Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent

Abstract

:1. Introduction

- Dynamic light scattering (DLS): by measuring the hydrodynamic radius of nanoparticles, it is possible to discern the occurrence of accumulation [22].

- Zeta Potential: the dispersion stability of nanolubricants is measured via zeta potential (electric potential at the slipping plane) analysis, where higher zeta potential values (positive or negative) indicate better stability [16].

- Fourier Transform Infrared Spectroscopy (FTIR): this technique is used to indicate stable physical interactions between the dispersed nanoparticle and the base lubricant oil, providing insights into chemical compatibility and bonding [25].

2. Materials and Methods

2.1. Materials

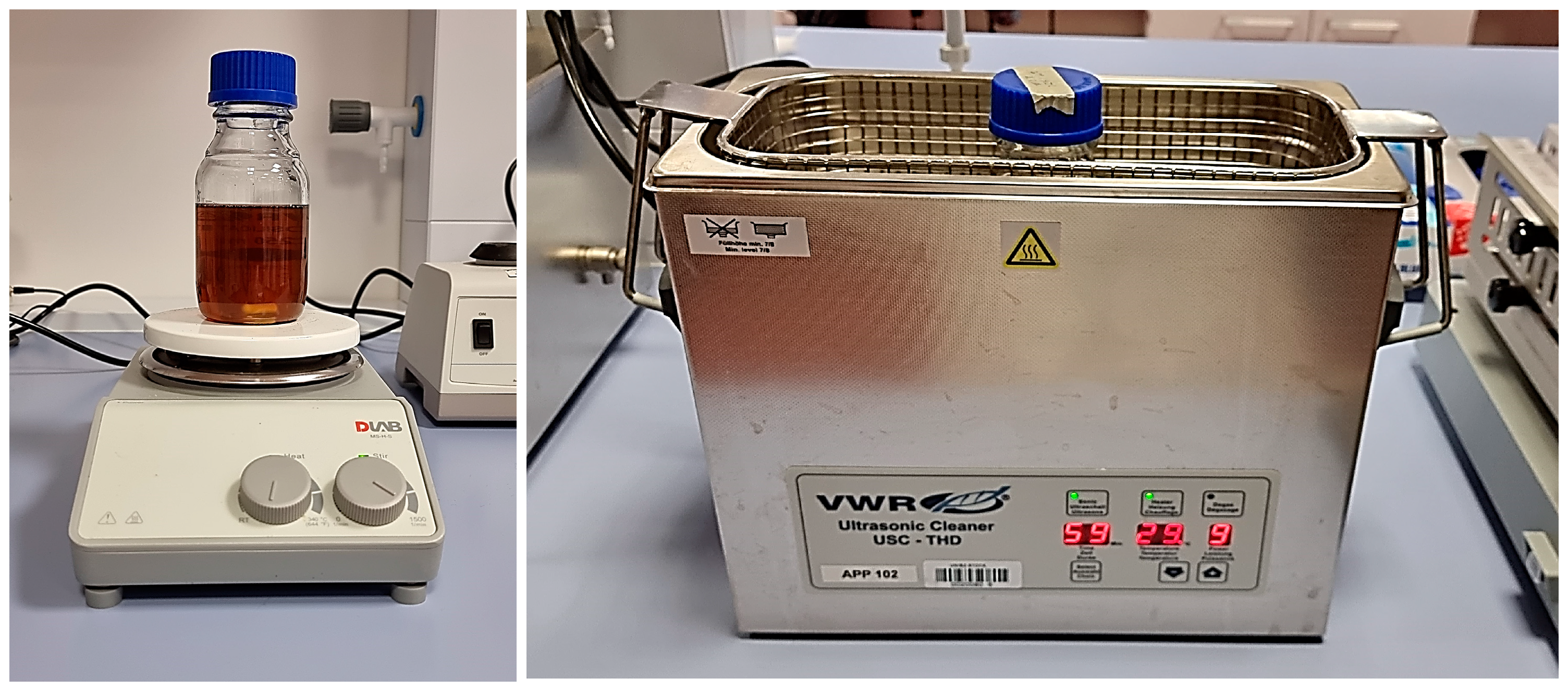

2.2. Formulation of Nanolubricants and Nanobiolubricants

2.3. Physicochemical Properties of Nanolubricants and Nanobiolubricants

2.4. Dispersion Analysis

3. Results and Discussion

3.1. Characterization and Assessment of Nanolubricants and Nanobiolubricants

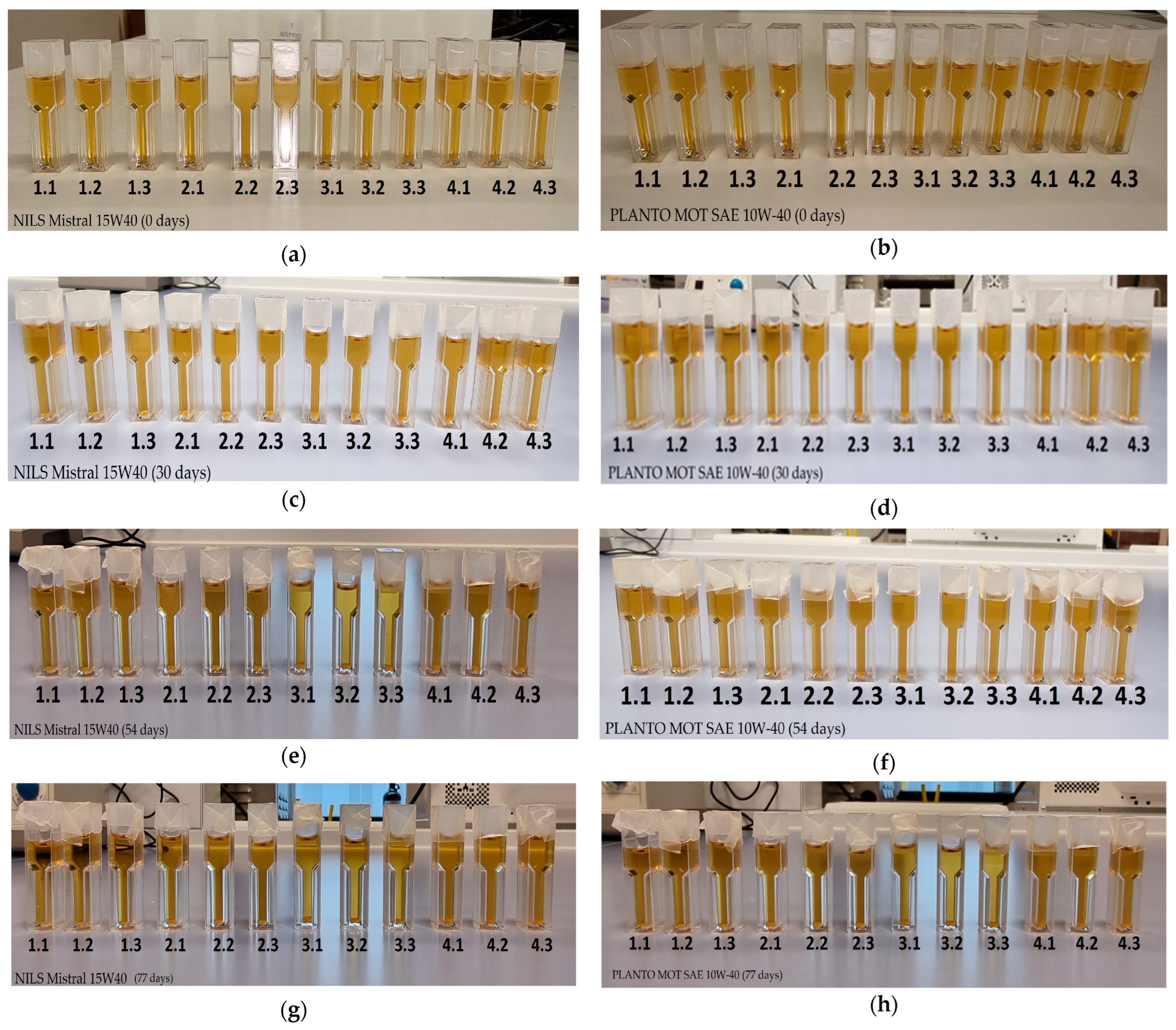

3.2. Visual Nanoparticle Settling Assessment

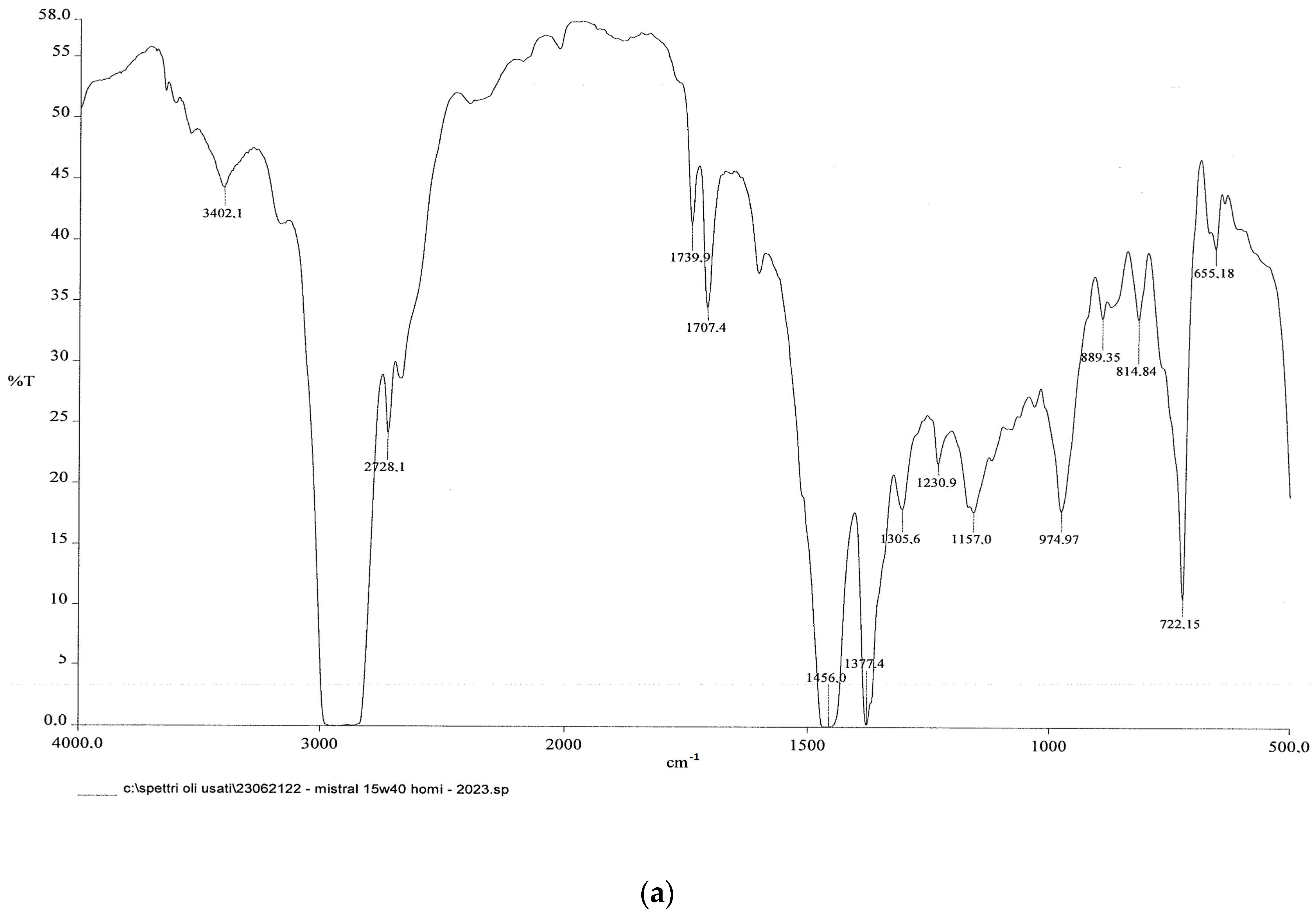

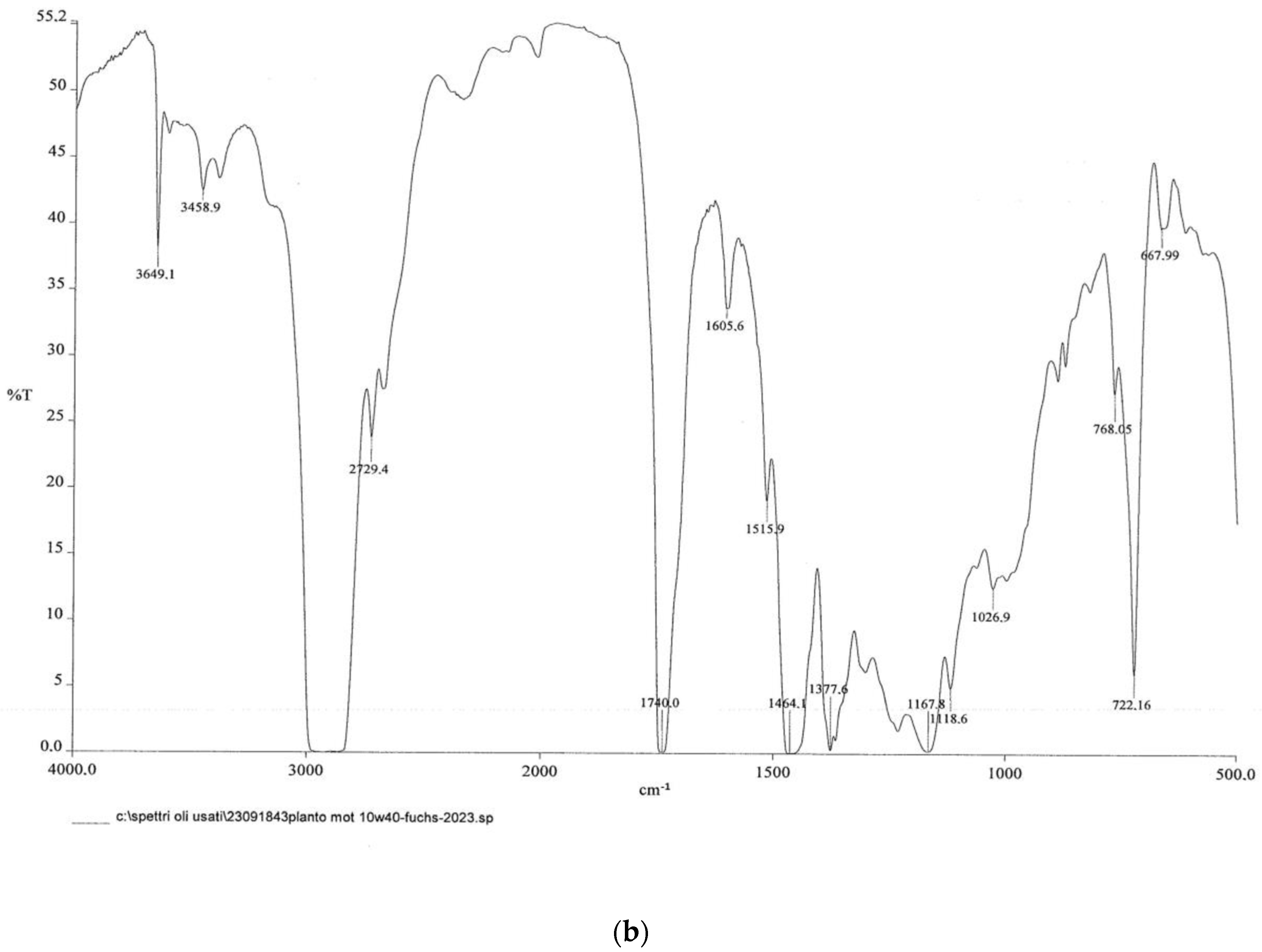

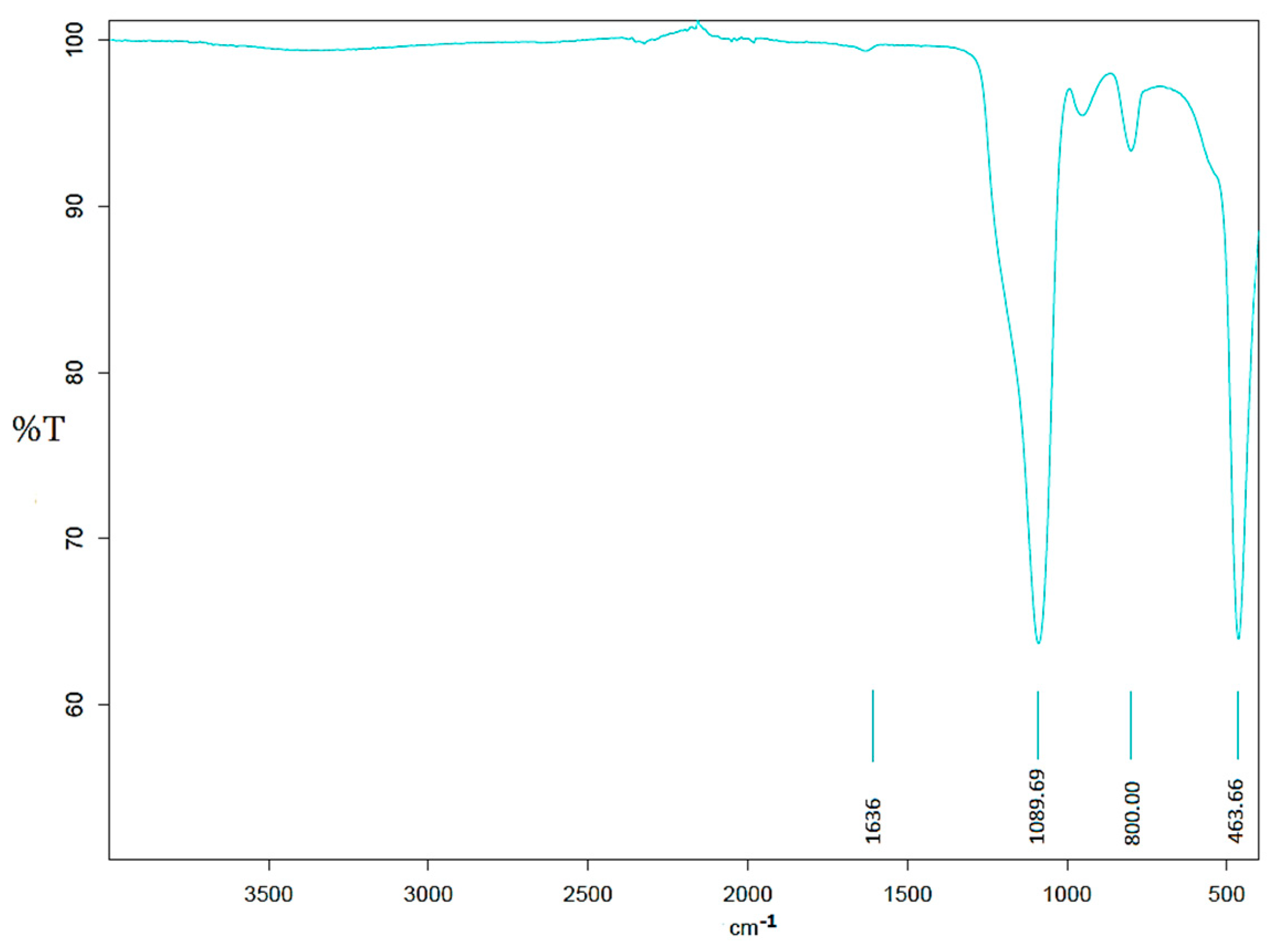

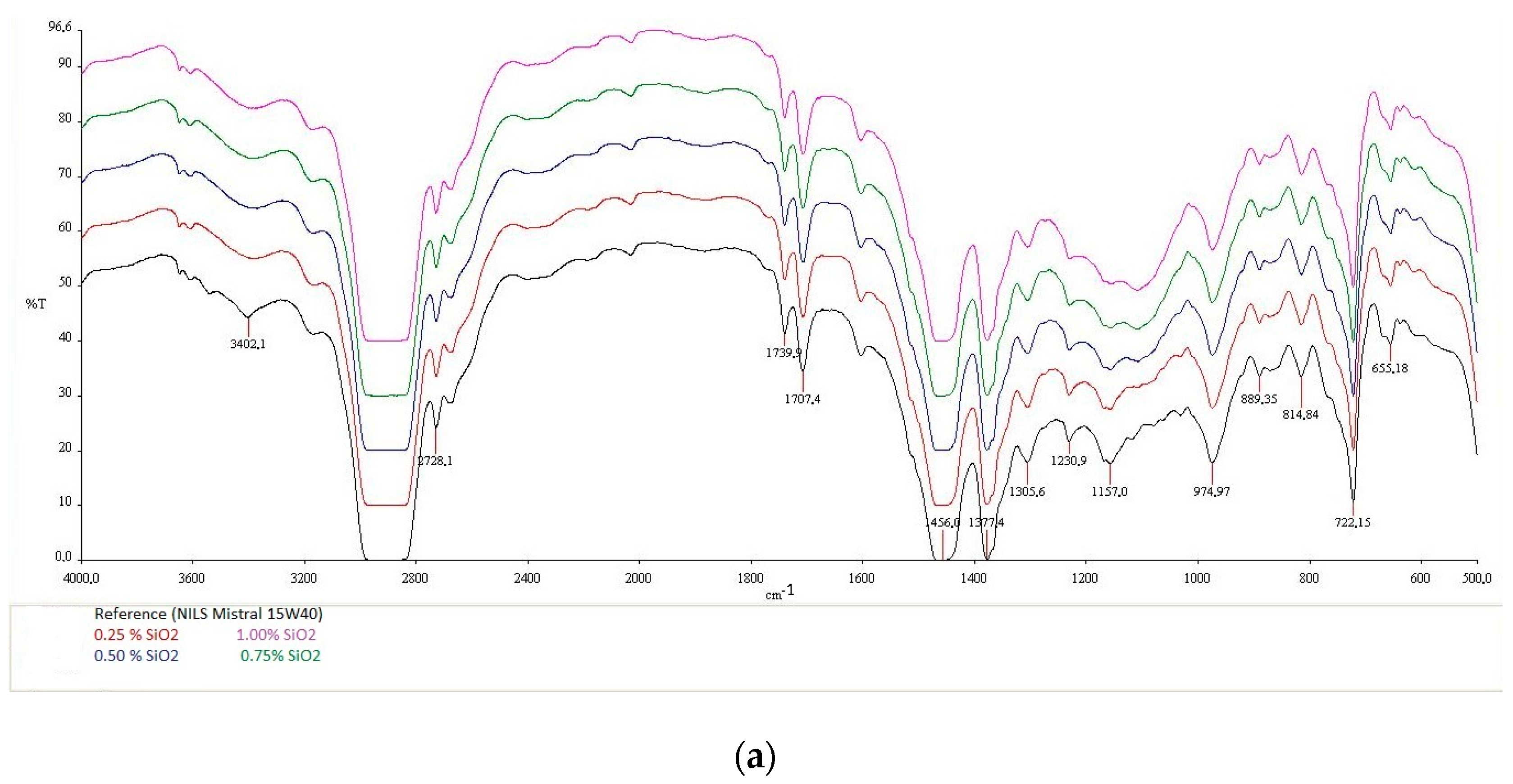

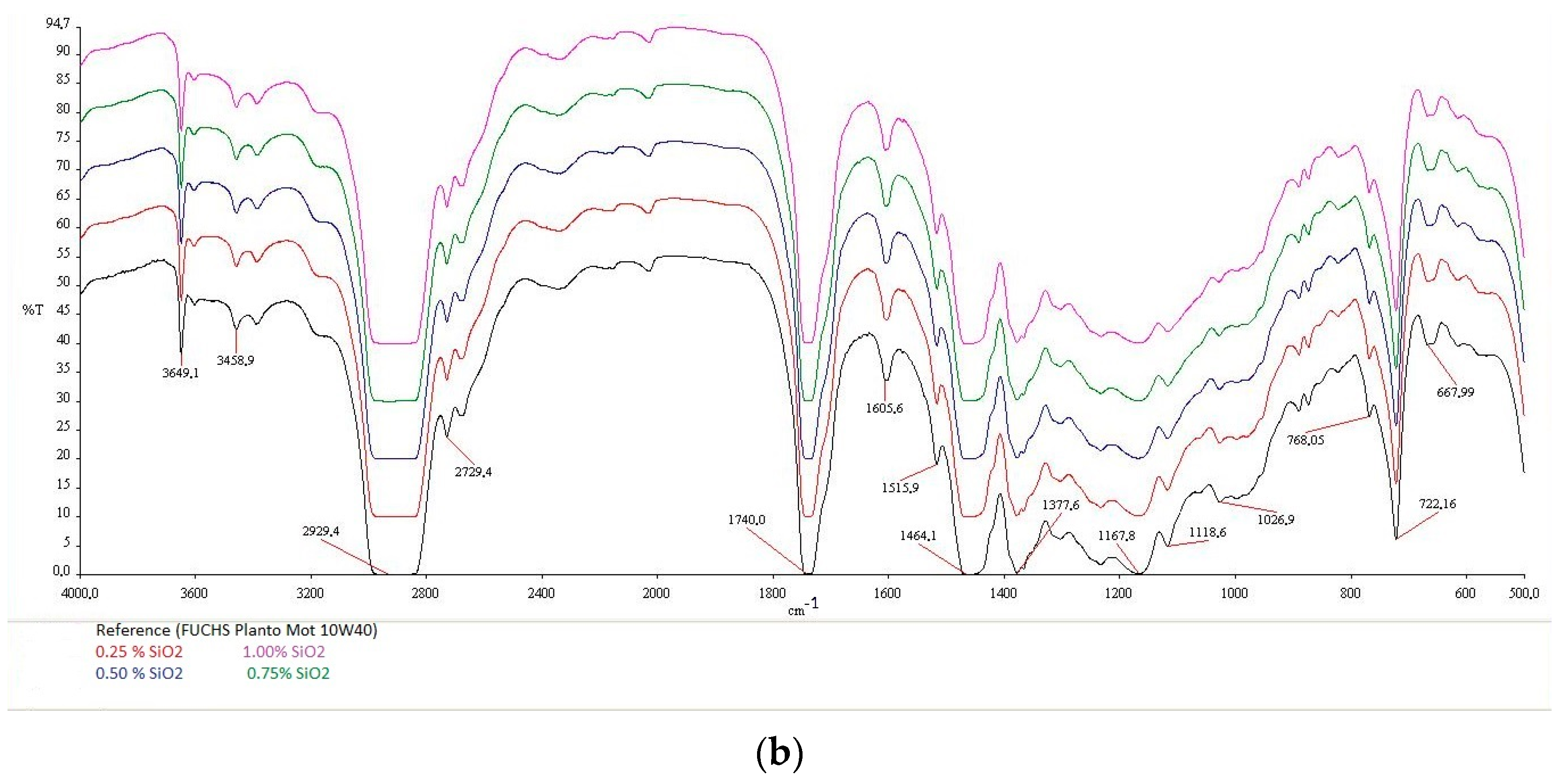

3.3. FTIR Characterization of Nanolubricant Stability

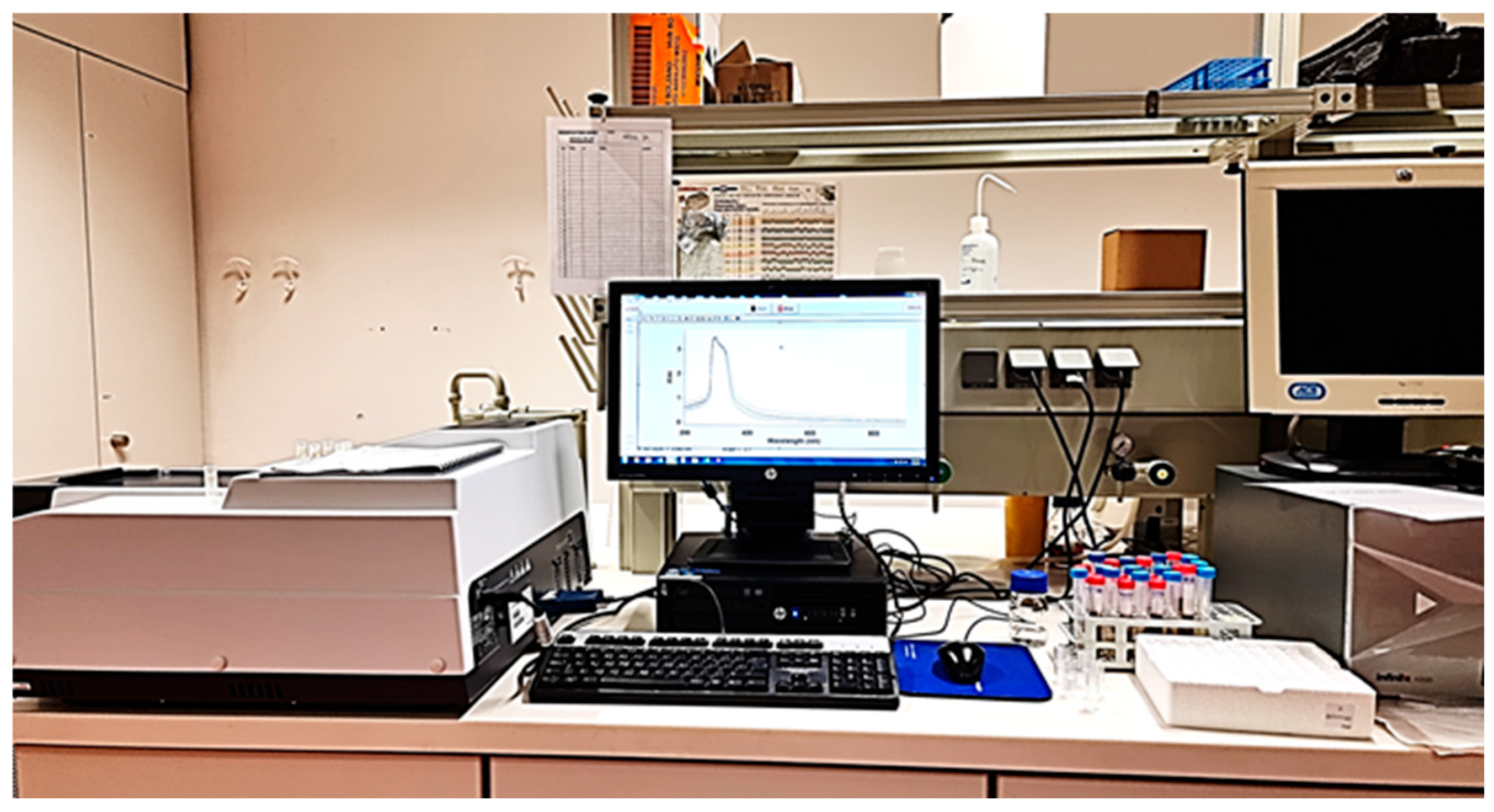

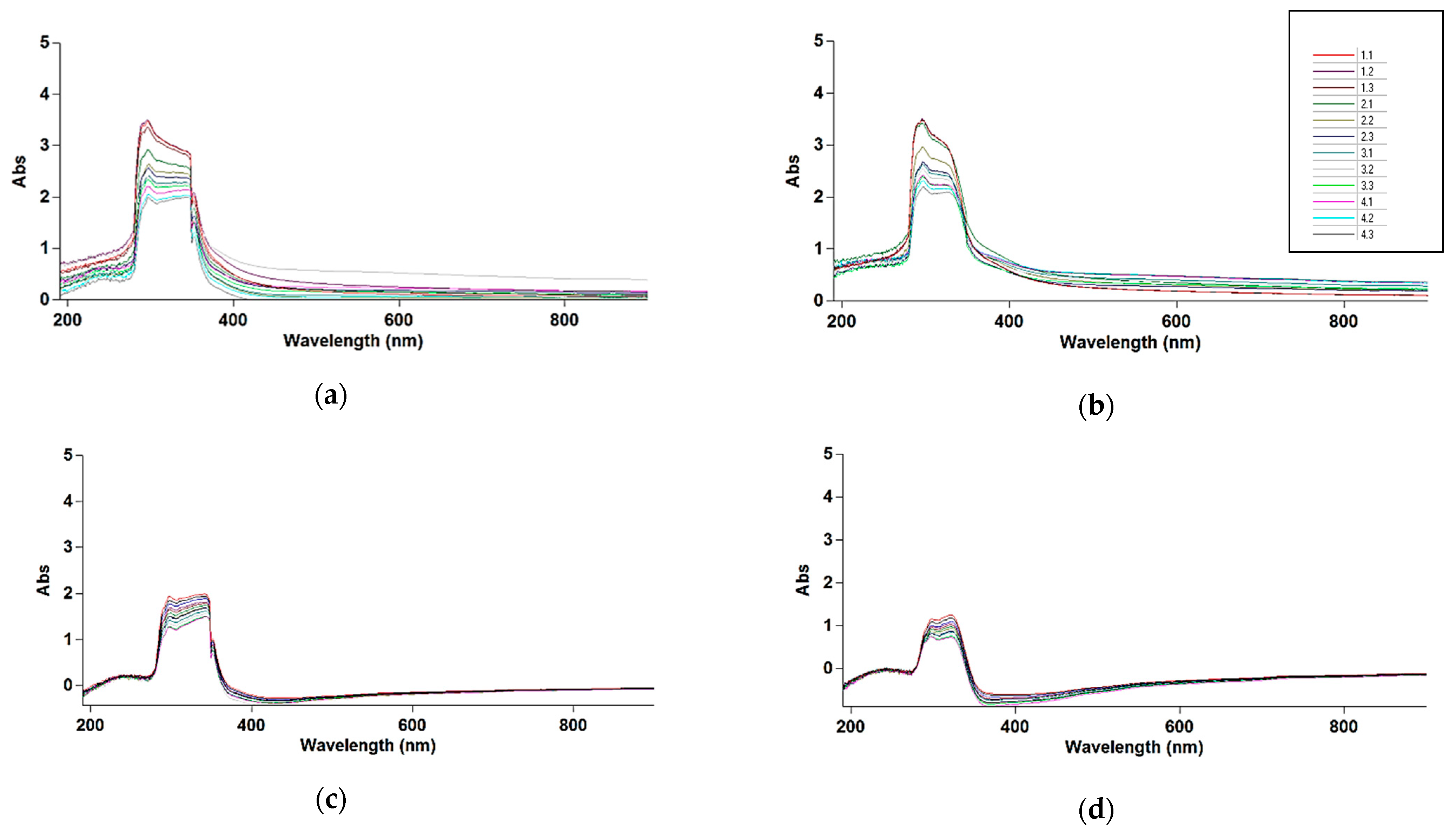

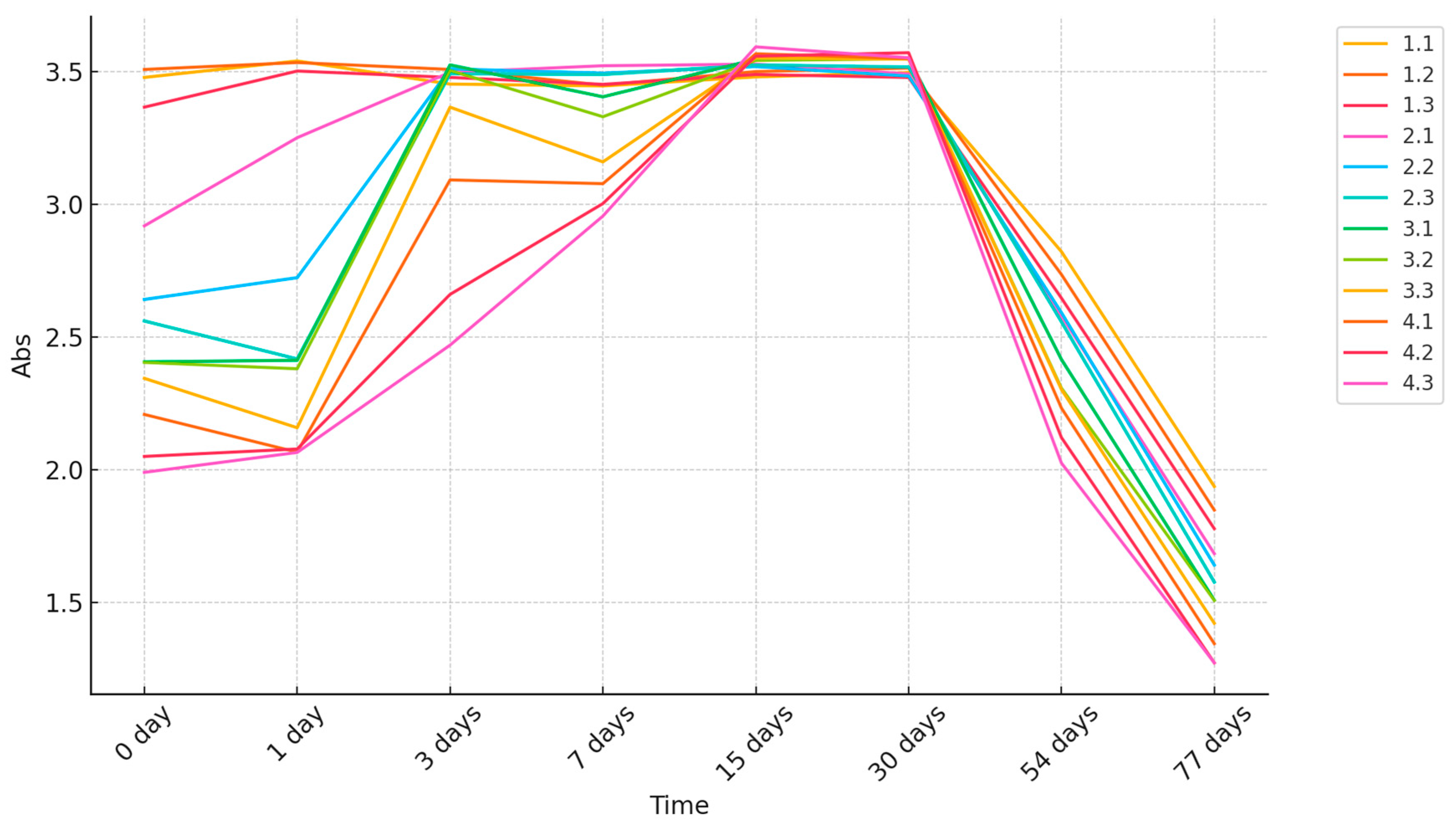

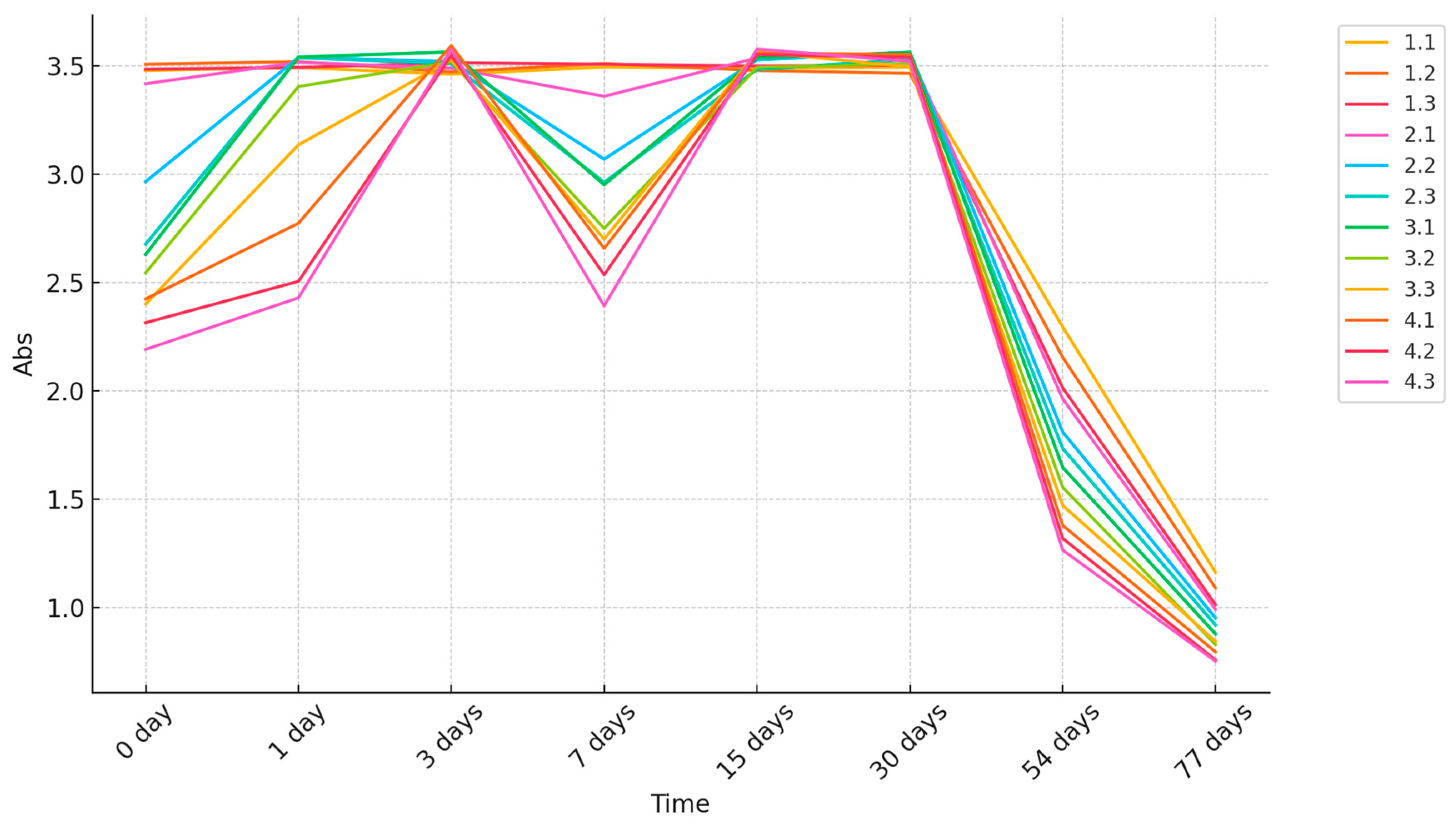

3.4. UV-Vis Analysis of Nanoparticle Dispersion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, J.; Zhou, X. Superlubricitive engineering—future industry nearly getting rid of wear and frictional energy consumption. Friction 2020, 8, 643–665. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Nie, C.; Gong, P.; Yang, J.; Hu, Z.; Li, B.; Ma, M. Research progress on the wear resistance of key components in agricultural machinery. Materials 2023, 16, 7646. [Google Scholar] [CrossRef]

- Joshi, U.; Pandey, K.K.; Uttarakhand, S.G. Lubrication: Purpose, properties, and use in agri-mechanics. Agric. Food E-Newsl. 2020, 2, 622–625. [Google Scholar]

- Calcante, A.; Brambilla, M.; Bisaglia, C.; Oberti, R. Estimating the total lubricant oil consumption rate in agricultural tractors. Trans. ASABE 2019, 62, 197–204. [Google Scholar] [CrossRef]

- Asonja, A.; Mikic, D.; Stojanovic, B.; Gligoric, R.; Savin, L.; Tomic, M. Examination of motor oils in exploitation of agricultural tractors in process of basic treatment of plot. J. Balk. Tribol. Assoc. 2013, 19, 314–322. [Google Scholar]

- Bietresato, M.; Calcante, A.; Mazzetto, F. A neural network approach for indirectly estimating farm tractors engine performances. Fuel 2015, 143, 144–154. [Google Scholar] [CrossRef]

- Agricultural Machinery Registrations. Available online: https://www.federunacoma.it/en/statistiche/agricultural-machinery-registrations.php (accessed on 4 March 2024).

- Zhao, J.; Huang, Y.; He, Y.; Shi, Y. Nanolubricant additives: A review. Friction 2021, 9, 891–917. [Google Scholar] [CrossRef]

- Zilabi, S.; Shareei, M.; Bozorgian, A.; Ahmadpour, A.; Ebrahimi, E. A review on nanoparticle application as an additive. Adv. J. Chem. Sect. B 2022, 4, 209–221. [Google Scholar] [CrossRef]

- Duan, H.; Li, W.; Kumara, C.; Jin, Y.; Meyer, H.M.; Luo, H.; Qu, J. Ionic liquids as oil additives for lubricating oxygen-diffusion case-hardened titanium. Tribol. Int. 2019, 136, 342–348. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- Ahmadpour, A.; Bozorgian, A.; Eslamimanesh, A.; Mohammadi, A.H. Photocatalytic treatment of spontaneous petrochemical effluents by TiO2 CTAB synthetic nanoparticles. Desalination Water Treat. 2022, 249, 297–308. [Google Scholar] [CrossRef]

- Han, K.; Zhang, Y.; Song, N.; Yu, L.; Zhang, P.; Zhang, Z.; Qian, L.; Zhang, S. The Current situation and future direction of nanoparticles lubricant additives in China. Lubricants 2022, 10, 312. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Chinas-Castillo, F.; Spikes, H.A. Mechanism of action of colloidal solid dispersions. J. Tribol. 2003, 125, 552–557. [Google Scholar] [CrossRef]

- Azman, N.F.; Samion, S. Dispersion stability and lubrication mechanism of nanolubricants: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 393–414. [Google Scholar] [CrossRef]

- Seymour, B.T.; Wright, R.A.; Parrott, A.C.; Gao, H.; Martini, A.; Qu, J.; Dai, S.; Zhao, B. Poly(alkyl methacrylate) brush-grafted silica nanoparticles as oil lubricant additives: Effects of alkyl pendant groups on oil dispersibility, stability, and lubrication property. ACS Appl. Mater. Interfaces 2017, 9, 25038–25048. [Google Scholar] [CrossRef] [PubMed]

- Sui, T.; Song, B.; Zhang, F.; Yang, Q. Effect of particle size and ligand on the tribological properties of amino functionalized hairy silica nanoparticles as an additive to polyalphaolefin. J. Nanomater. 2015, 2015, 492401. [Google Scholar] [CrossRef]

- Sui, T.; Song, B.; Zhang, F.; Yang, Q. Effects of functional groups on the tribological properties of hairy silica nanoparticles as an additive to polyalphaolefin. RSC Adv. 2015, 6, 393–402. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli NW, M.; Mufti, R.A.; Zahid, R.; Yunus, R. Dispersion stability and tribological characteristics of TiO2/SiO2 nanocomposite-enriched biobased lubricant. Tribol. Trans. 2017, 60, 670–680. [Google Scholar] [CrossRef]

- Sharif, M.Z.; Azmi, W.H.; Redhwan, A.A.M.; Zawawi, N.M.M. Preparation and stability of silicone dioxide dispersed in polyalkylene glycol based nanolubricants. MATEC Web Conf. 2017, 90, 01049. [Google Scholar] [CrossRef]

- Eiser, E. Dynamic Light Scattering. In Multi Length-Scale Characterisation; Wiley: Hoboken, NJ, USA, 2014; pp. 233–282. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Chen, G. Modification of graphene platelets and their tribological properties as a lubricant additive. Tribol. Lett. 2011, 41, 209–215. [Google Scholar] [CrossRef]

- Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V. Analysis of tribological and thermo-physical properties of surfactant-modified vegetable oil-based CuO nano-lubricants at elevated temperatures-An experimental study. Tribol. Online 2015, 10, 344–353. [Google Scholar] [CrossRef]

- Ramachandran, K.; Navaneethakrishnan, P.; Sivaraja, M. The influence of nickel oxide nanoparticle dispersion on the thermo stability of lubricant oil. Int. J. Nanosci. 2020, 19, 1850044. [Google Scholar] [CrossRef]

- Ismail, M.F.; Azmi, W.H.; Mamat, R.; Sharma, K.V.; Zawawi, N.N.M. Stability Assessment of Polyvinyl-Ether-Based TiO2, SiO2, and Their Hybrid Nanolubricants. Lubricants 2023, 11, 23. [Google Scholar] [CrossRef]

- Kashefi, M.H.; Saedodin, S.; Rostamian, S.H. Effect of silica nano-additive on flash point, pour point, rheological and tribological properties of lubricating engine oil: An experimental study. J. Therm. Anal. Calorim. 2022, 147, 4073–4086. [Google Scholar] [CrossRef]

- Cortes, V.; Sanchez, K.; Gonzalez, R.; Alcoutlabi, M.; Ortega, J.A. The performance of SiO2 and TiO2 nanoparticles as lubricant additives in sunflower oil. Lubricants 2020, 8, 10. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Bisaglia, C.; Cutini, M.; Grilli, R.; Betto, M.; Fornaciari, L. Vegetable-based oil as UTTO fluid for agricultural tractors application. Appl. Eng. Agric. 2020, 36, 79–88. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Bisaglia, C.; Cutini, M.; Grilli, R.; Fornaciari, L.; Betto, M.; Pari, L.; Gallucci, F.; Capuzzi, L.; et al. Test rig and method for comparative evaluation of conventional and bio-based hydraulic fluids and lubricants for agricultural transmissions. Sustainability 2020, 12, 8564. [Google Scholar] [CrossRef]

- Rudnick, L.R. (Ed.) Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2020; ISBN 9781351655743. Available online: https://www.routledge.com/Synthetics-Mineral-Oils-and-Bio-Based-Lubricants-Chemistry-and-Technology/Rudnick/p/book/9781138068216 (accessed on 29 June 2024).

- Malvindi, M.A.; Brunetti, V.; Vecchio, G.; Galeone, A.; Cingolani, R.; Pompa, P.P. SiO2 nanoparticles biocompatibility and their potential for gene delivery and silencing. Nanoscale 2012, 4, 486–495. [Google Scholar] [CrossRef]

- Tian, S.; Gao, W.; Liu, Y.; Kang, W.; Yang, H. Effects of surface modification Nano-SiO2 and its combination with surfactant on interfacial tension and emulsion stability. Colloids Surf. A Physicochem. Eng. Asp. 2020, 595, 124682. [Google Scholar] [CrossRef]

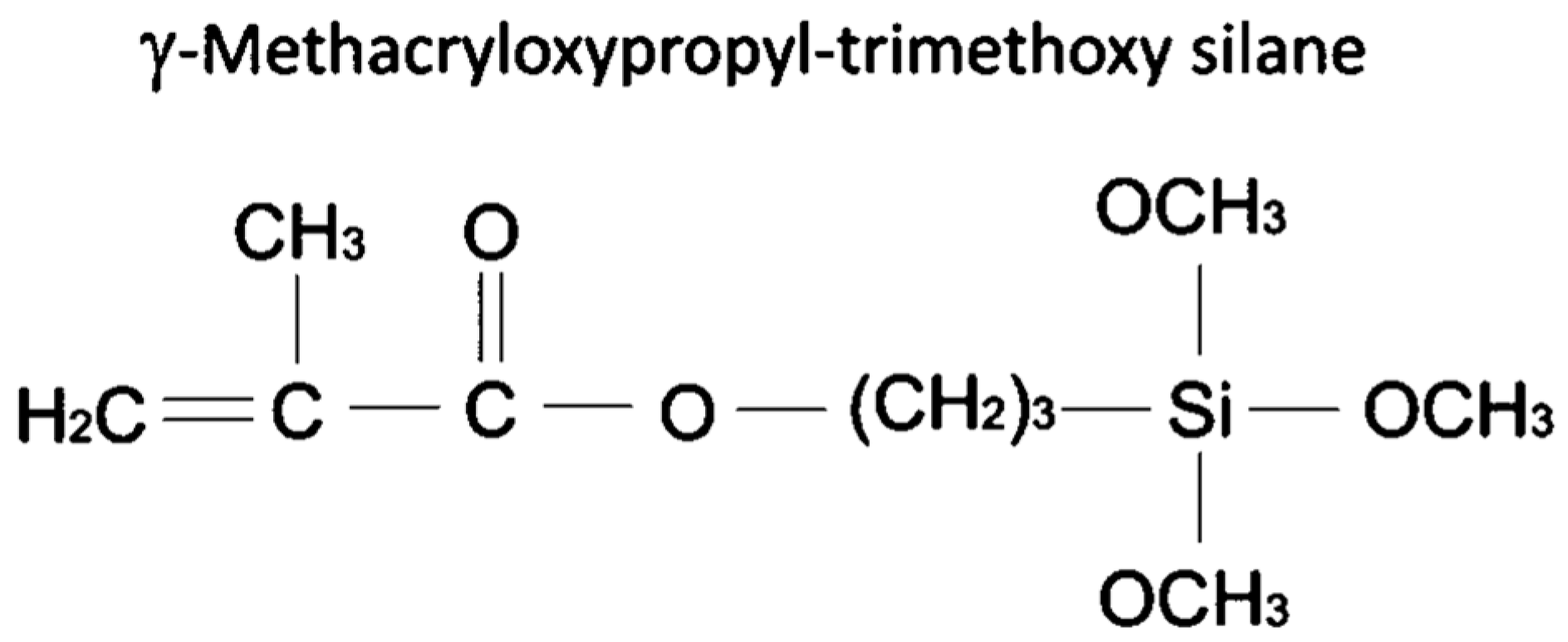

- Uzay, Ç. Investigation of physical, mechanical, and thermal properties of glass fiber reinforced polymer composites strengthened with KH550 and KH570 silane-coated silicon dioxide nanoparticles. J. Compos. Mater. 2022, 56, 2995–3011. [Google Scholar] [CrossRef]

- ASTM D445-24; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM: West Conshohocken, PA, USA, 2024. [CrossRef]

- ISO 2909:2002; Petroleum Products–Calculation of Viscosity Index from Kinematic Viscosity. International Organization for Standardization: Geneva, Switzerland, 2002.

- ASTM D4052-22; Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter. ASTM: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D4739-17; Standard Test Method for Base Number Determination by Potentiometric Hydrochloric Acid Titration. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D664-18e2; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM: West Conshohocken, PA, USA, 2018. [CrossRef]

- Ali, M.K.A.; Hou, X.; Abdelkareem, M.A.A. Anti-wear properties evaluation of frictional sliding interfaces in automobile engines lubricated by copper/graphene nanolubricants. Friction 2020, 8, 905–916. [Google Scholar] [CrossRef]

- Fitch, B.; Noria Corporation. The Critical Role of Viscosity Index in Lubrication. Available online: https://www.machinerylubrication.com/Read/32590/the-critical-role-of-viscosity-index-in-lubrication (accessed on 1 July 2024).

- Piri, H.; Renzi, M.; Bietresato, M. Technical implications of the use of biofuels in agricultural and industrial compression-ignition engines with a special focus on the interactions with (bio)lubricants. Energies 2023, 17, 129. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A review on nanofluids: Preparation, stability mechanisms, and applications. J. Nanomater. 2012, 2012, 435873. [Google Scholar] [CrossRef]

- Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R. Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 2016, 31, 1932–1938. [Google Scholar] [CrossRef]

- Amiruddin, H.; Abdollah, M.F.B.; Idris, A.M.; Abdullah, M.I.H.C.; Tamaldin, N. Stability of nano-oil by pH control in stationary conditions. In Proceedings of the Mechanical Engineering Research Day 2015, Melaka, Malaysia, 31 March 2015; pp. 55–56. Available online: https://eprints.utem.edu.my/id/eprint/14424/1/p55_56.pdf (accessed on 7 July 2024).

- Ali, M.K.A.; Xianjun, H. Role of bis(2-ethylhexyl) phosphate and Al2O3/TiO2 hybrid nanomaterials in improving the dispersion stability of nanolubricants. Tribol. Int. 2021, 155, 106767. [Google Scholar] [CrossRef]

- Ghadimi, A.; Saidur, R.; Metselaar, H.S.C. A review of nanofluid stability properties and characterization in stationary conditions. Int. J. Heat Mass Transf. 2011, 54, 4051–4068. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Kwon, L.; Kim, S.; Lee, J. Performance evaluation of nano-lubricants of fullerene nanoparticles in refrigeration mineral oil. Curr. Appl. Phys. 2009, 9, e128–e131. [Google Scholar] [CrossRef]

- Jiang, H.; Hou, X.; Dearn, K.D.; Su, D.; Ali, M.K.A. Thermal stability enhancement mechanism of engine oil using hybrid MoS2/h-BN nano-additives with ionic liquid modification. Adv. Powder Technol. 2021, 32, 4658–4669. [Google Scholar] [CrossRef]

- Kotia, A.; Haldar, A.; Kumar, R.; Deval, P.; Ghosh, S.K. Effect of copper oxide nanoparticles on thermophysical properties of hydraulic oil-based nanolubricants. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 259–266. [Google Scholar] [CrossRef]

- Haldar, A.; Kotia, A.; Kumar, N.; Ghosh, S.K. Enhancing the tribological properties of hydraulic oil-based nanolubricants using MWCNT-SiO2 hybrid nanoparticles. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 223. [Google Scholar] [CrossRef]

- Yadav, L.; Sihmar, A.; Kumar, S.; Dhaiya, H.; Vishwakarma, R. Review of nano-based smart coatings for corrosion mitigation: Mechanisms, performance, and future prospects. Environ. Sci. Pollut. Res. 2024, 31, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Farag, A.A. Applications of nanomaterials in corrosion protection coatings and inhibitors. Corros. Rev. 2020, 38, 67–86. [Google Scholar] [CrossRef]

- Ifeanyi-Nze, F.O.; Akhiehiero, E.T. Optimization of the process variables on biodegradable industrial lubricant basestock synthesis from Jatropha curcas seed oil via response surface methodology. Front. Energy Res. 2023, 11, 1169565. [Google Scholar] [CrossRef]

- Nguyen, H.K.D.; Van Vo, H.; Dinh, N.T. Role of silica on stability of mesoporous rice husk based catalyst and its activity in synthesis of biolubricant stock. J. Porous Mater. 2020, 27, 1349–1361. [Google Scholar] [CrossRef]

- Kamarudin, N.S.B.; Veny, H.; Sidek, N.F.B.; Abnisa, F.; Sazali, R.A.; Aziz, N. Investigation on synthesis of trimethylolpropane (TMP) ester from non-edible oil. Bull. Chem. React. Eng. Catal. 2020, 15, 808–817. [Google Scholar] [CrossRef]

- Song, X.; Fang, C.; Li, Y.; Wang, P.; Zhang, Y.; Xu, Y. Characterization of mechanical properties of jute/PLA composites containing nano SiO2 modified by coupling agents. Cellulose 2022, 29, 835–848. [Google Scholar] [CrossRef]

- Li, H.; Cheng, B.; Gao, W.; Feng, C.; Huang, C.; Liu, Y.; Lu, P.; Zhao, H. Recent Research Progress and Advanced Applications of Silica/Polymer Nanocomposites; De Gruyter Open Ltd.: Warsaw, Poland, 2022; Volume 11, pp. 2928–2964. [Google Scholar] [CrossRef]

| Technical Property | Unit of Measurement | Value |

|---|---|---|

| Purity | % | 95.9+ |

| Colour | – | white |

| Particle shape | – | amorphous |

| Average Particle Size | nm | 18–35 |

| Specific Surface Area | m2·g−1 | 150–550 |

| Bulk Density | g·cm−3 | <0.1 |

| True Density | g·cm−3 | 2.2 |

| Element | wt% |

|---|---|

| SiO2 | 95.9 |

| KH570 | 3–4 |

| Fe | 0.032 |

| Ca | 0.056 |

| Mg | 0.0085 |

| S | 0.025 |

| Property | Unit of Measurement | Reference | Mistral 15W40 | PLANTO MOT SAE 10W40 |

|---|---|---|---|---|

| Kinematic viscosity at 40 °C | cSt | ASTM D445-24 [35] | 97.3 | 87.0 |

| Kinematic viscosity at 100 °C | cSt | ASTM D445-24 [35] | 13.5 | 13.7 |

| Viscosity index | – | ISO 2909:2002 [36] | 138 | 160 |

| Density at 15 °C | g·cm−3 | ASTM D4052-22 [37] | 0.8769 | 0.8719 |

| TBN | mg(KOH)·g−1 | ASTM D4739-17 [38] | 10.5 | 9.7 |

| TAN | mg(KOH)·g−1 | ASTM D664-18e2 [39] | 2.2 | 1.7 |

| Sample Number | SiO2 (wt%) | Stirring Time (h) | Sonication Time (h) |

|---|---|---|---|

| 1.1 | 0.25 | 1.5 | 0.0 |

| 1.2 | 0.25 | 1.5 | 1.0 |

| 1.3 | 0.25 | 1.5 | 2.5 |

| 2.1 | 0.50 | 1.5 | 0.0 |

| 2.2 | 0.50 | 1.5 | 1.0 |

| 2.3 | 0.50 | 1.5 | 2.5 |

| 3.1 | 0.75 | 1.5 | 0.0 |

| 3.2 | 0.75 | 1.5 | 1.0 |

| 3.3 | 0.75 | 1.5 | 2.5 |

| 4.1 | 1.00 | 1.5 | 0.0 |

| 4.2 | 1.00 | 1.5 | 1.0 |

| 4.3 | 1.00 | 1.5 | 2.5 |

| Property | Lubricant (Pure) Mistral 15W40 | Nanolubricants 0.25% SiO2 | Nanolubricants 0.50% SiO2 | Nanolubricants 0.75% SiO2 | Nanolubricants 1.00% SiO2 |

|---|---|---|---|---|---|

| Appearance | dark yellow | dark yellow | dark yellow | dark yellow | dark yellow |

| Smell | characteristic | characteristic | characteristic | characteristic | characteristic |

| Density at 15 °C [g·cm−3] | 0.8769 | 0.8808 | 0.8819 | 0.8831 | 0.8842 |

| Viscosity at 40 °C [cSt] | 97.3 | 97.6 | 98.4 | 99.0 | 99.9 |

| Viscosity at 100 °C [cSt] | 13.5 | 13.7 | 13.8 | 13.9 | 14.0 |

| Viscosity Index [–] | 138 | 141 | 142 | 142 | 143 |

| TAN [mg(KOH)·g−1] | 2.17 | 1.9 | 1.9 | 2.1 | 2.2 |

| TBN [mg(KOH)·g−1] | 10.6 | 10.7 | 10.3 | 10.3 | 10.3 |

| Pollution–silicon [ppm] | 65 | 419 | 738 | 1101 | 1365 |

| Pollution–sodium [ppm] | 0 | 0 | 0 | 0 | 2 |

| Additives–calcium [ppm] | 3045 | 3118 | 3124 | 3084 | 3043 |

| Additives–magnesium [ppm] | 71 | 71 | 72 | 74 | 70 |

| Additives–zinc [ppm] | 928 | 926 | 923 | 915 | 889 |

| Additives–phosphorus [ppm] | 766 | 827 | 798 | 809 | 795 |

| Additives–boron [ppm] | 137 | 131 | 131 | 130 | 126 |

| Additives–molybdenum [ppm] | 6 | 9 | 9 | 9 | 9 |

| Property | Biolubricant (Pure) SAE 10W40 | Nanobiolubricants 0.25% SiO2 | Nanobiolubricants 0.50% SiO2 | Nanobiolubricants 0.75% SiO2 | Nanobiolubricants 1.00% SiO2 |

|---|---|---|---|---|---|

| Appearance | dark yellow | dark yellow | dark yellow | dark yellow | dark yellow |

| Smell | characteristic | characteristic | characteristic | characteristic | characteristic |

| Density at 15 °C [g·cm−3] | 0.8719 | 0.8733 | 0.8746 | 0.8758 | 0.877 |

| Viscosity at 40 °C [cSt] | 87.0 | 87.9 | 88.6 | 89.6 | 90.3 |

| Viscosity at 100 °C [cSt] | 13.7 | 14 | 14.2 | 14.3 | 14.4 |

| Viscosity Index [–] | 160 | 164 | 165 | 166 | 166 |

| TAN [mg KOH·g−1] | 1.7 | 2.2 | 2.4 | 2.5 | 2.6 |

| TBN [mg KOH·g−1] | 9.7 | 9.5 | 9.6 | 9.9 | 9.6 |

| Pollution–silicon [ppm] | 2 | 337 | 702 | 1020 | 1402 |

| Pollution–sodium [ppm] | 0 | 0 | 0 | 0 | 5 |

| Additives–calcium [ppm] | 1672 | 1720 | 1737 | 1720 | 1761 |

| Additives–magnesium [ppm] | 333 | 345 | 353 | 351 | 359 |

| Additives–zinc [ppm] | 693 | 690 | 678 | 668 | 658 |

| Additives–phosphorus [ppm] | 593 | 596 | 594 | 587 | 591 |

| Additives–boron [ppm] | 487 | 472 | 459 | 462 | 476 |

| Additives–molybdenum [ppm] | 74 | 73 | 75 | 73 | 74 |

| Wavelength (cm−1) | Mistral 15W40 | PLANTO MOT SAE 10W40 | Interpretation |

|---|---|---|---|

| 3649.1 | - | Peaks present | O-H stretching (hydroxyl groups) |

| 3458.9 | - | Peaks present | O-H stretching (hydroxyl groups) |

| 3402.1 | Peaks present | - | O-H stretching (hydroxyl groups) |

| 2729.4 | - | Peaks present | C-H stretching (hydrocarbons or additives) |

| 2728.1 | Peaks present | - | C-H stretching (hydrocarbons or additives) |

| 1740.0 | - | Peaks present | C=O stretching (esters) |

| 1739.9 | Peaks present | - | C=O stretching (esters) |

| 1707.4 | Peaks present | - | C=O stretching (esters) |

| 1605.6 | - | Peaks present | C=C stretching (unsaturated components) |

| 1515.9 | - | Peaks present | N-O asymmetric stretching (additives) |

| 1464.4 | - | Peaks present | CH2 bending (hydrocarbon chains) |

| 1456.0 | Peaks present | - | CH2 bending (hydrocarbon chains) |

| 1377.9 | - | Peaks present | CH3 bending (hydrocarbon chains) |

| 1377.4 | Peaks present | - | CH3 bending (hydrocarbon chains) |

| 1305.6 | Peaks present | - | C-O stretching (esters) |

| 1230.9 | Peaks present | - | C-O stretching (esters) |

| 1167.8 | - | Peaks present | C-O stretching (esters) |

| 1157.0 | Peaks present | - | C-O stretching (esters) |

| 1118.6 | - | Peaks present | C-O stretching (esters) |

| 1026.9 | - | Peaks present | C-O stretching (esters) |

| 974.97 | Peaks present | - | Various hydrocarbon-related vibrations |

| 889.35 | Peaks present | - | Various hydrocarbon-related vibrations |

| 814.84 | Peaks present | - | Various hydrocarbon-related vibrations |

| 768.05 | - | Peaks present | Aromatic or unsaturated components |

| 722.16 | Peaks present | Peaks present | CH2 rocking (long hydrocarbon chains) |

| 667.99 | - | Peaks present | Aromatic or unsaturated components |

| 655.18 | Peaks present | - | Aromatic or unsaturated components |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piri, H.; Renzi, M.; Bietresato, M. Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent. Appl. Sci. 2024, 14, 7943. https://doi.org/10.3390/app14177943

Piri H, Renzi M, Bietresato M. Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent. Applied Sciences. 2024; 14(17):7943. https://doi.org/10.3390/app14177943

Chicago/Turabian StylePiri, Homeyra, Massimiliano Renzi, and Marco Bietresato. 2024. "Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent" Applied Sciences 14, no. 17: 7943. https://doi.org/10.3390/app14177943

APA StylePiri, H., Renzi, M., & Bietresato, M. (2024). Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent. Applied Sciences, 14(17), 7943. https://doi.org/10.3390/app14177943