Multidisciplinary Optimization of Aircraft Aerodynamics for Distributed Propulsion Configurations

Abstract

:1. Introduction

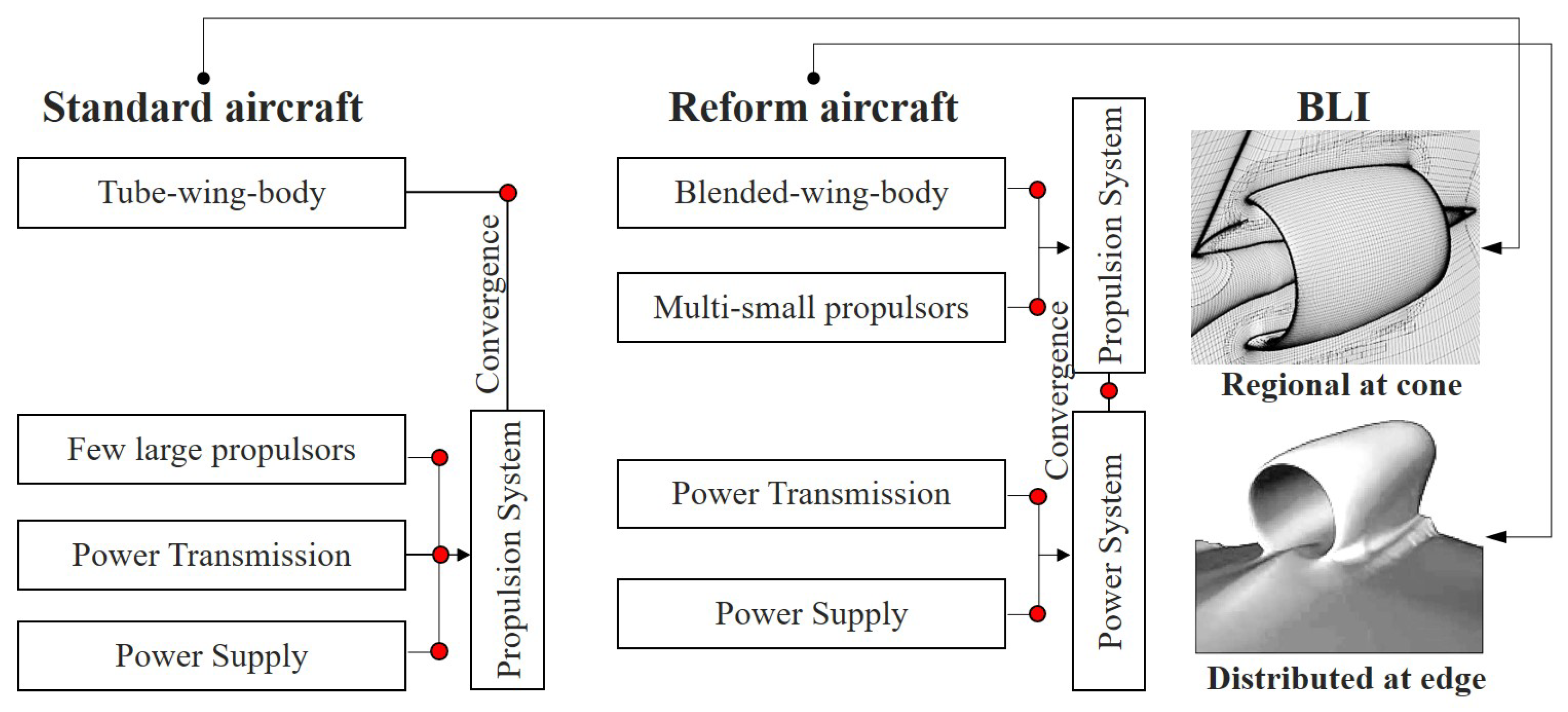

2. Development and Tendency of Aero-Propulsion

3. Performance and Coupling Effects of Aero-Propulsion

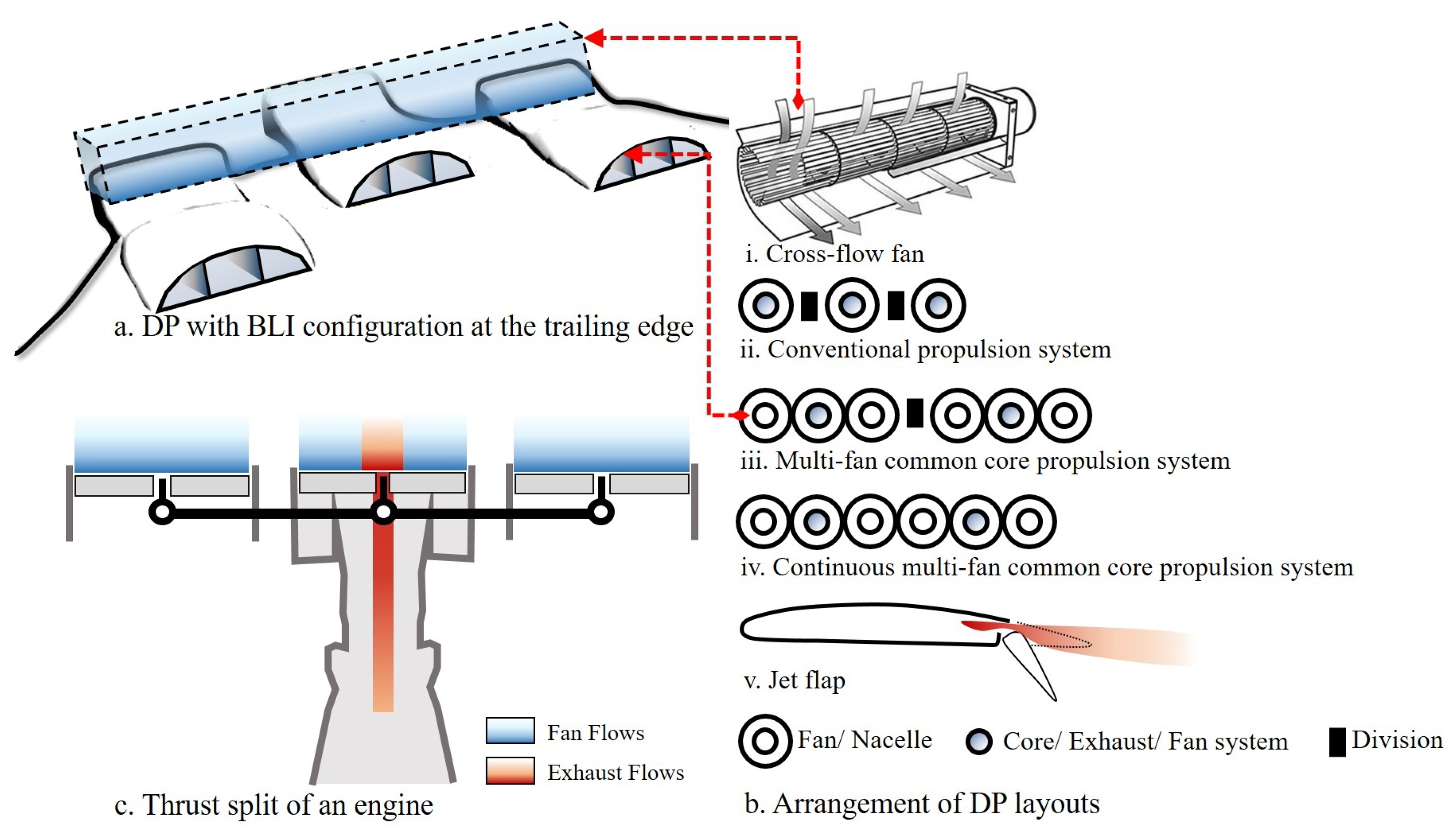

3.1. Configuration Design of Distributed Propulsion

3.2. Layout Features of Distributed Propulsion

3.3. Aero-Propulsive Coupling Effects

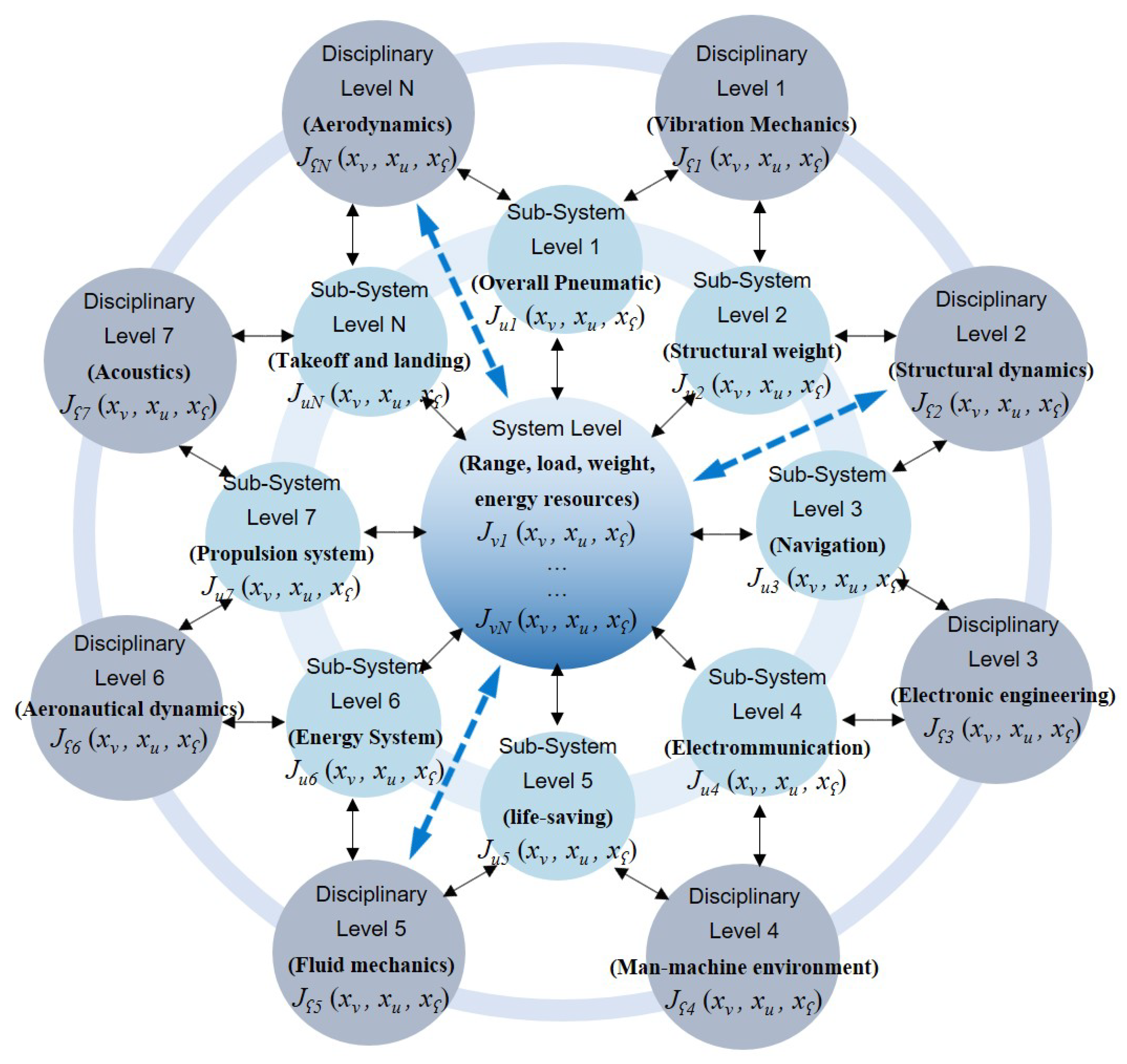

4. Multidisciplinary Analysis and Optimization in Aero-Propulsive Design

4.1. Interaction of Aero-Propulsion

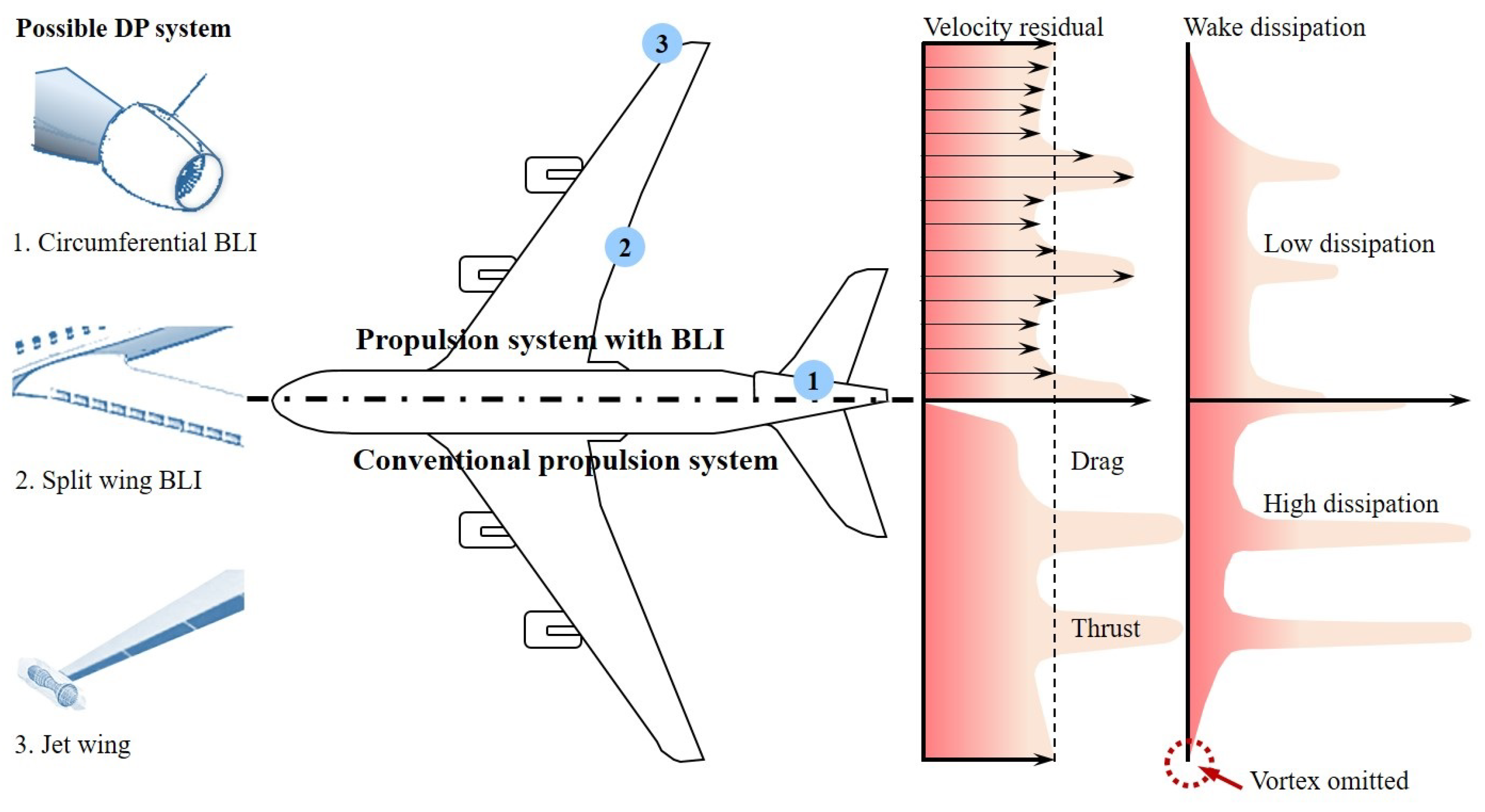

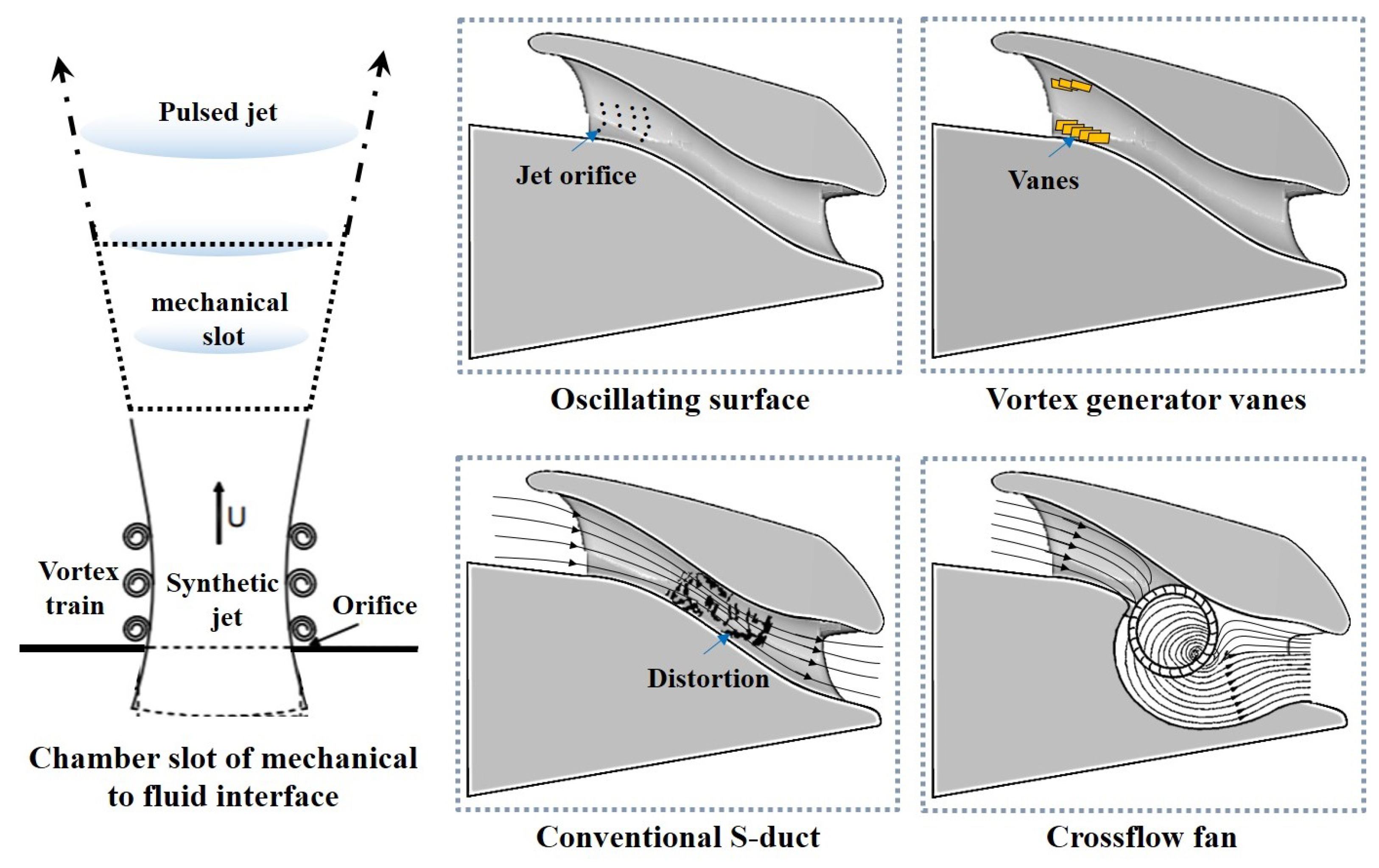

4.2. Wake Ingestion and Propulsion Technologies

- (i)

- Propulsion layout: In terms of the wingspan samples, distances between propulsors are all arranged in an even manner. Their thrust distributions are not arranged by considering the drag on each domain of an aircraft. This arrangement would cause a high drag domain (the central axis of an aircraft) to propel with low thrust and a low drag domain (the domain farther from the center axis) to propel with high thrust. If propulsor location is not considered according to the magnitude of the drag, the thrust might be dispersed and inadequate. It would cause the trailing edge to fail to reach the state of thrust balance, further causing the wake to dissipate. Ultimately, more propulsors would be requested, leading to higher energy consumption;

- (ii)

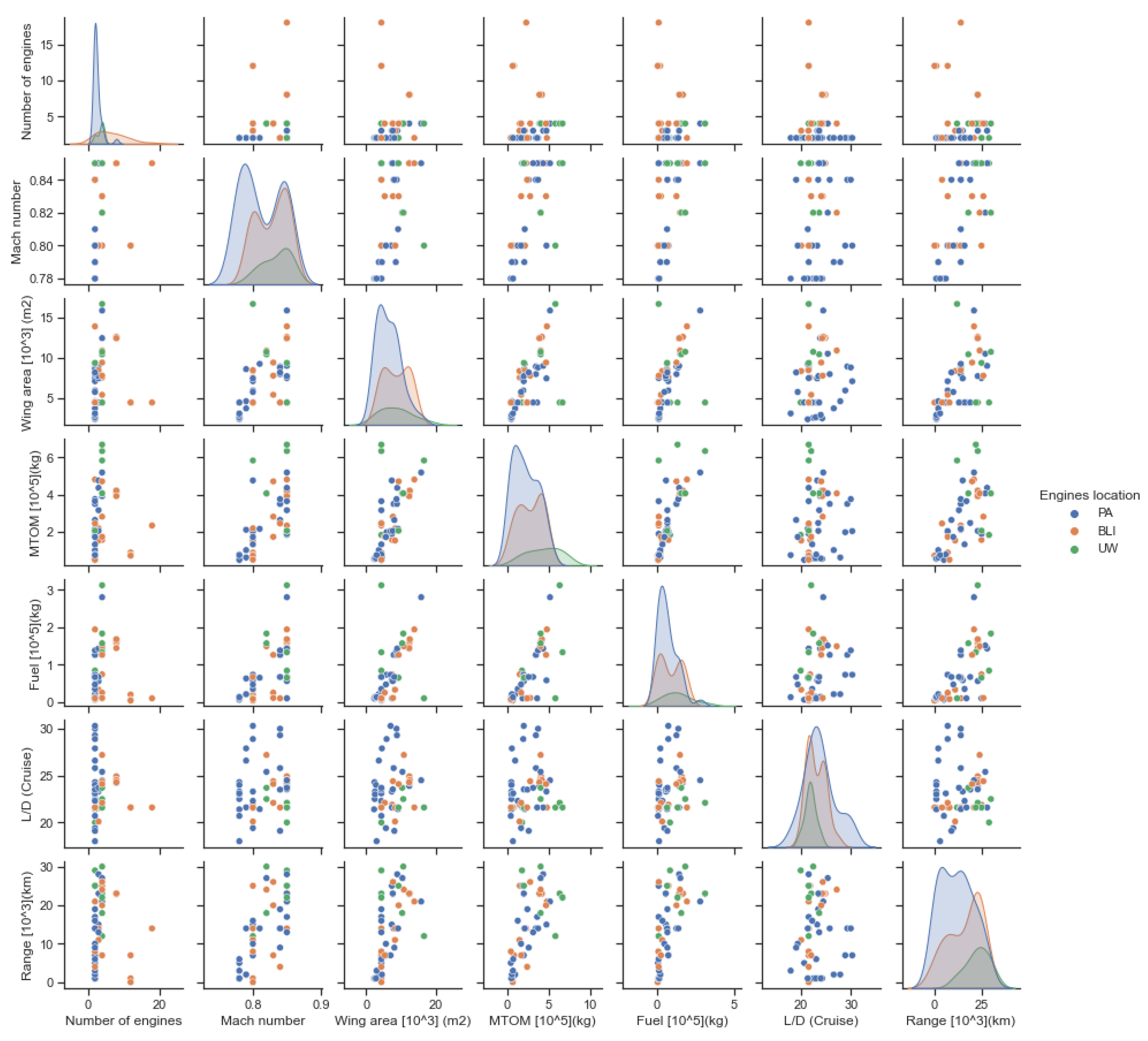

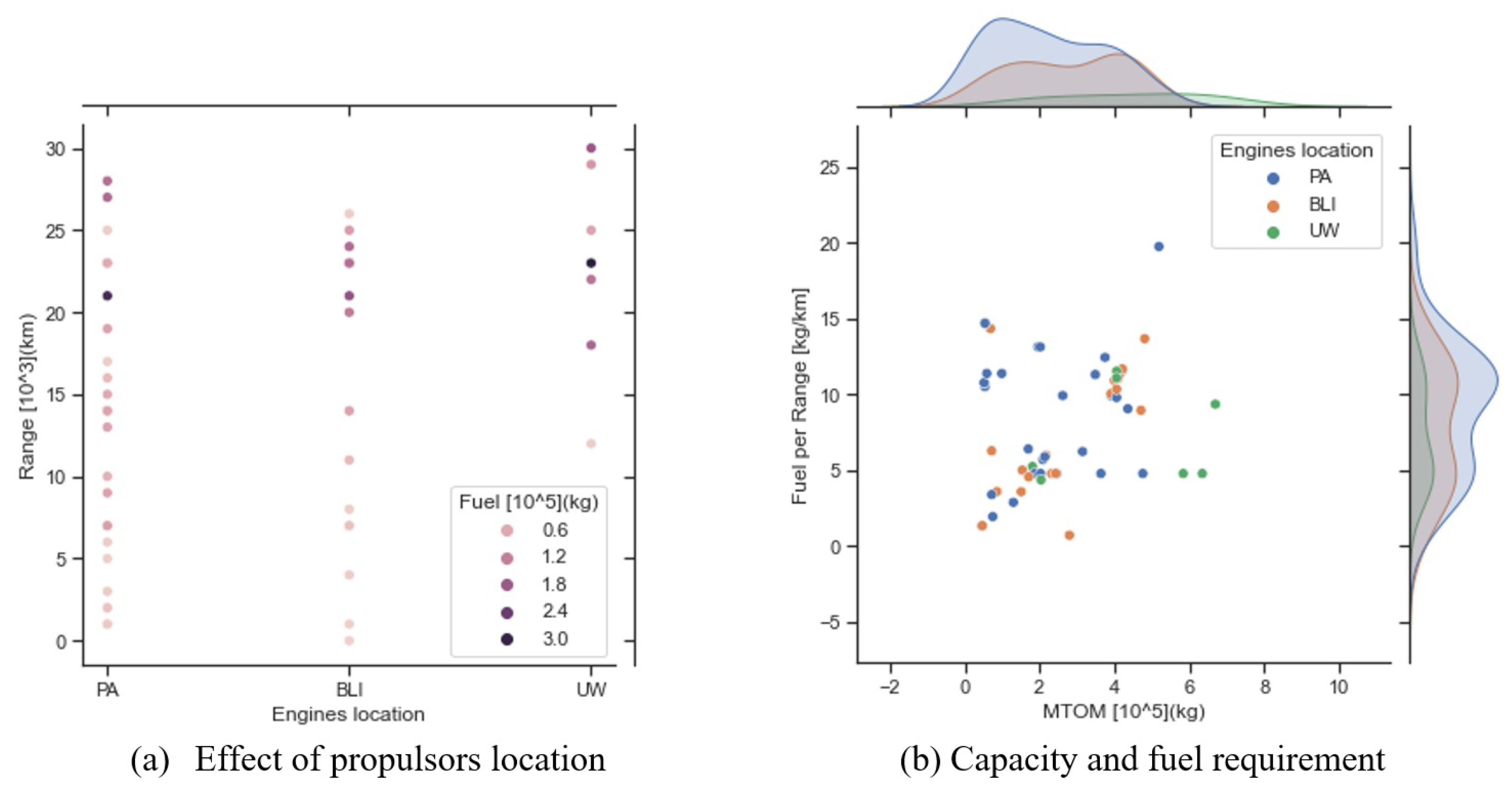

- Dilemmas in aero-propulsive integration: From the individual BLI local optimization to the aero-propulsive overall optimization, the difficulty of simulating and optimizing the performance of an overall aircraft is still sustained. The first reason is that local optimization results would mismatch the local optimization results of the overall optimization results. The second is that the computational methods and tools used to execute the overall aircraft optimization are more complex than the process for local optimization. In addition, the performance analysis of multidisciplinary objects is inherently flawed, such as the flight range, maximum take-off mass (MTOM), and fuel usage. The designer could adjust these at their discretion. Raising one factor’s performance to be advantaged and lowering the other two, or maximizing two of them and lowering one, can generate an illusion for readers that performance has been improved. Most proposal data are adjusted by optimization, in which the essential problem has not been solved, unless three of those performances are significantly better than others. Otherwise, advanced algorithms or MDAO must be performed on the displayed data.

4.3. Propulsion Controlled Aircraft

4.4. Frameworks of Multidisciplinary Optimization

5. Research Challenges and Future Trends

5.1. Scheme of Aero-Propulsive Configuration

5.2. Flow Distortion Optimization

5.3. Application of Energy Methods

| Ref. | Energy Sources | Consumables | Configuration | Gravimetric Energy (MJ/kg) | Composition Product | Emission Product |

|---|---|---|---|---|---|---|

| [97] | Mechanical | Gasoline | Jet fuel, power | , | + | |

| [98] | turbine, fan. | |||||

| . | ||||||

| [99] | Pneumatic | Liquefied Natural | Gas Generator, jet | |||

| [100] | Gas (Methane) | fuel, power turbine, | ||||

| Liquid hydrogen | gearbox, fan. | 142 | ||||

| [101] | Electrical | Lithium-ion | Battery, DC/AC | |||

| (All electric) | inverter, electric | |||||

| motor, gearbox, fan | ||||||

| [102] | Hybrid-electric | Liquefied Natural | Gas Generator, jet | , | , | |

| [103] | (Serial hybrid | Gas, lithium-ion | fuel, power turbine, | |||

| [104] | electric propulsion) | electric generator, | ||||

| AC/DC rectifier, | ||||||

| Battery, DC/AC | ||||||

| inverter, Electric | ||||||

| motor, fan. | ||||||

| [105] | Electroaerodynamic | Lithium-ion | Polymer cells | , | ||

| [106] | polymer cells |

5.4. Algorithm of Multidisciplinary Optimization

6. Conclusions

- Propulsion-airframe: The choice of configuration coupling objects lead to a huge performance difference in the aero-propulsive layout. An incorrect pairing potentially loses the layout benefits from an original configuration. When DP is mounted on the TWB wing, a regional propulsor has to be embedded simultaneously in the aft to rectify the problem of wake losses in the aft. Meanwhile, the larger and more concentrated thrust at the aft either fills or even penetrates the wake. These circumstances cause the DP layout to become invalid and redundant on TWB. Contrarily, the coupling relation between DP and BWB can maintain the original thrust characteristics of DP. It can add some extra benefits to aircraft configuration, such as omitting the area and weight of the rudder, improving the flight performance in the L/D ratio, shortening takeoff distance under specific conditions, etc. However, studies in boundary layer ingestion (BLI) in regional propulsion have shown that TWB has a propulsion efficiency advantage over BWB. The reason is that the current distributed method of BLI is unable to fill the wake loss in BWB completely. Since the drag of BWB is not concentrated on the central axis but is diffused, it makes the uniform thrust of DP unable to achieve the effect of thrust–drag balance after being integrated with BWB. To achieve complete distributed advancement, the distribution of thrust should not depend on the number of propulsors, but should take into account the drag on the aircraft;

- Scheme and design: The layouts and frameworks of 59 aero-propulsive cases from different research units are analyzed. Most layout ideas are constructed and based on the parametric model of the predecessors. The propulsor positions are mostly those predicted to be likely to have high propulsion efficiency. Then, various commercial MDO software is used to optimize the target performance, such as flight range, load, fuel quantity, etc. In fact, scheme selection, evaluation, and analysis of aero-propulsion should be conducted before constructing the parametric model, because conducting the MDO with the existing conventional propulsors and DP layout will not obtain a fresh and effective scheme. From an essential viewpoint of DP, DP does not refer to the distribution of propulsors but the distribution of thrust. These physical limitations lead to the neglect of elongated cross-flow fans that can fully cover the trailing edge of the BWB. Additionally, energy or more advanced propulsion systems that could assist the elongated cross-flow fan are also ignored. Thus, a thrust–drag analysis and calculation model framework for the aircraft’s trailing edge is urgently established such that thrust corresponding to the drag can be distributed and coordinated in each trailing part of the aircraft. This configuration could improve layout efficiency and effectiveness to promptly accomplish momentum balance and reduce the energy consumption of flight;

- MDO framework: In terms of multidisciplinary optimization, it can be found that the current goal of disciplinary integration is growing larger. The integrated disciplines include aerodynamics, propulsion, structure, weight, stability, control, and additional duct systems. In the wake of functional coordination and coupling, the problem of mutual interference also happened. In general, splitting or local computing methods are unable to solve these problems. Since there are too many interdisciplinary subjects, large-scale multi-level nesting multidisciplinary optimization modeling and efficient parallel algorithms that possess coupled performance analysis have to deal with these problems. Among them, the path design of system level and attribute classification can be used to improve scale precision and enhance the reliability of parallel algorithms. On the other hand, the current commercial MDO framework allows users to use optimization algorithms easily. However, they are mostly optimization programs with extremely slow convergence speeds. In addition, the codes of these algorithms cannot be modified in order to compare their efficiency. An optimization system that allows users to explore the coupling system and develop, improve, and update personally could accelerate the development of optimization methods. It has become one of the current trends of MDO development.

Funding

Conflicts of Interest

Correction Statement

Appendix A

| Ref. | Year | Selected BWB | Engines Location | Thrust Split | Number of Engines (Fans) | Mach Number | Wing Area (m2) | MTOM (kg) | Payload (kg) | Fuel (kg) | Pax | L/D (Cru) | Range (km) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [8] | 2011 | BWB-450-1 | PA | No | 4 | (4) | 0.85 | 1245 | 390,920 | 47,700 | 142,578 | 480 | 23.90 | 14,353 |

| [8] | 2011 | BWB-450-2 | PA | No | 8 | (8) | 0.85 | 1258 | 420,929 | 47,700 | 166,007 | 480 | 24.23 | 14,353 |

| [8] | 2011 | BWB-450-3 | BLI | No | 8 | (8) | 0.85 | 1248 | 410,432 | 47,700 | 159,442 | 480 | 24.90 | 14,353 |

| [8] | 2011 | BWB-450-4 | BLI | No | 8 | (8) | 0.85 | 1248 | 409,602 | 47,700 | 158,628 | 480 | 24.92 | 14,353 |

| [8] | 2011 | BWB-450-5 | BLI | No | 8 | (8) | 0.85 | 1249 | 399,603 | 47,700 | 156,947 | 480 | 24.54 | 14,353 |

| [8] | 2011 | BWB-450-6 | BLI | No | 8 | (8) | 0.85 | 1258 | 414,230 | 47,700 | 162,579 | 480 | 24.39 | 14,353 |

| [8] | 2011 | BWB-450-7 | BLI | No | 8 | (8) | 0.85 | 1260 | 420,712 | 47,700 | 167,787 | 480 | 24.52 | 14,353 |

| [8] | 2011 | BWB-450-8 | BLI | No | 8 | (8) | 0.85 | 1243 | 390,699 | 47,700 | 144,412 | 480 | 24.28 | 14,353 |

| [117] | 2007 | CESTOL-3000 nmi | BLI | No | 12 | (12) | 0.80 | 444 | 85,793 | 18,144 | 20,003 | 170 | - | 5556 |

| [117] | 2007 | CESTOL-500 nmi | BLI | No | 12 | (12) | 0.80 | 444 | 71,610 | 18,144 | 5821 | 170 | - | 926 |

| [117] | 2007 | CESTOL-150 nmi | BLI | No | 12 | (12) | 0.80 | 444 | 69,325 | 18,144 | 3988 | 170 | - | 278 |

| [82] | 2014 | FW-UWE | UW | No | 2 | (2) | 0.85 | - | 181,437 | 18,144 | 84,000 | 256 | 20.00 | 16,000 |

| [118] | 2011 | BWB-350 | BLI | No | 18 | (18) | 0.85 | - | 232,000 | - | - | 350 | - | 11,112 |

| [22] | 2016 | BW-11 mission | BLI | No | 2 | (2) | 0.85 | 1391 | 481,148 | 65,115 | 193,821 | 555 | - | 14,173 |

| [83] | 2001 | Hybrid layout-IWB | PA | No | 4 | (4) | 0.85 | 1588 | 518,910 | 103,419 | 280,000 | 975 | 24.5 | 14,168 |

| [83] | 2001 | Lifting-body | UW | No | 4 | (4) | 0.80 | 1670 | 583,774 | 121,294 | - | 940 | - | 10,000 |

| [35] | 2006 | SAX-12 | BLI | No | 4 | (4) | 0.80 | 754 | 154,290 | - | 74,224 | 215 | 21.9 | 14,816 |

| [36] | 2007 | SAX-40 | BLI | Yes | 3 | (9) | 0.80 | 836 | 150,847 | 23,405 | 33,253 | 215 | 20.1 | 9260 |

| [119] | 2014 | BWB | PA | No | 2 | (2) | 0.85 | 748 | 186,970 | 22,680 | - | 224 | - | 14,816 |

| [120] | 2015 | BWB100-02 | PA | No | 2 | (2) | 0.78 | 254 | 54,295 | 12,882 | 9752 | 105 | 22.5 | 926 |

| [120] | 2015 | BWB100-03 | PA | No | 2 | (2) | 0.78 | 261 | 54,295 | 12,882 | 9752 | 105 | 23.3 | 926 |

| [120] | 2015 | BWB100-10 | PA | No | 2 | (2) | 0.78 | 236 | 52,345 | 12,882 | 9979 | 105 | 21.4 | 926 |

| [120] | 2015 | BWB100-12 | PA | No | 2 | (2) | 0.78 | 248 | 52,345 | 12,882 | 9979 | 105 | 24.3 | 926 |

| [120] | 2015 | BWB300-00 | PA | No | 2 | (2) | 0.84 | 797 | 348,586 | 63,957 | 125,781 | 310 | 25.8 | 11,112 |

| [120] | 2015 | BWB300-02 | PA | No | 2 | (2) | 0.84 | 892 | 348,586 | 63,957 | 125,781 | 310 | 29.3 | 11,112 |

| [121] | 2014 | BWB100-1 | PA | No | 2 | (2) | 0.78 | 261 | 54,975 | 15,014 | 13,608 | 100 | 23.00 | 926 |

| [121] | 2014 | BWB160-1 | PA | No | 2 | (2) | 0.79 | 371 | 98,566 | 26,762 | 21,092 | 160 | 26.60 | 1852 |

| [121] | 2014 | BWB220-1 | PA | No | 2 | (2) | 0.80 | 594 | 196,224 | 60,872 | 73,028 | 220 | 28.90 | 5556 |

| [121] | 2014 | BWB300-1 | PA | No | 2 | (2) | 0.84 | 880 | 375,030 | 317,742 | 138,346 | 300 | 30.00 | 11,112 |

| [121] | 2014 | LFC100-1 | PA | No | 2 | (2) | 0.78 | 290 | 53,841 | 14,969 | 13,608 | 100 | 24.00 | 926 |

| [121] | 2014 | LFC160-1 | PA | No | 2 | (2) | 0.79 | 460 | 59,073 | 26,308 | 21,092 | 160 | 27.90 | 1852 |

| [121] | 2014 | LFC220-1 | PA | No | 2 | (2) | 0.80 | 709 | 201,577 | 61,643 | 73,028 | 220 | 30.30 | 5556 |

| [68] | 2018 | BWB | PA | No | 3 | (3) | 0.85 | 900 | 435,617 | 59,000 | 142,622 | 450 | - | 15,742 |

| [122] | 2016 | VELA 3 | UW | No | 4 | (4) | - | - | 635,029 | 124,284 | 312,072 | 750 | 22.10 | - |

| [123] | 2013 | OREIO | PA | No | 3 | (3) | 0.80 | 744 | 475,800 | 45,359 | 57,611 | - | 23.30 | 12,038 |

| [124] | 2011 | N2A | PA | No | 2 | (2) | 0.79 | 859 | 209,333 | 46,720 | 63,458 | - | 21.61 | 11,112 |

| [124] | 2011 | N2B | BLI | Yes | 3 | (9) | 0.80 | 846 | 216,545 | 46,720 | 66,587 | - | 21.55 | 11,112 |

| [124] | 2011 | N2A-EXTE | PA | No | 2 | (2) | 0.81 | 925 | 213,914 | 46,720 | 65,493 | - | 21.42 | 11,112 |

| [125] | 2017 | ACFA | PA | No | 2 | (2) | 0.85 | - | 363,781 | 45,359 | - | 450 | - | 13,334 |

| [126] | 2012 | BWB | PA | No | 4 | (4) | 0.82 | 1051 | 405,900 | 122,100 | 151,000 | - | 25.40 | 15,403 |

| [127] | 2011 | ERA-224 | PA | No | 3 | (3) | 0.85 | 772 | 202,756 | 45,545 | 56,246 | 223 | 23.53 | - |

| [128] | 2012 | HWB98 | PA | No | 2 | (2) | 0.78 | - | 45,813 | 9800 | 5906 | 98 | 20.70 | 4445 |

| [128] | 2012 | HWB160 | PA | No | 2 | (2) | 0.78 | - | 75,342 | 17,128 | 10,369 | 160 | 23.10 | 5325 |

| [128] | 2012 | HWB216 | PA | No | 2 | (2) | 0.80 | - | 130,136 | 20,185 | 35,349 | 216 | 22.30 | 12,223 |

| [128] | 2012 | HWB301 | PA | No | 2 | (2) | 0.84 | - | 246,119 | 53,569 | 66,506 | 301 | 23.50 | 13,890 |

| [128] | 2012 | HWB400 | PA | No | 3 | (3) | 0.85 | - | 314,612 | 67,059 | 67,064 | 400 | 23.70 | 10,742 |

| [129] | 2018 | Ascent 1000 | BLI | No | 2 | (2) | 0.80 | - | 46,802 | 17,091 | 7983 | 112 | 21.60 | 5926 |

| [84] | 2014 | Aft-mounted | BLI | No | 4 | (4) | 0.82 | 1091 | 406,000 | 66,400 | 149,000 | 400 | 27.20 | 14,400 |

| [84] | 2014 | Wing-mounted | UW | No | 4 | (4) | 0.82 | 1043 | 406,000 | 66,400 | 157,000 | 400 | 23.70 | 13,600 |

| [84] | 2014 | Forward-swept | UW | No | 4 | (4) | 0.82 | 1074 | 406,000 | 66,400 | 183,000 | 400 | 22.50 | 16,500 |

| [4] | 2016 | Baseline BWB | UW | No | 2 | (2) | 0.85 | 937 | 203,675 | 33,309 | 64,814 | 350 | - | 14,816 |

| [124] | 2008 | BWB | UW | No | 4 | (4) | 0.85 | - | 670,000 | 100,110 | 132,920 | 700 | - | 14,200 |

| [130] | 2010 | H1 | BLI | No | 4 | (4) | 0.83 | 540 | 171,287 | 18,371 | 25,368 | 180 | 22.10 | 5556 |

| [130] | 2010 | H2 | BLI | No | 4 | (4) | 0.83 | 778 | 279,950 | 44,707 | 11,126 | 256 | 24.40 | 15,372 |

| [130] | 2010 | H3 | BLI | No | 4 | (4) | 0.83 | 941 | 470,566 | 60,977 | 126,159 | 354 | 24.10 | 14,075 |

| [131] | 2018 | BWB150 | PA | No | 2 | (2) | 0.78 | 308 | 72,000 | 20,500 | 13,320 | 156 | 18.00 | 3917 |

| [131] | 2018 | BWB250 | PA | No | 2 | (2) | 0.80 | 575 | 170,000 | 43,800 | 46,580 | 248 | 19.40 | 7264 |

| [131] | 2018 | BWB400 | PA | No | 2 | (2) | 0.84 | 818 | 262,000 | 64,000 | 66,555 | 368 | 19.10 | 6700 |

| [132] | 2015 | baseline HWB | BLI | No | 2 | (2) | 0.84 | - | 243,253 | 29,030 | - | 300 | 21.60 | 4066 |

References

- Zhenli, C.; Zhang, M.; Yingchun, C.; Weimin, S.; Zhaoguang, T.; Dong, L.; Zhang, B. Assessment on critical technologies for conceptual design of blended-wing-body civil aircraft. Chin. J. Aeronaut. 2019, 32, 1797–1827. [Google Scholar]

- Greitzer, E.M.; Bonnefoy, P.A.; Dela Rosa Blanco, E.; Dorbian, C.S.; Drela, M.; Hall, D.K.; Hansman, R.J.; Hileman, J.I.; Liebeck, R.H.; Lovegren, J.; et al. N+3 Aircraft Concept Designs and Trade Studies; NASA Langley Research Center: Hanover, MD, USA, 2010. [Google Scholar]

- Valencia, E.; Alulema, V.; Rodriguez, D.; Laskaridis, P.; Roumeliotis, I. Novel fan configuration for distributed propulsion systems with boundary layer ingestion on an hybrid wing body airframe. Therm. Sci. Eng. Prog. 2020, 18, 100515. [Google Scholar] [CrossRef]

- Kirner, R.; Raffaelli, L.; Rolt, A.; Laskaridis, P.; Doulgeris, G.; Singh, R. An assessment of distributed propulsion: Advanced propulsion system architectures for conventional aircraft configurations. Aerosp. Sci. Technol. 2015, 46, 42–50. [Google Scholar] [CrossRef]

- Jones, C.E.; Norman, P.J.; Galloway, S.J.; Armstrong, M.J.; Bollman, A.M. Comparison of candidate architectures for future distributed propulsion aircraft. IEEE Trans. App. Supercond. 2016, 26, 1–9. [Google Scholar] [CrossRef]

- Todd, D.; Simpson, J. The World Aircraft Industry; Routledge: London, UK, 2019. [Google Scholar]

- Abbas, A.; De Vicente, J.; Valero, E. Aerodynamic technologies to improve aircraft performance. Aerosp. Sci. Technol. 2013, 28, 100–132. [Google Scholar] [CrossRef]

- Leifsson, L.; Ko, A.; Mason, W.H.; Schetz, J.A.; Grossman, B.; Haftka, R.T. Multidisciplinary design optimization of blended-wing-body transport aircraft with distributed propulsion. Aerosp. Sci. Technol. 2013, 25, 16–28. [Google Scholar] [CrossRef]

- Gohardani, A.S.; Doulgeris, G.; Singh, R. Challenges of future aircraft propulsion: A review of distributed propulsion technology and its potential application for the all electric commercial aircraft. Prog. Aerosp. Sci. 2011, 47, 369–391. [Google Scholar] [CrossRef]

- Isikveren, A.T.; Seitz, A.; Bijewitz, J.; Mirzoyan, A.; Isyanov, A.; Grenon, R.; Atinault, O.; Godard, J.L.; Stueckl, S. Distributed propulsion and ultra-high by-pass rotor study at aircraft level. Aeronaut. J. 2015, 119, 1327–1376. [Google Scholar] [CrossRef]

- Manneville, A.; Pilczer, D.; Spakovszky, Z. Noise reduction assessments and preliminary design implications for a functionally-silent aircraft. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004; p. 2925. [Google Scholar]

- Riboldi, C.E. An optimal approach to the preliminary design of small hybrid-electric aircraft. Aerosp. Sci. Technol. 2018, 81, 14–31. [Google Scholar] [CrossRef]

- Moore, K.R.; Ning, A. Takeoff and performance trade-offs of retrofit distributed electric propulsion for urban transport. J. Aircr. 2019, 56, 1880–1892. [Google Scholar] [CrossRef]

- Lv, P.; Rao, A.G.; Ragni, D.; Veldhuis, L. Performance analysis of wake and boundary-layer ingestion for aircraft design. J. Aircr. 2016, 53, 1517–1526. [Google Scholar] [CrossRef]

- Goldberg, C.; Nalianda, D.; Pilidis, P.; MacManus, D.; Felder, J. Installed performance assessment of a boundary layer ingesting distributed propulsion system at design point. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016; p. 4800. [Google Scholar]

- Epstein, A.H. Distributed Propulsion: New Opportunities for an Old Concept; Massachusetts Institute of Technology: Cambridge, MA, USA, 2007; HR0011-07-C-0005. [Google Scholar]

- Betz, A. Introduction to the Theory of Flow Machines; First English Edition; Pergamon Press: New York, NY, USA, 1966; pp. 215–217. [Google Scholar]

- Orefice, F.; Corcione, S.; Nicolosi, F.; Ciliberti, D.; De-Rosa, G. Performance Calculation for Hybrid-Electric Aircraft integrating Aero-Propulsive Interactions. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–15 & 19–21 January 2021; p. 1640. [Google Scholar]

- Orefice, F.; Della-Vecchia, P.; Ciliberti, D.; Nicolosi, F. Aircraft conceptual design including powertrain system architecture and distributed propulsion. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 22–24 August 2019; pp. 1–20. [Google Scholar]

- Kok, H.; Voskuijl, M.; van Tooren, M. Distributed propulsion featuring boundary layer ingestion engines for the blended wing body subsonic transport. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 18th AIAA/ASME/AHS Adaptive Structures Conference 12th, Orlando, FL, USA, 12–15 April 2010; p. 3064. [Google Scholar]

- Qin, N.; Vavalle, A.; Le Moigne, A.; Laban, M.; Hackett, K.; Weinerfelt, P. Aerodynamic considerations of blended wing body aircraft. Prog. Aerosp. Sci. 2004, 40, 321–343. [Google Scholar] [CrossRef]

- Okonkwo, P.; Smith, H. Review of evolving trends in blended wing body aircraft design. Prog. Aerosp. Sci. 2016, 82, 1–23. [Google Scholar] [CrossRef]

- Ammar, S.; Legros, C.; Trépanier, J.-Y. Conceptual design, performance and stability analysis of a 200 passengers Blended Wing Body aircraft. Aerosp. Sci. Technol. 2017, 71, 325–336. [Google Scholar] [CrossRef]

- Liebeck, R.; Page, M.; Rawdon, B. Blended-wing-body subsonic commercial transport. In Proceedings of the 36th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 12–15 January 1998; p. 438. [Google Scholar]

- Schrauf, G. Status and perspectives of laminar flow. Aeronaut. J. 2005, 109, 639–644. [Google Scholar] [CrossRef]

- Liebeck, R.H. Design of the blended wing body subsonic transport. J. Aircr. 2004, 41, 10–25. [Google Scholar] [CrossRef]

- Blumenthal, B.T.; Elmiligui, A.A.; Geiselhart, K.A.; Campbell, R.L.; Maughmer, M.D.; Schmitz, S. Computational investigation of a boundary-layer-ingestion propulsion system. J. Aircr. 2018, 55, 1141–1153. [Google Scholar] [CrossRef]

- Drela, M. Flight Vehicle Aerodynamics; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Snedeker, R.S.; Bilanin, A.J. Analysis of the Vortex Wakes of the Boeing 727, Lockheed L-1011, McDonnell Douglas DC-10, and Boeing 747 Aircraft; Transportation Systems Center: Cambridge, MA, USA, 1975; 1A844. [Google Scholar]

- Goulos, I.; Otter, J.; Tejero, F.; Rebassa, J.H.; MacManus, D.; Sheaf, C. Civil turbofan propulsion aerodynamics: Thrust-drag accounting and impact of engine installation position. Aerosp. Sci. Technol. 2021, 111, 106533. [Google Scholar] [CrossRef]

- Ko, A.; Leifsson, L.; Schetz, J.; Mason, W.; Grossman, B.; Haftka, R. MDO of a blended-wing-body transport aircraft with distributed propulsion. In Proceedings of the AIAA’s 3rd Annual Aviation Technology, Integration, and Operations (ATIO) Forum, Denver, CO, USA, 17–19 November 2003; p. 6732. [Google Scholar]

- Seitz, A. Advanced Methods for Propulsion System Integration in Aircraft Conceptual Design. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2012. [Google Scholar]

- De la Rosa Blanco, E.; Hall, C.; Crichton, D. Challenges in the silent aircraft engine design. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007; p. 454. [Google Scholar]

- Hall, C.A.; Crichton, D. Engine Design Studies for a Silent Aircraft. J. Turbomach. 2006, 129, 479–487. [Google Scholar] [CrossRef]

- Diedrich, A.; Hileman, J.; Tan, D.; Willcox, K.; Spakovszky, Z. Multidisciplinary design and optimization of the silent aircraft. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 1323. [Google Scholar]

- Hileman, J.; Spakovszky, Z.; Drela, M.; Sargeant, M. Airframe design for silent aircraft. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007; p. 453. [Google Scholar]

- Kawai, R.; Brown, D.; Roman, D.; Odle, R. Acoustic Prediction Methodology and Test Validation for an Efficient Low-Noise Hybrid Wing Body Subsonic Transport; NASA Langley Research Center: Hampton, VA, USA, 2011; NF1676L-14465. [Google Scholar]

- Hall, C.A.; Schwartz, E.; Hileman, J.I. Assessment of technologies for the silent aircraft initiative. J. Propuls. Power 2009, 25, 1153–1162. [Google Scholar] [CrossRef]

- Toffolo, A.; Lazzaretto, A.; Martegani, A.D. Cross-flow fan design guidelines for multi-objective performance optimization. Proc. Inst. Mech. Eng. Part A J. Power Energy 2004, 218, 33–42. [Google Scholar] [CrossRef]

- Khalid, S.J. Aerothermodynamic benefits of mixed exhaust turbofans. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016; p. 4641. [Google Scholar]

- Arntz, A.; Atinault, O.; Merlen, A. Exergy-based formulation for aircraft aeropropulsive performance assessment: Theoretical development. AIAA J. 2015, 53, 1627–1639. [Google Scholar] [CrossRef]

- Whurr, J.; Rolt, A.M. Distributed propulsion systems to maximize the benefits of boundary layer ingestion. In Proceedings of the ISABE, Phoenix, AZ, USA, 25–30 October 2016; p. 20288. [Google Scholar]

- Jansen, R.; Bowman, C.; Jankovsky, A.; Dyson, R.; Felder, J. Overview of NASA electrified aircraft propulsion research for large subsonic transports. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017; p. 4701. [Google Scholar]

- Kim, H.D.; Felder, J.L.; Tong, M.T.; Berton, J.J.; Haller, W.J. Turboelectric distributed propulsion benefits on the N3-X vehicle. Aircr. Eng. Aerosp. Technol. 2014, 86, 558–561. [Google Scholar] [CrossRef]

- Schiltgen, B.T.; Freeman, J. ECO-150-300 design and performance: A tube-and-wing distributed electric propulsion airliner. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019; p. 1808. [Google Scholar]

- Ameyugo, G.; Taylor, M.; Singh, R. Distributed propulsion feasibility studies. In Proceedings of the 25th International Congress of the Aeronautical Sciences, Hamburg, Germany, 3–8 September 2006; p. 06. [Google Scholar]

- Steiner, H.J.; Seitz, A.; Wieczorek, K.; Plötner, K.; Isikveren, A.T.; Hornung, M. Multi-disciplinary design and feasibility study of distributed propulsion systems. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; pp. 23–28. [Google Scholar]

- Kratz, J.L.; Thomas, G.L. Dynamic analysis of the STARC-ABL propulsion system. In Proceedings of the AIAA Propul Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019; p. 4182. [Google Scholar]

- Kenway, G.K.; Kiris, C.C. Aerodynamic shape optimization of the STARC-ABL concept for minimal inlet distortion. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018; p. 1912. [Google Scholar]

- Schmidt, K.; Vos, R. A semi-analytical weight estimation method for oval fuselages in conventional and novel aircraft. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014; p. 0026. [Google Scholar]

- Trancossi, M.; Stewart, J.; Pascoa, J.C. A New propelled wing aircraft configuration. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. 50510:V001T03A048. [Google Scholar]

- Felder, J.; Tong, M.; Chu, J. Sensitivity of mission energy consumption to turboelectric distributed propulsion design assumptions on the N3-X hybrid wing body aircraft. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012; p. 3701. [Google Scholar]

- Perry, A.T.; Ansell, P.J.; Kerho, M.F. Aero-propulsive and propulsor cross-coupling effects on a distributed propulsion system. J. Aircr. 2018, 55, 2414–2426. [Google Scholar] [CrossRef]

- Gibson, A.; Hall, D.; Waters, M.; Schiltgen, B.; Foster, T.; Papathakis, K. Superconducting electric distributed propulsion structural integration and design in a split-wing regional airliner. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; p. 223. [Google Scholar]

- Kuprikov, M. Cross-polar routes as a factor that changed the geometric layout of long-haul aircrafts flying over long distances. J. Mech. Eng. Res. 2018, 41, 53–57. [Google Scholar] [CrossRef]

- Trittler, M.; Fichter, W.; Voit-Nitschmann, R.; Schmoldt, R.; Kittmann, K. Preliminary system identification of the blended wing body flight demonstrator VELA 2 from flight data. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference and Exhibit, Honolulu, HI, USA, 18–21 August 2008; p. 6896. [Google Scholar]

- Nguyen, N.T.; Reynolds, K.; Ting, E.; Nguyen, N. Distributed propulsion aircraft with aeroelastic wing shaping control for improved aerodynamic efficiency. J. Aircr. 2018, 55, 1122–1140. [Google Scholar] [CrossRef]

- Zhang, J.; Kang, W.; Yang, L. Aerodynamic benefits of boundary layer ingestion for distributed propulsion configuration. Aircr. Eng. Aerosp. Technol. 2019, 91, 1285–1294. [Google Scholar] [CrossRef]

- Sturm, R.; Hepperle, M. Crashworthiness and ditching behaviour of blended-wing-body (BWB) aircraft design. Int. J. Crashworthiness 2015, 20, 592–601. [Google Scholar] [CrossRef]

- Smith, H. Airframe integration for an LH2 hybrid-electric propulsion system. Aircr. Eng. Aerosp. Technol. 2014, 86, 562–567. [Google Scholar] [CrossRef]

- Panagiotou, P.; Yakinthos, K. Parametric aerodynamic study of Blended-Wing-Body platforms at low subsonic speeds for UAV applications. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017; p. 3737. [Google Scholar]

- Siouris, S.; Qin, N. Study of the effects of wing sweep on the aerodynamic performance of a blended wing body aircraft. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 47–55. [Google Scholar] [CrossRef]

- Welstead, J.; Felder, J.L. Conceptual Design of a Single-Aisle Turboelectric Commercial Transport with Fuselage Boundary Layer Ingestion. In Proceedings of the 54th AIAA Aerospace Sciences Meetings, San Diego, CA, USA, 4–8 January 2016; p. 1027. [Google Scholar]

- Ranasinghe, K.; Guan, K.; Gardi, A.; Sabatini, R. Review of advanced low-emission technologies for sustainable aviation. Energy 2019, 188, 115945. [Google Scholar] [CrossRef]

- de Vries, R.; Brown, M.T.; Vos, R. A preliminary sizing method for hybrid-electric aircraft including aero-propulsive interaction effects. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018; p. 4228. [Google Scholar]

- Deters, R.W.; An a Krishnan, G.K.; Selig, M.S. Reynolds number effects on the performance of small-scale propellers. In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, Atlanta, GA, USA, 16–20 June 2014; p. 2151. [Google Scholar]

- Hardin, L.; Tillman, G.; Sharma, O.; Berton, J.; Arend, D. Aircraft system study of boundary layer ingesting propulsion. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012; p. 3993. [Google Scholar]

- Prakasha, P.S.; Della Vecchia, P.; Ciampa, P.; Ciliberti, D.; Charbonnier, D.; Jungo, A.; Fioriti, M.; Boggero, L.; Mirzoyan, A.; Anisimov, K.; et al. Model based collaborative design & optimization of blended wing body aircraft configuration: AGILE EU project. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018; p. 4006.

- Kawai, R.T.; Friedman, D.M.; Serrano, L. Blended Wing Body (BWB) Boundary Layer Ingestion (BLI) Inlet Configuration and System Studies; NASA Langley Research Center: Huntington Beach, CA, USA, 2006; NASA/CR-2006–214534. [Google Scholar]

- Laskaridis, P.; Pachidis, V.; Pilidis, P. Opportunities and challenges for distributed propulsion and boundary layer ingestion. Aircr. Eng. Aerosp. Technol. 2014, 86, 451–458. [Google Scholar] [CrossRef]

- Valencia, E.A.; Nalianda, D.; Laskaridis, P. Methodology to assess the performance of an aircraft concept with distributed propulsion and boundary layer ingestion using a parametric approach. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 682–693. [Google Scholar] [CrossRef]

- Allan, B.; Owens, L. Numerical modeling of flow control in a boundary-layer-ingesting offset inlet diffuser at transonic Mach numbers. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 845. [Google Scholar]

- Uranga, A.; Drela, M.; Greitzer, E.; Titchener, N.; Lieu, M.; Siu, N.; Huang, A.; Gatlin, G.M.; Hannon, J. Preliminary experimental assessment of the boundary layer ingestion benefit for the D8 aircraft. In Proceedings of the 52nd Aerospace Sciences Meetings, National Harbor, MD, USA, 13–17 January 2014; p. 0906. [Google Scholar]

- Pandya, S.A.; Uranga, A.; Espitia, A.; Huang, A. Computational Assessment of the Boundary Layer Ingesting Nacelle Design of the D8 Aircraft. In Proceedings of the 52nd Aerospace Sciences Meetings, National Harbor, MD, USA, 13–17 January 2014; p. 0907. [Google Scholar]

- Sabo, K.M.; Drela, M. Benefits of boundary layer ingestion propulsion. In Proceedings of the 53rd AIAA Aerospace Sciences Meetings, Kissimmee, FL, USA, 5–9 January 2015; p. 1667. [Google Scholar]

- Carrier, G.; Atinault, O.; Grenon, R. Numerical and experimental aerodynamic investigations of boundary layer ingestion for improving propulsion efficiency of future air transport. In Proceedings of the 31st AIAA Applied Aerodynamics Conference, San Diego, CA, USA, 24–27 June 2013; p. 2406. [Google Scholar]

- Sobieszczanski-Sobieski, J.; Haftka, R.T. Multidisciplinary aerospace design optimization: Survey of recent developments. Struct. Optim. 1997, 14, 1–23. [Google Scholar] [CrossRef]

- Zheng, J.; Chang, J.; Ma, J.; Yu, D. Modeling and analysis for integrated airframe/propulsion control of vehicles during mode transition of over-under turbine-based-combined-cycle engines. Aerosp. Sci. Technol. 2019, 95, 105462. [Google Scholar] [CrossRef]

- Burston, M.; Ranasinghe, K.; Gardi, A.; Parezanovic, V.; Ajaj, R.; Sabatini, R. Design principles and digital control of advanced distributed propulsion systems. Energy 2021, 241, 122788. [Google Scholar] [CrossRef]

- Seitz, A.; Gologan, C. Parametric design studies for propulsive fuselage aircraft concepts. CEAS Aeronaut. J. 2015, 6, 69–82. [Google Scholar] [CrossRef]

- Silva, H.L.; Resende, G.J.; Neto, R.; Carvalho, A.R.; Gil, A.A.; Cruz, M.A.; Guimarães, T.A.M. A multidisciplinary design optimization for conceptual design of hybrid-electric aircraft. Struct. Multidiscip. Optim. 2021, 64, 3505–3526. [Google Scholar] [CrossRef]

- Bolsunovsky, A.L.; Buzoverya, N.P.; Chernyshev, I.L.; Gurevich, B.I.; Tsyganov, A.P. Arrangement and aerodynamic studies for long-range aircraft in flying wing layout. In Proceedings of the 29th Congress of the International Council of the Aeronautical Sciences, St. Petersburg, Russia, 7–12 September 2014; pp. 1–10. [Google Scholar]

- Bolsunovsky, A.L.; Buzoverya, N.P.; Gurevich, B.I.; Denisov, V.E.; Dunaevsky, A.I.; Shkadov, L.M.; Sonin, O.V.; Udzhuhu, A.J.; Zhurihin, J.P. Flying wing-problems and decisions. Aircr. Des. 2001, 4, 193–219. [Google Scholar] [CrossRef]

- van Dommelen, J.; Vos, R. Conceptual design and analysis of blended-wing-body aircraft. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 228, 2452–2474. [Google Scholar] [CrossRef]

- Habermann, A.L.; Bijewitz, J.; Seitz, A.; Hornung, M. Performance bookkeeping for aircraft configurations with fuselage wake-filling propulsion integration. CEAS Aeronaut. J. 2015, 11, 529–551. [Google Scholar] [CrossRef]

- Drela, M. Power balance in aerodynamic flows. AIAA J. 2009, 47, 1761–1771. [Google Scholar] [CrossRef]

- Ashcraft, S.W.; Padron, A.S.; Pascioni, K.A.; Stout, G.W., Jr.; Huff, D.L. Review of Propulsion Technologies for N+ 3 Subsonic Vehicle Concepts; NASA Langley Research Center: Hanover, MD, USA, 2011; NASA TM-2011-217239. [Google Scholar]

- Geiselhart, K.A.; Daggett, D.L.; Kawai, R.; Friedman, D. Blended Wing Body Systems Studies: Boundary Layer Ingestion Inlets with Active Flow Control; NASA Langley Research Center: Hanover, MD, USA, 2003; NASA/CR-2003-212670. [Google Scholar]

- Gorton, S.; Owens, L.; Jenkins, L.; Allan, B.; Schuster, E. Active flow control on a boundary-layer-ingesting inlet. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; p. 1203. [Google Scholar]

- Girfoglio, M.; Greco, C.S.; Chiatto, M.; de Luca, L. Modelling of efficiency of synthetic jet actuators. Sens. Actuator A Phys. 2015, 233, 512–521. [Google Scholar] [CrossRef]

- Clingman, D.J. Development of an Aerodynamic Synthetic Jet Actuator Based on a Piezoceramic Buckled Beam; University of Maryland: College Park, MD, USA, 2006. [Google Scholar]

- Kamat, V.; Rao, V.; Xu, M.; Saxena, S. Flow Distortion Based S-Duct Optimization using Adjoint Methodology. In Proceedings of the AIAA Aviation 2020 Forum, Virtual Event, 15–19 June 2020; p. 2755. [Google Scholar]

- Sliwinski, J.; Gardi, A.; Marino, M.; Sabatini, R. Hybrid-electric propulsion integration in unmanned aircraft. Energy 2017, 140, 1407–1416. [Google Scholar] [CrossRef]

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- Jia, Y.; Rajashekara, K. An induction generator-based ac/dc hybrid electric power generation system for more electric aircraft. IEEE Trans. Ind. Appl. 2017, 53, 2485–2494. [Google Scholar] [CrossRef]

- Xu, H.; He, Y.; Strobel, K.L.; Gilmore, C.K.; Kelley, S.P.; Hennick, C.C.; Sebastian, T.; Woolston, M.R.; Perreault, D.J.; Barrett, S.R. Flight of an aeroplane with solid-state propulsion. Nature 2018, 563, 532–535. [Google Scholar] [CrossRef]

- Farokhi, S. Future Propulsion Systems and Energy Sources in Sustainable Aviation; University of Kansas Lawrence, Wiley: Lawrence, KS, USA, 2020. [Google Scholar]

- Armstrong, F. Jet Propulsion: A simple guide to the aerodynamic and thermodynamic design and performance of jet engines. Aeronaut. J. 1998, 102, 330. [Google Scholar] [CrossRef]

- Seyam, S.; Dincer, I.; Agelin-Chaab, M. Novel hybrid aircraft propulsion systems using hydrogen, methane, methanol, ethanol and dimethyl ether as alternative fuels. Energy Convers. Manag. 2021, 238, 114172. [Google Scholar] [CrossRef]

- Khandelwal, B.; Karakurt, A.; Sekaran, P.R.; Sethi, V.; Singh, R. Hydrogen powered aircraft: The future of air transport. Prog. Aerosp. Sci. 2013, 60, 45–59. [Google Scholar] [CrossRef]

- Thapa, N.; Ram, S.; Kumar, S.; Mehta, J. All electric aircraft: A reality on its way. Mater. Today Proc. 2021, 43, 175–182. [Google Scholar] [CrossRef]

- Sziroczak, D.; Jankovics, I.; Gal, I.; Rohacs, D. Conceptual design of small aircraft with hybrid-electric propulsion systems. Energy 2020, 204, 117937. [Google Scholar] [CrossRef]

- Dascalua, A.; Sharkha, S.; Crudena, A.; Stevenson, P. Performance of a hybrid battery energy storage system. Energy Rep. 2022, 8, 1–17. [Google Scholar] [CrossRef]

- Bravo, G.M.; Praliyev, N.; Veress, A. Performance analysis of hybrid electric and distributed propulsion system applied on a light aircraft. Energy 2021, 214, 118823. [Google Scholar] [CrossRef]

- Gomez-Vega, N.; Xu, H.; Abel, J.M.; Barrett, S.R. Performance of decoupled electroaerodynamic thrusters. Appl. Phys. Lett. 2021, 118, 074101. [Google Scholar] [CrossRef]

- Xu, H. Experiments in Electroaerodynamic Propulsion; Massachusetts Institute of Technology: Cambridge, MA, USA, 2020. [Google Scholar]

- Gray, J.S.; Hwang, J.T.; Martins, J.R.; Moore, K.T.; Naylor, B.A. OpenMDAO: An open-source framework for multidisciplinary design, analysis, and optimization. Struct. Multidiscip. Optim. 2019, 59, 1075–1104. [Google Scholar] [CrossRef]

- Jasa, J.P.; Hwang, J.T.; Martins, J.R. Open-source coupled aerostructural optimization using Python. Struct. Multidiscip. Optim. 2018, 57, 1815–1827. [Google Scholar] [CrossRef]

- Ramu, P.; Thananjayan, P.; Acar, E.; Bayrak, G.; Park, J.W.; Lee, I. A survey of machine learning techniques in structural and multidisciplinary optimization. Struct. Multidiscip. Optim. 2022, 65, 1–31. [Google Scholar] [CrossRef]

- Tang, Z. Solving Stackelberg equilibrium for multi objective aerodynamic shape optimization. Appl. Math. Model. 2019, 72, 588–600. [Google Scholar] [CrossRef]

- Su, H.; Gu, L.; Gong, C. Applying the disciplinary relation matrix to multidisciplinary design optimization modeling and solving. J. Syst. Eng. Electron. 2017, 28, 703–716. [Google Scholar]

- Wu, P.; Tang, Z.; Periaux, J. Multi-disciplinary Design Optimization of Air-Breathing Hypersonic Vehicle Using Pareto Games and Evolutionary Algorithms. In Advances in Evolutionary and Deterministic Methods for Design, Optimization and Control in Engineering and Sciences; Springer: Cham, Swizerland, 2019; pp. 317–331. [Google Scholar]

- Tang, Z.; Zhang, L. A new Nash optimization method based on alternate elitist information exchange for multi-objective aerodynamic shape design. Appl. Math. Model. 2019, 68, 244–266. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Chen, J.; Xie, F.; Zhang, J.; Périaux, J.; Tang, Z. Single/two-objective aerodynamic shape optimization by a Stackelberg/adjoint method. Eng. Optim. 2020, 52, 753–776. [Google Scholar] [CrossRef]

- Secco, N.R.; Kenway, G.K.; He, P.; Mader, C.; Martins, J.R. Efficient mesh generation and deformation for aerodynamic shape optimization. AIAA J. 2021, 59, 1151–1168. [Google Scholar] [CrossRef]

- Tang, Z.; Hu, X.; Périaux, J. Multi-level hybridized optimization methods coupling local search deterministic and global search evolutionary algorithms. Arch. Comput. Methods Eng. 2020, 27, 939–975. [Google Scholar] [CrossRef]

- Kim, H.; Berton, J.; Jones, S. Low noise cruise efficient short take-off and landing transport vehicle study. In Proceedings of the 6th AIAA Aviation Technology, Integration and Operations Conference, Wichita, KS, USA, 26–27 September 2006; p. 7738. [Google Scholar]

- Lian, Z.; Wu, J. Aerodynamics and Propulsive Efficiency of a Blended-Wing-Body Aircraft with Distributed Propulsion System During Takeoff. Int. J. Aeronaut. Space Sci. 2018, 19, 799–804. [Google Scholar] [CrossRef]

- Guo, Y.; Burley, C.L.; Thomas, R.H. On noise assessment for blended wing body aircraft. In Proceedings of the 52nd Aerospace Sciences Meetings, National Harbor, MD, USA, 13–17 January 2014; p. 0365. [Google Scholar]

- Reist, T.A.; Zingg, D.W. Optimization of the aerodynamic performance of regional and wide-body-class blended wing-body aircraft. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015; p. 3292. [Google Scholar]

- Reist, T.A.; Zingg, D.W. Aerodynamic design of blended wing-body and lifting-fuselage aircraft. In Proceedings of the 34th AIAA Applied Aerodynamics Conference, Washington, DC, USA, 13–17 June 2016; p. 3874. [Google Scholar]

- Goraj, Z. Design and optimisation of fuel tanks for BWB configurations. Arch. Mech. Eng. 2016, 63, 605–617. [Google Scholar] [CrossRef]

- Gern, F.H. Conceptual design and structural analysis of an open rotor hybrid wing body aircraft. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; p. 1688. [Google Scholar]

- Hansen, L.U.; Heinze, W.; Horst, P. Blended wing body structures in multidisciplinary pre-design. Struct. Multidiscip. Optim. 2008, 36, 93–106. [Google Scholar] [CrossRef]

- Maier, R. ACFA 2020—An FP7 project on active control of flexible fuel efficient aircraft configurations. Prog. Flight Dyn. Guid. Navig. Control. Fault Detect. Avion. 2016, 6, 585–600. [Google Scholar]

- Vos, R.; Van Dommelen, J. Conceptual design and structural analysis of an open rotor hybrid wing body aircraft. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Struct, Struct Dyn Mater Conf 20th AIAA/ASME/AHS Adapt Struct Conf 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1756. [Google Scholar]

- Pitera, D.M.; DeHaan, M.; Brown, D.; Kawai, R.T.; Hollowell, S.; Camacho, P.; Bruns, D.; Rawden, B.K. Blended Wing Body Concept Development with Open Rotor Engine Intergration; NASA Langley Research Center: Hanover, MD, USA, 2011; NF1676L-13758. [Google Scholar]

- Nickol, C. Hybrid wing body configuration scaling study. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 June 2012; p. 337. [Google Scholar]

- Yang, S.; Page, M.; Smetak, E.J. Achievement of NASA new aviation horizons n + 2 goals with a blended-wing-body x-plane designed for the regional jet and single-aisle jet markets. In Proceedings of the 2018 AIAA Aerospace Sciences Meetings, Kissimmee, FL, USA, 8–12 January 2018; p. 0521. [Google Scholar]

- Mody, P.; Sato, S.; Hall, D.; De la Rosa Blanco, E.; Hileman, J.; Wen, E. Conceptual design of an N+ 3 hybrid wing body subsonic transport. In Proceedings of the 28th AIAA Applied Aerodynamics Conference, Chicago, IL, USA, 28 June–1 July 2010; p. 4812. [Google Scholar]

- Brown, M.; Vos, R. Conceptual design and evaluation of blended-wing body aircraft. In Proceedings of the 2018 AIAA Aerospace Sciences Meetings, Kissimmee, FL, USA, 8–12 January 2018; p. 0522. [Google Scholar]

- Gladin, J.C. A Sizing and Vehicle Matching Methodology for Boundary Layer Ingesting Propulsion Systems; Georgia Institute of Technology: Atlanta, GA, USA, 2015. [Google Scholar]

| Selected Aircraft | Engine Location | Number of Engines (Fans) | Mach Number | Wing Area (m2) | MTOM (kg) | Payload (kg) | Max. Seat | L/D (Cruise) | Range (km) | Cumulative Noise (EPNdB) | Mission Fuel (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SAX-12 | BLI (IPS) | 4 (4) | 0.80 | - | 154,290 | - | 215 | 21.90 | 14,816 | - | - |

| SAX-40 | BLI (MPS) | 3 (9) | 0.80 | 836 | 150,847 | 23,405 | 215 | 20.10 | 9260 | 185.0 | 33,253 |

| N2A-EXTE | PA (IPS) | 2 (2) | 0.81 | 925 | 213,914 | 46,720 | - | 21.42 | 11,112 | 251.0 | 65,453 |

| N2B | BLI (MPS) | 3 (9) | 0.80 | 846 | 216,545 | 46,720 | - | 21.55 | 11,112 | 274.4 | 66,587 |

| N3-X | BLI (MPS) | 2 (15∼21) | 0.84 | - | - | 107,048 | 300 | - | 13,890 | - | - |

| Ref. | Section | Specific Condition | Benefits | Defects |

|---|---|---|---|---|

| [48] [49] | Fuselage/ body | TWB | ★ Flight performance is easier to discriminate by accumulated long-term experiences. | ★ The fuselage has to be elongated to embed a circle aft propulsion system, resulting in higher costs with low benefits. |

| ★ No maneuverability and integration problems; the division of operation for each unit is clear. | ★ The non-integrated “body" is difficult to deploy DP systems. | |||

| [50] | BWB | ★ The load distribution is more uniform and significant in load advantages. ★ Easier to implant DP in an integrated platform. | ★ Maneuverability problems have to be addressed for aircraft without rudder and flaps. ★ The interaction between wing, control surfaces, and DP adds complexity to the design. | |

| [51] [52] | Wing | Jet wing | ★ Reduces lift-induced drag. ★ The pitching moment of blades could change the direction and magnitude of the thrust vector. It could replace flaps and slats to improve flight performance in stability, controllability, and safety. | ★ In the case of replacing a rudder with wing jets, when the energy transmission process cannot be started on time, there is a dilemma that the control wheel cannot be driven. |

| Jet flap | ★ It provides an active circulation control of the airfoil through the suction-side blowing. ★ Ejects high-velocity air from a downward slot so flaps can obtain a high lift. | ★ It has a thinner exhaust port with lower exhaust flow volume, the effect is not as significant as other methods. | ||

| [53] [54] | Split wing | ★ Ingesting low-momentum air from the boundary layer can significantly reduce the required kinetic energy, while maintaining the required thrust velocity and thus increasing propulsion efficiency. ★ The truss structure of the split-wing provides adequate load-bearing capacity. It could significantly reduce the wing weight and bending moment. ★ It could garner a high lift coefficient via powered- lift. | ★ The inherent complexity of inboard structures in DP systems must be considered. | |

| [55] [56] | Under wing | ★ Can improve the aerodynamic efficiency of the L/D ratio. | ★ The under-wing duct is susceptible to foreign object damage, and its noise is relatively large. | |

| [57] | ★ Provide additional bending relief to the main wing structure. | |||

| [58] [59] | BLI | ★ Reduced the ram drag at the engine inlet and improved propulsive efficiency (energy-saving). ★ Produce wake filling to reduce the required thrust and energy, further reducing emissions. ★ Effectively balances the CG and offsets part of the load. ★ A noise-shielded configuration. | ★ Anergy comes with energy. It is almost impossible to achieve complete wake filling. ★ The straight duct does not achieve an actual function of BLI, while flow distortion occurs on the embedded S-duct. | |

| [60] | Pylon | ★ Provides an appropriate external surface to allow the intake and exhaust integration, access for inspection, removal, and maintenance requirements. | ★ Wetted area and load are increased, and the nose is downward at the thrust moment. ★ A drastic reduction in CG range happens via displaced thrust axis. ★ Have a high static instability. | |

| [61] [62] | Trailing edge | Parallel | ★ A parallel trailing edge with nearly 0° of wing sweep makes it easier to arrange the DP to attain momentum balance and reduce wake losses. | ★ Low L/D ratio. |

| [63] | Angular | ★ The trailing edge with an angular back sweep Wing has a higher L/D ratio. | ★ The angular trailing edge makes it difficult to shape DP in alignment. It becomes more complex to allocate the thrust speed to meet the momentum balance. | |

| Circumferential | ★ Removing a significant share of fuselage drag could substantially increase the L/D ratio. ★ Provides BLI to serve the wake filling (energy- saving.) | ★ To account for the axisymmetric contraction of the aft towards the fan inlet, fuselage length has to increase by 2.0 m. ★ The horizontal tail needs to be increased to balance the pitching moment of an aircraft; it leads the fuselage to a bending moment, and the weight is increased greatly. | ||

| [48] [49] | Propulsor | Regional | ★ The Mach number is generally ≈ 0.85, and the number of engines is less than 4. The thrust force is concentrated and easier to estimate. | ★ Wake losses occur in places without thrust, resulting in high energy consumption. |

| [50] [64] | Distributed | ★ A system with more engines has redundancy for increased safety and reliability. ★ Noise can be significantly reduced due to the low bypass ratio of the engine. ★ Smaller and lightly changeable propulsors could improve affordability and reduce the life-cycle cost by up to 50%. | ★ Have to ensure that the wake filling is filled precisely and not excessively. ★ Mach number is between 0.75 and 0.8, and more than 4 engines. The more dispersed the engines, the more the propulsion effect is significantly reduced. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, S.; Eng, T.Z.; Tang, Z.; Ma, Q.; Su, J.; Bugeda, G. Multidisciplinary Optimization of Aircraft Aerodynamics for Distributed Propulsion Configurations. Appl. Sci. 2024, 14, 7781. https://doi.org/10.3390/app14177781

Luo S, Eng TZ, Tang Z, Ma Q, Su J, Bugeda G. Multidisciplinary Optimization of Aircraft Aerodynamics for Distributed Propulsion Configurations. Applied Sciences. 2024; 14(17):7781. https://doi.org/10.3390/app14177781

Chicago/Turabian StyleLuo, Shaojun, Tian Zi Eng, Zhili Tang, Qianrong Ma, Jinyou Su, and Gabriel Bugeda. 2024. "Multidisciplinary Optimization of Aircraft Aerodynamics for Distributed Propulsion Configurations" Applied Sciences 14, no. 17: 7781. https://doi.org/10.3390/app14177781

APA StyleLuo, S., Eng, T. Z., Tang, Z., Ma, Q., Su, J., & Bugeda, G. (2024). Multidisciplinary Optimization of Aircraft Aerodynamics for Distributed Propulsion Configurations. Applied Sciences, 14(17), 7781. https://doi.org/10.3390/app14177781