An Assessment of the Mechanical Deformation Behavior of Three Different Clear Aligner Materials: A Digital Image Correlation Analysis

Abstract

1. Introduction

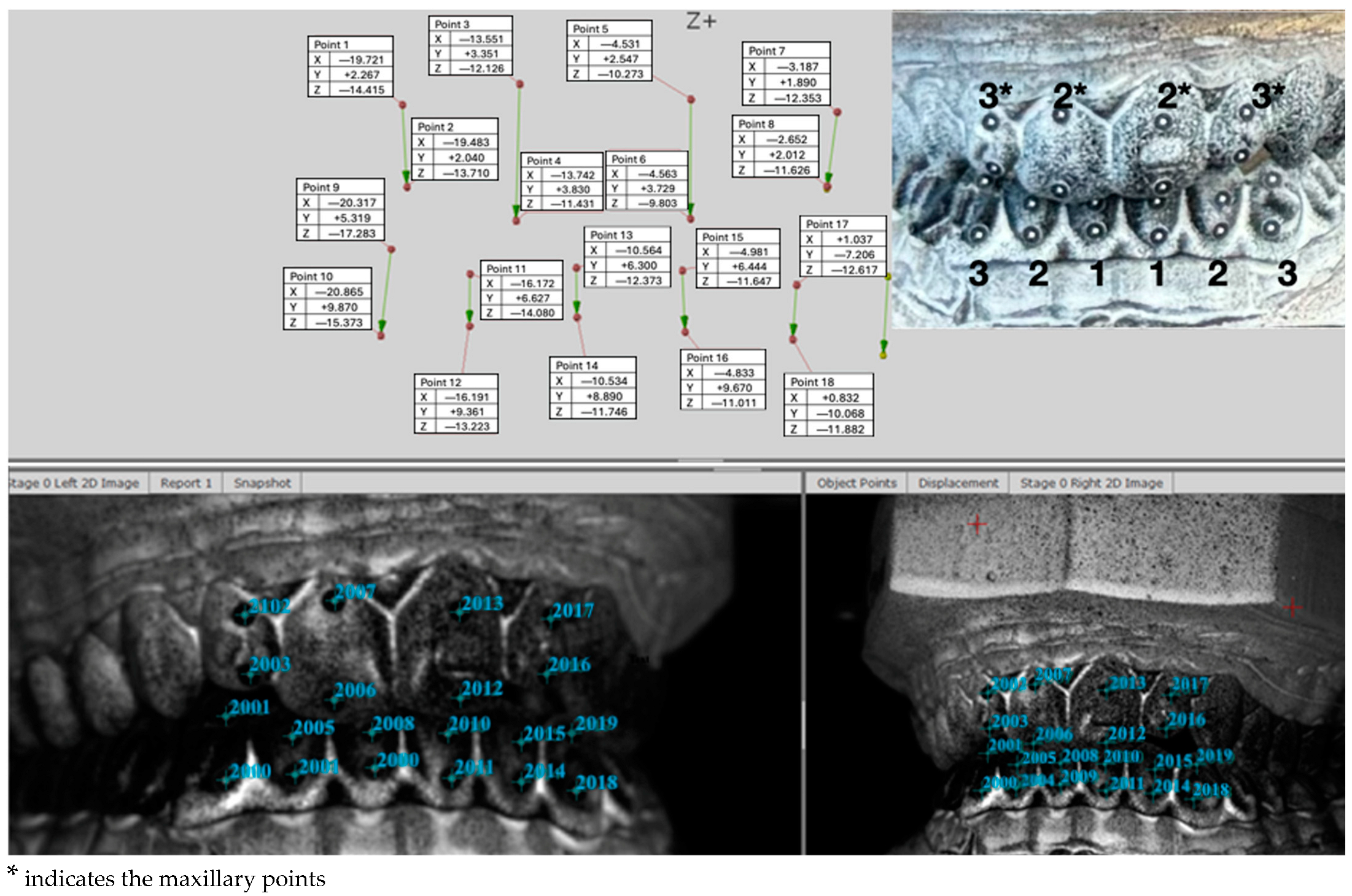

2. Materials and Methods

2.1. Sample Preparation

2.2. Deformation Behavior Testing

2.3. Statistical Analysis

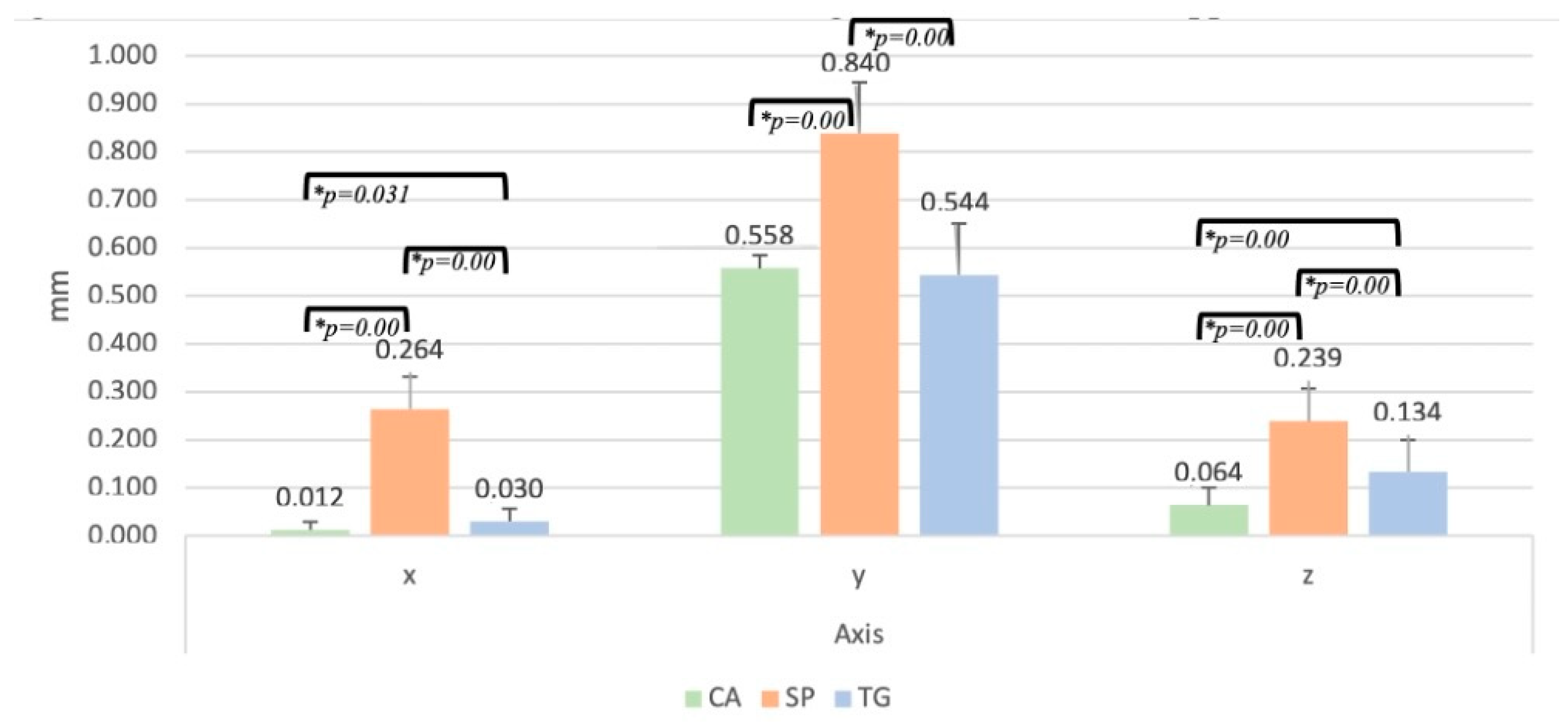

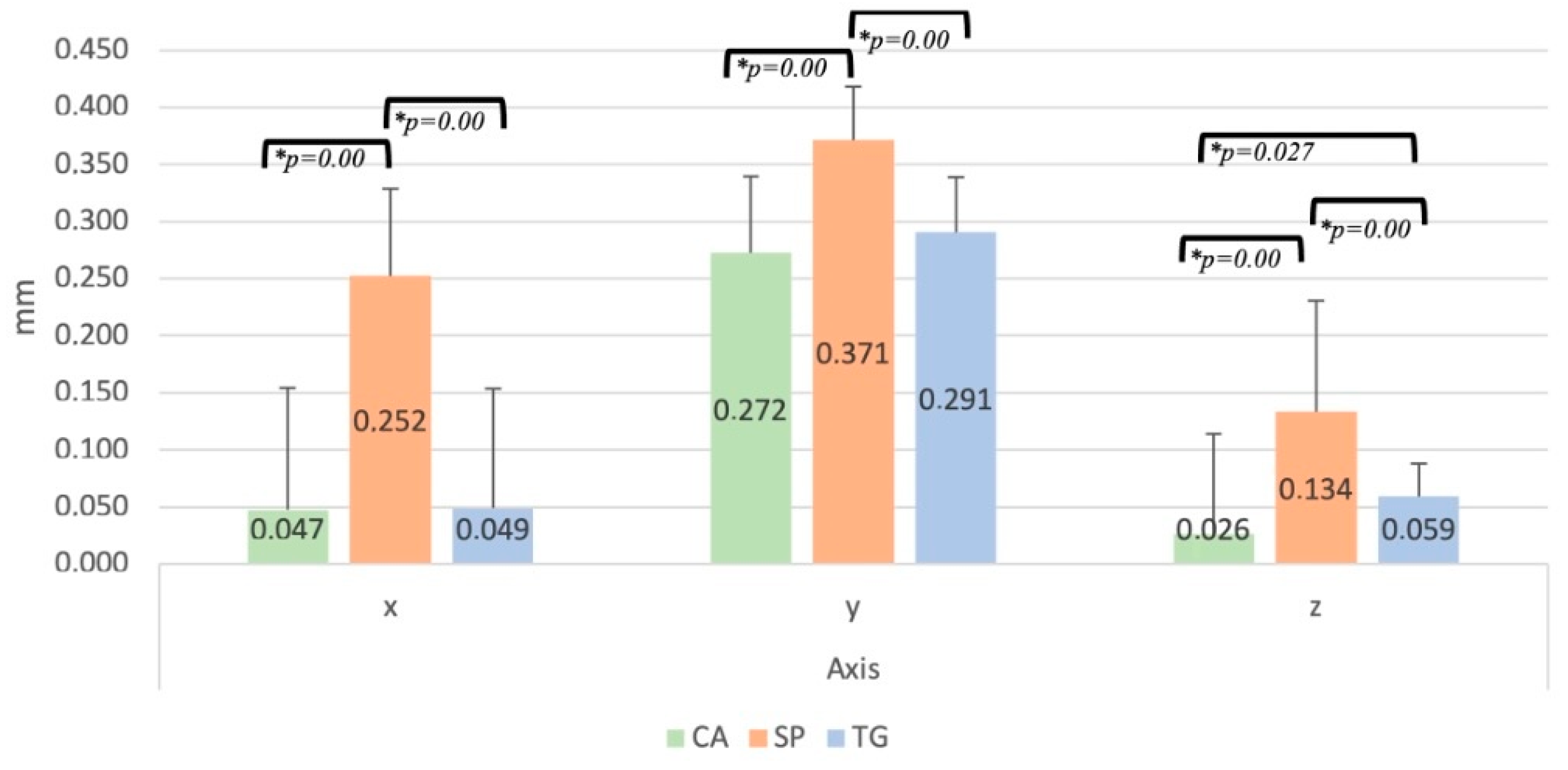

3. Results

4. Discussion

5. Conclusions

- In conclusion, the Spark Trugen clear aligner system demonstrated a lower stability to rigid displacement and elastic deformation under compression testing compared to the Scheu CA® Pro+ Clear Aligner and Taglus Premium systems.

- All three tested clear aligner systems showed an increased resistance to elastic displacement and rigid deformation in the mandibular arch.

- The Scheu CA® Pro+ Clear Aligner system showed the lowest elastic deformation values after compression testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bichu, Y.M.; Alwafi, A.; Liu, X.; Andrews, J.; Ludwig, B.; Bichu, A.Y.; Zou, B. Advances in orthodontic clear aligner materials. Bioact. Mater. 2023, 22, 384–403. [Google Scholar] [CrossRef] [PubMed]

- Hennessy, J.; Al-Awadhi, E.A. Clear aligners generations and orthodontic tooth movement. J. Orthod. 2016, 43, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Albertini, P.; Mazzanti, V.; Mollica, F.; Pellitteri, F.; Palone, M.; Lombardo, L. Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study. Bioengineering 2022, 9, 349. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Kim, H.; Kim, H.J.; Chung, C.J.; Choi, Y.J.; Kim, S.J.; Cha, J.Y. Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners. Sci. Rep. 2022, 12, 6246. [Google Scholar] [CrossRef]

- Voudouris, J.C.; Voudouris, J.D.; Nicolay, O.; Glaser, B.; Nicozisis, J.; Theodoridis, G.; Carrillo, R.; Moshiri, M.; Masoud, M. Clear aligners, dentofacial orthopedics, physics and supercorrection prescription biomechanics. A meeting of the minds. Semin. Orthod. 2022, 27, 202–258. [Google Scholar] [CrossRef]

- Bucci, R.; Rongo, R.; Levatè, C.; Michelotti, A.; Barone, S.; Razionale, A.V.; D’Antò, V. Thickness of orthodontic clear aligners after thermoforming and after 10 days of intraoral exposure: A prospective clinical study. Prog. Orthod. 2019, 20, 36. [Google Scholar] [CrossRef]

- Zinelis, S.; Panayi, N.; Polychronis, G.; Papageorgiou, S.N.; Eliades, T. Comparative analysis of mechanical properties of orthodontic aligners produced by different contemporary 3D printers. Orthod. Craniofac Res. 2022, 25, 336–341. [Google Scholar] [CrossRef]

- Jindal, P.; Juneja, M.; Siena, F.L.; Bajaj, D.; Breedon, P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofacial Orthop. 2019, 156, 694–701. [Google Scholar] [CrossRef]

- Shirey, N.; Mendonca, G.; Groth, C.; Kim-Berman, H. Comparison of mechanical properties of 3-dimensional printed and thermoformed orthodontic aligners. Am. J. Orthod. Dentofacial Orthop. 2023, 163, 720–728. [Google Scholar] [CrossRef]

- Mao, B.; Tian, Y.; Li, J.; Zhou, Y. Expansion rebound deformation of clear aligners and its biomechanical influence: A three-dimensional morphologic analysis and finite element analysis study. Angle Orthod. 2023, 93, 572–579. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, X.; Savoldi, F.; Han, J.; Su, R.K.L.; Fok, A.; Chen, J.; Tsoi, J.K. Validation of a double-semicircular notched configuration for mechanical testing of orthodontic thermoplastic aligner materials. J. Mech. Behav. Biomed. Mater. 2024, 155, 106543. [Google Scholar] [CrossRef] [PubMed]

- Can, E.; Panayi, N.; Polychronis, G.; Papageorgiou, S.N.; Zinelis, S.; Eliades, G.; Eliades, T. In-house 3D-printed aligners: Effect of in vivo ageing on mechanical properties. Eur. J. Orthod. 2022, 44, 51–55. [Google Scholar] [CrossRef] [PubMed]

- Jindal, P.; Worcester, F.; Siena, F.L.; Forbes, C.; Juneja, M.; Breedon, P. Mechanical behaviour of 3D printed vs thermoformed clear dental aligner materials under non-linear compressive loading using FEM. J. Mech. Behav. Biomed. Mater. 2020, 112, 104045. [Google Scholar] [CrossRef] [PubMed]

- Casavola, C.; Pappalettera, G.; Pappalettere, C.; Patronelli, M.; Renna, G.; Laurenziello, M.; Ciavarella, D. A full-field DIC analysis of the mechanical-deformation behavior of polyethylene terephthalate glycol (PET-G) aligners. J. Mech. Behav. Biomed. Mater. 2022, 134, 105391. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.J.; Sutton, M.A.; Michael, A.M.A.; Orteu, J.J.; Schreier, H.W. Single Camera Models and Calibration Procedures in Computer Vision. In Image Correlation for Shape, Motion and Deformation Measurements; Michael, A., Sutton, M.A., Orteu, J.J., Schreier, H.W., Eds.; Springer: New York, NY, USA, 2009; pp. 1–37. [Google Scholar]

- Kibitkin, V.; Savchenko, N.; Grigoriev, M.; Solodushkin, A.; Burlachenko, A.; Buyakov, A.; Zykova, A.; Rubtsov, V.; Tarasov, S. Digital Image Correlation Characterization of Deformation Behavior and Cracking of Porous Segmented Alumina under Uniaxial Compression. Ceramics 2023, 6, 102–131. [Google Scholar] [CrossRef]

- Casavola, C.; Pappalettera, G.; Pappalettere, C.; Patronelli, M.; Renna, G.; Ciavarella, D.; Laurenziello, M. DIC analysis of mechanical response of tooth aligners under simulated swallowing acts. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1275, 012023. [Google Scholar] [CrossRef]

- Lümkemann, N.; Klimenta, M.; Hoffmann, M.; Meinen, J.; Stawarczyk, B. Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models. Materials 2023, 16, 4835. [Google Scholar] [CrossRef]

- Tamburrino, F.; D’Antò, V.; Bucci, R.; Alessandri-Bonetti, G.; Barone, S.; Razionale, A.V. Mechanical properties of thermoplastic polymers for aligner manufacturing: In vitro study. Dent. J. 2020, 8, 47. [Google Scholar] [CrossRef]

- Hertan, E.; McCray, J.; Bankhead, B.; Kim, K.B. Force profile assessment of direct-printed aligners versus thermoformed aligners and the effects of non-engaged surface patterns. Prog. Orthod. 2022, 23, 49. [Google Scholar] [CrossRef]

- Keller, K.J.; Keller, K.J.; Giannini, P.J.; Gregory, M.S.; Oakley, G. Stress Relaxation in Orthodontic Aligner Plastics; An In Vitro Stress Relaxation in Orthodontic Aligner Plastics; An In Vitro Comparison Study Comparison Study Stress Relaxation In Orthodontic Aligner Plastics; An In Vitro Comparison Study [Internet]. 2020. Available online: https://digitalcommons.unmc.edu/etd (accessed on 5 June 2024).

- Kaur, H.; Truong, J.; Heo, G.; Mah, J.K.; Major, P.W.; Romanyk, D.L. An in vitro evaluation of orthodontic aligner biomechanics around the maxillary arch. Am. J. Orthod. Dentofacial Orthop. 2021, 160, 401–409. [Google Scholar] [CrossRef]

- Sawamura, M.; Nakano, H.; Shiogama, M.; Takano, N.; Maki, K. Using digital image correlation to measure displacement and strain during involving distal movement of anterior teeth with clear aligner. Dent. Mater. J. 2023, 42, 493–500. [Google Scholar] [CrossRef] [PubMed]

- Grünheid, T.; Bitner, T.F. Wear and fatigue resistance: An in-vitro comparison of three polyethylene terephthalate glycol and thermoplastic polyurethane materials for vacuum-formed retainers. Int. Orthod. 2023, 21, 100748. [Google Scholar] [CrossRef] [PubMed]

- Milovanović, A.; Sedmak, A.; Golubović, Z.; Mihajlović, K.Z.; Žurkić, A.; Trajković, I.; Milošević, M. The effect of time on mechanical properties of biocompatible photopolymer resins used for fabrication of clear dental aligners. J. Mech. Behav. Biomed. Mater. 2021, 119, 104494. [Google Scholar] [CrossRef] [PubMed]

- Lyu, X.; Cao, X.; Yan, J.; Zeng, R.; Tan, J. Biomechanical effects of clear aligners with different thicknesses and gingival-margin morphology for appliance design optimization. Am. J. Orthod. Dentofacial Orthop. 2023, 164, 239–252. [Google Scholar] [CrossRef]

- Nowak, C.M.; Othman, A.; Ströbele, D.A.; von See, C. Comparative mechanical testing for different orthodontic aligner materials over time—In vitro study. J. Clin. Exp. Dent. 2022, 14, e457–e463. [Google Scholar] [CrossRef]

- Dalaie, K.; Fatemi, S.M.; Ghaffari, S. Dynamic mechanical and thermal properties of clear aligners after thermoforming and aging. Prog. Orthod. 2021, 22, 15. [Google Scholar] [CrossRef]

- Golkhani, B.; Weber, A.; Keilig, L.; Reimann, S.; Bourauel, C. Variation of the modulus of elasticity of aligner foil sheet materials due to thermoforming. J. Orofac. Orthop. 2022, 83, 233–243. [Google Scholar] [CrossRef]

- Morris, R.S.; Hoye, L.N.; Elnagar, M.H.; Atsawasuwan, P.; Galang-Boquiren, M.T.; Caplin, J.; Viana, G.C.; Obrez, A.; Kusnoto, B. Accuracy of Dental Monitoring 3D digital dental models using photograph and video mode. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 420–428. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kwon, J.S.; Jiang, H.B.; Cha, J.Y.; Kim, K.M. Effects of thermoforming on the physical and mechanical properties of thermoplastic materials for transparent orthodontic aligners. Korean J. Orthod. 2018, 48, 316–325. [Google Scholar] [CrossRef]

- Doğramacı, E.J.; Chubb, D.W.R.; Rossi-Fedele, G. Orthodontic thermoformed retainers: A two-arm laboratory study into post-fabrication outcomes. Aust. Dent. J. 2018, 63, 347–355. [Google Scholar] [CrossRef]

| Group | Aligner System | Manufacturer | Composition and Material Thickness |

|---|---|---|---|

| CA (n = 15) | CA® Pro+ Clear Aligner | Scheu Dental, Iserlohn, Germany | Three layers (0.75 mm): 1. Copolyester layer (0.25 mm) 2. Thermoplastic elastomer (TPE) (0.25 mm) 3. Copolyester layer (0.25 mm) |

| TG (n = 15) | Taglus Premium | Taglus Company, Mumbai, India | Polyethylene terephtalate glycol (PET-G) (0.75 mm) |

| SP (n = 15) | Spark Trugen | Ormco Corp., Orange, CA, USA | TruGEN Technology (0.75 mm) |

| Camera Sensor | CMOS |

|---|---|

| Camera Resolution | 4096 × 3000 pixels |

| Frame Rate | 25 fps @ full resolution |

| 43 fps @ 2496 × 2096 pixels (5M mode) | |

| Illumination | Light Projector |

| Tracking Spots | |

| Measuring Area [mm] | Frame 150: 35|70|120|180 |

| Frame 300: 110|170|260|400|550 | |

| Frame 600: 750|1500 | |

| Frame 1200: 1500|3000 | |

| Frame 1600: 5000 | |

| Control Device | ARAMIS Controller |

| Sensor Size [mm] | Frame 150: approx. 260 × 330 × 300 |

| Frame 300: approx. 420 × 330 × 300 | |

| Frame 600: approx. 730 × 230 × 130 | |

| Frame 1200: approx. 1300 × 230 × 130 | |

| Frame 1600: approx. 1700 × 230 × 130 | |

| Strain Measuring Range | 0.005% up to >2000% |

| Strain Measuring Resolution | up to 0.005% |

| Aligner | No. Point | 3 * | 2 * | 1 | 2 * | 3 * | |

|---|---|---|---|---|---|---|---|

| Scheu Upper | Axis | [mm] | [mm] | [mm] | [mm] | [mm] | |

| X | 0.023 | 0.011 | 0.016 | 0.023 | |||

| Y | 0.002 | 0.005 | 0.006 | 0.001 | |||

| Z | 0.009 | 0.054 | 0.033 | 0.001 | |||

| Scheu Lower | 3 | 2 | 1 | 1 | 2 | 3 | |

| X | 0.007 | 0.007 | 0.002 | 0.003 | 0.006 | 0.013 | |

| Y | 0.003 | 0.003 | 0.003 | 0.002 | 0.001 | 0.002 | |

| Z | 0.017 | 0.017 | 0.01 | 0.017 | 0.014 | 0.003 |

| Aligner | No. Point | 3 * | 2 * | 1 | 2 * | 3 * | |

|---|---|---|---|---|---|---|---|

| Spark Upper | Axis | [mm] | [mm] | [mm] | [mm] | [mm] | |

| X | 0.007 | 0.008 | - | 0.033 | 0.034 | ||

| Y | 0.007 | 0.003 | - | 0.01 | 0.02 | ||

| Z | 0.005 | 0.05 | - | 0.024 | 0.027 | ||

| Spark Lower | 3 | 2 | 1 | 1 | 2 | 3 | |

| X | 0.01 | 0.002 | 0.0015 | 0.014 | 0.014 | 0.002 | |

| Y | 0.001 | 0 | 0.006 | 0.008 | 0.006 | 0.007 | |

| Z | 0.011 | 0.009 | 0.0015 | 0.021 | 0.027 | 0.03 |

| Aligner | No. Point | 3 * | 2 * | 1 | 2 * | 3 * | |

|---|---|---|---|---|---|---|---|

| Taglus Upper | Axis | [mm] | [mm] | [mm] | [mm] | [mm] | |

| X | 0.002 | 0.008 | 0.019 | 0.044 | |||

| Y | 0.005 | 0.016 | 0.01 | 0.009 | |||

| Z | 0.024 | 0.053 | 0.026 | 0.026 | |||

| Taglus Lower | 3 | 2 | 1 | 1 | 2 | 3 | |

| X | 0.002 | 0.008 | 0.002 | 0.004 | 0.009 | 0.002 | |

| Y | 0.001 | 0.01 | 0.005 | 0.006 | 0.003 | 0.007 | |

| Z | 0.01 | 0.048 | 0.017 | 0.02 | 0.018 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olteanu, N.D.; Szuhanek, C.; Rosu, S.N.; Chitariu, D.F.; Seghedin, N.; Panaite, T.; Casalean, A.; Zetu, I.N. An Assessment of the Mechanical Deformation Behavior of Three Different Clear Aligner Materials: A Digital Image Correlation Analysis. Appl. Sci. 2024, 14, 7496. https://doi.org/10.3390/app14177496

Olteanu ND, Szuhanek C, Rosu SN, Chitariu DF, Seghedin N, Panaite T, Casalean A, Zetu IN. An Assessment of the Mechanical Deformation Behavior of Three Different Clear Aligner Materials: A Digital Image Correlation Analysis. Applied Sciences. 2024; 14(17):7496. https://doi.org/10.3390/app14177496

Chicago/Turabian StyleOlteanu, Nicolae Daniel, Camelia Szuhanek, Sorana Nicoleta Rosu, Dragos Florin Chitariu, Nicolae Seghedin, Tinela Panaite, Amalia Casalean, and Irina Nicoleta Zetu. 2024. "An Assessment of the Mechanical Deformation Behavior of Three Different Clear Aligner Materials: A Digital Image Correlation Analysis" Applied Sciences 14, no. 17: 7496. https://doi.org/10.3390/app14177496

APA StyleOlteanu, N. D., Szuhanek, C., Rosu, S. N., Chitariu, D. F., Seghedin, N., Panaite, T., Casalean, A., & Zetu, I. N. (2024). An Assessment of the Mechanical Deformation Behavior of Three Different Clear Aligner Materials: A Digital Image Correlation Analysis. Applied Sciences, 14(17), 7496. https://doi.org/10.3390/app14177496