Effect of Processing and Storage of Very-Low-Sugar Apple Jams Prepared with Sugar Substitution by Steviol Glycosides on Chosen Physicochemical Attributes and Sensory and Microbiological Quality

Abstract

1. Introduction

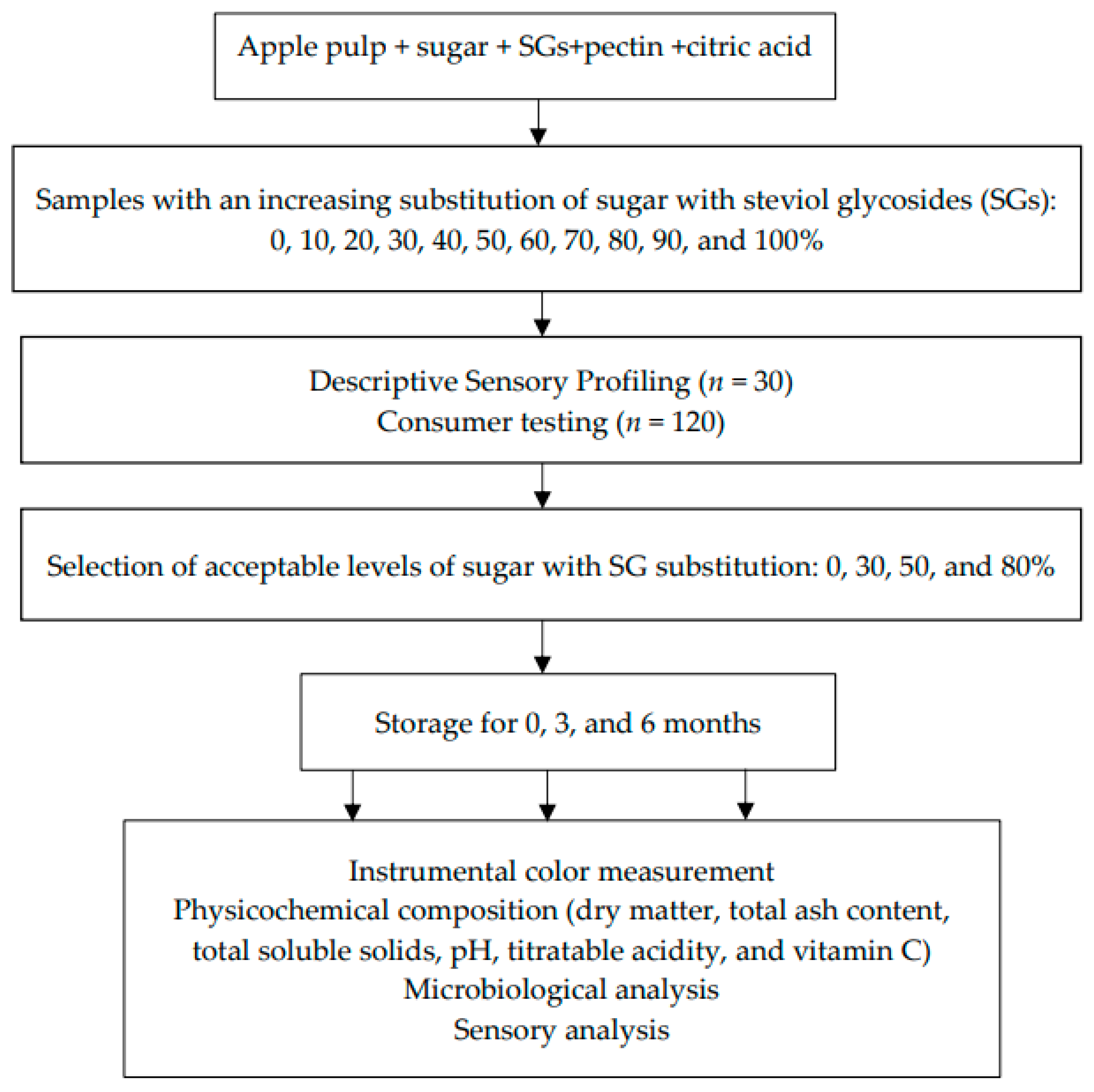

2. Materials and Methods

2.1. Materials and Preparation of Apple Jams

2.2. Storage of Jams

2.3. Sensory Analysis

2.3.1. Expert Evaluation

- -

- odor—apple, sweet, nectar, wine, metallic, sharp, and “other” (none–strong);

- -

- taste—sweet, bitter, and sour (none–strong);

- -

- flavor—apple, nectar, spicy (woody), metallic, bland, astringent, and “other” (none–strong);

- -

- color (light–dark);

- -

- sensory balance—the degree of harmonization between the sensory attributes (low–high).

2.3.2. Consumer Evaluation

2.4. Instrumental Color Measurements

- 0 < ΔE* < 1—the difference in color is visually nonrecognizable by a standard observer;

- 1 < ΔE* < 2—the difference is visually recognizable only by an experienced observer;

- 2 < ΔE* < 3.5—the difference can be visually recognized by an inexperienced observer;

- 3.5 < ΔE* < 5—every observer can easily see the difference;

- ΔE* > 5—an observer recognizes two different colors [41].

2.5. Physicochemical Composition

2.6. Microbiological Analysis

2.7. Statistical Analysis

3. Results

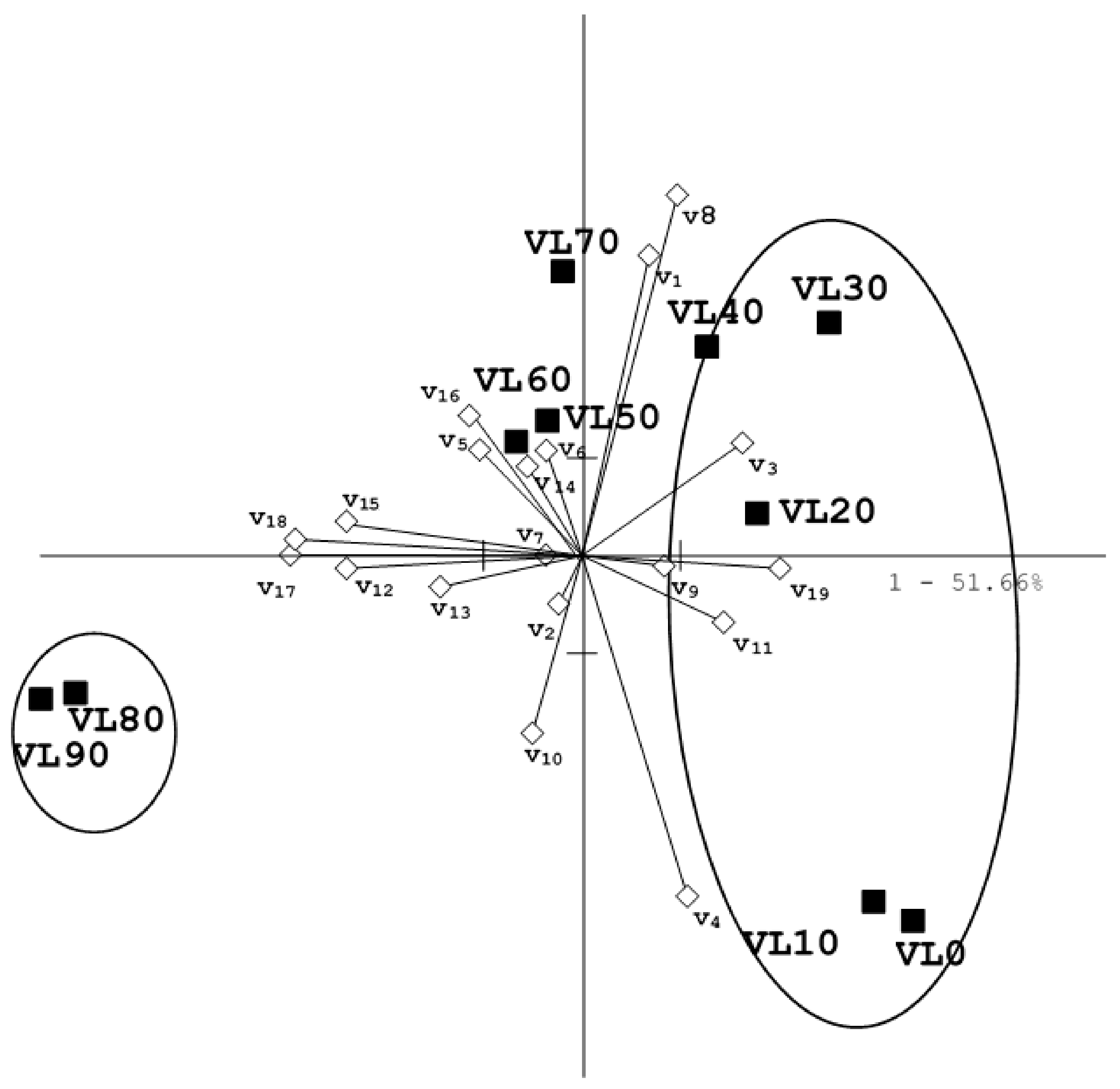

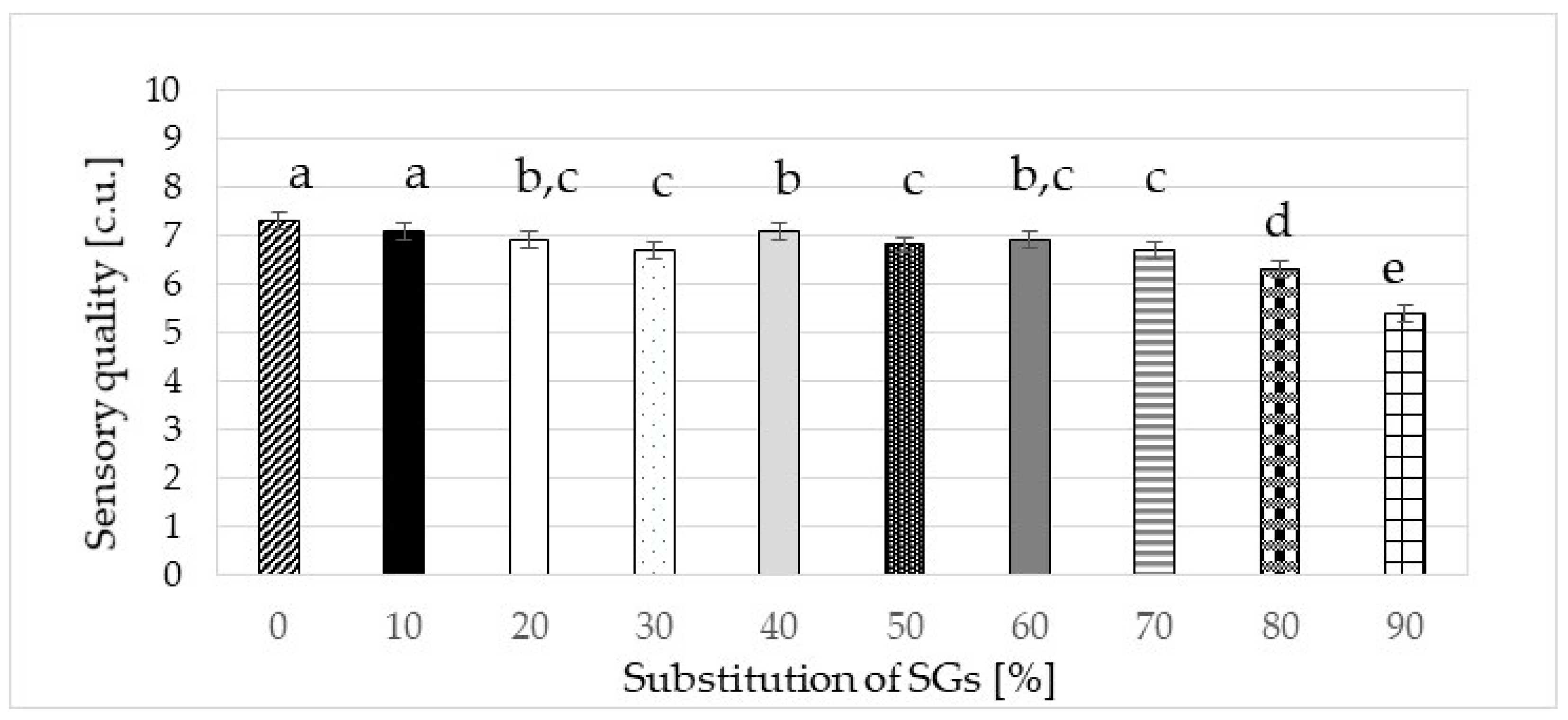

3.1. Optimization of the Addition of Steviol Glycosides to Very-Low-Sugar Apple Jams

3.2. Consumer Evaluation of Very-Low-Sugar Apple Jams with Added Steviol Glycosides

3.3. The Effect of Storage on the Sensory Quality of Very-Low-Sugar Apple Jams with Added SGs

3.4. The Effect of Storage on the Physicochemical Parameters of Very-Low-Sugar Apple Jams with Added Steviol Glycosides

3.5. The Effect of Storage on the Microbiological Quality of Very-Low-Sugar Apple Jams with Added Steviol Glycosides

4. Discussion

4.1. The Effect of Storage on the Sensory Quality of Very-Low-Sugar Apple Jams with Sugar Substitution by SGs

4.2. The Effect of Sugar Substitution with SGs on Physicochemical Parameters and Microbiological Quality of Very-Low-Sugar Apple Jams and Changes during Storage

4.3. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- WHO Regional Office for Europe. Sugars Factsheet; WHO Regional Office for Europe: Copenhagen, Denmark, 2022; Available online: https://www.who.int/europe/publications/m/item/sugars-factsheet (accessed on 7 July 2024).

- WHO. Regional Office for Europe Overweight. European Health Information Gateway Copenhagen. 2020. Available online: https://gateway.euro.who.int/en/indicators/h2020_6-overweight/visualizations/#id=17077 (accessed on 7 July 2024).

- Pielak, M.; Czarniecka-Skubina, E.; Trafiałek, J.; Głuchowski, A. Contemporary Trends and Habits in the Consumption of Sugar and Sweeteners—A Questionnaire Survey among Poles. J. Environ. Res. Public Health 2019, 16, 1164. [Google Scholar] [CrossRef] [PubMed]

- Alkhatib, A.; Tsang, C.; Tiss, A.; Bahorun, T.; Arefanian, H.; Barake, R.; Khadir, A.; Tuomilehto, J. Functional Foods and Lifestyle Approaches for Diabetes Prevention and Management. Nutrients 2017, 9, 1310. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Arcot, J.; Gill, T.; Louie, J.C.Y.; Rangan, A. A review of food reformulation of baked products to reduce added sugar intake. Trends Food Sci. Technol. 2019, 86, 412–425. [Google Scholar] [CrossRef]

- Chauhan, K.; Rao, A. Clean-Label Alternatives for Food Preservation: An Emerging Trend. Heliyon 2024, 10, e35815. [Google Scholar] [CrossRef]

- Cisneros-Yupanqui, M.; Lante, A.; Rizzi, C. Preliminary Characterization of a Functional Jam from Red Chicory By-Product. Open Biotechnol. J. 2021, 15, 183–189. [Google Scholar] [CrossRef]

- Mora, M.R.; Dando, R. The sensory properties and metabolic impact of natural and synthetic sweeteners. CRFSFS 2021, 20, 1554–1583. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Correa-Delgado, M.; Córdova-Almeida, R.; Lara-Nava, D.; Chávez-Muñoz, M.; Velásquez-Chávez, V.F.; Ahmad, M.Z. Natural sweeteners: Sources, extraction, and current uses in foods and food industries. Food Chem. 2022, 370, 130991. [Google Scholar] [CrossRef]

- Wang, F.; Ma, R.; Zhu, J.; Zhan, J.; Li, J.; Tian, Y. Physicochemical properties, in vitro digestibility, and pH-dependent release behavior of starch–steviol glycoside composite hydrogels. Food Chem. 2024, 434, 137420. [Google Scholar] [CrossRef] [PubMed]

- Pielak, M.; Czarniecka- Skubina, E.; Głuchowski, A. Effect of Sugar Substitution with Steviol Glycosides on Sensory Quality and Physicochemical Composition of Low-Sugar Apple Preserves. Foods 2020, 9, 293. [Google Scholar] [CrossRef] [PubMed]

- Orellana-Paucar, A.M. Steviol glycosides from Stevia rebaudiana: An updated overview of their sweetening activity, pharmacological properties, and safety aspects. Molecules 2023, 28, 1258. [Google Scholar] [CrossRef]

- de Andrade, M.V.S.; Lucho, S.R.; de Castro, R.D.; Ribeiro, P.R. Alternative for natural sweeteners: Improving the use of stevia as a source of steviol glycosides. Ind. Crops Prod. 2024, 208, 117801. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Y.; Zhou, C.; Fan, X.; Sun, Q.; Han, J.; Hua, C.; Li, Y.; Niu, Y.; Okonkwo, C.; et al. Properties, extraction and purification technologies of Stevia rebaudiana steviol glycosides: A review. Food Chem. 2024, 453, 139622. [Google Scholar] [CrossRef] [PubMed]

- Belovi’c, M.; Torbica, A.; Paji’c-Lijakovi´c, I.; Mastilovi´c, J. Development of low calorie jams with increased content of natural dietary fibre made from tomato pomace. Food Chem. 2017, 237, 1226–1233. [Google Scholar] [CrossRef] [PubMed]

- Council Directive 2004/84/EC of 10 June 2004 amending Directive 2001/113/EC relating to fruit jams. jellies and marmalades and sweetened chestnut purée intended for human consumption. Off. J. Eur. Union 2004, L219, 8–10.

- Basu, S.; Shivhare, U.S.; Singh, T.V.; Beniwal, V.S. Rheological. textural and spectral characteristics of sorbitol substituted mango jam. J. Food Eng. 2011, 105, 503–512. [Google Scholar] [CrossRef]

- De Souza, V.R.; Pereira, P.A.P.; Pinheiro, A.C.M.; Bolini, H.M.A.; Borges, S.V.; Queiroz, F. Analysis of various sweeteners in low-sugar mixed fruit jam: Equivalent sweetness. time intensity analysis and acceptance test. Int. J. Food Sci. 2013, 48, 1541–1548. [Google Scholar] [CrossRef]

- Abolila, R.M.; Barakat, H.; El-Tanahy, H.A.; El-Mansy, H.A. Chemical. Nutritional and Organoleptical Characteristics of Orange-Based Formulated Low-Calorie Jams. J. Nutr. Sci. 2015, 6, 1229–1244. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 1131/2011 of 11 November 2011 amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council with regard to steviol glycosides. Off. J. Eur. Union 2011, L295/205, 1.

- Kroyer, G. Stevioside and Stevia-sweetener in food: Application. stability and interaction with food ingredients. JCF 2010, 5, 225–229. [Google Scholar] [CrossRef]

- Wölwer-Rieck, U.; Tomberg, W.; Wawrzun, A. Investigations on the stability of Stevioside and Rebaudioside A in soft drinks. J. Agric. Food Chem. 2010, 58, 12216–12220. [Google Scholar] [CrossRef]

- Kovačević, D.B.; Maras, M.; Barba, F.J.; Granato, D.; Roohinejad, S.; Mallikarjunan, K.; Montesano, D.; Lorenzo, J.M.; Putnik, P. Innovative technologies for the recovery of phytochemicals from Stevia rebaudiana Bertoni leaves: A review. Food Chem. 2018, 268, 513–521. [Google Scholar] [CrossRef] [PubMed]

- Typek, R.; Dawidowicz, A.L.; Stankevič, M. Stability of stevioside in food processing conditions: Unexpected recombination of stevioside hydrolysis products in ESI source. Food Chem. 2020, 331, 127262. [Google Scholar] [CrossRef] [PubMed]

- Abbas, H.M. Utilization of stevia (Stevia rebaudiana Bertoni) leaves powder as natural non-caloric sweetener in production of pomegranate jam. Minia J. Agric. Res. Dev. 2007, 27, 457–479. [Google Scholar]

- Carvalho, A.C.G.D.; Oliveira, R.C.G.D.; Navacchi, M.F.P.; Costa, C.E.M.D.; Mantovani, D.; Dacôme, A.S.; Costa, S.C.D. Evaluation of the potential use of rebaudioside-A as a sweetener for diet jam. Food Sci. Technol. Int. 2013, 33, 555–560. [Google Scholar] [CrossRef]

- Ahmad, U.; Ahmad, R.S. Antidiabetic property of aqueous extract of Stevia rebaudiana Bertoni leaves in Streptozotocin-induced diabetes in albino rats. BMC Complement. Altern. Med. 2018, 18, 179. [Google Scholar] [CrossRef]

- Ahmad, J.; Khan, I.; Johnson, S.K.; Alam, I.; Din, Z.U. Effect of incorporating stevia and moringa in cookies on postprandial glycemia, appetite, palatability, and gastrointestinal well-being. J. Am. Coll. Nutr. 2018, 37, 133–139. [Google Scholar] [CrossRef]

- Anker, C.C.B.; Rafiq, S.; Jeppesen, P.B. Effect of steviol glycosides on human health with emphasis on type 2 diabetic biomarkers: A systematic review and meta-analysis of randomized controlled trials. Nutrients 2019, 11, 1965. [Google Scholar] [CrossRef]

- Farhat, G.; Berset, V.; Moore, L. Effects of stevia extract on postprandial glucose response, satiety, and energy intake: A three-arm crossover trial. Nutrients 2019, 11, 3036. [Google Scholar] [CrossRef]

- Sutwal, R.; Dhankhar, J.; Kindu, P.; Mehla, R. Development of low calorie jam by replacement of sugar with natural sweetener stevia. Int. J. Curr. Res. Rev. 2019, 11, 10. [Google Scholar] [CrossRef]

- Carrera-Lanestosa, A.; Coral-Martínez, T.; Ruíz-Ciau, D.; Moguel-Ordoñez, Y.; Segura-Campos, M.R. Phenolic compounds and major steviol glucosides by HPLC-DAD-RP and invitro evaluation of the biological activity of aqueous and ethanolic extracts of leaves and stems: S. rebaudiana Bertoni (creole variety INIFAP C01) S. rebaudiana Bertoni (creole variety INIFAP C01): Bioactive compounds and Functionality. J. Food Prop. 2020, 23, 199–212. [Google Scholar] [CrossRef]

- Khilar, S.; Singh, A.P.; Biagi, M.; Sharma, A. An Insight into attributes of Stevia rebaudiana Bertoni: Recent advances in extraction techniques, phytochemistry, food applications and health benefits. J. Agric. Res. 2022, 10, 100458. [Google Scholar] [CrossRef]

- Codex Alimentarius, International Food Standards. Standard for Jams, Jellies and Marmalades. CXS 296-2009. Adopted in 2009. Amended in 2017, 2020, 2022. FAO, WHO, Codex, 2009, 296. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B296-2009%252FCXS_296e.pdf (accessed on 7 July 2024).

- Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- PN-EN ISO 13299:2016-05; Sensory Analysis. Methodology. General Guidelines for Determining the Sensory Profile. International Organization for Standardization: Geneva, Switzerland, 2016.

- PN-ISO 3972:2016-07; Analiza Sensoryczna. Metodyka. Metoda Sprawdzania Wrażliwości Sensorycznej. Polish Committee for Standardization: Warsaw, Poland, 2016. (In Polish)

- PN-EN ISO 8586:2014-03; Polish Standard. Sensory Analysis. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2012.

- PN-EN ISO 11136:2017-08; Analiza Sensoryczna. Metodyka. Ogólne Wytyczne Przeprowadzania Testów Hedonicznych z Konsumentami na Obszarze Kontrolowanym. Polish Committee for Standardization: Warsaw, Poland, 2017. (In Polish)

- Baryłko-Pikielna, N.; Matuszewska, I. Sensoryczne Badania Żywności. Podstawy. Metody. Zastosowania. Wyd. II., Wydawnictwo Naukowe; PTTŻ: Kraków, Poland, 2014; pp. 181–199. (In Polish) [Google Scholar]

- Mokrzycki, W.; Tatol, M. Colour diference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- PN-A-75101-02:1990; Przetwory Owocowe i Warzywne. Przygotowanie Próbek i Metody Badań Fizykochemicznych. Polish Committee for Standardization: Warsaw, Poland, 1990. (In Polish)

- PN-90/A-75101-08/Az1:2002; Przetwory Owocowe i Warzywne. Przygotowanie Próbek i Metody Badań Fizykochemicznych. Oznaczanie Zawartości Popiołu Ogólnego i Jego Alkaliczności. Polish Committee for Standardization: Warsaw, Poland, 2002. (In Polish)

- EN 1132:1994; Fruit and Vegetable Juices—Determination of the pH Value. Committee Europeen de Normalisation: Brussels, Belgium, 1994.

- ISO 750:1998(en); Fruit and Vegetable Products. Determination of Titratable Acidity. International Organization for Standardization: Geneva, Switzerland; Warsaw, Poland, 1998.

- APHA, American Public Health Association. Compendium of Methods for the Microbiological Examination of Foods, 3rd ed.; Vanderzant, C., Splittsloesse, D.F., Eds.; APHA: Washington, DC, USA, 1992. [Google Scholar]

- PN-EN ISO 11290-2:2000+A1:2005+Ap1:2006+Ap2:2007; Mikrobiologia Żywności i Pasz—Horyzontalna Metoda Wykrywania Obecności i Oznaczania Liczby Listeria Monocytogenes Część 2: Metoda Oznaczania Liczby. Polish Committee for Standardization: Warsaw, Poland, 2006. (In Polish)

- PN-EN-ISO 11290-2:2017-07; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria Monocytogenes and of Listeria spp. Part 2: Enumeration Method. International Standard: Geneva, Switzerland, 2017.

- PN-EN ISO 6888-2:2001+A1:2004; Mikrobiologia Żywności i Pasz—Horyzontalna Metoda Oznaczania Liczby Gronkowców Koagulazo-Dodatnich (Staphylococcus aureus i Innych Gatunków). Część 2: Metoda z Zastosowaniem Pożywki Agarowej z Plazmą Króliczą i Fibrynogenem. Polish Committee for Standardization: Warsaw, Poland, 2004. (In Polish)

- PN-EN ISO 4833-1:2013-12; Mikrobiologia Łańcucha Żywnościowego-Horyzontalna Metoda Oznaczania Liczby Drobnoustrojów—Część 2: Oznaczanie Liczby Metodą Posiewu Zalewowego w Temperaturze 30 °C. Polish Committee for Standardization: Warsaw, Poland, 2013. (In Polish)

- PN-EN ISO 21527-2:2009; Mikrobiologia Żywności i Pasz—Horyzontalna Metoda Oznaczania Liczby Drożdży i Pleśni. Część 2: Metoda Liczenia Kolonii w Produktach o Aktywności Wody Niższej lub Równej 0.95. Polish Committee for Standardization: Warsaw, Poland, 2009. (In Polish)

- Borgognone, M.G.; Bussi, J.; Hough, G. Principal component analysis in sensory analysis: Covariance or correlation matrix? Food Qual. Pref. 2001, 12, 323–326. [Google Scholar] [CrossRef]

- Rozporządzenie Komisji (WE) nr 2073/2005 z dnia 15 Listopada 2005 r. w Sprawie kryteriów Mikrobiologicznych Dotyczących Środków Spożywczych (Dz. Urz. L 338 z 22.12.2008, str. 1–26; Sprostowanie: Dz. Urz. L 278/32 z 10.10.2006, ze zm.). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/PDF/?uri=CELEX:02005R2073-20111201&from=de (accessed on 7 July 2024). (In Polish).

- Rozporządzenie Komisji (WE) NR 1441/2007 z dnia 5 Grudnia 2007 r. Zmieniające Rozporządzenie (WE) nr 2073/2005 w Sprawie Kryteriów Mikrobiologicznych Dotyczących Środków Spożywczych (Tekst Mający Znaczenie dla EOG) (Dz.U. L 322 z 7.12.2007, s. 12). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/PDF/?uri=CELEX:02007R1441-20071227 (accessed on 7 July 2024). (In Polish).

- Rozporządzenie Ministra Zdrowia z dnia 13.01.2003 w Sprawie Maksymalnych Poziomów Zanieczyszczeń Chemicznych I Biologicznych, Które mogą się Znajdować w Żywności, Składnikach Żywności, Dozwolonych Substancjach Dodatkowych, Substancjach Pomagających w Przetwarzaniu albo na Powierzchni Żywności. Dz.U. 2003, nr 37, poz. 326. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20030370326 (accessed on 7 July 2024). (In Polish)

- Yazdi, A.P.G.; Pouya, A.; Hojjatoleslamy, M.; Kermat, J.; Shariati, M.A. Replacing sucrose by Stevioside and adding Arabic Gum: Investigation of Rheological properties of Apple Jam. IJAAS 2014, 9, 508–513. [Google Scholar]

- Hemada, H.M.; Shehata, E.N.; Mohamed, E.F.; Abd Elmagied, S.F. The Impact of Natural Stevia Extract (Stevioside) as Sucrose Replace on Quality Characteristics of Selected Food Products. Middle East J. Appl. Sci. 2016, 6, 40–50. [Google Scholar]

- Hellfritsch, C.; Brockhoff, A.; Stähler, F.; Meyerhof, W.; Hofmann, T. Human psychometric and taste receptor responses to steviol glycosides. J. Agric. Food Chem. 2012, 60, 6782–6793. [Google Scholar] [CrossRef]

- Hergesell, L.; Schöne, F.; Greiling, A.; Schaefer, U.; Jahreis, G. Possibilities and limitations of sugar reduction by steviol glycosides in yoghurt. Ernahrungs Umschau 2014, 61, 181–187. [Google Scholar] [CrossRef]

- Prakash, I.; DuBois, G.E.; Clos, J.F.; Wilkens, K.L.; Fosdick, L.E. Development of rebiana, a natural, non-caloric sweetener. Food Chem Toxicol. 2008, 46, S75–S82. [Google Scholar] [CrossRef]

- Yousefi, A.M.; Goli, S.A.H.; Kadivar, M. Optimization of low-calorie quince jam production with stevioside sweetener. J. Food Res. 2012, 22, 155–164. [Google Scholar]

- Banaś, A.; Korus, A.; Korus, J. The influence of storage conditions on texture parameters and sensory quality of sour cherry jams with various plant additives. Żywn. Nauka Technol. Jakość. 2018, 25, 100–115. [Google Scholar] [CrossRef]

- Korus, A.; Banaś, A.; Korus, J. Effects of plant ingredients with pro-health properties and storage conditions on texture. color and sensory attributes of strawberry (Fragaria × ananassa Duch.) jam. EJFA 2017, 29, 610–619. [Google Scholar] [CrossRef]

- Korus, A.; Jaworska, G.; Bernaś, E.; Juszczak, L. Characteristics of physico-chemical properties of bilberry (Vaccinium myrtillus L.) jams with added herbs. J. Food Technol. 2015, 52, 2815–2823. [Google Scholar] [CrossRef] [PubMed]

- Banaś, A.; Korus, A.; Korus, J. Texture, color, and sensory features of low-sugar gooseberry jams enriched with plant ingredients with prohealth properties. J. Food Qual. 2017, 1, 1646894. [Google Scholar] [CrossRef]

- Lespirand, A.R.; Bambicha, R.R.; Mascheroni, R.H. Quality parameters assessment in kiwi jam during pasteurization. Modeling and optimization of the thermal process. Food Bioprod. Process. 2012, 90, 799–808. [Google Scholar]

- Awulachew, M. Fruit jam production. IJFS 2021, 10, 532–537. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.P.; Tiwari, B.K.; Butler, F. Stability and degradation kinetics of bioactive compounds and colour in strawberry jam during storage. Food Sci. Biotechnol. 2011, 4, 1245–1252. [Google Scholar] [CrossRef]

- Alves de Oliveira, E.N.; da Costa Santos, D.; Gomes, J.P.; Rocha, A.P.T.; da Silva, W.P. Physicochemical stability of diet Umbu-Caja jams stored under ambient conditions. J. Food Process. Preserv. 2015, 39, 70–79. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M.; Khanum, F. Effect of Modified Atmospheric Packaging on Physicochemical, Sensory and Microbiological Properties of Spray-Dried Seabuckthorn Fruit Juice Powder Stored in Metallized Polyester Pouch at Room Temperature. J. Food Process. Preserv. 2015, 39, 231–238. [Google Scholar] [CrossRef]

- Martinsen, B.K.; Aaby, K.; Skrede, G. Effect of temperature on stability of anthocyanins, ascorbic acid and color in strawberry and raspberry jams. Food Chem. 2020, 316, 126297. [Google Scholar] [CrossRef]

- Touati, N.; Tarazona-Diaz, M.P.; Aguayo, E.; Louaileche, H. Effect of storage time and temperature on the physicochemical and sensory characteristics of commercial apricot jam. Food Chem. 2014, 145, 23–24. [Google Scholar] [CrossRef]

- Felicetti, E.; Mattheis, J.P. Quantification and histochemical localization of ascorbic acid in ‘Delicious’, ‘Golden Delisious’ amd ‘Fuji’ apple fruit during on-tree development and cold storage. Postharvest Biol. Technol. 2010, 56, 56–63. [Google Scholar] [CrossRef]

- Tobal, T.M.; Rodrigues, L.V. Effect of storage on the bioactive compounds, nutritional composition and sensory acceptability of pitanga jams. Food Sci. Technol. 2019, 39, 581–587. [Google Scholar] [CrossRef]

- Scrob, T.; Varodi, S.M.; Vintilă, G.A.; Casoni, D.; Cimpoiu, C. Estimation of degradation kinetics of bioactive compounds in several lingonberry jams as affected by different sweeteners and storage conditions. Food Chem. 2022, 16, 100471. [Google Scholar] [CrossRef] [PubMed]

- Savita, S.M.; Sheela, K.; Sunanda, S.; Shankar, A.G.; Ramakrishna, P. Stevia rebaudiana—A functional component for food industry. Hum. Ecol. 2004, 15, 261–264. [Google Scholar] [CrossRef]

| Variant | Sugar (g) | Steviol Glycosides | Pectin (g 100 g−1) | Citric Acids (g 100 g−1) | |

|---|---|---|---|---|---|

| (g) | (%) * | ||||

| VL0 | 10 | 0.00 | 0 | 0.3 | 0.52 |

| VL10 | 9 | 0.01 | 10 | 0.3 | 0.51 |

| VL20 | 8 | 0.02 | 20 | 0.3 | 0.50 |

| VL30 | 7 | 0.03 | 30 | 0.3 | 0.49 |

| VL40 | 6 | 0.04 | 40 | 0.3 | 0.48 |

| VL50 | 5 | 0.05 | 50 | 0.3 | 0.46 |

| VL60 | 4 | 0.06 | 60 | 0.3 | 0.45 |

| VL70 | 3 | 0.07 | 70 | 0.3 | 0.44 |

| VL80 | 2 | 0.08 | 80 | 0.3 | 0.43 |

| VL90 | 1 | 0.09 | 90 | 0.3 | 0.42 |

| VL100 | 0 | 0.10 | 100 | 0.3 | 0.41 |

| Content | Method |

|---|---|

| Dry matter | PN-A-75101-02:1990 [42] |

| Total ash | PN-90/A-75101-08/Az1:2002 [43] |

| Total soluble solids | measured using the refractometric method according to PN-A-75101-02:1990 [42] |

| pH | measured with the potentiometric method using pH-meter Knick 913 (Elektronische Messgeräte, GmbH & Co. KG, Berlin, Germany) according to EN 1132:1994 [44] |

| Titratable acidity | ISO 750:1998 [45]; the results were expressed as mg g−1 of malic acid equivalent (MAE) |

| Vitamin C | measurement conducted by high-performance liquid chromatography according to the method presented in a previous study [11] |

| Microorganisms | Method |

|---|---|

| Listeria monocytogenes | PN-EN ISO 11290-2:2000+; A1:2005+Ap1:2006+Ap2:2007 [47]; PN-EN-ISO 11290-2:2017-07 [48] |

| Coagulase-positive staphylococci | PN-EN ISO 6888-2:2001+A1:2004 [49] |

| Total number of colonies at 30 °C | PN-EN ISO 4833-1:2013-12 [50] |

| Yeast and mold counts | PN-EN ISO 21527-2:2009 [51] |

| Color (L*a*b*) | Addition of SGs (%) to Very-Low-Sugar (VL) Jams | |||

|---|---|---|---|---|

| 0 | 30 | 50 | 80 | |

| Color of Apple Jams at the Beginning of Storage * | ||||

| L* | 32.6 ± 0.74 | 33.89 ± 0.61 | 34.1 ± 0.56 | 34.53 ± 0.06 |

| ΔL | - | 1.29 | 1.5 | 1.93 |

| a* | −0.39 ± 0.02 | −0.41 ± 0.19 | −0.44 ± 0.36 | −0.48 ± 0.01 |

| Δa | - | −0.02 | −0.05 | −0.09 |

| b* | 15.77 ± 0.78 | 16.1 ± 0.65 | 16.31 ± 0.48 | 16.79 ± 0.09 |

| Δb | - | 0.33 | 0.54 | 1.02 |

| C | 15.76 | 16.09 | 16.30 | 16.78 |

| ΔC | - | 0.33 | 0.54 | 1.02 |

| (ΔE) | - | 1.33 | 1.60 | 2.18 |

| Color change after 3 months of storage ** | ||||

| L* | 32.51 ± 0.74 | 33.43 ± 0.01 | 33.87 ± 0.01 | 34.21 ± 0.2 |

| ΔL | −0.09 | −0.46 | −0.23 | −0.32 |

| a* | −0.05 ± 0.02 | −0.38 ± 0.02 | −0.43 ± 0.01 | −0.44 ± 0.02 |

| Δa | 0.02 | 0.03 | 0.01 | 0.04 |

| b* | 15.47 ± 0.02 | 15.3 ± 0.13 | 15.85 ± 0.05 | 16.19 ± 0.04 |

| Δb | −0.3 | −0.8 | −0.46 | −0.18 |

| C | 15.76 | 15.29 | 15.84 | 16.18 |

| ΔC | 0.3 | 0.8 | 0.46 | 0.18 |

| (ΔE) | 0.3 | 0.92 | 0.51 | 0.37 |

| Color change after 6 months of storage ** | ||||

| L* | 32.38 ± 0.01 | 33.18 ± 0.01 | 33.63 ± 0.01 | 33.9 ± 0.2 |

| ΔL | −0.22 | −0.71 | −0.47 | −0.63 |

| a* | −0.15 ± 0.08 | −0.32 ± 0.22 | −0.36 ± 0.16 | −0.4 ± 0.09 |

| Δa | 0.24 | 0.09 | 0.08 | 0.08 |

| b* | 15.47 ± 0.02 | 15.55 ± 0.13 | 15.84 ± 0.05 | 15.9 ± 0.04 |

| Δb | −0.3 | −0.55 | −0.47 | −0.89 |

| C | 15.76 | 15.54 | 15.83 | 15.89 |

| ΔC | 0.38 | 0.56 | 0.48 | 0.89 |

| (ΔE) | 0.38 | 0.9 | 0.67 | 1.09 |

| SGs (%) | Time of Storage | Average Value ± SD | |||||

|---|---|---|---|---|---|---|---|

| Dry Matter (%) | Vitamin C (mg/100 g) | Total Ash (%) | pH | Titratable Acidity (°) | Malic Acid (g/100 g) | ||

| 0 | 0 | 24.7 ± 0.2 ax | 0.58 ± 0.02 ax | 0.184 ± 0.012 ax | 3.48 ± 0.02 ax | 8.53 ± 0.04 ax | 0.573 ± 0.003 ax |

| 3 | 25.0 ± 0.1 a | 0.41 ± 0.01 b | 0.234 ± 0.008 b | 3.30 ± 0.08 b | 10.32 ± 0.03 b | 0.691 ± 0.002 b | |

| 6 | 25.1 ± 0.3 a | 0.22 ± 0.01 c | 0.334 ± 0.004 c | 3.12 ± 0.02 c | 13.90 ± 0.10 c | 0.931 ± 0.001 c | |

| 30 | 0 | 20.9 ± 0.2 ay | 0.56 ± 0.02 ax | 0.231 ± 0.017 ay | 3.41 ± 0.02 ay | 13.80 ± 0.25a y | 0.927 ± 0.002 ay |

| 3 | 20.7 ± 0.6 a | 0.37 ± 0.02 b | 0.250 ± 0.009 b | 3.36 ± 0.01 b | 14.78 ± 0.24 b | 0.970 ± 0.031 b | |

| 6 | 21.7 ± 1.0 a | 0.22 ± 0.01 c | 0.284 ± 0.004 c | 3.28 ± 0.03 c | 16.80 ± 0.40 c | 1.126 ± 0.004 c | |

| 50 | 0 | 17.9 ± 0.2 az | 0.55 ± 0.01 ax | 0.228 ± 0.009 ay | 3.44 ± 0.01 az | 15.81 ± 0.01 az | 1.060 ± 0.001 az |

| 3 | 18.3 ± 0.3 a | 0.34 ± 0.01 b | 0.235 ± 0.007 a | 3.40 ± 0.01 b | 14.88 ± 0.07 b | 0.993 ± 0.006 b | |

| 6 | 18.9 ± 0.6 a | 0.18 ± 0.01 c | 0.250 ± 0.002 b | 3.27 ± 0.02 c | 14.18 ± 0.05 c | 0.884 ± 0.004 c | |

| 80 | 0 | 16.9 ± 0.1 av | 0.57 ± 0.02 ax | 0.230 ± 0.030 ay | 3.38 ± 0.01 ay | 17.80 ± 0.20 av | 1.193 ± 0.020 av |

| 3 | 16.4 ± 0.9 a | 0.33 ± 0.01 b | 0.285 ± 0.060 b | 3.29 ± 0.01 b | 16.87 ± 0.31 b | 1.127 ± 0.021 b | |

| 6 | 16.3 ± 0.0 a | 0.14 ± 0.03 c | 0.320 ± 0.042 b | 3.20 ± 0.06 b | 16.50 ± 0.30 b | 1.033 ± 0.025 c | |

| SGs (%) | Storage (Month) | Coagulase- Positive Staphylococci * | Listeria monocytogenes ** | Yeast *** | Mold *** | Total Number of Colonies at 30 °C **** |

|---|---|---|---|---|---|---|

| [CFU/g] | ||||||

| 0 | 0 | n.d. | n.d. | <10 | <10 | <10 |

| 3 | n.d. | n.d. | <10 | <10 | <10 | |

| 6 | n.d. | n.d. | <10 | <10 | <10 | |

| 30 | 0 | n.d. | n.d. | <10 | <10 | <10 |

| 3 | n.d. | n.d. | <10 | <10 | <10 | |

| 6 | n.d. | n.d. | <10 | <10 | <10 | |

| 50 | 0 | n.d. | n.d. | <10 | <10 | <10 |

| 3 | n.d. | n.d. | <10 | <10 | <10 | |

| 6 | n.d. | n.d. | <10 | <10 | <10 | |

| 80 | 0 | n.d. | n.d. | <10 | <10 | <10 |

| 3 | n.d. | n.d. | <10 | <10 | <10 | |

| 6 | n.d. | n.d. | <10 | <10 | <10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pielak, M.; Czarniecka-Skubina, E. Effect of Processing and Storage of Very-Low-Sugar Apple Jams Prepared with Sugar Substitution by Steviol Glycosides on Chosen Physicochemical Attributes and Sensory and Microbiological Quality. Appl. Sci. 2024, 14, 8219. https://doi.org/10.3390/app14188219

Pielak M, Czarniecka-Skubina E. Effect of Processing and Storage of Very-Low-Sugar Apple Jams Prepared with Sugar Substitution by Steviol Glycosides on Chosen Physicochemical Attributes and Sensory and Microbiological Quality. Applied Sciences. 2024; 14(18):8219. https://doi.org/10.3390/app14188219

Chicago/Turabian StylePielak, Marlena, and Ewa Czarniecka-Skubina. 2024. "Effect of Processing and Storage of Very-Low-Sugar Apple Jams Prepared with Sugar Substitution by Steviol Glycosides on Chosen Physicochemical Attributes and Sensory and Microbiological Quality" Applied Sciences 14, no. 18: 8219. https://doi.org/10.3390/app14188219

APA StylePielak, M., & Czarniecka-Skubina, E. (2024). Effect of Processing and Storage of Very-Low-Sugar Apple Jams Prepared with Sugar Substitution by Steviol Glycosides on Chosen Physicochemical Attributes and Sensory and Microbiological Quality. Applied Sciences, 14(18), 8219. https://doi.org/10.3390/app14188219