Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer

Abstract

:1. Introduction

2. Materials and Methods

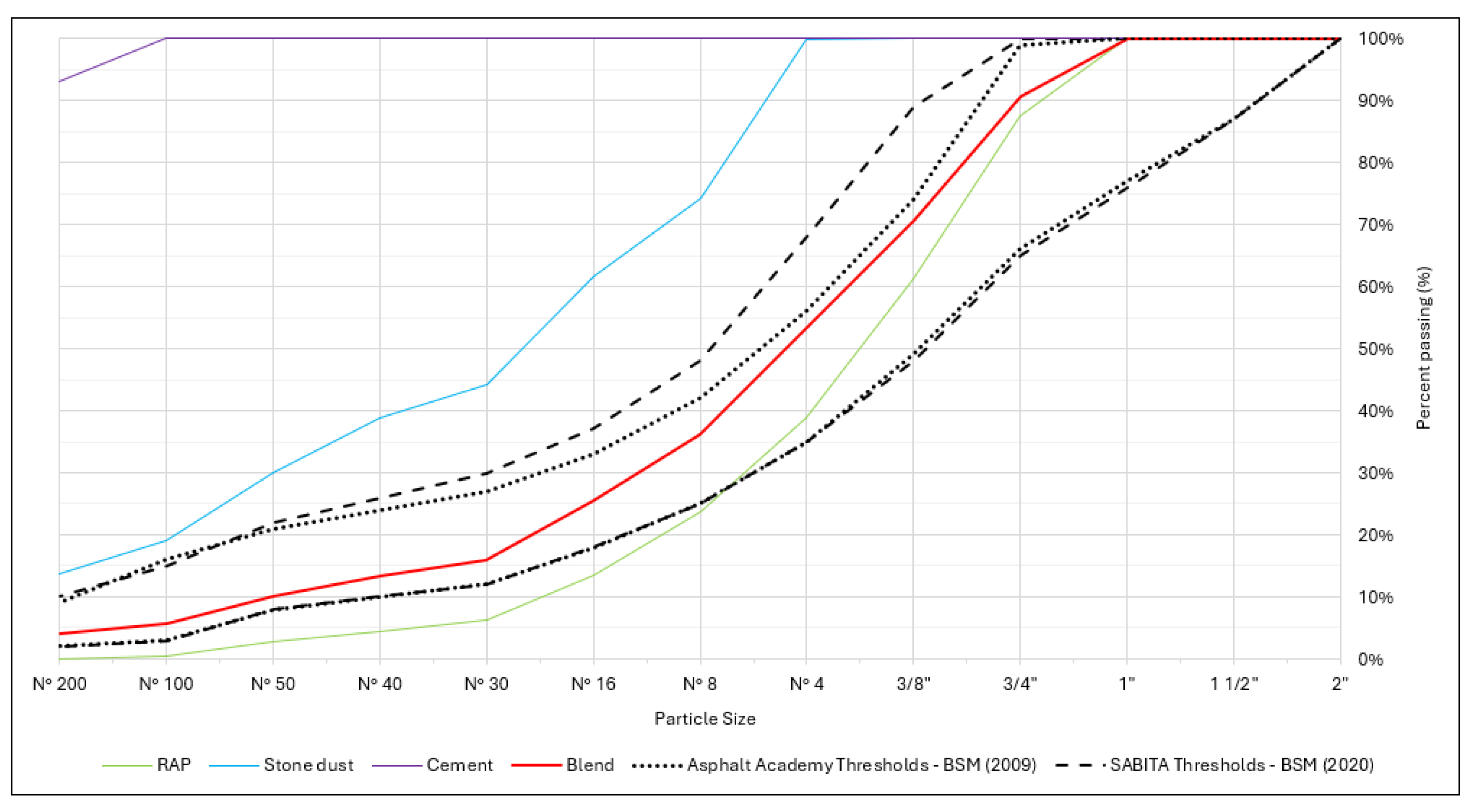

2.1. Materials Characterizatian

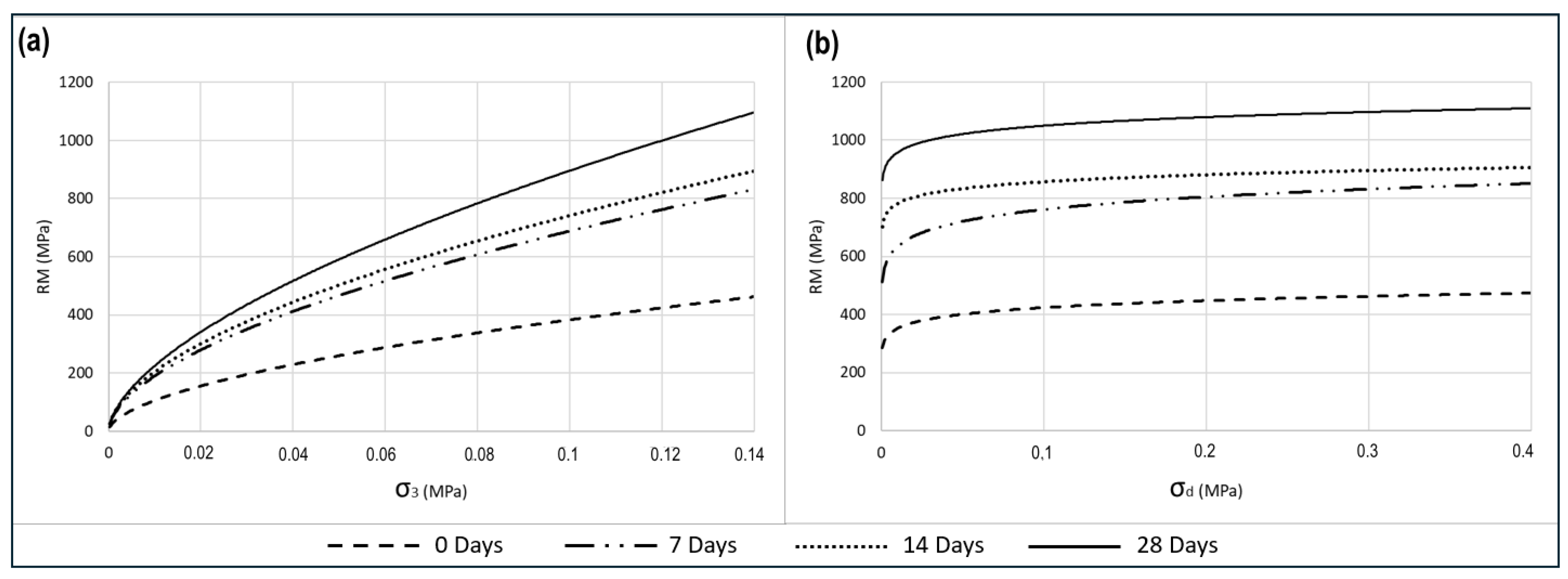

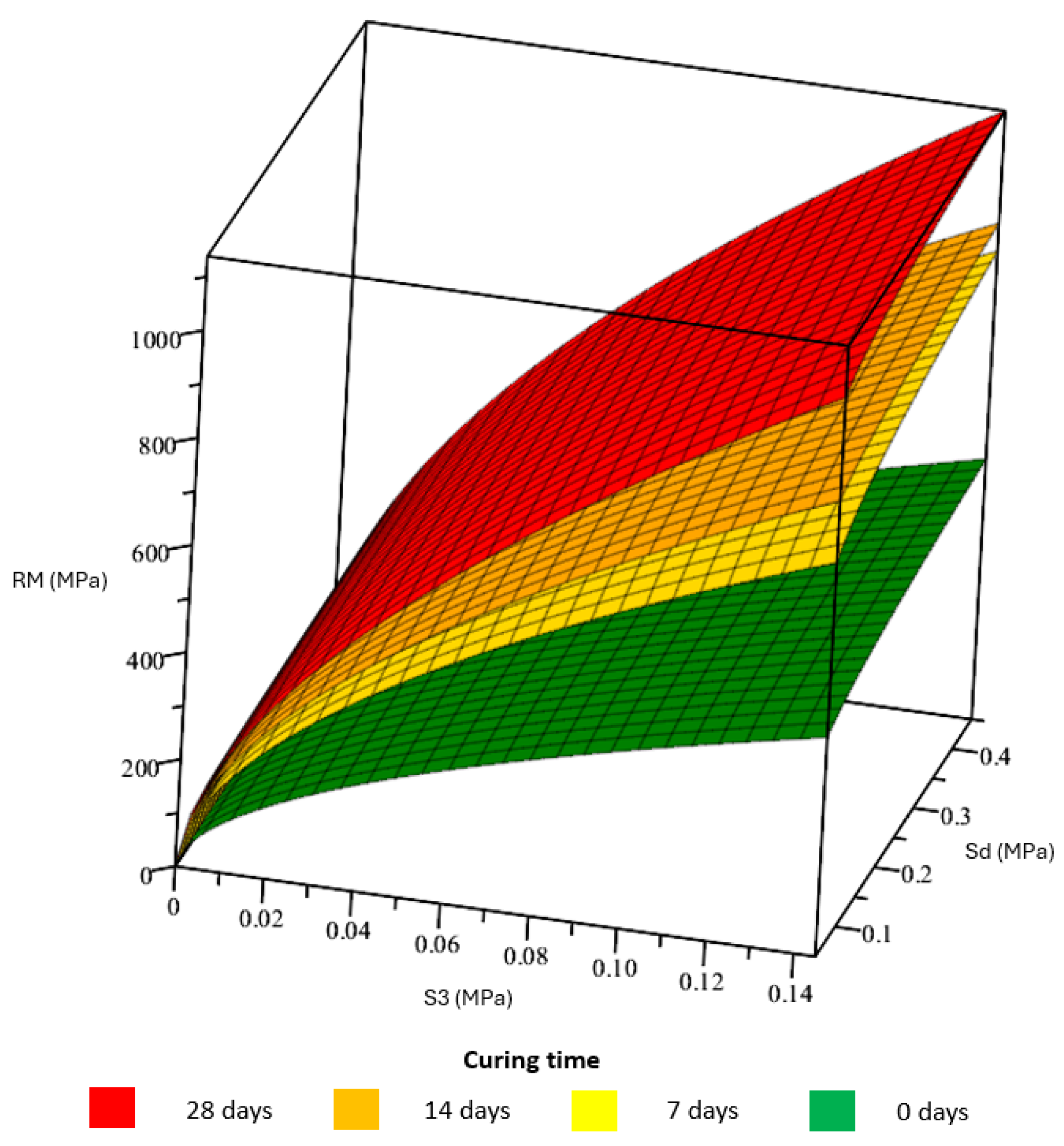

- The curing times for the resilient modulus (RM) test were 0, 7, 14, and 28 days after compaction.

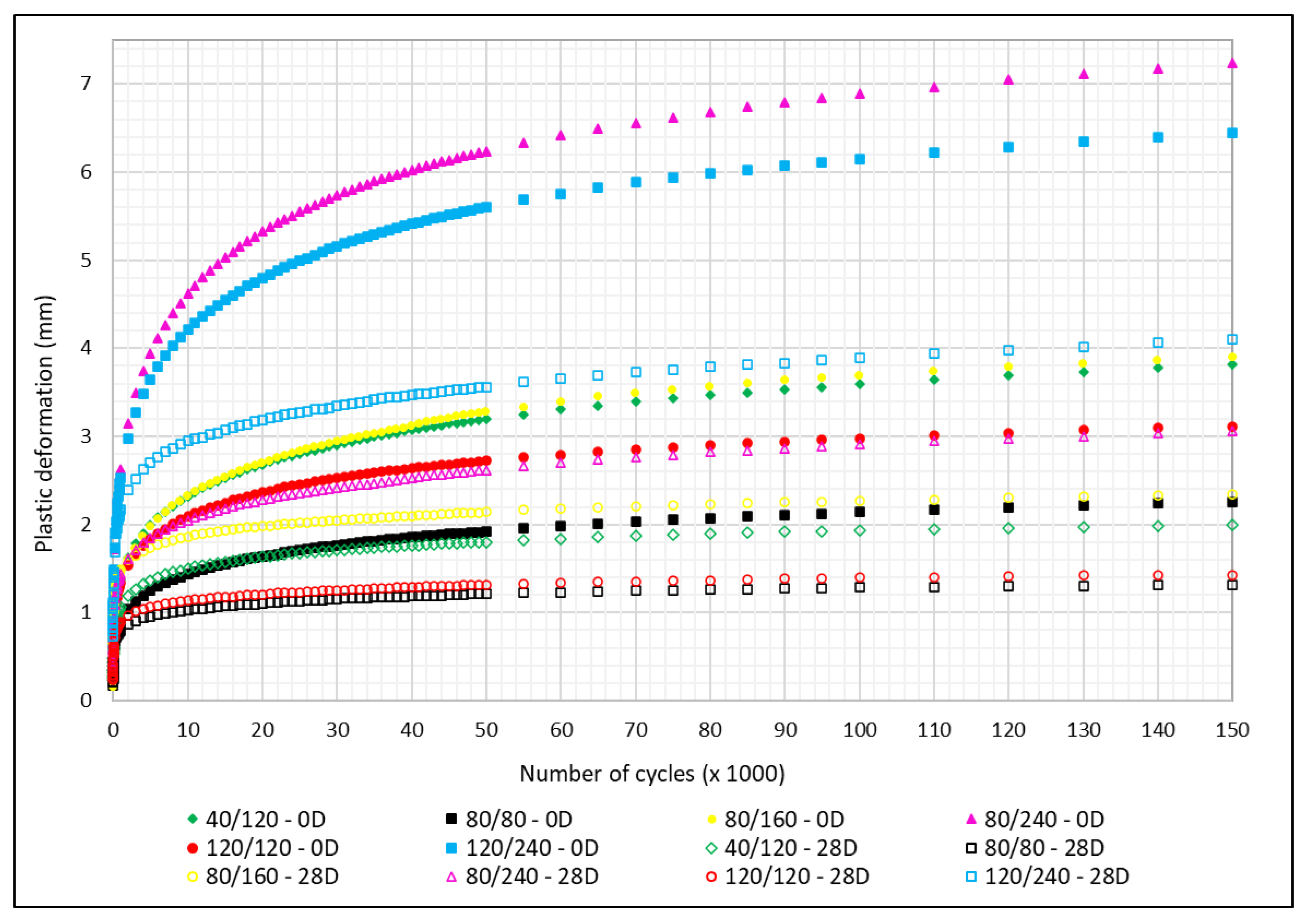

- For the permanent deformation (PD) test, the curing times were 0 days (0D) and 28 days (28D) after compaction.

2.2. Mechanical Analysis

2.2.1. Resilient Modulus

- : is the ratio of h to . h is the maximum vertical displacement, and is the initial reference length of the cylindrical specimen.

2.2.2. Permanent Deformation (PD)

3. Results and Discussion

Resilient Modulus

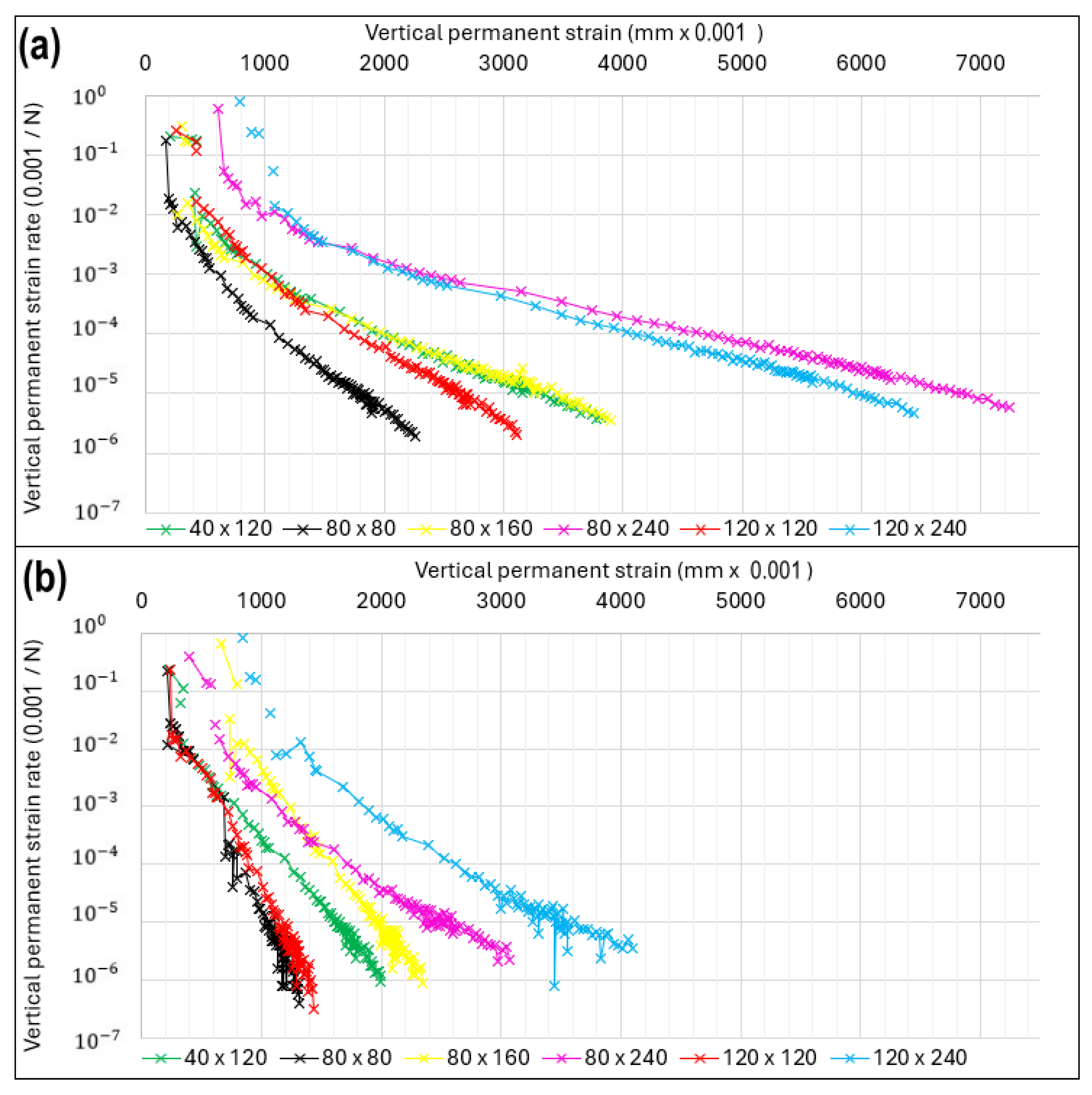

4. Permanent Deformation (PD)

5. Conclusions

- A minimum curing time of 7 days was required to achieve typical RM values for granular materials used in base courses. With values between 500 and 600 MPa. Indicating good behavior in terms of resilience modulus. The RM increased 80% increase compared to the material tested immediately after compaction.

- The samples were more susceptible to permanent deformation when subjected to the repeated load triaxial test. Although the 28-day curing reduced the material’s total PD by up to 58%, the material still showed high accumulated deformation at the end of the 150,000 cycles of the tests. None of the tests showed a plastic deformation rate below , but they exhibited a tendency towards accommodation after 150,000 cycles. This indicates that even after 28 days of curing, the emulsion was unable to completely stabilize the mixture.

- The plastic deformation behavior observed in the triaxial tests must be taken into account when designing pavements containing RAP and asphalt emulsion. In addition, the analysis of this material in the repeated load triaxial test explains the premature deformations observed during the technical inspection mentioned in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bonfim, V. Sustainable Pavement, 1st ed.; Exceção Editorial e Eventos: São Paulo, Brazil, 2020. [Google Scholar]

- Andrews, J.; Radhakrishnan, V.; Koshy, R. Laboratory Evaluation of Emulsion-Treated Base Layer Mixes Incorporating Reclaimed Asphalt Pavement Materials. J. Mater. Civ. Eng. 2023, 35, 04023198. [Google Scholar] [CrossRef]

- Renjith, R.; Robert, D.; Setunge, S.; Costa, S.; Mohajerani, A. Optimization of fly ash based soil stabilization using secondary admixtures for sustainable road construction. J. Clean. Prod. 2021, 294, 126264. [Google Scholar] [CrossRef]

- Silveira, V.; Guimarães, A.; Castro, C. Study of the application of coke boiler ash in base and sub-base layers of pavements. Transportes 2019, 27, 194–208. [Google Scholar] [CrossRef]

- Apaza, F.R.; Guimarães, A.C.R.; Sousa, M.A.d.S.; Castro, C.D. Study on the use of Iron Ore Residue in microsurfacing. Transportes 2018, 26, 118–138. [Google Scholar] [CrossRef]

- Silveira, V.; Guimarães, A.; Coelho, L.; dos Santos, W.; da Silveira, P.; Monteiro, S. Recycling Iron Ore Waste through Low-Cost Paving Techniques. Sustainability 2024, 16, 5570. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, X.; Qian, G.; Gong, X.; Nie, X. Evaluation of phosphorus slag (PS) content and particle size on the performance modification effect of asphalt. Constr. Build. Mater. 2020, 256, 119334. [Google Scholar] [CrossRef]

- Bona, A.; Silveira, V.; Guimarães, A.; Silva, C. Study on recycling of steel slag in pavement layers. Rev. Ibero Am. Ciências Ambient. 2020, 11, 167–183. [Google Scholar] [CrossRef]

- Loures, R.; Guimarães, A.; Silva, B.H.; Castro, C. Cold mix containing steel slag: A viable alternative for pavement construction. Transportes 2018, 26, 54–67. [Google Scholar] [CrossRef]

- Pinto Netto, Q.; Guimarães, A. Laboratory characterization of mining residues as alternative aggregates for asphalt mixtures. Rev. Ibero Am. Ciências Ambient. 2018, 9, 88–98. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Costa, K.Á.; Reis, M.d.M.; Santana, C.S.A.; Castro, C.D. Study of controlled leaching process of steel slag in soxhlet extractor aiming employment in pavements. Transp. Geotech. 2021, 27, 100485. [Google Scholar] [CrossRef]

- Friber, M.; Guimarães, A.; Martins, C.; Soares, J. Study of the Mining Waste in the Production of Calcined Aggregate for Use in Pavement. Minerals 2023, 13, 1543. [Google Scholar] [CrossRef]

- Barbosa, V.; Guimarães, A.; Marques, M.; Castro, C. Study of Acre soils for the production of calcined clay aggregates and mixtures for pavement bases—A strategic alternative for the state of Acre. Rev. Mil. Ciência Tecnol. 2020, 37, 5–18. [Google Scholar]

- Feng, W.; Liu, F.; Yang, F.; Jing, L.; Li, L.; Li, H.; Chen, L. Compressive behaviour and fragment size distribution model for failure mode prediction of rubber concrete under impact loads. Constr. Build. Mater. 2021, 273, 121767. [Google Scholar] [CrossRef]

- Jian, S.M.; Wu, B. Compressive behavior of compound concrete containing demolished concrete lumps and recycled aggregate concrete. Constr. Build. Mater. 2021, 272, 121624. [Google Scholar] [CrossRef]

- Specht, L. Evaluation of Asphalt Mixtures Incorporating Recycled Tire Rubber. Ph.D. Thesis, Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brazil, 2004. [Google Scholar]

- Chiu, C.T.; Lu, L.C. A laboratory study on stone matrix asphalt using ground tire rubber. Constr. Build. Mater. 2007, 21, 1027–1033. [Google Scholar] [CrossRef]

- Silva, J.d.; Pereira, I.; Pinheiro, É.C. Analysis of the technical feasibility of using waste tire rubber in asphalt pavements. Braz. J. Dev. 2021, 7, 108529–108544. [Google Scholar] [CrossRef]

- Flores, G.; Gallego, J.; Miranda, L.; Marcobal, J.R. Design methodology for in situ cold recycled mixtures with emulsion and 100% rap. Constr. Build. Mater. 2019, 216, 496–505. [Google Scholar] [CrossRef]

- Thakur, J.; Han, J. Recent development of recycled asphalt pavement (RAP) bases treated for roadway applications. Transp. Infrastruct. Geotechnol. 2015, 2, 68–86. [Google Scholar] [CrossRef]

- Naser, M.; Abdel-Jaber, M.; Al-Shamayleh, R.; Ibrahim, R.; Louzi, N.; AlKhrissat, T. Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler. Buildings 2023, 13, 132. [Google Scholar] [CrossRef]

- Gallo, P.; Belhaj, M.; Valentin, J. Laboratory Study of Asphalt Concrete for Base Course with Reclaimed Asphalt, Recycling Agents, and Jute Fibres. Appl. Sci. 2024, 14, 239. [Google Scholar] [CrossRef]

- Coelho, L.; Guimarães, A.; de Azevedo, A.; Monteiro, S. Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests. Sustainability 2024, 16, 5335. [Google Scholar] [CrossRef]

- Hu, Y.; Allanson, M.; Sreeram, A.; Ryan, J.; Wang, H.; Zhou, L.; Airey, G.D. Characterisation of bitumen through multiple ageing-rejuvenation cycles. Int. J. Pavement Eng. 2024, 25, 2365350. [Google Scholar] [CrossRef]

- Hu, Y.; Ryan, J.; Sreeram, A.; Allanson, M.; Pasandín, A.R.; Zhou, L.; Singh, B.; Wang, H.; Airey, G.D. Optimising the dosage of bio-rejuvenators in asphalt recycling: A rejuvenation index based approach. Constr. Build. Mater. 2024, 433, 136761. [Google Scholar] [CrossRef]

- Hu, Y.; Omairey, E.; Hughes, D.; Bailey, H.; Watkins, M.; Twitchen, J.; Airey, G.D.; Sreeram, A. Recovering the properties of aged bitumen using bio-rejuvenators derived from municipal wastes. Constr. Build. Mater. 2024, 438, 137268. [Google Scholar] [CrossRef]

- Adwani, D.; Pipintakos, G.; Mirwald, J.; Wang, Y.; Hajj, R.; Guo, M.; Bhasin, A. Examining the efficacy of promising antioxidants to mitigate asphalt binder oxidation: Insights from a worldwide interlaboratory investigation. Int. J. Pavement Eng. 2024, 25, 2332363. [Google Scholar] [CrossRef]

- Guimarães, A.; Motta, L.d. A Study on Permanent Deformation of Lateritic Soils Including the Shakedown Concept. In Advances in Transportation Geotechnics, 1st ed.; CRC Press: London, UK, 2008; p. 8. ISBN 9780429207280. [Google Scholar] [CrossRef]

- Modarres, A.; Rahimzadeh, M.; Zarrabi, M. Field investigation of in-place cold recycling pavement rehabilitation. Resour. Conserv. Recycl. 2014, 83, 112–120. [Google Scholar] [CrossRef]

- Fu, P.; Harvey, J. Temperature sensitivity of foamed asphalt mix stiffness: Field and lab study. Int. J. Pavement Eng. 2007, 8, 137–145. [Google Scholar] [CrossRef]

- Guatimosim, F.V.; Vasconcelos, K.L.; Bernucci, L.L.B.; Jenkins, K.J. Laboratory and field evaluation of cold recycling mixture with foamed asphalt. Road Mater. Pavement Des. 2016, 19, 385–399. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, H.; Heitzman, M. Validation of new mix design procedure for cold in-place recycling with foamed asphalt. J. Mater. Civ. Eng. 2007, 19, 1000–1010. [Google Scholar] [CrossRef]

- Diefenderfer, B.K.; Bowers, B.F.; Schwartz, C.W.; Farzaneh, A.; Zhang, Z. Dynamic modulus of recycled pavement mixtures. Transp. Res. Rec. J. Transp. Res. Board 2016, 2575, 19–26. [Google Scholar] [CrossRef]

- Smith, S.; Braham, A. Comparing layer types for the use of pavement ME for asphalt emulsion full depth reclamation design. Constr. Build. Mater. 2018, 158, 481–489. [Google Scholar] [CrossRef]

- Meocci, M.; Grilli, A.; Torre, F.L.; Bocci, M. Evaluation of mechanical performance of cement–bitumen-treated materials through laboratory and in-situ testing. Road Mater. Pavement Des. 2017, 18, 376–389. [Google Scholar] [CrossRef]

- DNIT. Asphalt Paving–Preparation of Specimens for for Mechanical Testing Using the Superpave or Marshall Gyratory Compactor–Procedure; Technical Report; National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- Comite Europeen de Normalisation, European. Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens; Technical Report; Comite Europeen de Normalisation, European: Brussels, Belgium, 2017. [Google Scholar]

- Comite Europeen de Normalisation, European. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 26: Stiffness; Technical Report; Comite Europeen de Normalisation, European: Brussels, Belgium, 2012. [Google Scholar]

- Unger Filho, W.; Klinsky, L.; Motta, R.; Bernucci, L.L. Cold Recycled Asphalt Mixture using 100% RAP with Emulsified Asphalt-Recycling Agent as a New Pavement Base Course. Adv. Mater. Sci. Eng. 2020, 2020, 5863458. [Google Scholar] [CrossRef]

- Bessa, I.S.; Almeida, L.R.; Vasconcelos, K.L.; Bernucci, L.L. Design of cold recycled mixes with asphalt emulsion and portland cement. Can. J. Civ. Eng. 2016, 43, 627–635. [Google Scholar] [CrossRef]

- Allah, S.; Tanyu, B.; Dawson, A. Reclaimed Asphalt Pavement (RAP) as an Unbound Base Course Material: A Mechanistic Design Approach Based on Multi-stage Repeated Load Triaxial Tests. Transp. Geotech. 2022, 33, 100729. [Google Scholar] [CrossRef]

- Kuchiishi, A.K.; Vasconcelos, K.; Bariani Bernucci, L.L. Effect of mixture composition on the mechanical behaviour of cold recycled asphalt mixtures. Int. J. Pavement Eng. 2019, 22, 984–994. [Google Scholar] [CrossRef]

- Ullah, S.; Tanyu, B. Methodology to develop design guidelines to construct unbound base course withreclaimed asphalt pavement (RAP). Constr. Build. Mater. 2019, 223, 463–476. [Google Scholar] [CrossRef]

- Guthrie, W.S.; Cooley, D.; Eggett, D.L. Effects of Reclaimed Asphalt Pavement on Mechanical Properties of Base Materials. Transp. Res. Rec. 2007, 2005, 44–52. [Google Scholar] [CrossRef]

- Guduru, G.; Tavva, T.; Kuna, K. Estimation of Reclaimed Asphalt Pavement (RAP) characteristics using simple indicative tests. Road Mater. Pavement Des. 2022, 23, 822–848. [Google Scholar] [CrossRef]

- Chakravarthi, S.; Kumar, G.; Shankar, S.; Vishnu, R. Effect of Emulsified Asphalt Content on Creep Behavior and Mechanical Properties of Cold Recycled Emulsified Asphalt Bases. J. Rehabil. Civ. Eng. 2021, 9, 133–147. [Google Scholar] [CrossRef]

- Pinilla, J.; Miller, G.; Cerato, A.; Snethen, D. Influence of curing time on the resilient modulus of chemically stabilized soils. Geotech. Test. J. 2011, 34, 364–372. [Google Scholar] [CrossRef]

- Mousa, E.; El-Badawy, S.; Azam, A. Evaluation of reclaimed asphalt pavement as base/subbase material in Egypt. Transp. Geotech. 2021, 26, 100414. [Google Scholar] [CrossRef]

- de Medeiros, A.S.; Sant’Anna Cardoso, M.H.; Vieira da Silva, M.A. Evaluation of the Mechanical Behavior of Soil Stabilized with Asphalt Emulsion Using Multi-Stage Loading. Civ. Eng. J. 2024, 10, 20–40. [Google Scholar] [CrossRef]

- Asphalt Institute. A Basic Asphalt Emulsion Manual. The Asphalt Institute Manual Series No. 19; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- Pi, Y.; Huang, Z.; Pi, Y.; Li, G.; Li, Y. Composition design and performance evaluation of emulsified asphalt cold recycled mixtures. Materials 2019, 12, 2682. [Google Scholar] [CrossRef] [PubMed]

- Asphalt Academy. Bitumen Stabilized Materials, a Guideline for Design and Construction of Bitumen Emulsion and Foamed Bitumen Stabilized Materials; TG2 Technical Guideline; Asphalt Academy: Pretoria, South Africa, 2009. [Google Scholar]

- Sabita. Technical Guideline: Bitumen Stabilised Materials, 3rd ed.; Southern African Bitumen Association (Sabita): Cape Town, South Africa, 2020. [Google Scholar]

- ABNT NBR 10235; Methylene Blue Solution—Determination of Factor by Titration with a Solution of Titanium Trichloride—(TiCl3)—Standardization. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2015.

- ABNT NBR 12052; Soils and Fine Aggregate–Determination of Sand Equivalent Value—Method of Test. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 1992.

- ABNT NBR MN 30; Fine Aggregate—Test Method for Water Absorption. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2021.

- ABNT NBR MN 52; Fine Aggregate—Determinação of the Bulk Specific Gravity and Apparent Specific Gravity. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2021.

- ABNT NBR 14491; Asphalt Emulsions—Determination of Saybolt Furol Viscosity. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2007.

- ABNT NBR 6570; Asphalt Binders—Determination of Sedimentation and Stability to Storage of Asphalt Emulsions. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2016.

- ABNT NBR 14393; Asphalt Emulsions—Determination of Sifting. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2012.

- ABNT NBR 6567; Asphalt Binders—Asphalt Emulsions—Determination of Particle Charge. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2015.

- ABNT NBR 14376; Asphaltic Emulsions—Determination of the Solids Content of Conventional or Modified Asphalt Emulsions—Expeditious Methods. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2019.

- ABNT NBR 6299; Asphalt Emulsions—Determination of pH. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2012.

- National Department of Transportation Infrastructure—DNIT. Pavement—Soils—Compaction Test Using Tripartite Molds; National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2023.

- DNIT. Pavement-Soils-Determination of Resilience Modulus; Technical Report; National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- National Department of Transportation Infrastructure—DNIT. Pavement—Soils—Determination of Permanent Deformation; National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- Lima, C.; Motta, L.; Aragão, F. Permanent deformation tests: Effect of the number of loading cycles on the interpretation of the behavior of soils and gravels. Rev. Matéria 2020, 26, e13044. [Google Scholar] [CrossRef]

- Dawson, A.; Wellner, F. Plastic Behavior of Granular Materials; Report ARC Project 933 Reference PRG99014; University of Nottingham: Nottingham, UK, 1999. [Google Scholar]

- Werkmeister, S. Permanent Deformation Behavior of Unbound Granular Materials in Pavement Constructions. Doctoral Thesis, Universidade Técnica de Dresden, Dresden, Germany, 2003. [Google Scholar]

- Cerni, S.; Cardone, F.; Virgili, A.; Camilli, S. Characterisation of Permanent Deformation Behaviour of Unbound Granular Materials Under Repeated Triaxial Loading. Constr. Build. Mater. 2012, 28, 79–87. [Google Scholar] [CrossRef]

- Brown, S.; Needham, D. A study of cement modified bitumen emulsion mixtures. In Proceedings of the Association of Asphalt Paving Technologists, Saint Paul, MN, USA, 2000; pp. 92–121. [Google Scholar]

- Betti, G.; Airey, G.; Jenkins, K.; Marradi, A.; Tebaldi, G. Active fillers’ effect on in situ performances of foam bitumen recycled mixtures. Road Mater. Pavement Des. 2016, 18, 281–296. [Google Scholar] [CrossRef]

- Ebels, L. Characterisation of Material Properties and Behaviour of Cold Bituminous Mixtures for Road Pavement. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2008. [Google Scholar]

- Guimarães, A.; Motta, L. Mechanical Behavior of Basaltic Rocks from Serra Geral Formation Used as Road Material in Santa Catarina State, Brazil. Soils Rocks 2016, 39, 203–210. [Google Scholar] [CrossRef]

- Zago, J.; Pinheiro, R.; Baroni, M.; Specht, L.; Delongui, L.; Sagrilo, A. Study of the Permanent Deformation of Three Soils Employed in Highway Subgrades in the Municipality of Santa Maria-RS, Brazil. Int. J. Pavement Res. Technol. 2021, 14, 729–739. [Google Scholar] [CrossRef]

- Pascoal, P.; Sagrilo, A.; Baroni, M.; Specht, L.; Pereira, D. Lateritic Soil Deformability Regarding the Variation of Compaction Energy in the Construction of Pavement Subgrade. Soils Rocks 2023, 46, e2023009922. [Google Scholar] [CrossRef]

- Sagrilo, A.V.; Pascoal, P.T.; Baroni, M.; Back, A.H.; Pinheiro, R.J.B.; Specht, L.P.; Guimarães, A.C.R. Contribution to Resilient and Permanent Deformation Investigation of Unbound Granular Materials with Different Geological Origins from Rio Grande do Sul, Brazil. Soils Rocks 2023, 46, e2023009822. [Google Scholar] [CrossRef]

- Bernucci, L.B.; Ceratti, J.A.P.; Soares, J.B.; da Motta, L.M.G. Asphalt Pavement, Basic Training for Engineers, 2nd ed.; PETROBRAS, ABEDA: Rio de Janeiro, Brazil, 2006; p. 504. [Google Scholar]

- Balbo, J.T. Pavimentação Asfáltica: Materiais, Projeto e Restauração, 1st ed.; Oficina de Textos: São Paulo, Brazil, 2007; p. 560.

- Guimarães, A.C.R.; de Lima, C.D.A.; Aragão, F.T.S.; da Motta, L.M.G.; dos Santos, J.T.A. Mechanical Characterization of an Alternative Laterite Gravel Used as Pavement Material. Soils Rocks 2024, 47, e2024010622. [Google Scholar] [CrossRef]

- Kuchiishi, A.K.; Andrade, L.R.d.; Bessa, I.S.; Esteves, S.F.; Vasconcelos, K.L.; Bernucci, L.L.B. Influência da granulometria nas propriedades mecânicas de misturas recicladas a frio estabilizadas com emulsão asfáltica e cimento Portland. In Proceedings of the Congreso Ibero-Latinoamericano del Asfalto, Medellin, Colombia, 27–30 November 2017. [Google Scholar]

- Lima, C.; Motta, L. Study of Permanent Deformation and Granulometric Distribution of Graded Crushed Stone Pavement Material. Procedia Eng. 2016, 143, 854–861. [Google Scholar] [CrossRef]

- Jallu, M.; Saride, S.; Arulrajah, A.; Challapalli, S.; Evans, R. Effect of Curing Time on the Performance of Fly Ash Geopolymer-Stabilized RAP Bases. J. Mater. Civ. Eng. 2021, 33, 04021001. [Google Scholar] [CrossRef]

| Test | Brazilian Standard | Result | Unit |

|---|---|---|---|

| Methylene Blue | NBR 10235 [54] | 1.5 | mg/g |

| Sand Equivalent | NBR 12052 [55] | 57.3 | % |

| Water Absorption | NBR NM 30 [56] | 0.1 | % |

| Real Dry Specific Gravity | NBR NM 52 [57] | 2.683 | cm3 |

| Apparent Specific Gravity | NBR NM 52 [57] | 2.679 | cm3 |

| Test | Brazilian Standard | Unit | Specified | Result |

|---|---|---|---|---|

| Saybolt Furol Viscosity, 25 °C | NBR 14491 [58] | Seconds | Max. 70 | 21 |

| Sedimentation, 5 days | NBR 6570 [59] | % mass | Max. 5.0 | 0.4 |

| Sieve, 0.84 mm | NBR 14393 [60] | % mass | Max. 0.1 | 0 |

| Particle Charge | NBR 6567 [61] | - | Positive | Positive |

| Dry Residue | NBR 14376 [62] | % mass | Min. 60 | 61 |

| pH | NBR 6299 [63] | - | Max. 6.5 | 3.32 |

| Water Content (%) | 1 | 3 | 5 | 7 | 9 |

|---|---|---|---|---|---|

| Wet Density (g/cm3) | 1.59 | 1.97 | 2.05 | 2.08 | 2.06 |

| Converted Density (g/cm3) | 1.84 | 1.91 | 1.95 | 1.94 | 1.89 |

| Optimum Water Content (%) | 5.6 | ||||

| Maximum Dry Density (g/cm3) | 1.95 |

| Conditioning Phase | |||

| Par | (KPa) | (KPa) | / |

| 1 | 70 | 70 | 2 |

| 2 | 70 | 210 | 4 |

| 3 | 105 | 315 | 4 |

| Loading Phase | |||

| Par | (KPa) | (KPa) | / |

| 1 | 20 | 20 | 2 |

| 2 | 40 | 3 | |

| 3 | 60 | 4 | |

| 4 | 35 | 35 | 2 |

| 5 | 70 | 3 | |

| 6 | 105 | 4 | |

| 7 | 50 | 50 | 3 |

| 8 | 100 | 2 | |

| 9 | 150 | 3 | |

| 10 | 70 | 70 | 2 |

| 11 | 140 | 3 | |

| 12 | 210 | 4 | |

| 13 | 105 | 105 | 2 |

| 14 | 210 | 3 | |

| 15 | 315 | 4 | |

| 16 | 140 | 140 | 2 |

| 17 | 280 | 3 | |

| 18 | 420 | 4 | |

| Stress Pair | (MPa) | (MPa) |

|---|---|---|

| 1 | 0.04 | 0.12 |

| 2 | 0.08 | 0.08 |

| 3 | 0.08 | 0.16 |

| 4 | 0.08 | 0.24 |

| 5 | 0.12 | 0.12 |

| 6 | 0.12 | 0.24 |

| Sequence | RM (MPa) (%) | |||||

|---|---|---|---|---|---|---|

| 0 Days | 7 Days | 14 Days | 28 Days | |||

| 1 | 0.02 | 0.022 | 115 | 213 (+85.8%) | 210 (−1.4%) | 225 (+7.1%) |

| 2 | 0.02 | 0.042 | 122 | 217 (+77.8%) | 233 (+7.4%) | 231 (−0.9%) |

| 3 | 0.02 | 0.062 | 131 | 245 (+87.1%) | 247 (+0.8%) | 255 (+3.2%) |

| 4 | 0.035 | 0.037 | 175 | 293 (+67.2%) | 336 (+14.7%) | 390 (+16.1%) |

| 5 | 0.035 | 0.072 | 188 | 345 (+83.6%) | 385 (+11.6%) | 416 (+8.1%) |

| 6 | 0.035 | 0.107 | 199 | 371 (+86.7%) | 392 (+5.7%) | 428 (+9.2%) |

| 7 | 0.05 | 0.052 | 226 | 411 (+81.7%) | 479 (+16.5%) | 532 (+11.1%) |

| 8 | 0.05 | 0.103 | 242 | 447 (+84.3%) | 502 (+12.3%) | 651 (+29.7%) |

| 9 | 0.05 | 0.153 | 251 | 483 (+92.7%) | 521 (+7.9%) | 659 (+26.5%) |

| 10 | 0.07 | 0.073 | 278 | 493 (+77.2%) | 628 (+27.4%) | 818 (+30.3%) |

| 11 | 0.069 | 0.143 | 293 | 527 (+79.9%) | 603 (+14.4%) | 837 (+38.8%) |

| 12 | 0.069 | 0.213 | 305 | 554 (+81.4%) | 620 (+11.9%) | 772 (+24.5%) |

| 13 | 0.105 | 0.108 | 377 | 646 (+71.3%) | 798 (+23.5%) | 894 (+12.0%) |

| 14 | 0.105 | 0.213 | 386 | 715 (+85.2%) | 753 (+5.3%) | 936 (+24.3%) |

| 15 | 0.105 | 0.319 | 398 | 713 (+79.2%) | 792 (+11.1%) | 915 (+15.5%) |

| 16 | 0.14 | 0.144 | 448 | 779 (+73.9%) | 845 (+8.5%) | 1029 (+21.8%) |

| 17 | 0.14 | 0.284 | 464 | 826 (+77.9%) | 898 (+8.7%) | 1029 (+14.6%) |

| 18 | 0.14 | 0.424 | 464 | 825 (+77.8%) | 862 (+4.5%) | 1042 (+20.9%) |

| Curing Time | RM Medium (MPa) | ||||

|---|---|---|---|---|---|

| 0 | 1531.6 | 0.56 | 0.08 | 281 | 0.996 |

| 7 | 2752.46 | 0.56 | 0.08 | 506 (+80.1%) | 0.992 |

| 14 | 2825.28 | 0.56 | 0.04 | 561 (+10.9%) | 0.974 |

| 28 | 3743.49 | 0.60 | 0.04 | 670 (+19.4%) | 0.935 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, L.M.; Kox, R.P.; Guimarães, A.C.R.; Travincas, R.; Monteiro, S.N. Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer. Appl. Sci. 2024, 14, 7612. https://doi.org/10.3390/app14177612

Coelho LM, Kox RP, Guimarães ACR, Travincas R, Monteiro SN. Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer. Applied Sciences. 2024; 14(17):7612. https://doi.org/10.3390/app14177612

Chicago/Turabian StyleCoelho, Lisley Madeira, Rafael Pereira Kox, Antônio Carlos Rodrigues Guimarães, Rafael Travincas, and Sergio Neves Monteiro. 2024. "Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer" Applied Sciences 14, no. 17: 7612. https://doi.org/10.3390/app14177612