Application of Ultrasound Homogenization in Milk Ice Cream Mixes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. The Hydrolyzates of Iota Carrageenan

2.3. Ice Cream Mix Manufacture

Homogenization Treatment

2.4. The Examination of the Stability of Milk Ice Cream Mixes

2.5. The Distribution of Particle Size of Milk Ice Cream Mixes

2.6. The Analysis of Rheological Properties of Milk Ice Cream Mixes

2.7. Characterization of the Microstructure of Milk Ice Cream Mix Emulsions

2.8. Statistical Analysis

3. Results and Discussion

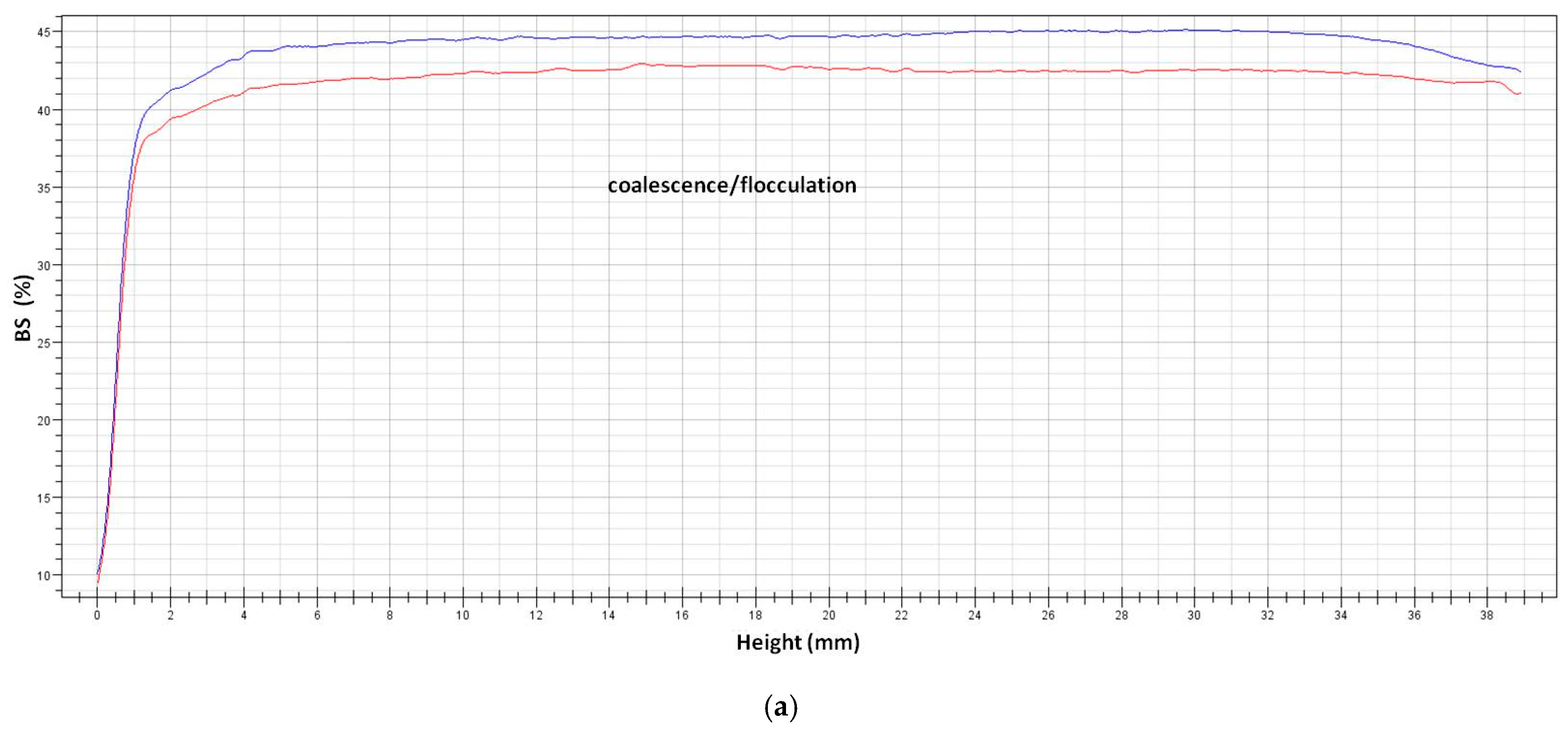

3.1. The Stability of Milk Ice Cream Mixes

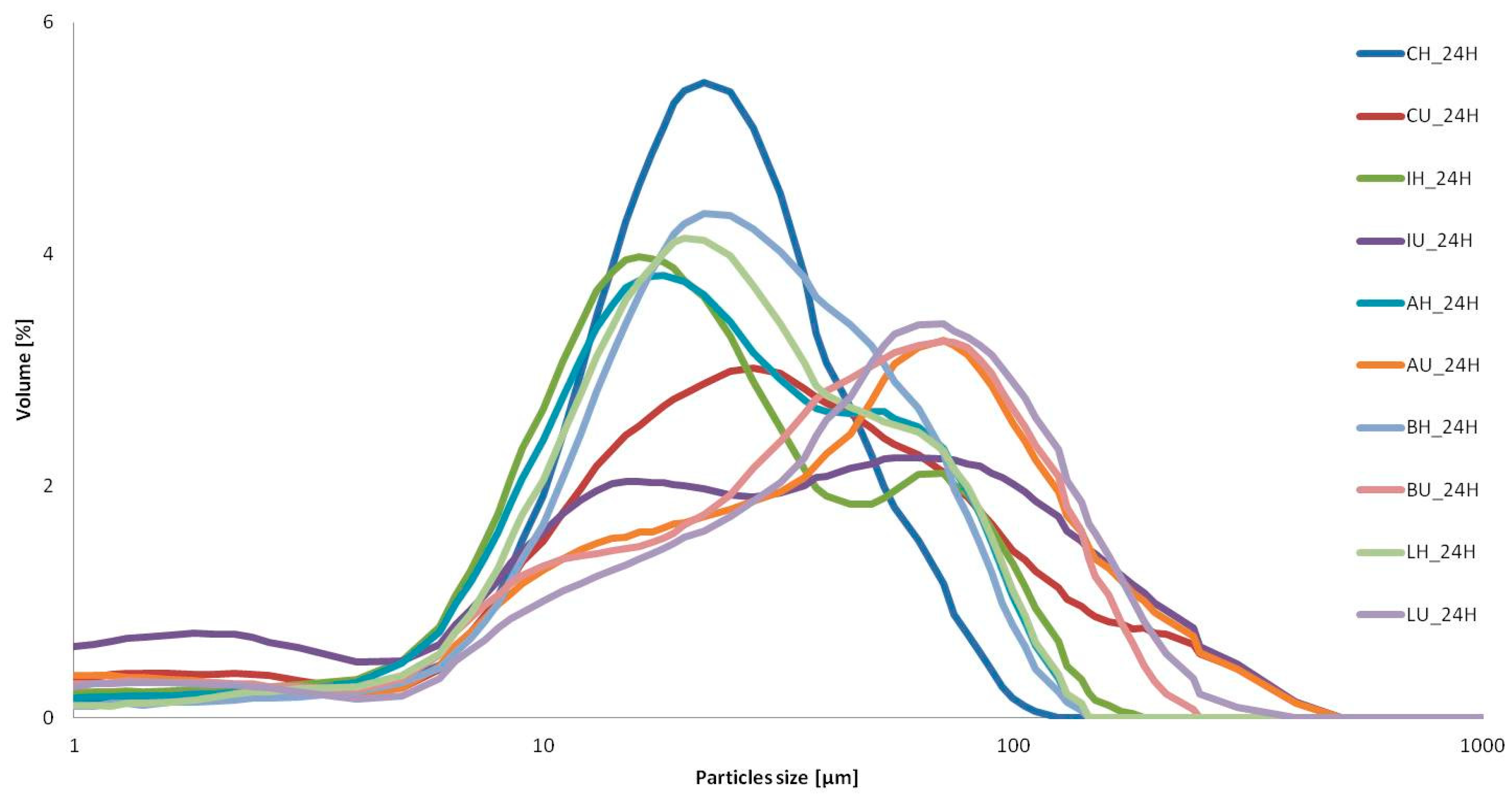

3.2. The Analysis of Particle Sizes of Milk Ice Cream Mixes

3.3. The Analysis of Rheological Properties of Milk Ice Cream Mixes

3.4. The Microscopic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akdeniz, V.; Akalin, A. New approach for yoghurt and ice cream production: High-intensity ultrasound. Trends Food Sci. Technol. 2019, 86, 392–398. [Google Scholar] [CrossRef]

- Chemat, F.; Khan; M.K. Application of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Zhang, M.; Xu, B.; Adhikari, B.; Sun, J. The principles of ultrasound and its application in freezing related processes of food materials: A review. Ultrason. Sonochem. 2015, 27, 576–585. [Google Scholar] [CrossRef] [PubMed]

- Bhargava, N.; Mor, R.S.; Kumar, K.; Sharanagat, V.S. Advances in application of ultrasound in food processing: A review. Ultrason. Sonochem. 2021, 70, 105293. [Google Scholar] [CrossRef] [PubMed]

- Carrillo-Lopez, L.M.; Garcia-Galicia, I.A.; Tirado-Gallegos, J.M.; Sanchez-Vega, R.; Huerta-Jimenez, M.; Ashokkumar, M.; Alarcon-Rojo, A.D. Recent advances in the application of ultrasound in dairy products: Effect on functional, physical, chemical, microbiological and sensory properties. Ultrason. Sonochem. 2021, 73, 105467. [Google Scholar] [CrossRef] [PubMed]

- Ashokkumar, M.; Bhaskaracharya, R.; Kentish, S.; Lee, J.; Palmer, M.; Zisu, B. The ultrasonic processing of dairy products—An overview. Dairy Sci. Technol. 2010, 90, 147–168. [Google Scholar] [CrossRef]

- Firouz, M.S. Application of high-intensity ultrasound in food processing for improvement of food quality. In design and optimization of innovative food processing techniques assisted by ultrasound. In Developing Healthier and Sustainable Food Products; Barba, F., Cravotto, G., Chemat, F., Lorenzo Rodriguez, J.M., Sichetti Munekata, P.E., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 155–159. [Google Scholar]

- Mortazavi, A.; Tabatabaie, F. Study of Ice Cream Freezing Process after Treatment with Ultrasound. World Appl. Sci. J. 2008, 4, 188–190. [Google Scholar]

- Kamińska-Dwórznicka, A.; Kot, A.; Jakubczyk, E.; Buniowska-Olejnik, M.; Nowacka, M. Effect of ultrasound-assisted freezing on the crystal structure of mango sorbet. Crystal 2023, 13, 396. [Google Scholar] [CrossRef]

- Nazarewicz, S.; Kozłowicz, K.; Kobus, Z.; Gładyszewska, B.; Matwijczuk, A.; Ślusarczyk, L.; Skrzypek, T.; Sujka, M.; Kozłowicz, N. The use of ultrasound in shaping the properties of ice cream with oleogel based on oil extracted from tomato seeds. Appl. Sci. 2022, 12, 9165. [Google Scholar] [CrossRef]

- Adapa, S.; Schmidt, K.A.; Jeon, I.J.; Herald, T.J.; Flores, R.A. Mechanisms of ice crystallization and recrystallization in ice cream: A review. Food Rev. Int. 2000, 16, 259–271. [Google Scholar] [CrossRef]

- Tüker, D.A.; Dogan, M. Effect of ultrasound homogenization on the structural and sensorial attributes of ice cream: Optimization with Taguchi and data envelopment analysis. J. Food Meas. Charact. 2021, 15, 4888–4898. [Google Scholar]

- Cheng, J.; Ma, Y.; Li, X.; Yan, T.; Cui, J. Effects of milk-proteinpolysaccharide interactions on the stability of ice cream model systems. Food Hydrocoll. 2015, 45, 327–336. [Google Scholar] [CrossRef]

- Pal, R. Modeling of sedimentation and creaming in suspensions and pickering emulsions. Fluids 2019, 4, 186. [Google Scholar] [CrossRef]

- Gelin, J.L.; Poyen, L.; Courthaudon, J.L.; Meste, M.L.; Lorient, D. Structural changes in oil-water emulsions during the manufacture of ice cream. Food Hydrocoll. 1994, 8, 299–308. [Google Scholar] [CrossRef]

- Goff, H.D. Colloidal aspects of ice cream—A review. Int. Dairy J. 1997, 7, 363–373. [Google Scholar] [CrossRef]

- Mendez-Velasco, C.; Goff, H.D. Fat structures as affected by unsaturated or saturated monoglyceride and their effect on ice cream structure, texture and stability. Int. Dairy J. 2012, 24, 33–39. [Google Scholar] [CrossRef]

- Berger, K.G.; White, G.W. An electron microscopical investigation of fat destabilization in ice cream. Int. J. Food Sci. Tech. 1971, 6, 285–294. [Google Scholar] [CrossRef]

- Goff, H.D.; Kinsella, J.E.; Jordan, W.K. Influence of various milk protein isolates on ice cream emulsion stability. J. Dairy Sci. 1989, 72, 385–397. [Google Scholar] [CrossRef]

- Koxholt, M.M.R.; Eisenmann, B.; Hinrichs, J. Effect of the fat globule sizes on the meltdown of ice cream. J. Dairy Sci. 2001, 84, 31–37. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A.; Jakubczyk, E. Study on the influence of ultrasound homogenisation on the physical properties of vegan ice cream mixes. Appl. Sci. 2022, 12, 8492. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A. The influence of ultrasound homogenization on recrystallization during storage of vegan ice cream. J.Food Process Eng. 2023, 46, e14472. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A.; Antczak, A.; Jakubczyk, E.; Matwijczuk, A. Effect of ɩ-carrageenan and its acidic and enzymatic hydrolysates on ice crystal structure changes in model sucrose solution. Coll. Surf. A Physicochem. Eng. Asp. 2022, 643, 1–12. [Google Scholar] [CrossRef]

- Kamińska-Dwórznicka, A.; Matusiak, M.; Samborska, K.; Witrowa-Rajchert, D.; Gondek, E.; Jakubczyk, E. The influence of kappa carrageenan and its hydrolysates on the recrystallization process in sorbet (Part B). J. Food Eng. 2015, 167, 162–165. [Google Scholar] [CrossRef]

- Kamińska-Dwórznicka, A.; Skrzypczak, P.; Gondek, E. Modification of kappa carrageenan by β-galactosidase as a new method to inhibit recrystallization. Food Hydrocoll. 2016, 61, 31–35. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Murray, B.; Flynn, C.; Norton, I. The effect of ultrasound treatment on the structural, physical and emulsifying of animal and vegetable protein. Food Hydrocoll. 2016, 53, 141–154. [Google Scholar] [CrossRef]

- da Silva, L.F.R.; da Silva Gomes, A.; Castro, D.R.G.; das Chagas do Amaral Souza, F.; Mar, J.M.; Souza da Silva, L.; Sanches, E.A.; de Araújo Bezerra, J.; Bakry, A.M.; Campelo, P.H. Ultrasound-assisted homogenisation and gum Arabic combined to physicochemical quality of cupuaçu juice. J. Food Process. Pres. 2019, 43, e14072. [Google Scholar] [CrossRef]

- Hu, Y.; Ting, Y.; Hu, J.; Hsieh, S. Techniques and methods to study functional characteristics of emulsions systems. J. Food Drug Anal. 2017, 25, 16–26. [Google Scholar] [CrossRef]

- Kot, A.; Jakubczyk, E.; Buniowska-Olejnik, M.; Kamińska-Dwórznicka, A. The effect of iota carrageenan and its hydrolysates on the stability of milk ice cream mixes. Pol. J. Food Nutr. Sci. 2023, 73, 196–204. [Google Scholar] [CrossRef]

- Albano, K.M.; Nicoletti, V.R. Ultrasound impact on whey protein concentrate-pectin complexes and in the O/W emulsions with low oil soybean content stabilization. Ultrason. Sonochem. 2018, 41, 562–571. [Google Scholar] [CrossRef]

- Kaltsa, O.; Michon, C.; Yanniotis, S.; Mandala, I. Ultrasonic energy input influence οn the production of sub-micron o/w emulsions containing whey protein and common stabilizers. Ultrason. Sonochem. 2013, 20, 881–891. [Google Scholar] [CrossRef]

- Alvi, M.A.U.R.; Martinez-Monteagudo, S.I. Impact of acoustic intensity on melting behavior of ice cream. LWT 2023, 186, 115234. [Google Scholar] [CrossRef]

- Bermúdez-Aguirre, D.; Mawson, R.; Barbosa-C’anovas, G.V. Microstructure of Fat Globules in Whole Milk after Thermosonication Treatment. J. Food Sci. 2008, 73, E325–E332. [Google Scholar] [CrossRef]

- Gallego-Ju´arez, J.A.; Graff, K.F. Introduction to power ultrasonics. Applications of high-intensity ultrasound. In Power Ultrasonics; Gallego-Juarez, J.A., Graff, K.F., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 1–6. [Google Scholar]

- Jiang, Y.S.; Zhang, S.B.; Zhang, S.Y.; Peng, Y.X. Comparative study of high-intensity ultrsound and high-pressure homogenization on physicochemical properties of peanut protein-stabilized emulsions and emulsion gels. J. Food Eng. 2021, 44, e13710. [Google Scholar]

- Liu, X.; Sala, G.; Scholten, E. Effect of fat aggregate size and percentage on the melting properties of ice cream. Food Res. Int. 2022, 160, 111709. [Google Scholar] [CrossRef]

- Cropper, S.L.; Kocaoglu-Vurma, N.A.; Tharp, B.W.; Harper, W.J. Effects of Locust Bean Gum and Mono- and Diglyceride Concentrations on Particle Size and Melting Rates of Ice Cream. J. Food Sci. 2013, 78, C811–C816. [Google Scholar] [CrossRef]

- Lozano, E.; Padilla, K.; Salcedo, J.; Arrieta, A.; Andrade-Pizarro, R. Effects of Yam (Dioscorea rotundata) Mucilage on the Physical, Rheological and Stability Characteristics of Ice Cream. Polymers 2022, 14, 3142. [Google Scholar] [CrossRef]

- Atalar, I.; Kurt, A.; Gul, O.; Yazici, F. Improved physicochemical, rheological and bioactive properties of ice cream: Enrichment with higher pressure homogenized hazelnut milk. Int. J. Gastron. Food Sci. 2021, 24, 100358. [Google Scholar] [CrossRef]

- Rao, M.A. Introduction: Food Rheology and Structure. In Rheology of Fluid and Semisolid Foods: Principles and Applications; Barbosa-Canovas, G.V., Ed.; Springer Science & Business Media: New York, NY, USA, 2007; pp. 1–23. [Google Scholar]

- Cavender, G.A.; Kerr, W.R. Microfluidization of full-fat ice cream mixes: Effects on rheology and microstructure. J. Food Process Eng. 2020, 43, e133520. [Google Scholar] [CrossRef]

- Mostafavi, F.S.; Tehrani, M.M.; Mohebbi, M. Rheological and sensory properties of fat reduced vanilla ice creams containing milk protein concentrate (MPC). J. Food Meas. Charact. 2017, 11, 567–575. [Google Scholar] [CrossRef]

- BahramParvar, M.; Razavi, S.M.A.; Khodaparast, M.H.H. Rheological Characterization and Sensory Evaluation of a Typical Soft Ice Cream Made with Selected Food Hydrocolloids. Food Sci. Tech. Int. 2010, 16, 79–88. [Google Scholar] [CrossRef]

- Alvarez, V.B.; Wolters, C.L.; Vodovotz, Y.; Ji, T. Physical properties of ice cream containing milk protein concentrates. J. Dairy Sci. 2005, 88, 862–871. [Google Scholar] [CrossRef] [PubMed]

- Goff, H.D. Ice Cream. In Advanced DairyChemistry Vol. 1. Proteins, 3rd ed.; Fox, P.F., McSweeney, P.L.H., Eds.; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2003; pp. 1063–1082. [Google Scholar]

- Goff, H.D.; Hartel, R.W. Composition and Formulations. In Ice Cream, 7th ed.; Goff, H.D., Hartel, W., Eds.; Springer: New York, NY, USA, 2013; pp. 19–44. [Google Scholar]

- Warren, M.M.; Hartel, R.W. Structural, compositional, and sensorial properties of United States commercial ice cream products. J. Food Sci. 2014, 79, E2005–E2013. [Google Scholar] [CrossRef] [PubMed]

- Ahn, N.; Park, J.-H.; Chai, C.; Imm, J.-Y. The interaction of milk sphingomyelin and proteins on stability and microstructure of dairy emulsions. J. Dairy Sci. 2022, 105, 3832–3845. [Google Scholar] [CrossRef] [PubMed]

| Sample | Characteristics |

|---|---|

| CH | control sample without the stabilizers and after the mechanical homogenization treatment |

| CU | control sample without the stabilizers and after the ultrasound homogenization treatment |

| IH | sample with the addition of the stabilizers (iota carrageenan, locust bean gum, and xanthan gum) and after the mechanical homogenization treatment |

| IU | sample with the addition of the stabilizers (iota carrageenan, locust bean gum, and xanthan gum) and after the ultrasound homogenization treatment |

| AH | sample with the addition of the stabilizers (the acid hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the mechanical homogenization treatment |

| AU | sample with the addition of the stabilizers (the acid hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the ultrasound homogenization treatment |

| BH | sample with the addition of the stabilizers (the enzymatic β-galactosidase hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the mechanical homogenization treatment |

| BU | sample with the addition of the stabilizers (the enzymatic β-galactosidase hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the ultrasound homogenization treatment |

| LH | sample with the addition of the stabilizers (the enzymatic commercial lactase hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the mechanical homogenization treatment |

| LU | sample with the addition of the stabilizers (the enzymatic commercial lactase hydrolyzates of iota carrageenan, locust bean gum, and xanthan gum) and after the ultrasound homogenization treatment |

| Sample | TSI | Median D50 | |

|---|---|---|---|

| Before Maturation | After Maturation | ||

| CH | 2.5 ± 0.3 b | 22.97 ± 1.13 a | 20.11 ± 0.29 ab |

| CU | 2.2 ± 0.1 ab | 31.12 ± 2.70 bc | 23.55 ± 0.95 ac |

| IH | 7.3 ± 0.3 e | 25.17 ± 0.99 ab | 18.63 ± 0.32 b |

| IU | 2.0 ± 0.2 ab | 28.92 ± 3.67 abc | 26.96 ± 2.82 c |

| AH | 4.1 ± 0.8 c | 25.25 ± 1.62 ab | 20.79 ± 0.51 ab |

| AU | 1.5 ± 0.1 ab | 39.72 ± 1.70 d | 37.14 ± 1.33 de |

| BH | 4.2 ± 0.5 c | 25.41 ± 0.75 ab | 23.95 ± 0.16 ac |

| BU | 1.3 ± 0.1 a | 33.72 ± 0.48 cd | 33.93 ± 0.98 d |

| LH | 5.8 ± 0.2 d | 24.45 ± 1.00 a | 22.87 ± 1.12 ab |

| LU | 1.5 ± 0.1 a | 39.78 ± 4.63 d | 39.75 ± 2.14 e |

| Sample | Before 24 h of Maturation | After 24 h of Maturation | ||||

|---|---|---|---|---|---|---|

| K, 10−3 · Pasn | n | R2 | K, 10−3 · Pasn | n | R2 | |

| CH | 0.006 ± 0.000 a | 0.994 ± 0.004 a | 1.00 | 0.007 ± 0.000 a | 0.984 ± 0.002 a | 0.98 |

| CU | 0.006 ± 0.001 a | 0.991 ± 0.028 a | 1.00 | 0.009 ± 0.005 a | 0.928 ± 0.0098 a | 1.00 |

| IH | 0.028 ± 0.000 cd | 0.871 ± 0.002 a | 1.00 | 0.031 ± 0.000 bcd | 0.862 ± 0.002 a | 0.95 |

| IU | 0.007 ± 0.003 a | 1.168 ± 0.141 b | 0.94 | 0.019 ± 0.014 bc | 1.025 ± 0.296 a | 1.00 |

| AH | 0.033 ± 0.000 d | 0.889 ± 0.005 a | 1.00 | 0.035 ± 0.000 cd | 0.887 ± 0.002 a | 0.98 |

| AU | 0.026 ± 0.000 c | 0.914 ± 0.002 a | 1.00 | 0.028 ± 0.003 bcd | 0.914 ± 0.023 a | 1.00 |

| BH | 0.029 ± 0.002 cd | 0.900 ± 0.013 a | 1.00 | 0.033 ± 0.000 bcd | 0.891 ± 0.003 a | 1.00 |

| BU | 0.020 ± 0.003 b | 0.957 ± 0.042 a | 1.00 | 0.018 ± 0.010 ab | 1.019 ± 0.165 a | 1.00 |

| LH | 0.030 ± 0.004 cd | 0.918 ± 0.026 a | 1.00 | 0.040 ± 0.001 cd | 0.878 ± 0.002 a | 1.00 |

| LU | 0.030 ± 0.001 cd | 0.915 ± 0.009 a | 1.00 | 0.034 ± 0.001 bcd | 0.905 ± 0.006 a | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kot, A.; Kamińska-Dwórznicka, A. Application of Ultrasound Homogenization in Milk Ice Cream Mixes. Appl. Sci. 2024, 14, 8689. https://doi.org/10.3390/app14198689

Kot A, Kamińska-Dwórznicka A. Application of Ultrasound Homogenization in Milk Ice Cream Mixes. Applied Sciences. 2024; 14(19):8689. https://doi.org/10.3390/app14198689

Chicago/Turabian StyleKot, Anna, and Anna Kamińska-Dwórznicka. 2024. "Application of Ultrasound Homogenization in Milk Ice Cream Mixes" Applied Sciences 14, no. 19: 8689. https://doi.org/10.3390/app14198689

APA StyleKot, A., & Kamińska-Dwórznicka, A. (2024). Application of Ultrasound Homogenization in Milk Ice Cream Mixes. Applied Sciences, 14(19), 8689. https://doi.org/10.3390/app14198689