An Investigation of the Effects of Thermo-Oxidative Aging and the Freeze–Thaw Cycle on the Performance of Polyester-Based, Self-Adhesive Asphalt Waterproofing Membranes

Abstract

:1. Introduction

2. Experimental

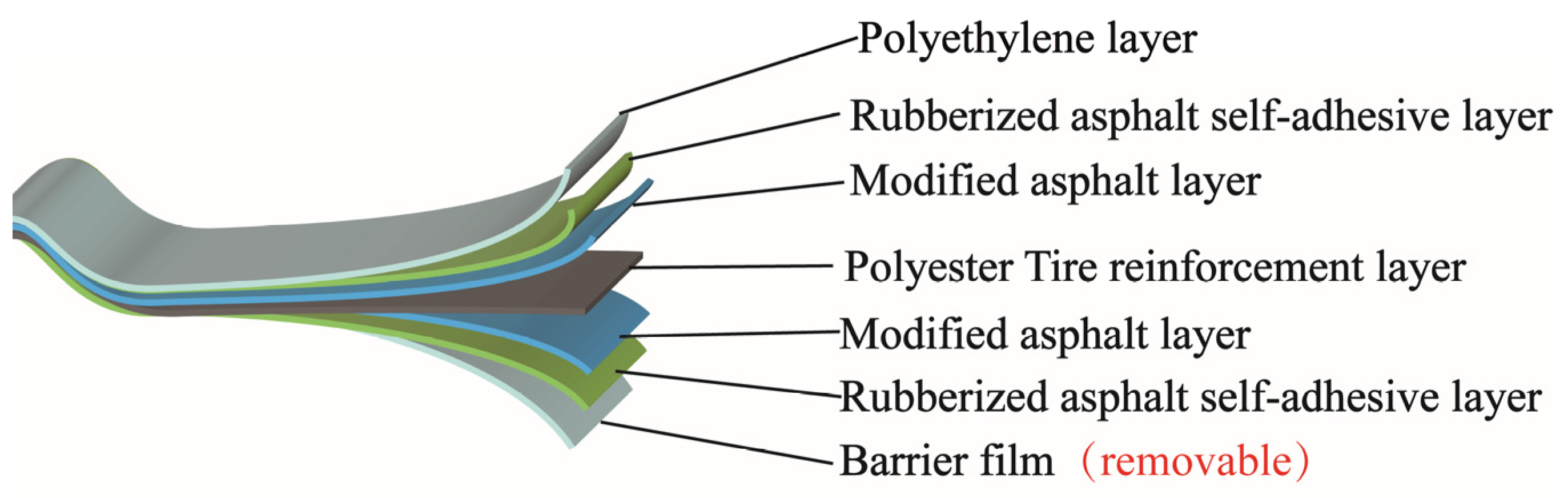

2.1. Materials

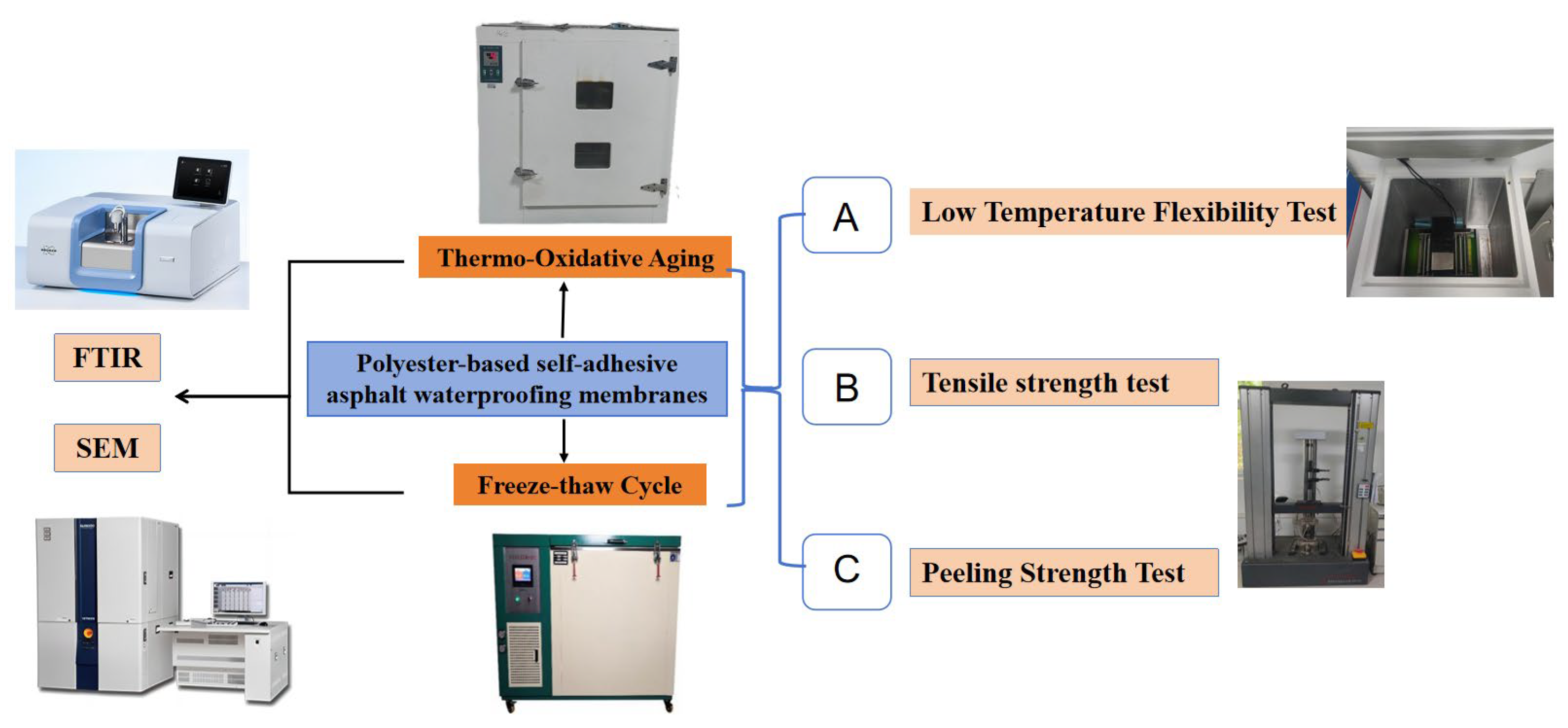

2.2. Pilot Programme

- (1)

- Specimen Preparation

- (2)

- Aging process

- (3)

- Test Methods

3. Results and Discussion

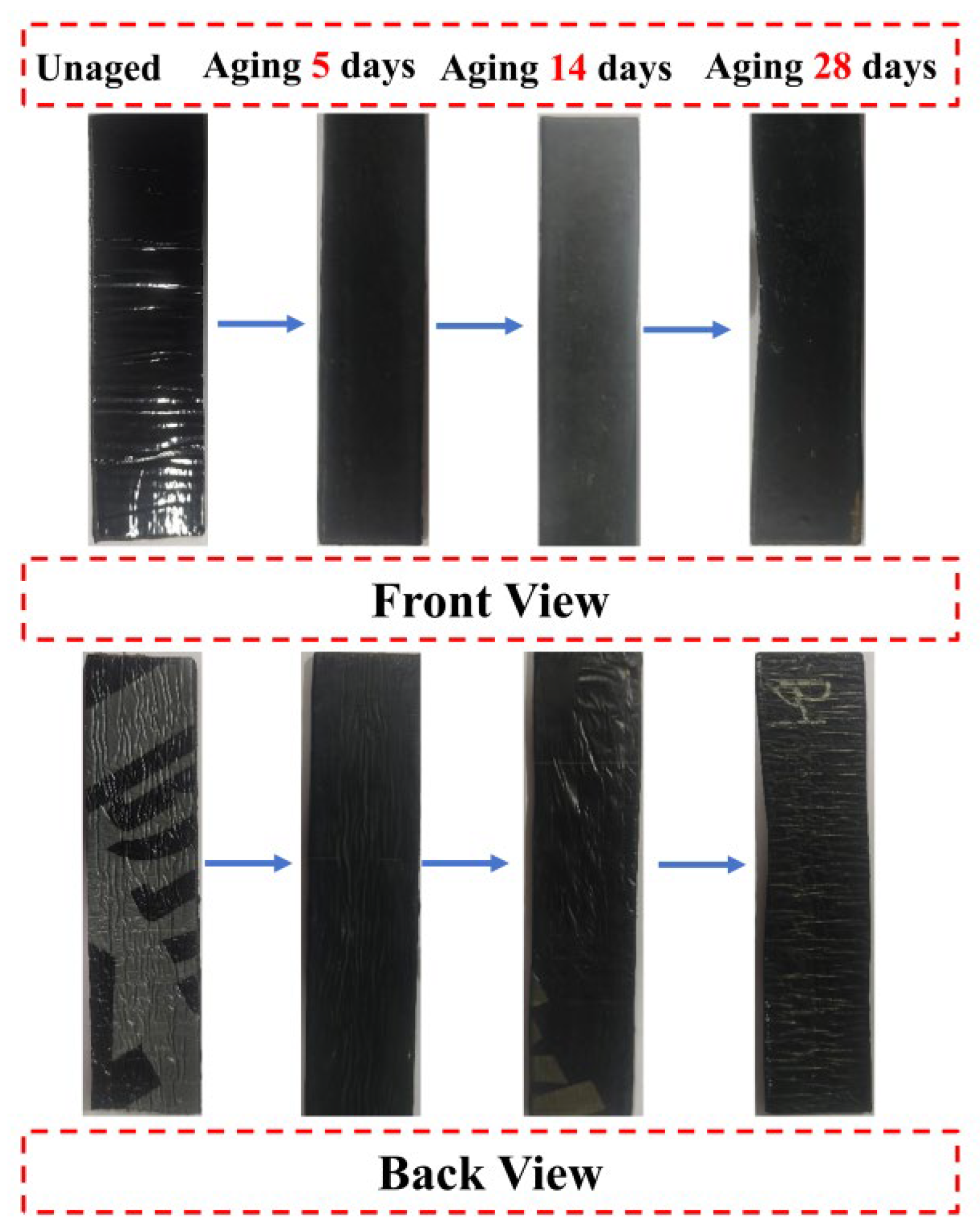

3.1. Apparent Appearance and SEM Analysis

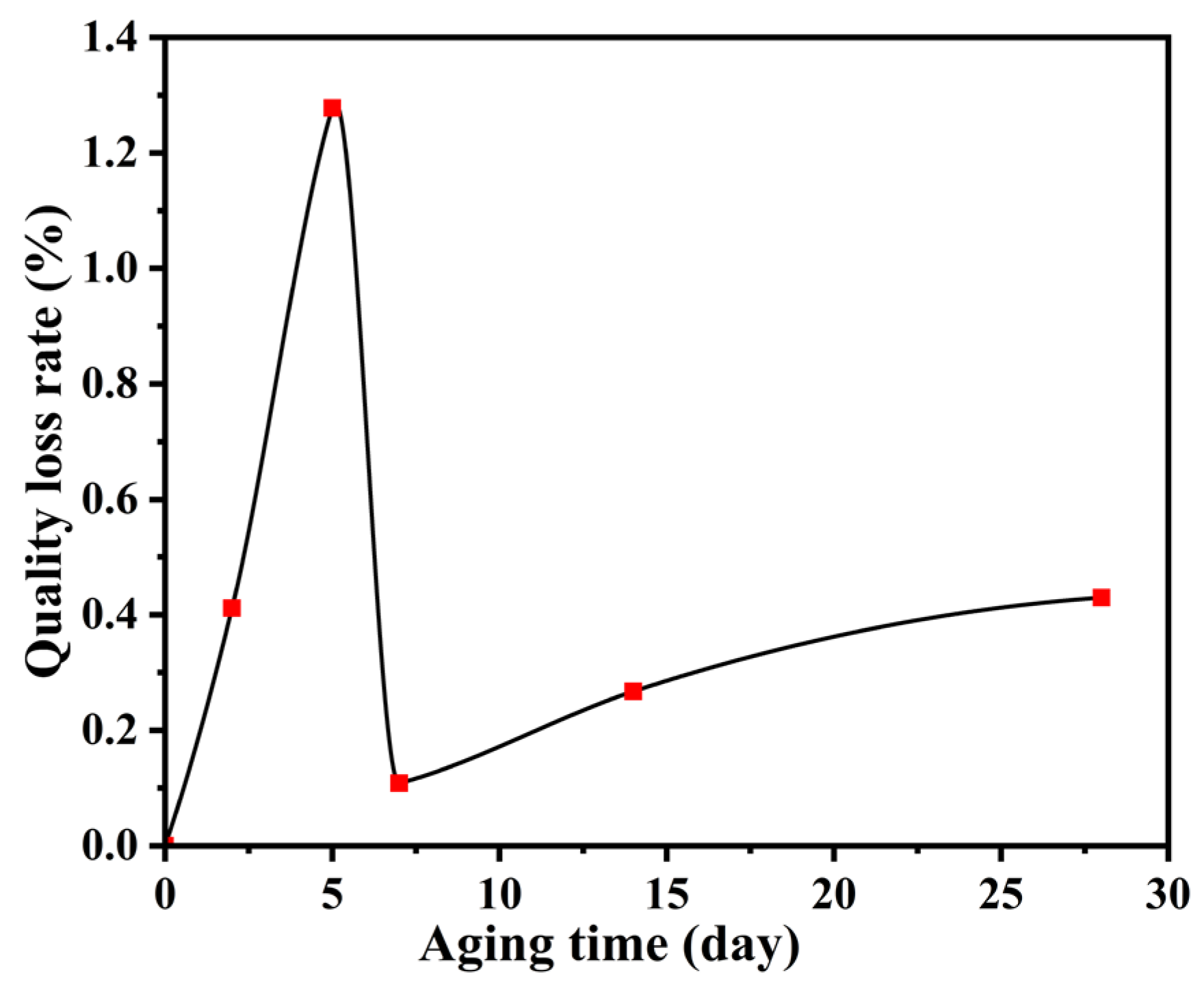

3.2. Quality Loss Rate

3.3. Low-Temperature Flexibility Analysis

3.4. FTIR Analysis

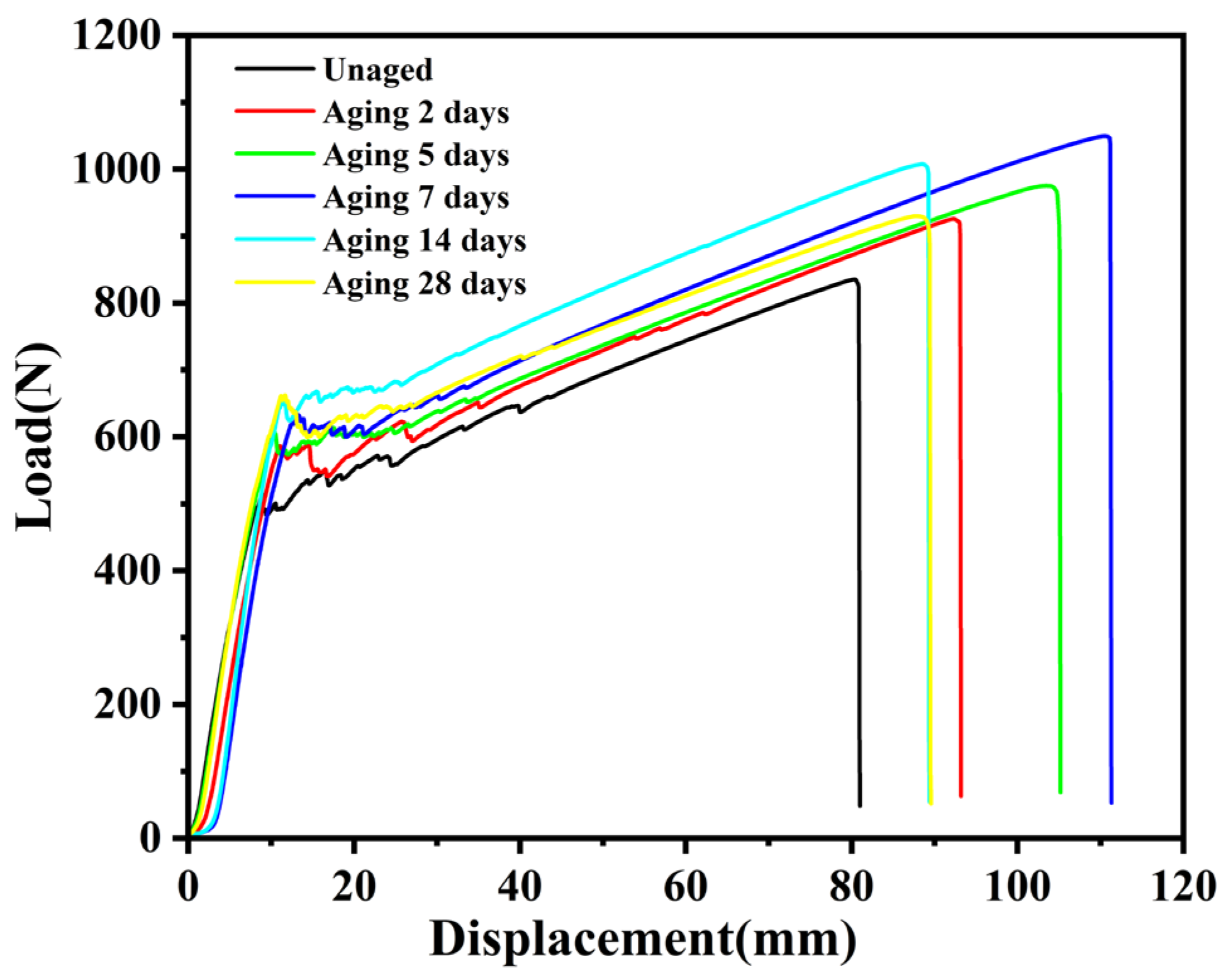

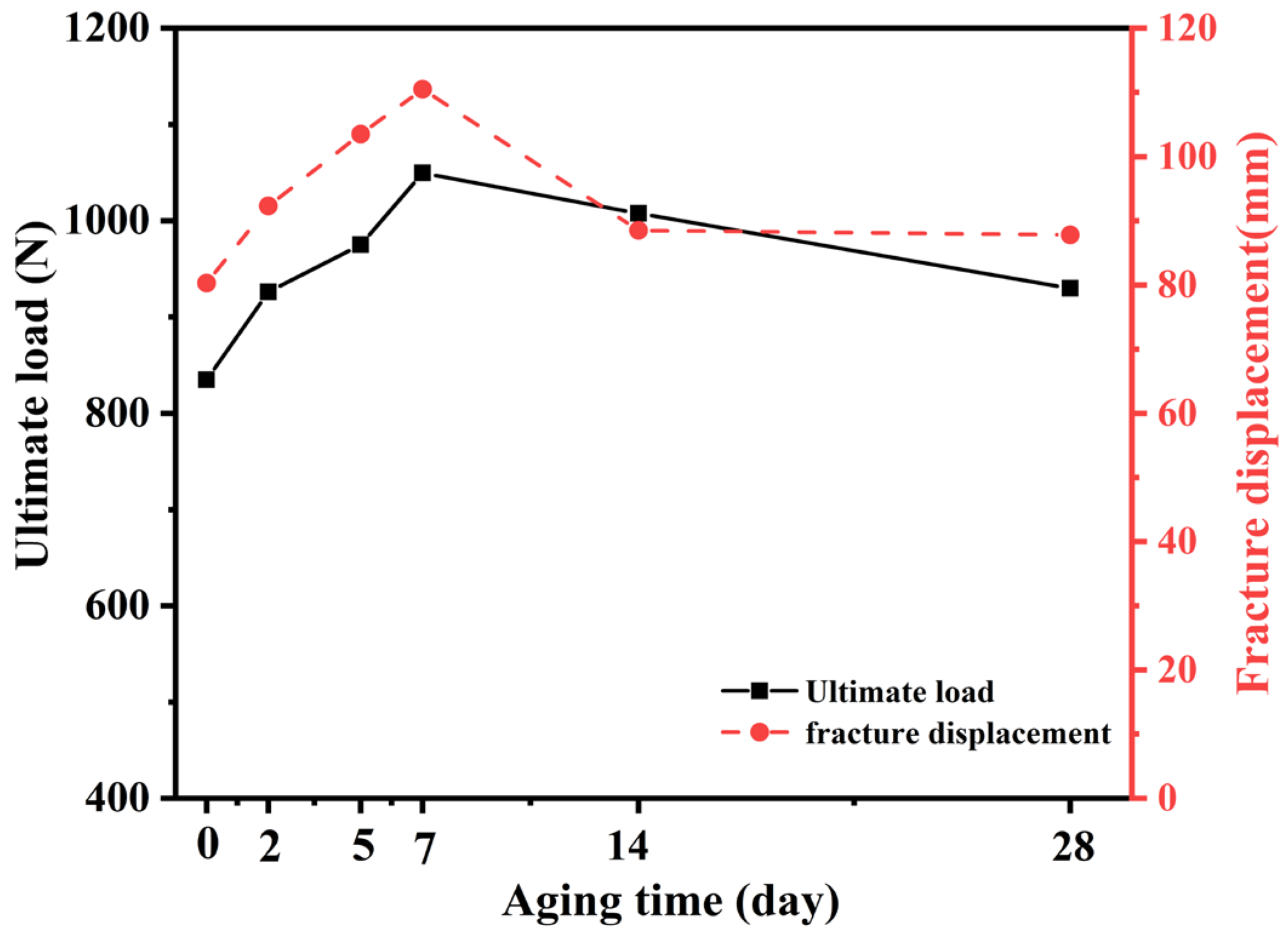

3.5. Tensile Properties of Waterproofing Membranes

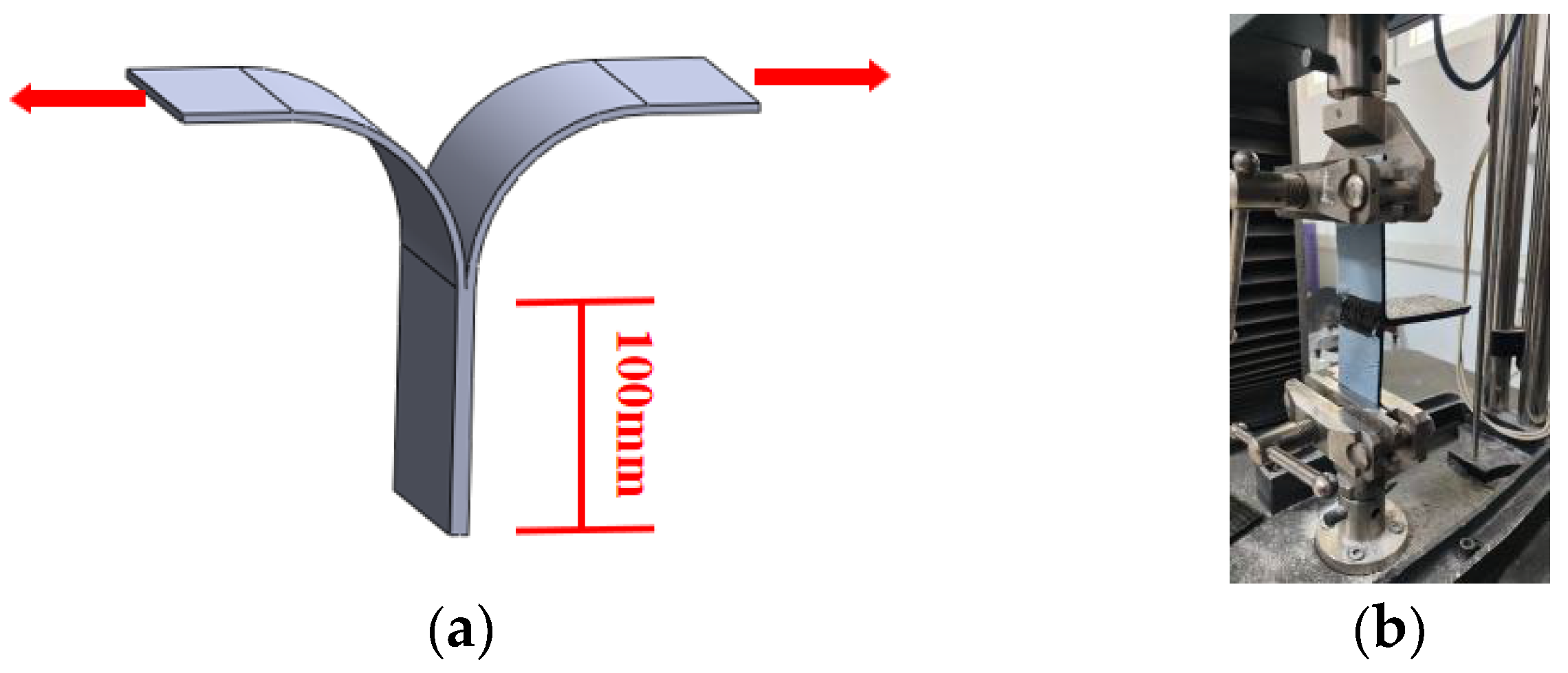

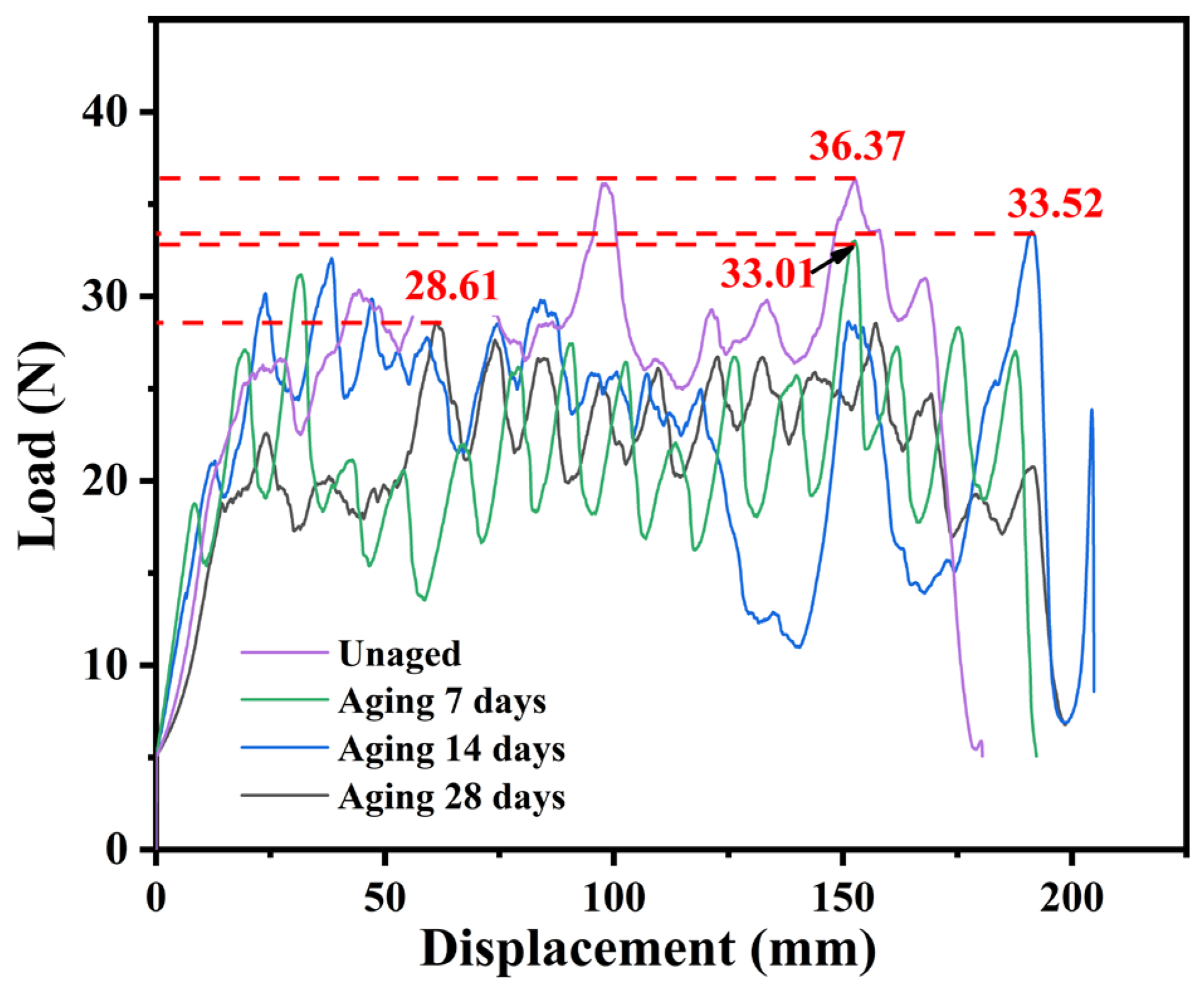

3.6. Waterproofing Membrane Peeling Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lopes, J.G.; Correia, J.R.; Machado, M.X. Dimensional stability of waterproofing bituminous sheets used in low slope roofs. Constr. Build. Mater. 2011, 25, 3229–3235. [Google Scholar] [CrossRef]

- He, Y.; Zhang, T.; Mao, S.; Zeng, S.; Wu, L.; Yu, J. Investigation of Antiaging Performance and Service Life of OMMT/SBS Modified Bitumen Waterproof Membranes. J. Mater. Civ. Eng. 2024, 36, 04024025. [Google Scholar] [CrossRef]

- Al-Bahar, S. Moisture effect on selected polymer-based membranes used for waterproofing building basements. Polym. Compos. 2005, 26, 276–286. [Google Scholar] [CrossRef]

- Li, L.; Guo, Z.; Ran, L.; Zhang, J. Study on Low-Temperature Cracking Performance of Asphalt under Heat and Light Together Conditions. Materials 2020, 13, 1541. [Google Scholar] [CrossRef] [PubMed]

- Abbas, H.A.; Manasrah, A.D.; Carbognani, L.; Sebakhy, K.O.; Nokab, M.E.H.E.; Hacini, M.; Nassar, N.N. A study on the characteristics of Algerian Hassi-Messaoud asphaltenes: Solubility and precipitation. Pet. Sci. Technol. 2021, 40, 1279–1301. [Google Scholar] [CrossRef]

- Yang, C.; Gong, X.; Han, X.; Li, X.; Xu, J. Influence of Thermal aging on the composition structure and properties of different asphalts. Sci. Technol. Eng. 2023, 23, 8839–8845. [Google Scholar] [CrossRef]

- Hu, M.; Sun, G.; Sun, D.; Lu, T.; Ma, J.; Deng, Y. Accelerated weathering simulation on rheological properties and chemical structure of high viscosity modified asphalt: A temperature acceleration effect analysis. Constr. Build. Mater. 2021, 268, 121120. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, N.; Ge, Y. Experimental Study on Durability of Polymer Film Reinforced Self-adhesive Waterproofing Membrane. China Build. Waterproofing 2023, 11, 1–5. [Google Scholar] [CrossRef]

- Song, S.; Liang, M.; Wang, L.; Li, D.; Guo, M.; Yan, L.; Zhang, X.; Ding, W. Effects of Different Natural Factors on Rheological Properties of SBS Modified Asphalt. Materials 2022, 15, 5628. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Wu, X.; Wang, S.; Ouyang, C. Weather aging resistance of different rubber modified asphalts. Constr. Build. Mater. 2016, 106, 443–448. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Zhou, X.; Yang, G.; Zhang, L. Evaluation of the Physical and Adhesive Properties of Natural Weathering Asphalt. Adv. Mater. Sci. Eng. 2021, 2021, 5783256. [Google Scholar] [CrossRef]

- Dong, W.; Guan, W.; Huang, W. Low Temperature Performance Analysis of SBS Modified Asphalt under Different Aging Process. J. Build. Mater. 2018, 21, 268–274. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Effect of polymer modification on the ageing properties of asphalt binders: Chemical and morphological investigation. Constr. Build. Mater. 2019, 205, 633–641. [Google Scholar] [CrossRef]

- Zhang, H. Experimental Study on Aging Resistance of Self-adhesive Polymer Modified Asphalt Waterproof Rol. Synth. Mater. Aging Appl. 2023, 52, 55–57. [Google Scholar]

- Donchenko, M.; Grynyshyn, O.; Demchuk, Y.; Topilnytskyy, P.; Turba, Y. Influence of Potassium Humate on the Technological Aging Processes of Oxidized Petroleum Bitumen. Chem. Chem. Technol. 2023, 17, 681–687. [Google Scholar] [CrossRef]

- Pyshyev, S.; Miroshnichenko, D.; Chipko, T.; Donchenko, M.; Bogoyavlenska, O.; Lysenko, L.; Miroshnychenko, M.; Prysiazhnyi, Y. Using bitumen emulsions based on oxidated, distillation and modified oxidated bitumens for slurry seal production. Chem. Chem. Technol. 2015, 9, 359–366. [Google Scholar] [CrossRef]

- Donchenko, M.; Grynyshyn, O.; Prysiazhnyi, Y.; Pyshyev, S.; Kohut, A. The Problem of Road Bitumen Technological Aging and Ways to Solve It: A Review. Chem. Chem. Technol. 2024, 18, 284–294. [Google Scholar] [CrossRef]

- Guo, M.; Guan, M.; Tan, Y.; Du, X. Study on the change rule of low-temperature properties of asphalt binder with aging time. Int. J. Pavement Eng. 2024, 25, 2324886. [Google Scholar] [CrossRef]

- Wang, J.; Ng, P.-L.; Gong, Y.; Su, H.; Du, J. Experimental Study of Low Temperature Performance of Porous Asphalt Mixture. Appl. Sci. 2021, 11, 4029. [Google Scholar] [CrossRef]

- Pyshyev, S.; Miroshnichenko, D.; Chipko, T.; Donchenko, M.; Bogoyavlenska, O.; Lysenko, L.; Miroshnychenko, M.; Prysiazhnyi, Y. Use of Lignite Processing Products as Additives to Road Petroleum Bitumen. Chemengineering 2024, 8, 27. [Google Scholar] [CrossRef]

- Feng, Z.-G.; Wang, S.-J.; Bian, H.-J.; Guo, Q.-L.; Li, X.-J. FTIR and rheology analysis of aging on different ultraviolet absorber modified bitumens. Constr. Build. Mater. 2016, 115, 48–53. [Google Scholar] [CrossRef]

- Huang, X.; Wang, L. Evolution of Low-Temperature Properties of Warm-Mix Rubber-Modified Asphalt under Freeze–Thaw Cycles. J. Mater. Civ. Eng. 2023, 35, 04022406. [Google Scholar] [CrossRef]

- Shan, M.; Wang, L.; Zhang, B. Low Temperature Properties of Warm-Mixed Crumb Rubber Asphalt Mixture under Salt and Freeze-Thaw Cycles. J. Build. Mater. 2019, 22, 467–473. [Google Scholar] [CrossRef]

- Ge, B.; Wang, J.; Wang, S.; Zhang, J.; Zhu, A. Experimental Research on Durability of SBS Modified Bituminous Sheet Materials (2) Soaking Aging and Freezing-Thawing Cycles Aging. Constr. Qual. 2015, 33, 28–32. [Google Scholar] [CrossRef]

- Hazleden, D.G. A decay risk model for wood frame walls using the 4Ds with special reference to New Zealand. J. Build. Eng. 2022, 49, 104070. [Google Scholar] [CrossRef]

- GB 23441-2009; Self-Adhering Polymer Modified Bituminous Waterproof Sheet. Standards Press of China: Beijing, China, 2009. (In Chinese)

- GB/T 328.1-2007; Test Methods for Building Sheets for Waterproofing. Standards Press of China: Beijing, China, 2007. (In Chinese)

- Yue, P.P.; Wang, L.L. Interface Temperature of EPS Exterior Insulation System in High Temperature Environment in Summer. Urban. Archit. 2019, 16, 96–99. [Google Scholar] [CrossRef]

- GB/T 328.8-2007; Test Methods for Building Sheets for Waterproofing. Standards Press of China: Beijing, China, 2007. (In Chinese)

- GB/T 328.20-2007; Test Methods for Building Sheets for Waterproofing. Standards Press of China: Beijing, China, 2007. (In Chinese)

| Property | Measured Values |

|---|---|

| Thicknesses (mm) | 3.0 |

| Tensile strength (N/50 mm) | 620/500 |

| Elongation at maximum tension (%) | 39 |

| Soluble matter content (g/m2) | 2208 |

| Aging time (day) | 0 | 2 | 5 | 7 | 14 | 28 |

| Cracking temperature (°C) | −28.5 | −26 | −22 | −21 | −18 | −15 |

| Projects | Unaged | Aging 5 Days | Aging 7 Days | Aging 14 Days | Aging 28 Days |

|---|---|---|---|---|---|

| Carbonyl functional group index | 0.22 | 0.046 | 0.026 | 0.022 | 0.018 |

| Sulfoxide functional group index | 0.06 | 0.115 | 0.135 | 0.172 | 0.187 |

| Butadiene double-bond functional group index | 0.06 | 0.115 | 0.132 | 0.172 | 0.187 |

| Sulfide ether functional group index | 0.16 | 0.012 | 0.003 | 0.001 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, J.; Zhang, C.; Sun, G.; Ma, X.; Du, H. An Investigation of the Effects of Thermo-Oxidative Aging and the Freeze–Thaw Cycle on the Performance of Polyester-Based, Self-Adhesive Asphalt Waterproofing Membranes. Appl. Sci. 2024, 14, 8237. https://doi.org/10.3390/app14188237

Tan J, Zhang C, Sun G, Ma X, Du H. An Investigation of the Effects of Thermo-Oxidative Aging and the Freeze–Thaw Cycle on the Performance of Polyester-Based, Self-Adhesive Asphalt Waterproofing Membranes. Applied Sciences. 2024; 14(18):8237. https://doi.org/10.3390/app14188237

Chicago/Turabian StyleTan, Jun, Chao Zhang, Guojun Sun, Xingpeng Ma, and Hongwei Du. 2024. "An Investigation of the Effects of Thermo-Oxidative Aging and the Freeze–Thaw Cycle on the Performance of Polyester-Based, Self-Adhesive Asphalt Waterproofing Membranes" Applied Sciences 14, no. 18: 8237. https://doi.org/10.3390/app14188237

APA StyleTan, J., Zhang, C., Sun, G., Ma, X., & Du, H. (2024). An Investigation of the Effects of Thermo-Oxidative Aging and the Freeze–Thaw Cycle on the Performance of Polyester-Based, Self-Adhesive Asphalt Waterproofing Membranes. Applied Sciences, 14(18), 8237. https://doi.org/10.3390/app14188237