Abstract

Surface roughness is a critical factor in restorative dentistry, as it influences both the esthetic and functional outcomes of dental materials. The choice of abrasive powders used during the air polishing of dental restorations can significantly impact the surface roughness, potentially affecting the longevity and performance of the restoration. This study aimed to compare the effects of three different air-polishing powders—sodium bicarbonate, erythritol, and glycine—on the surface roughness of a 3M Filtek™ Supreme XTE (3M St. Paul, Minnesota 55144-1000) United States composite resin and a Fuji™ IX glass ionomer cement. This study also examined how different application times (5 and 10 s) influenced these outcomes. Materials and Methods: An in vitro study was conducted using standardized blocks of 3M Filtek™ Supreme XTE composite resin and Fuji™ IX glass ionomer cement. Each material was treated with sodium bicarbonate, erythritol, and glycine at two different exposure times (5 s and 10 s) using a professional air-polishing device. Surface roughness (Ra) was measured before and after the treatments using a contact profilometer. The data were statistically analyzed using ANOVA and Tukey’s post hoc test to compare the mean roughness values among the different groups, with a significance level set at p < 0.05. Results: The results showed significant differences in surface roughness between the materials, powders, and application times. The composite resin exhibited lower roughness and variability compared with the Fuji™ IX, indicating a more uniform and predictable surface. Sodium bicarbonate produced the highest roughness values, particularly after 10 s of application, while glycine resulted in the lowest roughness with greater variability. Erythritol produced intermediate roughness with moderate variability. For the Fuji™ IX, sodium bicarbonate caused the greatest variability in roughness, while glycine produced the smoothest surfaces. The ANOVA results confirmed significant differences in mean roughness among the abrasive groups, with Tukey’s post hoc test showing that glycine had significantly lower roughness than sodium bicarbonate, and erythritol had higher roughness than glycine but was lower than sodium bicarbonate. Conclusions: This study demonstrated that the choice of air-polishing powder and application time significantly affected the surface roughness of both 3M Filtek™ Supreme XTE composite resin and Fuji™ IX glass ionomer cement. Glycine consistently produced the smoothest surfaces, making it a preferable option for clinical scenarios where minimal surface roughness is desired. Sodium bicarbonate, while effective in cleaning, resulted in rougher surfaces, particularly after longer exposure times. These findings suggest that careful selection of polishing powders can enhance the esthetic and functional outcomes of dental restorations, contributing to their longevity.

1. Introduction

Dental restorations are a fundamental aspect of modern dentistry, playing a crucial role in restoring the functionality and esthetics of patients’ teeth. The success of these restorations depends on various factors, one of the most important being the surface characteristics of the materials used [1]. Surface roughness, in particular, is a critical parameter that can significantly influence the longevity and performance of dental restorations. A rough surface not only increases the potential for plaque accumulation and bacterial colonization but also affects the wear resistance of the material and the adjacent dentition [2]. Therefore, understanding and controlling the surface roughness of restorative materials is essential for achieving optimal clinical outcomes.

Two commonly used restorative materials in pediatric dentistry are composite resins and glass ionomer cements, such as Fuji. Composite resins are favored for their excellent esthetic properties and strong bonding capabilities, making them suitable for a wide range of dental applications [3]. On the other hand, glass ionomer cements are valued for their ability to release fluoride and their biocompatibility, making them particularly useful in cases where fluoride release is beneficial, such as in pediatric dentistry and in patients with a high risk of caries [4]. Despite their widespread use, these materials can exhibit varying degrees of surface roughness depending on the clinical procedures and materials used during their placement and finishing [5].

The polishing and finishing of dental restorations are crucial steps that can significantly influence the final surface roughness of the material [6]. Traditionally, polishing has been performed using rotary instruments and polishing pastes, but the advent of air-polishing systems has introduced new possibilities. Air polishing involves the use of abrasive powders propelled by compressed air, which can efficiently remove plaque and stains from the surface of teeth and restorations. Commonly used powders in air polishing include sodium bicarbonate, erythritol, and glycine, each of which has distinct physical and chemical properties that influence their abrasiveness and effect on dental surfaces [7,8].

Sodium bicarbonate, one of the earliest powders used in air polishing, is known for its effectiveness in plaque removal. However, its relatively high abrasiveness can lead to increased surface roughness, which may compromise the integrity of the restoration [9]. Erythritol, a sugar alcohol, has gained popularity due to its lower abrasiveness compared with bicarbonate, making it gentler on the tooth surface while still effectively removing biofilm [7]. Glycine, an amino acid, is the least abrasive of the three and is often recommended for use on sensitive surfaces and subgingival applications [8].

The impact of these abrasive powders on different dental materials has been the subject of several studies. For instance, research has shown that the use of bicarbonate can lead to a significant increase in surface roughness, particularly in composite resins, which could potentially affect the material’s wear resistance and susceptibility to bacterial adhesion [9]. In contrast, glycine has been reported to produce a smoother surface, which may be advantageous in minimizing bacterial colonization and prolonging the restoration’s lifespan [10]. However, the extent of these effects can vary depending on factors such as exposure time and the specific type of restorative material being treated [11].

Despite these insights, there remains a lack of comprehensive studies that systematically compare the effects of different air-polishing powders on both composite resins and glass ionomer cements under controlled conditions [12]. Most existing studies focus on a single material or powder, leaving clinicians with limited information when it comes to selecting the most appropriate polishing agent for different clinical scenarios [13]. Moreover, the influence of exposure time—an important variable in clinical practice—on the surface roughness of these materials has not been fully explored [14]. This study aims to address these gaps by conducting a detailed comparative analysis of the effects of sodium bicarbonate, erythritol, and glycine on the surface roughness of 3M Filtek™ Supreme XTE composite resin and Fuji™ IX glass ionomer cement. Using advanced statistical methods, including ANOVA and post hoc tests, this research seeks to determine the optimal polishing powder and exposure time for achieving the smoothest possible surface on these widely used restorative materials. The findings of this study will provide valuable guidance for clinicians, helping them make informed decisions about the selection of polishing agents and techniques to ensure the best possible outcomes for their patients. Finally, the null hypotheses of the study are as follows:

The different air-polishing powders (sodium bicarbonate, erythritol, glycine) do not cause a statistically significant difference in the surface roughness of 3M Filtek™ Supreme XTE composite resin.

The different air-polishing powders do not cause a statistically significant difference in the surface roughness of Fuji™ IX glass ionomer cement.

The application times (5 s vs. 10 s) do not cause a statistically significant difference in surface roughness for both materials.

2. Materials and Methods

2.1. Study Design

This in vitro study was conducted to assess the impact of three different air-polishing powders—sodium bicarbonate, erythritol, and glycine—on the surface roughness of two dental materials: 3M Filtek™ Supreme XTE composite resin and Fuji IX™ (GC Corporation, Tokyo, Japan). This study was designed to simulate clinical conditions by varying the exposure times during air polishing to evaluate how these factors influence surface roughness.

2.2. Sample Preparation

A total of 24 standardized blocks of dental materials were prepared, including 12 blocks of 3M Filtek™ Supreme XTE composite resin and 12 blocks of Fuji IX™ glass ionomer cement. Each block measured 10 mm × 10 mm × 2 mm. The surfaces of these blocks were polished using silicon carbide papers up to 4000 grit under water cooling to create a smooth baseline. After polishing, the blocks were ultrasonically cleaned in distilled water for 10 min to remove debris and stored in a 0.9% saline solution at room temperature until use [15].

2.3. Air-Polishing Procedure

The air polishing was performed using a professional air-polishing device EMS Airflow® Prophylaxis Master (Electro Medical Systems, Nyon, Switzerland). The three different powders—sodium bicarbonate, erythritol, and glycine—were applied at a constant air pressure of 60 psi. The nozzle was held at a distance of 4 mm from the sample surface at a 90-degree angle. The procedure was carried out for two distinct exposure times: 5 s and 10 s. These times were selected based on previous studies, which demonstrated that such durations are sufficient to evaluate the effects on surface roughness without causing excessive damage [10]. Each combination of material, powder, and exposure time was treated as a separate group, resulting in the following 12 groups:

- -

- Group 1: 3M Filtek™ Supreme XTE + sodium bicarbonate (5 s);

- -

- Group 2: 3M Filtek™ Supreme XTE + sodium bicarbonate (10 s);

- -

- Group 3: 3M Filtek™ Supreme XTE + erythritol (5 s);

- -

- Group 4: 3M Filtek™ Supreme XTE + erythritol (10 s);

- -

- Group 5: 3M Filtek™ Supreme XTE + glycine (5 s);

- -

- Group 6: 3M Filtek™ Supreme XTE + glycine (10 s);

- -

- Group 7: Fuji™ IX + sodium bicarbonate (5 s);

- -

- Group 8: Fuji™ IX + sodium bicarbonate (10 s);

- -

- Group 9: Fuji™ IX + erythritol (5 s);

- -

- Group 10: Fuji™ IX + erythritol (10 s);

- -

- Group 11: Fuji™ IX + glycine (5 s);

- -

- Group 12: Fuji™ IX + glycine (10 s).

Each group contained 2 samples, with a total of 24 polishing procedures performed.

The sodium bicarbonate, erythritol, and glycine powders used in this study were the following:

- ▪

- Sodium bicarbonate: EMS Airflow® Plus (Electro Medical Systems, Nyon, Switzerland);

- ▪

- Erythritol: EMS Airflow® Soft (Electro Medical Systems, Nyon, Switzerland);

- ▪

- Glycine: EMS Airflow® Perio (Electro Medical Systems, Nyon, Switzerland).

2.4. Surface Roughness Measurement

Surface roughness (Ra) was measured using a contact profilometer (Talysurf CCI Lite, Taylor Hobson Ltd., Leicester, UK). The profilometer scans the surface to provide high-resolution topographical data. Measurements were taken at three different points on each sample before and after the air-polishing procedure to capture the changes in surface roughness induced by each powder. The mean Ra value was calculated for each group. The scanned area covered 1.3 × 0.6 mm2, and the device was equipped with a 20× magnification confocal objective [16].

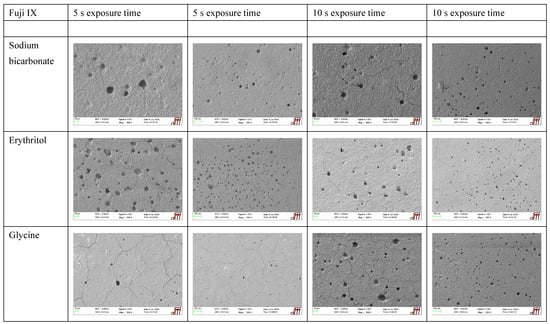

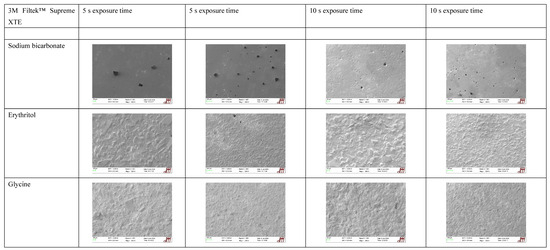

2.5. Scanning Electron Microscope (SEM)

Morphological characteristics of the samples were studied using the scanning electron microscope (SEM). To be observed correctly, samples must be conductive, so a metallic layer should be placed on top of them. In detail, samples in this study were coated with a gold layer of approximately 20 nm. The microscope used for the experimental activity was a Cambridge Stereoscan 440 (Cambridge Instruments, Cambridge, UK), equipped with a Philips PV9800 EDS (Philips, Eindhoven, Netherlands) microanalysis available at the Industrial Engineering Department of the University of Padua. Images were taken using the secondary electron detector.

2.6. Statistical Analysis

Statistical analysis was conducted using SPSS software (version 26.0, IBM Corp., Armonk, NY, USA). Levene’s test was used to assess the homogeneity of variances across the groups. If variances were homogeneous (p > 0.05), one-way ANOVA was used to compare mean surface roughness between the groups. When significant differences were found (p < 0.05), Tukey’s post hoc test was applied to identify specific differences between groups. If the variances were not homogeneous (p ≤ 0.05), Welch’s ANOVA was utilized, followed by the Games–Howell post hoc test where appropriate. A significance level of α = 0.05 was maintained for all statistical tests.

3. Results

The material composition, filler size, and filler content of the studied materials are represented in Table 1. Mohs hardness from each type of polishing powder is shown in Table 2.

Table 1.

Restorative material composition.

Table 2.

Polishing powder Mohs hardness values.

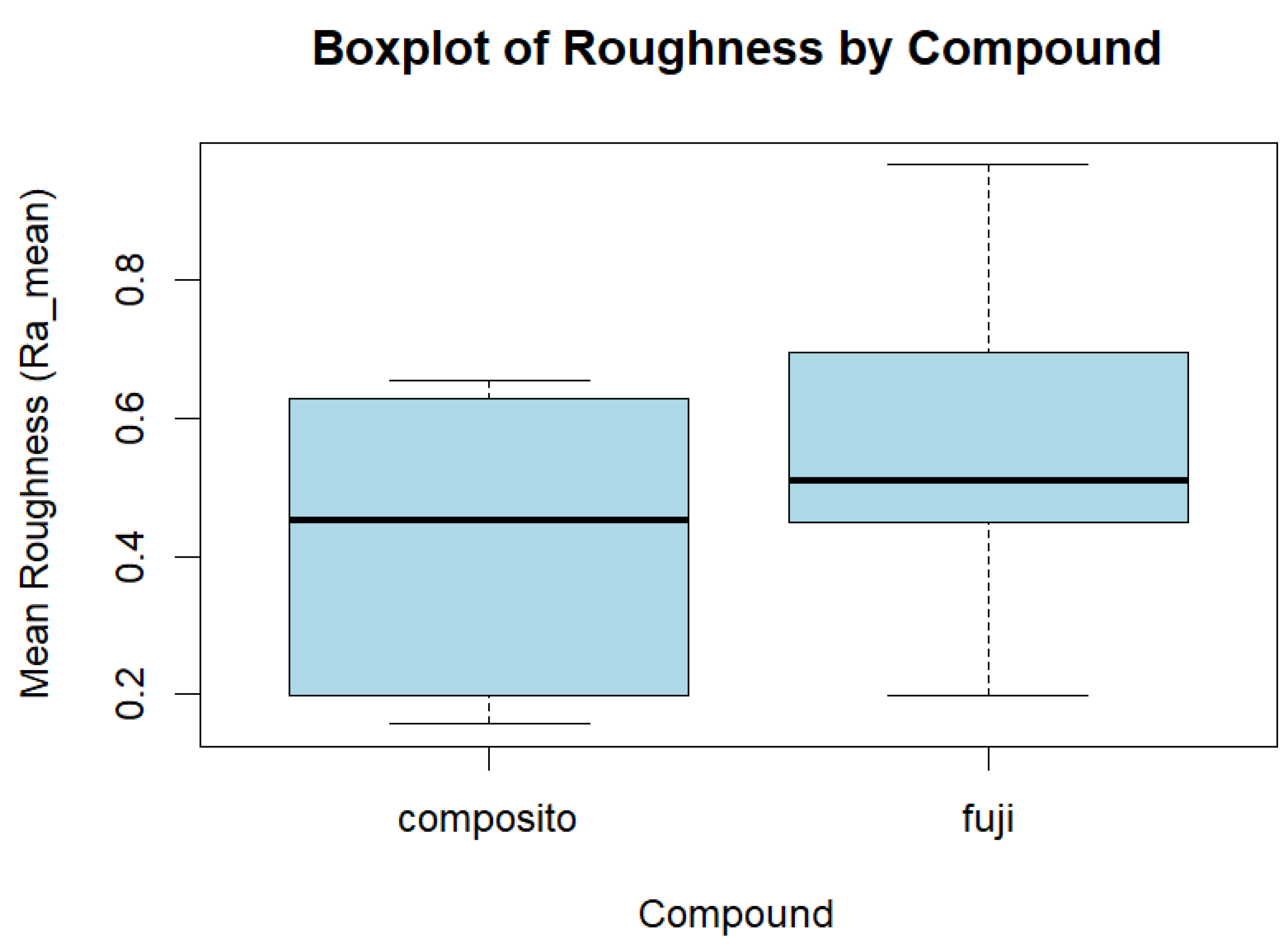

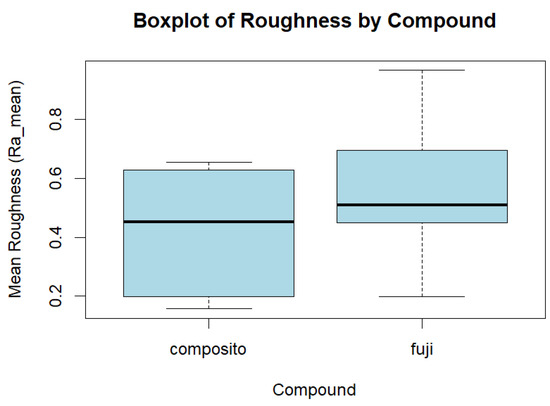

Roughness values (Ra) obtained for the two materials under study, following the various treatments, are presented in Table 3. The comparison of the mean roughness (Ra_mean) between the composite resin and the Fuji™ IX glass ionomer cement is illustrated in Figure 1. The figure demonstrates that the composite resin exhibits a lower mean roughness and less variability (as indicated by a narrower interquartile range) compared with Fuji™ IX. On the other hand, Fuji™ IX shows greater variability in roughness, suggesting that this material is more susceptible to variations in testing conditions. These results imply that the composite resin tends to produce more uniform and predictable surfaces, while Fuji™ IX may generate rougher and less consistent surfaces.

Table 3.

Materials roughness values following different treatments.

Figure 1.

Boxplot of roughness by compound.

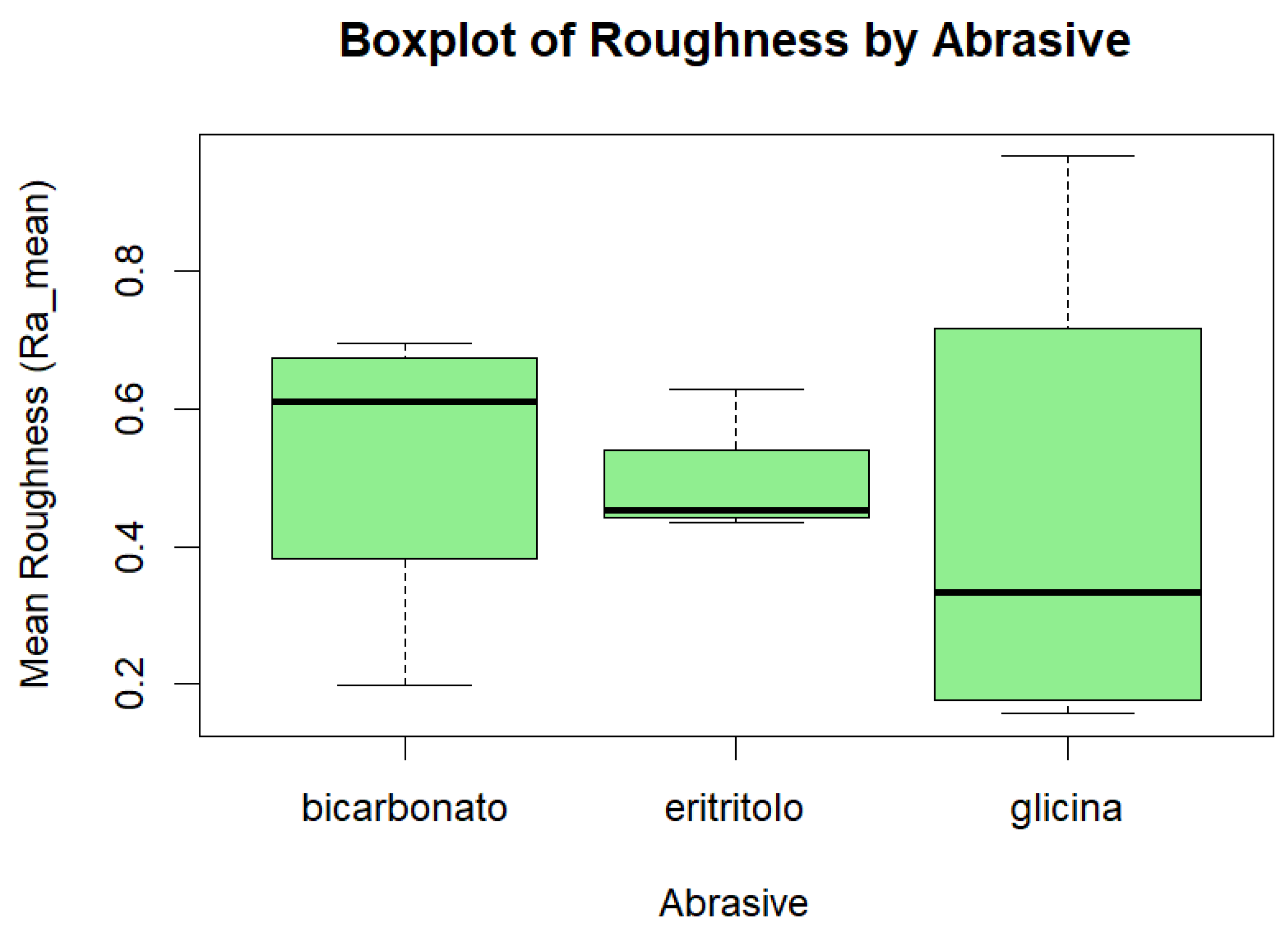

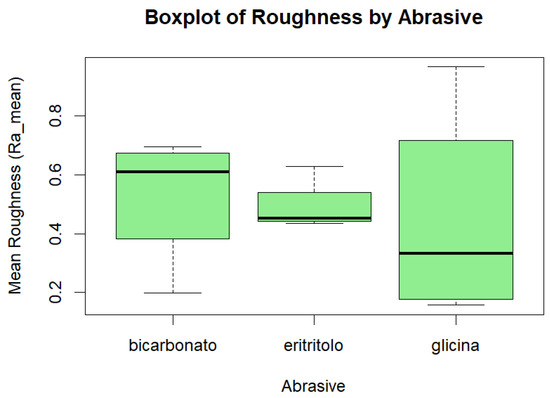

Figure 2 compares the mean roughness (Ra_mean) across the different powders—sodium bicarbonate, erythritol, and glycine. It is observed that sodium bicarbonate produces higher mean roughness compared with the other abrasives, with moderate variability. Erythritol causes intermediate roughness with less variability, although an outlier indicates an observation that deviates from the general pattern. Glycine, on the other hand, results in the lowest mean roughness but shows the greatest variability among the three abrasives, suggesting that its effect on the surface is more unpredictable, potentially generating both smooth and rougher surfaces. These results indicate that the choice of abrasive can significantly impact the final surface roughness, with sodium bicarbonate producing rougher surfaces and glycine showing a broader range of outcomes.

Figure 2.

Boxplot of roughness by abrasives.

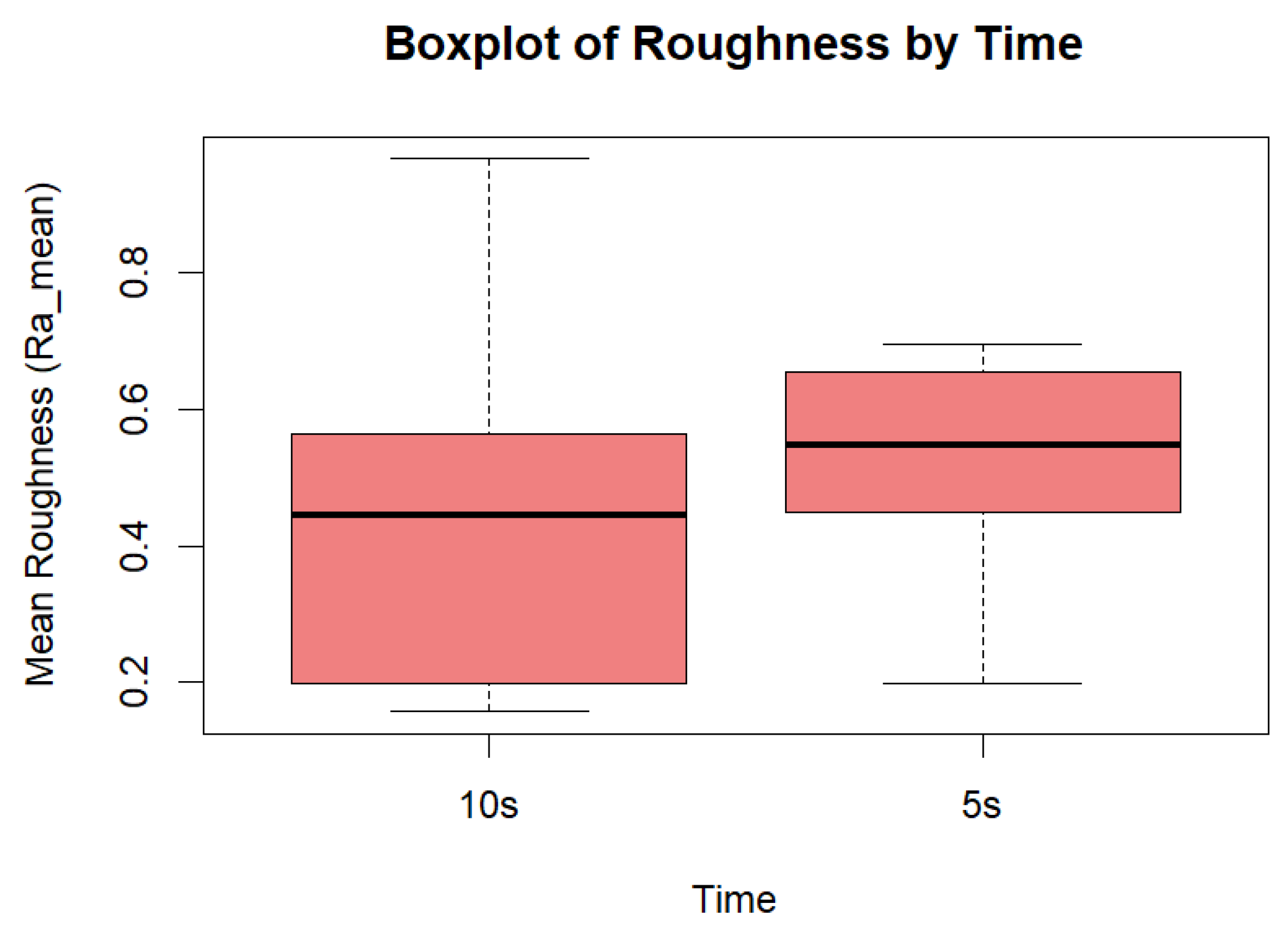

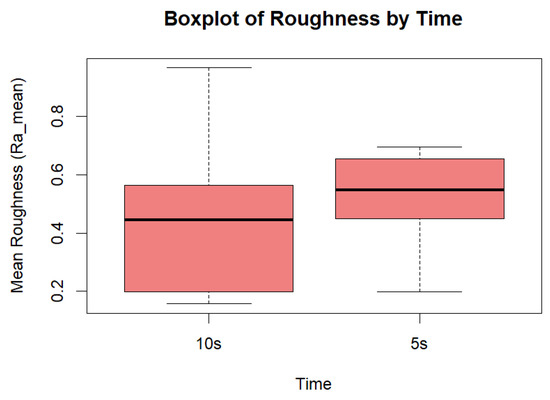

Figure 3 illustrates the comparison of mean roughness (Ra_mean) as a function of application times of 10 s and 5 s. The figure reveals that the mean roughness after 10 s of application is slightly higher and exhibits greater variability compared with after 5 s. This suggests that increasing the application time tends to generate rougher surfaces with a wider range of roughness variations. Additionally, the data spread is wider for 10 s, indicating that the impact of time on roughness might be more inconsistent if applied over longer periods. Conversely, 5 s of application results in lower and less variable roughness, indicating a more controlled and predictable effect on the surface.

Figure 3.

Boxplot of roughness by time.

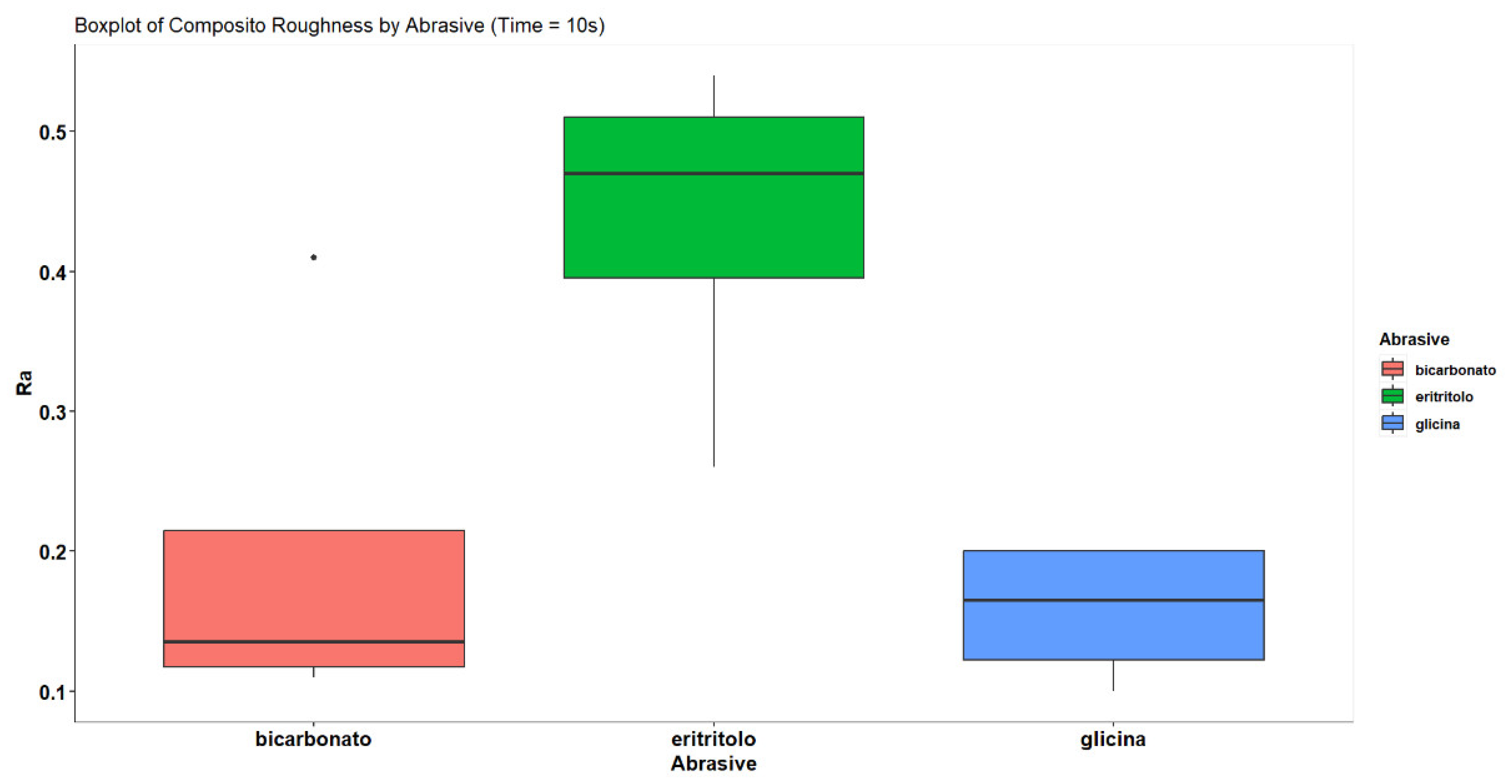

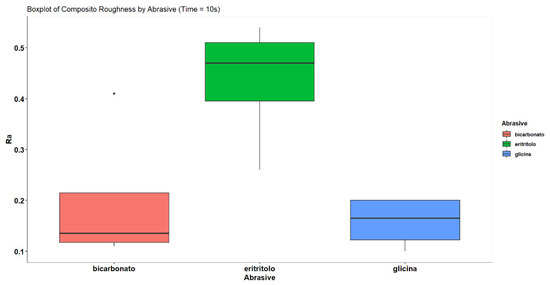

A closer examination of the roughness values for the composite resin after 10 s of application with the three abrasives is shown in Figure 4. The boxplot reveals significant variations in measured roughness (Ra). Erythritol has a range of Ra values varying from 0.26 to 0.54, with a mean around 0.44. The distribution is broad, with most data concentrated in the upper part of the range, suggesting moderate variation in roughness when using erythritol. Sodium bicarbonate, in contrast, presents Ra values between 0.11 and 0.41, with a significantly lower median than erythritol, reflecting overall lower roughness. The interquartile range (IQR) is narrower, and there is a greater concentration of data in the lower part of the range, indicating that sodium bicarbonate tends to produce more uniform and lower roughness. Glycine shows the lowest Ra values, ranging from 0.1 to 0.2, with minimal variation, indicating that this powder produces the smoothest surfaces among the three abrasives.

Figure 4.

Boxplot of composite roughness by abrasives (time 10 s).

To further analyze these findings, Levene’s test is performed to verify the homogeneity of variances among the abrasive groups. The test does not find any significant evidence of different variances (F = 0.2842, p = 0.7591), suggesting that the variances among the groups are homogeneous. Based on this result, an ANOVA test is conducted to compare the mean roughness (Ra) among the different powders. The ANOVA test indicates that there is a significant difference between the mean roughness of the abrasive groups (F = 7.066, p = 0.0143).

To identify which powders have significantly different mean roughness values, Tukey’s post hoc test is performed (Table 4). The results show that the mean roughness for erythritol is significantly higher than that for sodium bicarbonate (difference = 0.2375, p = 0.0375). Additionally, the mean roughness for glycine is significantly lower than that for erythritol (difference = −0.2775, p = 0.0173). No significant difference is found between the mean roughness for glycine and sodium bicarbonate (p = 0.8726). These results indicate that erythritol tends to cause greater surface roughness compared with the other powders studied, while glycine produces the lowest surface roughness compared with erythritol.

Table 4.

Tukey’s test results comparing means.

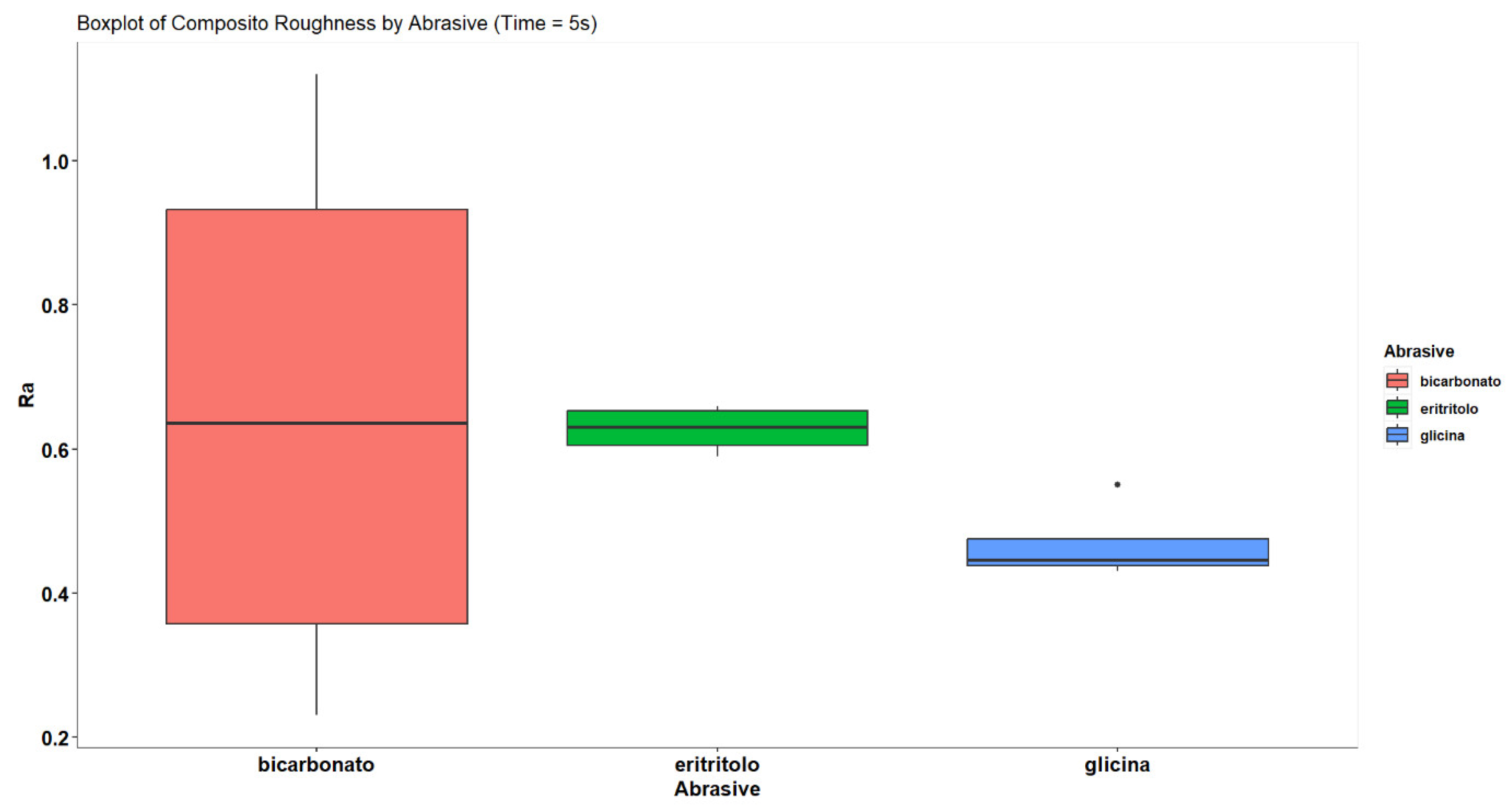

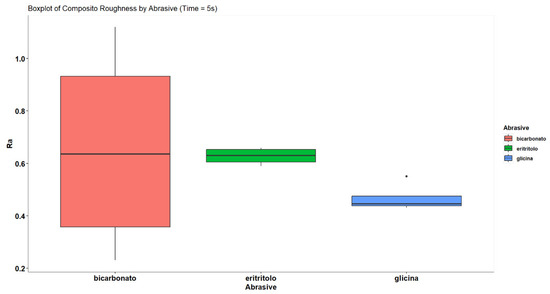

The roughness data after 5 s of application for the composite resin using the three powders—sodium bicarbonate, erythritol, and glycine—are illustrated in Figure 5. Sodium bicarbonate exhibits the greatest variability in roughness values, with a wider interquartile range and higher maximum values, reflecting greater data dispersion. Erythritol shows a more concentrated distribution, with roughness values relatively close to each other, suggesting greater consistency in the results. Glycine, in turn, shows the lowest variability and roughness values, indicating that it is the abrasiveness that causes the smallest variation in surface roughness. The position of the medians in the boxplot reveals that sodium bicarbonate tends to produce more extreme roughness values, while erythritol and glycine tend to produce more moderate and uniform values.

Figure 5.

Boxplot of composite roughness by abrasives (time 5s).

Statistical analysis begins with Levene’s test to verify the homogeneity of variances among the abrasive groups. The test result indicates that the variances are not homogeneous (p < 0.001), suggesting that the groups have significantly different variances. Due to the lack of homogeneity of variances, Welch’s test is performed instead of the standard ANOVA, as Welch’s test is more robust in situations where variances among groups differ. Welch’s test reveals a significant difference in mean roughness (Ra) among the abrasives (p < 0.05).

Following Welch’s test, a Games–Howell post hoc test is conducted (Table 5) to identify where the differences among the groups are. The results show a significant difference between erythritol and glycine (p < 0.05), while comparisons between sodium bicarbonate and erythritol, and between sodium bicarbonate and glycine, are not significant. This indicates that erythritol and glycine differ significantly in their impact on roughness, but sodium bicarbonate does not differ significantly from either.

Table 5.

Games–Howell post hoc test results.

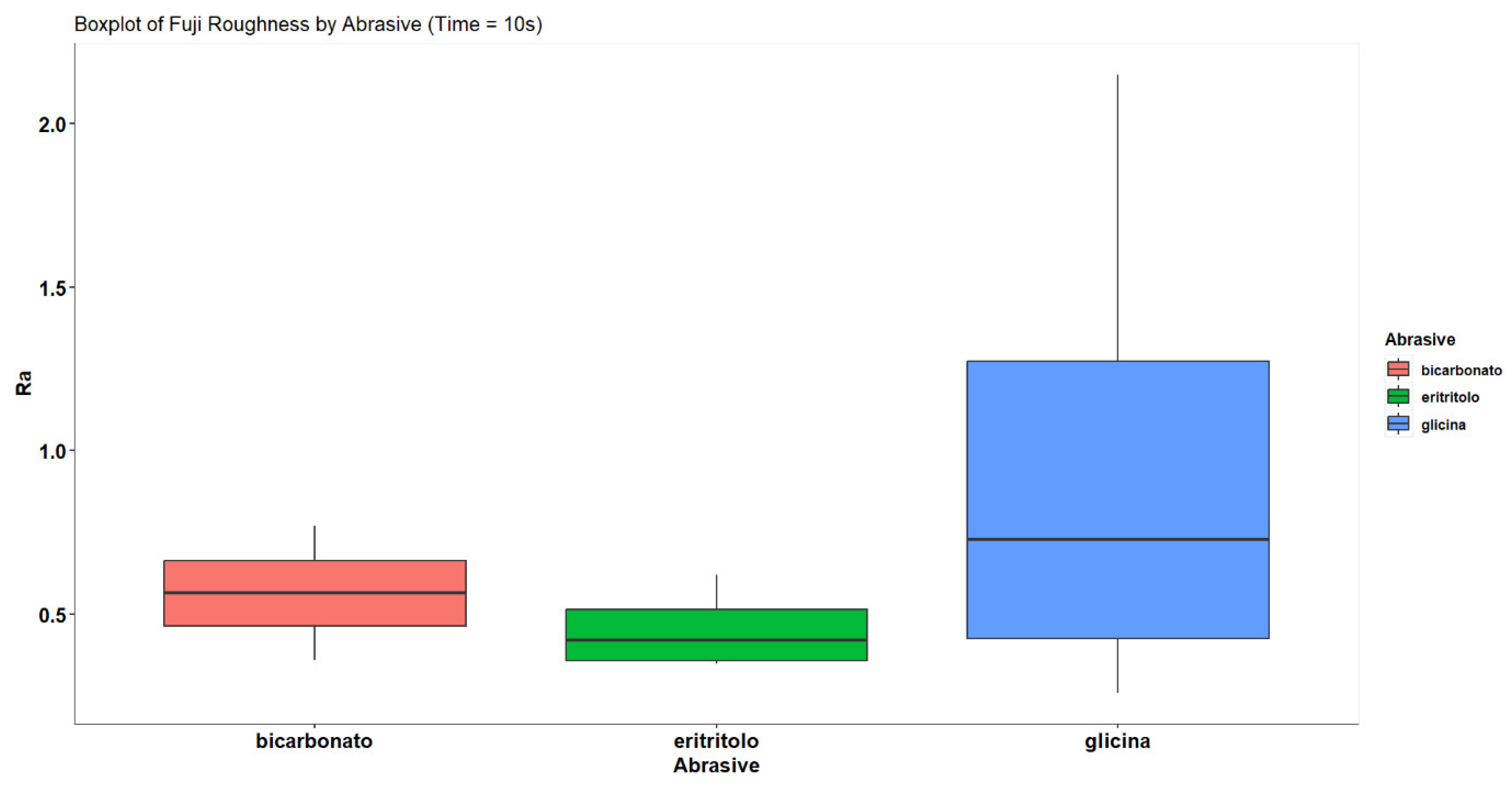

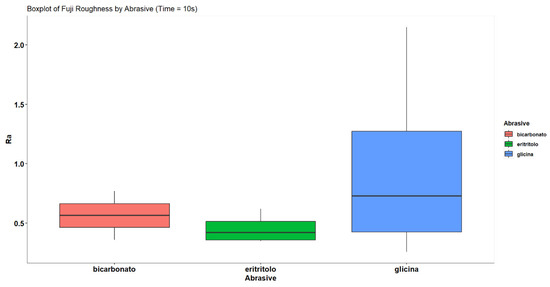

The roughness data for Fuji™ IX after 10 s of application with the different powders reveals significant variability, as shown in Figure 6. Erythritol causes relatively low and consistent roughness, with Ra values ranging from 0.35 to 0.62. In contrast, glycine produces greater variability, with Ra values ranging dramatically from 0.26 to 2.15, indicating a more aggressive or inconsistent effect on the material’s surface. Sodium bicarbonate, in turn, presents intermediate variability, with Ra values ranging from 0.36 to 0.77, suggesting a moderate impact on roughness.

Figure 6.

Boxplot of Fuji™ roughness by abrasives (time 10s).

The ANOVA conducted to compare the roughness (Ra) among the powders used on Fuji™ IX after 10 s does not reveal any statistically significant differences among the groups (F = 1.159, p = 0.357). This suggests that the observed variations in roughness among erythritol, glycine, and sodium bicarbonate are not large enough to be considered statistically significant, meaning that the Ra means among the different abrasives are similar within the adopted confidence level.

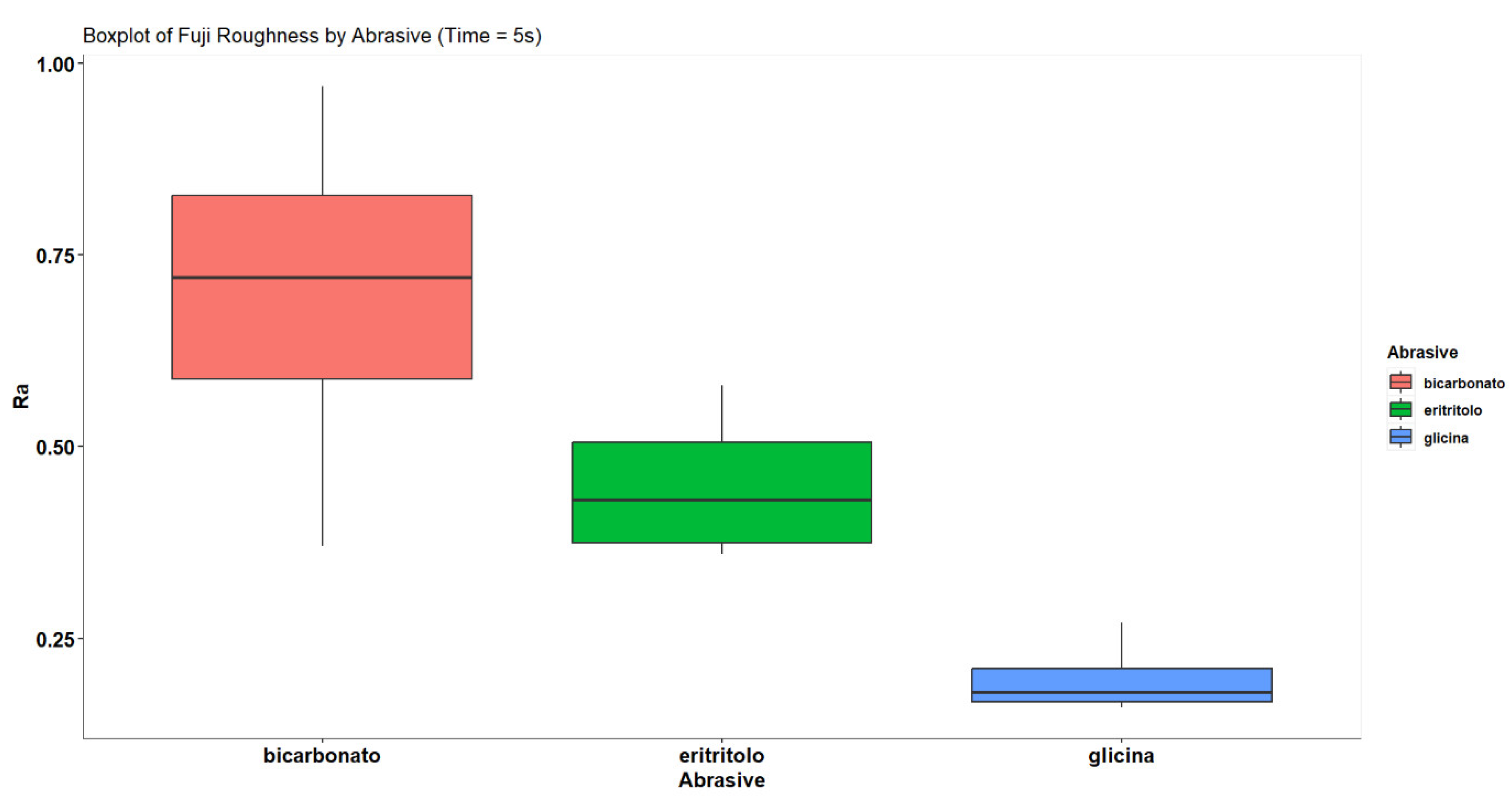

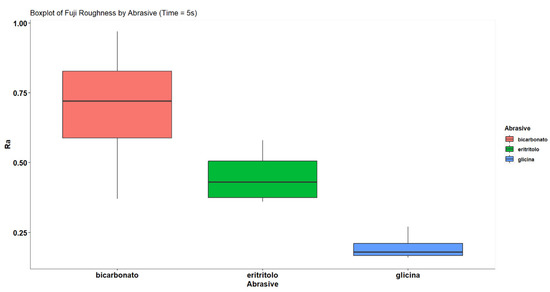

Figure 7 presents roughness (Ra) values after 5 s of abrasion on Fuji™ IX using the three powders under study—sodium bicarbonate, erythritol, and glycine. The Ra measurements vary depending on the powder used. It is observed that, for sodium bicarbonate, Ra values range from 0.37 to 0.97, indicating a greater variability in roughness. Erythritol shows more consistent Ra values, ranging from 0.36 to 0.58. Glycine, in turn, has the lowest Ra values, between 0.16 and 0.27, indicating less surface roughness after application. These data suggest that the type of powder used significantly influences the surface roughness of Fuji™ IX, with sodium bicarbonate producing the roughest surfaces and glycine the smoothest.

Figure 7.

Boxplot of Fuji™ roughness by abrasives (time 5s).

Statistical analysis aims to compare the mean surface roughness (Ra) of Fuji™ IX after 5 s of abrasion with the three different powders—sodium bicarbonate, erythritol, and glycine. Initially, Levene’s test is conducted to assess the homogeneity of variances among the groups. The test result indicates a p-value of 0.116, suggesting that the variances are homogeneous, as there is no significant difference between them (p > 0.05). Based on this, it is appropriate to proceed with an analysis of variance (ANOVA) to compare the group means.

The ANOVA results show a significant difference in the mean roughness associated with the different powders (F(2.9) = 9.772, p = 0.00555). This significant difference implies that the type of powder used has a statistically significant effect on surface roughness.

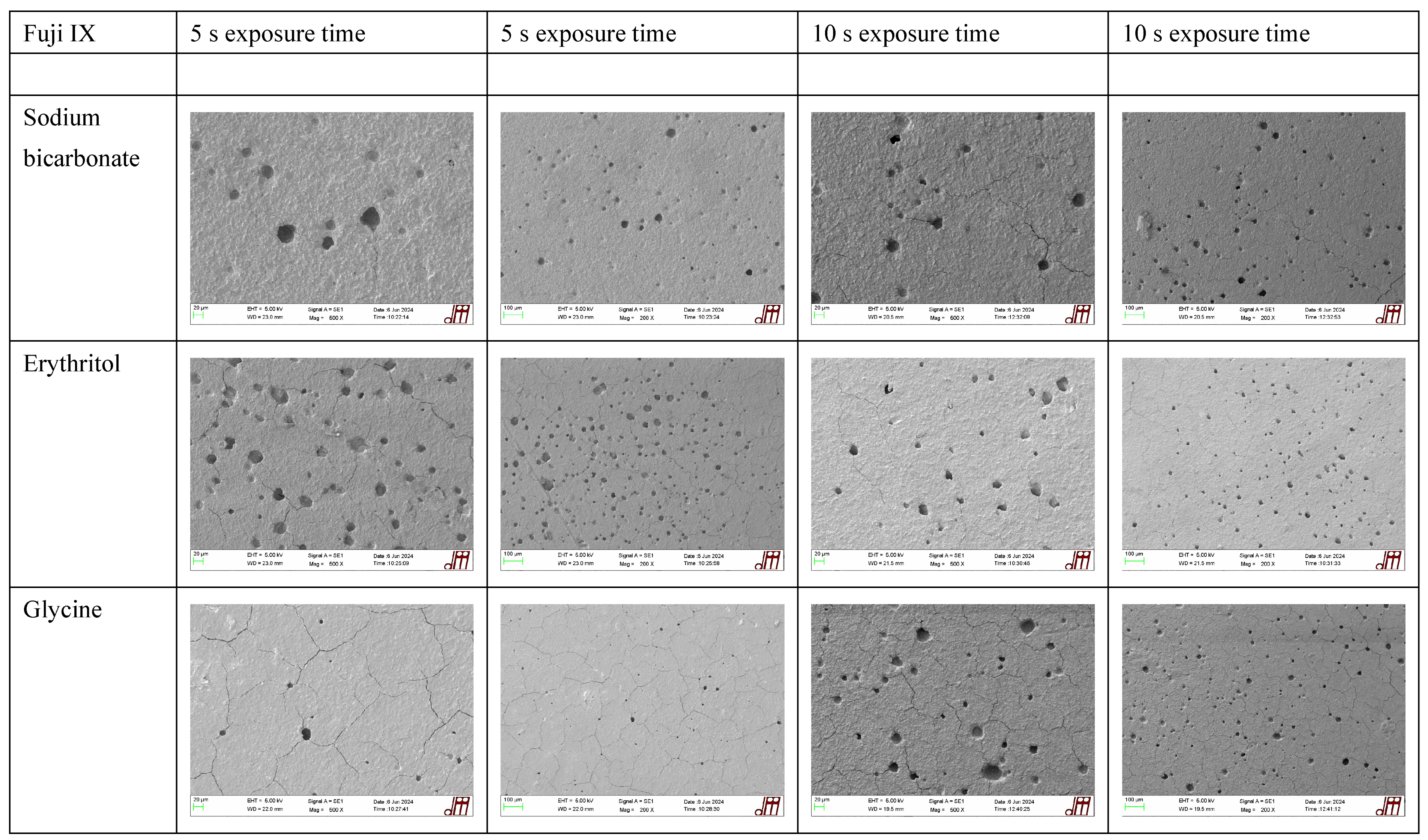

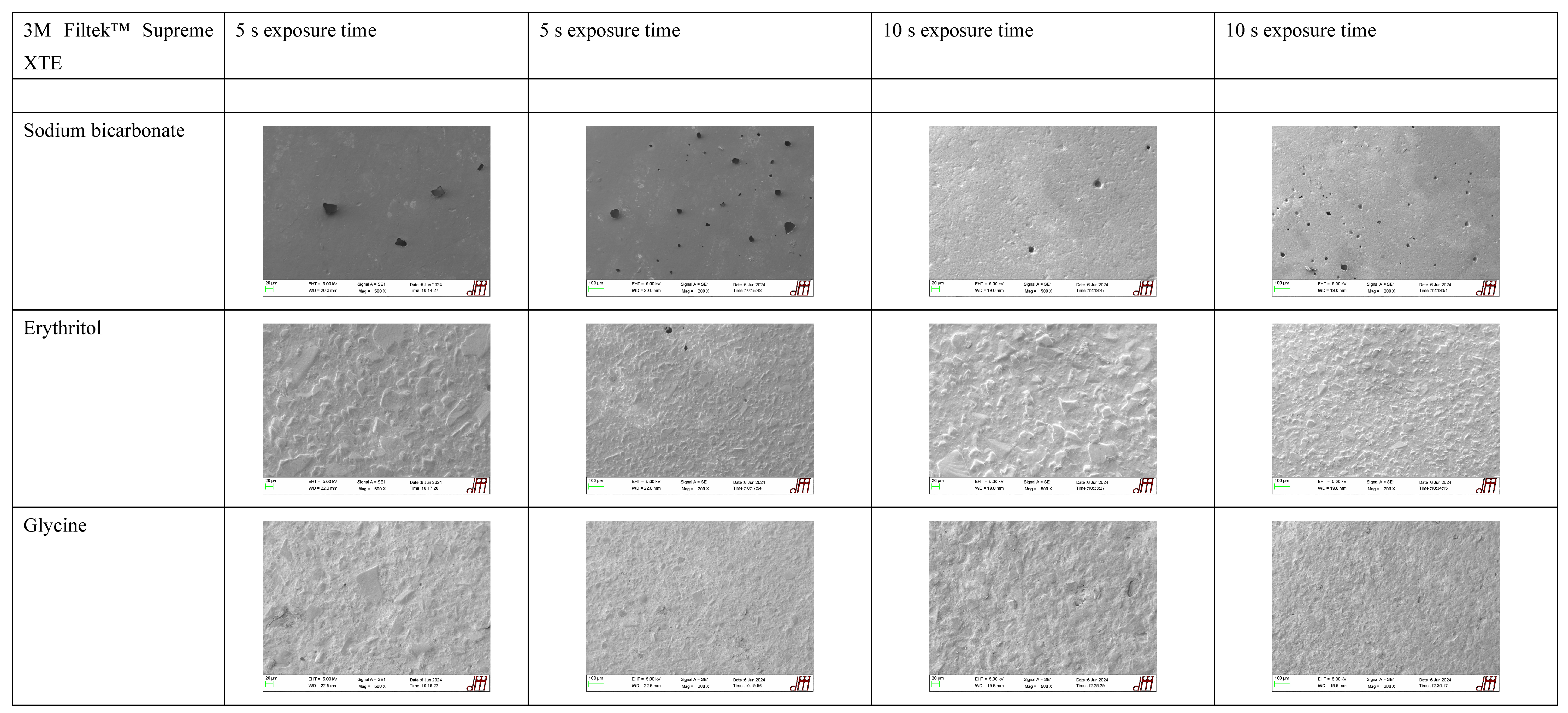

To identify which pairs of groups differ from each other, Tukey’s post hoc test is performed (Table 6). The results indicate that the mean roughness associated with the use of glycine is significantly lower than that associated with the use of sodium bicarbonate (difference = −0.4975, p = 0.00427). However, no significant difference is found between the other comparison pairs (erythritol/bicarbonate and glycine-erythritol), with p-values of 0.12898 and 0.11663, respectively. SEM analysis of the materials’ surface is represented in Figure 8 and Figure 9. At 500× magnification, the Fuji™ IX surfaces treated with different powders shows clear variations in surface roughness. Sodium bicarbonate consistently produces the highest roughness, especially after 10 s of application, characterized by pronounced abrasions and grooves. In contrast, glycine-treated surfaces exhibit the least amount of roughening, with smoother textures even after 10 s. Erythritol-treated surfaces are intermediate in roughness, with moderate abrasions and uniformity.

Table 6.

Tukey’s post hoc test results.

Figure 8.

Fuji IX SEM images at 500 and 200 magnification.

Figure 9.

3M Filtek SEM images at 500 and 200 magnification.

At 200× magnification, the topographical differences between the treatments become more apparent. Sodium bicarbonate generates visible coarse surface alterations, with the extent of disruption increasing significantly after 10 s. Erythritol also causes surface roughening but to a lesser extent than sodium bicarbonate, maintaining a more homogeneous texture. Glycine continues to demonstrate minimal surface alterations, suggesting its gentler impact on the material.

Regarding 3M Filtek Supreme XTE, at 500× magnification, sodium bicarbonate results in significant surface roughness after just 5 s, characterized by visible abrasions and deep grooves. When the exposure time is increased to 10 s, the roughness intensifies, producing even deeper more widespread surface damage. Erythritol, although less abrasive than sodium bicarbonate, still causes noticeable surface alterations after 5 s, with small abrasions visible across the surface. Extending the exposure to 10 s amplifies these effects, although the surface remains less disrupted compared with sodium bicarbonate. Glycine, in contrast, shows the least impact on the composite surface. After 5 s, minimal surface changes are observed, and even after 10 s, the surface maintains a relatively smooth texture, with only slight roughening visible.

At 200× magnification, the differences in the overall topography are more evident. The surfaces treated with sodium bicarbonate display substantial roughening and a general increase in surface texture. Erythritol produces a moderate level of roughness, with the abrasions becoming more pronounced after 10 s. Glycine continues to show a minimal effect, preserving much of the composite’s smoothness, even after 10 s of treatment.

4. Discussion

The findings of this study provide valuable insights into the effects of different air-polishing powders on the surface roughness of the 3M Filtek™ Supreme XTE composite resin and the Fuji™ IX glass ionomer cement. Surface roughness is a critical factor in restorative dentistry as it influences not only the esthetic outcome but also the material’s resistance to bacterial colonization and wear [10]. The results demonstrate that the type of abrasive powder and the duration of exposure have significant impacts on the surface characteristics of these dental materials.

This study reveals that sodium bicarbonate consistently produces higher surface roughness values compared with erythritol and glycine, regardless of the material or exposure time. This outcome is consistent with previous research indicating that sodium bicarbonate, due to its relatively larger particle size and higher abrasiveness, tends to create a more uneven surface [17]. The increased surface roughness associated with sodium bicarbonate may be detrimental in clinical scenarios, where a smooth finish is crucial for minimizing plaque accumulation and enhancing the longevity of restorations [9].

This study’s findings align with earlier research that has shown the roughening effect of sodium bicarbonate on enamel and restorative materials. Babina et al. [18] note that the frequent use of sodium bicarbonate in air polishing could exacerbate surface wear, especially on materials that are less resilient to mechanical stress, such as glass ionomer cements. These findings highlight the need for caution when using sodium bicarbonate, particularly in patients with restorations made from materials that are more susceptible to surface roughening.

Conversely, erythritol and glycine, both of which are characterized by finer particle sizes, result in significantly lower surface roughness. These findings align with studies that have highlighted the gentler action of these powders on dental surfaces, making them suitable for procedures where minimal surface alteration is desired [19,20]. Glycine, in particular, shows the lowest roughness values across all groups, corroborating its use in subgingival applications where surface preservation is paramount. This suggests that glycine could be the preferred choice in situations where maintaining the integrity of the restorative surface is essential.

The clinical implications of these findings are substantial. Glycine, with its minimal impact on surface roughness, is increasingly being recognized as a safe and effective option for both supra- and subgingival polishing [21]. Its gentle action reduces the risk of damaging restorative surfaces while still providing effective biofilm removal. This balance between efficacy and safety makes glycine particularly useful in maintenance therapies for patients with complex restorative cases, such as those involving multiple types of restorations or areas prone to wear [22].

Interestingly, the effect of exposure time is more pronounced with sodium bicarbonate than with erythritol or glycine. Specifically, extending the polishing time from 5 to 10 s leads to a substantial increase in surface roughness for sodium bicarbonate, while the changes are less significant for the other powders. This observation underscores the importance of controlling exposure time, especially when using more abrasive powders, to prevent excessive roughening of the restoration surface [23]. It also suggests that, while longer exposure times may be necessary for effective cleaning, they must be balanced against the potential for increased surface damage.

The influence of exposure time on surface roughness has been documented in the literature, where prolonged exposure to abrasive powders has been shown to increase the risk of surface degradation [6]. This study adds to that body of evidence, demonstrating that careful management of polishing time is crucial, particularly when using sodium bicarbonate. Clinicians should be aware of the potential trade-offs between cleaning efficacy and surface preservation, especially in scenarios where extended polishing might be necessary, such as in cases of heavy plaque accumulation or staining.

The difference in response between 3M Filtek™ Supreme XTE composite resin and Fuji™ IX glass ionomer cement is also noteworthy. The composite resin generally exhibits lower roughness values compared with Fuji™ IX when subjected to the same polishing conditions. This difference could be attributed to the intrinsic material properties, such as the hardness and filler content, which affect how each material interacts with the abrasive particles [24]. The higher variability in roughness observed in Fuji IX samples, particularly with sodium bicarbonate, suggests that this material may be more susceptible to surface alterations, potentially compromising its clinical performance over time.

Fuji™ IX, as a glass ionomer cement, is known for its fluoride release and biocompatibility, which makes it a material of choice in many clinical situations, particularly in pediatric dentistry and in patients with high caries risk [25]. However, its relatively softer surface compared with composite resins means that it may not be as resilient to mechanical polishing, especially with more abrasive agents like sodium bicarbonate. The findings of this study suggest that, while Fuji IX offers distinct clinical advantages, its surface characteristics must be carefully managed, particularly during maintenance procedures.

These findings have important clinical implications. In the context of restorative dentistry, selecting the appropriate polishing powder is crucial for optimizing the surface finish of the restoration. While sodium bicarbonate remains a popular choice due to its effectiveness in plaque removal, its use should be carefully considered, especially on materials like Fuji™ IX that are more prone to surface roughening. Erythritol and glycine, offering a gentler alternative, may be better suited for maintaining smooth surfaces, particularly in esthetically demanding areas or when working with materials sensitive to abrasion [26].

Moreover, this study highlights the need for further research to explore the long-term effects of these polishing agents on the mechanical properties of restorative materials. Understanding how surface roughness evolves over time, especially under functional loading, will be critical for developing guidelines that ensure both the esthetic and functional longevity of restorations [27]. Future studies should also consider evaluating the impact of these polishing agents on newer restorative materials and their potential role in the prevention of secondary caries and other complications.

The potential for future research extends beyond just the mechanical properties. There is also a need to investigate the biological implications of surface roughness changes, particularly concerning bacterial adhesion and biofilm formation. Rougher surfaces are more prone to biofilm accumulation, which can increase the risk of secondary caries and periodontal disease. Thus, the choice of polishing agent should not only focus on mechanical outcomes but also consider the biological environment in which the restoration will function.

In conclusion, the choice of air-polishing powder and the control of exposure time are key factors in managing the surface roughness of 3M Filtek™ Supreme XTE composite resins and Fuji™ IX glass ionomer cements. Sodium bicarbonate, while effective in cleaning, poses a risk of increasing surface roughness, particularly with extended exposure. Erythritol and glycine, on the other hand, offer safer alternatives for maintaining smoother surfaces, making them preferable in many clinical situations.

5. Conclusions

This study demonstrates that the choice of air-polishing powder and the duration of its application significantly influence the surface roughness of both 3M Filtek™ Supreme XTE composite resin and Fuji™ IX glass ionomer cement. Sodium bicarbonate, while effective, increases surface roughness, particularly with longer exposure times. In contrast, erythritol and glycine are less abrasive, with glycine showing the most favorable results in maintaining surface smoothness.

Clinicians should carefully consider these findings when selecting polishing agents to optimize the longevity and esthetics of restorations. Further research is needed to explore the long-term effects of these polishing agents on restorative materials.

Author Contributions

Conceptualization, F.S.L. and S.M.; methodology, R.B.; software, A.G.S.; validation, P.L. and S.M.; formal analysis, M.B.; investigation, L.P.; data curation, F.S.L.; writing—original draft preparation, M.G.; writing—review and editing, F.S.L.; visualization, F.S.L.; supervision, S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zafar, M.S.; Amin, F.; Fareed, M.A.; Ghabbani, H.; Riaz, S.; Khurshid, Z.; Kumar, N. Biomimetic Aspects of Restorative Dentistry Biomaterials. Biomimetics 2020, 5, 34. [Google Scholar] [CrossRef] [PubMed]

- Salerno, M.; Loria, P.; Matarazzo, G.; Tomè, F.; Diaspro, A.; Eggenhöffner, R. Surface Morphology and Tooth Adhesion of a Novel Nanostructured Dental Restorative Composite. Materials 2016, 9, 203. [Google Scholar] [CrossRef] [PubMed]

- Chisini, L.A.; Collares, K.; Cademartori, M.G.; de Oliveira, L.J.C.; Conde, M.C.M.; Demarco, F.F.; Corrêa, M.B. Restorations in primary teeth: A systematic review on survival and reasons for failures. Int. J. Paediatr. Dent. 2018, 28, 123–139. [Google Scholar] [CrossRef] [PubMed]

- Krishnakumar, K.; Kalaskar, R.; Kalaskar, A.; Bhadule, S.; Joshi, S. Clinical Effectiveness of High-viscosity Glass Ionomer Cement and Composite Resin as a Restorative Material in Primary Teeth: A Systematic Review of Clinical Trials. Int. J. Clin. Pediatr. Dent. 2024, 17, 221–228. [Google Scholar]

- Madhyastha, P.S.; Hegde, S.; Srikant, N.; Kotian, R.; Iyer, S.S. Effect of finishing/polishing techniques and time on surface roughness of esthetic restorative materials. Dent. Res. J. 2017, 14, 326–330. [Google Scholar]

- Güler, A.; Duran, I.; Ozkan, P. Effects of air polishing powders on the surface roughness of composite resins. J. Dent. Sci. 2010, 5, 136–143. [Google Scholar] [CrossRef][Green Version]

- Cobb, C.M.; Daubert, D.M.; Davis, K.; Deming, J.; Flemmig, T.F.; Pattison, A.; Roulet, J.F.; Stambaugh, R.V. Consensus conference findings on Supragingival and subgingival air polishing. Compend. Contin. Educ. Dent. 2017, 38, e1–e4.1. [Google Scholar]

- Lu, H.; He, L.; Zhao, Y.; Meng, H. The effect of supragingival glycine air polishing on periodontitis during maintenance therapy: A randomized controlled trial. PeerJ. 2018, 6, e4371. [Google Scholar] [CrossRef]

- Giacomelli, L.; Salerno, M.; Derchi, G.; Genovesi, A.; Paganin, P.P.; Covani, U. Effect of air polishing with glycine and bicarbonate powders on a nanocomposite used in dental restorations: An in vitro study. Int. J. Periodontics Restor. Dent. 2011, 31, e51–e56. [Google Scholar]

- Bühler, J.; Schmidli, F.; Weiger, R.; Walter, C. Analysis of the effects of air polishing powders containing sodium bicarbonate and glycine on human teeth. Clin. Oral. Investig. 2015, 19, 877–885. [Google Scholar] [CrossRef]

- Janiszewska-Olszowska, J.; Drozdzik, A.; Tandecka, K.; Grocholewicz, K. Effect of air-polishing on surface roughness of composite dental restorative material—Comparison of three different air-polishing powders. BMC Oral. Health 2020, 20, 30. [Google Scholar] [CrossRef] [PubMed]

- Galal, R.; Kadi, A.; Ghoneim, M. Surface roughness and solubility of a nano-filled resin modified glass-ionomer (invitro study). Alex. Dent. J. 2018, 43, 123–127. [Google Scholar] [CrossRef]

- Bajwa, N.K.; Pathak, A. Change in surface roughness of esthetic restorative materials after exposure to different immersion regimes in a cola drink. ISRN Dent. 2014, 2014, 353926. [Google Scholar] [CrossRef] [PubMed]

- Yudhit, A.; Harahap, K.; Dewi, Y. Effect fresh milk on surface roughness of resin modified glass ionomer cement. Dentika Dent. J. 2019, 22, 12–14. [Google Scholar] [CrossRef]

- Mazzoleni, S.; Gargani, A.; Parcianello, R.G.; Pezzato, L.; Bertolini, R.; Zuccon, A.; Stellini, E.; Ludovichetti, F.S. Protection against Dental Erosion and the Remineralization Capacity of Non-Fluoride Toothpaste, Fluoride Toothpaste and Fluoride Varnish. Appl. Sci. 2023, 13, 1849. [Google Scholar] [CrossRef]

- Ludovichetti, F.S.; Zambon, G.; Cimolai, M.; Gallo, M.; Signoriello, A.G.; Pezzato, L.; Bertolini, R.; Mazzoleni, S. Efficacy of Two Toothpaste in Preventing Tooth Erosive Lesions Associated with Gastroesophageal Reflux Disease. Appl. Sci. 2022, 12, 1023. [Google Scholar] [CrossRef]

- Miličević, A.; Goršeta, K.; van Duinen, R.N.; Glavina, D. Surface Roughness of Glass Ionomer Cements after Application of Different Polishing Techniques. Acta Stomatol. Croat. 2018, 52, 314–321. [Google Scholar] [CrossRef]

- Babina, K.; Polyakova, M.; Sokhova, I.; Doroshina, V.; Arakelyan, M.; Zaytsev, A.; Novozhilova, N. The Effect of Ultrasonic Scaling and Air-Powder Polishing on the Roughness of the Enamel, Three Different Nanocomposites, and Composite/Enamel and Composite/Cementum Interfaces. Nanomaterials 2021, 11, 3072. [Google Scholar] [CrossRef]

- Aydın, N.; Topçu, F.T.; Karaoğlanoğlu, S.; Oktay, E.A.; Erdemir, U. Effect of finishing and polishing systems on the surface roughness and color change of composite resins. J. Clin. Exp. Dent. 2021, 13, e446–e454. [Google Scholar] [CrossRef]

- Eram, A.; Kr, R.V.; Chethan, K.N.; Keni, L.G.; Shetty, D.D.; Zuber, M.; Kumar, S.; Pradeep, S. Air-Abrasion in Dentistry: A Short Review of the Materials and Performance Parameters. J. Biomed. Phys. Eng. 2024, 14, 99–110. [Google Scholar]

- DelPriore, K.; Ismail, H.S.; Morrow, B.R.; Hill, A.E.; Garcia-Godoy, F. Comparative evaluation of subgingival scaling and polishing techniques on dental material surface roughness. Am. J. Dent. 2023, 36, 207–212. [Google Scholar] [PubMed]

- Gong, J.; Huang, X.; Yuan, S. Comparative study on the effects of different polishing methods on tooth surface microstructure and roughness following initial periodontal treatment. Clin. Exp. Dent. Res. 2024, 10, e851. [Google Scholar] [CrossRef] [PubMed]

- Németh, K.D.; Haluszka, D.; Seress, L.; Lovász, B.V.; Szalma, J.; Lempel, E. Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites. Polymers 2022, 14, 1643. [Google Scholar] [CrossRef]

- Nithya, K.; Sridevi, K.; Keerthi, V.; Ravishankar, P. Evaluation of Surface Roughness, Hardness, and Gloss of Composites After Three Different Finishing and Polishing Techniques: An In Vitro Study. Cureus 2020, 12, e7037. [Google Scholar] [CrossRef] [PubMed]

- Francisconi, L.F.; Scaffa, P.M.; Barros, V.R.P.; Coutinho, M.; Francisconi, P.A. Glass ionomer cements and their role in the restoration of non-carious cervical lesions. J. Appl. Oral. Sci. 2009, 17, 364–369. [Google Scholar] [CrossRef]

- Simon, C.J.; Munivenkatappa Lakshmaiah Venkatesh, P.; Chickanna, R. Efficacy of glycine powder air polishing in comparison with sodium bicarbonate air polishing and ultrasonic scaling—A double-blind clinico-histopathologic study. Int. J. Dent. Hyg. 2015, 13, 177–183. [Google Scholar] [CrossRef]

- Ludovichetti, F.S.; Trindade, F.Z.; Adabo, G.L.; Pezzato, L.; Fonseca, R.G. Effect of grinding and polishing on the roughness and fracture resistance of cemented CAD-CAM monolithic materials submitted to mechanical aging. J. Prosthet. Dent. 2019, 121, e1–e866. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).