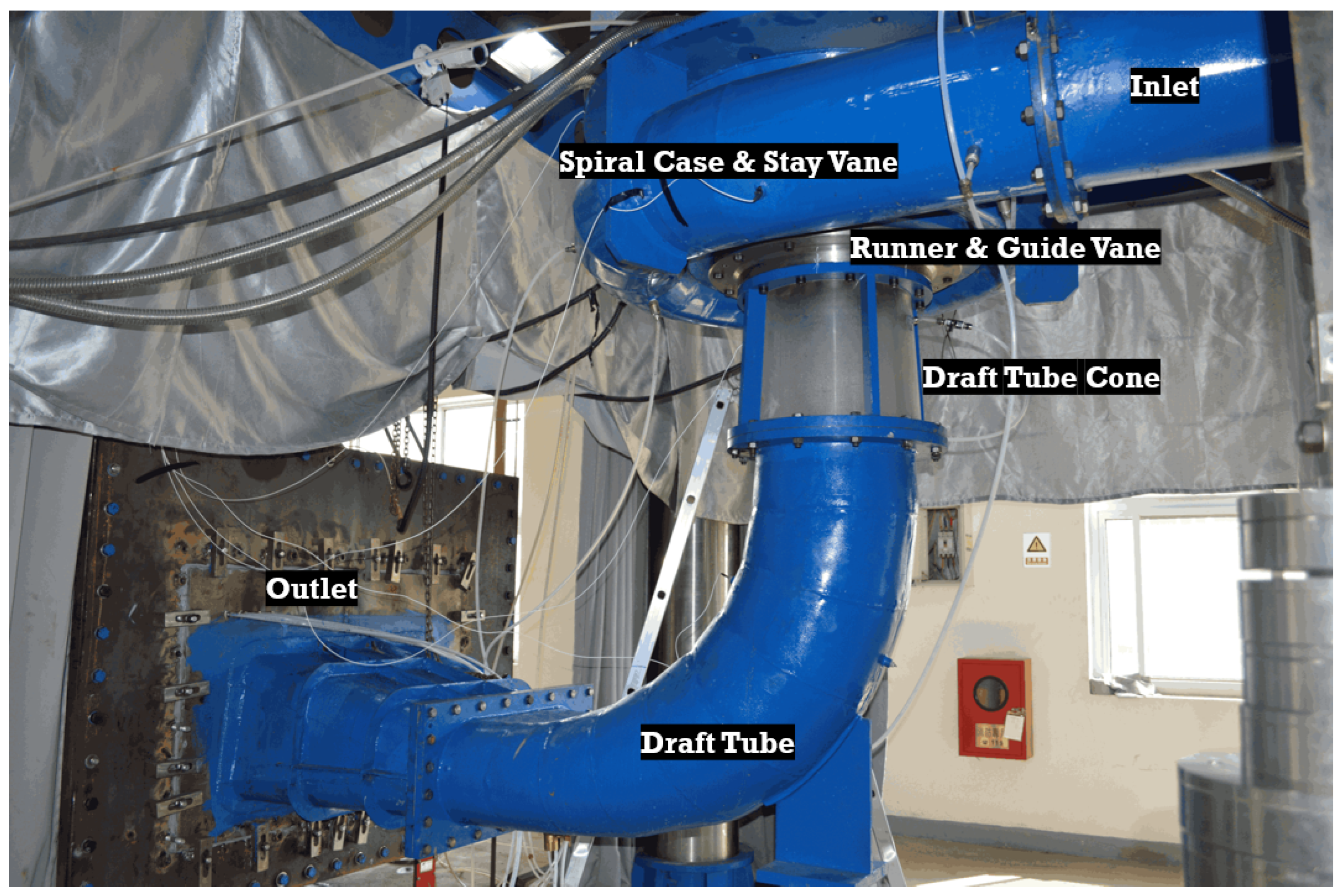

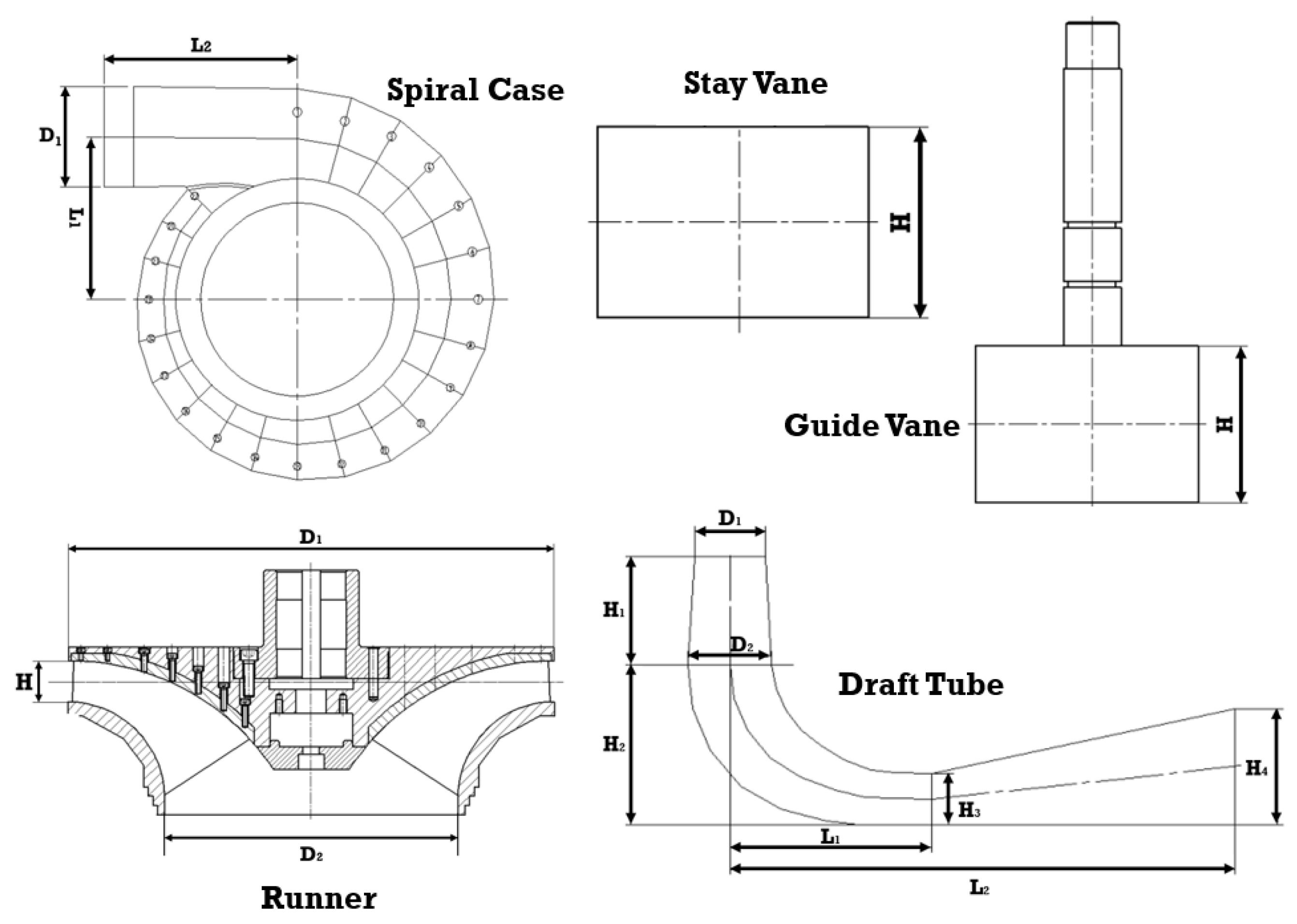

2.1. Experimental Test Rig

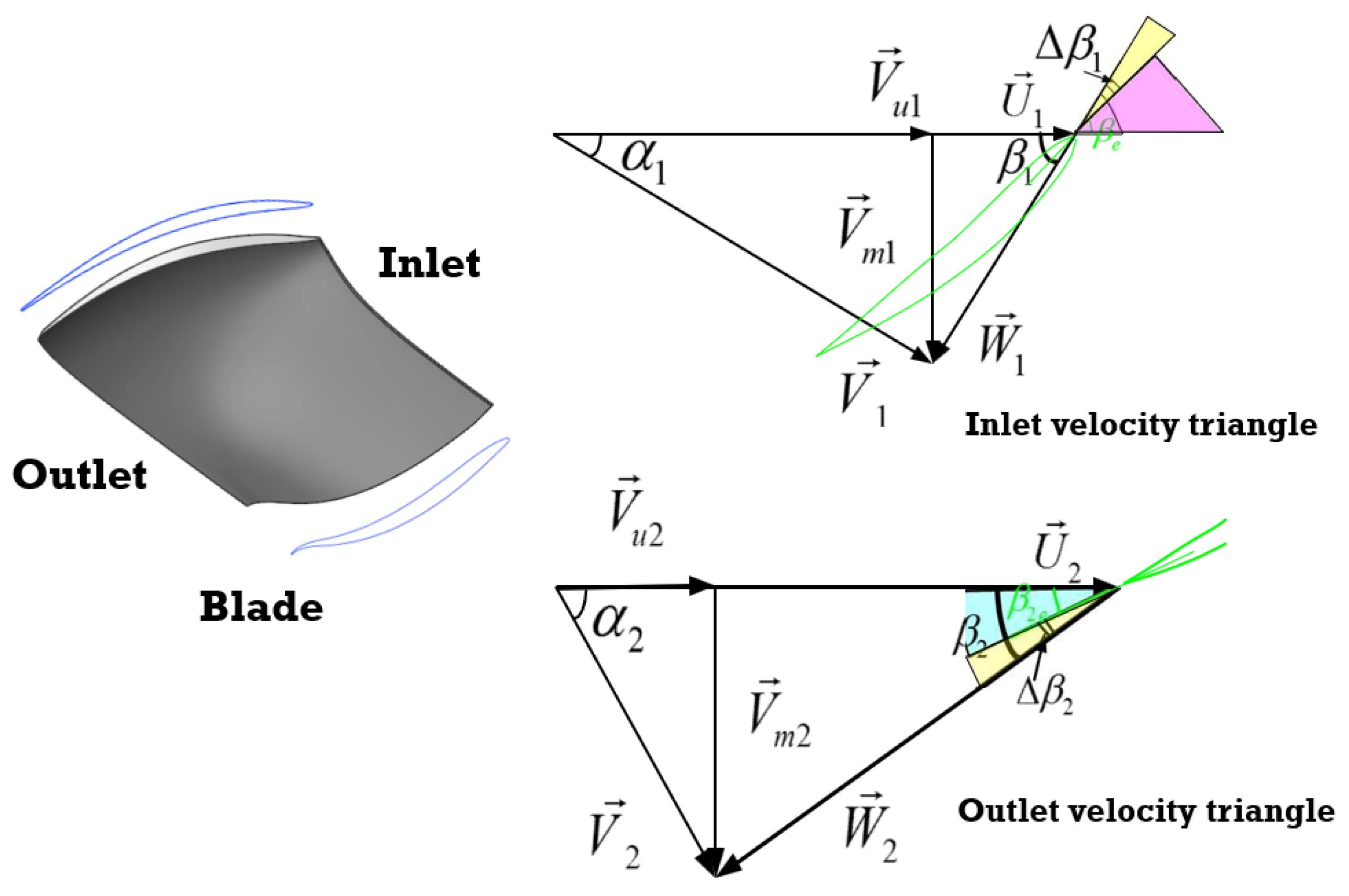

2.2. Similarity Theory between the Francis Turbine Model and Prototype

3. Experimental Results and Discussions

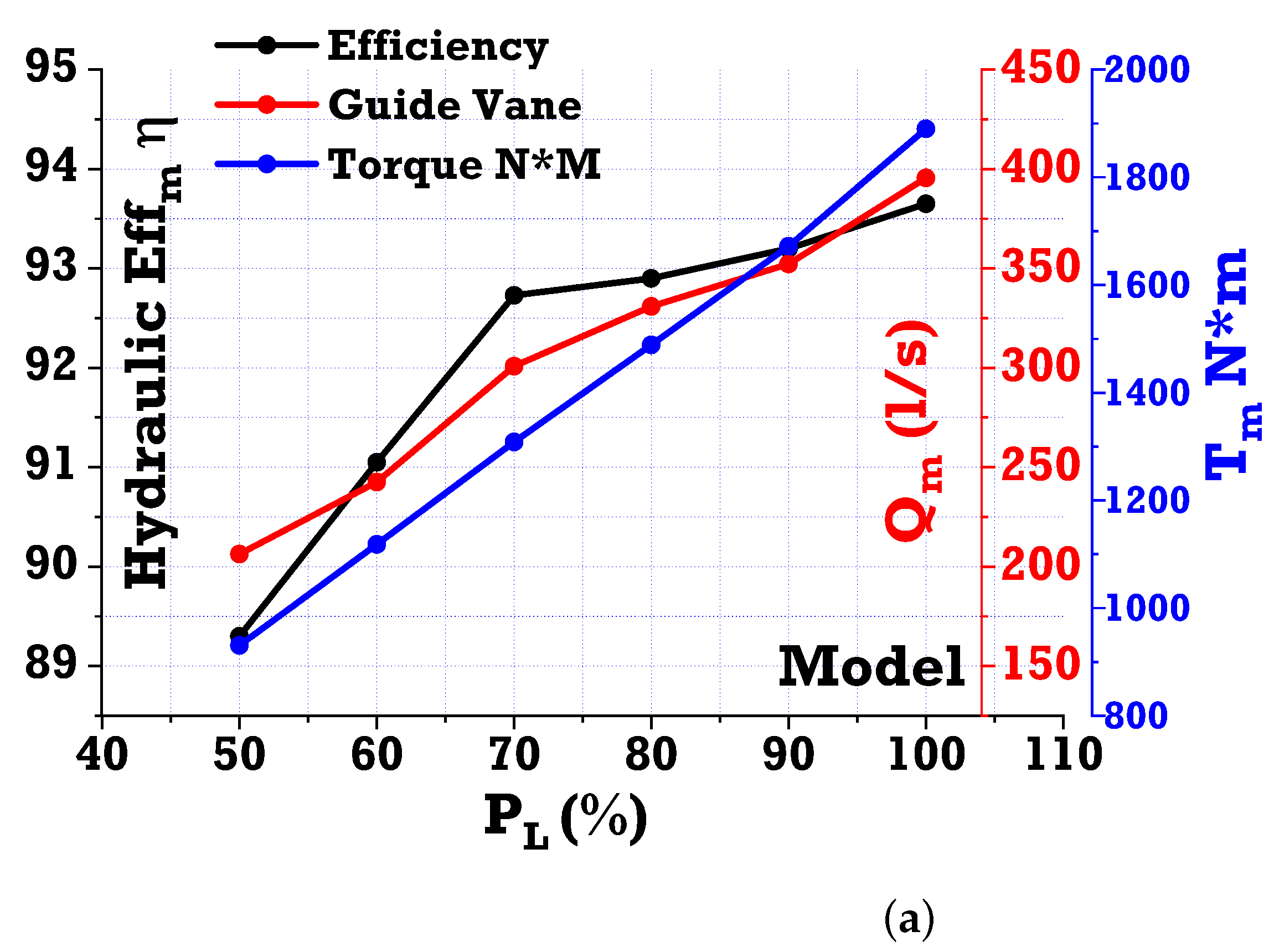

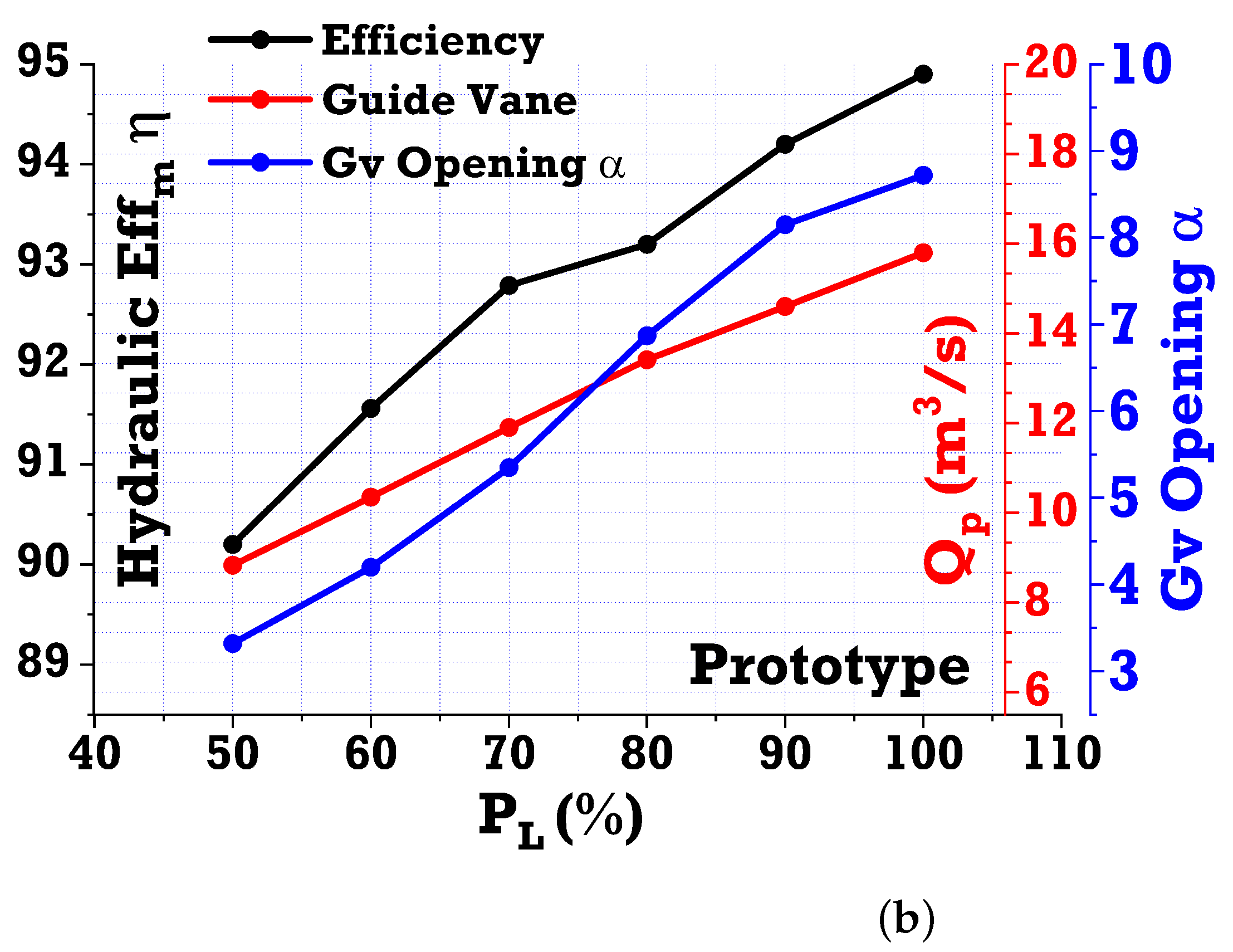

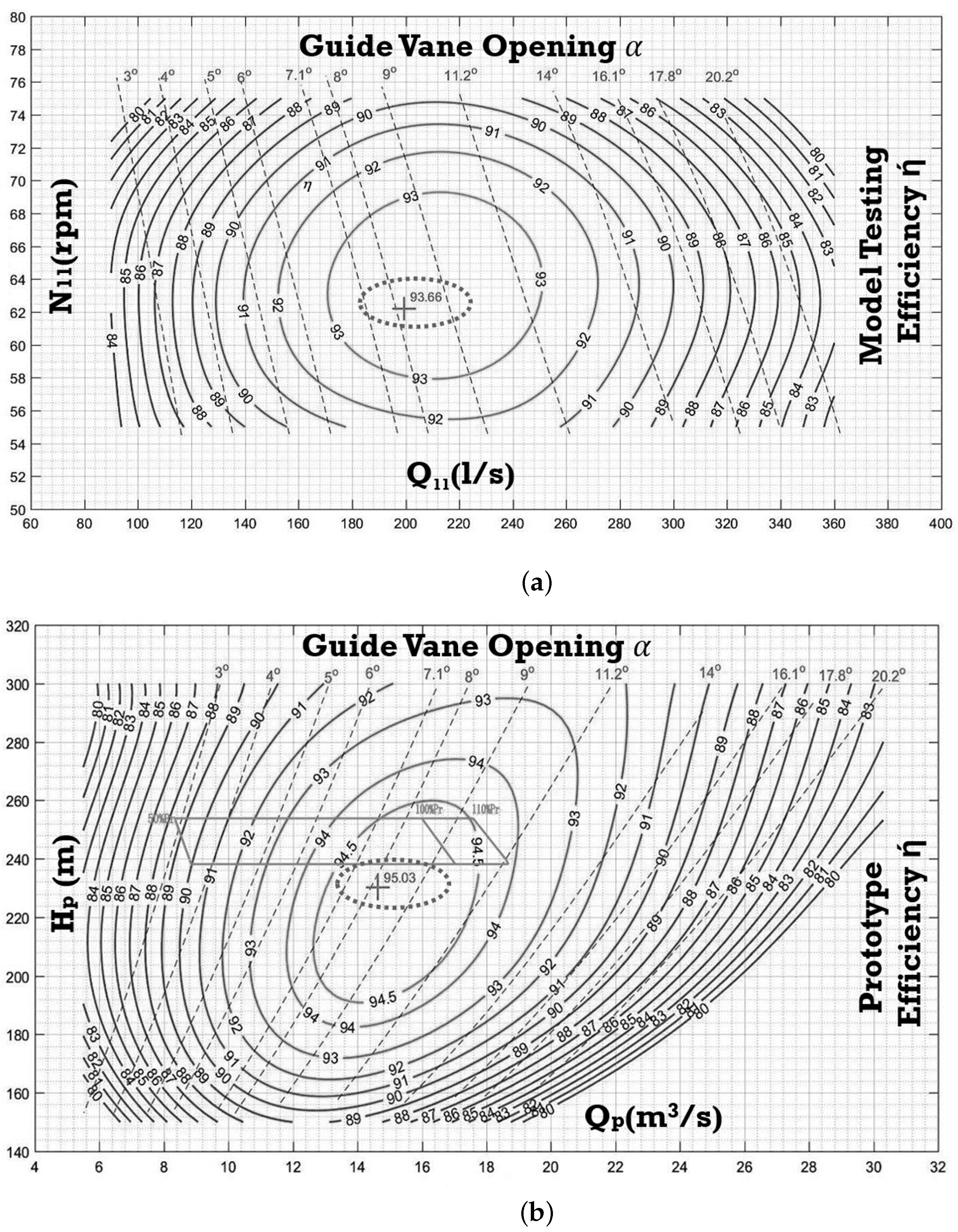

3.1. Performance Observation through Hill Chart and Torque

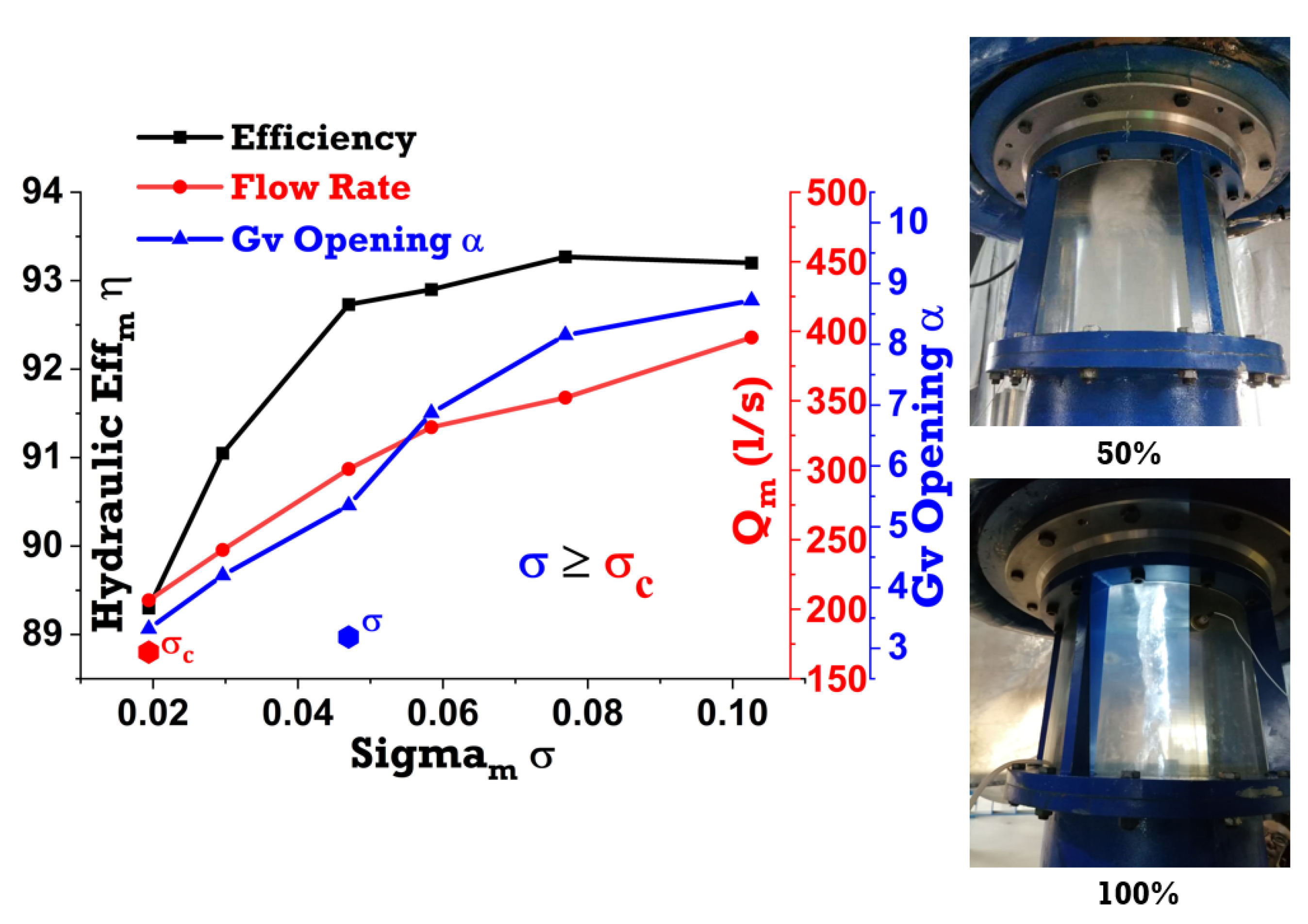

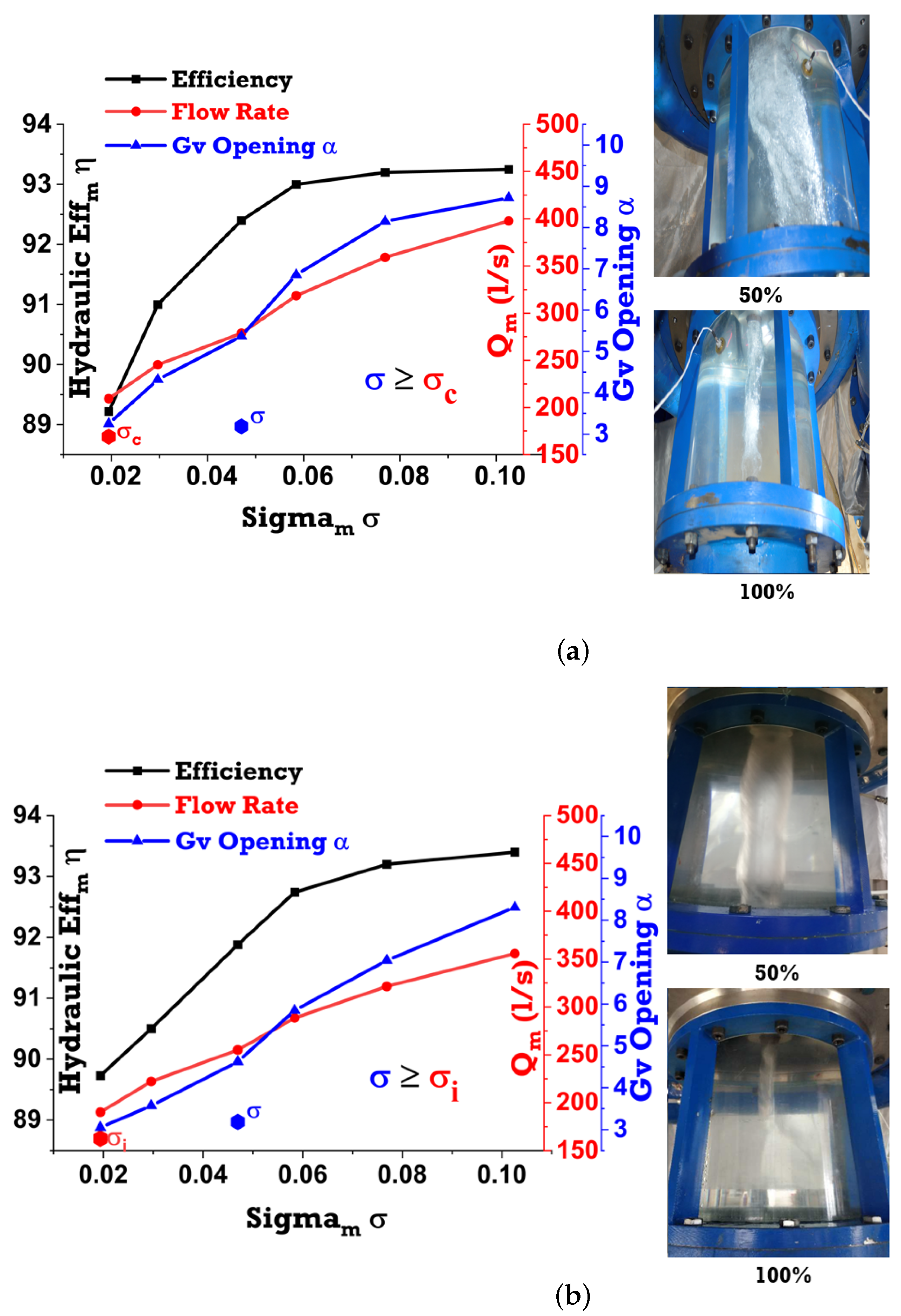

3.2. Cavitation Development and Effects on Hydraulic Performance

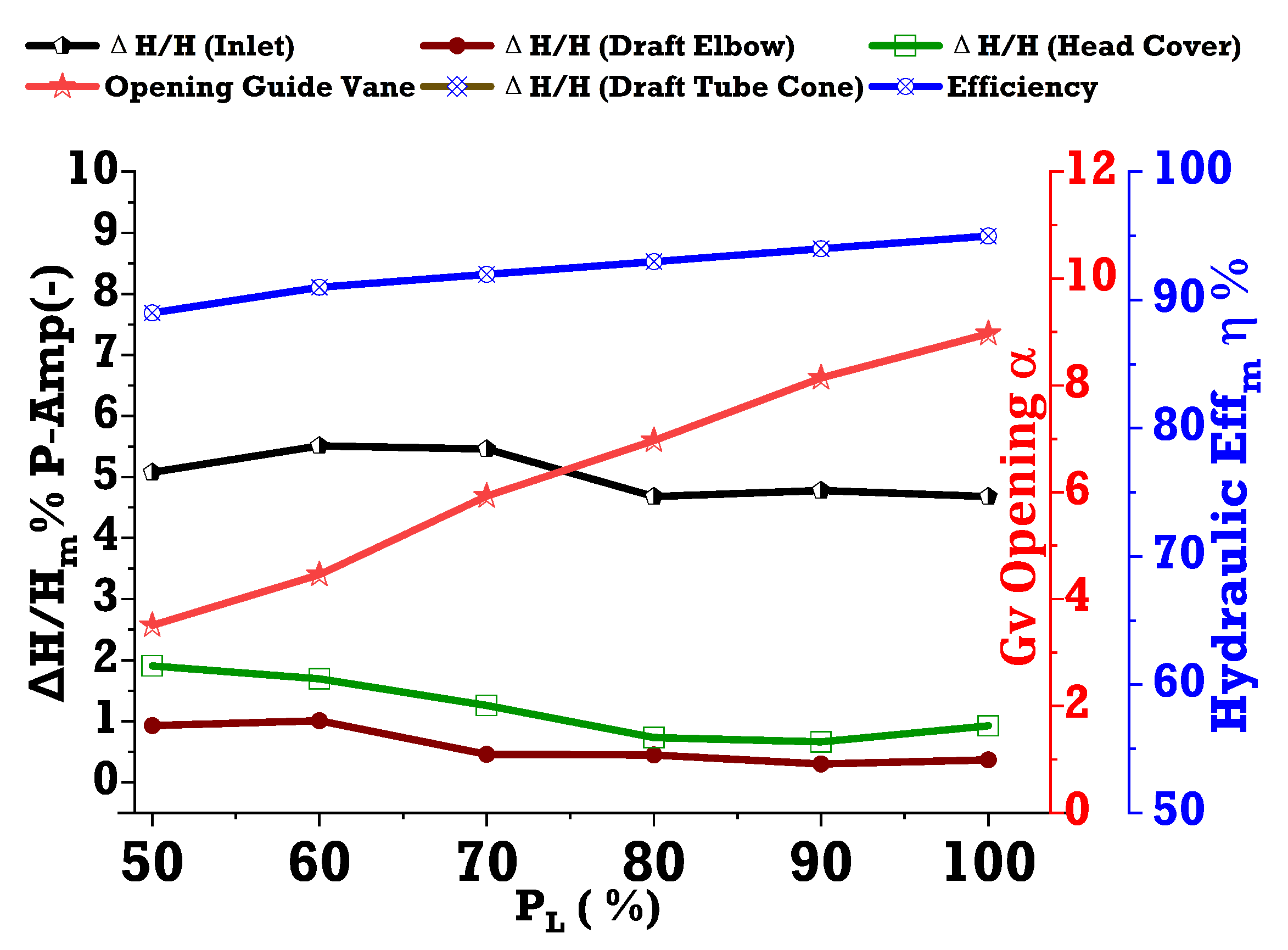

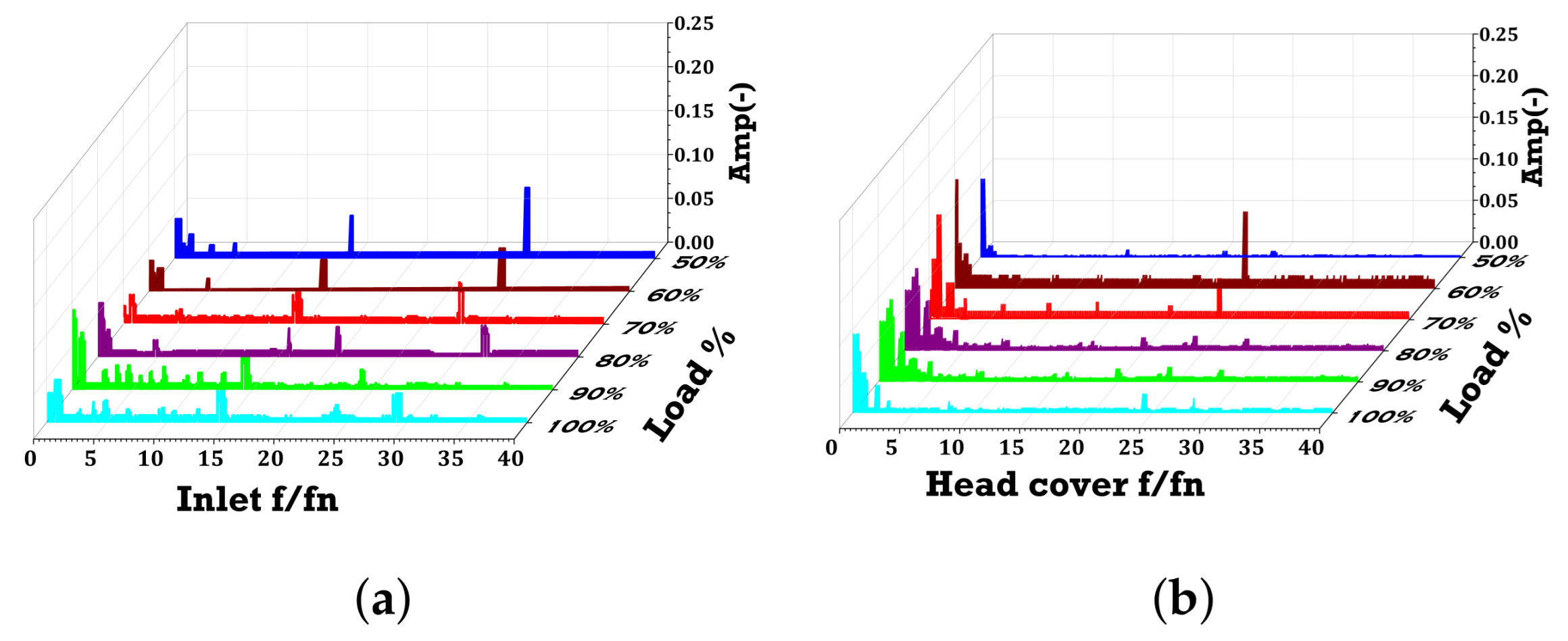

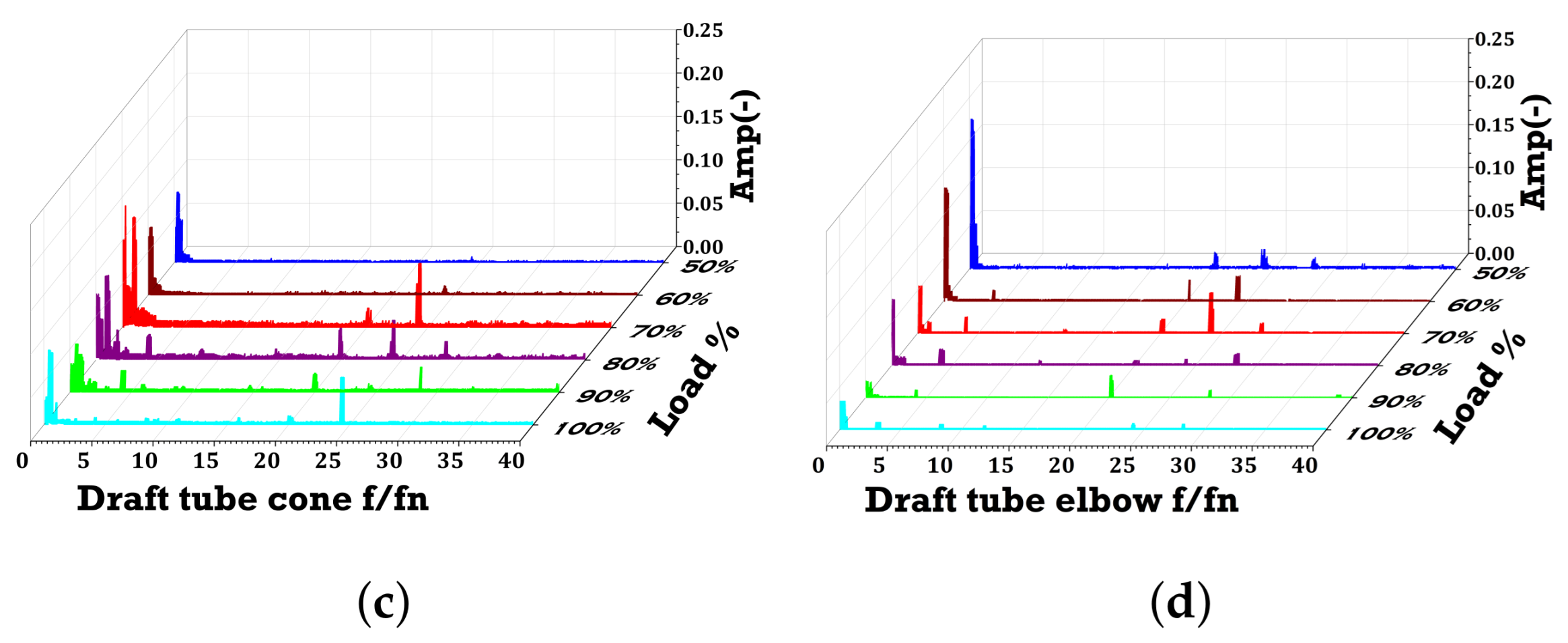

3.3. Pressure Pulsation Impacts on Hydraulics Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature and Abbreviations

| Symbol | Unit | Definition |

| ° | Guide vane opening | |

| - | Cavitation coefficient | |

| - | Critical cavitation coefficient | |

| rad/s | Angular velocity | |

| - | Inlet blade angle | |

| - | Outlet blade angle | |

| m | Model diameter | |

| f | Hz | Frequency |

| Hz | Rotational frequency | |

| N | Axial hydraulic thrust | |

| g | m/s2 | Gravitational acceleration |

| m | Model head | |

| m | Atmospheric pressure | |

| H | m | Head |

| L | m | Length |

| n | r/min | Speed |

| r/min | Unit speed | |

| P | Pa | Pressure |

| Pa | Absolute pressure | |

| Pa | Vaporizing pressure | |

| P | kW | Turbine output |

| kW | Unit output | |

| m3/s | Model flow rate | |

| L/s | Unit discharge | |

| - | Inlet blade radius | |

| - | Outlet blade radius | |

| Nm | Model torque | |

| Nm | Motor-generator torque | |

| Nm | Friction torque | |

| °C | Water temperature | |

| - | Inlet tangential velocity | |

| - | Outlet tangential velocity | |

| z | m | Elevation, difference of elevation |

| - | Guide vane number | |

| - | Best efficiency point | |

| - | Rotating vortex rope | |

| - | Particle image velocimetry | |

| - | Laser Doppler anemometry |

References

- Ullah, A.; Topcu, B.A.; Dogan, M.; Imran, M. Exploring the nexus among hydroelectric power generation, financial development, and economic growth: Evidence from the largest 10 hydroelectric power-generating countries. Energy Strategy Rev. 2024, 52, 101339. [Google Scholar] [CrossRef]

- Gupta, A.; Kumar, A.; Khatod, D. Optimized scheduling of Hydropower with increase in solar and wind installations. Energy 2019, 183, 716–732. [Google Scholar] [CrossRef]

- Singh, S.; Kharub, M.; Singh, J.; Singh, J.; Jangid, V. Brief survey on mechanical failure and preventive mechanism of turbine blades. Mater. Today Proc. 2020, 38, 2515–2524. [Google Scholar] [CrossRef]

- Luna-Ramírez, A.; Campos-Amezcua, A.; Dorantes-Gómez, O.; Mazur-Czerwiec, Z.; Muñoz-Quezada, R. Failure analysis of runner blades in a Francis hydraulic turbine—Case study. Eng. Fail. Anal. 2016, 59, 314–325. [Google Scholar] [CrossRef]

- Dorji, U.; Ghomashchi, R. Hydro turbine failure mechanisms: An overview. Eng. Fail. Anal. 2014, 44, 136–147. [Google Scholar] [CrossRef]

- Thapa, B.S.; Dahlhaug, O.G.; Thapa, B. Sediment erosion in hydro turbines and its effect on the flow around guide vanes of Francis turbine. Renew. Sustain. Energy Rev. 2015, 49, 1100–1113. [Google Scholar] [CrossRef]

- Guangjie, P.; Zhengwei, W.; Yexiang, X.; Yongyao, L. Abrasion predictions for Francis turbines based on liquid–solid two-phase fluid simulations. Eng. Fail. Anal. 2013, 33, 327–335. [Google Scholar] [CrossRef]

- Zuo, Z.; Liu, S.; Liu, D.; Qin, D.; Wu, Y. Numerical Predictions of the Incipient and Developed Interblade Vortex Lines of a Model Francis Turbine by Cavitation Calculations. Adv. Mech. Eng. 2013, 5, 397583. [Google Scholar] [CrossRef]

- Yamamoto, K.; Müller, A.; Favrel, A.; Avellan, F. Experimental evidence of inter-blade cavitation vortex development in Francis turbines at deep part load condition. Exp. Fluids 2017, 58, 1–14. [Google Scholar] [CrossRef]

- Celebioglu, K.; Altintas, B.; Aradag, S.; Tascioglu, Y. Numerical research of cavitation on Francis turbine runners. Int. J. Hydrogen Energy 2017, 42, 17771–17781. [Google Scholar] [CrossRef]

- Berbecaru, A.C.; Coman, G.; Gradinaru, C.S.; Sohaciu, M.G.; Predescu, C.; Dumitrescu, R.E.; Ciuca, S.; Gherghescu, I.A. Microstructural Characterization of Some Turbine Blade Martensitic Stainless Steels. Rev. Chim. 2019, 70, 1132–1139. [Google Scholar] [CrossRef]

- Escaler, X.; Egusquiza, E.; Farhat, M.; Avellan, F.; Coussirat, M. Detection of cavitation in hydraulic turbines. Mech. Syst. Signal Process. 2006, 20, 983–1007. [Google Scholar] [CrossRef]

- Bajic, B. Methods for vibro-acoustic diagnostics of turbine cavitation. J. Hydraul. Res. 2003, 41, 87–96. [Google Scholar] [CrossRef]

- Li, S.C.; Zuo, Z.G.; Liu, S.H.; Wu, Y.L.; Li, S. Cavitation Resonance. J. Fluids Eng. 2008, 130, 031302. [Google Scholar] [CrossRef]

- Hart, D.; Whale, D. A Review of Cavitation-Erosion Resistant Weld Surfacing Alloys for Hydroturbines; Eutectic Australia Pty. Ltd.: Sydney, Australia, 2007; Volume 8, pp. 180–187. [Google Scholar]

- Caron, J.-F.; Farhat, M.; Avellan, F. Physical investigation of the cavitation phenomenon. In Proceedings of the Sixth International Symposium on Fluid Control, Measurement and Visualization (Flucome 2000), Sherbrooke, QC, Canada, 13–17 August 2000. [Google Scholar]

- Jacob, T.; Prénat, J.-E. Francis turbine surge: Discussion and data base. In Proceedings of the Hydraulic Machinery and Cavitation: The XVIII IAHR Symposium on Hydraulic Machinery and Cavitation, Valencia, Spain, 16–19 September 1996; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Wang, F.J.; Li, X.Q.; Yang, M.; Zhu, Y.L. Experimental investigation of characteristic frequency in unsteady hydraulic behaviour of a large hydraulic turbine. J. Hydrodyn. Ser. B 2009, 21, 12–19. [Google Scholar] [CrossRef]

- Nicolet, C.; Zobeiri, A.; Maruzewski, P.; Avellan, F. Experimental Investigations on Upper Part Load Vortex Rope Pressure Fluctuations in Francis Turbine Draft Tube. Int. J. Fluid Mach. Syst. 2011, 4, 179–190. [Google Scholar] [CrossRef]

- Favrel, A.; Müller, A.; Landry, C.; Yamamoto, K.; Avellan, F. Study of the vortex-induced pressure excitation source in a Francis turbine draft tube by particle image velocimetry. Exp. Fluids 2015, 56, 1–15. [Google Scholar] [CrossRef]

- Trivedi, C.; Agnalt, E.; Dahlhaug, O.G. Experimental study of a Francis turbine under variable-speed and discharge conditions. Renew. Energy 2018, 119, 447–458. [Google Scholar] [CrossRef]

- Litvinov, I.; Shtork, S.; Gorelikov, E.; Mitryakov, A.; Hanjalic, K. Unsteady regimes and pressure pulsations in draft tube of a model hydro turbine in a range of off-design conditions. Exp. Therm. Fluid Sci. 2018, 91, 410–422. [Google Scholar] [CrossRef]

- Iliev, I.; Trivedi, C.; Agnalt, E.; Dahlhaug, O.G. Variable-speed operation and pressure pulsations in a Francis turbine and a pump-turbine. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Wang, W.; Chen, Q.; Yan, D.; Geng, D. A novel comprehensive evaluation method of the draft tube pressure pulsation of Francis turbine based on EEMD and information entropy. Mech. Syst. Signal Process. 2019, 116, 772–786. [Google Scholar] [CrossRef]

- Zeng, W.; Yang, J.; Hu, J.; Yang, J. Guide-vane closing schemes for pump-turbines based on transient characteristics in S-shaped region. J. Fluids Eng. 2016, 138, 051302. [Google Scholar] [CrossRef]

- Trivedi, C.; Cervantes, M.J.; Gandhi, B.K.; Ole, D.G. Experimental investigations of transient pressure variations in a high head model Francis turbine during start-up and shutdown. J. Hydrodyn. 2014, 26, 277–290. [Google Scholar] [CrossRef]

- Andolfatto, L.; Avellan, F. Model testing beyond the scope of International Standards: An outlook. Hydro 2018. 2018. Available online: https://infoscience.epfl.ch/bitstreams/26b3d312-065a-4ec0-94cf-0bb48cdf65f8/download (accessed on 19 August 2024).

- Mahawar, R.; Dwivedi, P.; Agrawal, R.; Karn, A. Computational tool for teaching learning velocity triangle of hydraulic turbines. Preprints 2020. [Google Scholar] [CrossRef]

- Trivedi, C.; Cervantes, M.J.; Dahlhaug, O.G. Experimental and Numerical Studies of a High-Head Francis Turbine: A Review of the Francis-99 Test Case. Energies 2016, 9, 74. [Google Scholar] [CrossRef]

| Instruments | Purpose | Range | Uncertainty |

|---|---|---|---|

| BOI Measurement and Testing | Frequency | 0–10 MHz | ±0.08 |

| Pressure Calibration | Pressure | 0.1~6 Mpa | ±0.005 |

| Emerson Instrument | Temperature sensor | 0–100 °C | ±0.04 |

| Emerson Instrument | Barometer | 0–600 KPa | ±0.5% |

| Load cell | Generator torque | 0–1600 N·m | ±0.05 |

| Load cell | Friction torque | 0–22 N·m | ±0.0025 |

| China Electronics CKCW36 | Inlet pressure | 0–400 KPa | ±0.0019 |

| China Electronics CKCW36 | Outlet pressure | 0–400 KPa | ±0.001 |

| Head | Turbine | Working Conditions Loads | |||||

|---|---|---|---|---|---|---|---|

| m | Type | 100% | 90% | 80% | 70% | 60% | 50% |

| 38.10 | Model () | 93.25 | 93.15 | 93.06 | 92.40 | 91.02 | 89.22 |

| 238.6 | Prototype () | 94.30 | 94.10 | 93.42 | 92.87 | 91.26 | 89.50 |

| 38.50 | Model () | 93.33 | 93.25 | 93.03 | 92.61 | 91.06 | 89.30 |

| 240 | Prototype () | 95.03 | 94.93 | 94.54 | 93.86 | 92.27 | 91.10 |

| 37.50 | Model () | 93.45 | 93.20 | 92.88 | 92.10 | 90.50 | 89.73 |

| 254 | Prototype () | 94.60 | 93.92 | 93.18 | 92.53 | 91.05 | 89.20 |

| Model Head | Suction Head | Air Compensation Coefficient = 0 (%) (without Air) | Air Compensation Coefficient = 0 (%) (with Air) |

|---|---|---|---|

| m | m | ΔH/H(%) and f/ | ΔH/H(%) and f/ |

| 38.10 | −2.63 | 1.12 and 0.07 | 2.14 and 0.172 |

| 38.50 | −2.58 | 1.01 and 0.284 | 0.58 and 0.03 |

| 37.50 | −2.55 | 1.02 and 0.058 | 0.86 and 0.105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirza Umar, B.; Huang, X.; Wang, Z. Experimental Flow Performance Investigation of Francis Turbines from Model to Prototype. Appl. Sci. 2024, 14, 7461. https://doi.org/10.3390/app14177461

Mirza Umar B, Huang X, Wang Z. Experimental Flow Performance Investigation of Francis Turbines from Model to Prototype. Applied Sciences. 2024; 14(17):7461. https://doi.org/10.3390/app14177461

Chicago/Turabian StyleMirza Umar, Baig, Xingxing Huang, and Zhengwei Wang. 2024. "Experimental Flow Performance Investigation of Francis Turbines from Model to Prototype" Applied Sciences 14, no. 17: 7461. https://doi.org/10.3390/app14177461

APA StyleMirza Umar, B., Huang, X., & Wang, Z. (2024). Experimental Flow Performance Investigation of Francis Turbines from Model to Prototype. Applied Sciences, 14(17), 7461. https://doi.org/10.3390/app14177461