Performance Assessment of Flat Plate Solar Collector Using Simple and Hybrid Carbon Nanofluids at Low Thermal Capacity

Abstract

Featured Application

Abstract

1. Introduction

1.1. Metal Oxide Nanofluids in FSCs

1.2. Carbon Nanofluids in FSCs

2. Materials and Methods

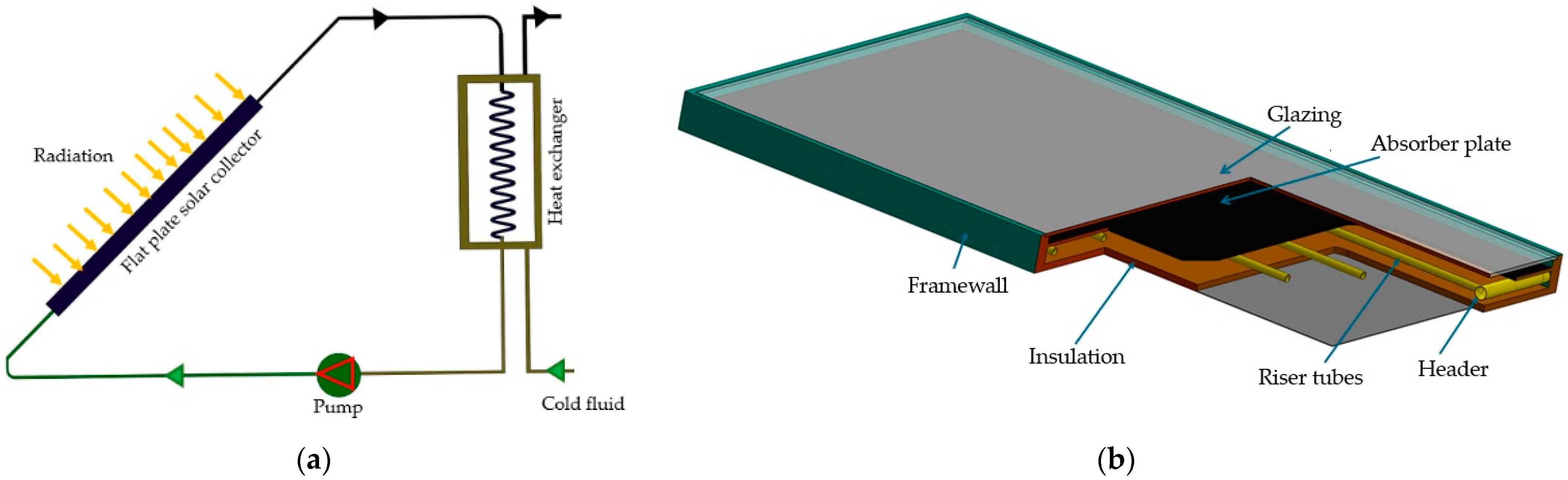

2.1. Phisical Model

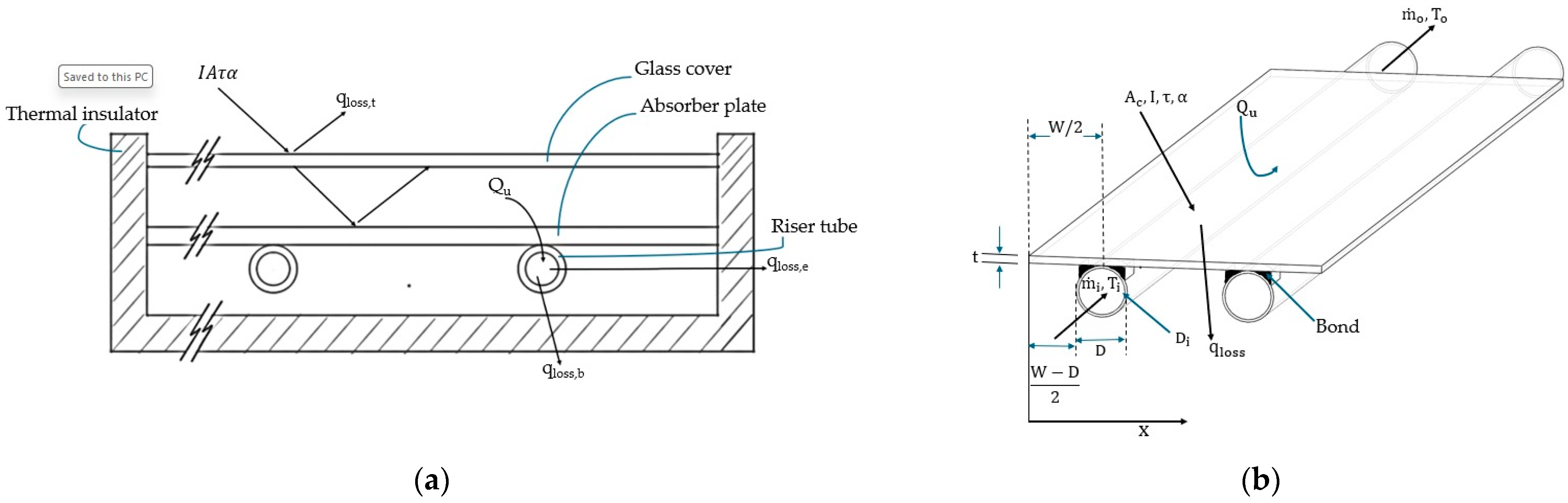

2.2. Mathematicl Modeling

2.2.1. Governing Equations

2.2.2. Heat Removal and Collector Efficiency Factors

2.2.3. Convection Heat Transfer Coefficient

2.2.4. Overall Heat Loss Coefficient

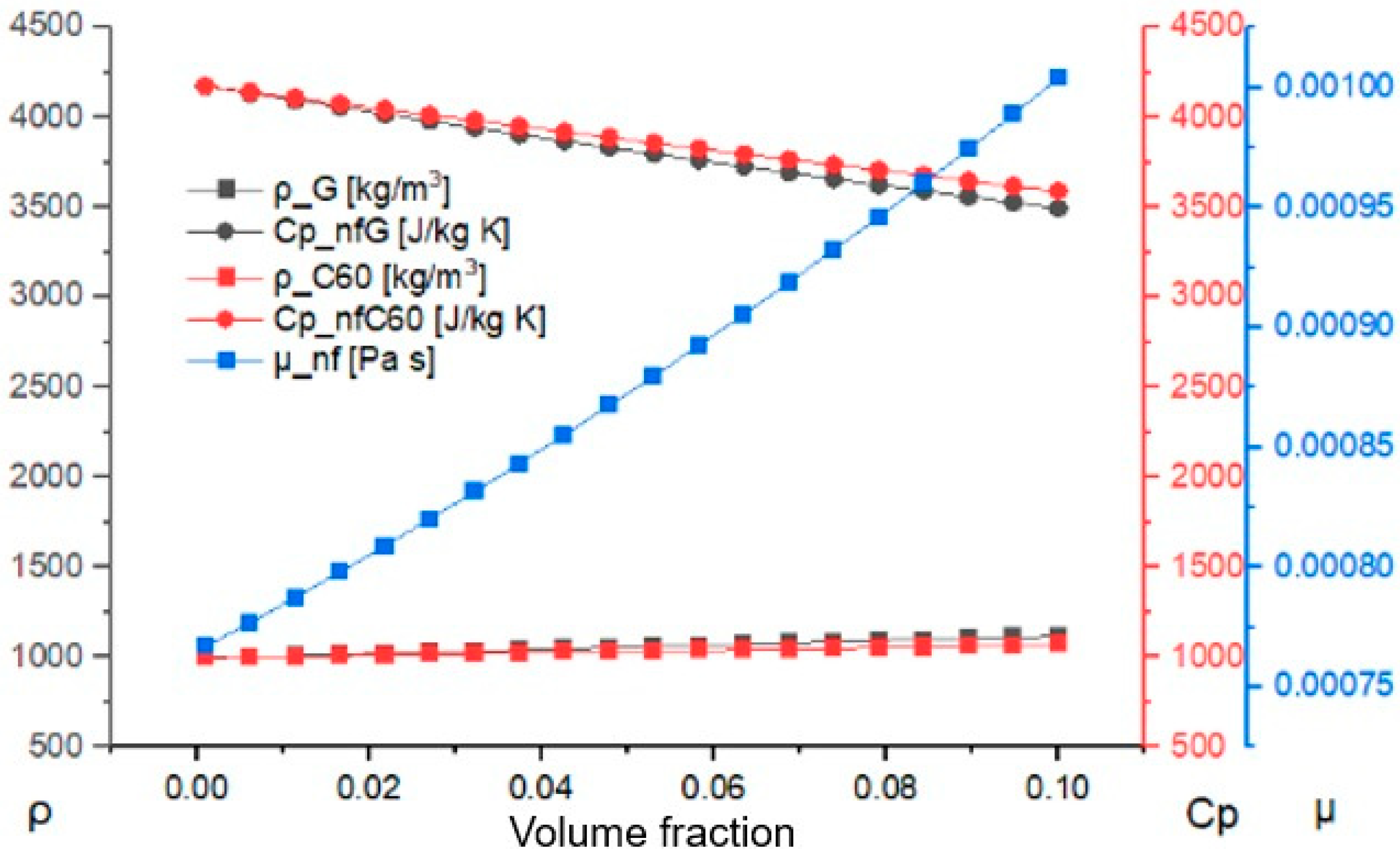

2.2.5. Simple Nanofluid Properties

2.2.6. Hybrid Nanofluid Properties

2.3. Model Validation

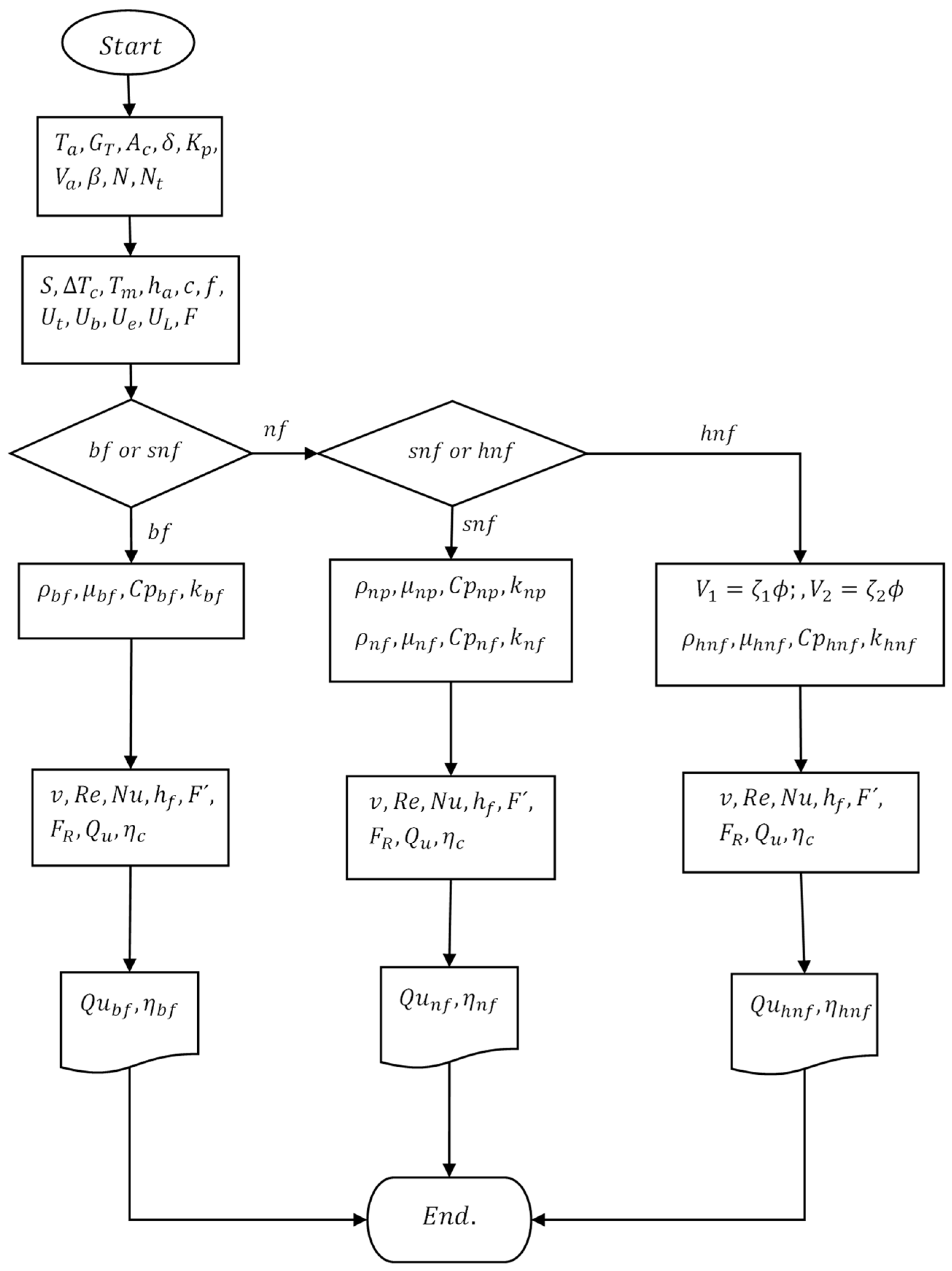

2.4. Simulation

Assumptions

- Fully developed flow and stable conditions.

- The ambient temperature at the top and bottom of the collector are the same.

- Negligible addition to the collector surface by the header.

- In all pipes, the fluid is in uniform flow.

3. Results and Discussion

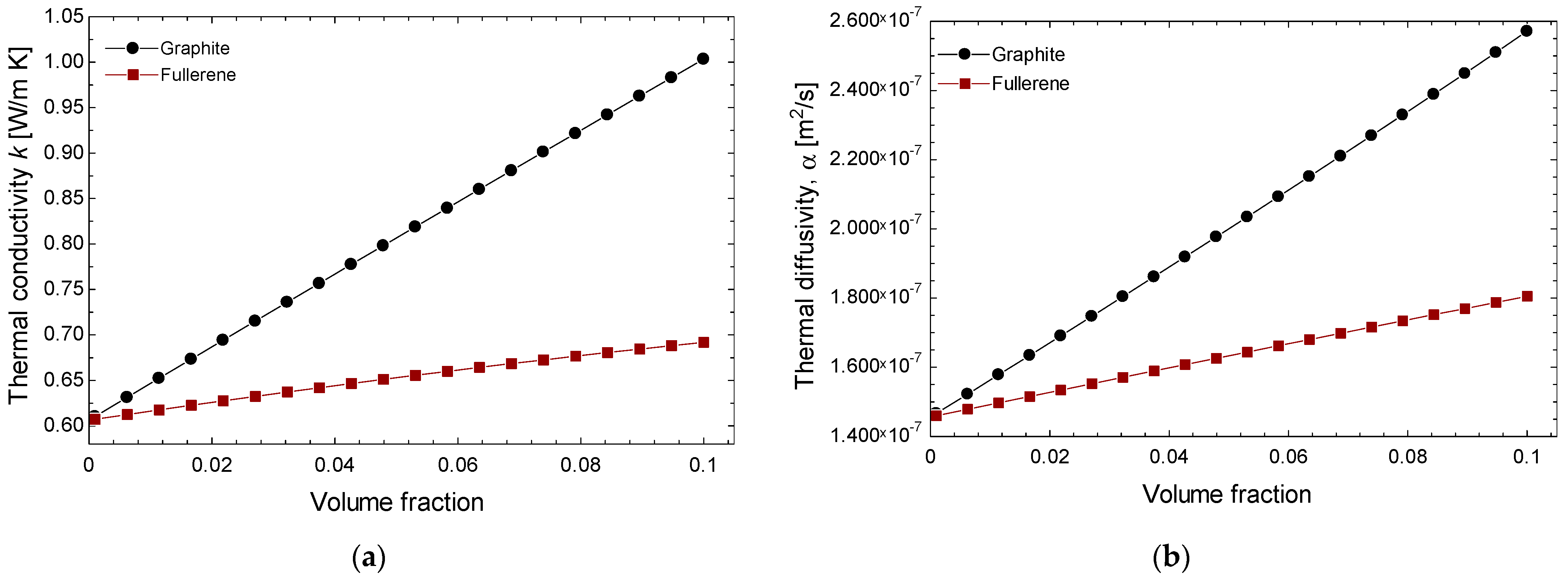

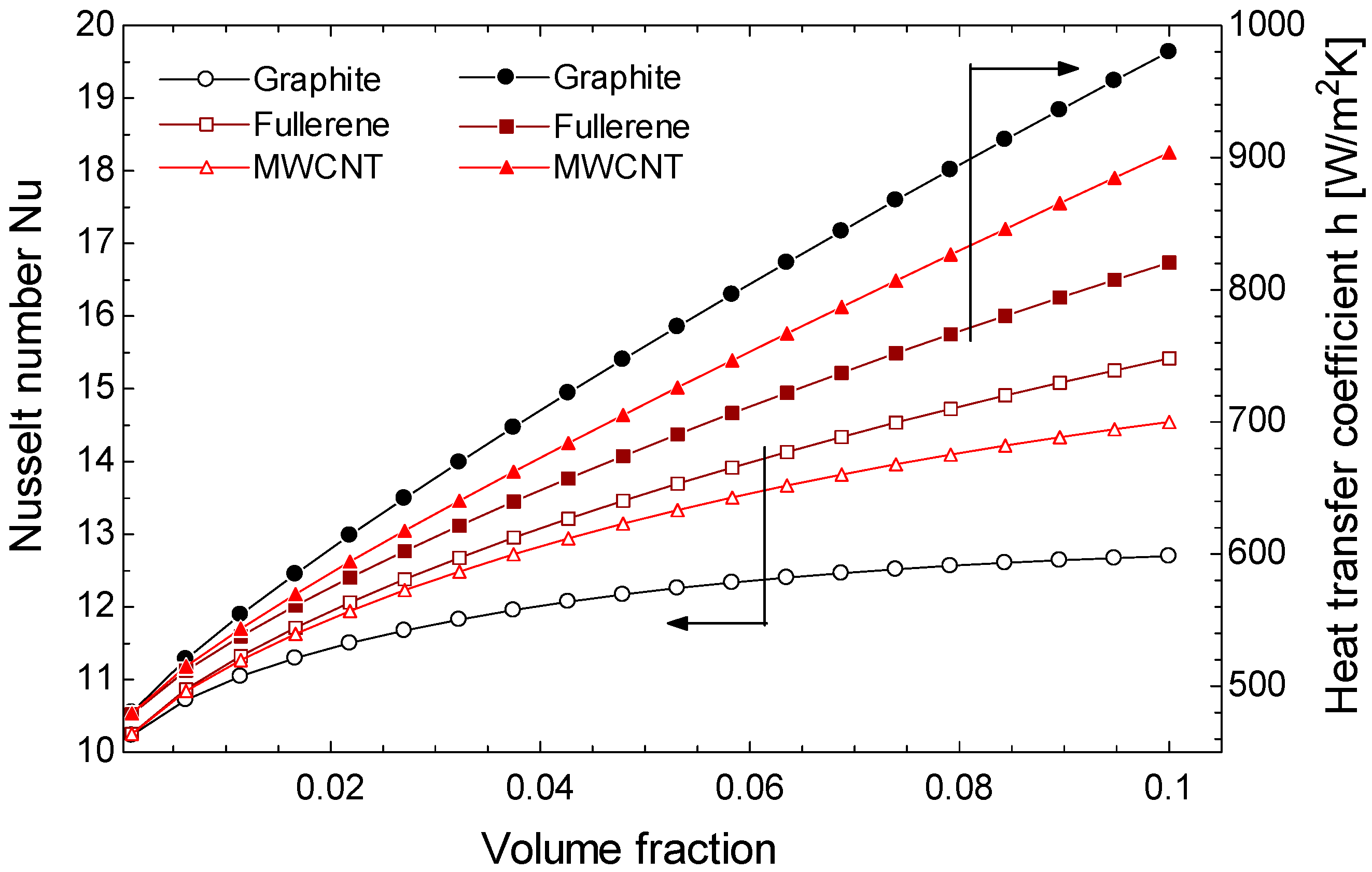

3.1. FSCs with Graphite and Fullerene Nanofluids

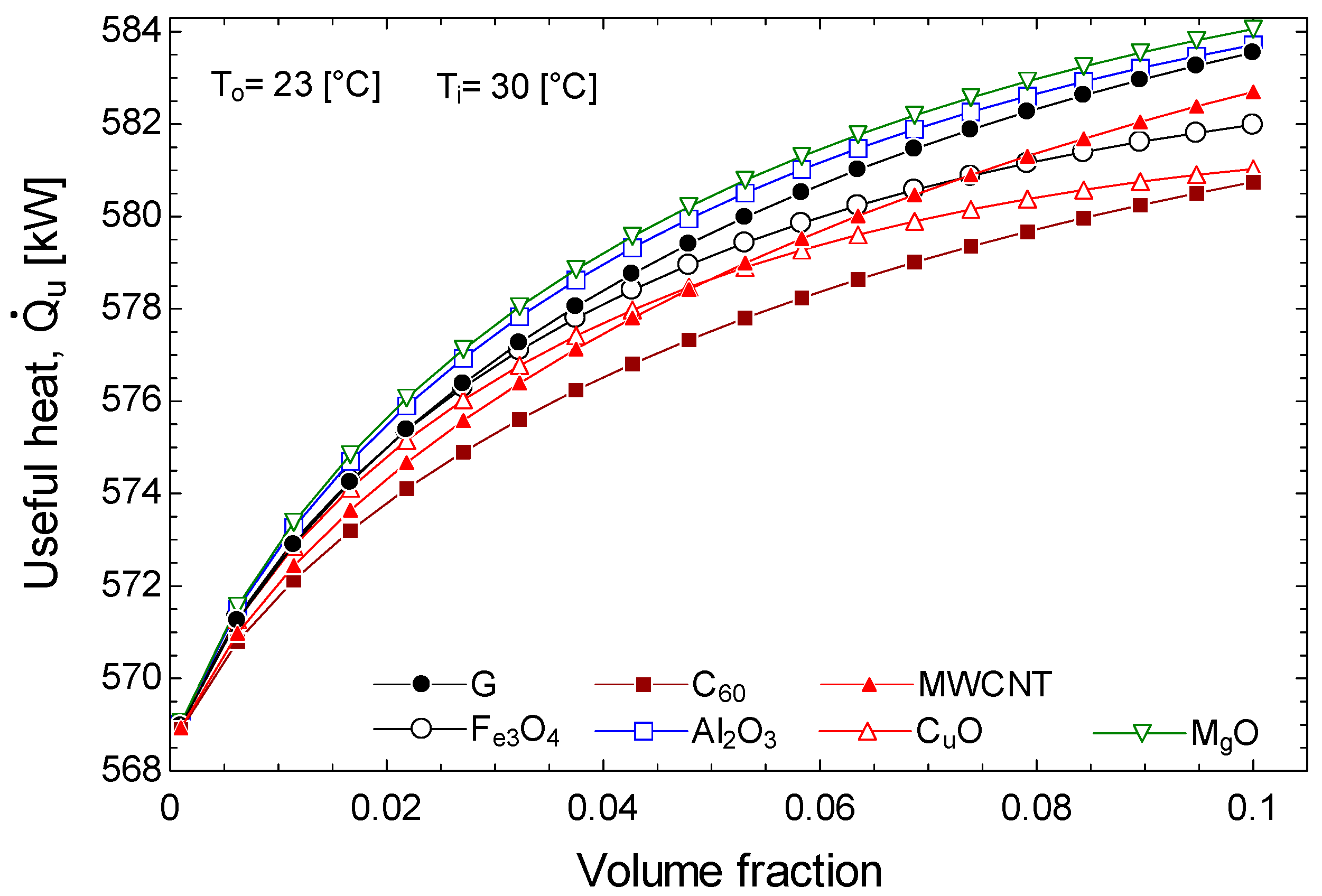

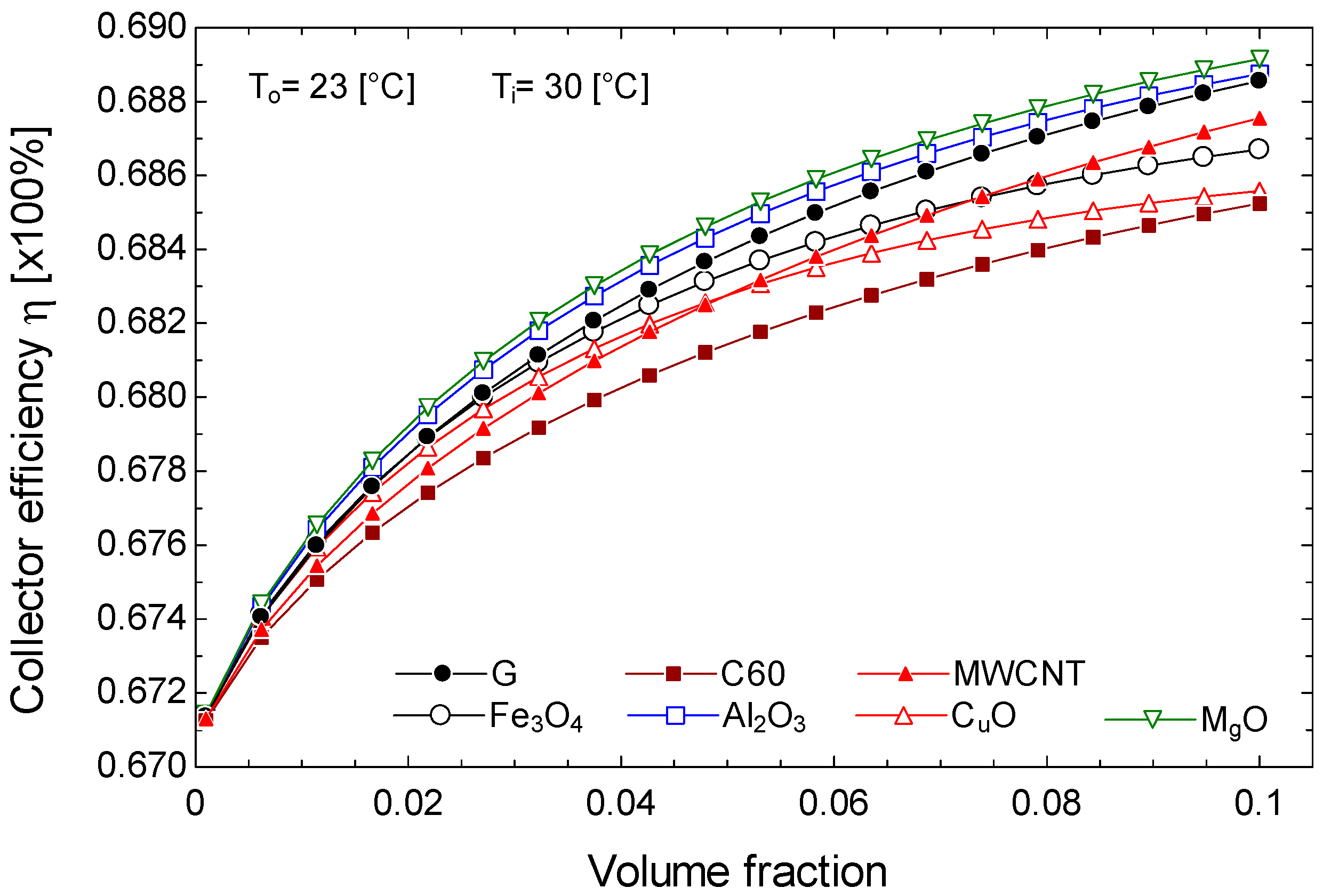

3.2. FSCs with Simple Metal Oxide and Carbon Nanofluids

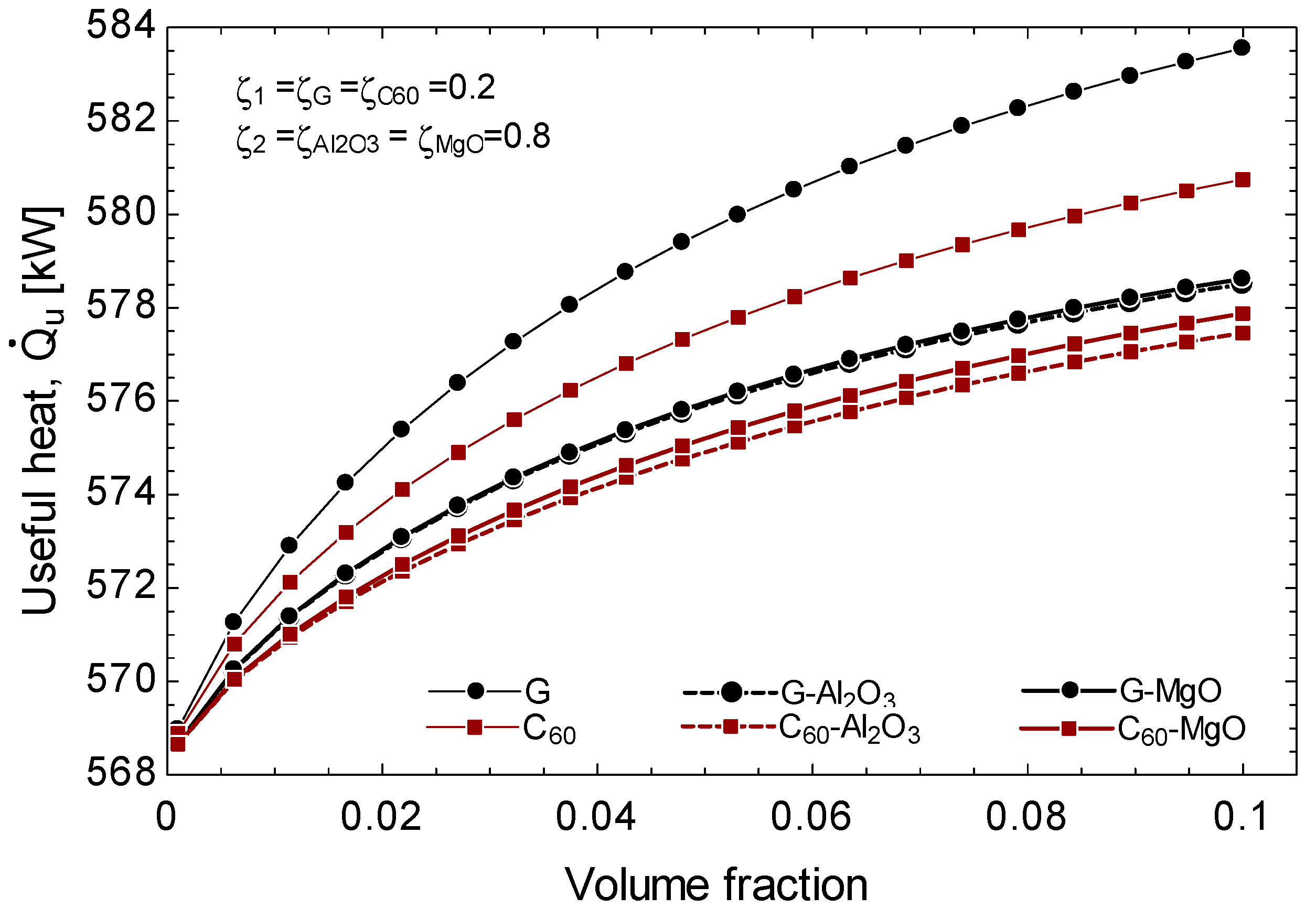

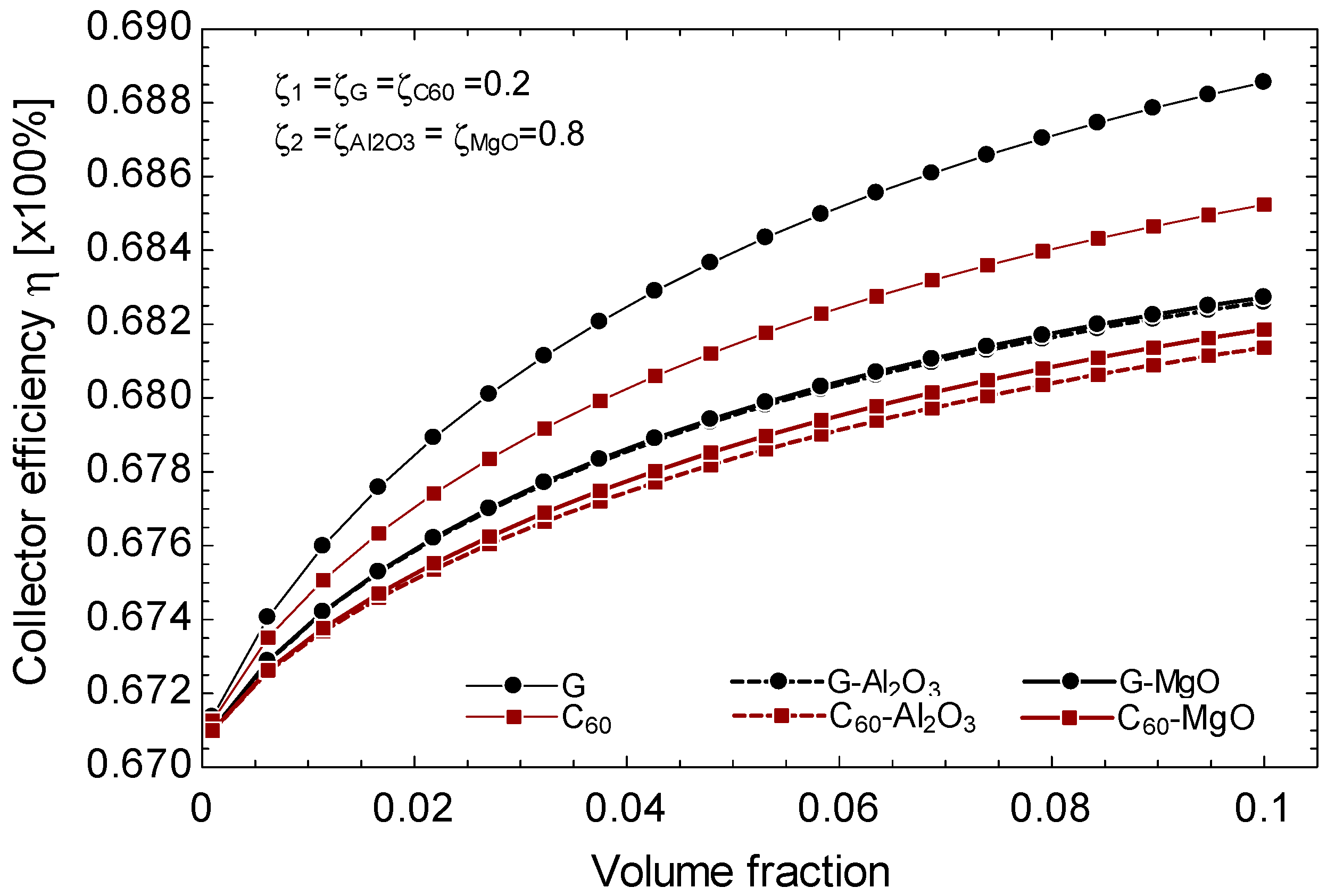

3.3. FSCs with Hybrid Carbon Nanofluids

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | area (m2), absorber |

| b | joint length (m) |

| C | conductance (W/m K) |

| Cp | heat capacity (kJ/kg K) |

| diameter (m) | |

| standard fin efficiency | |

| heat removal factor | |

| solar collector efficiency factor | |

| heat transfer coefficient (W/m2 K) | |

| solar radiation (W/m2) | |

| TC (W/m K) | |

| mass flow (kg/s) | |

| Nusselt number | |

| Prandtl number | |

| heat flux (W) | |

| global heat transfer coefficient (W/m K) | |

| Reynolds number | |

| temperature (K) | |

| distance between fins (m) | |

| bottom insulation thickness (m) | |

| Subscripts | |

| ambient | |

| b | joint between fins and pipes, lower loss |

| base fluid | |

| absorber | |

| border surface | |

| glass | |

| internal | |

| hybrid nanofluids | |

| inlet, internal | |

| external | |

| outlet | |

| nanofluids | |

| nanoparticle | |

| flat plate | |

| useful | |

| Greek symbols | |

| absorptance | |

| collector inclination angle (°) | |

| absorber thickness (m) | |

| emissivity | |

| efficiency | |

| average joint thickness (m) | |

| viscosity (Pa s) | |

| volume fraction (%) | |

| density (kg/m3) | |

| Stefan Boltzmann’s constant (W/m2 K4) | |

| transmittance | |

| lateral losses | |

| volume concentration | |

References

- Said, Z.; Saidur, R.; Rahim, N.A. Optical Properties of Metal Oxides Based Nanofluids. Int. Commun. Heat Mass Transf. 2014, 59, 46–54. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Lab. (ANL): Argonne, IL, USA, 1995; pp. 1–2. [Google Scholar]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and Heat Transfer Study of Dispersed Fluids with Submicron Metallic Oxide Particles. Exp. Heat Transf. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Madhesh, D.; Kalaiselvam, S. Experimental Analysis of Hybrid Nanofluid as a Coolant. Procedia Eng. 2014, 97, 1667–1675. [Google Scholar] [CrossRef]

- Alawi, O.A.; Kamar, H.M.; Mallah, A.R.; Mohammed, H.A.; Kazi, S.N.; Che Sidik, N.A.; Najafi, G. Nanofluids for Flat Plate Solar Collectors: Fundamentals and Applications. J. Clean. Prod. 2021, 291, 125725. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Synthesis of Al2O3-Cu/Water Hybrid Nanofluids Using Two Step Method and Its Thermo Physical Properties. Colloids Surf. A Physicochem. Eng. Asp. 2011, 388, 41–48. [Google Scholar] [CrossRef]

- Kasaeian, A.; Eshghi, A.T.; Sameti, M. A Review on the Applications of Nanofluids in Solar Energy Systems. Renew. Sustain. Energy Rev. 2015, 43, 584–598. [Google Scholar] [CrossRef]

- Hendraningrat, L.; Torsæter, O. Metal Oxide-Based Nanoparticles: Revealing Their Potential to Enhance Oil Recovery in Different Wettability Systems. Appl. Nanosci. 2015, 5, 181–199. [Google Scholar] [CrossRef]

- Minakov, A.V.; Rudyak, V.Y.; Pryazhnikov, M.I. Rheological Behavior of Water and Ethylene Glycol Based Nanofluids Containing Oxide Nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2018, 554, 279–285. [Google Scholar] [CrossRef]

- Yousefi, T.; Shojaeizadeh, E.; Veysi, F.; Zinadini, S. An Experimental Investigation on the Effect of PH Variation of MWCNT-H2O Nanofluid on the Efficiency of a Flat-Plate Solar Collector. Sol. Energy 2012, 86, 771–779. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Chauhan, D.S. Performance Augmentation in Flat Plate Solar Collector Using MgO/Water Nanofluid. Energy Convers. Manag. 2016, 124, 607–617. [Google Scholar] [CrossRef]

- Sint, N.K.C.; Choudhury, I.A.; Masjuki, H.H.; Aoyama, H. Theoretical Analysis to Determine the Efficiency of a CuO-Water Nanofluid Based-Flat Plate Solar Collector for Domestic Solar Water Heating System in Myanmar. Sol. Energy 2017, 155, 608–619. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Tiwari, S.; Chauhan, D.S. Performance Analysis of Hybrid Nanofluids in Flat Plate Solar Collector as an Advanced Working Fluid. Sol. Energy 2018, 167, 231–241. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Saedodin, S.; Biglari, M.; Rostamian, H. Experimental Investigation of Thermal Conductivity of CNTs-Al2O3/Water: A Statistical Approach. Int. Commun. Heat Mass Transf. 2015, 69, 29–33. [Google Scholar] [CrossRef]

- Ahmadi, A.; Ganji, D.D.; Jafarkazemi, F. Analysis of Utilizing Graphene Nanoplatelets to Enhance Thermal Performance of Flat Plate Solar Collectors. Energy Convers. Manag. 2016, 126, 1–11. [Google Scholar] [CrossRef]

- Alawi, O.A.; Mohamed Kamar, H.; Mallah, A.R.; Kazi, S.N.; Sidik, N.A.C. Thermal Efficiency of a Flat-Plate Solar Collector Filled with Pentaethylene Glycol-Treated Graphene Nanoplatelets: An Experimental Analysis. Sol. Energy 2019, 191, 360–370. [Google Scholar] [CrossRef]

- Tong, Y.; Chi, X.; Kang, W.; Cho, H. Comparative Investigation of Efficiency Sensitivity in a Flat Plate Solar Collector According to Nanofluids. Appl. Therm. Eng. 2020, 174, 115346. [Google Scholar] [CrossRef]

- Alim, M.A.; Abdin, Z.; Saidur, R.; Hepbasli, A.; Khairul, M.A.; Rahim, N.A. Analyses of Entropy Generation and Pressure Drop for a Conventional Flat Plate Solar Collector Using Different Types of Metal Oxide Nanofluids. Energy Build. 2013, 66, 289–296. [Google Scholar] [CrossRef]

- Liang, R.; Ma, L.; Zhang, J. Thermal performance test of U-type evacuated glass tubular solar collector filled with graphite. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010; pp. 4066–4069. [Google Scholar]

- Chandrashekara, M.; Yadav, A. Experimental Study of Exfoliated Graphite Solar Thermal Coating on a Receiver with a Scheffler Dish and Latent Heat Storage for Desalination. Sol. Energy 2017, 151, 129–145. [Google Scholar] [CrossRef]

- Nagaraj, A. Experimental Study of Epoxy Based Graphite Coating on Parabolic Trough Solar Collector. J. Phys. Conf. Ser. 2022, 2180, 012001. [Google Scholar] [CrossRef]

- Lamosa, R.A.; Motovoy, I.; Khliiev, N.; Nikulin, A.; Khliyeva, O.; Moita, A.S.; Krupanek, J.; Grosu, Y.; Zhelezny, V.; Moreira, A.L.; et al. Tetralin + Fullerene C60 Solutions for Thermal Management of Flat-Plate Photovoltaic/Thermal Collector. Energy Convers. Manag. 2021, 248, 114799. [Google Scholar] [CrossRef]

- Barrera, E.E.; Medina, A.; Díaz-Barriga, L.G.; Zacarías, A.; Rubio, J.d.J.; Gutiérrez, G.L.; Cruz, J.M.; De Vega, M.; García, N.; Venegas, M. Performance Assessment of Low-Temperature Solar Collector with Fullerenes C60 Manufactured at Low Cost in an Emerging Country. Appl. Sci. 2022, 12, 3161. [Google Scholar] [CrossRef]

- Hawwash, A.A.; Ahamed, M.; Nada, S.A.; Radwan, A.; Abdel-Rahman, A.K. Thermal Analysis of Flat Plate Solar Collector Using Different Nanofluids and Nanoparticles Percentages. IEEE Access 2021, 9, 52053–52066. [Google Scholar] [CrossRef]

- García, A.; Martin, R.H.; Pérez-García, J. Experimental Study of Heat Transfer Enhancement in a Flat-Plate Solar Water Collector with Wire-Coil Inserts. Appl. Therm. Eng. 2013, 61, 461–468. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems, 3rd ed.; Academic Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Kletn, S.A. Calculation of Fiat-Plate Collector Loss Coefficients; Pergamon Press: Oxford, UK, 1975; Volume 17. [Google Scholar]

- Xuan, Y.; Li, Q.; Hu, W. Aggregation Structure and Thermal Conductivity of Nanofluids. AIChE J. 2003, 49, 1038–1043. [Google Scholar] [CrossRef]

- Yang, J.C.; Li, F.C.; Zhou, W.W.; He, Y.R.; Jiang, B.C. Experimental Investigation on the Thermal Conductivity and Shear Viscosity of Viscoelastic-Fluid-Based Nanofluids. Int. J. Heat. Mass. Transf. 2012, 55, 3160–3166. [Google Scholar] [CrossRef]

- Hamilton, R.L.; Crosser, O.K. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Varamesh, A.; Nait Amar, M.; Husein, M.M.; Dong, M. On the Evaluation of Thermal Conductivity of Nanofluids Using Advanced Intelligent Models. Int. Commun. Heat Mass Transf. 2020, 118, 104825. [Google Scholar] [CrossRef]

- Sarkar, S.; Pal, P.; Ghosh, N.K. Enhancing the Thermal Conductivity and Viscosity of Ethylene Glycol-Based Single-Walled Carbon Nanotube (SWCNT) Nanofluid: An Investigation Utilizing Equilibrium Molecular Dynamics Simulation. Chem. Thermodyn. Therm. Anal. 2024, 16, 100142. [Google Scholar] [CrossRef]

- Minea, A.A. Challenges in Hybrid Nanofluids Behavior in Turbulent Flow: Recent Research and Numerical Comparison. Renew. Sustain. Energy Rev. 2017, 71, 426–434. [Google Scholar] [CrossRef]

- Hajabdollahi, F.; Premnath, K. Numerical Study of the Effect of Nanoparticles on Thermoeconomic Improvement of a Solar Flat Plate Collector. Appl. Therm. Eng. 2017, 127, 390–401. [Google Scholar] [CrossRef]

- Farahat, S.; Sarhaddi, F.; Ajam, H. Exergetic Optimization of Flat Plate Solar Collectors. Renew. Energy 2009, 34, 1169–1174. [Google Scholar] [CrossRef]

- Klein, S.A. Engineering Equation Solver, f-Chart Software. V11.926. Available online: https://fchartsoftware.com/ees/ (accessed on 10 July 2024).

- Cengel, Y.A.; Boles, M.A. Termodinámica, 7th ed.; Mc Graw Hill: New York, NY, USA, 2012. [Google Scholar]

- Khan, A.; Shabir, D.; Ahmad, P.; Khandaker, M.U.; Faruque, M.R.I.; Din, I.U. Biosynthesis and Antibacterial Activity of MgO-NPs Produced from Camellia-Sinensis Leaves Extract. Mater. Res. Express 2021, 8, 015402. [Google Scholar] [CrossRef]

- Valencia, A.; Zacarías, A.; Eduardo, E.; De Jesús, J.; Jiménez, C.; Gustavo, J. Tema A4 Termofluidos “ Evaluación Numérica Del Rendimiento de Un Colector Solar de Absorción Directa Usando Nanopartículas de Grafito”. Congr. SOMIM 2021, 194–200. [Google Scholar]

- Mostafizur, R.M.; Rasul, M.G.; Nabi, M.N. Energy and Exergy Analyses of a Flat Plate Solar Collector Using Various Nanofluids: An Analytical Approach. Energies 2021, 14, 4305. [Google Scholar] [CrossRef]

- Sarviya, R.M.; Fuskele, V. Review on Thermal Conductivity of Nanofluids. Mater. Today Proc. 2017, 4, 4022–4031. [Google Scholar] [CrossRef]

| Nanofluids | Metal Oxide | Carbon | Metal–Oxide–Metal | Metal–Oxide–Carbon | Reference |

|---|---|---|---|---|---|

| Fe3O4 | x | [8,17] | |||

| Al2O3 | x | [5,8,9,10,16,17,18] | |||

| MgO | x | [5,8,11,13] | |||

| CuO | x | [5,9,12,17,18] | |||

| TiO2 | x | [5,8,9,18] | |||

| SiO2 | x | [5,9,16,18] | |||

| ZrO2 | x | [5,9] | |||

| CeO2 | x | [8] | |||

| ZnO | x | [8] | |||

| MWCNT | x | [5,13,17] | |||

| SWCNT | x | [5] | |||

| Graphene | x | [15,16] | |||

| Al2O3-Cu | x | [6] | |||

| CuO-MWCNT | x | [13] | |||

| MgO-MWCNT | x | [13] |

| Parameter | Value |

|---|---|

| Collector area, Ac, [m2] | 1.13 |

| Number of covers, N | 1 |

| Number of riser pipes, Nt | 6 |

| [m] | 1.13 |

| [m] | 1 |

| , [m] | 0.013 |

| , [m] | 0.016 |

| [m] | 0.166 |

| Plate thickness, δ [m] | 0.0002 |

| ] | 384 |

| 0.84 | |

| 0.05 | |

| ] | 0.038 |

| [m] | 0.0254 |

| Transmittance, Absorbance, τα, taken from [34] | 0.84 |

| Parameter | [35] | This Work | Error, [%] |

|---|---|---|---|

| Useful heat, W | 2055 | 2010 | 2.1 |

| Efficiency, % | 44.9 | 45 | −0.22 |

| Nanoparticles | Density (kg/m3) | Specific Heat (J/kg K) | TC, (W/m K) | Reference |

|---|---|---|---|---|

| Fe3O4 | 4950 | 670 | 6 | [17] |

| Al2O3 | 3600 | 880 | 30 | [24] |

| CuO | 6000 | 551 | 33 | [24] |

| MgO | 3560 | 955 | 45 | [38] |

| MWCNT | 1350 | 650 | 1500 | [17] |

| SWCNT | 2100 | 600 | 3500 | [1] |

| Graphite, G | 2210 | 709 | 1950 | [39] |

| Fullerene, C60 | 1720 | 506.7 | 0.4 | [23] |

| Parameter | Range |

|---|---|

| FPSC inclination, β [°] data from [34] | 20 |

| Irradiance, GT, W/m2 | 750 |

| Air velocity, Va, m/s | 5 |

| Inlet temperature, Ti [°C] | 30, 40 y 50 |

| , [kg/s] | 0.01–0.1 |

| Nanoparticle diameter, dp, nm | 15 |

| 0.001–0.1 | |

| 0.2 | |

| 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz, J.M.; Crepaldi, S.A.; Gutiérrez-Urueta, G.L.; Rubio, J.d.J.; Zacarías, A.; Jiménez, C.; Romage, G.; Jiménez, J.A.; López, A.; Balcazar, R. Performance Assessment of Flat Plate Solar Collector Using Simple and Hybrid Carbon Nanofluids at Low Thermal Capacity. Appl. Sci. 2024, 14, 8732. https://doi.org/10.3390/app14198732

Cruz JM, Crepaldi SA, Gutiérrez-Urueta GL, Rubio JdJ, Zacarías A, Jiménez C, Romage G, Jiménez JA, López A, Balcazar R. Performance Assessment of Flat Plate Solar Collector Using Simple and Hybrid Carbon Nanofluids at Low Thermal Capacity. Applied Sciences. 2024; 14(19):8732. https://doi.org/10.3390/app14198732

Chicago/Turabian StyleCruz, José Michael, Sandra Angélica Crepaldi, Geydy Luz Gutiérrez-Urueta, José de Jesús Rubio, Alejandro Zacarías, Cuauhtémoc Jiménez, Guerlin Romage, José Alfredo Jiménez, Abel López, and Ricardo Balcazar. 2024. "Performance Assessment of Flat Plate Solar Collector Using Simple and Hybrid Carbon Nanofluids at Low Thermal Capacity" Applied Sciences 14, no. 19: 8732. https://doi.org/10.3390/app14198732

APA StyleCruz, J. M., Crepaldi, S. A., Gutiérrez-Urueta, G. L., Rubio, J. d. J., Zacarías, A., Jiménez, C., Romage, G., Jiménez, J. A., López, A., & Balcazar, R. (2024). Performance Assessment of Flat Plate Solar Collector Using Simple and Hybrid Carbon Nanofluids at Low Thermal Capacity. Applied Sciences, 14(19), 8732. https://doi.org/10.3390/app14198732