Research on Safety Performance Evaluation and Improvement Path of Prefabricated Building Construction Based on DEMATEL and NK

Abstract

:1. Introduction

2. Evaluation Indicators

2.1. Sample Collection

2.2. Substantive Coding

2.3. Saturation Test

3. Methodology

3.1. Research Framework of DEMATEL Method and NK Model

3.2. Exploring the Causal Relationship of Indicators Using the DEMATEL Method

3.3. Simulation of Fitness Landscape Graph Based on NK Model

4. Empirical Analysis

4.1. Case Introduction

4.2. Causal Relationship Analysis Based on DEMATEL

4.3. Fitness Modeling Simulation Based on NK Model

5. Conclusions

- (1)

- Through survey interviews, policy review, and literature analysis, a total of 386 pieces of raw data were obtained. Using grounded theory, substantive coding and saturation testing were performed on the raw data, combining the opinions and suggestions of field experts and the experience of relevant practitioners. This ultimately formed the prefabricated building construction safety performance indicator system with 16 main categories (X1 to X16) and four core categories (personnel, management, environment, and equipment).

- (2)

- Based on the DEMATEL decision matrix causal relationship analysis, X6 (construction and implementation of safety management systems) has the highest influence on other factors, while X14 (quality and safety status of prefabricated components) is the most influenced by other indicators. From the perspectives of centrality and causality, X6 (construction and implementation of safety management systems), X1 (personnel safety awareness and attitude), X14 (quality and safety status of prefabricated components), and X12 (construction site working environment) are the top four performance indicators and should be focused on in the improvement path selection for prefabricated building construction safety performance.

- (3)

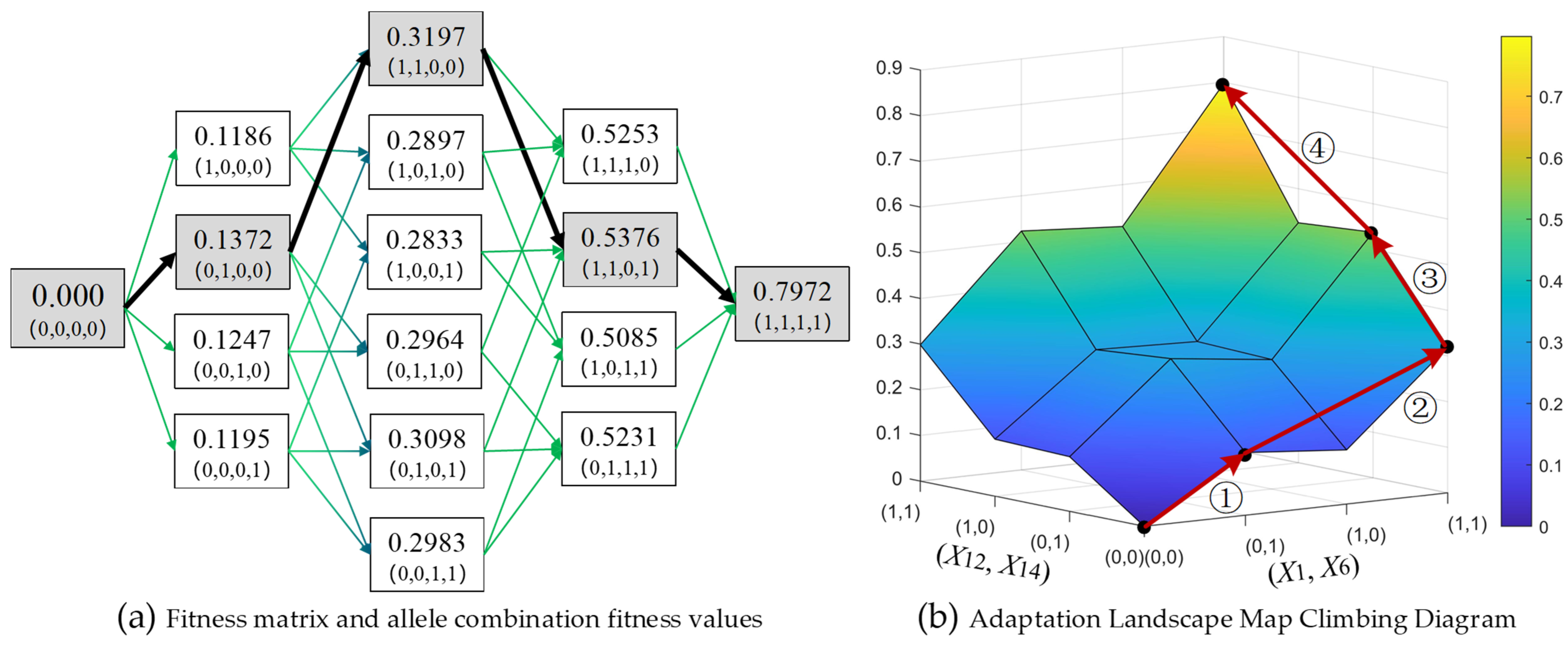

- Based on the NK model simulation analysis, key subjects were modeled for four key indicators, constructing an adaptive three-dimensional landscape climbing schematic. According to the landscape climbing process representation and the overall fitness value criteria for alleles, the optimal path for improving prefabricated building construction safety performance was determined, focusing on X6 (construction and implementation of safety management systems) → X1 (personnel safety awareness and attitude) → X14 (quality and safety status of prefabricated components) → X12 (construction site working environment).

- (4)

- To simplify the study, the NK model in this paper only considers two scenarios (0 and 1), lacking consideration of intermediate degrees, which affects the reasonable allocation of resources for safety performance improvement strategies to some extent. In the future, introducing intermediate degree values in the range of (0,1) or adopting a graded representation of state degrees to take reasonable resource allocation based on the optimal degree of implementation of each key indicator will be attempted, thereby obtaining the optimal performance improvement of prefabricated building construction safety performance under reasonable resource allocation.

- (5)

- At the same time, this study focuses on practical issues encountered during the construction process of a certain subway line in Wuhan. It can be said that the complete method framework system formed by this research provides a certain reference for other similar engineering projects to solve the same problems. However, there are certain particularities in case samples, basic data, etc. Therefore, in solving problems in other engineering projects, specific problem analysis should be carried out.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chourasia, A.; Manivannan, S.S. Prefabricated volumetric modular construction: A review on current systems, challenges, and future prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar] [CrossRef]

- Chen, W.; Qiao, Z.; Xiong, F.; Niu, L.; Yang, D. SD-MOP model for safety accident prevention in prefabricated building construction. Chin. J. Saf. Sci. 2019, 29, 19–24. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Yi, X.; Li, S.S.; Qiu, H. Evolutionary game of government safety supervision for prefabricated building construction using system dynamics. Eng. Constr. Archit. Manag. 2022, 30, 2947–2968. [Google Scholar] [CrossRef]

- Fard, M.M.; Terouhid, S.A.; Kibert, C.J.; Hakim, H. Safety concerns related to modular/prefabricated building construction. Int. J. Inj. Control. Saf. Promot. 2017, 24, 10–23. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhu, K.; Guo, P.; Guo, Z.; Zhang, B. Construction safety risk assessment of prefabricated building based on interaction matrix fuzzy cognitive map. J. Saf. Environ. 2023, 23, 2191–2202. [Google Scholar] [CrossRef]

- Wang, C.; Zou, F.Q.; Yap, J.B.; Wood, L.C.; Li, H.; Ding, L. System dynamics tool for entropy-based risk control on sleeve grouting in prefabricated buildings. Eng. Constr. Archit. Manag. 2023, 30, 538–567. [Google Scholar] [CrossRef]

- Liu, J.K.; Gong, E.Q.; Wang, D.; Teng, Y. Cloud model-based safety performance evaluation of prefabricated building project in China. Wirel. Pers. Commun. 2018, 102, 3021–3039. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, K.; Wang, J.; Guo, P.; Shen, W. Bibliometric analysis of engineering project risk management literature. China Saf. Sci. J. 2021, 31, 15–23. [Google Scholar] [CrossRef]

- Fontela, E.; Gabus, A. DEMATEL: Progress achieved. Futures 1974, 6, 361–363. [Google Scholar] [CrossRef]

- Kuzu, A.C. Application of fuzzy DEMATEL approach in maritime transportation: A risk analysis of anchor loss. Ocean. Eng. 2023, 273, 113786. [Google Scholar] [CrossRef]

- Mohandes, S.; Sadeghi, H.; Fazeli, A.; Mahdiyar, A.; Hosseini, M.R.; Arashpour, M.; Zayed, T. Causal analysis of accidents on construction sites: A hybrid fuzzy Delphi and DEMATEL approach. Saf. Sci. 2022, 151, 105730. [Google Scholar] [CrossRef]

- Kauffman, S.A. Origins of order in evolution: Self-organization and selection. In Understanding Origins; Springer: Dordrecht, The Netherlands, 1992; Volume 130, pp. 153–181. [Google Scholar] [CrossRef]

- Liu, Z.K.; Ma, Q.; Cai, B.P.; Shi, X.; Zheng, C.; Liu, Y. Risk coupling analysis of subsea blowout accidents based on dynamic Bayesian network and NK model. Reliab. Eng. Syst. Saf. 2022, 218, 108160. [Google Scholar] [CrossRef]

- Bull, L. Exploring distributed control with the NK model. Int. J. Parallel Emergent Distrib. Syst. 2020, 35, 413–422. [Google Scholar] [CrossRef]

- Ebrahimi, H.; Zarei, E.; Ansari, M.; Nojoumi, A.; Yarahmadi, R. A system theory based accident analysis model: STAMP-fuzzy DEMATEL. Saf. Sci. 2024, 173, 106445. [Google Scholar] [CrossRef]

- Ji, Y.; Tong, W.; Yao, F.; Zhang, Y.; Li, H.X.; Zhu, F. Factors influencing fire accidents in urban complexes: A combined DEMATEL and ISM study. Environ. Sci. Pollut. Res. Int. 2024, 31, 27897–27912. [Google Scholar] [CrossRef] [PubMed]

- La Fata, C.M.; Adelfio, L.; Micale, R.; La Scalia, G. Human error contribution to accidents in the manufacturing sector: A structured approach to evaluate the interdependence among performance shaping factors. Saf. Sci. 2023, 161, 106067. [Google Scholar] [CrossRef]

- Suo, W.; Zhang, J.; Sun, X. Risk assessment of critical infrastructures in a complex interdependent scenario: A four-stage hybrid decision support approach. Saf. Sci. 2019, 120, 692–705. [Google Scholar] [CrossRef]

- Emel, Y.; Şölen, Z. Assessment of sustainability criteria with DEMATEL and MORRAR methods: A case study in textile sector. Environ. Eng. Manag. J. 2024, 23, 11–28. [Google Scholar] [CrossRef]

- Lee, C.K.; Chai, C.; Bujna, M.; Fauzi, M.A.; Boo, Y.Q. Understanding the causes of design errors in construction projects: A DEMATEL-based framework. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2024, 16, 04524002.1–04524002.10. [Google Scholar] [CrossRef]

- Lee, C.K.; Bujna, M.; Jamil, A.H.A.; Ee, P.T. A cause and effect of a nonpayment model based on the DEMATEL algorithm. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2023, 15, 04522050. [Google Scholar] [CrossRef]

- Feng, Y.; Hu, B.; Wang, L.; Ke, C. Invulnerability research of logistics network with dynamic recovery strategy based on NK model. Xitong Gongcheng Lilun Yu Shijian/Syst. Eng. Theory Pract. 2024, 44, 1405–1423. [Google Scholar] [CrossRef]

- Mai, Q.; Zhao, Y.; An, S. Discrete decision model and multi-agent simulation of the Liang Zong two-chain hierarchical organization in a complex project. J. Syst. Eng. Electron. 2018, 29, 311–320. [Google Scholar] [CrossRef]

| No. | Original Corpus | Open Coding | Axis Coding | ||

|---|---|---|---|---|---|

| Labeling | Initial Conceptualization | Conceptualization | Categorization | ||

| A001 | Workers engaged in prefabricated building construction generally exhibit issues such as weak safety awareness, indifference to safety protection, and insufficient safety consciousness. It is necessary to strengthen safety training and education to enhance the safety awareness and skills of practitioners. | Weak safety awareness Indifference to safety protection Insufficient safety consciousness Workers’ safety awareness and skills | Safety Awareness Safety attitude Safety skills | Safety awareness and attitude Safety technical level | Personnel factors |

| Strengthening safety training and education | Safety education Safety training | Safety education and training | Management factors | ||

| — | — | — | Environmental factors | ||

| — | — | — | Equipment factors | ||

| A002 | Necessary emergency rescue equipment and devices should be equipped at the construction site for regular inspection and maintenance to ensure the safety and stability of the construction site, and to promptly identify and address potential safety hazards. | — | — | — | Personnel factors |

| Regular inspection and maintenance | Security system | Security management system situation | Management factors | ||

| Safety at the construction site Stability of construction site Potential safety hazards | Natural environment Surrounding environment Work environment | Natural environment of construction site Construction site yard environment Construction site working environment | Environmental factors | ||

| Emergency rescue equipment and devices | Safety equipment | Equipping with protective and rescue equipment | Equipment factors | ||

| …… | …… | …… | …… | …… | …… |

| Core Category | Main Category | Abbreviation |

|---|---|---|

| Personnel factors Z1 | Personnel safety awareness and attitude | X1 |

| Personnel safety knowledge and technical proficiency | X2 | |

| Personnel compliance with safety management systems | X3 | |

| Personnel physiological and psychological health | X4 | |

| Management factors Z2 | Safety education, training, and promotion | X5 |

| Construction and implementation of safety management system | X6 | |

| Safety technical disclosure and construction organization design | X7 | |

| Formulation and implementation of safety emergency plans | X8 | |

| Environmental factors Z3 | Natural environment at the construction site | X9 |

| Surrounding environment of the construction site | X10 | |

| Storage environment at the construction site | X11 | |

| Construction site working environment | X12 | |

| Equipment factors Z4 | Safety status of construction machinery and equipment | X13 |

| Quality and safety status of prefabricated components | X14 | |

| Monitoring and maintenance of machinery and equipment | X15 | |

| Provision of protective and rescue equipment | X16 |

| Valid Questionnaire | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X11 | X12 | X13 | X14 | X15 | X16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 2 | 3 | 3 | 3 | 3 | 2 | 2 | 0 | 0 | 1 | 2 | 3 | 3 | 1 | 3 |

| 2 | 0 | 2 | 3 | 3 | 2 | 3 | 2 | 2 | 0 | 1 | 0 | 3 | 3 | 3 | 1 | 3 |

| 3 | 0 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 0 | 1 | 1 | 3 | 3 | 3 | 3 | 3 |

| 4 | 0 | 3 | 2 | 2 | 2 | 4 | 3 | 3 | 0 | 0 | 1 | 3 | 3 | 3 | 3 | 3 |

| 5 | 0 | 3 | 2 | 2 | 3 | 4 | 3 | 3 | 0 | 1 | 0 | 2 | 3 | 2 | 3 | 2 |

| 6 | 0 | 2 | 2 | 2 | 3 | 4 | 2 | 3 | 0 | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| 7 | 0 | 2 | 2 | 2 | 3 | 4 | 2 | 3 | 0 | 0 | 1 | 2 | 2 | 2 | 2 | 2 |

| 8 | 0 | 3 | 4 | 2 | 3 | 4 | 2 | 2 | 0 | 1 | 0 | 2 | 2 | 2 | 2 | 2 |

| 9 | 0 | 3 | 4 | 2 | 3 | 4 | 2 | 2 | 0 | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| 10 | 0 | 3 | 2 | 2 | 3 | 4 | 2 | 2 | 0 | 0 | 1 | 2 | 2 | 2 | 2 | 2 |

| 11 | 0 | 3 | 2 | 2 | 3 | 3 | 2 | 2 | 0 | 1 | 0 | 2 | 2 | 2 | 2 | 2 |

| 12 | 0 | 4 | 1 | 2 | 3 | 3 | 2 | 2 | 0 | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| 13 | 0 | 2 | 3 | 3 | 3 | 3 | 2 | 2 | 0 | 0 | 1 | 2 | 3 | 3 | 1 | 3 |

| T16×16 | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X11 | X12 | X13 | X14 | X15 | X16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | 0.0000 | 2.9302 | 2.1938 | 2.0193 | 2.9807 | 3.6128 | 2.0193 | 2.1938 | 0.0000 | 0.8062 | 0.9270 | 2.0193 | 2.1938 | 2.0730 | 2.0161 | 2.0730 |

| X2 | 3.9968 | 0.0000 | 1.0730 | 0.9807 | 0.0000 | 3.9968 | 0.3904 | 3.0730 | 0.0000 | 0.0000 | 0.0000 | 1.1938 | 2.0193 | 3.0730 | 1.8062 | 0.9270 |

| X3 | 2.6128 | 1.6128 | 0.0000 | 1.0730 | 0.8062 | 4.0000 | 1.2449 | 2.9968 | 0.0000 | 0.0000 | 0.0000 | 0.9807 | 2.0730 | 2.9270 | 1.9270 | 1.9807 |

| X4 | 3.1938 | 1.0730 | 2.0730 | 0.0000 | 0.3872 | 3.9968 | 1.3872 | 2.0762 | 0.0000 | 0.0000 | 0.0000 | 0.9807 | 0.0000 | 3.0193 | 1.2131 | 1.1938 |

| X5 | 3.9270 | 2.9807 | 2.6160 | 0.6128 | 0.0000 | 3.9807 | 0.0000 | 2.1460 | 0.0000 | 0.0000 | 0.0000 | 1.0386 | 2.0193 | 3.0029 | 1.0193 | 0.9270 |

| X6 | 3.9807 | 3.0032 | 2.9839 | 2.0063 | 2.1938 | 0.0000 | 2.0032 | 3.6128 | 0.0000 | 1.1938 | 2.0000 | 1.0000 | 3.1938 | 4.0000 | 2.1938 | 2.0730 |

| X7 | 3.3872 | 1.3872 | 1.8062 | 0.0000 | 1.1938 | 3.0032 | 0.0000 | 1.9270 | 0.0000 | 0.6128 | 0.9270 | 3.0000 | 1.0193 | 2.9807 | 2.0193 | 1.6128 |

| X8 | 3.0193 | 2.9807 | 2.1938 | 1.8062 | 1.1938 | 2.0730 | 1.0193 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 2.0730 | 1.0730 | 2.9270 | 2.0000 | 1.0730 |

| X9 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.1938 | 1.0000 | 0.9270 | 1.0000 | 0.0000 | 1.9270 | 1.9807 | 2.9968 | 1.0193 | 3.0730 | 2.0193 | 1.1938 |

| X10 | 0.0000 | 1.9807 | 1.9968 | 1.9270 | 1.0032 | 2.0193 | 0.1938 | 0.8062 | 0.6128 | 0.0000 | 0.0193 | 2.9807 | 1.1938 | 2.8062 | 2.0000 | 1.0193 |

| X11 | 1.0000 | 1.9270 | 1.6128 | 2.0000 | 1.1941 | 2.0000 | 1.0032 | 1.0730 | 0.6128 | 0.9807 | 0.0000 | 2.9968 | 0.9968 | 3.0000 | 2.0000 | 0.0000 |

| X12 | 3.9270 | 0.0000 | 0.0000 | 0.0000 | 2.0032 | 2.1208 | 2.0032 | 0.0000 | 0.0000 | 2.6128 | 2.0730 | 0.0000 | 1.8062 | 3.6128 | 2.9270 | 2.9968 |

| X13 | 3.0032 | 1.0193 | 1.0032 | 0.0000 | 1.0762 | 2.0000 | 1.0032 | 0.0000 | 0.9807 | 0.9270 | 0.9807 | 2.0000 | 0.0000 | 4.0000 | 1.9807 | 0.9807 |

| X14 | 2.9968 | 1.9270 | 2.9968 | 1.0000 | 2.8062 | 1.6128 | 1.6128 | 2.9807 | 0.0000 | 0.0000 | 0.9807 | 3.9968 | 2.9807 | 0.0730 | 0.0032 | 0.0032 |

| X15 | 3.0032 | 1.0032 | 1.0730 | 0.0000 | 1.0195 | 2.0000 | 0.9807 | 0.6128 | 0.0000 | 0.0000 | 0.0000 | 1.9807 | 0.0000 | 2.6128 | 0.0000 | 1.6128 |

| X16 | 3.0730 | 0.0730 | 0.9807 | 0.0000 | 0.6128 | 2.0000 | 0.8062 | 0.9807 | 0.0000 | 0.0000 | 0.0000 | 2.9937 | 1.0193 | 3.0730 | 2.0730 | 0.0000 |

| Q16×16 | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X11 | X12 | X13 | X14 | X15 | X16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | 0.0896 | 0.1755 | 0.1455 | 0.1137 | 0.1680 | 0.2299 | 0.1211 | 0.1489 | 0.0030 | 0.0498 | 0.0594 | 0.1424 | 0.1433 | 0.1748 | 0.1360 | 0.1283 |

| X2 | 0.2373 | 0.0429 | 0.0887 | 0.0664 | 0.0377 | 0.2269 | 0.0478 | 0.1747 | 0.0022 | 0.0129 | 0.0177 | 0.0966 | 0.1270 | 0.1964 | 0.1160 | 0.0720 |

| X3 | 0.1844 | 0.1126 | 0.0448 | 0.0700 | 0.0719 | 0.2305 | 0.0843 | 0.1738 | 0.0022 | 0.0128 | 0.0178 | 0.0904 | 0.1308 | 0.1946 | 0.1231 | 0.1176 |

| X4 | 0.1991 | 0.0857 | 0.1285 | 0.0227 | 0.0509 | 0.2241 | 0.0876 | 0.1322 | 0.0012 | 0.0113 | 0.0160 | 0.0840 | 0.0396 | 0.1887 | 0.0878 | 0.0813 |

| X5 | 0.2405 | 0.1726 | 0.1567 | 0.0528 | 0.0384 | 0.2335 | 0.0324 | 0.1416 | 0.0023 | 0.0131 | 0.0181 | 0.0917 | 0.1320 | 0.1989 | 0.0857 | 0.0742 |

| X6 | 0.2672 | 0.1878 | 0.1875 | 0.1191 | 0.1430 | 0.0904 | 0.1263 | 0.2164 | 0.0040 | 0.0673 | 0.1064 | 0.1122 | 0.1926 | 0.2667 | 0.1503 | 0.1326 |

| X7 | 0.2169 | 0.1032 | 0.1209 | 0.0251 | 0.0905 | 0.1905 | 0.0322 | 0.1282 | 0.0023 | 0.0413 | 0.0584 | 0.1773 | 0.0881 | 0.1981 | 0.1291 | 0.1042 |

| X8 | 0.1986 | 0.1668 | 0.1345 | 0.0993 | 0.0860 | 0.1506 | 0.0733 | 0.0458 | 0.0017 | 0.0124 | 0.0164 | 0.1330 | 0.0868 | 0.1908 | 0.1242 | 0.0787 |

| X9 | 0.0463 | 0.0261 | 0.0279 | 0.0150 | 0.0340 | 0.0805 | 0.0602 | 0.0687 | 0.0025 | 0.0941 | 0.0979 | 0.1648 | 0.0707 | 0.1783 | 0.1144 | 0.0727 |

| X10 | 0.0611 | 0.1161 | 0.1188 | 0.0998 | 0.0716 | 0.1368 | 0.0335 | 0.0714 | 0.0281 | 0.0117 | 0.0156 | 0.1655 | 0.0851 | 0.1776 | 0.1188 | 0.0716 |

| X11 | 0.1079 | 0.1188 | 0.1069 | 0.1059 | 0.0835 | 0.1416 | 0.0705 | 0.0866 | 0.0284 | 0.0552 | 0.0163 | 0.1707 | 0.0801 | 0.1909 | 0.1221 | 0.0309 |

| X12 | 0.2364 | 0.0449 | 0.0467 | 0.0248 | 0.1254 | 0.1529 | 0.1161 | 0.0451 | 0.0034 | 0.1256 | 0.1063 | 0.0556 | 0.1199 | 0.2249 | 0.1666 | 0.1605 |

| X13 | 0.1863 | 0.0793 | 0.0798 | 0.0202 | 0.0795 | 0.1369 | 0.0696 | 0.0393 | 0.0441 | 0.0526 | 0.0585 | 0.1294 | 0.0375 | 0.2282 | 0.1189 | 0.0703 |

| X14 | 0.2051 | 0.1281 | 0.1717 | 0.0678 | 0.1580 | 0.1386 | 0.1012 | 0.1734 | 0.0030 | 0.0165 | 0.0610 | 0.2178 | 0.1719 | 0.0801 | 0.0472 | 0.0382 |

| X15 | 0.1765 | 0.0720 | 0.0755 | 0.0164 | 0.0706 | 0.1274 | 0.0636 | 0.0584 | 0.0010 | 0.0098 | 0.0129 | 0.1175 | 0.0310 | 0.1573 | 0.0280 | 0.0924 |

| X16 | 0.1838 | 0.0347 | 0.0736 | 0.0171 | 0.0568 | 0.1298 | 0.0590 | 0.0744 | 0.0015 | 0.0119 | 0.0150 | 0.1638 | 0.0760 | 0.1815 | 0.1189 | 0.0265 |

| Influencing Factors | Oi | Oi Rank | Pi | Pi Rank | Ri | Ri Rank | Si | Factor Types |

|---|---|---|---|---|---|---|---|---|

| X1 | 2.0292 | 2 | 2.8369 | 2 | 4.8662 | 2 | −0.8077 | Resultant Factors |

| X2 | 1.5630 | 9 | 1.6672 | 8 | 3.2302 | 7 | −0.1042 | Resultant Factors |

| X3 | 1.6617 | 7 | 1.7079 | 7 | 3.3696 | 6 | −0.0463 | Resultant Factors |

| X4 | 1.4406 | 11 | 0.9360 | 13 | 2.3766 | 13 | 0.5047 | Causal Factors |

| X5 | 1.6844 | 6 | 1.3659 | 10 | 3.0502 | 8 | 0.3185 | Causal Factors |

| X6 | 2.3699 | 1 | 2.6207 | 3 | 4.9907 | 1 | −0.2508 | Resultant Factors |

| X7 | 1.7061 | 5 | 1.1787 | 12 | 2.8848 | 11 | 0.5275 | Causal Factors |

| X8 | 1.5988 | 8 | 1.7788 | 6 | 3.3776 | 5 | −0.1800 | Resultant Factors |

| X9 | 1.1541 | 15 | 0.1309 | 16 | 1.2850 | 16 | 1.0232 | Causal Factors |

| X10 | 1.3831 | 13 | 0.5984 | 15 | 1.9814 | 15 | 0.7847 | Causal Factors |

| X11 | 1.5164 | 10 | 0.6935 | 14 | 2.2099 | 14 | 0.8228 | Causal Factors |

| X12 | 1.7549 | 4 | 2.1126 | 4 | 3.8676 | 4 | −0.3577 | Resultant Factors |

| X13 | 1.4304 | 12 | 1.6125 | 9 | 3.0429 | 9 | −0.1821 | Resultant Factors |

| X14 | 1.7796 | 3 | 3.0276 | 1 | 4.8072 | 3 | −1.2480 | Resultant Factors |

| X15 | 1.1101 | 16 | 1.7870 | 5 | 2.8970 | 10 | −0.6769 | Resultant Factors |

| X16 | 1.2243 | 14 | 1.3519 | 11 | 2.5762 | 12 | −0.1276 | Resultant Factors |

| C4×4 | X1 | X6 | X12 | X14 | Cα• | Eα |

|---|---|---|---|---|---|---|

| X1 | 0.0896 | 0.2299 | 0.1424 | 0.1748 | 0.6368 | 0.1186 |

| X6 | 0.2672 | 0.0904 | 0.1122 | 0.2667 | 0.7365 | 0.1372 |

| X12 | 0.2364 | 0.1529 | 0.0556 | 0.2249 | 0.6698 | 0.1247 |

| X14 | 0.2051 | 0.1386 | 0.2178 | 0.0801 | 0.6416 | 0.1195 |

| C•β | 0.7983 | 0.6118 | 0.5281 | 0.7464 | ∑Cα• = ∑C•β = 5.3694 | — |

| Serial Number | X1 | X6 | X12 | X14 | Fd | Path |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 0.0000 | |

| 2 | 1 | 0 | 0 | 0 | 0.1186 | |

| 3 | 0 | 1 | 0 | 0 | 0.1372 | ① |

| 4 | 0 | 0 | 1 | 0 | 0.1247 | |

| 5 | 0 | 0 | 0 | 1 | 0.1195 | |

| 6 | 1 | 1 | 0 | 0 | 0.3197 | ② |

| 7 | 1 | 0 | 1 | 0 | 0.2897 | |

| 8 | 1 | 0 | 0 | 1 | 0.2833 | |

| 9 | 0 | 1 | 1 | 0 | 0.2964 | |

| 10 | 0 | 1 | 0 | 1 | 0.3098 | |

| 11 | 0 | 0 | 1 | 1 | 0.2983 | |

| 12 | 1 | 1 | 1 | 0 | 0.5253 | |

| 13 | 1 | 1 | 0 | 1 | 0.5376 | ③ |

| 14 | 1 | 0 | 1 | 1 | 0.5085 | |

| 15 | 0 | 1 | 1 | 1 | 0.5231 | |

| 16 | 1 | 1 | 1 | 1 | 0.7972 | ④ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Z.; Lin, Y.; Wang, Q.; Yang, W.; Shen, C.; Zhang, J.; Zhu, K. Research on Safety Performance Evaluation and Improvement Path of Prefabricated Building Construction Based on DEMATEL and NK. Appl. Sci. 2024, 14, 8010. https://doi.org/10.3390/app14178010

Xiong Z, Lin Y, Wang Q, Yang W, Shen C, Zhang J, Zhu K. Research on Safety Performance Evaluation and Improvement Path of Prefabricated Building Construction Based on DEMATEL and NK. Applied Sciences. 2024; 14(17):8010. https://doi.org/10.3390/app14178010

Chicago/Turabian StyleXiong, Zhihua, Yuting Lin, Qiankun Wang, Wanjun Yang, Chuxiong Shen, Jiaji Zhang, and Ke Zhu. 2024. "Research on Safety Performance Evaluation and Improvement Path of Prefabricated Building Construction Based on DEMATEL and NK" Applied Sciences 14, no. 17: 8010. https://doi.org/10.3390/app14178010