Decision Tree Regression vs. Gradient Boosting Regressor Models for the Prediction of Hygroscopic Properties of Borassus Fruit Fiber

Abstract

Featured Application

Abstract

1. Introduction

1.1. Background

1.2. Challenges

1.3. Literature Review

1.4. Focus of the Study and Statement of Originality

- Theoretical contributions:

- The study introduces BNF as a potential engineering material, expanding the scope of natural fiber research, and it comprehensively studies its hygroscopic properties using Dynamic Vapor Sorption (DVS).

- The creation, application, and comparison of GBR and DTR models for predicting hygroscopic properties based on primary and small-size experimental data.

- Practical contributions:

- Eco-friendly extraction of Borassus fruit fibres and their identification as potential sustainable materials for construction application.

- Creation of a valuable dataset for future research and informative model comparison for selecting appropriate models in similar cases.

- Application of practical tools for BNF characterization and product development.

2. Materials and Methods

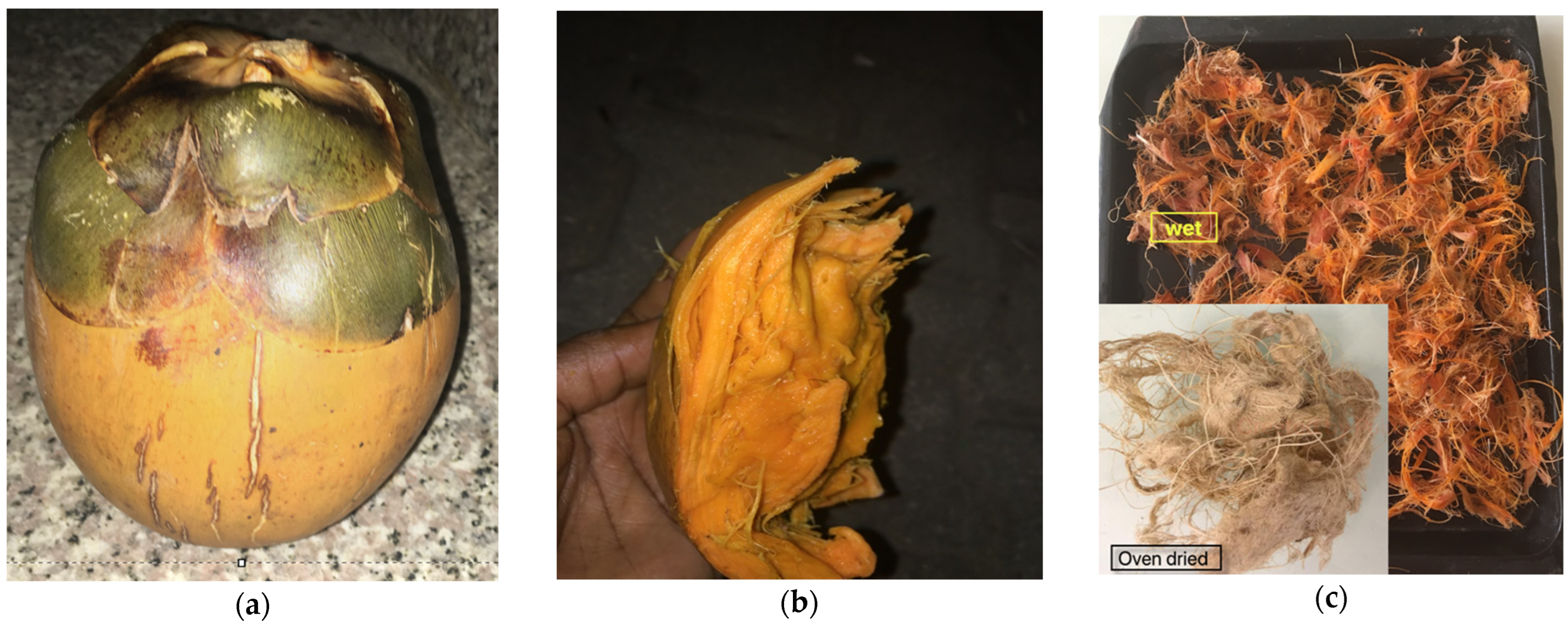

2.1. Extraction of Fiber

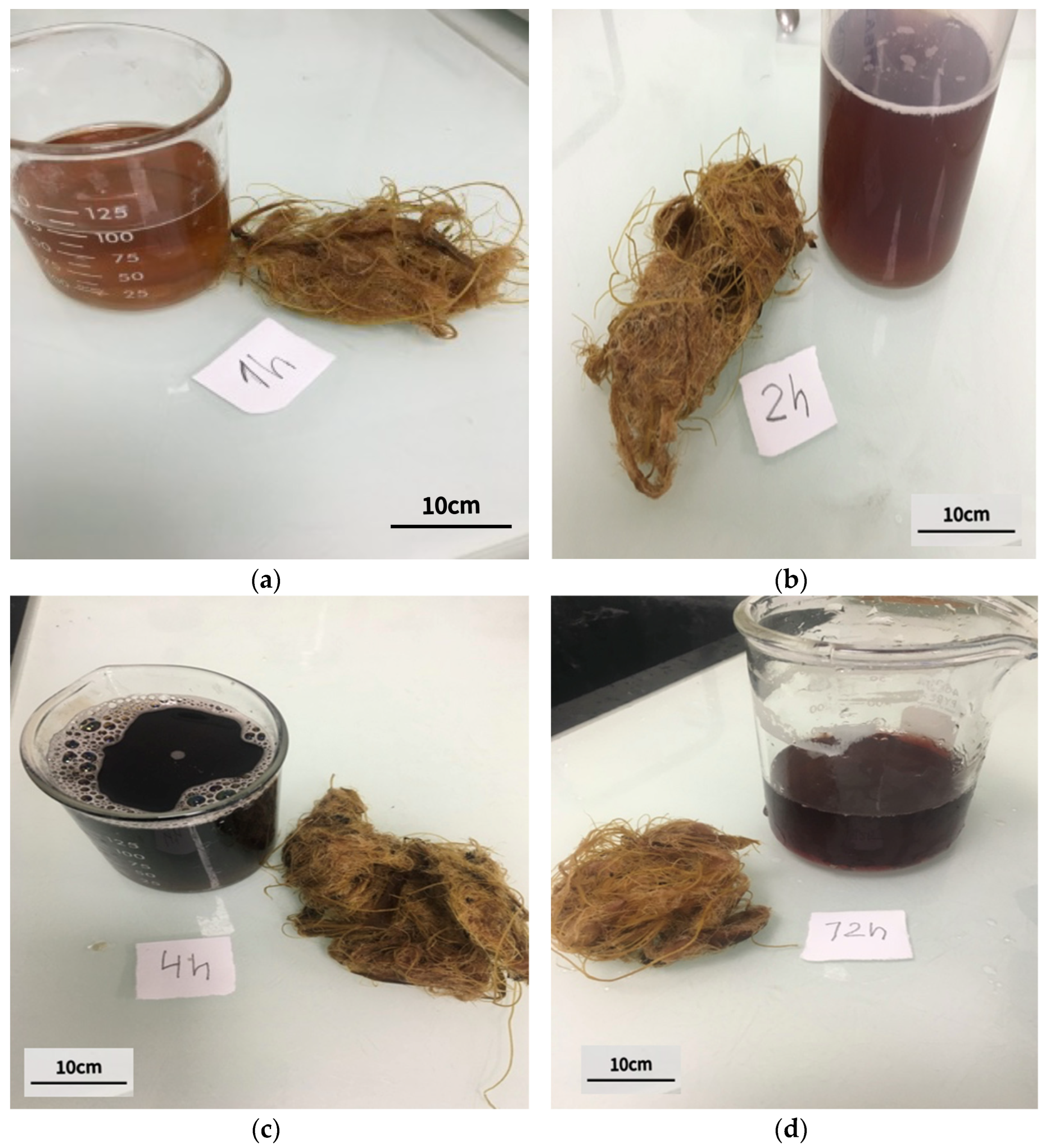

2.2. Chemical Treatment

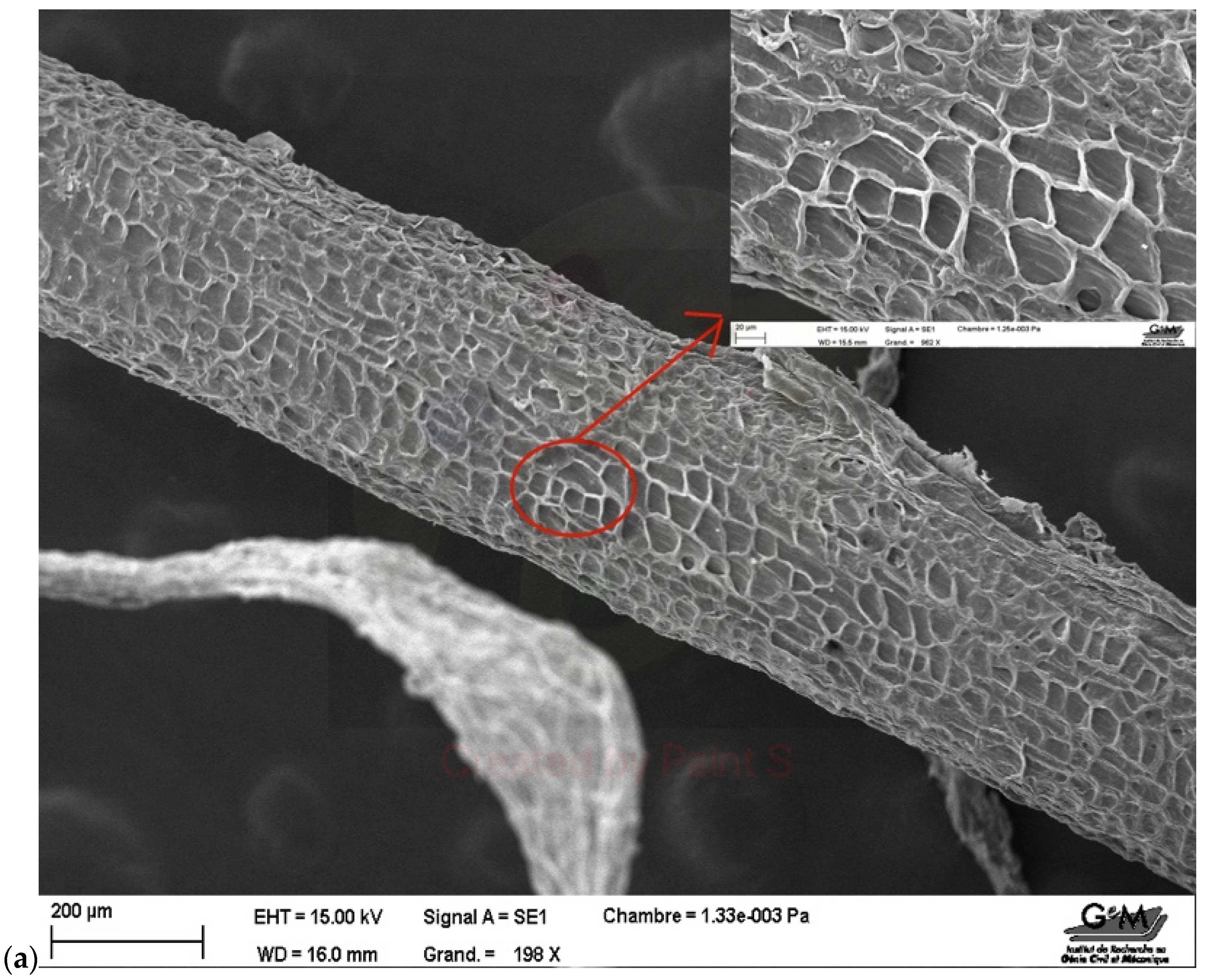

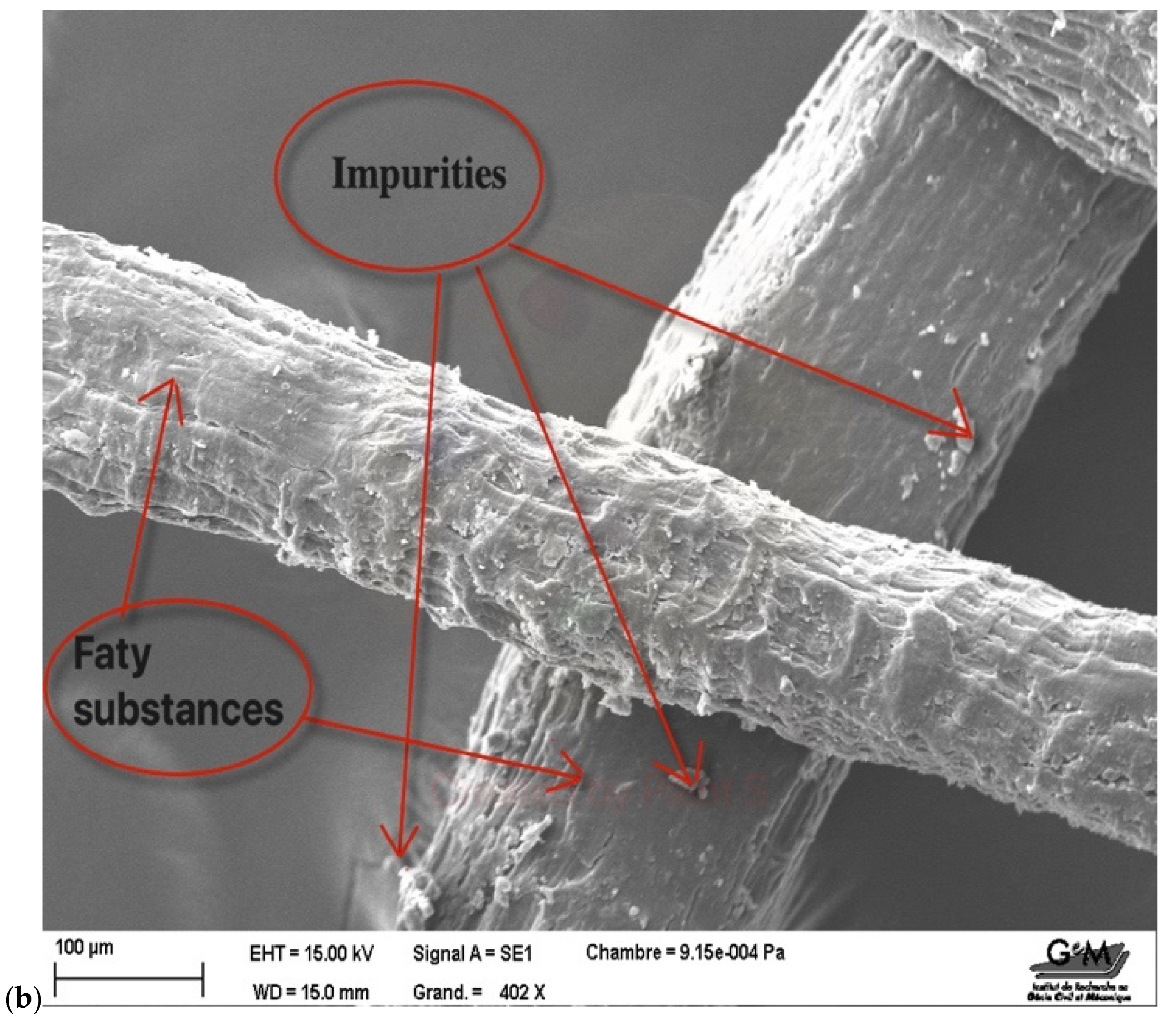

2.3. Physical and Morphological Properties

2.4. Hygroscopic Behavior (Sorption–Desorption)

2.5. Machine-Learning Models

2.5.1. Decision Tree Regression (DTR)

- •

- T.build(X_train, y_train)

- ○

- Recursively split nodes:

- ▪

- Find the best feature f using a splitting criterion (e.g., Giniimpurity, information gain)

- ▪

- Split node into child nodes based on f

- ○

- Stop splitting when criteria met

- •

- ŷ = T.predict(x)

- •

- Metrics on X_test

2.5.2. Gradient Boosting Regressor (GBR)

- •

- ŷ0 = initial model prediction (e.g., average target value)

- •

- M = ensemble of weak learners

- •

- For m = 1 to M:

- ○

- Calculate residuals: ri = yi − ŷi−1

- ○

- Train weak learner hm(x) on (X, r)

- ○

- Update ensemble: ŷi = ŷi−1 + α * hm(xi)

- •

- ŷ = Σ[αm * hm(x)]

- •

- Metrics on X_test

2.5.3. Evaluation Metrics

2.5.4. Framework for Experiments

3. Results and Discussions

3.1. Effect of the Alkaline Treatment on the Fibers’ Morphology and Microstructure

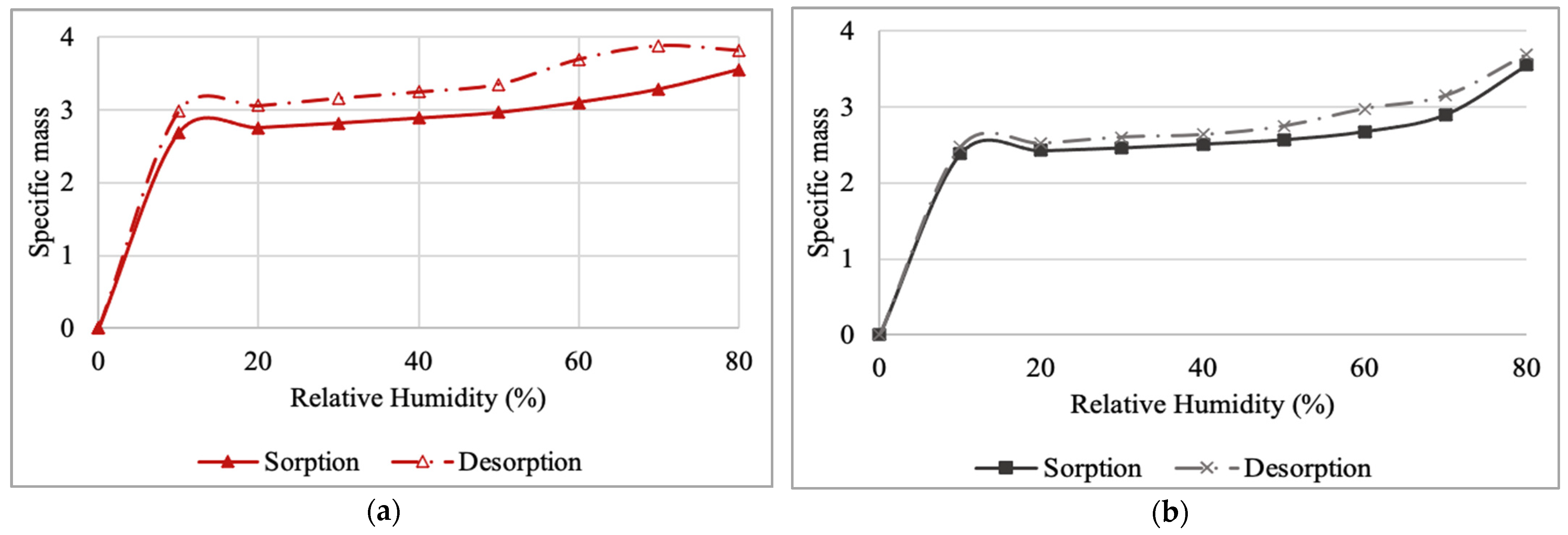

3.2. Sorption–Desorption Characteristics

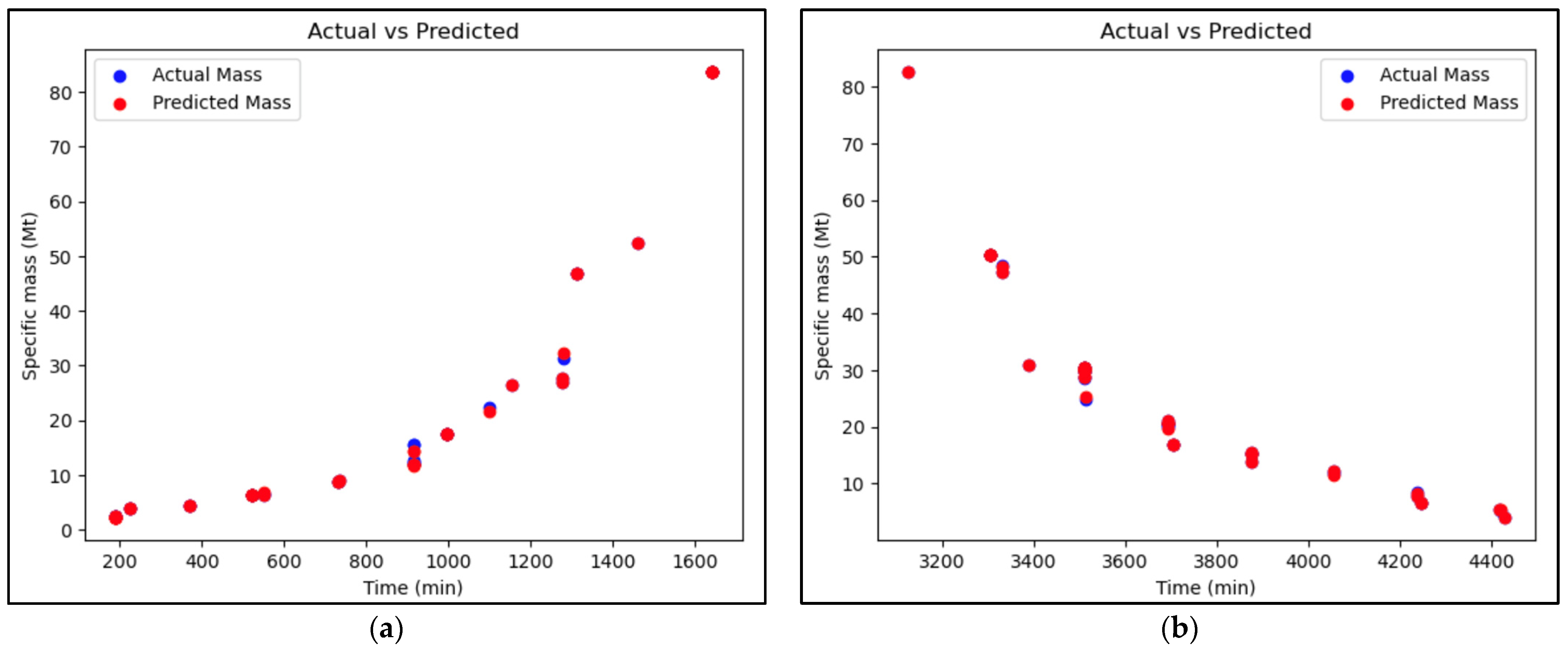

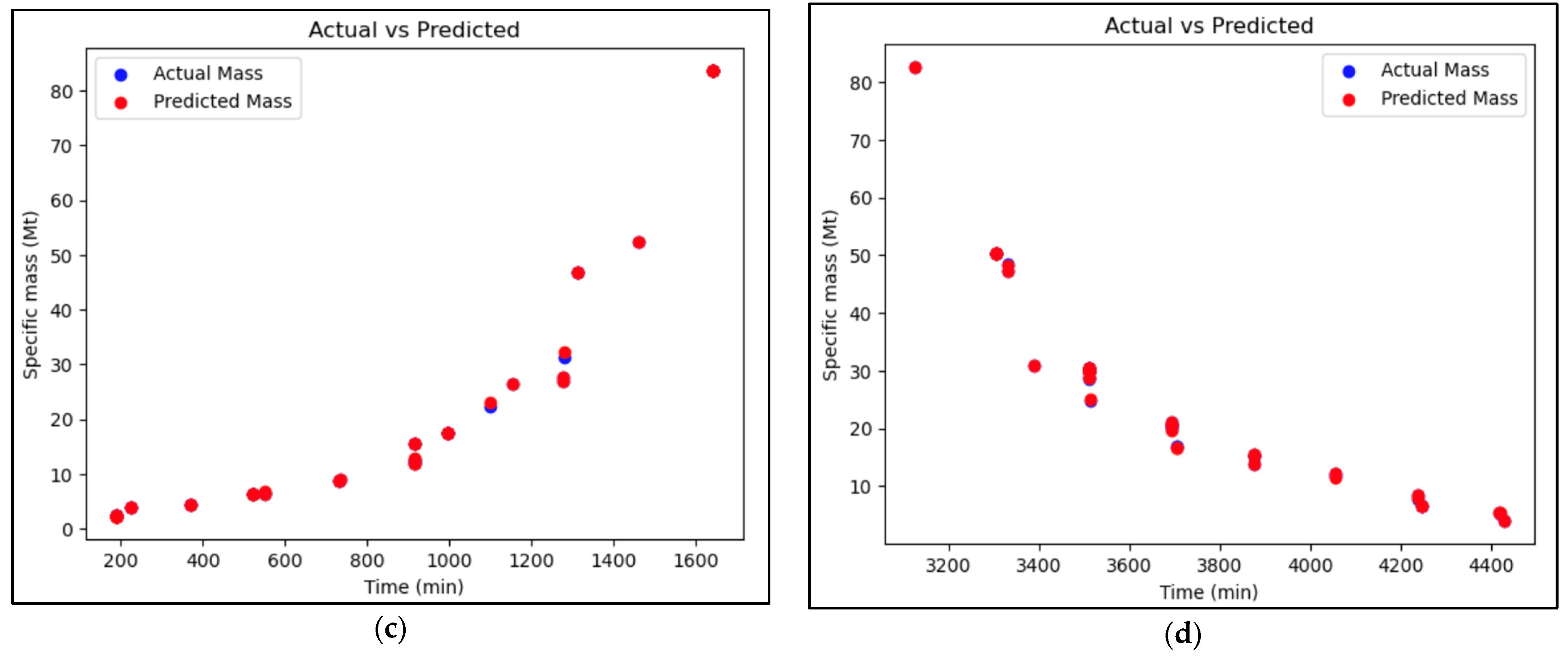

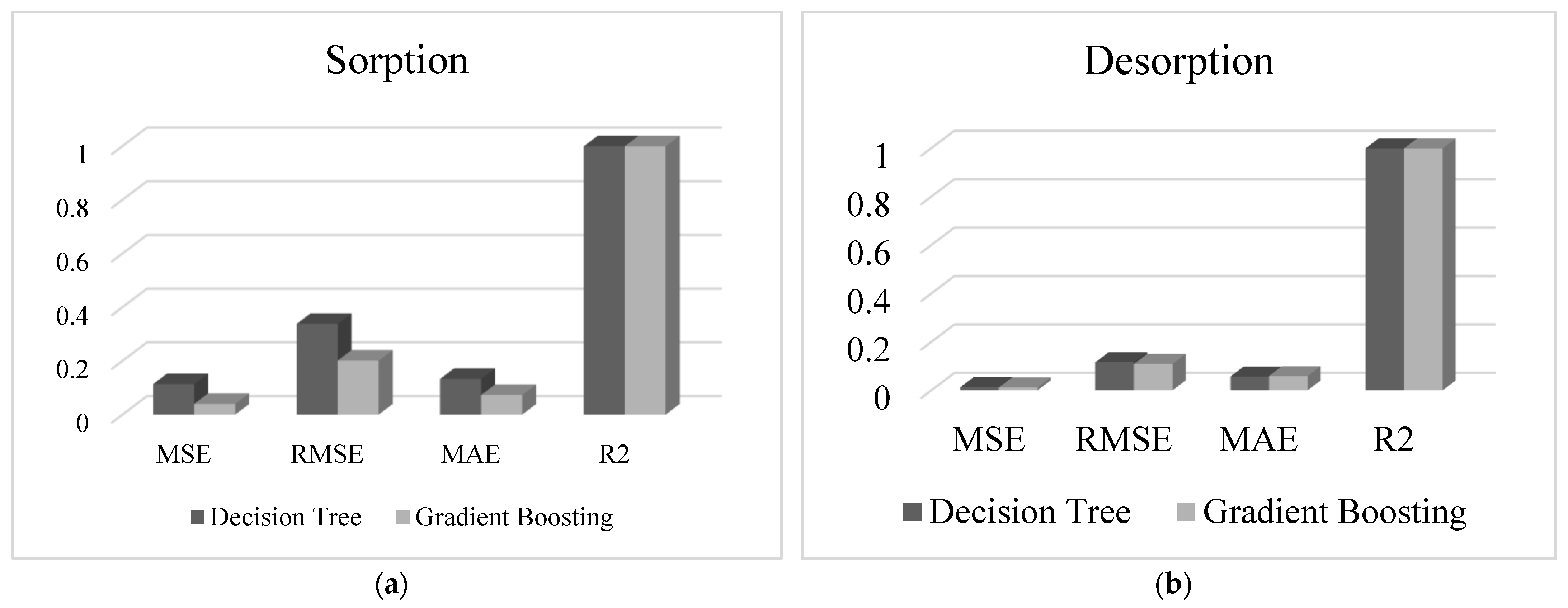

3.3. Comparative Assessment of DTR and GBR during the Forecasting Process

4. Practical and Theoretical Implications with Examples to Enhance Decision-Making

5. Conclusions

- Borassus fruit fibers exhibit hysteresis in moisture absorption and desorption, influenced by their cellular structure.

- Alkaline treatment alters fiber morphology, leading to increased porosity and a more uniform diameter.

- GBR and DTR models accurately predict the hygroscopic properties of both treated and untreated fibers.

- GBR outperforms DTR in terms of model-fit metrics (R2, MSE, RMSE, and MAE)

- Practical Applications: The developed models can be used to optimize the production and application of Borassus fruit-based materials, leading to improved product performance and reduced costs.

- Research Advancement: The findings provide a foundation for further research into the relationship between fiber structure, chemical treatment, and hygroscopic behavior.

- Industry Impact: The study offers a potential alternative to traditional, time-consuming methods for characterizing fiber properties, contributing to the development of more sustainable and cost-effective materials.

6. Possible Directions for Future Studies

- The manual extraction of fibers may introduce inconsistencies in fiber purity and damage the fiber structure.

- Data variability as natural fibers exhibit variable intrinsic properties

- The ML models may not be optimal for all types of fibers and experimental data.

- Expanding the characterization of Borassus fruit fiber to include mechanical properties, thermal properties, and chemical composition.

- Developing scalable and efficient extraction processes for large-scale fiber production.

- Enhancing the predictive capabilities of the models by incorporating more data and exploring other machine-learning techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahamat, A.A.; Bih, N.L.; Ayeni, O.; Onwualu, P.A.; Savastano, H.; Soboyejo, W.O. Development of Sustainable and Eco-Friendly Materials from Termite Hill Soil Stabilized with Cement for Low-Cost Housing in Chad. Buildings 2021, 11, 86. [Google Scholar] [CrossRef]

- Reddy, K.O.; Guduri, B.R.; Rajulu, A.V. Structural characterization and tensile properties of Borassus fruit fibers. J. Appl. Polym. Sci. 2009, 114, 603–611. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Leklou, N.; Obianyo, I.I.; Poullain, P.; Stanislas, T.T.; Ayeni, O.; Bih, N.L.; Savastano, H. Assessment of hygrothermal and mechanical performance of alkali activated Borassus fiber reinforced earth-based bio-composite. J. Build. Eng. 2022, 62, 105411. [Google Scholar] [CrossRef]

- Reddy, K.O.; Shukla, M.; Maheswari, C.U.; Rajulu, A.V. Mechanical and physical characterization of sodium hydroxide treated Borassus fruit fibers. J. For. Res. 2012, 23, 667–674. [Google Scholar] [CrossRef]

- Sudhakara, P.; Reddy, K.O.; Prasad, C.V.; Jagadeesh, D.; Kim, H.; Kim, B.; Bae, S.; Song, J. Studies on Borassus fruit fiber and its composites with Polypropylene. Compos. Res. 2013, 26, 48–53. [Google Scholar] [CrossRef]

- Megalingam, A.; Kumar, M.; Sriram, B.; Jeevanantham, K.; Vishnu, P.R. Borassus fruit fiber reinforced composite: A review. Mater. Today Proc. 2021, 45, 723–728. [Google Scholar] [CrossRef]

- Morton, J. Notes on Distribution, Propagation, and Products of Borassus Palms (Arecaceae). Econ. Bot. 1988, 3, 420–441. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Dayyabu, A.; Sanusi, A.; Ado, M.; Obianyo, I.I.; Stanislas, T.T.; Bih, N.L. Dimensionnal stability and strength appraisal of termite hill soil stabilisation using hybrid bio-waste and cement for eco-friendly housing. Heliyon 2022, 8, e09406. [Google Scholar] [CrossRef]

- Farahani, G.N.; Ahmad, I.; Mosadeghzad, Z. Effect of Fiber Content, Fiber Length and Alkali Treatment on Properties of Kenaf Fiber/UPR Composites Based on Recycled PET Wastes. Polym. Technol. Eng. 2012, 51, 634–639. [Google Scholar] [CrossRef]

- Kubat, M. An Introduction to Machine Learning; Springer Nature: Dordrecht, The Netherlands, 2017. [Google Scholar]

- Weber, M.; Borcherding, K. Behavioral influences on weight judgments in multiattribute decision making. Eur. J. Oper. Res. 1993, 67, 1–12. [Google Scholar] [CrossRef]

- AlKhereibi, A.H.; Wakjira, T.G.; Kucukvar, M.; Onat, N.C. Predictive Machine Learning Algorithms for Metro Ridership Based on Urban Land Use Policies in Support of Transit-Oriented Development. Sustainability 2023, 15, 1718. [Google Scholar] [CrossRef]

- Pamučar, D.; Stević, Ž.; Sremac, S. A New Model for Determining Weight Coefficients of Criteria in MCDM Models: Full Consistency Method (FUCOM). Symmetry 2018, 10, 393. [Google Scholar] [CrossRef]

- Sabziparvar, A.; Boulos, L.; Foruzanmehr, M.R. Effect of fiber length and treatments on the hygroscopic properties of milkweed fibers for superabsorbent applications. Environ. Technol. Innov. 2022, 28, 102930. [Google Scholar] [CrossRef]

- Obianyo, I.I.; Onwualu, A.P.; Mahamat, A.A. Evaluation of Predictive Models for Mechanical Properties of Earth-Based Composites for Sustainable Building Applications. In New Advances in Soft Computing in Civil Engineering, AI-Based Optimization and Prediction; Bekdaş, G., Nigdeli, S.M., Eds.; in Studies in Systems, Decision and Control; Springer Nature: Cham, Switzerland, 2024; Volume 547, pp. 179–190. [Google Scholar] [CrossRef]

- Célino, A.; Fréour, S.; Jacquemin, F.; Casari, P. The hygroscopic behavior of plant fibers: A review. Front. Chem. 2014, 1, 43. [Google Scholar] [CrossRef]

- El Hachem, Z.; Célino, A.; Challita, G.; Moya, M.-J.; Fréour, S. Hygroscopic multi-scale behavior of polypropylene matrix reinforced with flax fibers. Ind. Crop. Prod. 2019, 140, 111634. [Google Scholar] [CrossRef]

- Obianyo, I.I.; Auta, J.T.; Sciacca, D.; Mahamat, A.A.; Kelechi, S.E.; Onwualu, A.P. Machine learning models for predicting the compressive strength of agro-waste stabilized bricks for sustainable buildings. Discov. Civ. Eng. 2024, 1, 45. [Google Scholar] [CrossRef]

- Gadagi, A.; Sivaprakash, B.; Adake, C.; Deshannavar, U.; Hegde, P.G.; Santhosh, P.; Osman, A.I. Epoxy composite reinforced with jute/basalt hybrid—Characterisation and performance evaluation using machine learning techniques. Compos. Part C Open Access 2024, 14, 100453. [Google Scholar] [CrossRef]

- Lee, S.; Vo, T.P.; Thai, H.-T.; Lee, J.; Patel, V. Strength prediction of concrete-filled steel tubular columns using Categorical Gradient Boosting algorithm. Eng. Struct. 2021, 238, 112109. [Google Scholar] [CrossRef]

- Ma, H.; Liu, J.; Zhang, J.; Huang, J. Estimating the Compressive Strength of Cement-Based Materials with Mining Waste Using Support Vector Machine, Decision Tree, and Random Forest Models. Adv. Civ. Eng. 2021, 2021, 6629466. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A.; Guettala, S.; Kriker, A. Mechanical properties and hygroscopicity behavior of compressed earth block filled by date palm fibers. Constr. Build. Mater. 2014, 59, 161–168. [Google Scholar] [CrossRef]

- Stanislas, T.T.; Komadja, G.C.; Obianyo, I.I.; Ayeni, O.; Mahamat, A.A.; Tendo, J.F.; Junior, H.S. Multivariate regression approaches to predict the flexural performance of cellulose fibre reinforced extruded earth bricks for sustainable buildings. Clean. Mater. 2023, 7. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Boukar, M.M.; Ibrahim, N.M.; Stanislas, T.T.; Bih, N.L.; Obianyo, I.I.; Savastano, H. Machine Learning Approaches for Prediction of the Compressive Strength of Alkali Activated Termite Mound Soil. Appl. Sci. 2021, 11, 4754. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, C.; Deng, D. Content Estimation of Foreign Fibers in Cotton Based on Deep Learning. Electronics 2020, 9, 1795. [Google Scholar] [CrossRef]

- Neo, P.K.; Leong, Y.W.; Soon, M.F.; Goh, Q.S.; Thumsorn, S.; Ito, H. Development of a Machine Learning Model to Predict the Color of Extruded Thermoplastic Resins. Polymers 2024, 16, 481. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Kumar, S.; Pal, R.; Singh, M.K.; Saini, D. Graph- and Machine-Learning-Based Texture Classification. Electronics 2023, 12, 4626. [Google Scholar] [CrossRef]

- Pawlak, T.; Pilarska, A.A.; Przybył, K.; Stangierski, J.; Ryniecki, A.; Cais-Sokolińska, D.; Pilarski, K.; Peplińska, B. Application of Machine Learning Using Color and Texture Analysis to Recognize Microwave Vacuum Puffed Pork Snacks. Appl. Sci. 2022, 12, 5071. [Google Scholar] [CrossRef]

- Alam, S.; Sultana, N.; Hossain, S.Z. Bayesian optimization algorithm based support vector regression analysis for estimation of shear capacity of FRP reinforced concrete members. Appl. Soft Comput. 2021, 105, 107281. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Boukar, M.M.; Leklou, N.; Obianyo, I.I.; Stanislas, T.T.; Bih, N.L.; Ayeni, O.; Ibrahim, N.M.; Savastano, H. A Machine Learning Led Investigation Predicting the Thermos-mechanical Properties of Novel Waste-based Composite in Construction. Waste Biomass Valorization 2024, 15, 5445–5461. [Google Scholar] [CrossRef]

- Shang, M.; Li, H.; Ahmad, A.; Ahmad, W.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Majka, T.M. Predicting the Mechanical Properties of RCA-Based Concrete Using Supervised Machine Learning Algorithms. Materials 2022, 15, 647. [Google Scholar] [CrossRef]

- Ahmad, A.; Ostrowski, K.A.; Maślak, M.; Farooq, F.; Mehmood, I.; Nafees, A. Comparative Study of Supervised Machine Learning Algorithms for Predicting the Compressive Strength of Concrete at High Temperature. Materials 2021, 14, 4222. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Boukar, M.M. On the Use of Machine Learning Technique to Appraise Thermal Properties of Novel Earthen Composite for Sustainable Housing in Sub-Saharan Africa. In Innovations and Interdisciplinary Solutions for Underserved Areas; Springer: Cham, Switzerland, 2023; pp. 161–170. [Google Scholar]

- Spiegel, M.R.; Stephens, L.J. Schaum’s Outline of Statistics, 4th ed.; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Shao, Q.; Zhang, W.; Cao, X.; Yang, J.; Yin, J. Threshold and moderating effects of land use on metro ridership in Shenzhen: Implications for TOD planning. J. Transp. Geogr. 2020, 89, 102878. [Google Scholar] [CrossRef]

- Priya, K.S. Linear Regression Algorithm in Machine Learning through MATLAB. Int. J. Res. Appl. Sci. Eng. Technol. 2021, 9, 989–995. [Google Scholar] [CrossRef]

- Bentéjac, C.; Csörgő, A.; Martínez-Muñoz, G. A comparative analysis of gradient boosting algorithms. Artif. Intell. Rev. 2021, 54, 1937–1967. [Google Scholar] [CrossRef]

- Le, H.-A.; Le, D.-A.; Le, T.-T.; Le, H.-P.; Hoang, H.-G.T.; Nguyen, T.-A. An Extreme Gradient Boosting approach to estimate the shear strength of FRP reinforced concrete beams. Structures 2022, 45, 1307–1321. [Google Scholar] [CrossRef]

- Pishro, A.A.; Zhang, S.; Hu, Q.; Zhang, Z.; Pishro, M.A.; Zhang, L.; L’hostis, A.; Hejazi, F.; Liu, Y.; Zhao, Y. Advancing ultimate bond stress–slip model of UHPC structures through a novel hybrid machine learning approach. Structures 2024, 62, 106162. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.; Liu, W.; Fu, T.; Qiu, R.; Wu, S. Tensile Performance Mechanism for Bamboo Fiber-Reinforced, Palm Oil-Based Resin Bio-Composites Using Finite Element Simulation and Machine Learning. Polymers 2023, 15, 2633. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xu, X. Machine learning tensile strength and impact toughness of wheat straw reinforced composites. Mach. Learn. Appl. 2021, 6, 100188. [Google Scholar] [CrossRef]

- Antil, S.K.; Antil, P.; Singh, S.; Kumar, A.; Pruncu, C.I. Artificial Neural Network and Response Surface Methodology Based Analysis on Solid Particle Erosion Behavior of Polymer Matrix Composites. Materials 2020, 13, 1381. [Google Scholar] [CrossRef] [PubMed]

- Pati, P.R. Prediction and wear performance of red brick dust filled glass–epoxy composites using neural networks. Int. J. Plast. Technol. 2019, 23, 253–260. [Google Scholar] [CrossRef]

- Alakara, E.H.; Nacar, S.; Sevim, O.; Korkmaz, S.; Demir, I. Determination of compressive strength of perlite-containing slag-based geopolymers and its prediction using artificial neural network and regression-based methods. Constr. Build. Mater. 2022, 359, 129518. [Google Scholar] [CrossRef]

- Manikandan, P.; Selija, K.; Vasugi, V.; Kumar, V.P.; Natrayan, L.; Santhi, M.H.; Kumaran, G.S. An Artificial Neural Network Based Prediction of Mechanical and Durability Characteristics of Sustainable Geopolymer Composite. Adv. Civ. Eng. 2022, 2022, 9343330. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Célino, A.; Fréour, S.; Jacquemin, F.; Casari, P. Characterization and modeling of the moisture diffusion behavior of natural fibers. J. Appl. Polym. Sci. 2013, 130, 297–306. [Google Scholar] [CrossRef]

- Alghamdi, S.J. Classifying High Strength Concrete Mix Design Methods Using Decision Trees. Materials 2022, 15, 1950. [Google Scholar] [CrossRef]

- Sipper, M.; Moore, J.H. AddGBoost: A gradient boosting-style algorithm based on strong learners. Mach. Learn. Appl. 2022, 7, 100243. [Google Scholar] [CrossRef]

- Kang, M.-C.; Yoo, D.-Y.; Gupta, R. Machine learning-based prediction for compressive and flexural strengths of steel fiber-reinforced concrete. Constr. Build. Mater. 2021, 266, 121117. [Google Scholar] [CrossRef]

- Ben Chaabene, W.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- Anysz, H.; Brzozowski, Ł.; Kretowicz, W.; Narloch, P. Feature Importance of Stabilised Rammed Earth Components Affecting the Compressive Strength Calculated with Explainable Artificial Intelligence Tools. Materials 2020, 13, 2317. [Google Scholar] [CrossRef]

- Naveen, E.; Venkatachalam, N.; Maheswaran, N. Alkalichemical Treatment on the Surface of Natural Fiber. 2007. Available online: https://www.ijirset.com/upload/2015/tapsa/25_ME009.pdf (accessed on 17 July 2024).

- Xia, C.; Zhang, S.; Shi, S.Q.; Cai, L.; Huang, J. Property enhancement of kenaf fiber reinforced composites by in situ aluminum hydroxide impregnation. Ind. Crop. Prod. 2016, 79, 131–136. [Google Scholar] [CrossRef]

- Tripura, D.D.; Gupta, S.; Debbarma, B.; Deep, R.S.S. Flexural strength and failure trend of bamboo and coir reinforced cement stabilized rammed earth wallettes. Constr. Build. Mater. 2020, 242, 117986. [Google Scholar] [CrossRef]

- van der Lugt, P.; Van den Dobbelsteen, A.A.J.F.; Janssen, J.J.A. An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Simon, M.; Fulchiron, R.; Gouanvé, F. Water Sorption and Mechanical Properties of Cellulosic Derivative Fibers. Polymers 2022, 14, 2836. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Obianyo, I.I.; Ngayakamo, B.; Bih, N.L.; Ayeni, O.; Azeko, S.T.; Savastano, H. Alkali activation of compacted termite mound soil for eco-friendly construction materials. Heliyon 2021, 7, e06597. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Norton, A.; Newman, G. The water vapor sorption behavior of natural fibers. J. Appl. Polym. Sci. 2009, 112, 1524–1537. [Google Scholar] [CrossRef]

- Chen, C.M.; Wangaard, F.F. Wettability and the IIysteresis Effect in the Sorption of Water Vapor by Wood. Wood Sci. Technol. 1968, 2, 177–187. [Google Scholar] [CrossRef]

- Upreti, K.; Verma, M.; Agrawal, M.; Garg, J.; Kaushik, R.; Agrawal, C.; Singh, D.; Narayanasamy, R. Prediction of Mechanical Strength by Using an Artificial Neural Network and Random Forest Algorithm. J. Nanomater. 2022, 2022, 7791582. [Google Scholar] [CrossRef]

- Koyamparambath, A.; Adibi, N.; Szablewski, C.; Adibi, S.A.; Sonnemann, G. Implementing Artificial Intelligence Techniques to Predict Environmental Impacts: Case of Construction Products. Sustainability 2022, 14, 3699. [Google Scholar] [CrossRef]

- Mahamat, A.A.; Boukar, M.M. Machine learning techniques versus classical statistics in strength predictions of eco-friendly masonry units. In Proceedings of the 2021 16th International Conference on Electronics Computer and Computation (ICECCO), Kaskelen, Kazakhstan, 25–26 November 2021; pp. 1–4. [Google Scholar]

- Tran, V.Q. Hybrid gradient boosting with meta-heuristic algorithms prediction of unconfined compressive strength of stabilized soil based on initial soil properties, mix design and effective compaction. J. Clean. Prod. 2022, 355, 131683. [Google Scholar] [CrossRef]

| Reference | Material Type | ML Technique Used | Inputs | Predicted Outputs | Statistical Evaluation Metrics |

|---|---|---|---|---|---|

| [27] | Brodatz and Salzburg texture image (fiber) | Decision tree (DT), random forest (RF), support vector machine (SVM), and K-nearest neighbor (KNN) | Fibers images (Brodatz and Salzburg) | Texture | Accuracy |

| [26] | Thermoplastic Resins | Decision Tree Regression (DTR) and Random Forest Regression (RFR), Multi Linear Regression (MLR) | Polycarbonate resin with different pigments | Fiber’s color | Pearson correlation coefficient (PCC) |

| [19] | Epoxy composite reinforced with jute/basalt hybrid | Gradient Boosting (GB), AdaBoost, and XGBoost | Spindle speed, Feed rate, Depth of cut | Surface roughness | Average, and maximum error |

| [40] | Bamboo Fiber-Reinforced, Palm Oil-Based Resin Bio-Composites | Decision Tree Regression (DTR) and Random Forest Regression (RFR), Gradient Boosting (GB), CatBoost, and XGBoost | Bamboo Fiber volume fraction, fiber length (L), fiber diameter (D), the ratio of length to diameter, resin failure stress and resin failure strain | Tensile strength | R2, MSE, and MAE |

| [41] | Wheat straw-reinforced polypropylene composites | Gaussian Process Regression (GPR) | Fiber content, hold time, molding pressure, hold temperature | Tensile strength and impact toughness | R2, RMSE, and MAE |

| [42] | Glass Fiber Polymer matrix composite | Artificial Neural Network (ANN), Response Surface Methodology (RSM) | Slurry Pressure, Impingement Angle, Nozzle Diameter | Erosion rate | R and MSE |

| [43] | Red brick dust-filled glass epoxy composite | Artificial Neural Network (ANN) | Impact velocity, impingement angle, erodent size & temperature | Erosion rate | R2, RMSE, and MAE |

| [20] | Concrete-filled steel tubular columns | Gradient Boosting (GB) | Section type, load, specimens, violin plot, and Heat-map | Strengths | R2, MSE, RMSE, MAE, and CoV |

| [44] | Eco-Friendly Concrete | Support vector machine (SVM), linear regression (LR) | W/C, RAC%, superplasticizer, and age | Compressive strength | R2 and RMSE |

| [29] | FRP-reinforced concrete members | Bayesian optimization algorithm (BOA), support vector regression (SVR) | Epsilon, box constraint, and kernel scale and kernel function | Shear capacity | R2, RMSE, MAE, and FB |

| [45] | Sustainable geopolymer composite | Artificial Neural Network (ANN) | RHA substitution proportion, NaOH concentration, and fiber content | Compressive and flexural strength | R2 and RMSE |

| Time (min) | Mass (mg) | Relative Humidity RH (%) | Temp. (°C) | Specific Mass Mt (%) | Time (min) | Mass (mg) | Relative Humidity RH (%) | Temp. (°C) | Specific Mass Mt (%) |

|---|---|---|---|---|---|---|---|---|---|

| 7.78 | 10.01 | 24.26 | 2.68 | 0.01 | … | … | … | … | … |

| 7.97 | 10.3 | 24.26 | 2.69 | 0.06 | … | … | … | … | … |

| 8.05 | 10.4 | 24.26 | 2.69 | 0.08 | … | … | … | … | … |

| 8.17 | 10.5 | 24.26 | 2.69 | 0.11 | … | … | … | … | … |

| 187.74 | 10.66 | 24.27 | 2.75 | 2.28 | 1310.67 | 80.00 | 24.21 | 3.94 | 46.79 |

| 187.76 | 11.01 | 24.27 | 2.75 | 2.28 | 1310.69 | 80.00 | 24.21 | 3.94 | 46.79 |

| 187.78 | 11.33 | 24.27 | 2.75 | 2.28 | 1310.71 | 80.00 | 24.21 | 3.94 | 46.79 |

| 187.8 | 11.61 | 24.27 | 2.75 | 2.28 | 1310.72 | 80.00 | 24.21 | 3.94 | 46.79 |

| 187.81 | 11.87 | 24.27 | 2.75 | 2.28 | 1310.74 | 80.00 | 24.21 | 3.94 | 46.79 |

| 187.83 | 12.09 | 24.27 | 2.75 | 2.28 | 1310.76 | 80.00 | 24.20 | 3.94 | 46.79 |

| 187.84 | 12.29 | 24.27 | 2.75 | 2.28 | 1278.97 | 80.00 | 24.24 | 3.55 | 32.37 |

| 187.86 | 12.47 | 24.27 | 2.75 | 2.28 | 1278.99 | 80.02 | 24.24 | 3.55 | 32.42 |

| 187.88 | 12.66 | 24.27 | 2.75 | 2.28 | 1458.86 | 81.26 | 24.25 | 3.95 | 47.09 |

| 187.9 | 12.83 | 24.27 | 2.75 | 2.28 | 1459.12 | 82.10 | 24.26 | 3.95 | 47.31 |

| 187.91 | 12.99 | 24.27 | 2.75 | 2.28 | 1459.44 | 83.00 | 24.28 | 3.97 | 47.78 |

| 187.93 | 13.16 | 24.27 | 2.75 | 2.28 | 1459.84 | 83.90 | 24.31 | 3.99 | 48.65 |

| 187.95 | 13.33 | 24.27 | 2.75 | 2.28 | 1461.01 | 84.90 | 24.31 | 4.07 | 51.80 |

| 187.96 | 13.48 | 24.27 | 2.75 | 2.28 | 1461.22 | 85.00 | 24.31 | 4.09 | 52.41 |

| 187.98 | 13.65 | 24.27 | 2.75 | 2.28 | 1461.24 | 85.00 | 24.31 | 4.09 | 52.46 |

| 188 | 13.81 | 24.27 | 2.75 | 2.28 | 1642.64 | 85.00 | 24.26 | 4.93 | 83.64 |

| 188.01 | 13.97 | 24.27 | 2.75 | 2.28 | 1642.66 | 85.00 | 24.26 | 4.93 | 83.64 |

| 188.03 | 14.1 | 24.27 | 2.75 | 2.28 | 1642.67 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.05 | 14.27 | 24.27 | 2.75 | 2.28 | 1642.69 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.06 | 14.42 | 24.27 | 2.75 | 2.28 | 1642.71 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.08 | 14.56 | 24.27 | 2.75 | 2.29 | 1642.72 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.1 | 14.69 | 24.27 | 2.75 | 2.29 | 1642.74 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.11 | 14.85 | 24.27 | 2.75 | 2.29 | 1642.76 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.13 | 14.99 | 24.27 | 2.75 | 2.29 | 1642.77 | 85.00 | 24.27 | 4.93 | 83.64 |

| 188.15 | 15.12 | 24.27 | 2.75 | 2.29 | 1642.79 | 85.00 | 24.27 | 4.93 | 83.64 |

| DTR | GBR |

|---|---|

| Structure: Comprises a tree-like structure where nodes represent decisions based on feature values, and leaves represent the output (predicted values). Functioning:

| Structure: An ensemble of multiple weak learners (usually shallow decision trees) combined to form a strong predictive model. Functioning:

|

| Evaluation Metrics and Their Equations | Parameter’s Definition | |

|---|---|---|

| (1) | Where n = represents the total number of data values y i,exp = represents the actual value yi,pred = represents predicted value | |

| (2) | n = represents the total number of data values yi,exp = represents the actual value yi,pred = represents predicted value | |

| (3) | RMSE= | n = represents the total number of data values yi,exp = represents the actual value yi,pred = represents predicted value |

| (4) | n = represents the total number of data values yi,exp = represents the actual value yi,pred = represents predicted value |

| Practical Implications | Theoretical Implications |

|---|---|

| DTR | DTR |

| Easy interpretability | Prone to overfitting |

| Handling numerical and categorical features without extensive preprocessing | Inaccurate for complex relationships |

| Quick development of the model and its training | Inadequate for continuous features |

| Best for categorical features | |

| Can identify the most important features | |

| Wide range applications | |

| GBR | GBR |

| Easy interpretability | Requires hyperparameter tuning |

| High accuracy on complex datasets | Reduce variance |

| Flexibility in handling various data types and non-linear relationship | Ensemble of multiple trees thus hard to understand the internal working |

| Less prone to overfitting | Accurate for complex nonlinear relationships |

| Examples of how the models can enhance decision-making | |

| The rationale behind the model’s forecasts can be comprehended during the application of the BNF thanks to the decision rules of the tree’s simplicity. | |

| Both models can be used to predict accurately the engineering properties of BNF based on moisture absorption, mass, temperature, etc. by allowing an understanding of the most important factors | |

| Models can be used to identify factors to alternate the BNF characteristics to enable improve their properties based on their application | |

| Models can be used to determine the BNF failure characteristics for early prevention or reinforcement | |

| Models can be used to produce BNF based on specific applications | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahamat, A.A.; Boukar, M.M.; Leklou, N.; Celino, A.; Obianyo, I.I.; Bih, N.L.; Stanislas, T.T.; Savastanos, H., Jr. Decision Tree Regression vs. Gradient Boosting Regressor Models for the Prediction of Hygroscopic Properties of Borassus Fruit Fiber. Appl. Sci. 2024, 14, 7540. https://doi.org/10.3390/app14177540

Mahamat AA, Boukar MM, Leklou N, Celino A, Obianyo II, Bih NL, Stanislas TT, Savastanos H Jr. Decision Tree Regression vs. Gradient Boosting Regressor Models for the Prediction of Hygroscopic Properties of Borassus Fruit Fiber. Applied Sciences. 2024; 14(17):7540. https://doi.org/10.3390/app14177540

Chicago/Turabian StyleMahamat, Assia Aboubakar, Moussa Mahamat Boukar, Nordine Leklou, Amandine Celino, Ifeyinwa Ijeoma Obianyo, Numfor Linda Bih, Tido Tiwa Stanislas, and Holmer Savastanos, Jr. 2024. "Decision Tree Regression vs. Gradient Boosting Regressor Models for the Prediction of Hygroscopic Properties of Borassus Fruit Fiber" Applied Sciences 14, no. 17: 7540. https://doi.org/10.3390/app14177540

APA StyleMahamat, A. A., Boukar, M. M., Leklou, N., Celino, A., Obianyo, I. I., Bih, N. L., Stanislas, T. T., & Savastanos, H., Jr. (2024). Decision Tree Regression vs. Gradient Boosting Regressor Models for the Prediction of Hygroscopic Properties of Borassus Fruit Fiber. Applied Sciences, 14(17), 7540. https://doi.org/10.3390/app14177540