Abstract

Consumer demand for food and drink products with special nutritional properties is constantly increasing. To respond to new consumption trends, research in winemaking focuses on optimizing the technological process to increase quality while preserving the traditional character and typicality of the product. Lately, winemakers are implementing a range of physical non-thermal (ultrasound technology and cold plasma technology) and thermal (microwave treatment) processes to streamline and optimize winemaking technologies, reduce costs, speed up production, and improve sustainability. This study examines the existing literature regarding the effects of various physical approaches on the quality of wines. Scientific articles are concentrating on enhancing the extraction of phenolic compounds and other active compounds—especially those that contribute positively to wine quality. The reviewed literature only offers a limited amount of information on this subject; further investigation is required to determine the significance, applicability, and efficacy of thermal and non-thermal procedures in the wine industry.

1. Introduction

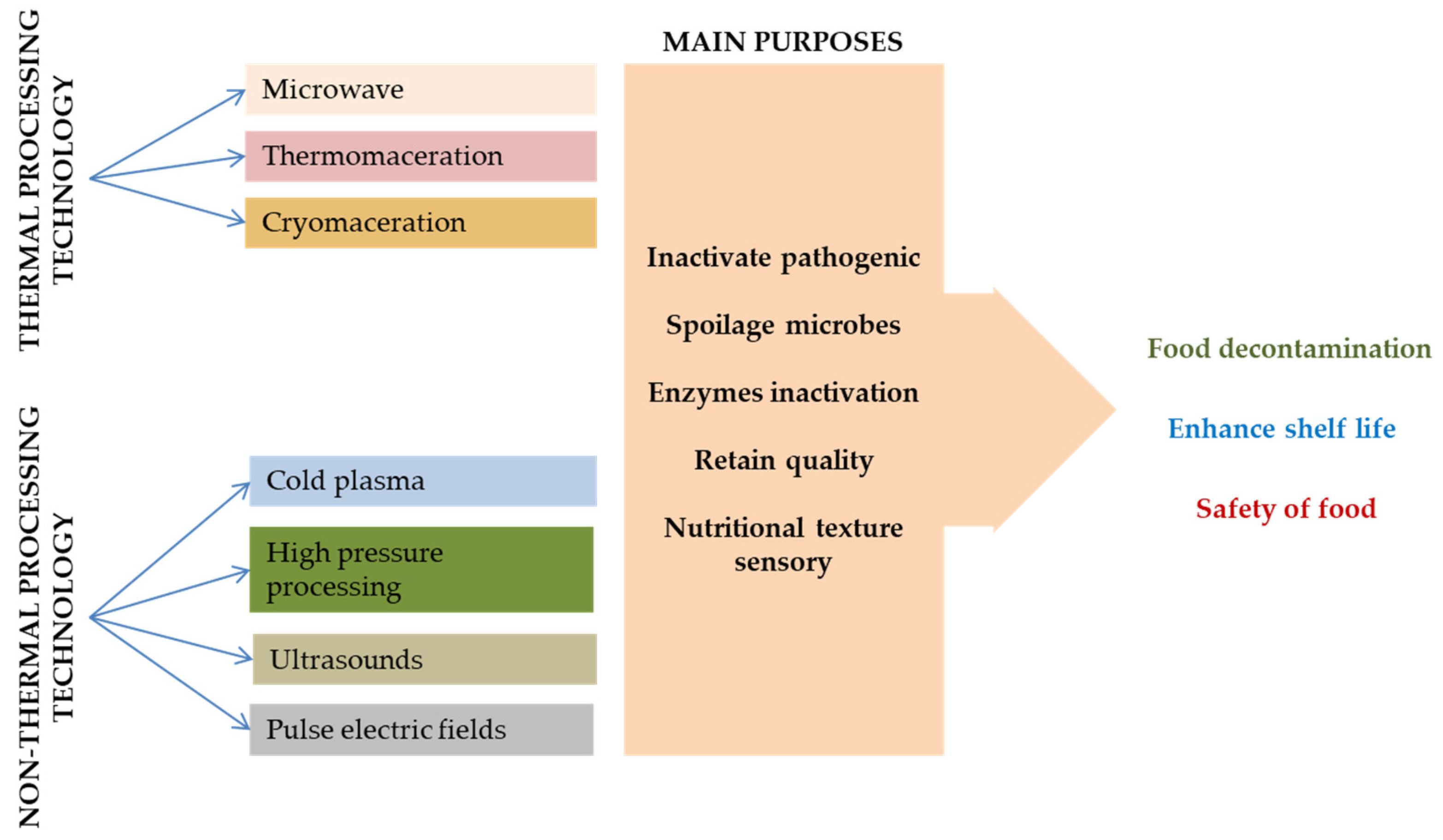

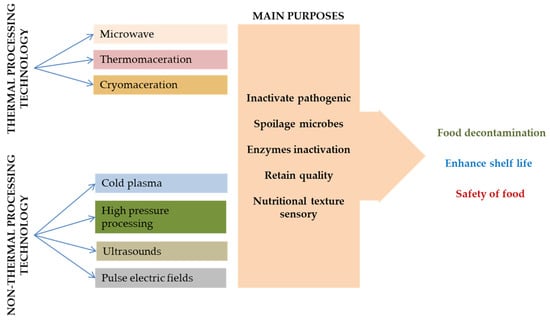

Wine’s features have been extensively investigated due to its diverse composition and health-promoting properties. Its quality depends on various factors, including cultivation techniques, raw material features, winemaking practices, and fermentation conditions [1]. Nowadays, consumers are looking for natural, safe, healthy beverages with low concentrations of external chemical substances, thereby maintaining their nutraceutical properties [2]. To meet these demands and reduce costs, winemakers are increasingly using both thermal (e.g., microwave treatment) and non-thermal (e.g., ultrasound and cold plasma technologies) processes to optimize winemaking methods [2]. Current trends focus on using these techniques in wine aging to create innovative products with complex sensory profiles that align with consumer expectations. Figure 1 illustrates the primary thermal and non-thermal procedures effectively applied in the food and beverages industry.

Figure 1.

Thermal and non-thermal physical procedures used in food and beverage processing.

Heat processing is a common treatment used in the food and beverage industry but may have unfavorable effects on the nutritional quality and physicochemical and sensory characteristics of heat-sensitive products, such as grape juice. However, microwave technology is a faster alternative that helps maintain beverage quality by acting on molecules with permanent dipoles, leading to internal cell heating and dehydration. This process improves the extraction of different primary aromas and phenolic compounds from grapes, particularly during maceration in red wine production, resulting in wines with stronger fruity and floral aromas. For example, this method achieves the swift extraction of phenolic compounds, particularly in grapes where the cellular wall tissue needs more extractive techniques to destroy its pectin structure (in American hybrids for juice like Chambourcin). Microwaves can also accelerate the aging process of wine by intensifying the extraction of components from wood (phenolic compounds, amino acids, polysaccharides, etc.) [3].

On the other side, cryomaceration involves the direct contact of the grape mash with a cryogenic gas, providing a quick and efficient cooling technique that prevents yeast proliferation, alcoholic fermentation, and the loss of volatile compounds. Pre-fermentative cryomaceration enhances the varietal character of white wine by extracting the skin aroma under controlled conditions [4,5]. Cold pre-fermentative maceration (between 4 and 10 °C) positively affects the extraction of aroma substances and phenolic compounds, thus increasing varietal aromas. Direct contact with the cryogen reduces the diffusion of atmospheric oxygen, decreasing the oxidation of phenolic and volatile compounds and affecting the color, taste, and structure of the wine. Cryomaceration equipment typically uses liquid CO2 for rapid cooling, temperature control being crucial to prevent ice formation, which can alter the physicochemical properties of wines [5].

Non-thermal practices (radiofrequency, pulsed electric fields, ultrasounds, supercritical carbon dioxide, high pressure processing, electrolyzed oxidizing water, oscillating magnetic fields, and cold plasma) can be used to partially or totally replace conventional thermal treatments [6]. Cold atmospheric plasma represents a partially ionized gas that contains an array of reactive species, including electrons, positive and negative ions, free radicals, photons, and ultraviolet photons, capable of breaking covalent bonds and initiating various chemical reactions [4]. This system can utilize different gases such as air, nitrogen, argon, or helium, either directly or indirectly (via a liquid medium), for antiseptic purposes [2]. Recently, this sustainable technique has been validated for sterilizing laboratory and biomedical devices and treating biological materials, and it even extends to food processing [7]. Atmospheric cold plasma technology shows significant potential for the microbial decontamination of fresh products, inactivation of spoilage enzymes, pesticides degradation, and modification of rheological properties. It serves as an innovative alternative to reduce nutrient loss in processed foods, impacting the overall quality of juices, wines, fruits, vegetables, and meats by affecting factors like pH, vitamin C content, antioxidant activity, and color. Cold plasma treatment is rapid, cost-effective, environmentally friendly, and can improve production techniques and plant growth without leaving chemical residues [7,8,9,10].

Pulsed electric fields have found applications in oenological processing. The treatment involves applying microsecond pulses of a high-power electric field to a sample placed between two electrodes, requiring minimal processing times. Moreover, it operates in continuous flow. Pulsed electric fields have several beneficial effects on winemaking, including the removal of pathogenic bacteria, a shorter maceration period, greater phenolic compound extraction, quicker aging, and inactivation of oxidative enzymes. Also, this technique can be used to improve the quality of wine throughout the winemaking process since they produce eukaryotic cell membrane permeabilization without drastically increasing the product’s temperature [11,12,13].

High-pressure processing is a non-thermal commercial technology that uses uniform pressures, typically ranging from 100 to 600 MPa, to inactivate undesired microbes and enzymes in food and drinks. Research shows that this treatment inactivates microorganisms in wine without affecting key parameters like alcohol content, pH, total and volatile acidity, malic acid content, lactic acid, protein stability, reducing sugars, and polyphenol oxidase activity. Approved for oenology by the OIV in 2019 (resolution OENO 594A-2019), high-pressure processing at pressures above 150 MPa can reduce microbial content, decrease SO2 concentration, and accelerate maceration [14,15,16,17].

Ultrasonic technology presents numerous benefits, including sustainability, cost-effectiveness, and rapid and efficient processes. It enhances food shelf life while preserving quality, freshness, taste, and nutritional elements without energy loss. This technology operates through mechanical waves of frequencies over 20 kHz, inducing cavitation, where collapsing bubbles release energy, increasing temperature and pressure, and potentially damaging surfaces. In the food industry, ultrasonic technology is utilized to improve processing methods such as gelation and crystallization, as well as to modify food structure and properties (e.g., polysaccharides and fats) and facilitate beneficial reactions (like glycosylation and enzymatic cross-linking). This technique is also reported to eliminate pesticides and allergens and reduce microbial contaminants in milk, fruits, and vegetables. In winemaking, ultrasounds are applied to reduce SO2 usage, accelerate the sur lie effect, enhance polysaccharide release, and improve the organoleptic properties of red wine. Additionally, sonication is tested as an artificial aging method to enhance wine quality by shortening processing time [4]. It is well known that wooden barrels can be used to obtain quality wines up to three times, but this process generates significant amounts of waste [18]. Thus, classical aging in wooden barrels is not the only option at the moment, and in recent years studies have focused on different procedures (e.g., wood fragments, ultrasound treatments) that could be applied at the industrial level. The oak species typically used for wine aging include Quercus alba (American white oak), Quercus petraea, and Quercus robur (French oak). The characteristics of the oak chips, such as species, origin, porosity, granularity, permeability, and toasting level, as well as the duration of contact, significantly influence the quality of the final product [18]. Exploring innovative techniques for wine aging has the potential to reduce traditional aging times, making wines available on the market more quickly.

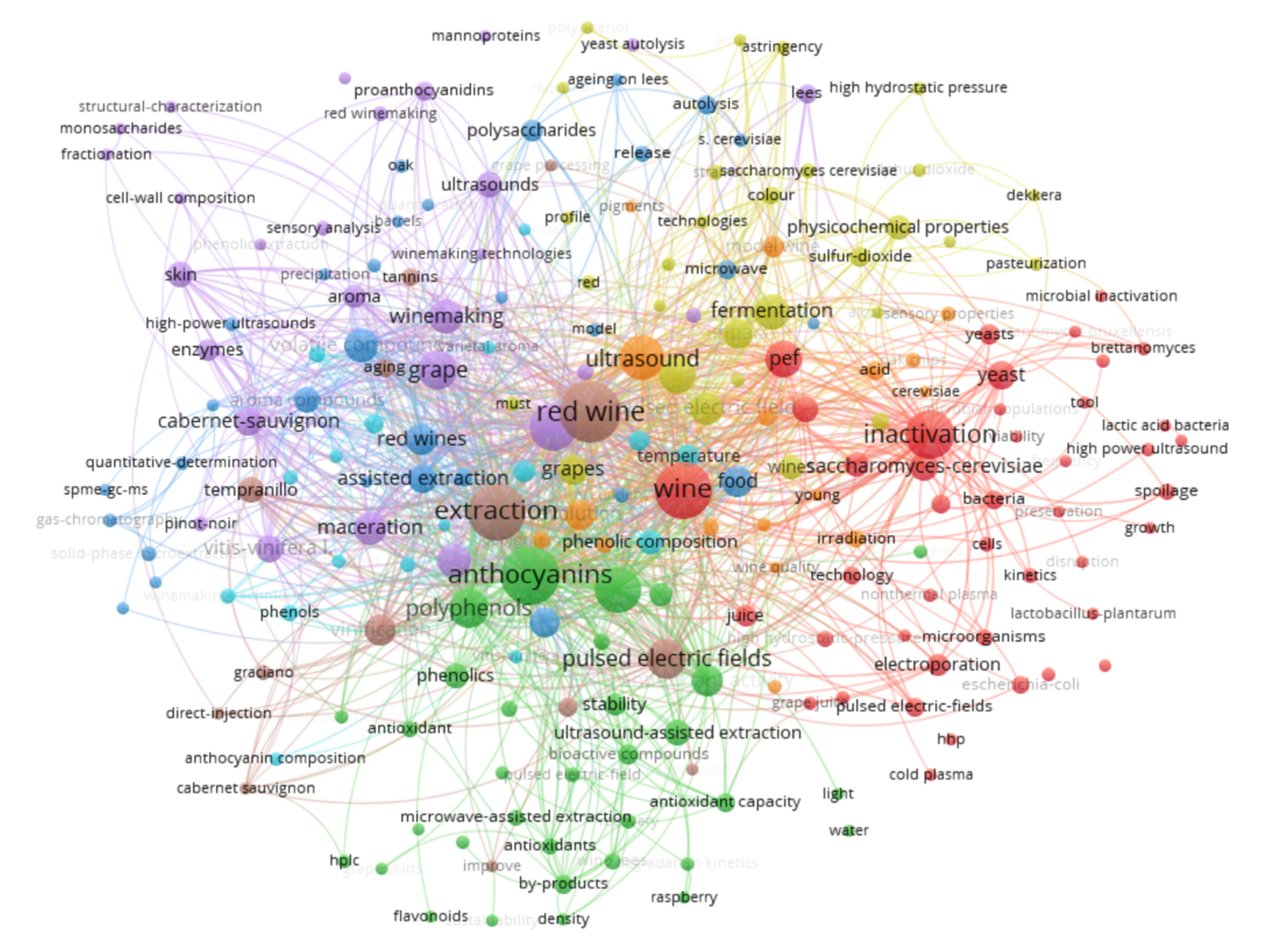

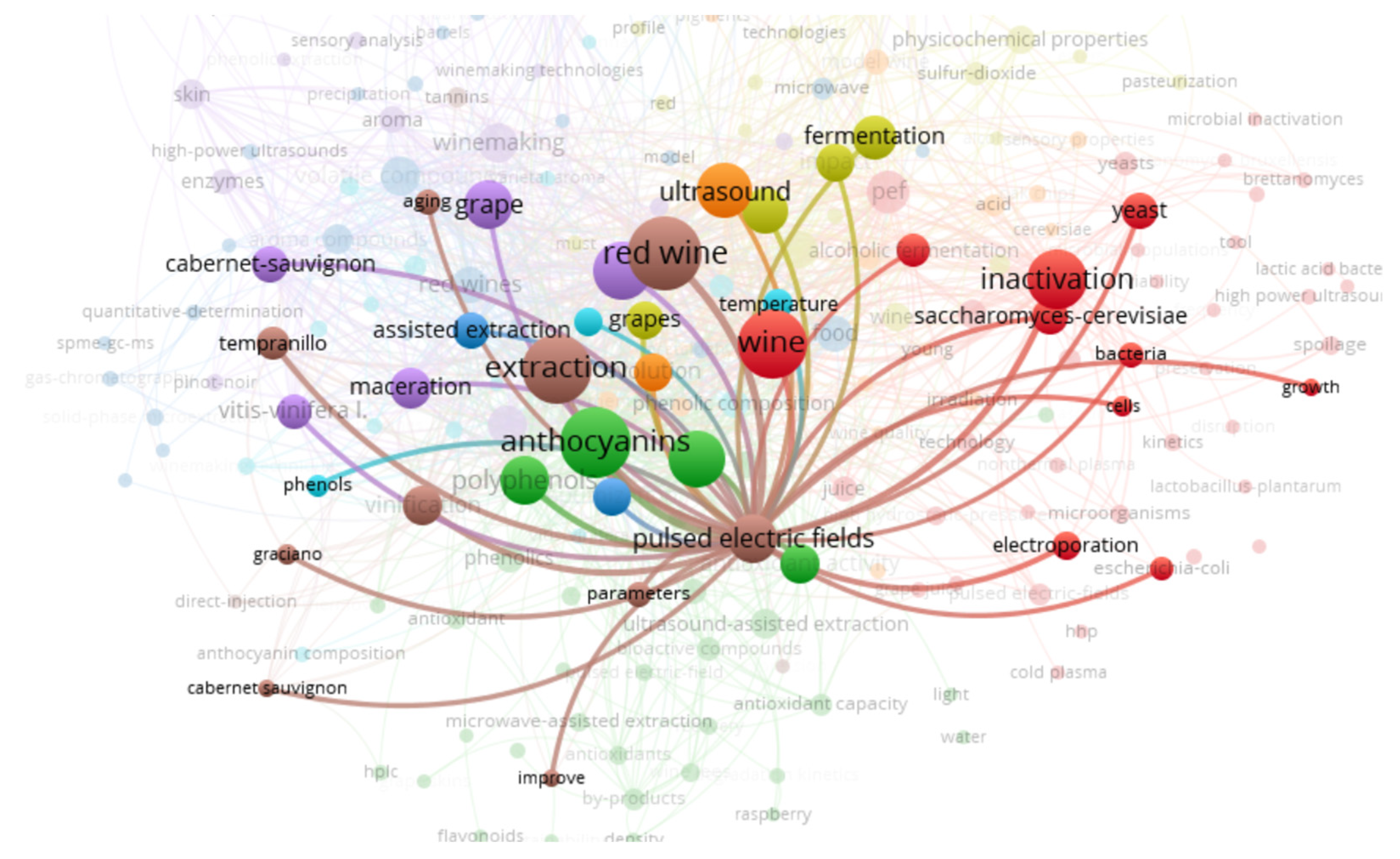

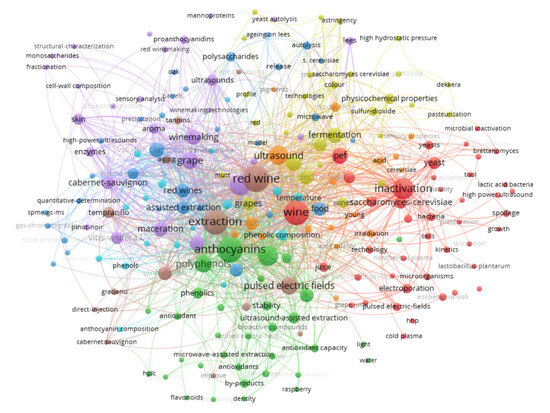

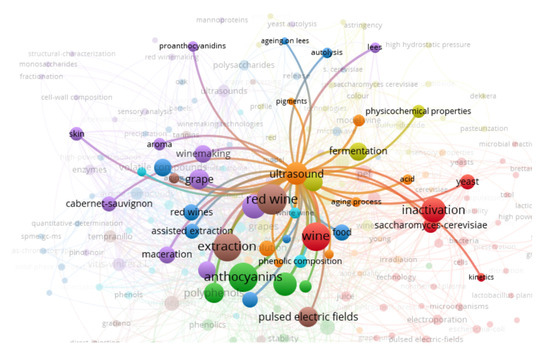

This review focuses on synthesizing publications related to the use of some thermal and non-thermal processes in winemaking. Although these optimization techniques are increasingly studied for the food industry, there are limited studies relating to their application to winemaking. Overall, 303 papers were found in the Web of Science Core Collection when searching with the following titles: ‘cold plasma in wine’ (12 papers), ‘ultrasounds in wine’ (117 papers), ‘microwaves in wine’ (36 papers), ‘cryomaceration in wine’ (17 papers), ‘high pressure processing in wine’(4 papers), ‘pulsed electric field in wine’ (117 papers). Figure 2 presents the co-occurrence of the studied subjects. Out of 1150 keywords, 211 meet the threshold of three co-occurrences. It can be observed that ultrasound and pulsed electric field treatments are the most analyzed techniques between those mentioned above, while the cold plasma procedure is less studied. In general, the existing papers are focused on phenolic compound extraction in red wine production, Cabernet Sauvignon, Tempranillo, and Pinot noir wines being predominant (Figure 3). The same set of data was used for all presented figures.

Figure 2.

Co-occurrence of the keywords found in the existing research on non-thermal and thermal physical technologies in winemaking. The size of node signifies the number of occurrences, while the distance of the linking lines characterizes the relation between two nodes. The color of the items indicates the cluster to which they belong.

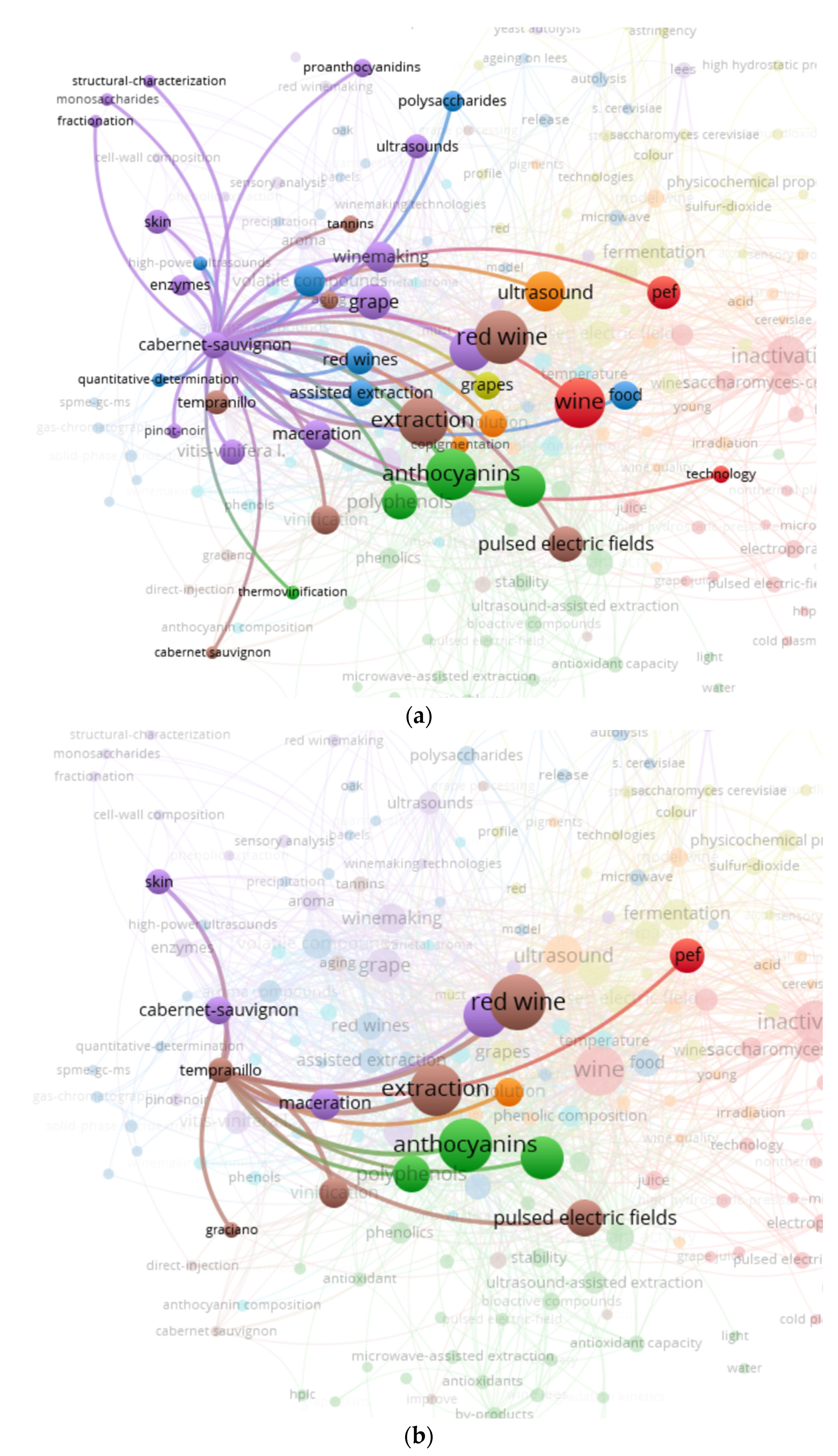

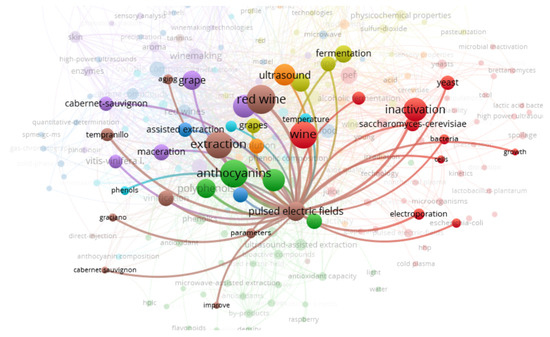

Figure 3.

Principal particularities of experimental research when Cabernet Sauvignon, Pinot noir (a), and Tempranillo (b) wines are analyzed. The size of node signifies the number of occurrences, while the distance of the linking lines characterizes the relation between two nodes. The color of the items indicates the cluster to which they belong.

According to Figure 3a, when Cabernet Sauvignon and Pinot noir were analyzed, the focus was on the evaluation of the influence of different modern extraction methods (pulsed electric fields, thermovinification, high-power ultrasounds) of phenolic compounds. Regarding the Tempranillo variety (Figure 3b), the extraction of bioactive compounds following the application of pulsed electric fields is predominant. The chromatic characteristics of the samples, correlated with the content of anthocyanin, are the most analyzed parameters.

2. The Use of Non-Thermal Techniques in Winemaking Optimization

2.1. Ultrasound Technique

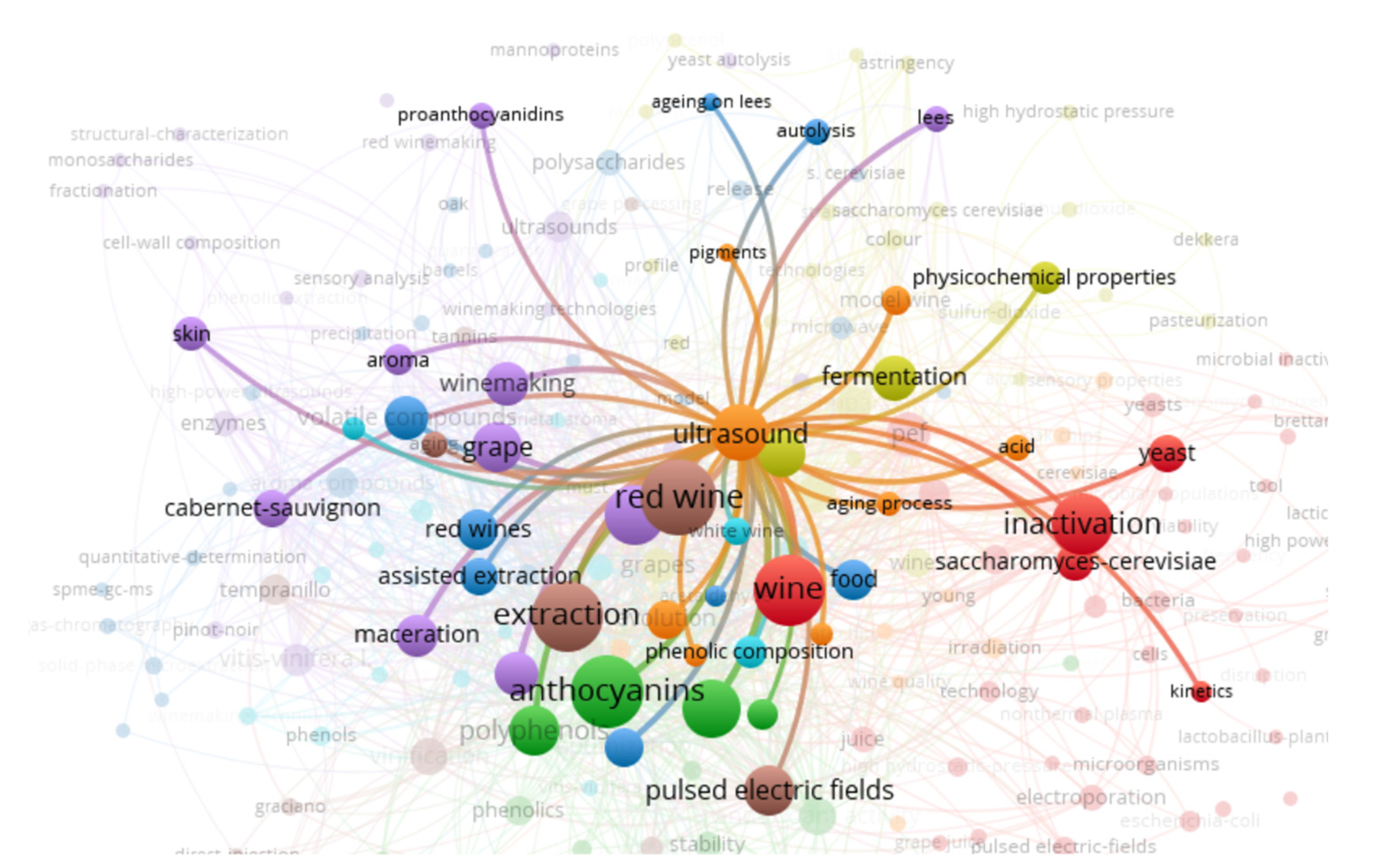

Low-intensity ultrasounds (<1 W) are commonly used to assess the physicochemical quality of food and beverages, while high-intensity treatments are applied to induce changes in their physical, microbial, and chemical attributes [19]. One major focus of the existing papers is the potential use of ultrasound technology in the aging process of wine, highlighting its effectiveness in modifying the chromatic characteristics and phenolic properties of wines [20]. In Figure 4, the frequently used keywords regarding the application of ultrasounds in wine quality are highlighted.

Figure 4.

Co-occurrence of the keywords found in the existing research on the use of ultrasounds in winemaking. The size of node signifies the number of occurrences, while the distance of the linking lines characterizes the relation between two nodes. The color of the items indicates the cluster to which they belong.

Ultrasounds have been shown to induce chemical and structural changes similar to those occurring during natural aging, thus reducing aging time [21]. Natolino & Celotti [22] highlighted that an increase in amplitude (30%, 60%, and 90%) and sonication time (2, 6, and 10 min) did not affect the initial polyphenol profile of red wines, but an increase in the polymerization of tannins was induced, accompanied by a significant reduction in astringency perception, likely attributed to structural alterations in proanthocyanidins (by acoustic cavitation).

This treatment has been effective for the microbial quality and safety of wine samples analyzed by Muñoz et al. [19], the results being dependent on different variables like time and waves intensity, but also on the microorganism’s species and strain. Brettanomyces spp. was more sensitive on ultrasounds than other species, while Lactiplantibacillus plantarum was the more resistant. It seems that ultrasound waves manifest variable effects on yeast vitality and viability.

An important impact of ultrasound maceration on the physicochemical characteristics of wine was presented by our team [23]. A lower acidity was obtained in Busuioacă de Bohotin samples treated with ultrasounds, compared with other maceration procedures like cryomaceration, microwave maceration, thermomaceration, or classical method. The authors highlighted that the chemical composition of the grapes (strongly related to the climate variables) is more important in the effectiveness of different maceration techniques, while in different years they obtained contrary results regarding the total polyphenol content. The samples obtained with ultrasounds were generally less colored [23].

Ultrasound treatment during maceration involves the production of micro bubbles due to the action of ultrasonic cavitation, and their breakdown produces several physical and thermal changes, which will ultimately accelerate the transfer of compounds from the solid parts of the fruit into the must. The results are influenced by ultrasound frequency, power, amplitude, and applied temperature. Palma et al. [24] studied the ultrasound-assisted extraction of organic acids from grapes and wine by-products using ultrasonic probes at 200 W, 24 kHz, amplitudes from 30 to 90%, and treatment times from 2 to 25 min. The authors aimed to recover acids from wine by-products, and they obtained higher concentrations of tartaric and malic acids in the analyzed samples when they applied the ultrasound treatment. Dujmic et al. [25] presented a significant improvement in the extraction rate of polyphenols in the by-products resulting from the wine industry when using ultrasound (400 W, 90% amplitude, 25 min extraction time). Also, Bautista-Ortín et al. [26] confirmed that ultrasound maceration treatment generates an enriched volatile profile, as well as higher concentrations of tannins, in a much shorter time.

Despite extensive research in this area, the translation of findings to industrial-scale operations has been limited, primarily due to the absence of scalable protocols and strategies [27].

Various in-depth investigations have shown that ultrasounds can improve the polysaccharide composition of wine while also reducing the aging period. Moreover, ultrasound shows effectiveness in facilitating many essential chemical reactions for the maturation and aging processes of fermented beverages (oxidation, esterification, and proteolysis). Additionally, ultrasounds play a significant role in enhancing the overall quality of these products by promoting favorable attributes related to texture, color, and aroma [28]. Ruiz-Rodríguez et al. [29] provided empirical evidence indicating that ultrasound treatments facilitate the extraction of volatile compounds in wines. Gracin et al. [30] suggested the use of both high-power ultrasound and thermal treatment to deactivate Brettanomyces bruxellensis in red wines, while Xie et al. [31] recorded a significant increase in antioxidant activity in wines treated with ultrasounds combined with reduced temperatures.

In our team’s previous publications [27,32], we emphasized the significant impact of ultrasound treatment as an effective alternative for reducing aging time in contact with wood chips. A notable influence on the phenolic and sensory profile of white wines was observed. Also, these results were correlated with a shorter contact time compared to conventional aging procedures. The samples treated with oak chips exhibited more intense fruity, woody, and spicy notes. The authors highlighted the significant influence of the type of oak fragment, the dosage, and the contact time on wine’s quality. Exploring innovative wine aging techniques has the potential to reduce traditional aging times, making wines available to the market more quickly. Some studies have also investigated combinations with micro-oxygenation to imitate traditional barrel-aging conditions [18].

Celotti et al. [33] evaluated the impact of ultrasound amplitude (41% and 81%) and treatment time (1, 3, and 5 min) on phenolic profile. They found that anthocyanins and phenolic compounds were not degraded with increased amplitude and sonication time, and the chromatic properties of the wines remained preserved. The study also examined the effect of amplitude and ultrasound time on the evolution of anthocyanin content and phenolic stability indices during the first thirty days of storage. The higher amplitude level (81%) led to a greater percentage decrease in tannins, with a reduction of 15% and 40% after 15 and 30 days of storage, respectively, compared to untreated wine, which did not exhibit significant changes during storage.

Tiwari et al. [20] proposed sonication as an efficient preservation method for fruit juices, particularly when high retention of anthocyanins is required. They obtained significant degradation of the main anthocyanins from wine (cyanidin-3-O-glucosides, malvanidin-3-O-glucosides, and delphinidin-3-O-glucosides). The authors postulated that the cavitation-generated hydroxyl radicals or hydrogen peroxide may participate in the breakdown of anthocyanins through ring opening and the production of chalcone structures. The intense temperature and pressure conditions experienced during sonication result in the rapid isomerization of color pigments. Ignat et al. [34] obtained twice lower values in anthocyanin content in Merlot wines obtained with ultrasound maceration (128 mg/L) comparing to maceration in rotating tanks (302.9 mg/L).

Ultrasounds have also been effective in the sterilization process when combined with other methods, such as heat treatment and the addition of sulfur dioxide [35]. Some significant findings are shown in Table 1 in order to summarize the existing studies and enable it to be clearer in establishing correlations between winemaking and practical experimental settings.

Table 1.

Key results on using ultrasound treatment in winemaking.

2.2. Cold Plasma Technology

Non-thermal procedures like cold plasma are easy to use and inexpensive. Cold plasma is usually used for the inactivation of microorganisms and oxidative enzymes in food and beverages, and it is effective in food preservation and pesticides elimination [36,37,38,39,40]. This treatment has been shown to have a minor impact on the physicochemical parameters of wine, but it leads to important changes in some chromatic parameters, such as lower hue and increased color intensity and luminosity [41]. Guo et al. [42] reported the inactivation of yeast on grapes using plasma-activated water, without presenting specific results regarding dilution of the final samples. Similar to these results, Sainz-García et al. [2] obtained wine with an intense color, lower tonality, and higher content in phenolic compounds and anthocyanins, when atmospheric pressure cold plasma was involved. Pankaj et al. [40] postulated that cold plasma influences grape juice quality through yeast inactivation and non-enzymatic browning. It also changes the total phenolic, flavonoid, and flavonol concentrations.

Niedźwiedź et al. [43] examined the impact of cold plasma as a preservation method on the physicochemical and biological properties of red wine compared to those commonly used, in accordance with International Organization of Vine and Wine regulations. Color changes were least noticeable in samples treated with combined and cold plasma methods, while traditional methods showed significant color alterations. A reduction in phenolic compounds and antioxidant activity was observed in stored samples. Cold plasma treatment resulted in less microorganisms in wine samples compared to traditional methods. The authors suggest that cold plasma in a helium or nitrogen medium may reduce the use of sulfur dioxide in winemaking.

Although cold plasma technology is being increasingly studied for the food industry, there are limited studies pertaining to its application on winemaking. The removal of pesticides and allergens is part of food and beverages safety, but the studies on these fields are just starting and there is not enough data to consider a comprehensive and detailed description of the process.

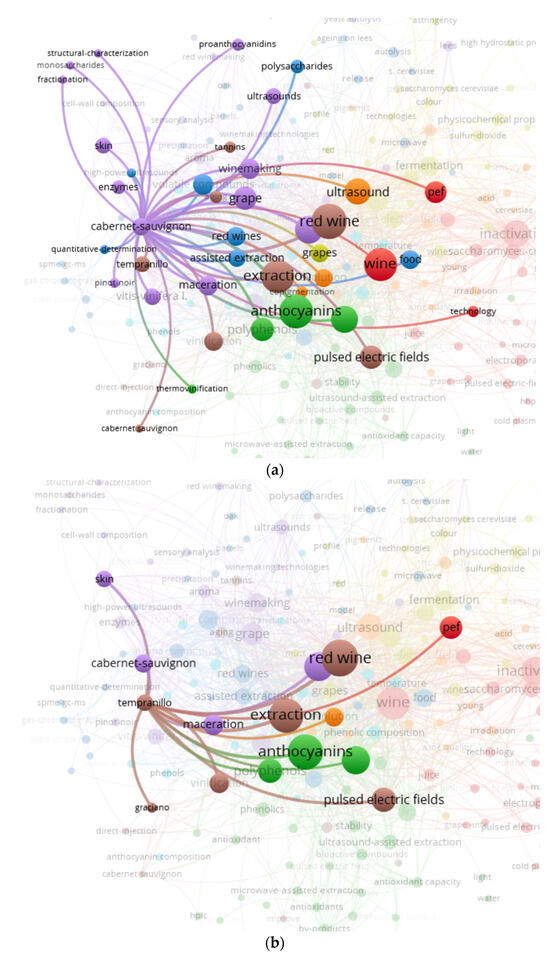

2.3. Pulse Electric Fields Treatment

Several authors have examined the pulse electric field technique to extract phenolic components from red wines (Figure 5). For example, Silva et al. [44] focused on the use of this treatment to increase must yield from Arinto (1.2 kV/cm) and Moscatel de Setúbal (1.6 kV/cm) grapes. In this sense, a flow rate of 4 tons/h was subjected to a monopolar of 100 Hz and with a 50 µs width. The color coordinates a* (green-red) and b* (blue-yellow) indicated important changes without also affecting the brightness L* of the wines obtained from the Arinto variety. The Moscatel samples showed significant variations in the chromatic parameters. Also, extraction using pulse electric fields did not affect the aroma characteristics of the wines, but some physicochemical parameters were changed, such as increasing the total phenolic content and the turbidity value. The results were influenced by the variety analyzed, thus requiring additional studies to apply pulse electric fields to other varieties as well.

Figure 5.

Co-occurrence of the keywords found in the existing research on the use of pulse electric fields in winemaking. The size of node signifies the number of occurrences, while the distance of the linking lines characterizes the relation between two nodes. The color of the items indicates the cluster to which they belong.

Toulaki et al. [45] examined the effect of pulse electric field utilization and different assortments of wood fragments in order to optimize the aging process of some red wines obtained from the Xinomavro variety. The results indicated that the use of wood fragments caused a significant increase in the concentration of polyphenols in the wines. The application of the pulse electric field treatment led to a considerable increase in the concentration of the main volatile compounds in the wine, without having the same impact on the phenolic compounds. The data were significantly influenced by the type of oak fragments but also by the chemical composition of the wine. The investigated study provides arguments for considering that the procedure is a viable option for wine aging, considerably reducing work time.

The results published by Feng et al. [12] confirmed the sterilization effects of pulse electric fields in wine, having a lethal effect on different spoilage yeasts like Saccharomyces, Zygosaccharomyces, Candida, Pichia, and Hansenula species. In the same study, the authors demonstrated that a high intensity (>15 kV/cm) of this type of treatment can favor the synthesis of various volatile components (thiols, esters, acids, etc.) in Merlot wines [9].

Puértolas et al. [46] suggested pulse electric fields as an efficient approach for improving phenolic extraction from grape skins during the maceration–fermentation process (when moderate (0.8 kV/cm) and high (5 kV/cm) intensities are used). After the application of a 13.2 kJ treatment, a major impact was registered on the sensory perception of Merlot wines produced by Evrendilek [47]. Pulse electric field-treated samples were found to have a sweeter taste and less sour aftertaste and were clearer. It was demonstrated that cold maceration combined with pulsed electric fields (moderate intensity) can improve the phenolic compound extraction in red wines [11].

Applying a treatment with a total specific energy of 22 kJ/kg allowed Comuzzo et al. [48] to obtain an enhanced extraction of varietal aroma precursors from Garganega white grapes without significantly changing the color of the wine or the concentration in phenolic compounds, apparently increasing the wine’s resistance to oxidation.

Ntourtoglou et al. [49] studied the impact of a low intensity treatment (1 kV/cm for 30 min) for increasing the extraction of phenolic and volatile (phenylethyl alcohol, n-hexadecanoic acid, 14-heptadecenal, 16-heptadecenal etc.) compounds in grape-stem extracts.

Analyzing the research that has been done, it can be shown that the indicated findings vary depending on the working conditions of the procedure, and there is no validated process in the regulations used for winemaking.

2.4. High-Pressure Processing

The impact of high-pressure processing in winemaking was poorly examined. Table 2 illustrates some of the published results that correlate the operating conditions of the work equipment with parameters assessed in accordance with the study goals. Van Wyk et al. [50] found no effect on total phenolic content, pH, color parameters, or antioxidant activity in Pinot noir and Sauvignon blanc samples. The physicochemical structure of the wine samples tested over two months of storage after a treatment that can induce >6 log reductions of Brettanomyces bruxellensis indicates that this technique represents a potential preservation strategy, according to the authors.

Sensorial-wise, authors have analyzed the development of the spoilage volatile phenols 4-ethylguaiacol and 4-ethylphenol, which give Brettanomyces off-aromas, and it was shown to be effectively inhibited by this treatment. Small dosages of SO2 could be necessary, nonetheless, in order to protect wine color and total phenolic content and improve the quality of the treated wine beyond six months of storage [51]. According to Silva & van Wyk [52], high-pressure processing has demonstrated efficacy in the pasteurization of wine by quickly inhibiting wine-spoiling yeasts and bacteria. This method can be used to stop fermentation or manage undesired microbial development through its antiseptic effect and stabilize and protect the quality of the final wine until consumption, reducing the use of SO2 at different phases of wine production. Compared to sterile filtration, this innovative method is cost-effective as sterile filters are not necessary and the possible sensorial impact on the final product is inexistent. Furthermore, the authors postulated that there is little impact on the wines’ physico-chemical and sensory character. In another study, Van Qyk & Silva [53] obtained similar results in Chardonnay wines, where 15 s at 200 MPa resulted in the inactivation of Brettanomyces bruxellensis (>6 log reduction).

Table 2.

High-pressure operating conditions correlated to wine physicochemical structure.

Table 2.

High-pressure operating conditions correlated to wine physicochemical structure.

| Intensity (MPa) | Time (min) | Temperature (°C) | Samples | Main Results | References |

|---|---|---|---|---|---|

| 500 | 5 | 4 | white wines red wines |

| [54] |

| 100–350 | 0–30 | 25 | low-alcohol red wines |

| [55] |

| 350 | 10 | 8 | red wine |

| [56] |

| 600 | 5 | - | white and red wines |

| [50] |

3. The Influence of Thermal Technologies in Wine Quality

3.1. Microwave Application

Several authors examined the impact of microwave treatment on wine parameters. Table 3 illustrates some of the published results that correlate the operating conditions of the microwave apparatus with the physicochemical parameters of wine. This treatment generated higher values in total dry extract and higher volatile acidity in the Busuioacă de Bohotin samples analyzed by Tarțian et al. [23], compared to other non-thermal techniques. Ignat et al. [34] obtained similar levels in anthocyanins content in Merlot wines when microwave maceration was compared to thermomaceration in an experimental study, but in a shorter time (15 min vs. 30 min), thus promoting reduced energy consumption. Furthermore, membrane proteins undergo conformational changes, resulting in the formation of pores in the cell wall. All of these processes promote the migration of chemicals from grape to must. The increase of phenolic compound extraction was analyzed, in comparison with classical thermomaceration. Similar to these results, Dumitriu et al. [57] obtained higher levels of total polyphenols in Fetească neagră and Băbească neagră variants treated with microwaves at the maceration stage, compared with those that underwent thermal or classical skin maceration. Georgescu et al. [58] studied the impact of classical maceration procedures (120 h) and microwave maceration (a power of 750 W at 15 vs. 30 min) on the quality of Băbească neagră wines. The treatment generated some important changes in physicochemical parameters (higher reducing sugar value, increased density, total acidity, pH and total dry extract, lower volatile acidity) compared to classical maceration methods. Regarding color parameters, a significant decrease in clarity was registered, as well as an increase of the “a*“ in the red-green coordinate, which demonstrate the efficiency of this procedure to obtain a better extraction and migration of color chemical compounds. Contrary to these results, Tudose Sandu-Ville et al. [59] showed a minor decrease of reductive sugar, density, and total acidity, but also of the total phenolic index in Cabernet Sauvignon wines, when microwave maceration was applied compared to skin maceration for 3 days at 20 °C. According to Colibaba et al. [60], microwave maceration induces significant changes in the volatile profile of Tămâioasă românească wines. Thus, an increased level of hotrienol and trans-geraniol was observed, while lower proportions were registered for linalool compared to the classical maceration procedure. According to Yuan et al. [61], microwave exposure presents a prolonged influence on wine color and phenolic compound evolution during the maturation phase. The authors postulated that utilizing microwave-assisted maceration technology could potentially reach the same results regarding wine color changes as barrel maturation. Microwaves promoted the breakdown of crushed grape cell walls, greatly increasing the concentration of polysaccharides rich in arabinose and galactose in musts. Microwave-treated samples had higher total polyphenol indexes. Microwaves generate the release of some favorable chemical components regarding wine color but, as a main disadvantage, this technique also causes sensory alteration.

Table 3.

Correlations of microwave treatment on physicochemical parameters of wine.

3.2. Pre-Fermentative Low Temperature Treatments

Authors have also shown that low temperature treatments (cryomaceration and cold soak maceration) influence the concentration of different volatile compounds (geraniol, linalool, nerol, α-terpinene) and manifest a significant impact on wine sensory profile [23]. Mihnea et al. [66] postulated that lower levels of some volatile compounds (lactones, benzaldehyde) are obtained when cryomaceration is involved, compared with classical methods.

Kechagia et al. [67] obtained higher concentrations of terpenes when cryomaceration was used. Also, Colibaba et al. [60] promoted this technique for elevating the concentrations of esters in Tămâioasă românească wines.

Tudose Sandu-Ville et al. [59] demonstrated a significant reduction in delphinidin 3-glucoside, cyanidin-3-glucoside, petunidin-3-glucoside, peonidin-3-glucoside, peonidin-3-glucoside acetate, peonidin-3-glucoside coumarin, and malvidin-3-glucoside coumarin, but a twofold increase in malvidin-3-glucoside levels in Merlot wines obtained with this technique. On the other hand, the authors observed elevated concentrations of malvidin-3-glucoside, peonidin-3-glucoside acetate, and malvidin-3-glucoside in Fetească neagră wines. Moreover, Tarțian et al. [23] highlighted a significant improvement of chromatic properties (increased clarity—a positive factor in the case of rosé wine) of Busuioacă de Bohotin wines when cryomaceration is used in comparison with classical maceration. Cryomaceration presents minor influences (a small increase in acidity and dry extract, reduced total sugars, density) regarding the physicochemical parameters of Cabernet Sauvignon wines obtained by Tudose Sandu-Ville et al. [59]. It was found that prolonged contact with grape skins (12, 18, and 24 h) at low temperatures (5 and 10 °C) significantly increased the levels of phenolics in wines, such as caffeic acid. It was also found that the wines visually had an unaltered commercial appearance [5,68,69].

4. Key Results and Considerations

Numerous studies have examined the composition of wine (physicochemical parameters, phenolic and volatile compounds extraction, color modification, sensory properties, etc.) correlated with process optimization (reducing the maturation time, minimum costs, increased quality). Ultrasound and pulse electric field treatments are the most analyzed techniques, while the cold plasma procedure is less studied in winemaking. In general, the existing papers are focused on phenolic compound extraction in red wine production, Cabernet Sauvignon, Pinot noir, and Tempranillo wines being predominant. Also, the chromatic characteristics of the samples, correlated with the content of anthocyanin, are the most analyzed parameters. The paper discusses six innovative techniques (ultrasounds, high pressure processing, pulse electric fields, cold plasma, microwave, and cryomaceration) and their applications in winemaking. Ultrasound technology has shown promise in accelerating wine aging by simulating natural aging processes, influencing polyphenol profiles, and enhancing microbial quality. Investigating novel methods for wine maturation holds promise for shortening conventional aging durations, thus expediting the availability of wines on the market. Pulse electric field technology has been utilized in wine production to provide better color, texture, taste, and preservation of nutritional content by non-thermally inactivating microorganisms, as opposed to traditional thermal processing methods. This treatment seems to be an effective alternative to increase the extraction yield and to enhance the proportion of bioactive compounds in the must. High-pressure processing in winemaking, in combination with low proportions of sulfur dioxide, can be effective in managing unwanted microbial growth, stabilizing and protecting the final quality of the wine. This treatment may also be effective for inhibiting volatile phenols such as 4-ethylguaiacol and 4-ethylphenol. Cold plasma treatment, known for its ability to inactivate microorganisms and oxidative enzymes, presents potential benefits for improving wine quality and safety, although research in winemaking remains limited. Microwave technology has been studied for its effects on various wine parameters, including volatile compounds, anthocyanins, and polyphenols, showing potential as an alternative method in winemaking. Cryomaceration, a cold maceration technique, has been found to enhance the concentration of volatile compounds and improve sensory profiles, although with variable effects on anthocyanin levels and physicochemical parameters. Depending on the specific goals, a combination of thermal and non-thermal technologies may be employed to achieve desired results while maintaining the quality and stability of the wine. Overall, these innovative techniques offer opportunities for optimizing winemaking processes and improving wine quality, but most of the studies reported their results at a pilot-scale. To be applied on an industrial level, further research is needed to fully understand their effects and applications.

Author Contributions

Conceptualization, C.E.L. and L.C.C.; methodology, C.E.L.; software, E.C.S.; investigation, C.E.L. and I.M.; resources, V.V.C.; writing—original draft preparation, E.C.S.; writing—review and editing, C.E.L.; visualization, E.C.S. and L.C.C.; supervision, C.E.L. and V.V.C.; funding acquisition, V.V.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Iași University of Life Sciences.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aneja, K.R.; Dhiman, R.; Aggarwal, N.K.; Kumar, V.; Kaur, M. Microbes associated with freshly prepared juices of citrus and carrots. Int. J. Food Sci. 2014, 2014, 408085. [Google Scholar] [CrossRef]

- Sainz-García, E.; López-Alfaro, I.; Múgica-Vidal, R.; López, R.; Escribano-Viana, R.; Portu, J.; Alba-Elías, F.; González-Arenzana, L. Effect of the atmospheric pressure cold plasma treatment on Tempranillo red wine quality in batch and flow systems. Beverages 2019, 5, 50. [Google Scholar] [CrossRef]

- Muñoz García, R.; Oliver-Simancas, R.; Arévalo-Villena, M.; Martínez-Lapuente, L.; Ayestarán, B.; Marchante-Cuevas, L.; Díaz-Maroto, M.C.; Pérez-Coello, M.S. Use of microwave maceration in red winemaking: Effect on fermentation and chemical composition of red wines. Molecules 2022, 27, 3018. [Google Scholar] [CrossRef] [PubMed]

- Natrella, G.; Noviello, M.; Trani, A.; Faccia, M.; Gambacorta, G. The effect of ultrasound treatment in winemaking on the volatile compounds of Aglianico, Nero di Troia, and Primitivo red wines. Foods 2023, 12, 648. [Google Scholar] [CrossRef]

- Naviglio, D.; Formato, A.; Scaglione, G.; Montesano, D.; Pellegrino, A.; Villecco, F.; Gallo, M. Study of the grape cryo-maceration process at different temperatures. Foods 2018, 7, 107. [Google Scholar] [CrossRef] [PubMed]

- Saremnezhad, S.; Soltani, M.; Faraji, A.; Hayaloglu, A.A. Chemical changes of food constituents during cold plasma processing: A review. Food Res. Int. 2021, 147, 110552. [Google Scholar] [CrossRef]

- Lin, Y.; Pangloli, P.; Meng, X.; Dia, V.P. Effect of heating on the digestibility of isolated hempseed (Cannabis sativa L.) protein and bioactivity of its pepsin-pancreatin digests. Food Chem. 2020, 314, 126198. [Google Scholar] [CrossRef]

- Thirumdas, R. Exploitation of cold plasma technology for enhancement of seed germination. ARTOAJ 2018, 13, 25–29. [Google Scholar] [CrossRef]

- Bermudez-Aguirre, D. Advances in Cold Plasma Applications for Food Safety and Preservation, 1st ed.; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Kumar, Y.; Marangon, M.; Marangon, C.M. The application of non-thermal technologies for wine processing, preservation, and quality enhancement. Beverages 2023, 9, 30. [Google Scholar] [CrossRef]

- Ozturk, B.; Anli, E. Pulsed electric fields (PEF) applications on wine production: A review. Bio Web Conf. 2017, 9, 02008. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, T.; Zhang, Y.; Zhang, A.; Gai, L.; Niu, D. Potential applications of pulsed electric field in the fermented wine industry. Front. Nutr. 2022, 9, 1048632. [Google Scholar] [CrossRef] [PubMed]

- Ricci, A.; Parpinello, G.; Versari, A. Recent advances and applications of pulsed electric fields (PEF) to improve polyphenol extraction and color release during red winemaking. Beverages 2018, 4, 18. [Google Scholar] [CrossRef]

- Shahbaz, H.M.; Kim, J.U.; Kim, S.; Park, J. Advances in nonthermal processing technologies for enhanced microbiological safety and quality of fresh fruit and juice products. In Handbook of Food Bioengineering, Food Processing for Increased Quality and Consumption; Academic Press: Cambridge, MA, USA, 2018; pp. 179–217. [Google Scholar] [CrossRef]

- Lisanti, M.T.; Blaiotta, G.; Nioi, C.; Moio, L. Alternative methods to SO2 for microbiological stabilization of wine. CRFSFS 2019, 18, 455–479. [Google Scholar] [CrossRef]

- Lukić, K.; Brnčić, M.; Ćurko, N.; Tomašević, M.; Tušek, A.J.; Ganić, K.K. Quality characteristics of white wine: The short- and long-term impact of high power ultrasound processing. Ultrason. Sonochem. 2020, 68, 105194. [Google Scholar] [CrossRef]

- OIV. International Code of Oenological Practices; OIV: Paris, France, 2022. [Google Scholar]

- Bozalongo, R.; Carillo, J.D.; Torroba, M.A.F.; Tena, M.T. Analysis of French and American oak chips with different toasting degrees by headspace solid-phase microextraction-gas chromatography-mass spectrometry. J. Chromatogr. A 2017, 1173, 10–17. [Google Scholar] [CrossRef]

- Muñoz, R.; Viveros, N.; Bevilacqua, A.; Pérez, M.S.V.; Arévalo-Villena, M. Effects of ultrasound treatments on wine microorganisms. Ultrason. Sonochem. 2021, 79, 105775. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Patras, A.; Brunton, N.P.; Cullen, P.J.; O’Donnell, C.P. Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason. Sonochem. 2010, 17, 598–604. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, R.; Ratchaneesiripap, P. An ultrasound-assisted extraction system to accelerate production of Mhiskey, a rice spirit-based product, inside oak barrel: Total phenolics, color, and energy consumption. J. Food Process Eng. 2021, 45, e13861. [Google Scholar] [CrossRef]

- Natolino, A.; Celotti, E. Ultrasound treatment of red wine: Effect on polyphenols, mathematical modeling, and scale-up considerations. LWT 2022, 154, 112843. [Google Scholar] [CrossRef]

- Tarțian, A.C.; Cotea, V.V.; Niculaua, M.; Zamfir, C.I.; Colibaba, C.L.; Moroșanu, A.M. The influence of the different techniques of maceration on the aromatic and phenolic profile of the Busuioaca de Bohotin wine. Bio Web Conf. 2017, 9, 02032. [Google Scholar] [CrossRef]

- Palma, M.; Barroso, C.G. Ultrasound-assisted extraction and determination of tartaric and malic acids from grapes and winemaking by-products. Anal. Chim. Acta 2002, 458, 119–130. [Google Scholar] [CrossRef]

- Dujmic, F.; Gani, K.K.; Uri, D.; Karlovi, S.; Bosiljkov, T.; Jeek, D.; Vidrih, R.; Hribar, J.; Zlati, E.; Prusina, T. Non-thermal ultrasonic extraction of polyphenolic compounds from red wine lees. Foods 2020, 9, 472. [Google Scholar] [CrossRef]

- Bautista-Ortín, A.B.; Jiménez-Martínez, M.D.; Jurado, R.; Iniesta, J.A.; Terrades, S.; Andrés, A.; Gomez-Plaza, E. Application of high-power ultrasounds during red wine vinification. Int. J. Food Sci. Technol. 2017, 52, 1314–1323. [Google Scholar] [CrossRef]

- Luchian, C.E.; Focea, E.C.; Scutarașu, E.C.; Motrescu, I.; Vlase, A.M.; Vlase, L.; Colibaba, L.C.; Cotea, V. Oak aging and ultrasound treatment for improving the sensory profile of Sauvignon Blanc wines. In Recent Advances in Technology Research and Education; Ono, Y., Kondoh, J., Eds.; LNNS; Inter-Academia: 2023; Springer: Berlin/Heidelberg, Germany, 2024; volume 939, pp. 104–121. [Google Scholar] [CrossRef]

- Mărgean, A.; Pădureanu, V. The influence of ultrasound treatment on must fermentation process. Bull. Transilv. Univ. 2018, 11, 127–132. [Google Scholar]

- Ruiz-Rodríguez, A.; Carrera, C.; Palma, M.; Barroso, C.G. Ultrasonic treatments during the alcoholic fermentation of red wines: Effects on “Syrah” wines. Vitis: J. Grapevine Res. 2019, 58, 83–88. [Google Scholar] [CrossRef]

- Gracin, L.; Križanović, S.; Jambrak, A.R.; Tomašević, M.; Kelšin, K.; Lukić, K.; Ganić, K.K. Monitoring the influence of high power ultrasound treatment and thermosonication on inactivation of Brettanomyces bruxellensis in red wine. Croat. J. Food Technol. Biotechnol. Nutr. 2017, 12, 107–112. [Google Scholar]

- Xie, Q.; Tang, Y.; Wu, X.; Luo, Q.; Zhang, W.; Liu, H.; Fang, Y.; Ju, Y. Combined ultrasound and low temperature pretreatment improve the content of anthocyanins, phenols and volatile substance of Merlot red wine. Ultrason. Sonochem. 2023, 100, 106636. [Google Scholar] [CrossRef] [PubMed]

- Focea, E.C.; Luchian, C.E.; Colibaba, L.C.; Scutarașu, E.C.; Popîrdă, A.; Focea, M.C.; Niculaua, M.; Cotea, V. Application of ultrasounds to improve oak aging of white wines. Bio Web Conf. 2022, 56, 02021. [Google Scholar] [CrossRef]

- Celotti, E.; Stante, S.; Ferraretto, P.; Román, T.; Nicolini, G.; Natolino, A. High power ultrasound treatments of red young wines: Effect on anthocyanins and phenolic stability indices. Foods 2020, 9, 1344. [Google Scholar] [CrossRef]

- Ignat, G.; Balan, G.; Sandu, I.; Costuleanu, C.L.; Tudose Sandu-Ville, Ș. Study of phenolic compounds in Merlot red wines obtained by different technologies. Rev. Chim. 2016, 64, 1560–1565. [Google Scholar]

- Zhang, Q.; Zheng, H.; Lin, J.; Nie, G.; Fan, X.; García-Martin, J.F. The state-of-art research of the application of ultrasound to winemaking: A critical review. Ultrason. Sonochem. 2023, 95, 106384. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, J.; Yang, Y.; Guo, L.; Zhang, C. Degradation of organophosphorus pesticide induced by oxygen plasma: Effects of operating parameters and reaction mechanisms. Chemosphere 2010, 81, 408–414. [Google Scholar] [CrossRef]

- Reddy, M.K.; Mahammadunnisa, S.; Subrahmanyam, C. Catalytic non-thermal plasma reactor for mineralization of endosulfan in aqueous medium: A green approach for the treatment of pesticide contaminated water. Chem. Eng. J. 2014, 238, 157–163. [Google Scholar] [CrossRef]

- Toyokawa, Y.; Yagyu, Y.; Yamashiro, R.; Ninomya, K. Roller conveyer system for the reduction of pesticides using non-thermal gas plasma—A potential food safety control measure? Food Control 2018, 87, 211–217. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, S.; Dang, J.; Wang, S.; Liu, Z.; Fang, J.; Han, P.; Zhang, J. Reduction of phoxim pesticide residues from grapes by atmospheric pressure non-thermal air plasma activated water. J. Hazard. Mater. 2019, 377, 98–105. [Google Scholar] [CrossRef]

- Pankaj, S.K.; Keener, K.M. Cold plasma: Background, applications and current trends. Curr. Opin. Food Sci. 2017, 16, 49–52. [Google Scholar] [CrossRef]

- Huzum, R.; Nastuta, A.V. Helium atmospheric pressure plasma jet source treatment of white grapes juice for winemaking. Appl. Sci. 2021, 11, 8498. [Google Scholar] [CrossRef]

- Guo, J.; Huang, K.; Wang, X.; Lyu, C.; Yang, N.; Li, Y.; Wang, J. Inactivation of yeast on grapes by plasma-activated water and its effects on quality attributes. J. Food Prot. 2017, 80, 225–230. [Google Scholar] [CrossRef] [PubMed]

- Niedźwiedź, I.; Simeonov, V.; Waśko, A.; Polak-Berecka, M. Comparison of the effect of cold plasma with conventional preservation methods on red wine quality using chemometrics analysis. Molecules 2022, 27, 7048. [Google Scholar] [CrossRef]

- Silva, F.V.M.; Borgo, R.; Guanziroli, A.; Ricardo-Da-Silva, J.M.; Aguiar-Macedo, M.; Redondo, L.M. Pilot Scale Continuous Pulsed Electric Fields Treatments for Vinification and Stabilization of Arinto and Moscatel Graúdo (Vitis vinifera L.) White Grape Varieties: Effects on Sensory and Physico-Chemical Quality of Wines. Beverages 2024, 10, 6. [Google Scholar] [CrossRef]

- Toulaki, A.K.; Athanasiadis, V.; Chatzimitakos, T.; Kalompatsios, D.; Bozinou, E.; Roufas, K.; Mantanis, G.I.; Dourtoglou, V.G.; Lalas, S.I. Investigation of Xinomavro red wine aging with various wood chips using pulsed electric field. Beverages 2024, 10, 13. [Google Scholar] [CrossRef]

- Puértolas, E.; López, N.; Condón, S.; Álvarez, I.; Raso, J. Potential applications of PEF to improve red wine quality. Trends Food Sci. Technol. 2010, 21, 247–255. [Google Scholar] [CrossRef]

- Evrendilek, G.A. Pulsed electric field processing of red wine: Effect on wine quality and microbial inactivation. Beverages 2022, 8, 78. [Google Scholar] [CrossRef]

- Comuzzo, P.; Marconi, M.; Zanella, G.; Querzè, M. Pulsed electric field processing of white grapes (cv. Garganega): Effects on wine composition and volatile compounds. Food Chem. 2018, 264, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Ntourtoglou, G.; Drosou, F.; Chatzimitakos, T.; Athanasiadis, V.; Bozinou, E.; Dourtoglou, V.G.; Elhakem, A.; Sami, R.; Ashour, A.A.; Shafie, A.; et al. Combination of pulsed electric field and ultrasound in the extraction of polyphenols and volatile compounds from grape stems. Appl. Sci. 2022, 12, 6219. [Google Scholar] [CrossRef]

- Van Wyk, S.; Hong, L.; Silva, F.V.M. Non-thermal high pressure processing, pulsed electric fields and ultrasound preservation of five different table wines. Beverages 2021, 7, 69. [Google Scholar] [CrossRef]

- Van Wyk, S.; Farid, M.M.; Silva, F.V. SO2, high pressure processing and pulsed electric field treatments of red wine: Effect on sensory, Brettanomyces inactivation and other quality parameters during one year storage. Innov. Food Sci. Emerg. Technol. 2018, 48, 204–211. [Google Scholar] [CrossRef]

- Silva, F.V.M.; Van Wyk, S. Emerging Non-Thermal technologies as alternative to SO2 for the production of wine. Foods 2021, 10, 2175. [Google Scholar] [CrossRef]

- Van Wyk, S.; Silva, F.V. High pressure inactivation of Brettanomyces bruxellensis in red wine. Food Microbiol. 2017, 63, 199–204. [Google Scholar] [CrossRef]

- Santos, M.C.; Nunes, C.; Saraiva, J.A.; Coimbra, M.A. Chemical and physical methodologies for the replacement/reduction of sulfur dioxide use during winemaking: Review of their potentialities and limitations. Eur. Food Res. Technol. 2012, 234, 1–12. [Google Scholar] [CrossRef]

- Mok, C.; Song, K.-T.; Park, Y.-S.; Lim, S.; Ruan, R.; Chen, P. High hydrostatic pressure pasteurization of red wine. J. Food Sci. 2006, 71, M265–M269. [Google Scholar] [CrossRef]

- Christofi, S.; Malliaris, D.; Katsaros, G.; Panagou, E.; Kallithraka, S. Limit SO2 Content of wines by applying high hydrostatic pressure. Innov. Food Sci. Emerg. Technol. 2020, 62, 102342. [Google Scholar] [CrossRef]

- Dumitriu, D.; Cotea, V.; Moraru, I.; Niculaua, M.; Nechita, C.B.; Colibaba, C.; Vararu, F. Comparative study on the influence of macerations technology on the red wines phenolic compound. J. Hortic. USAMV Iași 2013, 56, 325–330. [Google Scholar]

- Georgescu, O.; Cotea, V.; Zamfir, C.; Colibaba, C.; Gherghină, N.; Moraru, I. Comparative study of red Băbească neagră wines from Nicoreşti vineyard obtained through classical technology of maceration fermentation and through innovative maceration technologies. J. Hortic. USAMV Iași 2010, 53, 431–436. [Google Scholar]

- Tudose Sandu-Ville, Ș.; Cotea, V.V.; Colibaba, C.; Buburuzanu, C.; Georgescu, O.; Niculaua, M. Study of phenolic compounds in Cabernet Sauvignon red wines obtained in Iaşi vineyard by six different maceration-fermentation techniques. J. Hortic. USAMV Iași 2010, 53, 63–69. [Google Scholar]

- Colibaba, L.C.; Cotea, V.V.; Nechita, B.; Lăcureanu, G.; Tudose Sandu-Ville, Ș. Studies on the influence of maceration techniques on Tămâioasă românească wine’s free terpenic compounds. J. Hortic. USAMV Iași 2010, 53, 359–364. [Google Scholar]

- Yuan, J.F.; Lai, Y.T.; Chen, Z.Y.; Song, H.X.; Zhang, J.; Wang, D.H.; Gong, M.G.; Sun, J.R. Microwave irradiation: Effects on the change of colour characteristics and main phenolic compounds of Cabernet Gernischt dry red wine during storage. Foods 2022, 11, 1778. [Google Scholar] [CrossRef] [PubMed]

- Carew, A.L.; Sparrow, A.M.; Curtin, C.D.; Close, D.C.; Dambergs, R.G. Microwave maceration of Pinot noir grape must: Sanitation and extraction effects and wine phenolics outcomes. Food Bioprocess Technol. 2014, 7, 954–963. [Google Scholar] [CrossRef]

- Casassa, L.; Sari, S.; Bolcato, E.; Fanzone, M. Microwave-assisted extraction applied to merlot grapes with contrasting maturity levels: Effects on phenolic chemistry and wine color. Fermentation 2019, 5, 15. [Google Scholar] [CrossRef]

- Pérez-Porras, P.; Gómez-Plaza, E.; Muñoz García, R.; Díaz-Maroto, M.C.; Moreno-Olivares, J.D.; Bautista-Ortín, A.B. Prefermentative grape microwave treatment as a tool for increasing red wine phenolic content and reduce maceration time. Appl. Sci. 2022, 12, 8164. [Google Scholar] [CrossRef]

- Yuan, J.F.; Wang, T.T.; Chen, Z.Y.; Wang, D.H.; Gong, M.G.; Li, P.Y. Microwave irradiation: Impacts on physicochemical properties of red wine. CyTA J. Food 2020, 18, 281–290. [Google Scholar] [CrossRef]

- Mihnea, M.; José, M.L.G.S.; Velasco-López, M.T.; Rivero-Pérez, M.D.; Ortega-Herás, M.; Pérez-Magariño, S. Effect of pre-fermentative strategies on the composition of Prieto Picudo (Vitis vinifera) red wines. OAlib 2016, 3, e3197. [Google Scholar] [CrossRef]

- Kechagia, D.; Paraskevopoulos, Y.; Symeou, E.; Galiotou-Panayotou, M.; Kotseridis, Y. Influence of prefermentative treatments to the major volatile compounds of Assyrtiko wines. J. Agric. Food Chem. 2008, 56, 4555–4563. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, B.; Wang, Y.; Lu, L.; Lan, Y.; Reeves, M.J.; Duan, C. Influence of pre-fermentation cold maceration treatment on aroma compounds of Cabernet Sauvignon wines fermented in different industrial scale fermenters. Food Chem. 2014, 154, 217–229. [Google Scholar] [CrossRef]

- Gómez-Míguez, M.J.; González-Miret, M.L.; Hernanz, D.; Fernández, M.Á.; Vicario, I.M.; Heredia, F.J. Effects of prefermentative skin contact conditions on colour and phenolic content of white wines. J. Food Eng. 2007, 78, 238–245. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).