Mechanical Responses and Fracture Evolution of Marble Samples Containing Stepped Fissures under Increasing-Amplitude Cyclic Loading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rock Sample Preparation

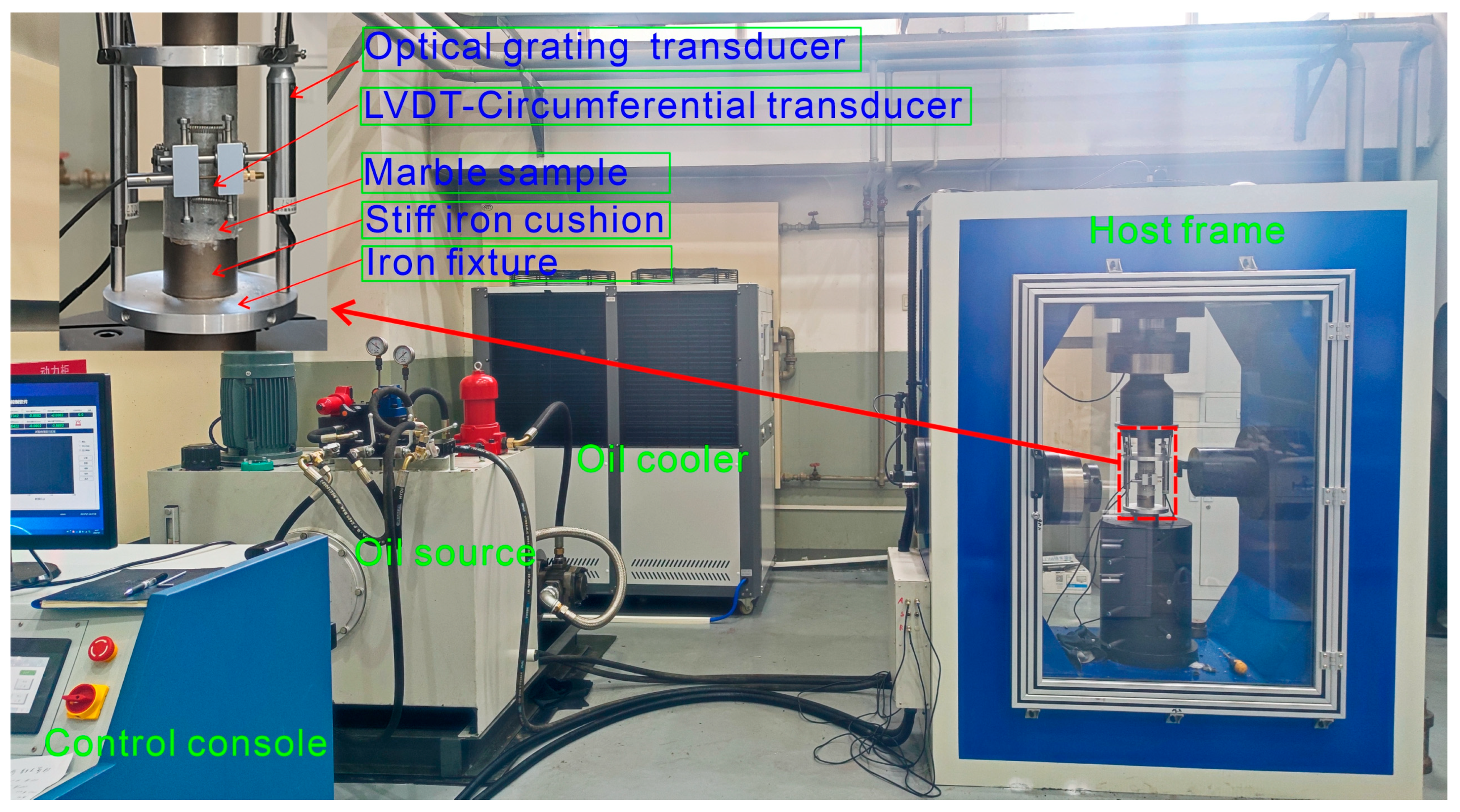

2.2. Experimental Setup

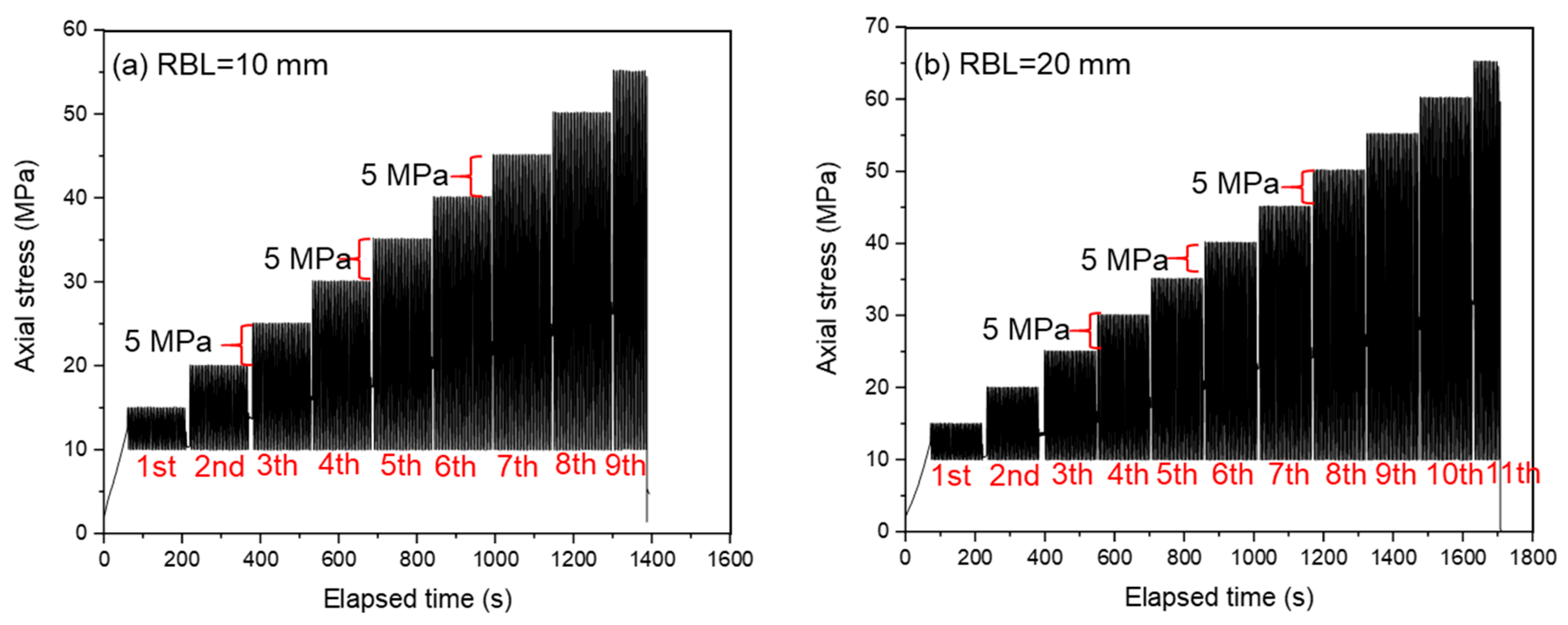

2.3. Testing Procedures

3. Testing Results

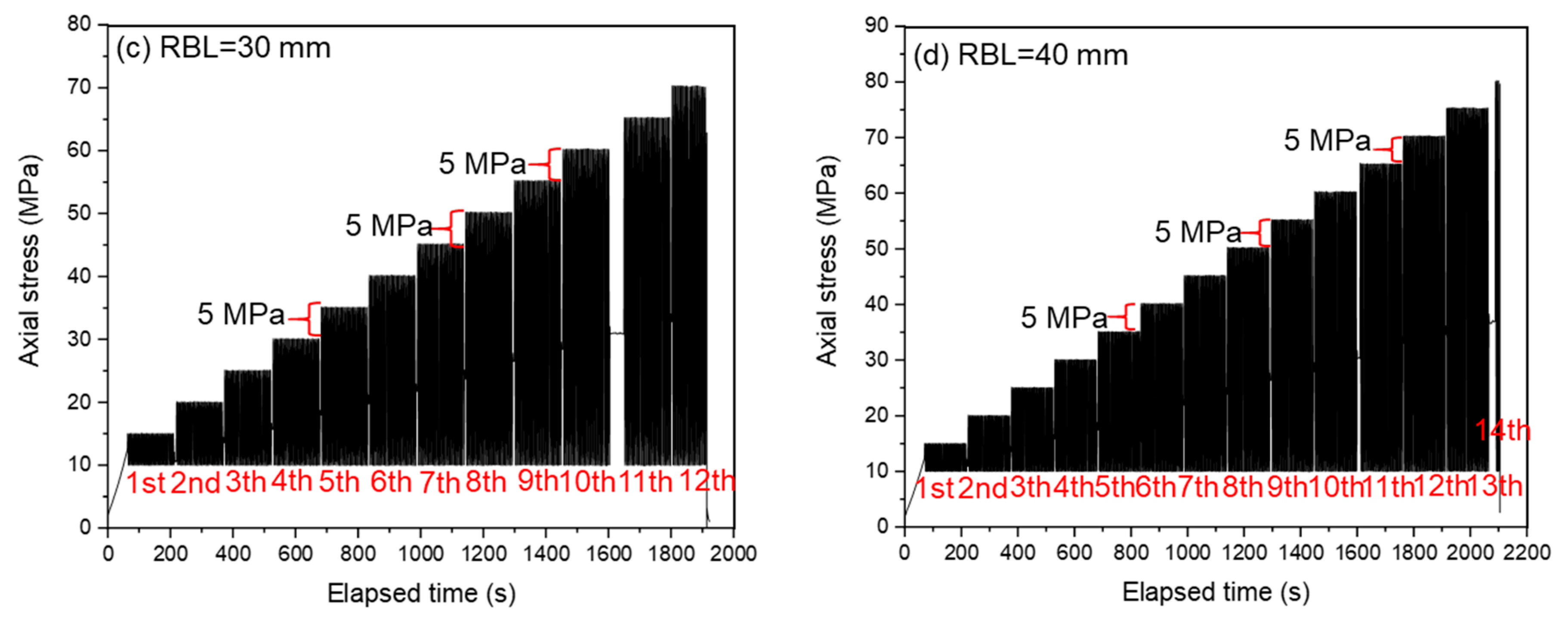

3.1. Typical Stress–Strain Responses

3.2. Deformation Characteristics Analysis

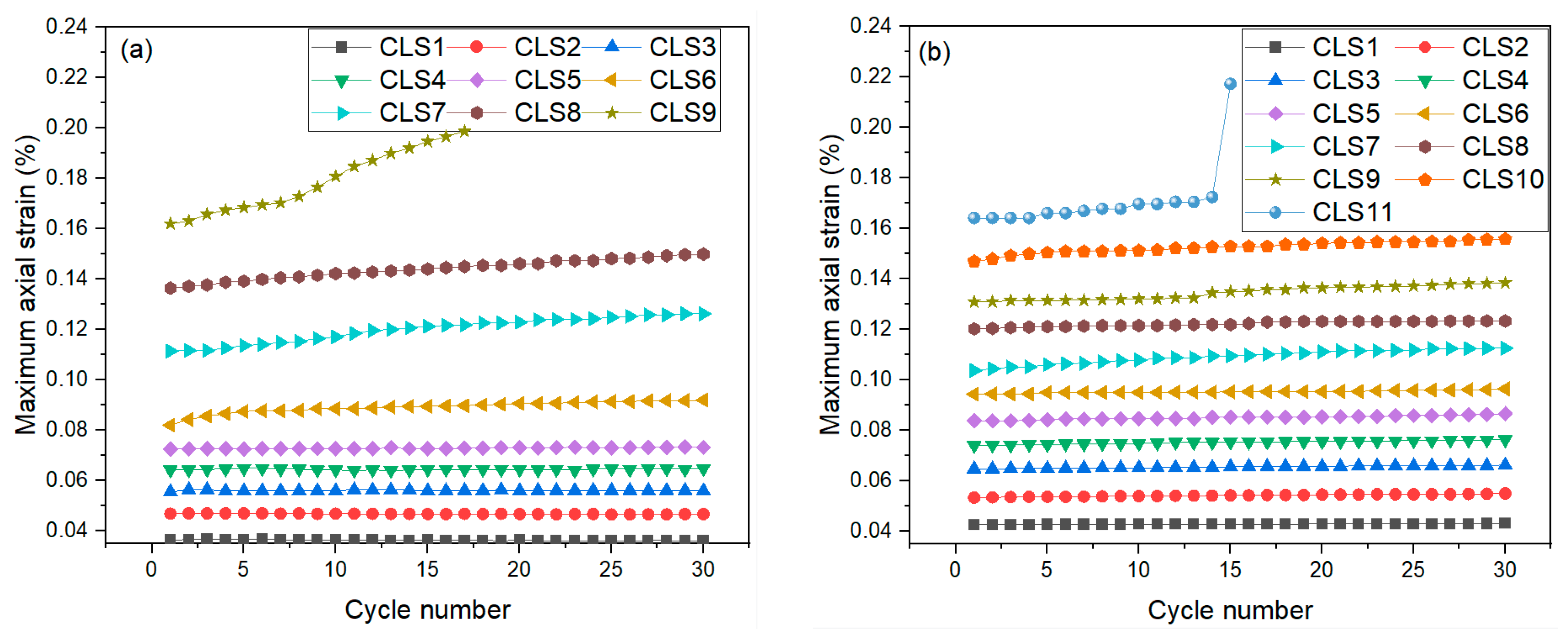

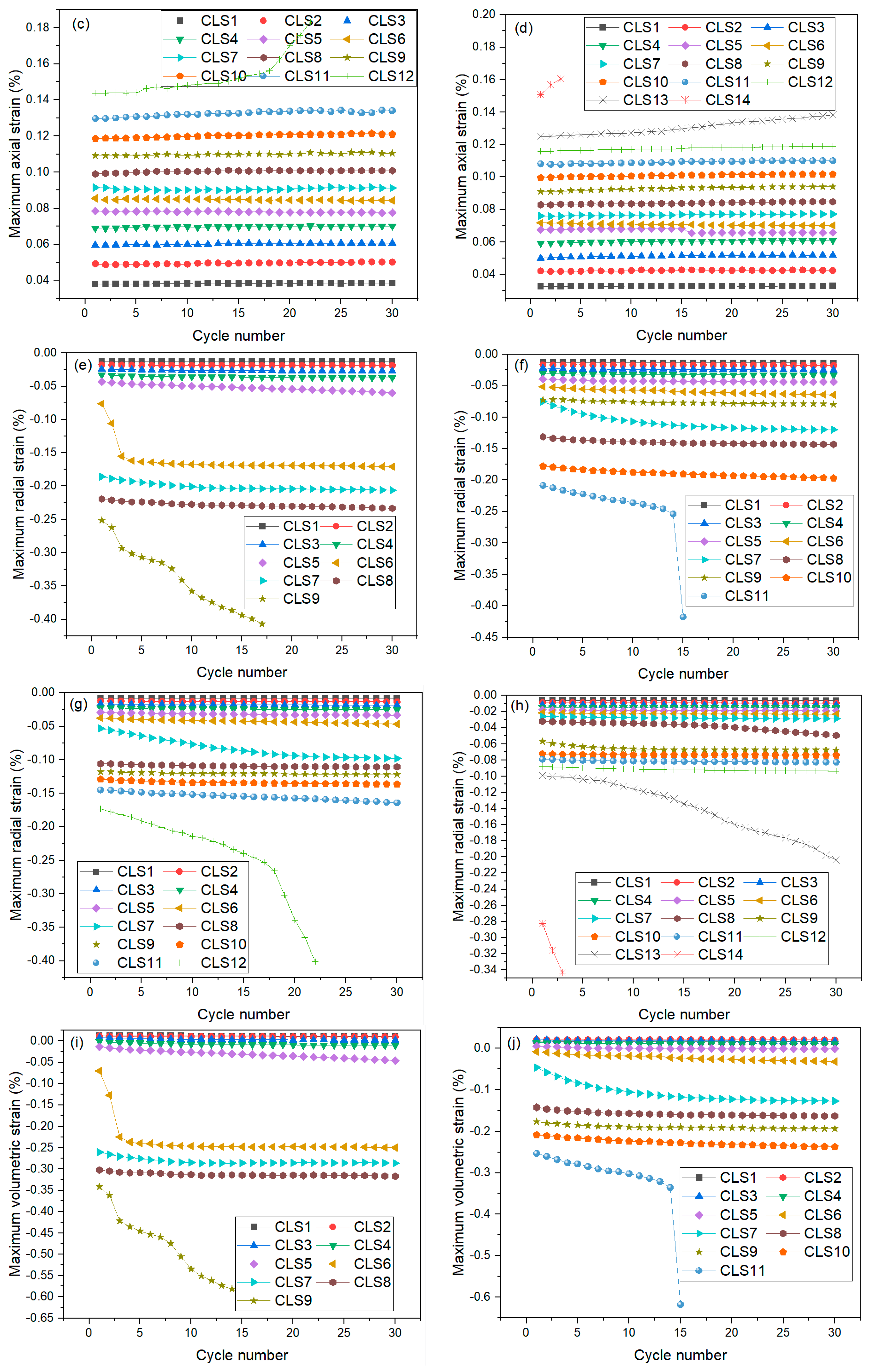

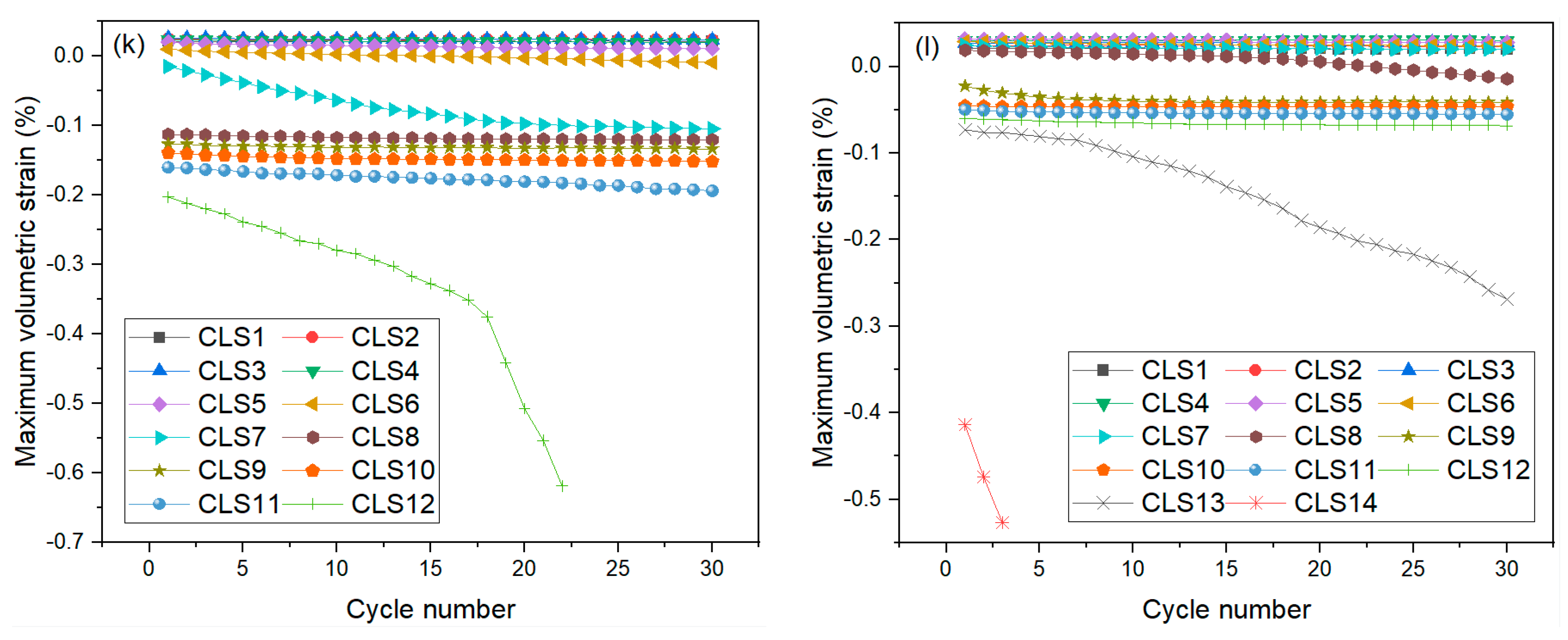

3.3. Dynamic Parameter Analysis

3.4. Strain Incremental Rate Analysis

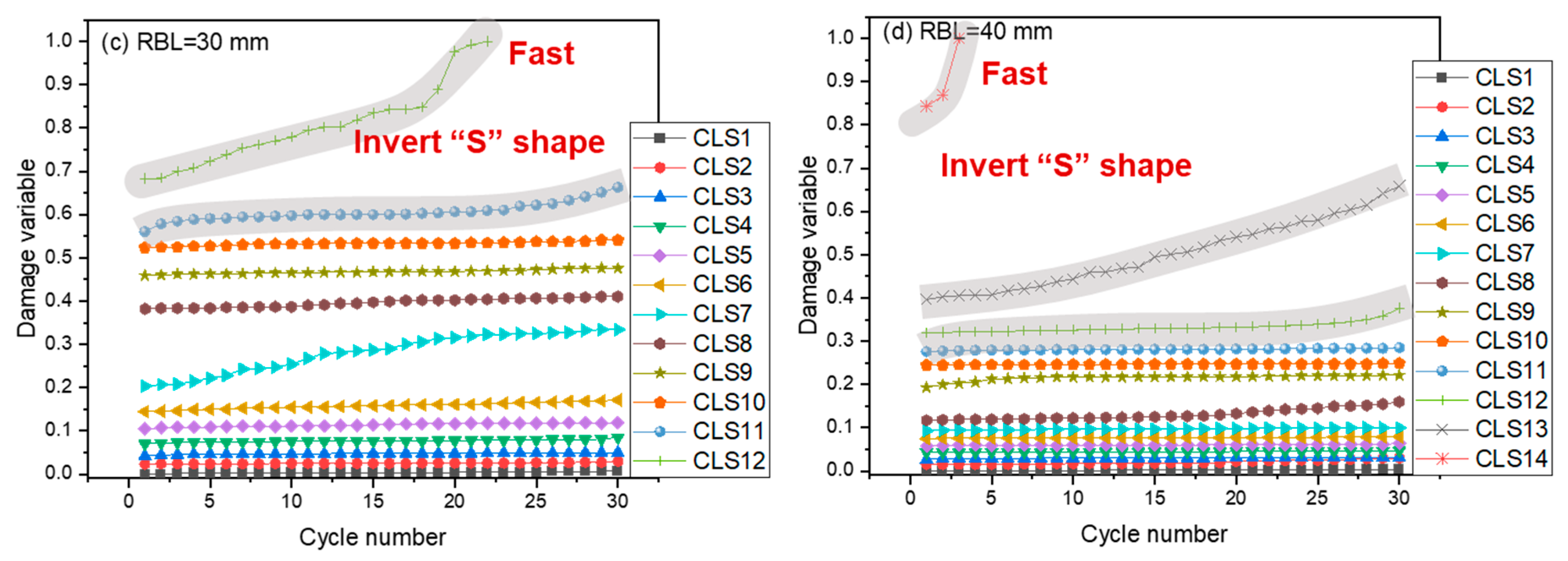

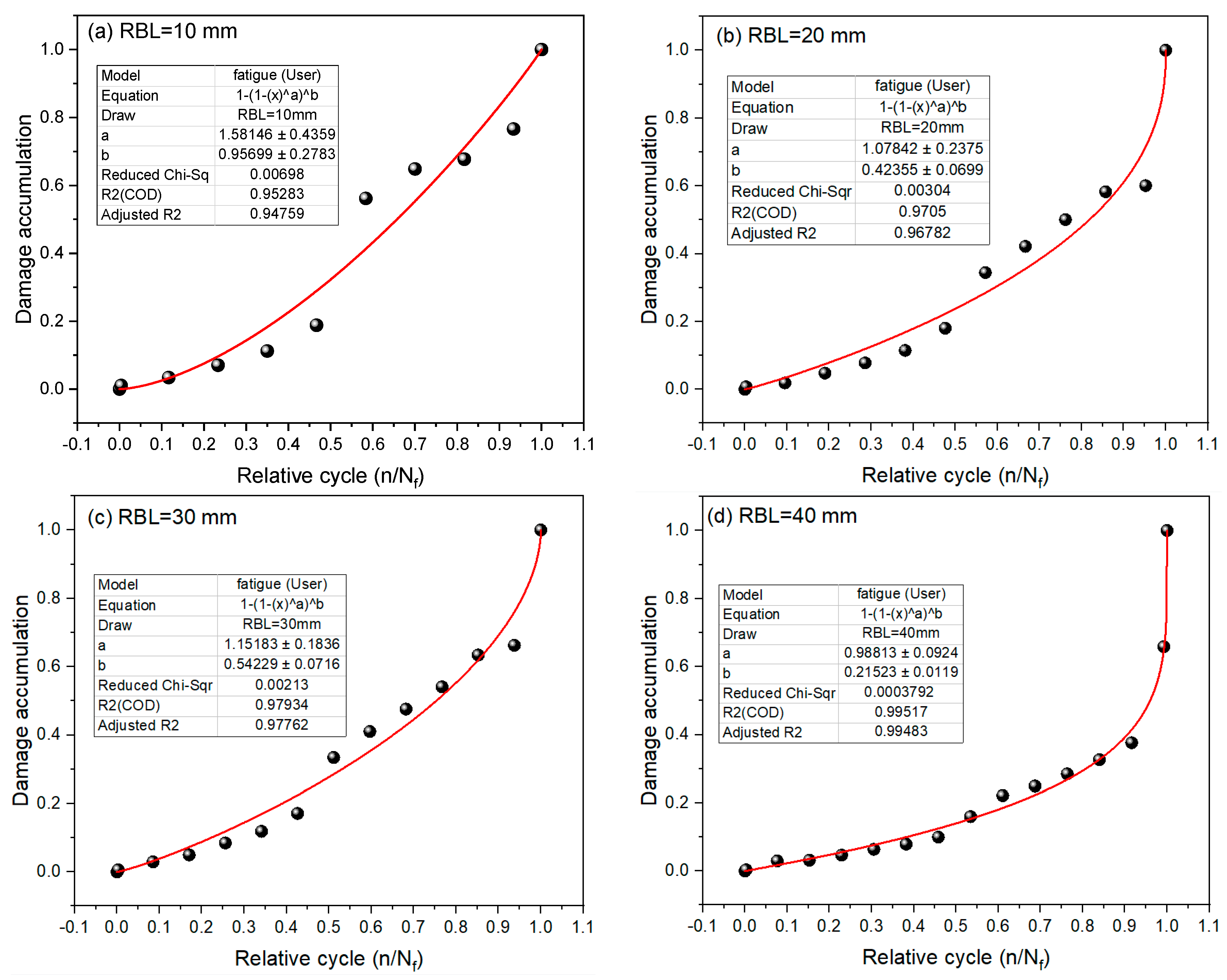

3.5. Modelling of Damage Evolution

4. Summary and Conclusions

- (1)

- The presence of pre-existing rock bridge segments significantly impacts crack propagation and coalescence. As the length of the rock bridge increases, both rock fatigue deformation and fatigue lifetime decrease. Notably, the sample with the longest rock bridge segment exhibited the lowest volumetric deformation, suggesting that damage propagation was least pronounced in this case.

- (2)

- Both damping ratio and dynamic elastic modulus are influenced by the presence of a rock bridge segment. The damping ratio reveals significant energy dissipation, particularly during the final stages of cyclic loading, highlighting substantial energy consumption driving crack propagation.

- (3)

- A strain incremental rate index is introduced to forecast the progression of rock failure. It is observed that volumetric strain rate serves as an effective early warning indicator compared to axial strain rate. The warning time diminishes as rock bridge length increases, suggesting that rocks with larger segments exhibit greater resistance to external fatigue loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, B.; Wang, S.; Sloan, S.W.; Sheng, D.; Tang, C.A. Modelling rock failure with a novel continuous to discontinuous method. Rock Mech. Rock Eng. 2019, 52, 3183–3195. [Google Scholar] [CrossRef]

- Bobet, A.; Fakhimi, A.; Johnson, S.; Morris, J.; Tonon, F.; Yeung, M.R. Numerical models in discontinuous media: Review of advances for rock mechanics applications. J. Geotech. Geoenvironmental Eng. 2009, 135, 1547–1561. [Google Scholar] [CrossRef]

- Lisjak, A.; Grasselli, G. A review of discrete modeling techniques for fracturing processes in discontinuous rock masses. J. Rock Mech. Geotech. Eng. 2014, 6, 301–314. [Google Scholar] [CrossRef]

- Shirani Faradonbeh, R.; Taheri, A.; Karakus, M. Fatigue failure characteristics of sandstone under different confining pressures. Rock Mech. Rock Eng. 2022, 55, 1227–1252. [Google Scholar] [CrossRef]

- Zheng, Q.; Liu, E.; Yu, D.; Liu, M. Fatigue and damage properties of non-consecutive jointed mudstone samples subjected to cyclic triaxial loading. Bull. Eng. Geol. Environ. 2020, 79, 2467–2481. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F.; Dong, L.; Xu, N.; Feng, P. Experimental investigation on the fatigue mechanical properties of intermittently jointed rock models under cyclic uniaxial compression with different loading parameters. Rock Mech. Rock Eng. 2018, 51, 47–68. [Google Scholar] [CrossRef]

- Jafari, M.K.; Pellet, F.; Boulon, M.; Hosseini, K.A. Experimental study of mechanical behaviour of rock joints under cyclic loading. Rock Mech. Rock Eng. 2004, 37, 3–23. [Google Scholar] [CrossRef]

- Cerfontaine, B.; Collin, F. Cyclic and fatigue behaviour of rock materials: Review, interpretation and research perspectives. Rock Mech. Rock Eng. 2018, 51, 391–414. [Google Scholar] [CrossRef]

- Fathi, A.; Moradian, Z.; Rivard, P.; Ballivy, G. Shear mechanism of rock joints under pre-peak cyclic loading condition. Int. J. Rock Mech. Min. Sci. 2016, 83, 197–210. [Google Scholar] [CrossRef]

- Li, K.; Yang, S.; Liu, C.; Chen, Y.; Zhang, G.; Ma, Q. Mechanical response and microscopic damage mechanism of pre-flawed sandstone subjected to monotonic and multilevel cyclic loading: A laboratory-scale investigation. Int. J. Min. Sci. Technol. 2023, 33, 1487–1510. [Google Scholar] [CrossRef]

- Moghaddam, R.H.; Golshani, A. Fatigue behavior investigation of artificial rock under cyclic loading by using discrete element method. Eng. Fail. Anal. 2024, 160, 108105. [Google Scholar] [CrossRef]

- Brown, E.T.; Hudson, J.A. Fatigue failure characteristics of some models of jointed rock. Earthq. Eng. Struct. Dyn. 1973, 2, 379–386. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, W.; Wang, H.; Wang, R.; Yan, L.; Shi, A. Anisotropic mechanical characteristics and energy evolution of artificial columnar jointed rock masses subjected to multi-level cyclic loading. Int. J. Fatigue 2022, 165, 107215. [Google Scholar] [CrossRef]

- Vaneghi, R.G.; Thoeni, K.; Dyskin, A.V.; Sharifzadeh, M.; Sarmadivaleh, M. Fatigue damage response of typical crystalline and granular rocks to uniaxial cyclic compression. Int. J. Fatigue 2020, 138, 105667. [Google Scholar] [CrossRef]

- Erarslan, N.; Williams, D.J. Mechanism of rock fatigue damage in terms of fracturing modes. Int. J. Fatigue 2012, 43, 76–89. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.H.; Han, J.Q. On the effect of stress amplitude on fracture and energy evolution of pre-flawed granite under uniaxial increasing-amplitude fatigue loads. Eng. Fract. Mech. 2020, 240, 107366. [Google Scholar] [CrossRef]

- Karakus, M.; Akdag, S.; Bruning, T. Rock fatigue damage assessment by acoustic emission. In Proceedings of the International Conference on Geo-Mechanics, Geo-Energy and Geo-Resources (IC3G), Melbourne, Australia, 28–29 September 2016; pp. 9–82. [Google Scholar]

- Shu, L.Y.; Liu, Z.S.; Wang, K.; Zhu, N.N.; Yang, J. Characteristics and classification of microseismic signals in heading face of coal mine: Implication for coal and gas outburst warning. Rock Mech. Rock Eng. 2022, 55, 6905–6919. [Google Scholar] [CrossRef]

- Xu, B.; Liu, X.; Zhou, X.; Xie, Y.; Suliman, L.; Liu, X.; Lin, G.; Huang, J. Investigation on the macro-meso fatigue damage mechanism of rock joints with multiscale asperities under pre-peak cyclic shear loading. Soil Dyn. Earthq. Eng. 2021, 151, 106958. [Google Scholar] [CrossRef]

- Singh, M.; Khalkho, P. Modelling of Fatigue Damage Evolution of Two Natural Rocks Under Cyclic Loading. Int. J. Geosynth. Ground Eng. 2022, 8, 8. [Google Scholar] [CrossRef]

- Tao, Y.; Hu, R.Z.; Zhu, F.L.; Ma, Y.S.; Ye, L.; Cheng, Z.T. Ore-forming age and the geodynamic background of the Hetaoping lead-zinc deposit in Baoshan, Yunnan. Acta Petrol. Sin. 2010, 26, 1760–1772. [Google Scholar]

- Deng, M.G.; Zhao, J.X.; Liu, F.X.; Yu, H.J.; Sun, B.D.; Liu, F.; Li, S.B. Discussion on sources of metallogenic fluids and materials of the Shuitoushan Pb-Zn deposit in Zhenkang, western Yunnan: Evidence from H, O, S and Pb isotopes. Acta Petrol. Sin. 2017, 33, 2001–2017. [Google Scholar]

- Li, W.; Yin, G.; Lu, Y.; Wang, Y.; Yu, H.; Cao, X.; Zhang, S. Delineation and significance of the Hongshan-Shudu serpentinite mélange zone within the “Sanjiang” volcanic-magmatic arc in Southwest China. Acta Petrol. Sin. 2010, 26, 1661–1671. [Google Scholar]

- Wang, Y.; Wei, X.M.; Li, C.H. Dynamic behavior of soil and rock mixture using cyclic triaxial tests and X-ray computed tomography. Arab. J. Geosci. 2019, 12, 229. [Google Scholar] [CrossRef]

- Lamas-Lopez, F. Field and Laboratory Investigation on the Dynamic Behavior of Conventional Railway Track-Bed Materials in the Context of Traffic Upgrade. Ph.D. Thesis, Ecole Nationale des Ponts et Chaussees, Universite Paris-Est, Paris, France, 2016. [Google Scholar]

- Wang, Y.; Li, C.; Han, J.; Wang, H. Mechanical behaviours of granite containing two flaws under uniaxial increasing-amplitude fatigue loading conditions: An insight into fracture evolution analyses. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2055–2070. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, H.N.; Han, J.Q.; Zhu, C. Effect of rock bridge length on fracture and damage modelling in granite containing hole and fissures under cyclic uniaxial increasing-amplitude decreasing-frequency (CUIADF) loads. Int. J. Fatigue 2022, 158, 106741. [Google Scholar] [CrossRef]

- Brantut, N.; Heap, M.J.; Meredith, P.G.; Baud, P. Time-dependent cracking and brittle creep in crustal rocks: A review. J. Struct. Geol. 2013, 52, 17–43. [Google Scholar] [CrossRef]

- Li, X.; Konietzky, H.; Li, X.; Wang, Y. Failure pattern of brittle rock governed by initial microcrack characteristics. Acta Geotech 2019, 14, 1437–1457. [Google Scholar] [CrossRef]

| Specimen ID | σmin | σmaxi | σa | σmaxf | CLS | Cycles in Each CLS | CDF |

|---|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (MPa) | (/) | (Cycle) | (Hz) | |

| RTSF -1,2,3 | 10 | 15 | 5 | 55 | 9 | 30 | 0.5 |

| RTSF -4,5,6 | 10 | 15 | 5 | 65 | 11 | 30 | 0.5 |

| RTSF -7,8,9 | 10 | 15 | 5 | 70 | 12 | 30 | 0.5 |

| RTSF -10,11,12 | 10 | 15 | 5 | 80 | 14 | 30 | 0.5 |

| CLS | Maximum Stress (MPa) | Axial Strain Rate [%/N − 1] | |||

|---|---|---|---|---|---|

| RBL = 10 mm | RBL = 20 mm | RBL = 30 mm | RBL = 40 mm | ||

| 1 | 15 | 6.666 × 10-5 | 1.333 × 10−5 | 3 × 10−5 | 1 × 10−5 |

| 2 | 20 | 1.533 × 10−4 | 3.033 × 10−4 | 3.866 × 10−4 | 3.146 × 10−4 |

| 3 | 35 | 2.1 × 10−4 | 4.666 × 10−4 | 3.5 × 10−4 | 3.146 × 10−4 |

| 4 | 40 | 3.933 × 10−4 | 5.4 × 10−4 | 3.133 × 10−4 | 3.04 × 10−4 |

| 5 | 45 | 4.8 × 10−4 | 6.466 × 10−4 | 2.466 × 10−4 | 1.6 × 10−4 |

| 6 | 50 | 6.266 × 10−4 | 3.233 × 10−4 | 2.266 × 10−4 | 1.466 × 10−4 |

| 7 | 55 | 0.00114 * | 5.4 × 10−4 | 2.3 × 10−4 | 2.346 × 10−4 |

| 8 | 60 | 0.00133 | 3.633 × 10−4 | 3.2 × 10−4 | 2.533 × 10−4 |

| 9 | 65 | 0.00163 | 5.033 × 10−4 | 3.233 × 10−4 | 3.093 × 10−4 |

| 10 | 70 | 5.733 × 10−4 | 3.533 × 10−4 | 2.56 × 10−4 | |

| 11 | 75 | 0.00119 * | 0.00121 * | 2.746 × 10−4 | |

| 12 | 80 | 0.00154 | 2.96 × 10−4 | ||

| 13 | 85 | 0.00106 * | |||

| 14 | 0.00165 | ||||

| CLS | Maximum Stress (MPa) | Volumetric Strain Rate [%/N − 1] | |||

|---|---|---|---|---|---|

| RBL = 10 mm | RBL = 20 mm | RBL = 30 mm | RBL = 40 mm | ||

| 1 | 15 | 1 × 10−6 | 1 × 10−6 | 6.667 × 10−6 | 1.666 × 10−6 |

| 2 | 20 | 4.6 × 10−5 | 3.333 × 10−6 | 1.04 × 10−4 | 1.213 × 10−4 |

| 3 | 35 | 2.5 × 10−4 | 9.733 × 10−5 | 1.4 × 10−5 | 1.346 × 10−4 |

| 4 | 40 | 4.066 × 10−4 | 2.68 × 10−4 | 1.266 × 10−4 | 7.733 × 10−5 |

| 5 | 45 | 0.00122 * | 3.893 × 10−4 | 3.133 × 10−4 | 8.667 × 10−5 |

| 6 | 50 | 0.00677 | 4.032 × 10−4 | 6.667 × 10−4 | 1.4 × 10−4 |

| 7 | 55 | 0.00117 | 4.653 × 10−4 | 3.16 × 10-4 | 1.32 × 10−4 |

| 8 | 60 | 0.00107 | 0.00234 * | 5.533 × 10−4 | 1.14 × 10−4 |

| 9 | 65 | 0.01166 | 0.00105 | 4.3 × 10−4 | 8.773 × 10−4 |

| 10 | 70 | Failure | 0.00301 | 0.00103 * | 1.907 × 10−4 |

| 11 | 75 | -- | 0.01285 | 0.00143 | 2.987 × 10−4 |

| 12 | 80 | -- | Failure | 0.01294 | 0.00329 |

| 13 | 85 | -- | -- | Failure | 0.00667 * |

| 14 | -- | -- | -- | 0.00861 | |

| -- | -- | -- | Failure | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Wang, Y.; Yi, X.; Chen, Z. Mechanical Responses and Fracture Evolution of Marble Samples Containing Stepped Fissures under Increasing-Amplitude Cyclic Loading. Appl. Sci. 2024, 14, 7919. https://doi.org/10.3390/app14177919

Yu Y, Wang Y, Yi X, Chen Z. Mechanical Responses and Fracture Evolution of Marble Samples Containing Stepped Fissures under Increasing-Amplitude Cyclic Loading. Applied Sciences. 2024; 14(17):7919. https://doi.org/10.3390/app14177919

Chicago/Turabian StyleYu, Yongchun, Yu Wang, Xuefeng Yi, and Zhenzhen Chen. 2024. "Mechanical Responses and Fracture Evolution of Marble Samples Containing Stepped Fissures under Increasing-Amplitude Cyclic Loading" Applied Sciences 14, no. 17: 7919. https://doi.org/10.3390/app14177919

APA StyleYu, Y., Wang, Y., Yi, X., & Chen, Z. (2024). Mechanical Responses and Fracture Evolution of Marble Samples Containing Stepped Fissures under Increasing-Amplitude Cyclic Loading. Applied Sciences, 14(17), 7919. https://doi.org/10.3390/app14177919