Comprehensive Cost–Energy Evaluation of Wall Insulation for Diverse Orientations and Seasonal Usages

Abstract

:1. Introduction

2. Mathematical Model

2.1. Degree-Day Approach and Solar Radiation Effect

2.2. Heating and Cooling Energy Demands on an Annual Scale

2.3. Economic Evaluation of Insulation Thickness

3. Results and Discussion

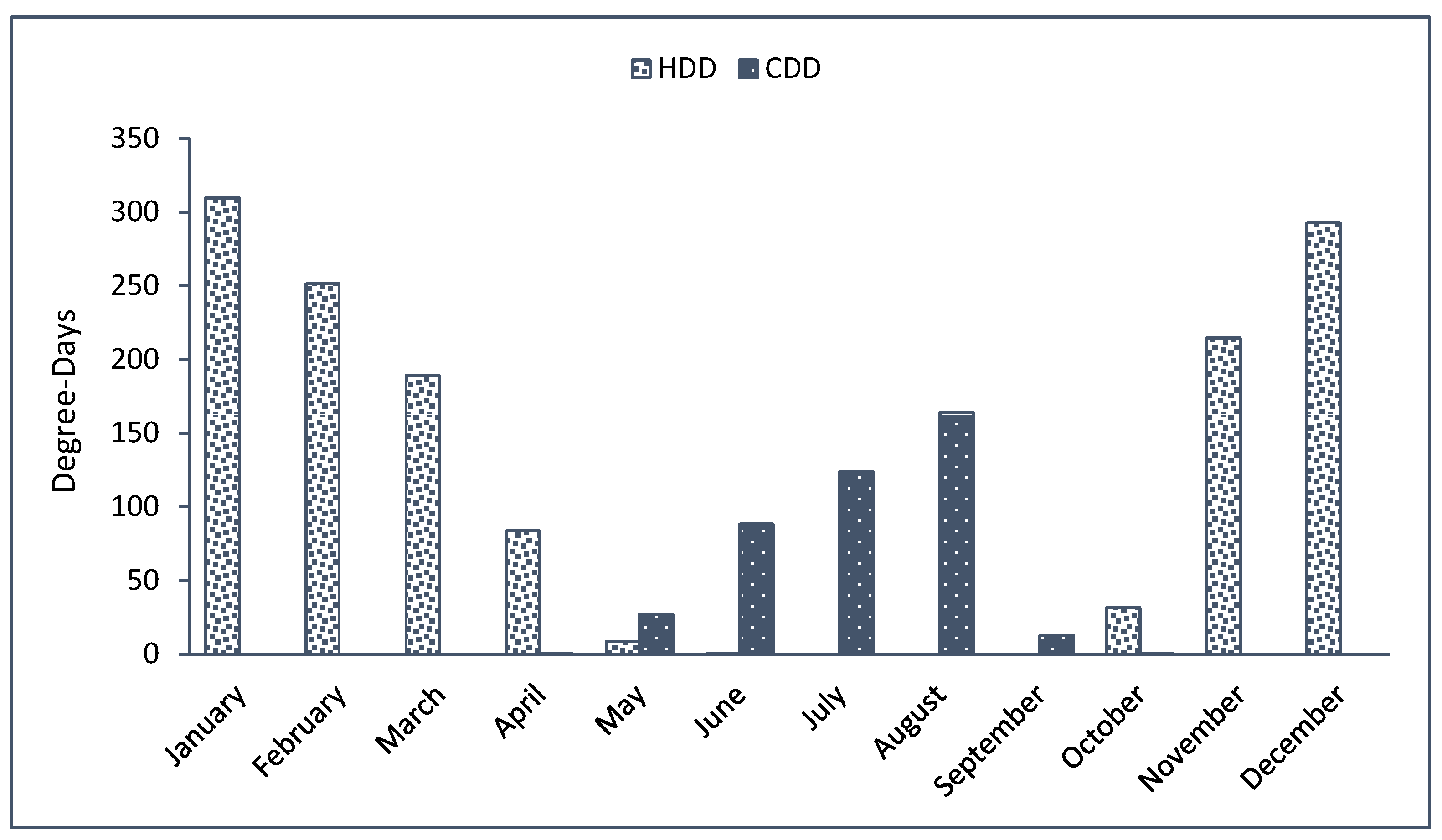

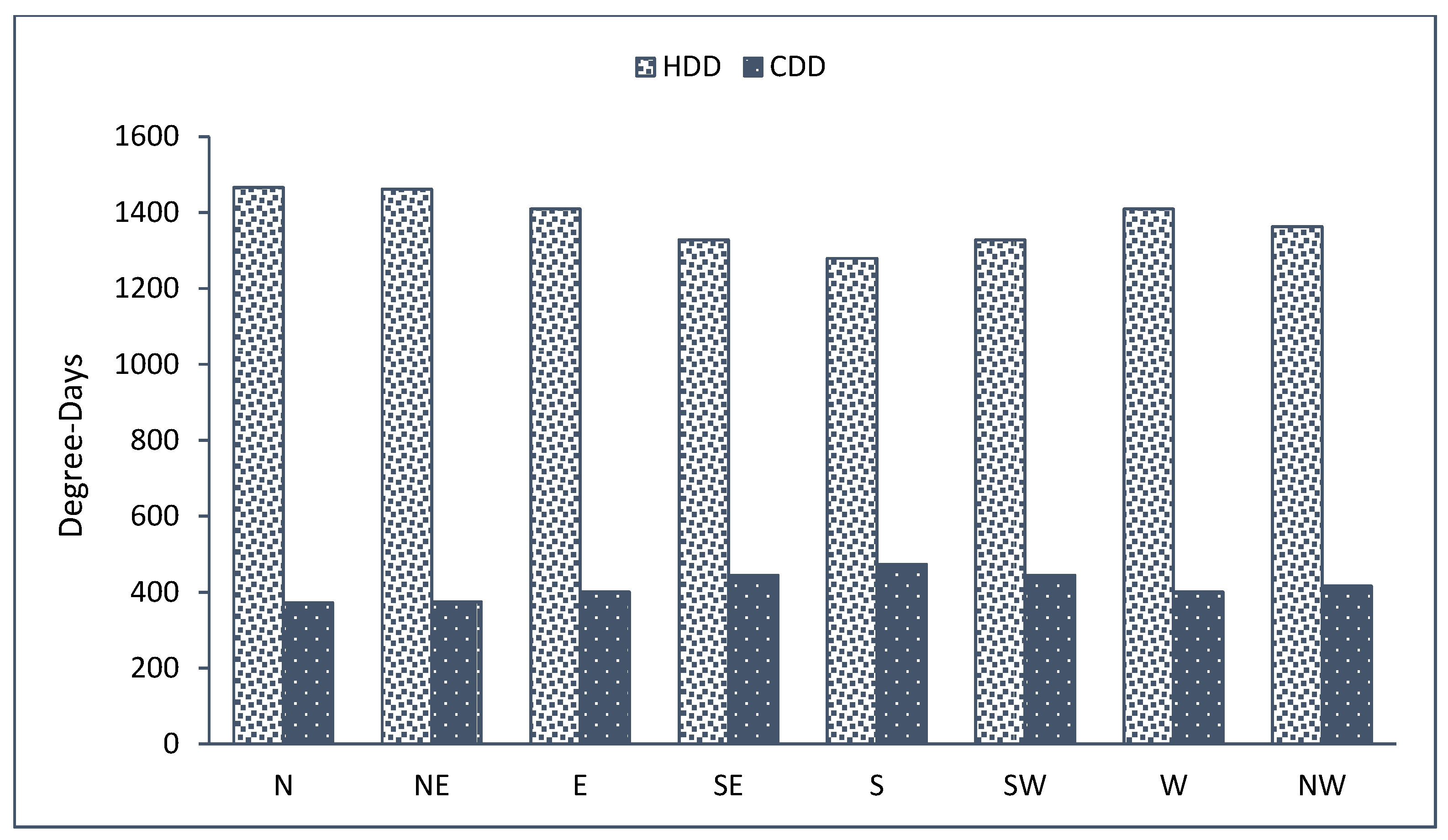

3.1. Heating and Cooling Degree Days

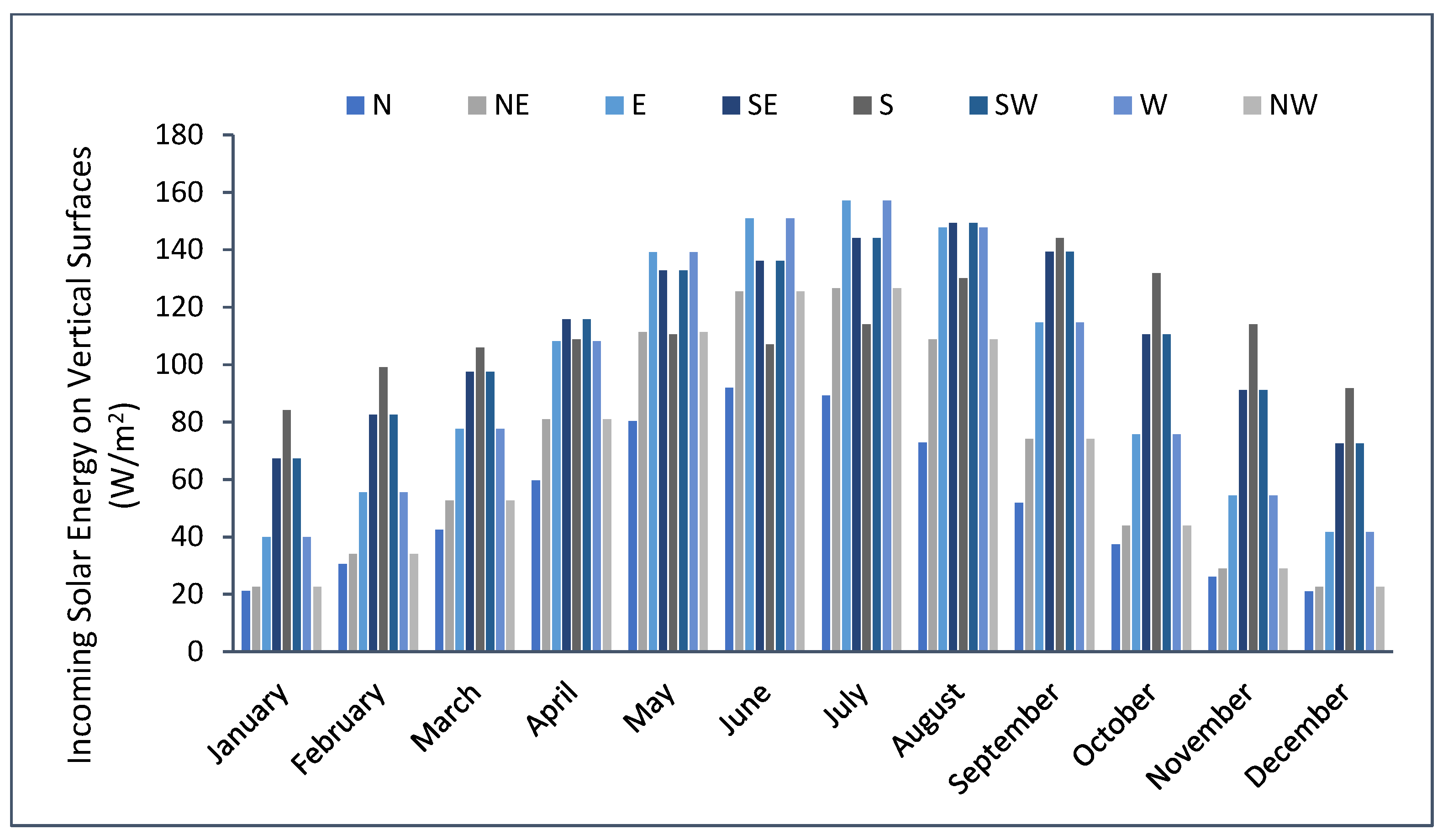

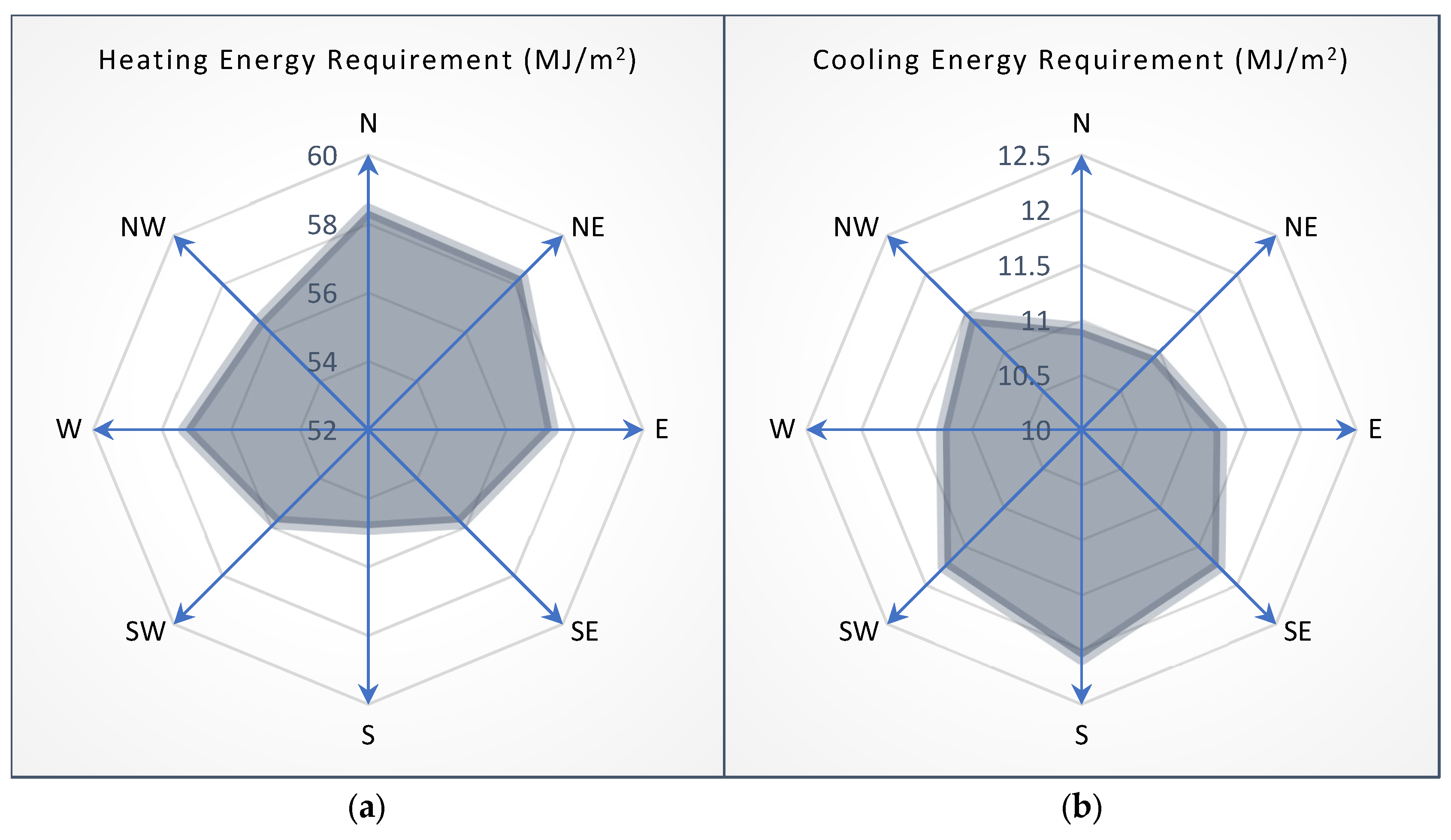

3.2. Solar Radiation and Energy Requirements

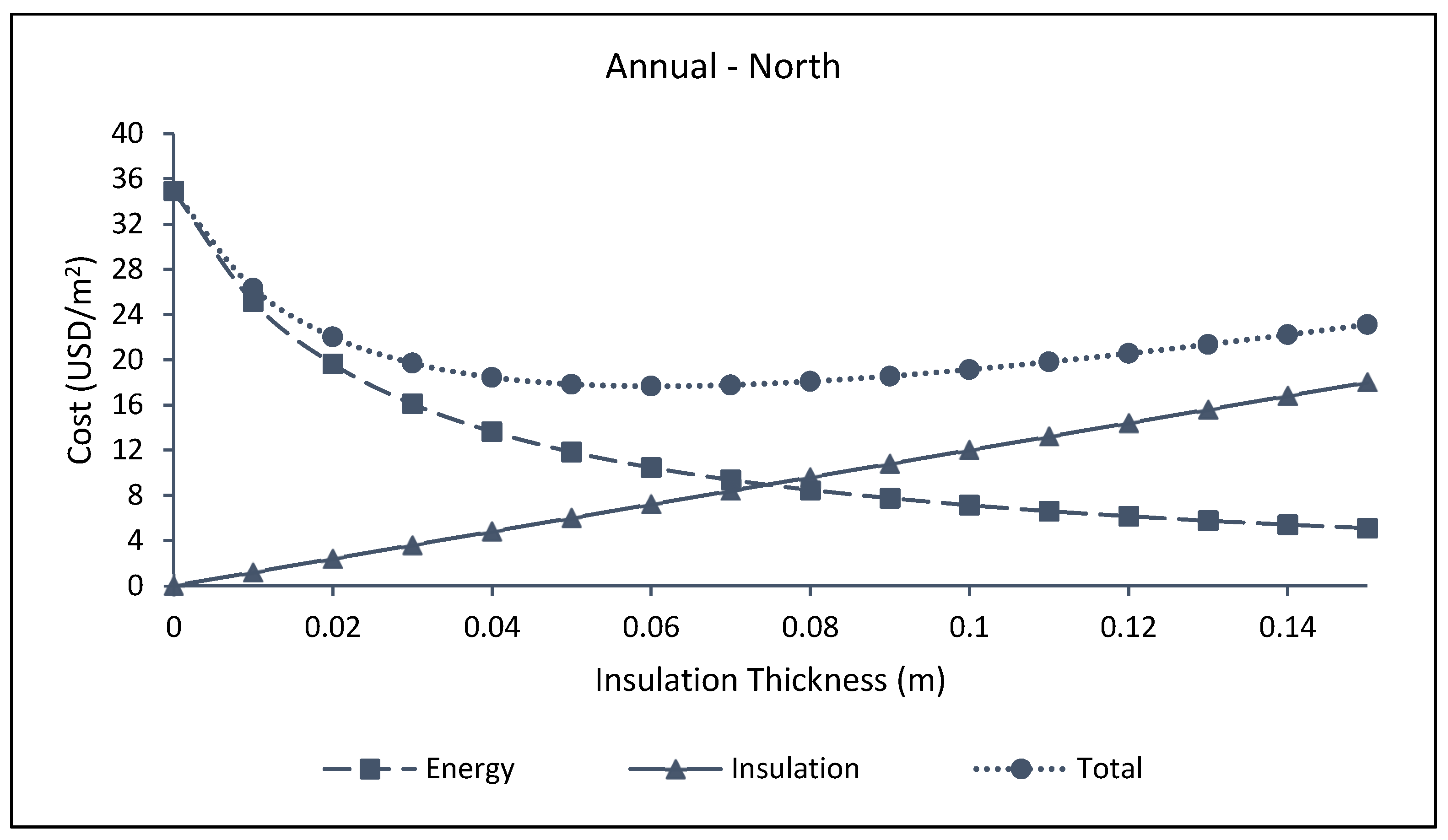

3.3. Optimum Insulation Thicknesses for Different Directions and Seasonal Usages

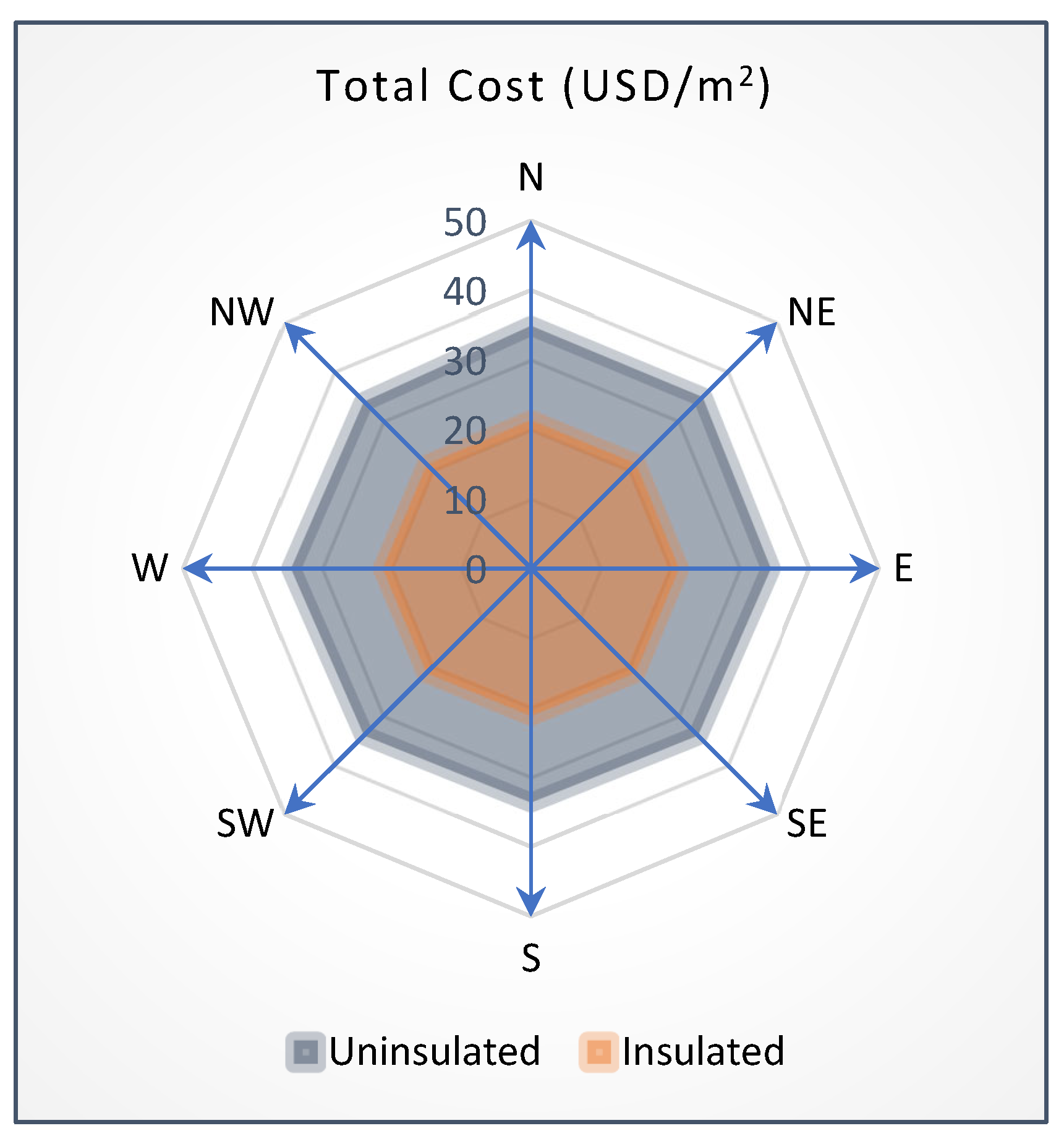

3.4. Comparative Analysis

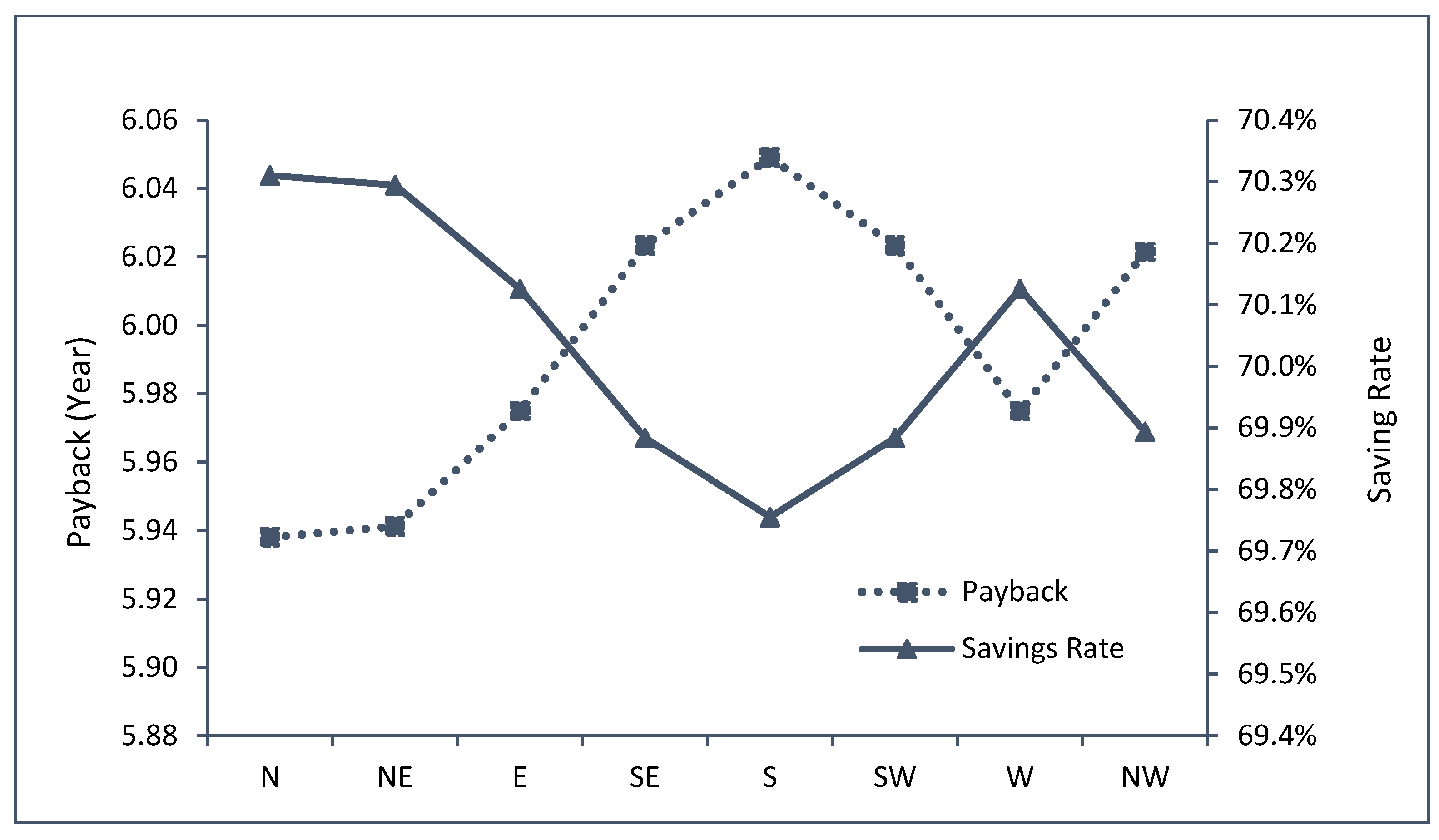

3.5. Cost Saving Rates with Payback Period

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | cost or price, [USD/m2 or USD/m3] |

| CDDs | cooling degree days |

| COP | coefficient of cooling system performance |

| E | east |

| energy cost savings | |

| g | discount rate [%] |

| solar constant | |

| HDDs | heating degree days |

| h | heat transfer coefficient, [W/m2°C] |

| i | inflation rate [%] |

| k | thermal conductivity, [W/m°C] |

| clearness index | |

| LCCA | life cycle cost analysis |

| Hu | lower heating value, [J/m3] |

| LT | lifetime, [year] |

| N | north |

| NE | northeast |

| NW | northwest |

| PWF | present worth factor |

| solar radiation incident, [W/m2] | |

| Rt,w | total wall thermal resistances excluding the insulation layer, [m2°C/W] |

| S | south |

| SE | southeast |

| SW | southwest |

| T | temperature, [°C] |

| U | overall heat transfer coefficient, [W/m2°C] |

| W | west |

| x | thermal insulation thickness, [m] |

| Z | altitude |

| solar absorption rate | |

| ε | radiative emission coefficient of surface |

| reflectance of the ground | |

| β | inclination angle of the surface |

| azimuth angle | |

| Stefan-Boltzmann constant, [W/m2°C4] | |

| incidence’s angle of direct solar irradiance | |

| declination angle | |

| latitude angle | |

| ω | sunset hour angle |

| η | heating system efficiency |

| Subscript | |

| b | base |

| C | cooling |

| e | electricity |

| f | fuel |

| H | heating |

| i | inside |

| ins | insulation material |

| o | outside |

| opt | optimum |

| sol-air | solar air |

| surr | sky and surrounding surface |

References

- Trading Economics. Available online: https://tradingeconomics.com/commodity/natural-gas (accessed on 8 September 2024).

- International Energy Agency. Available online: https://www.iea.org/topics/global-energy-crisis (accessed on 15 May 2024).

- Kaynakli, O. Parametric investigation of optimum thermal insulation thickness for external walls. Energies 2011, 4, 913–927. [Google Scholar] [CrossRef]

- Ozel, M. Determination of optimum insulation thickness based on cooling transmission load for building walls in a hot climate. Energy Convers. Manag. 2013, 66, 106–114. [Google Scholar] [CrossRef]

- Canbolat, A.; Bademlioglu, A.; Saka, K.; Kaynakli, O. Investigation of parameters affecting the optimum thermal insulation thickness for buildings in hot and cold climates. Therm. Sci. 2019, 24, 2891–2903. [Google Scholar] [CrossRef]

- Kurekci, N.A. Determination of optimum insulation thickness for building walls by using heating and cooling degree-day values of all Turkey’s provincial centers. Energy Build. 2016, 118, 197–213. [Google Scholar] [CrossRef]

- Özel, M. Determination of Indoor Design Temperature, Thermal Characteristics and Insulation Thickness Under Hot Climate Conditions. J. Therm. Sci. Technol. 2022, 42, 49–64. [Google Scholar] [CrossRef]

- Kaynakli, O. A review of the economical and optimum thermal insulation thickness for building applications. Renew. Sustain. Energy Rev. 2012, 16, 415–425. [Google Scholar] [CrossRef]

- Verichev, K.; Serrano-Jiménez, A.; Carpio, M.; Barrios-Padura, Á.; Díaz-López, C. Influence of degree days calculation methods on the optimum thermal insulation thickness in life-cycle cost analysis for building envelopes in Mediterranean and Semi-Arid climates. J. Build. Eng. 2023, 79, 107783. [Google Scholar] [CrossRef]

- Albatayneh, A. Optimising the Parameters of a Building Envelope in the East Mediterranean Saharan, Cool Climate Zone. Buildings 2021, 11, 43. [Google Scholar] [CrossRef]

- Onan, C.; Erdem, S.; Ozkan, D.B.; Baykal, C. Analysis of optimum insulation thickness for external walls at different orientations based on real-time measurements. Therm. Sci. 2020, 24, 2035–2046. [Google Scholar] [CrossRef]

- Cyrille Vincelas, F.F.; Ghislain, T. The determination of the most economical combination between external wall and the optimum insulation material in Cameroonian’s buildings. J. Build. Eng. 2017, 9, 155–163. [Google Scholar] [CrossRef]

- As, M.; Bilir, T. Enhancing energy efficiency and cost-effectiveness while reducing CO2 emissions in a hospital building. J. Build. Eng. 2023, 78, 107792. [Google Scholar] [CrossRef]

- Altun, A.F. Determination of Optimum Building Envelope Parameters of a Room concerning Window-to-Wall Ratio, Orientation, Insulation Thickness and Window Type. Buildings 2022, 12, 383. [Google Scholar] [CrossRef]

- Yuan, J.; Farnham, C.; Emura, K. Optimum insulation thickness for building exterior walls in 32 regions of China to save energy and reduce CO2 Emissions. Sustainability 2017, 9, 1711. [Google Scholar] [CrossRef]

- Gigasari, A.R.; Cárcel-Carrasco, J.; Palermo Iglesias, L.M.; Amani, N. Evaluating carbon payback time by optimizing insulation materials for different orientations: A cradle-to-gate life cycle assessment. Energy Environ. 2023. [Google Scholar] [CrossRef]

- Xu, H.; Ding, J.; Li, T.; Mu, C.; Gu, X.; Wang, R. A Study on Optimum Insulation Thickness in Walls of Chinese Solar Greenhouse for Energy Saving. Agronomy 2022, 12, 1104. [Google Scholar] [CrossRef]

- Akan, A.E. Determination and Modeling of Optimum Insulation Thickness for Thermal Insulation of Buildings in All City Centers of Turkey; Springer: New York, NY, USA, 2021; Volume 42, ISBN 0123456789. [Google Scholar]

- Bademlioğlu, A.H.; Kaynakli, Ö.; Yamankaradeniz, N. The effect of water vapor diffusion resistance factor of insulation materials for outer walls on condensation. J. Therm. Sci. Technol. 2018, 38, 15–23. [Google Scholar]

- Canbolat, A.S. An integrated assessment of the financial and environmental impacts of exterior building insulation application. J. Clean. Prod. 2023, 435, 140376. [Google Scholar] [CrossRef]

- Omle, I.; Kovács, E.; Bolló, B. Applying recent efficient numerical methods for long-term simulations of heat transfer in walls to optimize thermal insulation. Results Eng. 2023, 20, 101476. [Google Scholar] [CrossRef]

- Canbolat, A.S.; Albak, E.İ. Multi-Objective Optimization of Building Design Parameters for Cost Reduction and CO2 Emission Control Using Four Different Algorithms. Appl. Sci. 2024, 14, 7668. [Google Scholar] [CrossRef]

- Kaynakli, O. A study on residential heating energy requirement and optimum insulation thickness. Renew. Energy 2008, 33, 1164–1172. [Google Scholar] [CrossRef]

- Bolattürk, A. Optimum insulation thicknesses for building walls with respect to cooling and heating degree-hours in the warmest zone of Turkey. Build. Environ. 2008, 43, 1055–1064. [Google Scholar] [CrossRef]

- Cengel, Y. Heat Transfer: A Practical Approach, 2nd ed.; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Duffie, J.A.; Beckman, W.A.; Blair, N. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Kilic, A.; Ozturk, A. Solar Energy; Kipas Distribution Inc.: Istanbul, Turkey, 1983. (In Turkish) [Google Scholar]

- Yiğit, A.; Atmaca, İ. Solar Energy; Alfa Aktüel: Bursa, Turkey, 2010. (In Turkish) [Google Scholar]

- Tiris, M.; Tiris, Ç.; Türe, I.E. Diffuse solar radiation correlations: Applications to Turkey and Australia. Energy 1995, 20, 745–749. [Google Scholar] [CrossRef]

- Central Bank of Türkiye. Available online: https://www.tcmb.gov.tr (accessed on 5 April 2024).

- Bolattürk, A. Determination of optimum insulation thickness for building walls with respect to various fuels and climate zones in Turkey. Appl. Therm. Eng. 2006, 26, 1301–1309. [Google Scholar] [CrossRef]

- Kaynakli, Ö. Optimum Thermal Insulation Thicknesses and Payback Periods for Building Walls in Turkey. J. Therm. Sci. Technol. 2013, 33, 45–55. [Google Scholar]

- Bektas Ekici, B.; Aytac Gulten, A.; Aksoy, U.T. A study on the optimum insulation thicknesses of various types of external walls with respect to different materials, fuels and climate zones in Turkey. Appl. Energy 2012, 92, 211–217. [Google Scholar] [CrossRef]

- Guven, S. Calculation of optimum insulation thickness of external walls in residential buildings by using exergetic life cycle cost assessment method: Case study for Turkey. Environ. Prog. Sustain. Energy 2019, 38, e13232. [Google Scholar] [CrossRef]

- TS 825; Thermal Insulation Requirements for Buildings. Turkish Standards Institution: Ankara, Turkey, 2013.

- Kaynakli, O.; Ozdemir, S.; Karamangil, I. Determinatıon of Optimum Thermal Insulation Thickness Considering Solar Radiation and Wall Orientation. J. Fac. Eng. Archit. Gazi Univ. 2012, 27, 367–374. [Google Scholar]

| Parameters | Value | |

|---|---|---|

| x cm | Insulation material | k = 0.03 W/mK |

| 3 cm | Exterior plaster | k = 0.87 W/mK |

| 2 cm | Interior plaster | k = 0.87 W/mK |

| 20 cm | Hollow brick | k = 0.45 W/mK |

| Heat transfer coefficient (Inside) | hi = 8.29 W/m2K | |

| Heat transfer coefficient (Outside) | ho = 28.35 W/m2K | |

| Expanded polystyrene (EPS) | ||

| Material cost | Cins = 120 $/m3 | |

| Conductivity | k = 0.039 W/mK | |

| Density | ρ = 20 kg/m3 | |

| Natural gas | ||

| Price | Cf = 0.29 $/m3 | |

| Lower heating value | Hu = 34526.103 J/m3 | |

| Heating system’s efficiency | η = 93% | |

| Electricity | ||

| Price | Ce = 0.0947 $/kWh | |

| Coefficient of cooling system performance | COP = 2.5 | |

| Discount rate | g = 20% | |

| Inflation rate | i = 17% | |

| Lifetime | LT = 20 | |

| Present worth factor | PWF = 15.5 |

| N | NE | E | SE | S | SW | W | NW | |

| Only Heated, xopt,H (cm) | 5.02 | 5.01 | 4.88 | 4.66 | 4.52 | 4.66 | 4.88 | 4.75 |

| Only Cooled, Xopt,C (cm) | 1.56 | 1.58 | 1.72 | 1.95 | 2.09 | 1.95 | 1.72 | 1.80 |

| Both Heated and Cooled, Xopt,A (cm) | 6.08 | 6.07 | 6.02 | 5.95 | 5.92 | 5.95 | 6.02 | 5.96 |

| Only Heated, xopt,H (cm) | |

|---|---|

| N | Cost = 26.43997 − 622.0711*x + 11259.94*x2 − 79956.95*x3 + 208548.9*x4 |

| NE | Cost = 26.35419 − 619.6636*x + 11223.41*x2 − 79697.54*x3 + 207872.3*x4 |

| E | Cost = 25.41728 − 593.3679*x + 10824.41*x2 − 76864.23*x3 + 200482.3*x4 |

| SE | Cost = 23.96003 − 552.4683*x + 10203.81*x2 − 72457.36*x3 + 188988.0*x4 |

| S | Cost = 23.07432 − 527.6099*x + 9826.619*x2 − 69778.91*x3 + 182001.9*x4 |

| SW | Cost = 23.96003 − 552.4683*x + 10203.81*x2 − 72457.36*x3 + 188988.0*x4 |

| W | Cost = 25.41728 − 593.3679*x + 10824.41*x2 − 76864.23*x3 + 200482.3*x4 |

| NW | Cost = 24.58018 − 569.8737*x + 10467.92*x2 − 74332.77*x3 + 193879.6*x4 |

| Only Cooled, xopt,C (cm) | |

| N | Cost = 7.828451 − 99.71533*x + 3333.880*x2 − 23673.97*x3 + 61747.98*x4 |

| NE | Cost = 7.877767 − 101.0994*x + 3354.890*x2 − 23823.10*x3 + 62136.96*x4 |

| E | Cost = 8.430012 − 116.5989*x + 3590.074*x2 − 25493.15*x3 + 66492.88*x4 |

| SE | Cost = 9.345131 − 142.2829*x + 3979.794*x2 − 28260.55*x3 + 73711.00*x4 |

| S | Cost = 9.948581 − 159.2194*x + 4236.784*x2 − 30085.44*x3 + 78470.79*x4 |

| SW | Cost = 9.345131 − 142.2829*x + 3979.794*x2 − 28260.55*x3 + 73711.00*x4 |

| W | Cost = 8.430012 − 116.5989*x + 3590.074*x2 − 25493.15*x3 + 66492.88*x4 |

| NW | Cost = 8.746919 − 125.4933*x + 3725.034*x2 − 26451.50*x3 + 68992.52*x4 |

| Both Heated and Cooled, Xopt,A (cm) | |

| N | Cost = 34.26842 − 841.7864*x + 14593.83*x2 − 103630.9*x3 + 270296.9*x4 |

| NE | Cost = 34.23196 − 840.7630*x + 14578.30*x2 − 103520.6*x3 + 270009.3*x4 |

| E | Cost = 33.84729 − 829.9668*x + 14414.48*x2 − 102357.4*x3 + 266975.1*x4 |

| SE | Cost = 33.30516 − 814.7511*x + 14183.61*x2 − 100717.9*x3 + 262699.0*x4 |

| S | Cost = 33.02290 − 806.8294*x + 14063.40*x2 − 99864.35*x3 + 260472.7*x4 |

| SW | Cost = 33.30516 − 814.7511*x + 14183.61*x2 − 100717.9*x3 + 262699.0*x4 |

| W | Cost = 33.84729 − 829.9668*x + 14414.48*x2 − 102357.4*x3 + 266975.1*x4 |

| NW | Cost = 33.32710 − 815.3670*x + 14192.95*x2 − 100784.3*x3 + 262872.1*x4 |

| Study | City | Insulation Thickness (cm) | |||

| N | E | S | W | ||

| Present Study | Bursa | 5.02 | 4.88 | 4.52 | 4.88 |

| Kaynakli et al. [36] | Istanbul | 5.15 | 4.79 | 4.33 | 4.77 |

| Heating Degree Days (HDDs) | |||||

| N | E | S | W | ||

| Present Study | Bursa | 1466 | 1409 | 1327 | 1409 |

| Kaynakli et al. [36] | Istanbul | 1719 | 1633 | 1535 | 1628 |

| Incoming Solar Radiation (W/m2) | |||||

| N | E | S | W | ||

| Present Study | Bursa | 52 | 97 | 112 | 97 |

| Kaynakli et al. [36] | Istanbul | 50 | 90 | 109 | 94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canbolat, A.S. Comprehensive Cost–Energy Evaluation of Wall Insulation for Diverse Orientations and Seasonal Usages. Appl. Sci. 2024, 14, 8239. https://doi.org/10.3390/app14188239

Canbolat AS. Comprehensive Cost–Energy Evaluation of Wall Insulation for Diverse Orientations and Seasonal Usages. Applied Sciences. 2024; 14(18):8239. https://doi.org/10.3390/app14188239

Chicago/Turabian StyleCanbolat, Ahmet Serhan. 2024. "Comprehensive Cost–Energy Evaluation of Wall Insulation for Diverse Orientations and Seasonal Usages" Applied Sciences 14, no. 18: 8239. https://doi.org/10.3390/app14188239