Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methods

2.2.1. Water Content

2.2.2. Water Activity

2.2.3. Colour

2.2.4. Apparent Density

2.2.5. Bulk Density

2.2.6. Water Vapour Adsorption Kinetics

2.2.7. Water Vapour Adsorption Isotherms

- ➢

- Coefficient of determination (R2)

- ➢

- Value of mean square error (MRE):

- ➢

- Root mean square deviation (RMS):

- ➢

- Sum of residual squares (RSS):

- ➢

- Moisture estimation error (SEE):

2.2.8. Thermal Properties

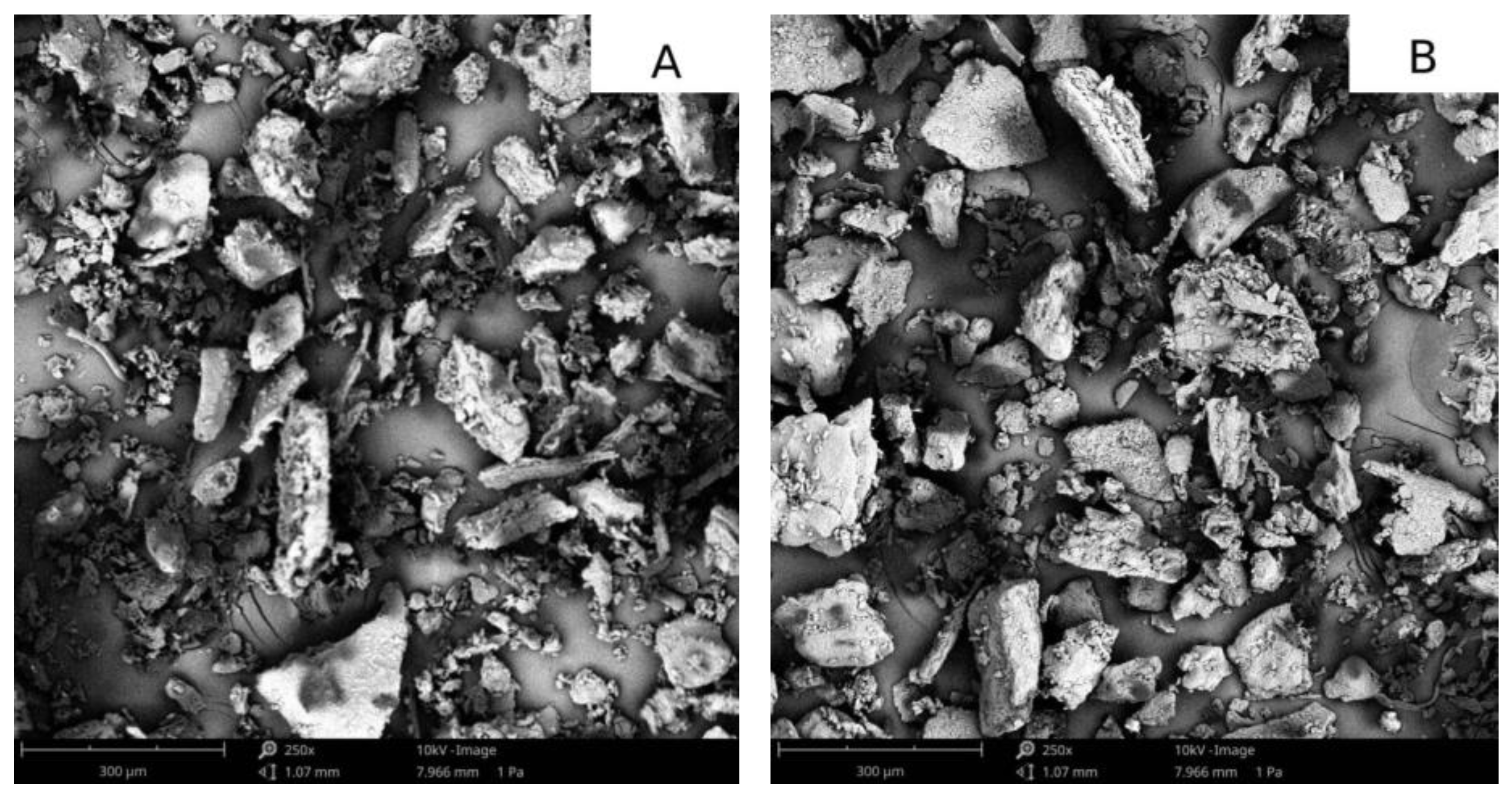

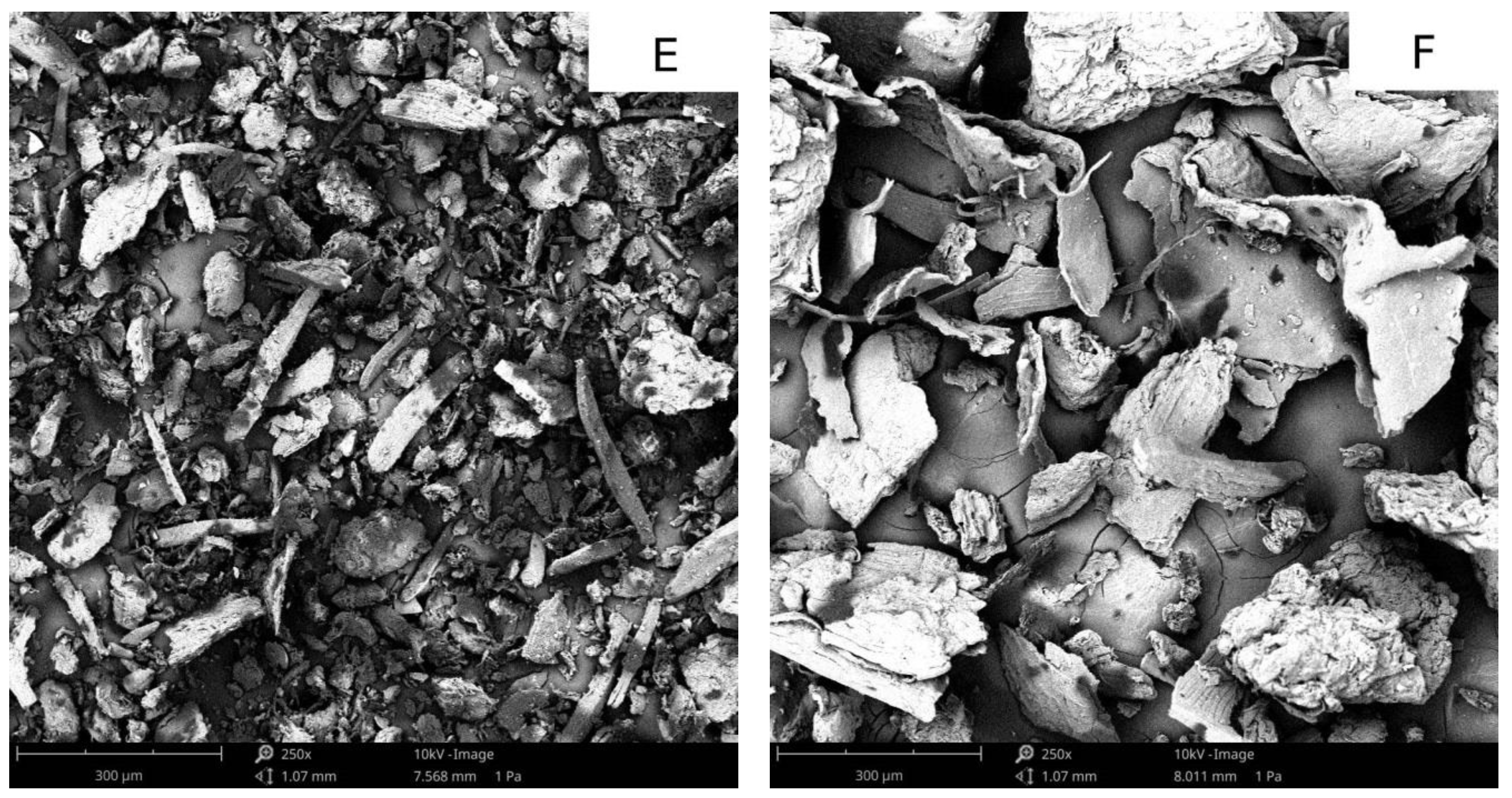

2.2.9. Microstructure

2.3. Statistical Analysis

3. Results and Discussion

3.1. General Characteristics of Fruit Fibres and Pomace

3.2. Water Content of Fruit Fibres and Pomace

3.3. Water Activity of Fruit Fibres and Pomace

3.4. Colour of Fruit Fibres and Pomace

3.5. Apparent Density of Fruit Fibres and Pomace

3.6. Bulk Density of Fruit Fibres and Pomace

3.7. Water Vapor Sorption Kinetics of Fruit Fibres and Pomace

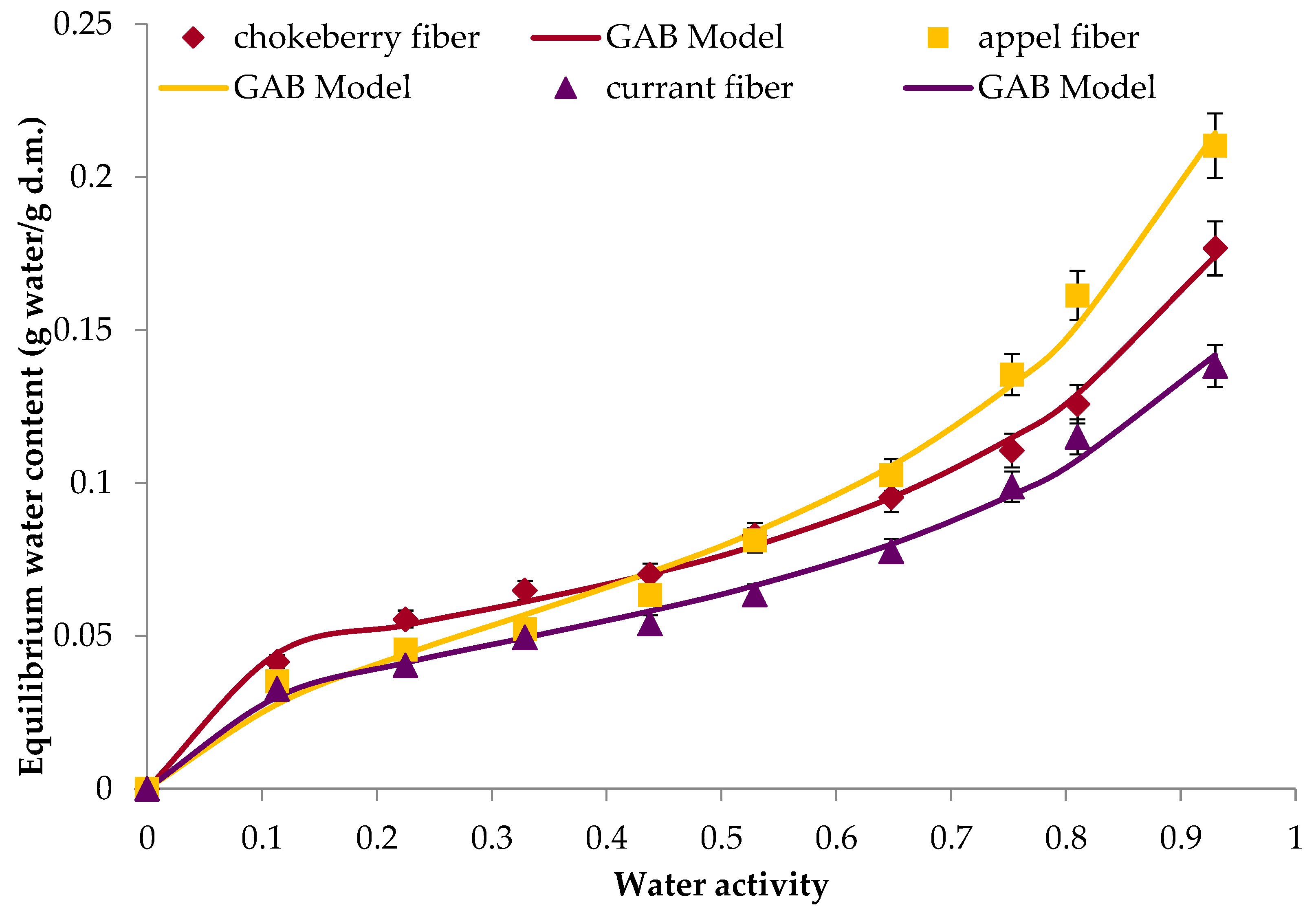

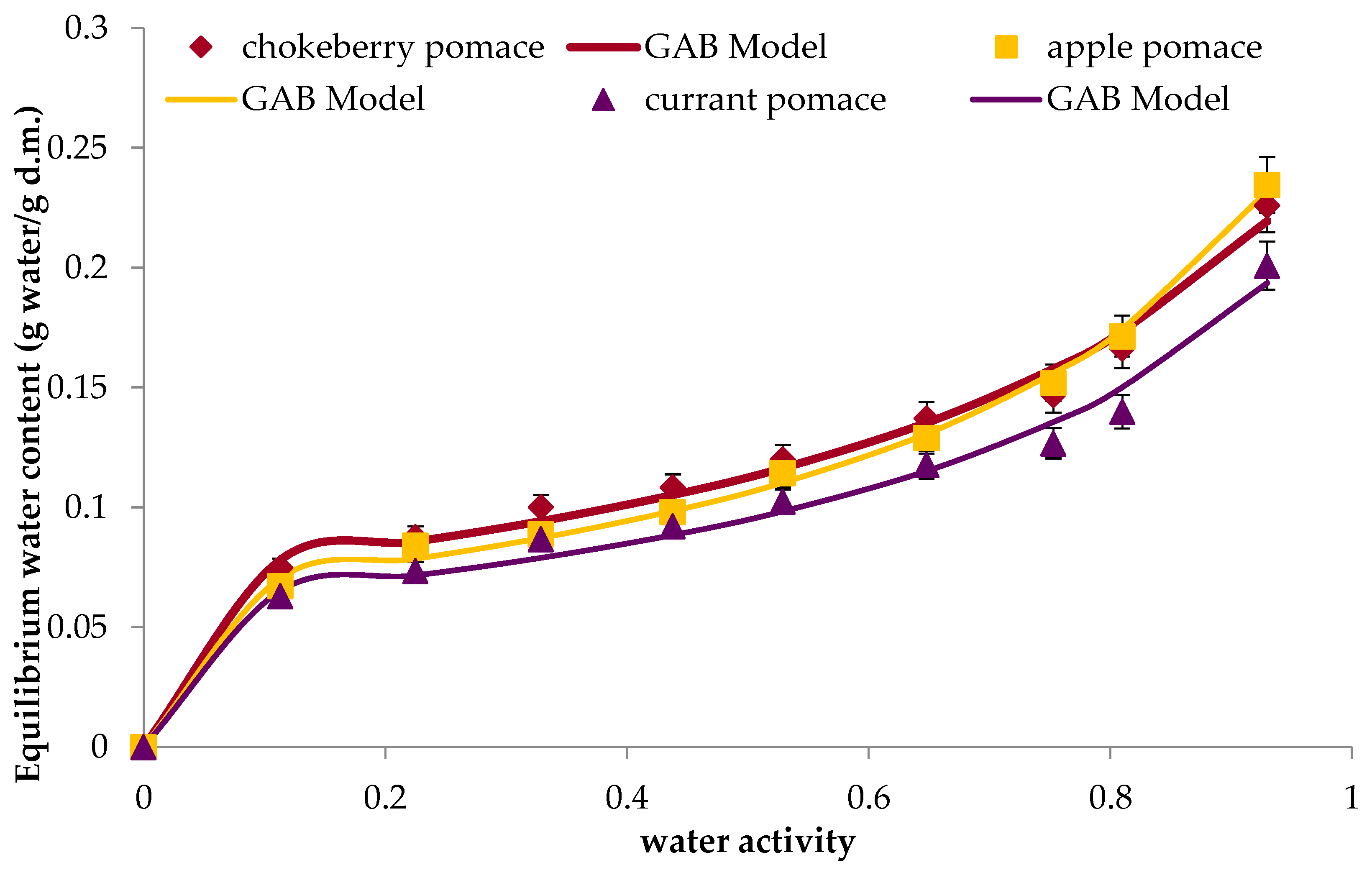

3.8. Isotherms of Water Vapour Sorption of Fruit Fibres and Pomace

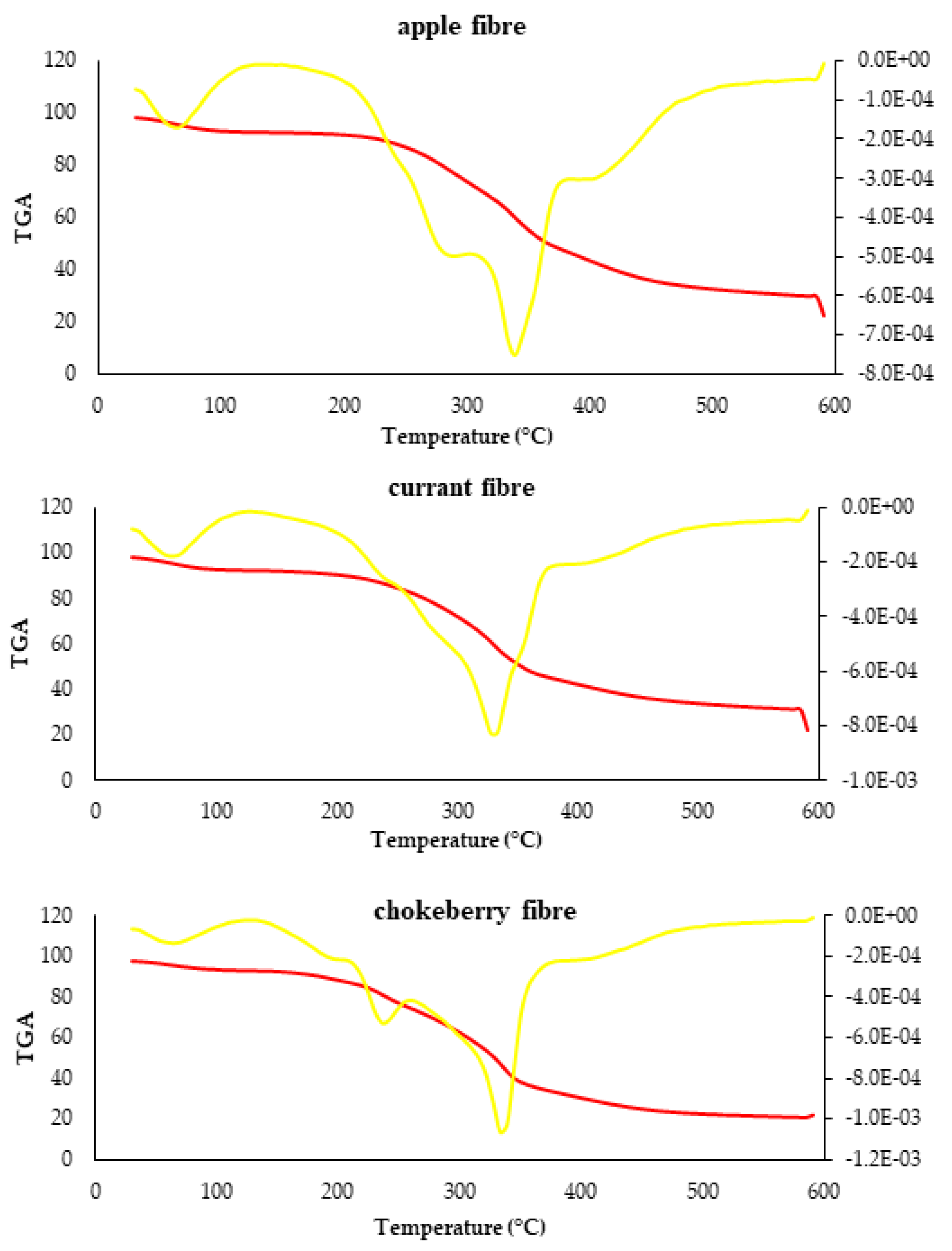

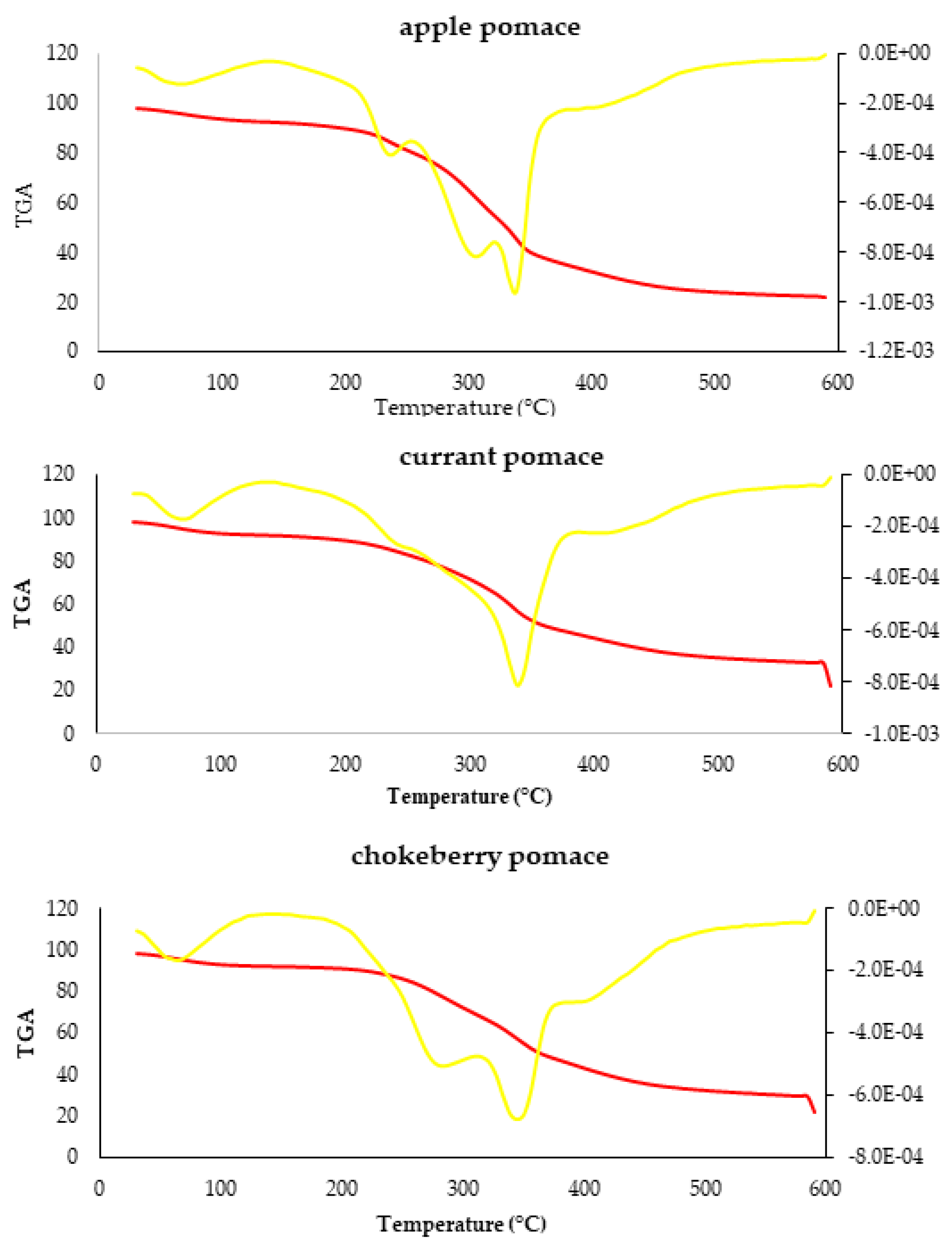

3.9. Thermal Properties of Fruit Fibres and Pomace

3.10. Microstructure of Fruit Fibres and Pomace

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Hereu-Morales, J.; Segarra, A.; Valderrama, C. The European (Green?) Deal: A systematic analysis of environmental sustainability. Sustain. Dev. 2024, 32, 647–661. [Google Scholar] [CrossRef]

- Kara, S.; Hauschild, M.; Sutherland, J.; McAloone, T. Closed-loop systems to circular economy: A pathway to environmental sustainability? CIRP Ann. 2022, 71, 505–528. [Google Scholar] [CrossRef]

- Chavan, P.; Singh, A.K.; Kaur, G. Recent progress in the utilization of industrial waste and by-products of citrus fruits: A review. J. Food Process Eng. 2018, 41, 8. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Pandiselvam, R. Valorization of fruit waste for bioactive compounds and their applications in the food industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Roussis, I.; Bilalis, D.; Priniotakis, G. Dietary fiber from plant-based food wastes: A comprehensive approach to cereal, fruit, and vegetable waste valorization. Processes 2023, 11, 1580. [Google Scholar] [CrossRef]

- Campos, D.A.; Gómez-García, R.; Vilas-Boas, A.A.; Madureira, A.R.; Pintado, M.M. Management of fruit industrial by-products—A case study on circular economy approach. Molecules 2020, 25, 320. [Google Scholar] [CrossRef]

- Dreher, M.L. Whole fruits and fruit fiber emerging health effects. Nutrients 2018, 10, 1833. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Jõudu, I.; Bhat, R. Dietary fiber from underutilized plant resources—A positive approach for valorization of fruit and vegetable wastes. Sustainability 2020, 12, 5401. [Google Scholar] [CrossRef]

- Cui, J.; Lian, Y.; Zhao, C.; Du, H.; Han, Y.; Gao, W.; Xiao, H.; Zheng, J. Dietary fibers from fruits and vegetables and their health benefits via modulation of gut microbiota. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1514–1532. [Google Scholar] [CrossRef]

- Skwarek, P.; Karwowska, M. Fruit and vegetable processing by-products as functional meat product ingredients-a chance to improve the nutritional value. LWT 2023, 189, 115442. [Google Scholar] [CrossRef]

- Kruczek, M.; Drygaś, B.; Habryka, C. Pomace in fruit industry and their contemporary potential application. World Sci. News 2016, 48, 259–265. [Google Scholar]

- Katnić, Đ.; Marinović-Cincović, M.; Porobić, S.J.; Vujčić, I.; Šaponjić, A.; Sikirić, B.; Živojinović, D. Characterization and kinetics of thermal decomposition behavior of plum and fig pomace biomass. J. Clean. Prod. 2022, 352, 131637. [Google Scholar] [CrossRef]

- Spiess, W.E.L.; Wolf, W. Critical evaluation of methods to determine moisture sorption isotherms. In Water Activity; Theory and Applications to Food: Boca Raton, FL, USA, 1987. [Google Scholar]

- Lewicki, P.P. The applicability of the GAB model to food water sorption isotherm. Int. J. Food Sci. Technol. 1997, 32, 553–557. [Google Scholar] [CrossRef]

- OstroVIT 1. Available online: https://ostrovit.com/pl/products/ostrovit-blonnik-z-aronii-vege-200-g-25736.html?utm_source=iai_ads&utm_medium=google_shopping&curr=PLN (accessed on 31 January 2024).

- OstroVIT 2. Available online: https://ostrovit.com/pl/products/ostrovit-blonnik-jablkowy-vege-200-g-25738.html?query_id=1 (accessed on 31 January 2024).

- OstroVIT 3. Available online: https://ostrovit.com/pl/products/ostrovit-blonnik-z-czarnej-porzeczki-vege-150-g-25737.html?query_id=1 (accessed on 31 January 2024).

- Witczak, T.; Stępień, A.; Gumul, D.; Zięba, T.; Witczak, M. The influence of the extrusion proces with a minimal addition of corn meal on selected properties of fruit pomaces. J. Food Process Eng. 2020, 43, 4. [Google Scholar] [CrossRef]

- Reißner, A.M.; Al-Hamimi, S.; Quiles, A.; Schmidt, C.; Struck, S.; Hernando, I.; Turnerb, C.; Rohm, H. Composition and physicochemical properties of dried berry pomace. J. Sci. Food Agric. 2019, 99, 1284–1293. [Google Scholar] [CrossRef]

- Labuza, T.P.; Altunakar, B. Water activity prediction and moisture sorption isotherms. In Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2020; pp. 161–205. [Google Scholar] [CrossRef]

- Alongi, M.; Melchior, S.; Anese, M. Reducing the glycemic index od short dough biscuit by using apple pomace as a functional ingredient. LWT Food Sci. Technol. 2018, 100, 300–305. [Google Scholar] [CrossRef]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Samborska, K.; Wiktor, A.; Jedlińska, A.; Matwijczuk, A.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Tułodziecki, M.; Błażowski, Ł.; Witrowa-Rajchert, D. Development and characterization of physical properties of honey-rich powder. Food Bioprod. Process. 2019, 115, 78–86. [Google Scholar] [CrossRef]

- Rosland Abel, S.E.; Yusof, Y.A.; Chin, N.L.; Chang, L.S.; Ghazali, H.M.; Ghani, M.A.; Ishak, I. The effect of particle size on the physical properties of Arabic gum powder. J. Food Process Eng. 2020, 43, 4. [Google Scholar] [CrossRef]

- Witczak, T.; Stępień, A.; Gumul, D.; Witczak, M.; Fiutak, G.; Zięba, T. The influence of the extrusion process on the nutritional composition, physical properties and storage stability of black chokeberry pomaces. Food Chem. 2021, 334, 127548. [Google Scholar] [CrossRef] [PubMed]

- Chojnacki, J.; Zdanowicz, A.; Ondruška, J.; Šooš, Ľ.; Smuga-Kogut, M. The Influence of apple, carrot and red beet pomace content on the properties of pellet from barley straw. Energies 2021, 14, 405. [Google Scholar] [CrossRef]

- Li, X.; Bi, J.; Jin, X.; Wu, X.; Lyu, J.; Li, X.; Hu, L. Effect of the moisture equilibrium process on the expansion behavior of instant controlled pressure drop (DIC) drying of dried apple cubes. J. Sci. Food Agric. 2020, 100, 1635–1642. [Google Scholar] [CrossRef]

- Brunauer, S.; Deminig, L.S.; Deming, W.E.; Teller, E. On the theory of the van der Waals adsorption of gases. J. Am. Chem. Soc. 1940, 62, 1723–1732. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, L. Evaluation of the BET and GAB models for interpretation of soil water isotherms: A molecular simulation study. Comput. Geotech. 2023, 159, 105454. [Google Scholar] [CrossRef]

- Machado, C.M.; Benelli, P.; Tessaro, I.C. Study of interactions between cassava starch and peanut skin on biodegradable foams. Int. J. Biol. Macromol. 2020, 147, 1343–1353. [Google Scholar] [CrossRef] [PubMed]

- Cazzaniga, A.; Brousse, M.M.; Linares, R.A. Evaluation of sorption isotherms in snacks with pregelatinized cassava. Repos. Español Cienc. Y Tecnol. A 2022, 24, 28–35. [Google Scholar] [CrossRef]

- Fidriyanto, R.; Singh, B.P.; Manju, K.M.; Widyastuti, Y.; Goel, G. Multivariate analysis of structural and functional properties of fibres from apple pomace using different extraction methods. FoodProd. Process. Nutr. 2023, 5, 6. [Google Scholar] [CrossRef]

- Tulej, W.; Głowacki, S. Analysis of material-characterization properties of post-production waste—The case of apple pomace. Materials 2022, 15, 3532. [Google Scholar] [CrossRef]

- Afrin, S.M.; Acharjee, A.; Sit, N. Convective drying of orange pomace at different temperatures and characterization of the obtained powders. J. Food Sci. Technol. 2022, 59, 1040–1052. [Google Scholar] [CrossRef]

- O’shea, N.; Ktenioudaki, A.; Smyth, T.P.; McLoughlin, P.; Doran, L.; Auty MA, E.; Arendt, E.; Gallagher, E. Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. J. Food Eng. 2015, 153, 89–95. [Google Scholar] [CrossRef]

| Nutritional Value per 100 g | Chokeberry Fibre | Apple Fibre | Currant Fibre |

|---|---|---|---|

| Energy value | 111 kJ/270 kcal | 1105 kJ/268 kcal | 1084 kJ/264 kcal |

| Fat —saturated | 4.5 g 0.4 g | 3.2 g 0.6 g | 5.0 g 1.1 g |

| Carbohydrates —sugars | 17.4 g 16.7 g | 24.0 g 13.7 g | 12.0 g 5.3 g |

| Fibre | 62.0 g | 60.0 g | 65.5 g |

| Protein | 9.0 g | 5.8 g | 10.5 g |

| Salt | 0.000 g | 0.001 g | 0.000 g |

| Sample | Water Content (g/g d.m.) |

|---|---|

| chokeberry fibre | 0.0550 ± 0.0006 b |

| apple fibre | 0.0402 ± 0.0012 a |

| currant fibre | 0.0381 ± 0.0006 c |

| chokeberry pomace | 0.0798 ± 0.0128 a |

| apple pomace | 0.0713 ± 0.0009 e |

| currant pomace | 0.0768 ± 0.0005 d |

| Sample | Water Activity |

|---|---|

| chokeberry fibre | 0.424 ± 0.000 |

| apple fibre | 0.341 ± 0.000 |

| currant fibre | 0.324 ± 0.000 |

| chokeberry pomace | 0.321 ± 0.000 |

| apple pomace | 0.327 ± 0.000 |

| clack currant pomace | 0.364 ± 0.000 |

| Sample | L* | a* | b* |

|---|---|---|---|

| chokeberry fibre | 42.16 ± 0.25 c | 12.70 ± 0.08 e | 4.73 ± 0.03 c |

| chokeberry pomace | 36.54 ± 0.25 a | 8.53 ± 0.11 b | 4.38 ± 0.08 b |

| apple fibre | 69.08 ± 0.26 f | 8.05 ± 0.11 a | 24.29 ± 0.25 f |

| apple pomace | 57.35 ± 0.71 e | 9.22 ± 0.22 c | 21.81 ± 0.21 e |

| currant fibre | 48.18 ± 1.11 d | 14.41 ± 0.43 f | 5.37 ± 0.11 d |

| currant pomace | 37.71 ± 0.31 b | 11.60 ± 0.27 d | 3.91 ± 0.15 a |

| Sample | Density (g/cm3) | Bulk Density Lose (g/cm3) | Bulk Density Shaken (g/cm3) | Hausner Ratio | Carr’s Index |

|---|---|---|---|---|---|

| chokeberry fibre | 1.3669 ± 0.0014 c | 0.4537 ± 0.0059 b | 0.5427 ± 0.0064 b | 1.1964 ± 0.0208 ab | 16.40 ± 1.44 ab |

| apple fibre | 1.3747 ± 0.0014 c | 0.5146 ± 0.0155 c | 0.6225 ± 0.0005 c | 1.2104 ± 0.0371 c | 17.33 ± 2.57 b |

| currant fibre | 1.4671 ± 0.0037 f | 0.4822 ± 0.0105 b | 0.5572 ± 0.0061 b | 1.1557 ± 0.0134 ab | 13.47 ± 1.01 ab |

| chokeberry pomace | 1.3463 ± 0.0029 a | 0.5261 ± 0.0050 c | 0.6293 ± 0.0003 c | 1.1962 ± 0.0057 ab | 16.40 ± 0.40 ab |

| apple pomace | 1.4219 ± 0.0026 d | 0.4620 ± 0.0155 b | 0.5447 ± 0.0113 b | 1.1795 ± 0.0202 ab | 15.20 ± 1.44 ab |

| currant pomace | 1.4371 ± 0.0010 de | 0.4203 ± 0.0053 a | 0.4813 ± 0.0032 a | 1.1453 ± 0.0213 a | 12.66 ± 1.61 a |

| Sample | Equation Coefficient | R2 |

|---|---|---|

| chokeberry fibre | a = 27.280 | 0.981 |

| b = 0.889 | ||

| c = 0.051 | ||

| apple fibre | a = 75.399 | 0.995 |

| b = 0.955 | ||

| c = 0.026 | ||

| currant fibre | a = 24.573 | 0.971 |

| a = 0.897 | ||

| c = 0.057 | ||

| chokeberry pomace | a = 34.613 | 0.985 |

| b = 0.908 | ||

| c = 0.044 | ||

| apple pomace | a = 57.145 | 0.995 |

| b = 0.960 | ||

| c = 0.034 | ||

| currant pomace | a = 30.215 | 0.986 |

| b = 0.912 | ||

| c = 0.055 |

| Fibre | |||

|---|---|---|---|

| Chokeberry | Apple | Currant | |

| Equation coefficient | um = 0.048 | um = 0.056 | um = 0.043 |

| C = 55.960 | C = 8.047 | C = 18.816 | |

| k = 0.783 | k = 0.804 | k = 0.756 | |

| R2 | 0.995 | 0.990 | 0.989 |

| MRE(%) | 3.091 | 4.534 | 3.259 |

| RMS | 3.739 | 9.163 | 4.842 |

| RSS | 0.013 | 0.105 | 0.036 |

| SEE | 0.112 | 0.324 | 0.190 |

| Pomace | |||

| Chokeberry | Apple | Currant | |

| Equation coefficient | um = 0.072 | um = 0.065 | um = 0.059 |

| C = 2489.925 | C = 589.143 | C = 1.362 | |

| k = 0.723 | k = 0.772 | k = 0.744 | |

| R2 | 0.983 | 0.996 | 0.976 |

| MRE(%) | 3.354 | 2.156 | 4.409 |

| RMS | 4.201 | 3.293 | 5.272 |

| RSS | 0.030 | 0.017 | 0.049 |

| SEE | 0.173 | 0.131 | 0.221 |

| Sample | 1st Stage 30.00–130.00 °C | 2nd Stage 130.00–310.00 °C | 3rd Stage 310.00–380.00 °C | 4th Stage 380.00–600.00 °C | ||||

|---|---|---|---|---|---|---|---|---|

| T (°) | Weight Loss (%) | T (°) | Weight Loss (%) | T (°) | Weight Loss (%) | T (°) | Weight Loss (%) | |

| apple fibre | 66.88 | 5.21 | 243.36 | 29.89 | 344.74 | 9.89 | 422.23 | 5.10 |

| currant fibre | 64.31 | 6.65 | 242.88 | 19.56 | 340.07 | 10.19 | 428.17 | 12.17 |

| chokeberry fibre | 65.95 | 6.15 | 287.33 | 13.36 | 348.58 | 5.61 | 425.23 | 12.31 |

| apple pomace | 67.32 | 3.89 | 242.45 | 24.31 | 346.80 | 4.76 | 430.22 | 10.03 |

| currant pomace | 66.95 | 6.03 | 239.72 | 18.59 | 343.32 | 7.82 | 425.76 | 7.89 |

| chokeberry pomace | 66.54 | 6.14 | 288.30 | 14.25 | 353.96 | 4.21 | 418.42 | 15.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakulska, A.; Kawecka, L.; Galus, S. Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications. Appl. Sci. 2024, 14, 9051. https://doi.org/10.3390/app14199051

Pakulska A, Kawecka L, Galus S. Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications. Applied Sciences. 2024; 14(19):9051. https://doi.org/10.3390/app14199051

Chicago/Turabian StylePakulska, Anna, Ludwika Kawecka, and Sabina Galus. 2024. "Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications" Applied Sciences 14, no. 19: 9051. https://doi.org/10.3390/app14199051

APA StylePakulska, A., Kawecka, L., & Galus, S. (2024). Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications. Applied Sciences, 14(19), 9051. https://doi.org/10.3390/app14199051