A Novel Small-Scale Bladeless Wind Turbine Using Vortex-Induced Vibration and a Discrete Resonance-Shifting Module

Abstract

:1. Introduction

- This study proposes a novel bladeless wind turbine that can shift the structural resonance to operate at a wider range of wind speeds to improve the effective power generation region.

- This study designed an on–off resonance-tuning module based on a variable-stiffness smart material that can effectively shift the BWT resonance by 60%.

- A series of experiments validated the widening of the operation range with the Low-K and High-K modes, which improved power generation efficiency by as much as 1.9 times for various wind speeds.

2. Principle of Vortex Bladeless Wind Turbines

2.1. Vortex-Induced Vibration

2.2. The Need for System Resonance Tuning

3. Design of a Resonance-Tunable BWT

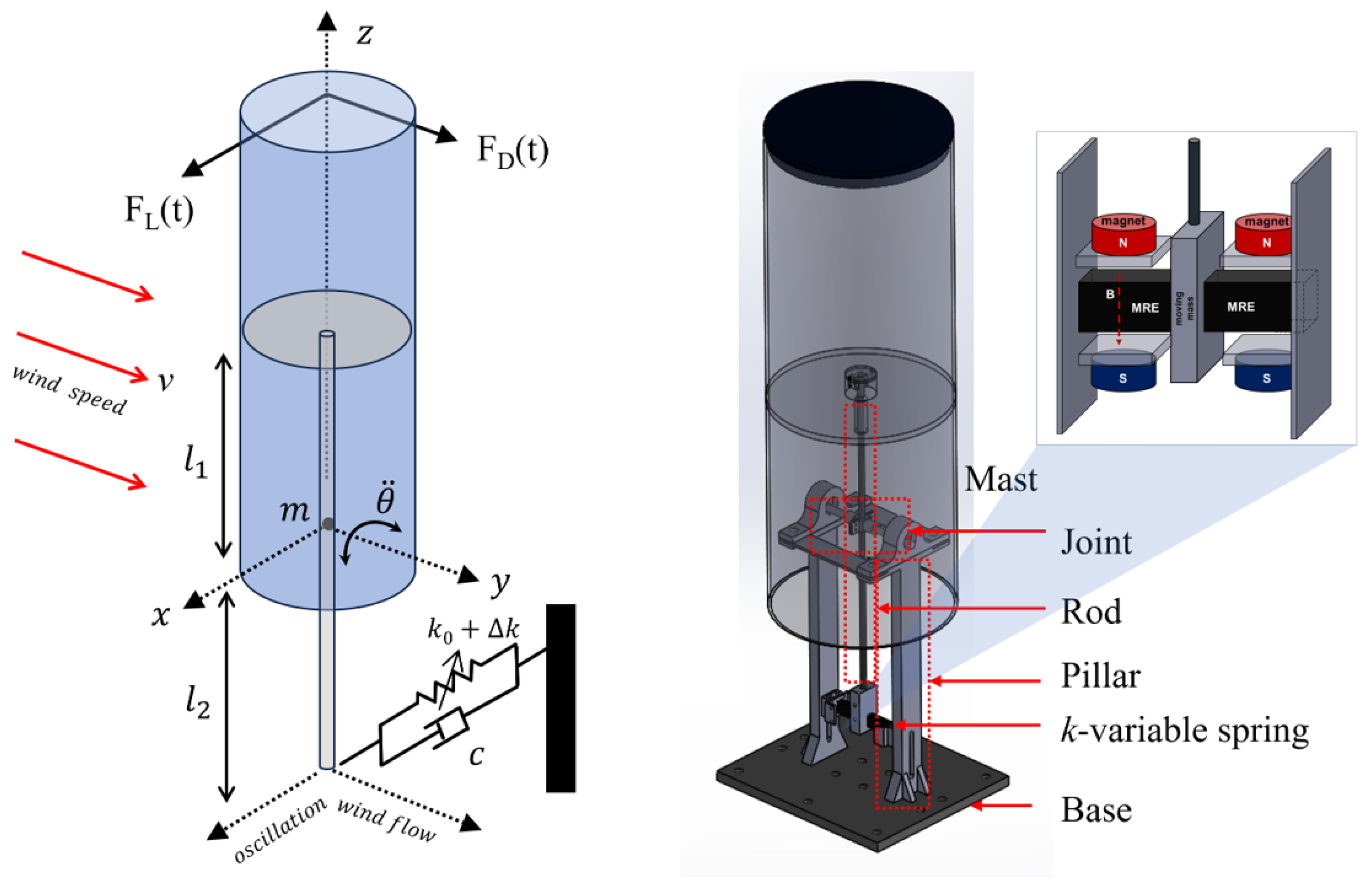

3.1. BWT Design and System Modeling

3.2. Hardware Design Parameters

3.2.1. Mast Design Parameter

3.2.2. VIV Frequency

3.3. Comparison to Conventional BWT

4. Design of the On–Off Resonance-Tuning Module

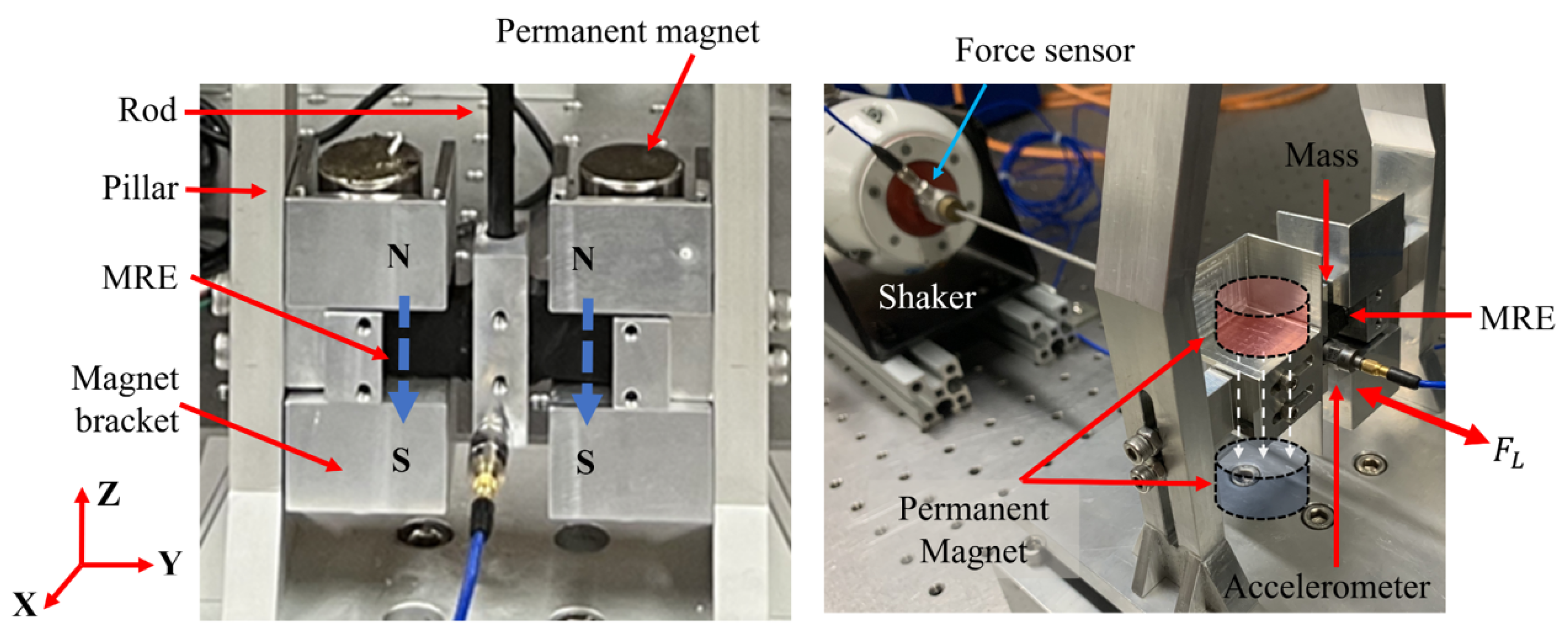

4.1. Design Parameters

4.2. MRE Manufacturing Process

4.3. MRE Property Analysis

5. Experimental Results

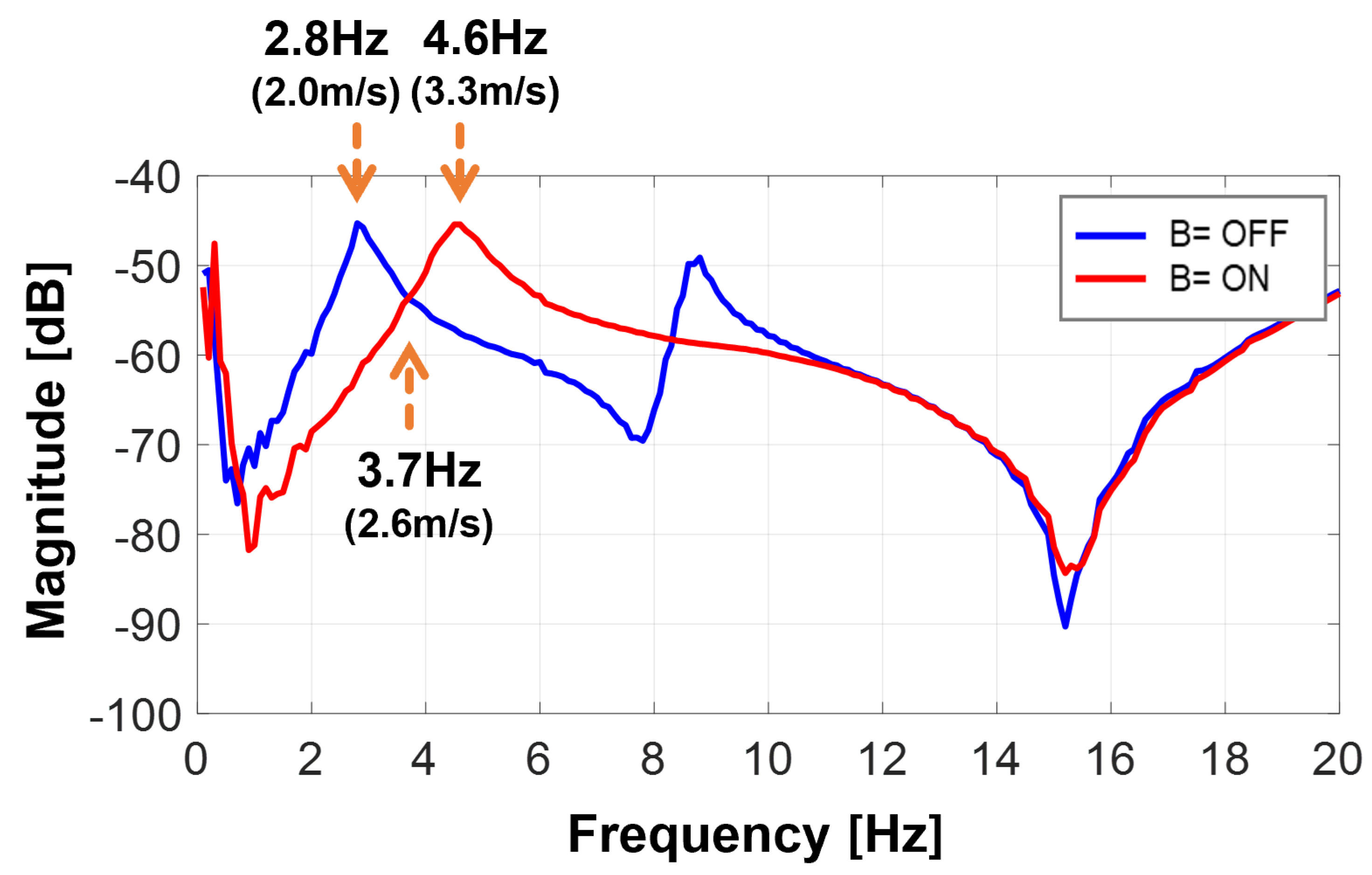

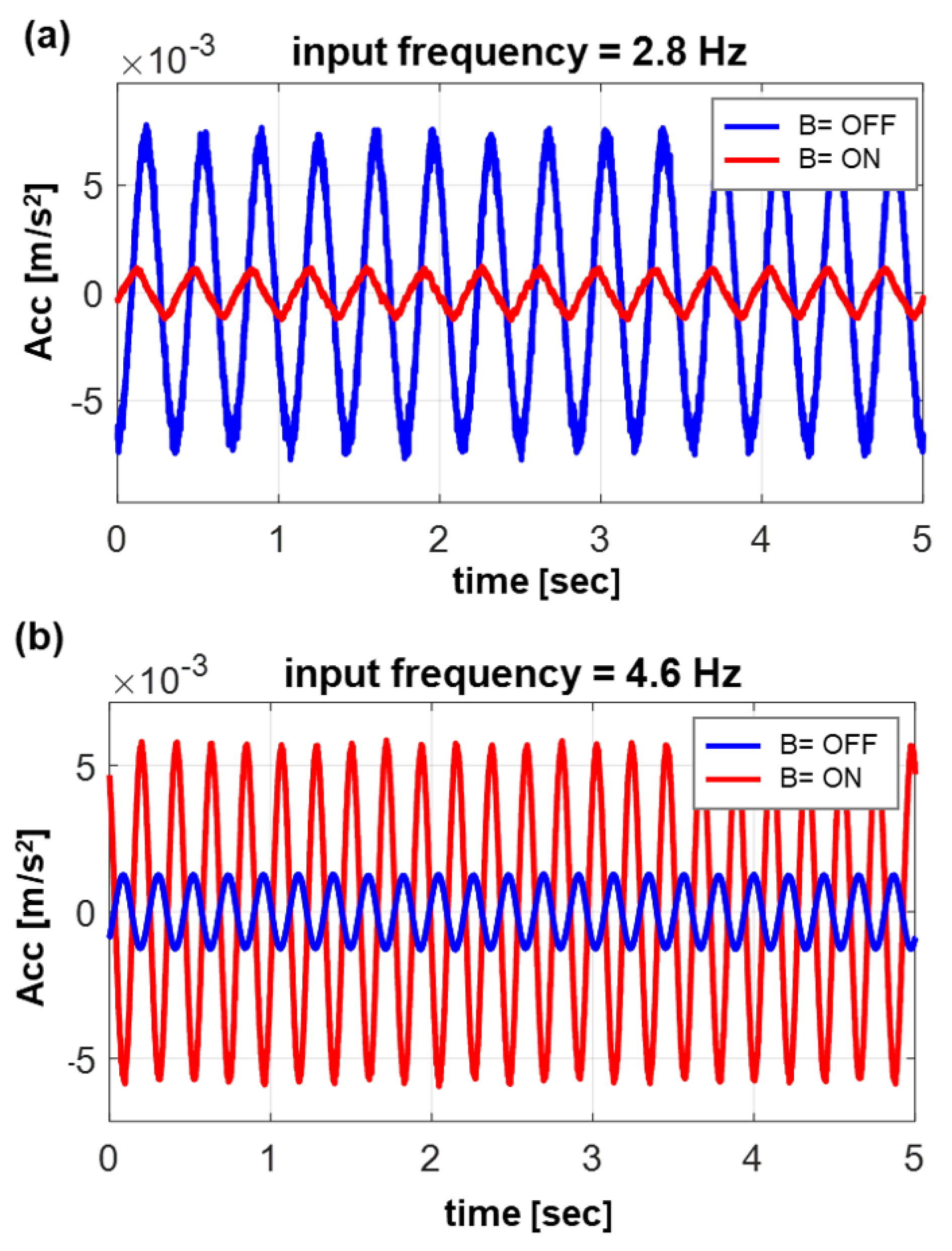

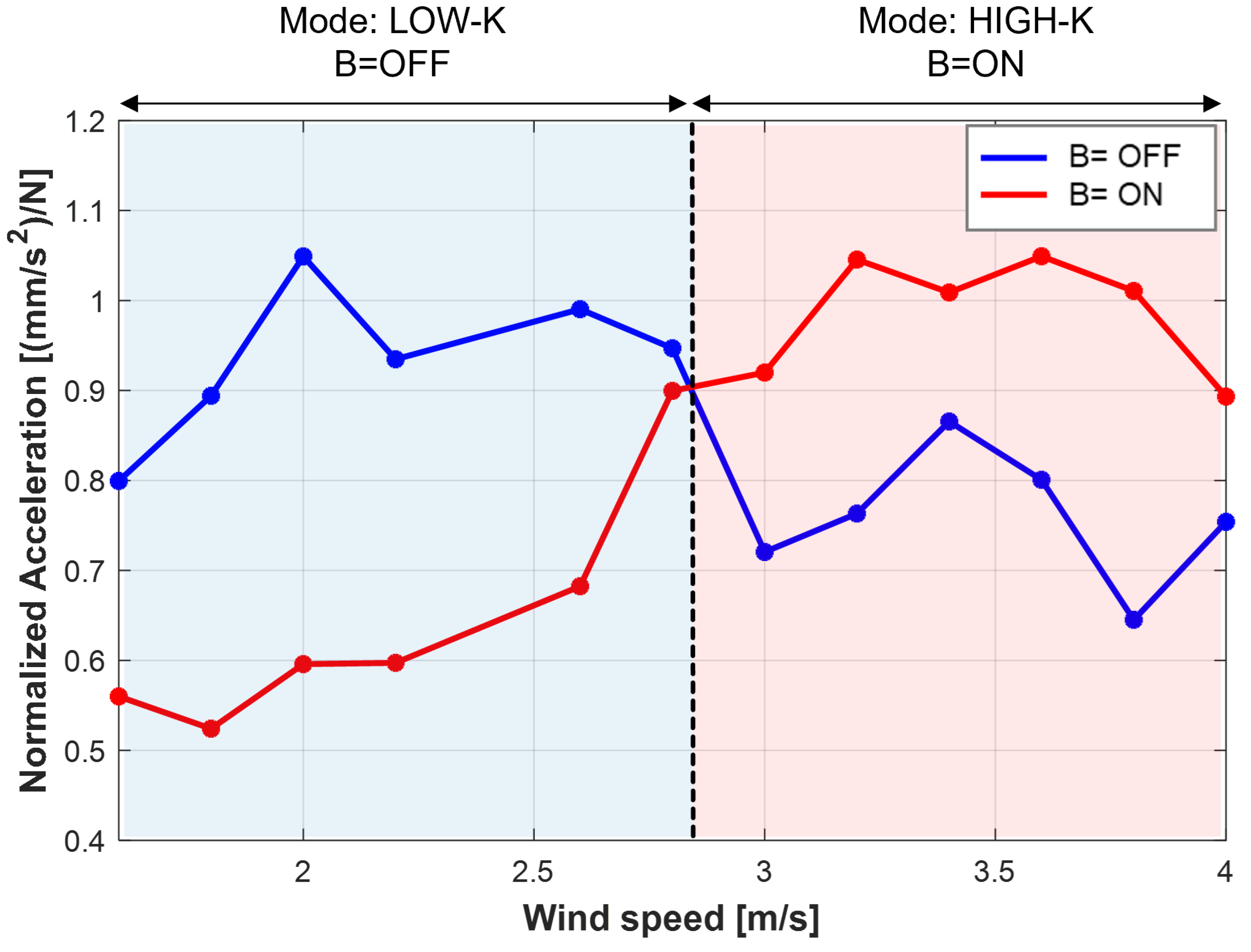

5.1. Vibration Test for Resonance Tuning

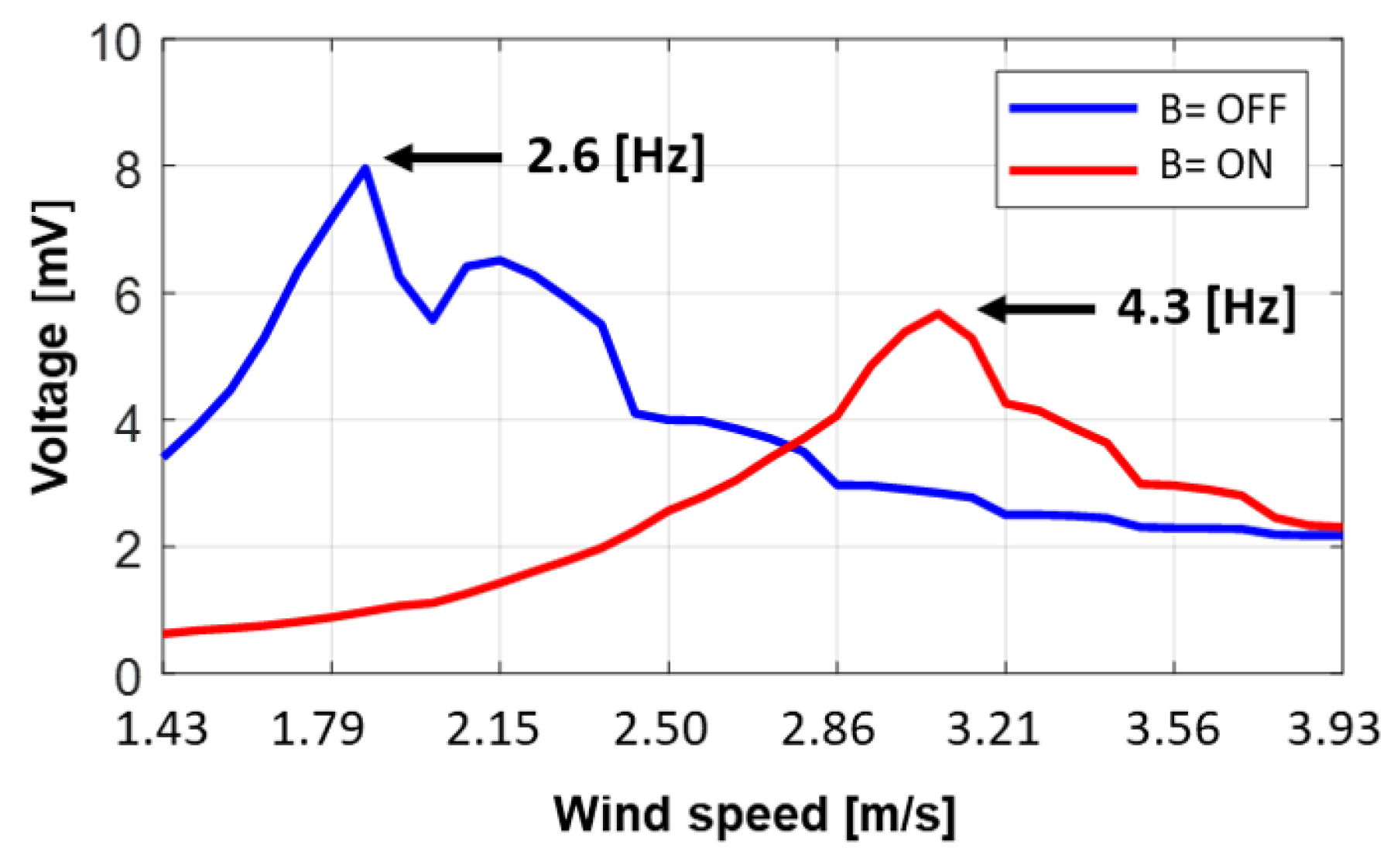

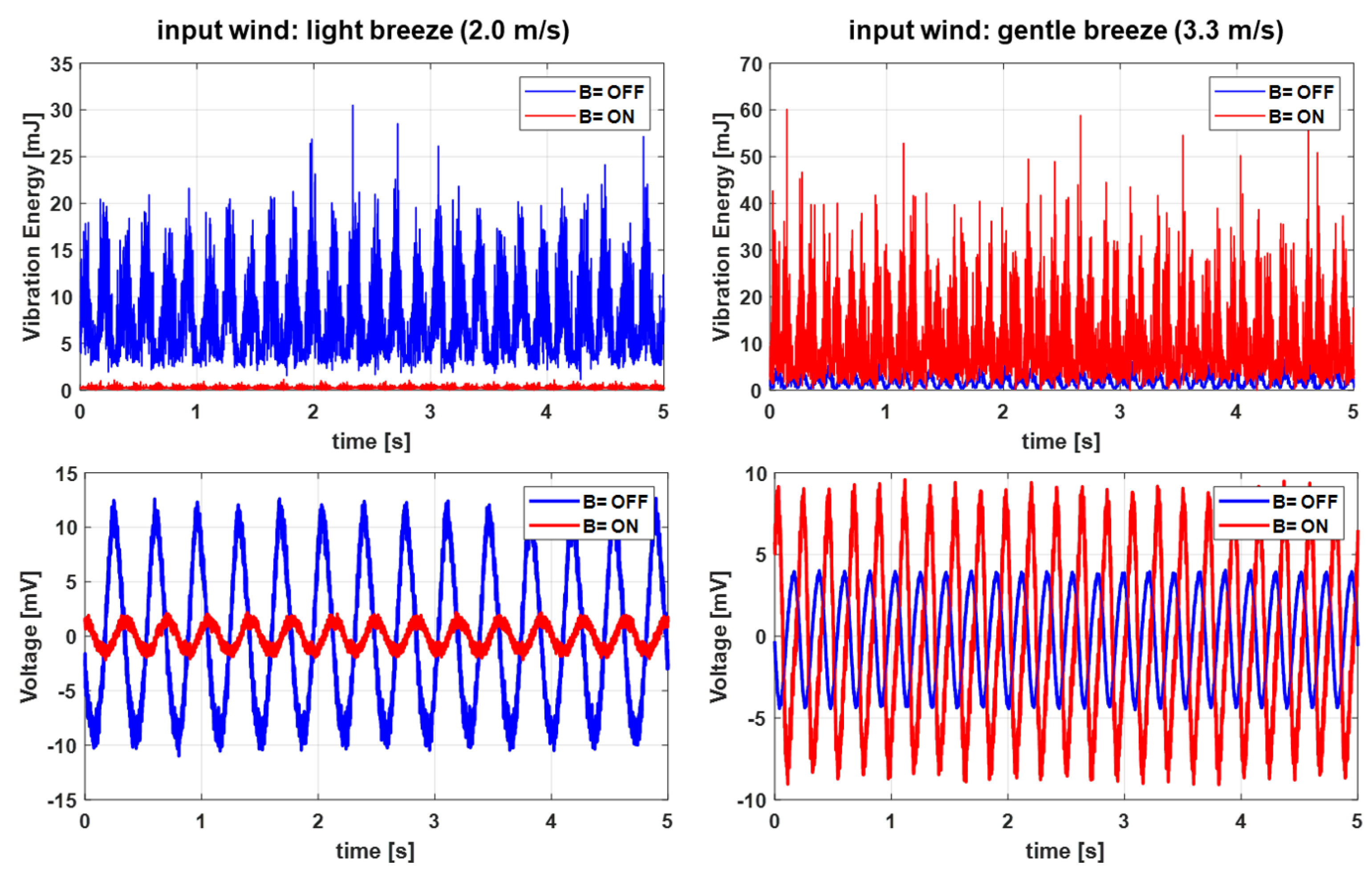

5.2. Power Generation Comparison

5.3. Wind Tunnel Test

5.4. Shortcomings and Future Improvements

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Premalatha, M.; Abbasi, T.; Abbasi, S.A. Wind energy: Increasing deployment, rising environmental concerns. Renew. Sustain. Energy Rev. 2014, 31, 270–288. [Google Scholar]

- Everaert, J.; Stienen, E.W. Impact of wind turbines on birds in Zeebrugge (Belgium). In Biodiversity and Conservation in Europe; Springer: Berlin/Heidelberg, Germany, 2006; pp. 103–117. [Google Scholar]

- El-Shahat, A.; Keys, D.; Ajala, L.; Haddad, R.J. Bladeless wind turbine (case study). In Proceedings of the 2019 SoutheastCon, Huntsville, AL, USA, 11–14 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Villarreal, D.Y.; Sl, V.B.; VIV Resonant Wind Generators. Vortex Blade-Less SL. 2018. Available online: https://vortexbladeless.com (accessed on 1 March 2024).

- Gabbai, R.D.; Benaroya, H. An overview of modeling and experiments of vortex-induced vibration of circular cylinders. J. Sound Vib. 2005, 282, 575–616. [Google Scholar] [CrossRef]

- Chizfahm, A.; Yazdi, E.A.; Eghtesad, M. Dynamic modeling of vortex induced vibration wind turbines. Renew. Energy 2018, 121, 632–643. [Google Scholar] [CrossRef]

- Bourguet, R.; Karniadakis, G.E.; Triantafyllou, M.S. Lock-in of the vortex-induced vibrations of a long tensioned beam in shear flow. J. Fluids Struct. 2011, 27, 838–847. [Google Scholar] [CrossRef]

- Hu, G.; Tse, K.T.; Kwok, K.C.S.; Song, J.; Lyu, Y. Aerodynamic modification to a circular cylinder to enhance the piezoelectric wind energy harvesting. Appl. Phys. Lett. 2016, 109, 193902. [Google Scholar] [CrossRef]

- Ding, L.; Yang, L.; Yang, Z.; Zhang, L.; Wu, C.; Yan, B. Performance improvement of aeroelastic energy harvesters with two symmetrical fin-shaped rods. J. Wind Eng. Ind. Aerodyn. 2020, 196, 104051. [Google Scholar] [CrossRef]

- Chang, C.C.J.; Kumar, R.A.; Bernitsas, M.M. VIV and galloping of single circular cylinder with surface roughness at 3.0 × 104 Re 1.2 × 105. Ocean Eng. 2011, 38, 1713–1732. [Google Scholar] [CrossRef]

- Roman, M.; Sobh, R.; Sedrak, M.; Ali, M. Power performance enhancement of vortex-induced vibration wind turbines using a semi-active control approach. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–19. [Google Scholar] [CrossRef]

- Bahri, Z.S.; Barday, W.; Ez-Zabri, S.; Salih-Alj, Y. Design Considerations of a Hybrid Piezoelectric-Electromagnetic Tuning System for Vortex Induced Vibration Bladeless Turbines: Morocco Case Study. In Proceedings of the 2022 IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–10 August 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 611–616. [Google Scholar]

- Ayala-Garcia, I.; Mitcheson, P.; Yeatman, E.; Zhu, D.; Tudor, J.; Beeby, S. Magnetic tuning of a kinetic energy harvester using variable reluctance. Sens. Actuators A Phys. 2013, 189, 266–275. [Google Scholar] [CrossRef]

- Bahadur, I. Dynamic Modeling and Investigation of a Tunable Vortex Bladeless Wind Turbine. Energies 2022, 15, 6773. [Google Scholar] [CrossRef]

- Kuder, I.K.; Arrieta, A.F.; Raither, W.E.; Ermanni, P. Variable stiffness material and structural concepts for morphing applications. Prog. Aerosp. Sci. 2013, 63, 33–55. [Google Scholar] [CrossRef]

- Jolly, M.R.; Carlson, J.D.; Muñoz, B.C.; Bullions, T.A. The magnetoviscoelastic response of elastomer composites consisting of ferrous particles embedded in a polymer matrix. J. Intell. Mater. Syst. Struct. 1996, 7, 613–622. [Google Scholar] [CrossRef]

- Yang, C.; Fu, J.; Yu, M.; Zheng, X.; Ju, B. A new magnetorheological elastomer isolator in shear–compression mixed mode. J. Intell. Mater. Syst. Struct. 2015, 26, 1290–1300. [Google Scholar] [CrossRef]

- Ginder, J.M.; Nichols, M.E.; Elie, L.D.; Clark, S.M. Controllable-stiffness components based on magnetorheological elastomers. In Proceedings of the Smart Structures and Materials 2000: Smart Structures and Integrated Systems, Newport Beach, CA, USA, 6–9 March 2000; SPIE: Bellingham, WA, USA, 2000; Volume 3985, pp. 418–425. [Google Scholar]

- Lee, K.H.; Park, J.E.; Kim, Y.K. Design of a stiffness variable flexible coupling using magnetorheological elastomer for torsional vibration reduction. J. Intell. Mater. Syst. Struct. 2019, 30, 2212–2221. [Google Scholar] [CrossRef]

- Kim, Y.K.; Bae, H.I.; Koo, J.H.; Kim, K.S.; Kim, S. Note: Real time control of a tunable vibration absorber based on magnetorheological elastomer for suppressing tonal vibrations. Rev. Sci. Instrum. 2012, 83, 046108. [Google Scholar] [CrossRef]

- Kim, Y.K.; Koo, J.; Kim, K.S.; Kim, S. Suppressing harmonic vibrations of a miniature cryogenic cooler using an adaptive tunable vibration absorber based on magneto-rheological elastomers. Rev. Sci. Instrum. 2011, 82, 035103. [Google Scholar] [CrossRef]

- Jang, D.I.; Yun, G.E.; Park, J.E.; Kim, Y.K. Designing an attachable and power-efficient all-in-one module of a tunable vibration absorber based on magnetorheological elastomer. Smart Mater. Struct. 2018, 27, 085009. [Google Scholar] [CrossRef]

- Dalton, C. Fundamentals of Vortex Induced Vibration; University of Houston: Houston, TX, USA, 2013. [Google Scholar]

- Sassi, P.; Freiría, J.; Mendina, M.; Draper, M.; Usera, G. Simulation of vorticity wind turbines. Heliyon 2020, 6, e05155. [Google Scholar] [CrossRef]

- Saengsaen, S.; Chantharasenawong, C.; Wu, T.L. A 2–d mathematical model of vortex induced vibration driven bladeless wind turbine. MATEC Web Conf. 2019, 291, 02007. [Google Scholar] [CrossRef]

- Zhang, L.; Abdelkefi, A.; Dai, H.; Naseer, R.; Wang, L. Design and experimental analysis of broadband energy harvesting from vortex-induced vibrations. J. Sound Vib. 2017, 408, 210–219. [Google Scholar] [CrossRef]

- Sun, W.; Seok, J. A novel self-tuning wind energy harvester with a slidable bluff body using vortex-induced vibration. Energy Convers. Manag. 2020, 205, 112472. [Google Scholar] [CrossRef]

| B = OFF (0 mT) | B = ON (170 mT) | Increment (%) | |

|---|---|---|---|

| Stiffness, (N/m) | 146.1 | 368.8 | 152% |

| Young’s modulus, E (kPa) | 641.4 | 1619.3 | 152 |

| Damping coefficient, (Ns/m) | 2.2 | 2.8 | 27% |

| B = OFF | B = ON | Increment (%) | |

|---|---|---|---|

| Structural resonance () | 2.8 Hz | 4.6 Hz | 65% |

| Lock-in wind speed (v) | 2.0 m/s | 3.3 m/s | 65% |

| Tuning Strategy | Vibration Energy Excited at | Induced Voltage Excited at | ||||

|---|---|---|---|---|---|---|

| Mode | Tuned wind description | Tuned structural resonance | 2.8 Hz (2.0 m/s) | 4.6 Hz (3.3 m/s) | 2.8 Hz (2.0 m/s) | 4.6 Hz (3.3 m/s) |

| B = OFF | Light Breeze (2.0 m/s) | 2.8 Hz | 7.5 mJ | 1.8 mJ | 6.9 mV | 2.8 mV |

| B = ON | Gentle Breeze (3.3 m/s) | 4.6 Hz | 0.3 mJ | 9.6 mJ | 1.1 mV | 5.3 mV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.; Kook, J.; Lee, J.; Kim, Y.-K. A Novel Small-Scale Bladeless Wind Turbine Using Vortex-Induced Vibration and a Discrete Resonance-Shifting Module. Appl. Sci. 2024, 14, 8217. https://doi.org/10.3390/app14188217

Kang H, Kook J, Lee J, Kim Y-K. A Novel Small-Scale Bladeless Wind Turbine Using Vortex-Induced Vibration and a Discrete Resonance-Shifting Module. Applied Sciences. 2024; 14(18):8217. https://doi.org/10.3390/app14188217

Chicago/Turabian StyleKang, Heeyun, Jinho Kook, Jaeyoung Lee, and Young-Keun Kim. 2024. "A Novel Small-Scale Bladeless Wind Turbine Using Vortex-Induced Vibration and a Discrete Resonance-Shifting Module" Applied Sciences 14, no. 18: 8217. https://doi.org/10.3390/app14188217

APA StyleKang, H., Kook, J., Lee, J., & Kim, Y.-K. (2024). A Novel Small-Scale Bladeless Wind Turbine Using Vortex-Induced Vibration and a Discrete Resonance-Shifting Module. Applied Sciences, 14(18), 8217. https://doi.org/10.3390/app14188217