Abstract

The depletion of conventional light petroleum reserves has intensified the search for alternative sources, notably, low-quality heavy oils and byproducts from heavy crude processing, to meet the global demand for fuels, energy, and petrochemicals. Heavy crude oil (HO) and extra heavy crude oil (EHO) represent nearly 70% of the world’s reserves but require extensive upgrading to satisfy refining and petrochemical specifications. Their high asphaltene content results in elevated viscosity and reduced API gravity, posing significant challenges in extraction, transportation, and refining. Advanced catalytic approaches are crucial for efficient asphaltene removal and the conversion of heavy feedstocks into valuable light fractions. Kaolin, an aluminosilicate mineral, has emerged as a key precursor for zeolite synthesis and a promising catalyst in upgrading processes. This article provides a comprehensive exploration of kaolin’s geological origins, chemical properties, and structural characteristics, as well as the various modification techniques designed to improve its catalytic performance. Special focus is given to its application in the transformation of heavy crudes, particularly in facilitating asphaltene breakdown and enhancing light distillate yields. Finally, future research avenues and potential developments in kaolin-based catalysis are discussed, emphasizing its vital role in addressing the technological challenges linked to the growing reliance on heavier crude resources.

1. Introduction

Kaolin, which is an essential mineral found abundantly on the earth’s surface, has been extensively studied in both ancient and modern geological research. Named after a mountain region in southeast China, where it was first discovered and mined, kaolin translates to “gem” and is highly valued in various industrial applications [1,2]. Kaolin, a hydrated aluminosilicate mineral, predominantly comprises the crystalline mineral kaolinite [3], which is a triclinic, two-layer clay mineral that belongs to the class of phyllosilicates. The theoretical chemical composition of kaolinite is represented by the formula Al2Si2O5(OH)4, which translates to 46.54% SiO2, 39.5% Al2O3, and 13.96% H2O by weight. However, other minerals can be found in kaolin raw materials, in addition to kaolinite, including halloysite, dickite, nacrite, mica, and quartz, as well as metal oxides such as K2O, CaO, TiO2,Fe2O3,Na2O, MgO, MnO, and P2O5 as impurities. These minerals are typically found in hydrothermal deposits and are often combined with kaolinite. Halloysite, for instance, has relatively few pure deposits, with one of the few working commercial halloysite deposits located on the North Island of New Zealand.

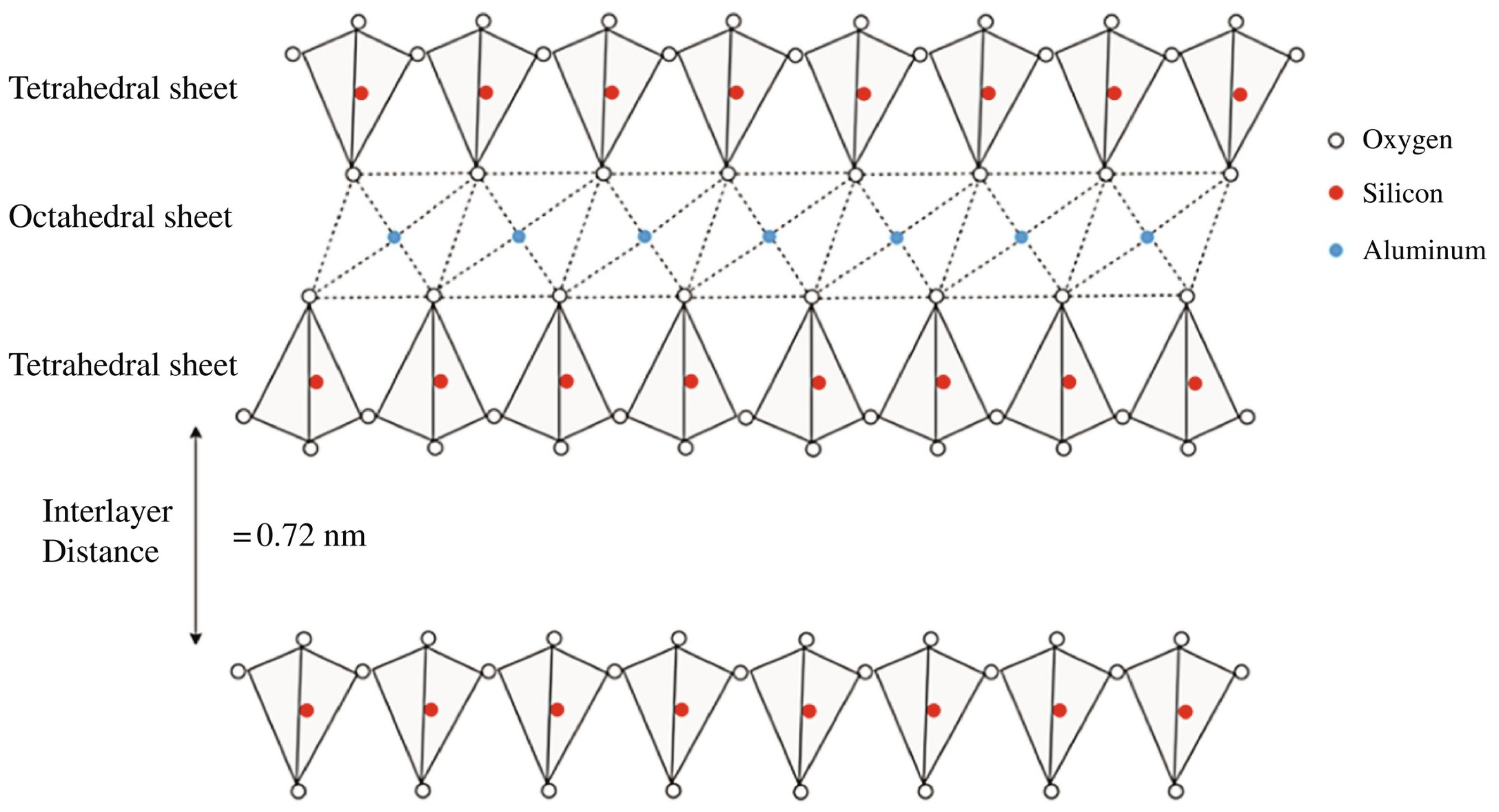

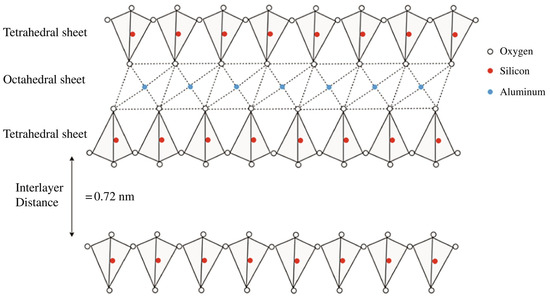

The structure of kaolinite is characterized by a layered arrangement consisting of alternating tetrahedral and octahedral sheets (Figure 1) [4]. The tetrahedral sheets are composed of silicon–oxygen (SiO4) tetrahedra, in which each silicon atom is surrounded by four oxygen atoms, forming a tetrahedral shape. These tetrahedra are linked together in a hexagonal pattern through shared oxygen atoms, creating a continuous two-dimensional sheet of SiO4. Directly bonded to the tetrahedral sheet is the octahedral sheet, which is composed of aluminum–oxygen–hydroxyl (AlO6(OH)4) octahedra. In this configuration, each aluminum atom is surrounded by six oxygen or hydroxyl groups, forming an octahedral shape. The octahedral sheets are connected to the tetrahedral sheets through shared oxygen atoms, which act as bridging atoms between the silicon and aluminum layers. This composite structure results in a two-layered arrangement in which one tetrahedral sheet is bonded to one octahedral sheet, forming a “1:1 layer”. The layers are held together by hydrogen bonds between the hydroxyl groups of the octahedral sheet and the oxygen atoms of the tetrahedral sheet in adjacent layers.

Figure 1.

Schematic structure of the kaolin minerals. Figure extracted from A. Hamza et al. (2023) [4]. Reproduced with the permission of Elsevier.

Based on its structure, kaolin exhibits unique properties, such as its non-swelling nature, small particle size, well-defined dimensions, specific chemical structure, elemental makeup, and low cation exchange capacity (CEC) [5]. These characteristics make it suitable for use in coatings and materials requiring dimensional stability, as well as for food-grade applications due to its minimal reactivity with other compounds [6]. Its small particle size and dimensional properties enhance the wettability, smoothness, and durability of materials, while its chemical composition contributes to its utility in environments requiring chemical and heat resistance. Therefore, kaolin’s versatility and abundance render it a valuable raw material for numerous applications across various industrial sectors. Advancements in kaolin-based materials have enabled their use in multiple forms, particularly in paper manufacturing as a filler and coating agent to enhance printing quality. Its low abrasiveness, combined with its softness and low thermal and electrical conductivity, further increases its commercial value. Although kaolin primarily serves applications in the paper industry, it is also extensively used in ceramics, rubber, plastics, paints, adhesives, and catalysis [7].

Recent advancements have facilitated the production of microporous zeolite frameworks and mesoporous aluminosilicates from kaolin [8,9,10,11]. However, its natural acidity and surface area are lower compared to smectites, palygorskite, and sepiolite, which is attributed to the limited substitution in the kaolin layer [12]. Consequently, enhancing the acidity of kaolin requires the incorporation of specific components into its structure [13]. Research indicates that acid-treated kaolin can improve catalytic efficacy, increase specific surface area, and introduce new acid sites on the surface of the material. This characteristic makes kaolin suitable for various chemical processes, such as enhancing the production of aromatic compounds and improving deoxidation activity [14,15].

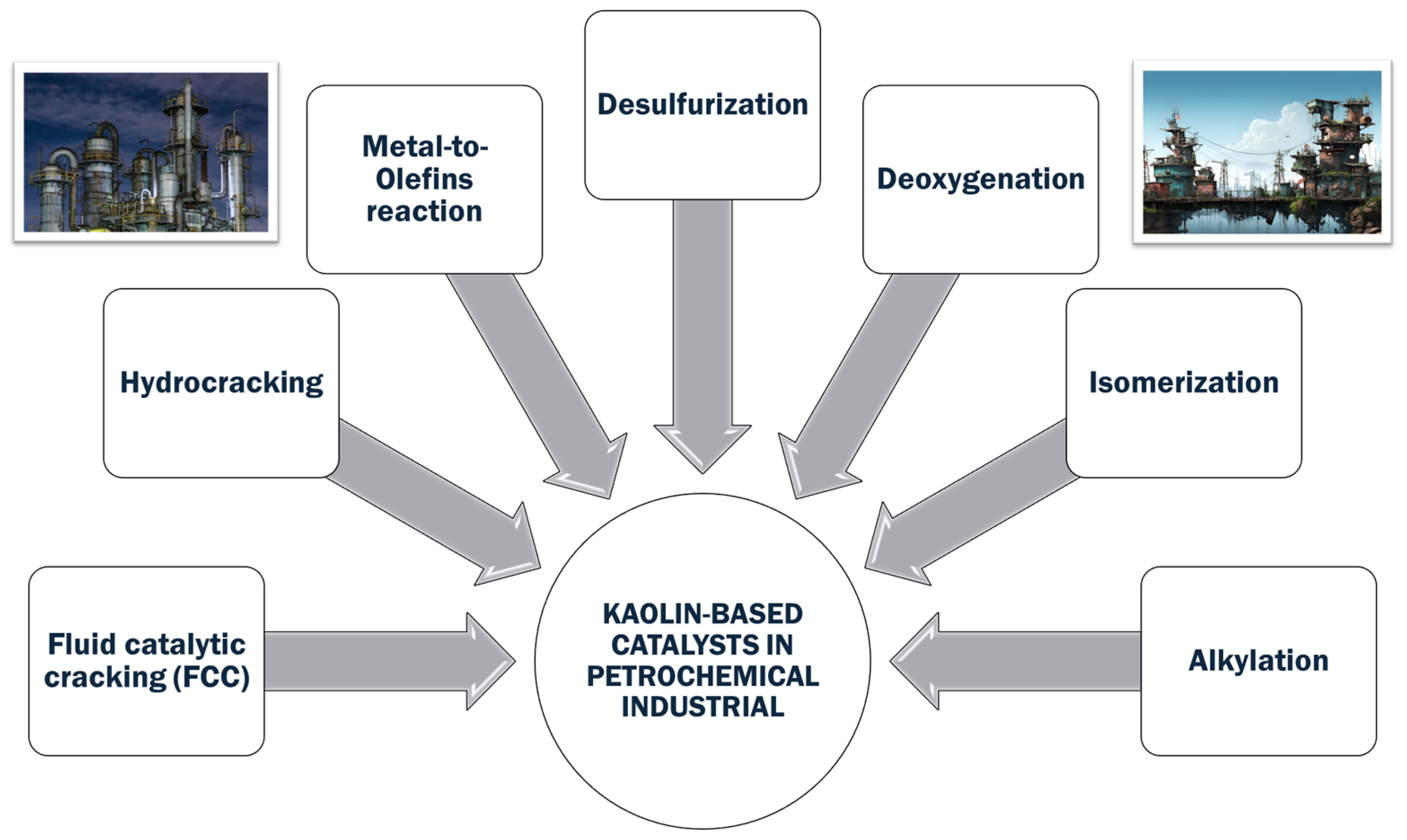

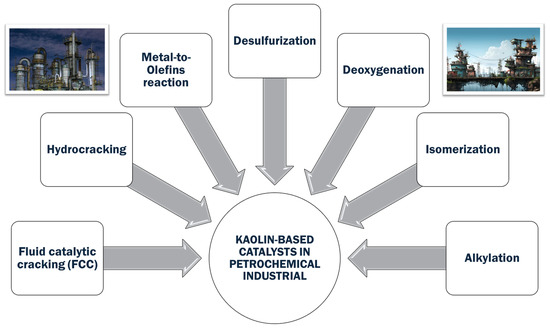

Moreover, kaolin has gained prominence in the petrochemical sector as a catalyst and precursor for many significant industrial processes [16]. As mentioned before, the modification of kaolin-introducing acid sites is a crucial methodology for its use in catalytic cracking reactions, in which kaolin-based catalysts are used to break down large hydrocarbon molecules into more valuable light olefins like ethylene and propylene. In the context of petrochemical applications, kaolin has been extensively studied for its role in producing zeolites and mesoporous materials. Zeolites synthesized from kaolin exhibit excellent thermal stability, acidity, and pore structure, making them effective catalysts for a wide range of chemical reactions. These properties are particularly beneficial in fluid catalytic cracking units, in which zeolite-based catalysts derived from kaolin help optimize the conversion of heavy crude oil into lighter, more valuable products [17]. Moreover, kaolin’s ability to improve the mechanical strength and thermal stability of catalysts further underscores its importance in the petrochemical industry. The incorporation of kaolin into catalyst formulations enhances their resistance to sintering and deactivation, thereby extending the catalyst’s operational life and efficiency. This durability is essential in high-temperature processes, such as hydrocracking and catalytic reforming, in which maintaining catalyst performance over prolonged periods is critical [18].

In addition to its catalytic applications, kaolin also plays a significant role in the production of proppants used in hydraulic fracturing [19,20]. Proppants are materials injected into shale formations to keep the fractures open, allowing for the extraction of oil and gas. Kaolin-based proppants offer high strength and conductivity, ensuring efficient resource recovery and reducing the environmental impact of drilling operations. Recent research has also explored the potential of kaolin in environmental applications related to the petrochemical industry. Modified kaolin has been investigated for its capacity to adsorb and remove pollutants from wastewater, including heavy metals and organic contaminants [21,22]. This application not only helps mitigate the environmental footprint of petrochemical processes but also contributes to sustainable industrial practices.

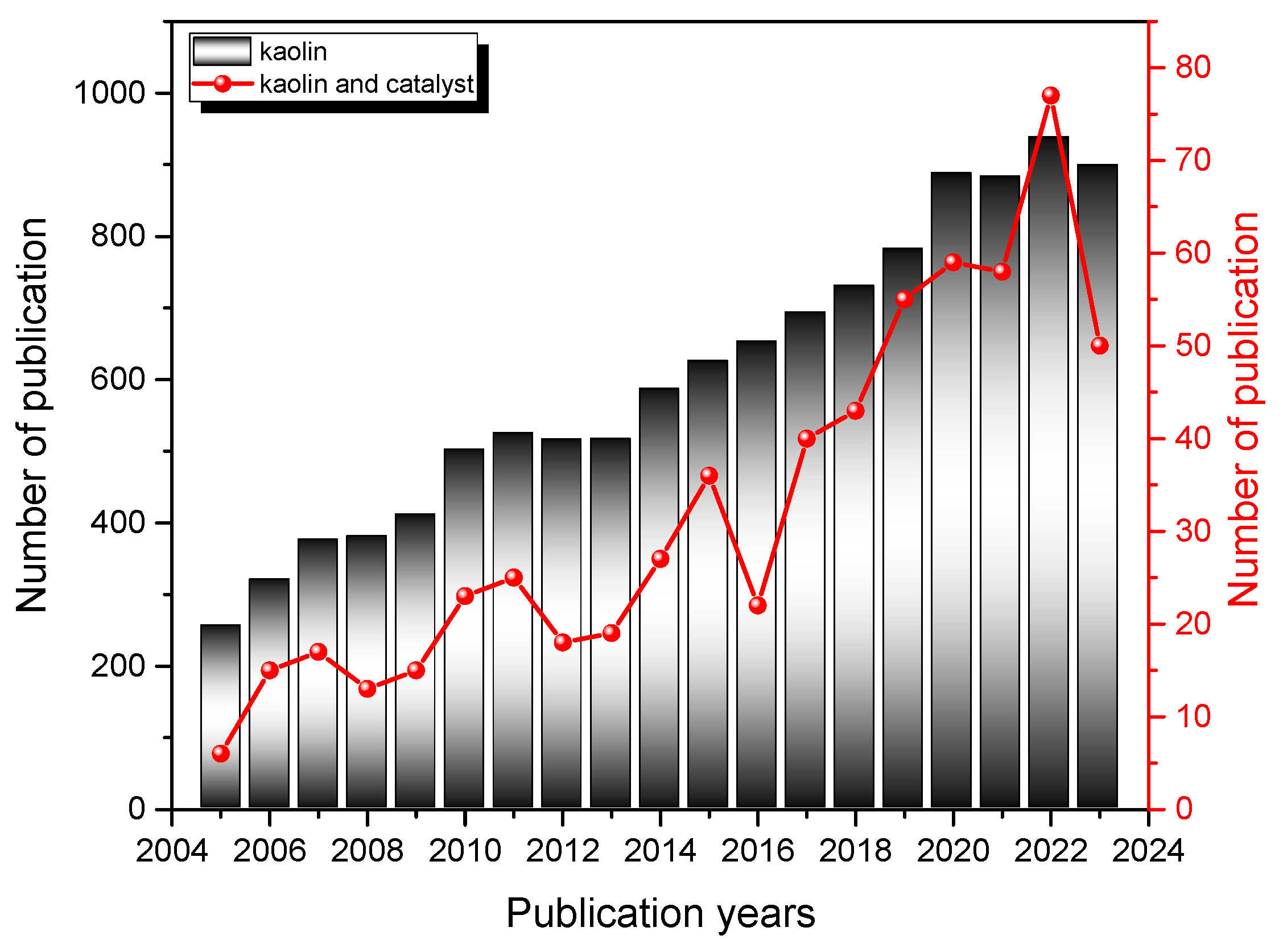

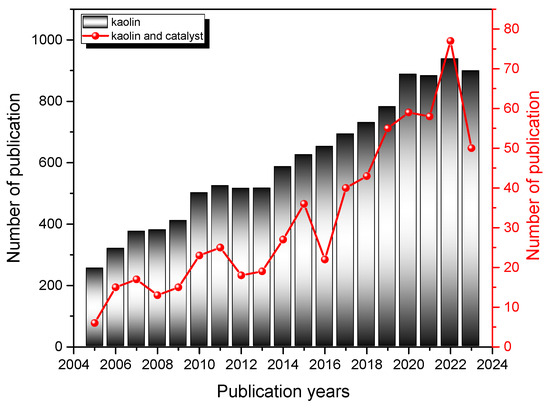

As research and technology continue to advance, the significance of kaolin in the petrochemical sector is expected to grow, driving innovation and efficiency in this critical industry. Figure 2 shows a bibliometric analysis that highlights how interest in kaolin-based materials in general (columns), and kaolin applied in the catalysis field in particular (line), as a research topic has grown in recent years.

Figure 2.

Number of publications containing the words “kaolin” and “kaolin and catalysis” per year in the period (2005–2024) in the Web of Science (WOS) database. Columns and lines correspond to searches with words in the title, abstract, or keywords, as reported in the inset.

Herein, a comprehensive overview of kaolin is provided, exploring the physicochemical properties of kaolin that make it suitable for catalysis in the petrochemical industry. The review comprises six sections, as follows: it begins with an introduction (Section 1), followed by a geological perspective on the classification of kaolin based on its origin in Section 2. Section 3 discusses worldwide kaolin clay production, demand patterns, and market trends. Section 4 delves into key chemical, structural, and functional properties of kaolin. Section 5 covers modification processes to enhance its industrial applicability, while Section 6 unlocks the potential advanced applications of kaolin in various industries. Section 7 specifically focuses on kaolin in petrochemical catalysis, from fundamental principles to recent innovations. The discussion concludes with Section 8, highlighting promising solutions and future outlooks to ensure the continued prominence of kaolin in modern industrial catalysis for petrochemical processes, including recent advancements in the development of new materials.

2. Classification of Kaolin Based on the Origin: A Geological Perspective

Kaolins can be classified based on their origin into primary categories of pure aluminum silicate minerals with hydroxyl groups, such as kaolinite, dickite, halloysite, and nacrite. These minerals share the chemical formula [Al2(OH)4Si2O5], are predominantly found as fine particles, small sheet-like crystals, or clusters of white earth (<2 μm), and are seldom observed as macroscopic crystals [23]. A summary of the historical milestones in the classification of kaolin minerals is provided below [24,25,26]. The term “kaolinite” was first applied by Johanson and Blake in 1867 based on samples from Kau Ling (High Ridge), a hill near Jauchau Fu, China [27,28]. “Dickite” was named by Allan Brugh Dick in 1908 from specimens found on the Island of Anglesey, Wales, UK [27,28]. The mineral “nacrite” was identified by Brongniart in 1807 at the Einigkeit mine in Brand-Erbisdorf, Freiberg, Saxony, Germany [27,28]. Lastly, “halloysite” was first described by Berthier in 1826 from samples collected in Liege, Belgium [29,30].

Kaolin minerals, which are crucial for various industrial applications, are distributed globally, but only a few deposits meet high quality standards. The grade classification of raw kaolin typically influences its price and suitability for different industrial uses. The main constituents of kaolin are SiO2, which makes up about 46%, and Al2O3, which makes up around 38% [27]. The quality of natural kaolin fillers is regulated by ISO 3262, Part 8, which specifies that high-quality kaolin must contain at least 90% kaolinite (a hydrated aluminum silicate). Commercial kaolin typically comprises kaolinite as the primary component, along with other minor minerals that vary depending on the deposit’s characteristics. This material, which is commonly referred to as kaolin or China clay [28], is extensively used in various industries. Notably, dickite and nacrite are not subject to large-scale exploitation, and this overview does not cover other industrial minerals that also contain significant amounts of kaolinite.

The mineral kaolinite, which imparts the characteristic white hue to kaolin, is prevalent in sedimentary formations akin to kaolin deposits found worldwide. Kaolin is found as sedimentary rock, and its deposits are broadly classified into primary (residual) and secondary (redeposited) types [7]. Primary kaolin forms in situ from the weathering of feldspar-rich crystalline rocks, such as granite (feldspar, muscovite, and quartz) [29]. This process, known as “kaolinization”, disintegrates the rocks into smaller fragments, which are subsequently transported by wind or water. Then, these primary deposits remain at their original location of formation. The modification may involve hydrothermal transformation or weathering under humid, acidic climatic conditions (involving CO2-containing waters). Primary deposits often contain 15% to 30% kaolin, with the remainder consisting of unaltered granite components like feldspar, muscovite, and quartz. In contrast, secondary kaolin deposits result from the erosion of primary deposits, with the eroded materials being transported and subsequently deposited in sedimentary environments like streams, lakes, and basins. Smaller and lighter kaolin particles can travel longer distances, eventually settling in lakes, estuaries, and lagoons to form secondary deposits. In other words, secondary kaolin deposits are generated when existing kaolin deposits undergo reworking through alteration or other geological processes, leading to the accumulation of new kaolinite layers over older ones. Primary deposits include China clay found in Cornwall, England [30]. Secondary deposits, exemplified by those in Georgia and South Carolina (USA), are also a result of this process [31,32]. Impurities in secondary kaolin deposits may include graphite, anatase, pyrite, quartz, muscovite, and smectite. The color of kaolinite can vary from white to grayish-white, depending on the presence of these impurities. There are notable differences between primary and secondary kaolin deposits. Primary clays tend to have larger particle sizes and lower concentrations of anatase and iron oxide compared to secondary clays. Then, the formation of kaolin involves complex geological processes that differentiate primary and secondary deposits, each with distinct characteristics and compositions. These distinctions are critical for various industrial applications, including their role in catalysis for petrochemical processes.

3. Worldwide Kaolin Clay Production, Demand Patterns, and Market Trends

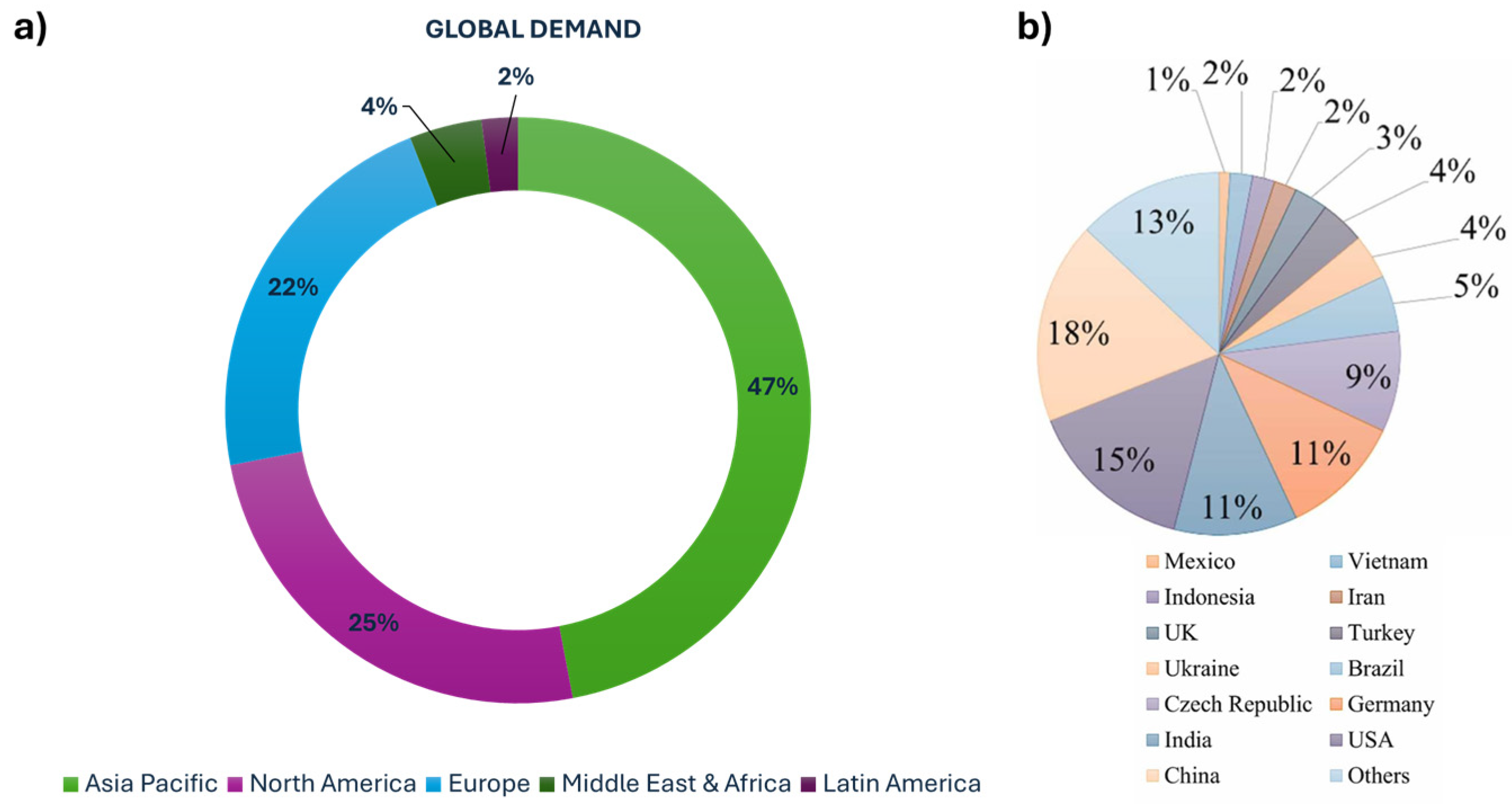

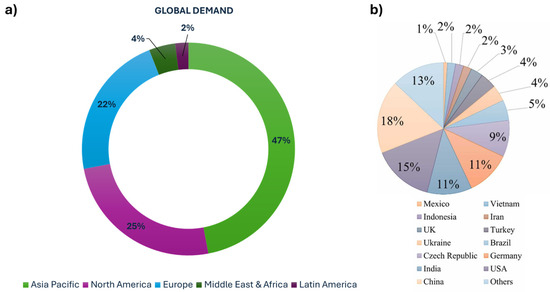

Due to the versatile applications of kaolin, global demand is expected to continue growing. According to “Precedence Research Market Company” (Figure 3a) [33], the regional demand for kaolin in 2022 showed that the Asia–Pacific region had the highest demand at 47% of 24.8 million metric tons (MMts), according to the stats released by the United States Geological Survey (USGS) in 2022, while the Middle East, Africa, and Latin America had the lowest demand at 6%. Other regions, including Europe and North America, demonstrated moderate demand for the mineral. This high demand correlates with the global production pattern of kaolin.

Figure 3.

(a) Regional demand [33] and (b) production by country of kaolin clay [34].

Over the past 15 years, kaolin production worldwide has shown an upward trend, increasing by 22% from 31.5 million tonnes (Mt) in 2010 to 38.5 Mt in 2018. In 2018, the United States led in kaolin production, with 7.3 Mt, followed by Germany (4.3 Mt), India (4.1 Mt), the Czech Republic (3.5 Mt), China (3.2 Mt), Brazil (2.0 Mt), Turkey (1.9 Mt), and Ukraine (1.8 Mt), according to data provided by the study on the EU’s list of critical raw materials in 2020 [34]. Between 2009 and 2016, kaolin production increased by an average of 500 kilotons (kT) per year, with a significant surge of +5 Mt in 2017, mainly due to contributions from the United States, India, Germany, and the Czech Republic (Figure 3b). Developing countries like India and China have steadily increased their kaolin processing capabilities and expanded their industrial production capacity, leading to greater participation in the global kaolin trade. However, these countries primarily produce rough-processed kaolin, with most of their kaolin sales directed to geo-developing nations.

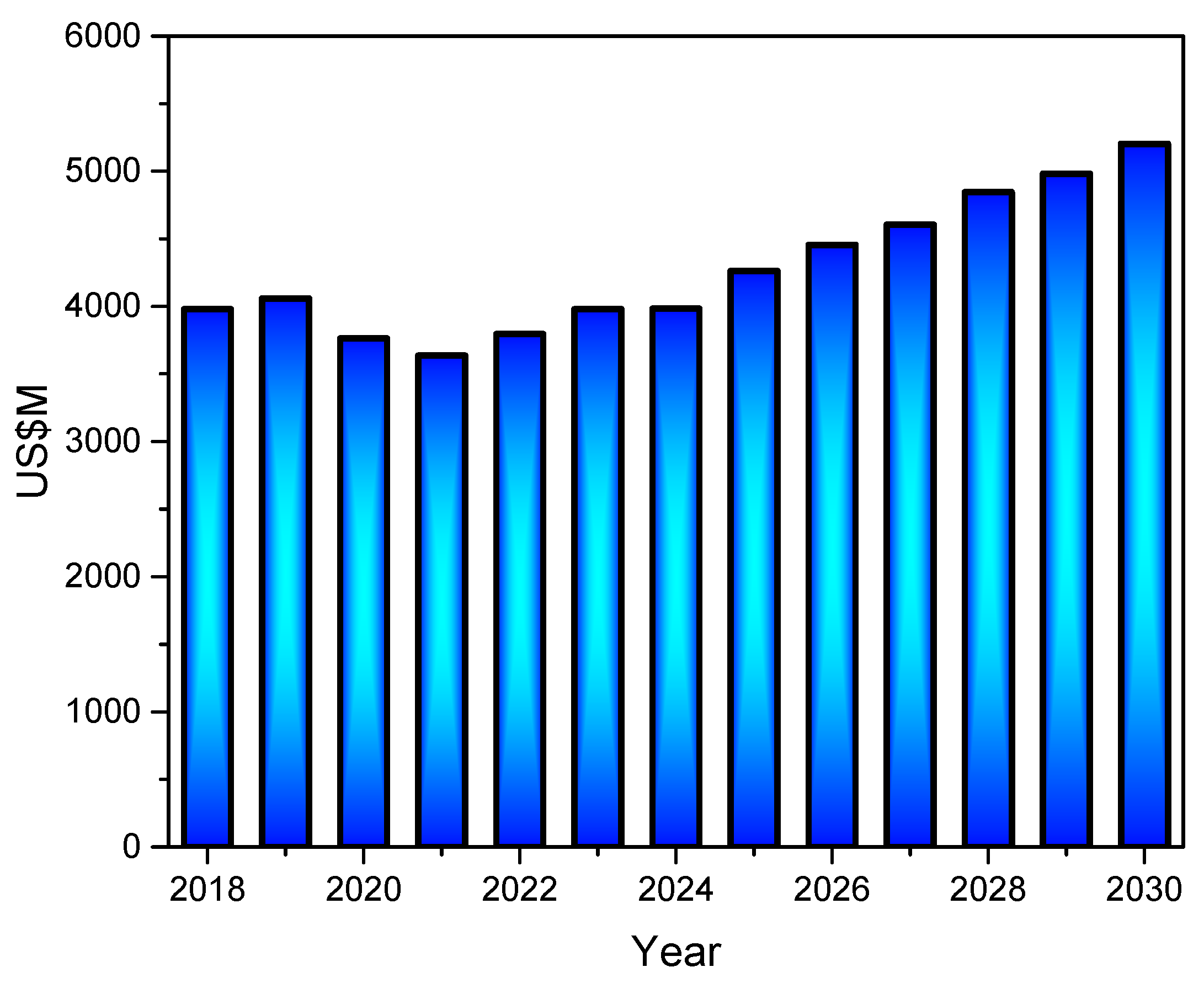

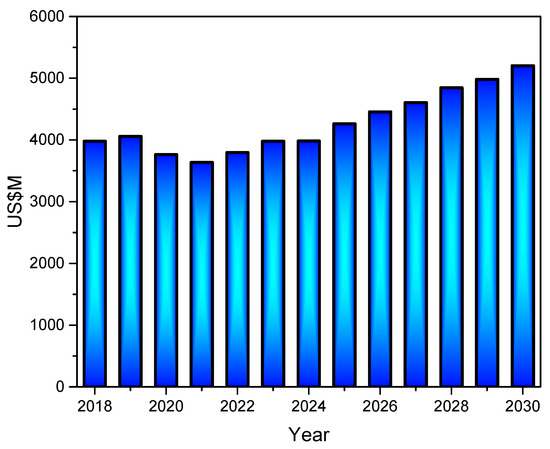

According to market research, the kaolin market was valued at USD 3.98 billion in 2023 and is projected to increase at a compound annual growth rate (CAGR) of 3.9% from 2024 to 2030, with a revenue forecast in 2030 of USD 5.20 billion (Figure 4) [35]. The growing investment in the construction and infrastructure sectors is augmenting the demand for paints and coatings, ceramic-based products, and cement, thereby driving market growth.

Figure 4.

Global kaolin market from 2018 to 2030, following Grand View Research database [35].

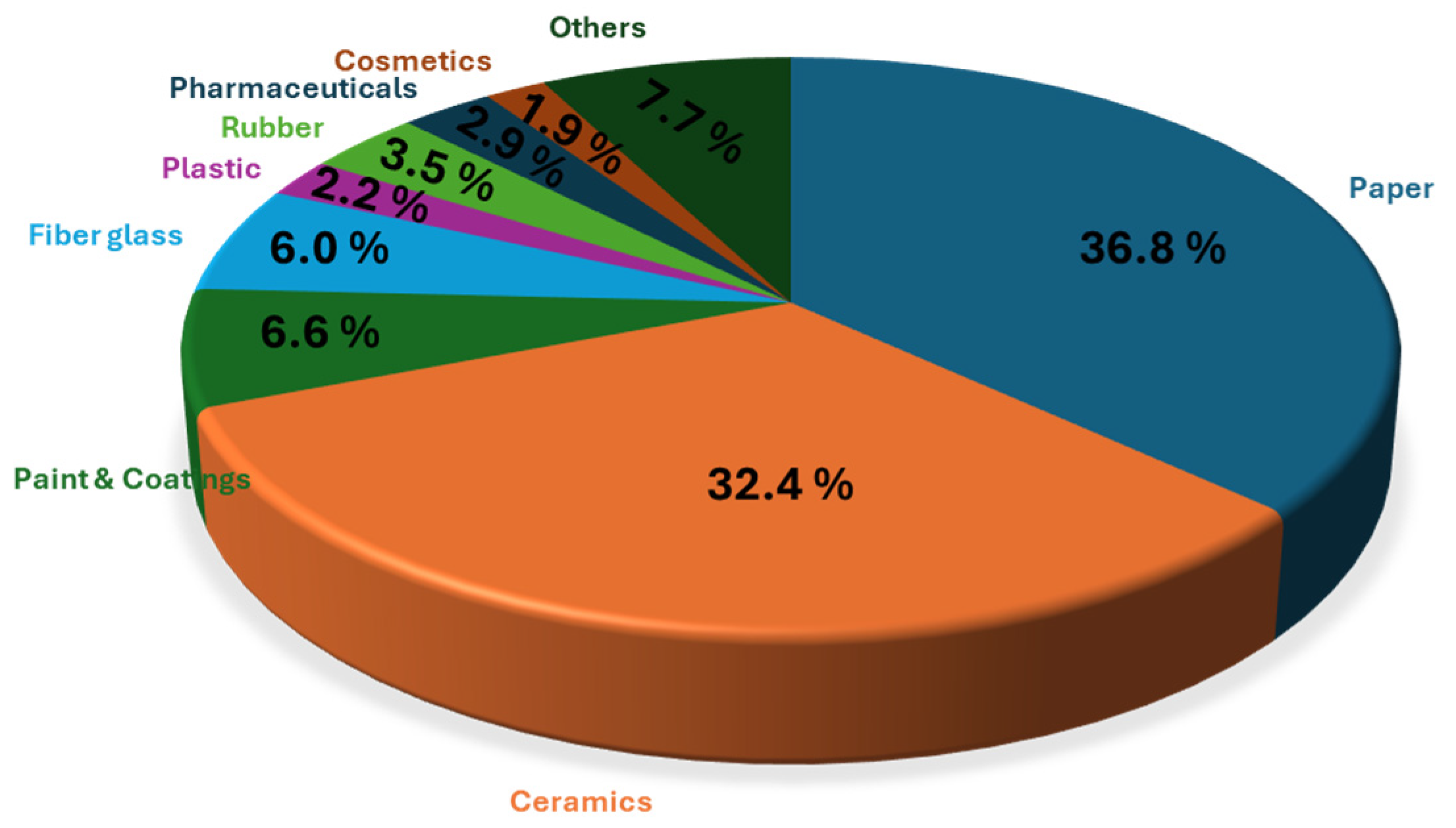

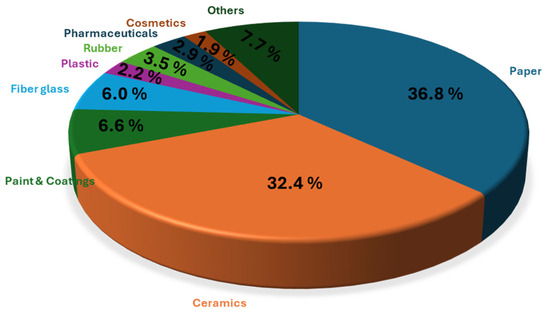

Regarding trends of the global kaolin market, the paper industry led the kaolin market, holding nearly 37.0% of the revenue share in 2023 (Figure 5) [36]. Kaolin improves paper’s brightness, opacity, smoothness, and printability, thereby enhancing ink absorption and pigment holdout. The ceramics segment was the second largest, with an expected revenue CAGR of 5.4% due to kaolin’s fine particle size, chemical inertness, and high fusion temperature, making it ideal for porcelain and bone china. Paints and coatings also showed significant growth potential, driven by construction demand and kaolin’s properties like better suspension and water resistance. Conversely, the rubber segment is projected to decline due to the rise of substitutes and increased use of calcined products for heavy-duty insulation rubber. The sector encompassing other applications, which represents approximately 8%, includes areas such as catalysis, environmental remediation, medicine, agriculture, etc.

Figure 5.

Application insights of the global kaolin market for 2024, according to the Grand View Research database [36].

4. Key Properties of Kaolin: Chemical, Structural, and Functional Insights

Kaolin’s unique properties, including its chemical inertness, adsorbent capabilities, non-swelling nature, and soothing and detoxifying effects, make it a valuable material for diverse applications. This clay appears bright white upon extraction, but it can develop yellow or rust-colored stains due to contact with iron oxide. Naturally, kaolin exists as a finely textured powder with the following characteristics [37]:

- Chemistry: Unprocessed kaolin has the chemical formula Al2Si2O5(OH)4. Kaolinite, an aluminum silicate mineral, is formed through the chemical weathering of aluminum-rich feldspars found in pegmatites and granites.

- Structure: Kaolin consists of hexagonal crystals ranging from 0.1 to 10 μm in size. The layered structure of these crystals enhances the desirable properties of kaolin.

- Chemically Inert: Kaolin’s lack of reactivity makes it ideal for use in pharmaceuticals, cosmetics, and various industrial applications. Its neutral pH ensures it does not alter the chemical composition of products or promote bacterial growth.

- Adsorbent: Kaolin’s natural absorbency allows it to remove unwanted pollutants, pathogens, and other components from mixtures, thereby enhancing its effectiveness in various applications.

- Non-swelling: The hydrogen bonds between kaolinite crystals prevent water molecules from infiltrating the layers, resulting in kaolin’s non-swelling properties. This makes it a stable additive that does not alter the physical properties of mixtures or products.

- Molecular Stability: Kaolinite exhibits non-expanding behavior and minimal isomorphous replacement due to its high molecular stability. While kaolinite is the least reactive clay, its sensitivity to pH can influence metal adsorption. Metal adsorption occurs through the release of hydrogen (H+) ions at the mineral’s edge sites and on the exposed planar surfaces of the silica and alumina sheets.

- Soothing Properties: Kaolin’s calming properties make it useful for soothing red, irritated skin, benefiting those with sensitive or sunburned skin by reducing redness and irritation.

- Detoxification: Kaolin’s cleansing properties help remove dirt, oil, and impurities from the skin, revitalizing and freshening the complexion by eliminating dead skin cells and debris.

- Gentle Exfoliation: The slightly abrasive texture of kaolin clay enables it to exfoliate the skin gently, promoting a smoother, more luminous complexion by clearing away dead skin cells and unclogging pores.

- Healing Qualities: Kaolin clay is believed to have healing properties and can help treat skin issues such as psoriasis, eczema, and acne. While more research is needed to confirm its efficacy for specific conditions, kaolin clay is widely used in the cosmetic and skincare industries due to its versatility, gentleness, and beneficial properties for various skin issues.

5. Modification Processes of Kaolin: Enhancing Industrial Applicability

Kaolin is a widely available and cost-effective layered silicate mineral. Prior to any modifications, the raw material is collected, crushed, and sieved to achieve the desired particle size. However, unprocessed kaolin often exhibits limitations such as low purity, large particle size, hardness, and suboptimal performance, rendering it inadequate for modern industrial applications. To overcome these limitations and increase kaolin’s value and economic effectiveness across various industries, various methods have been developed to enhance its specific surface area, catalytic activity, and adsorption efficiency. Its high specific surface area, ion exchange capacity, and unique layered structure provide excellent reactive activity and adsorption capabilities.

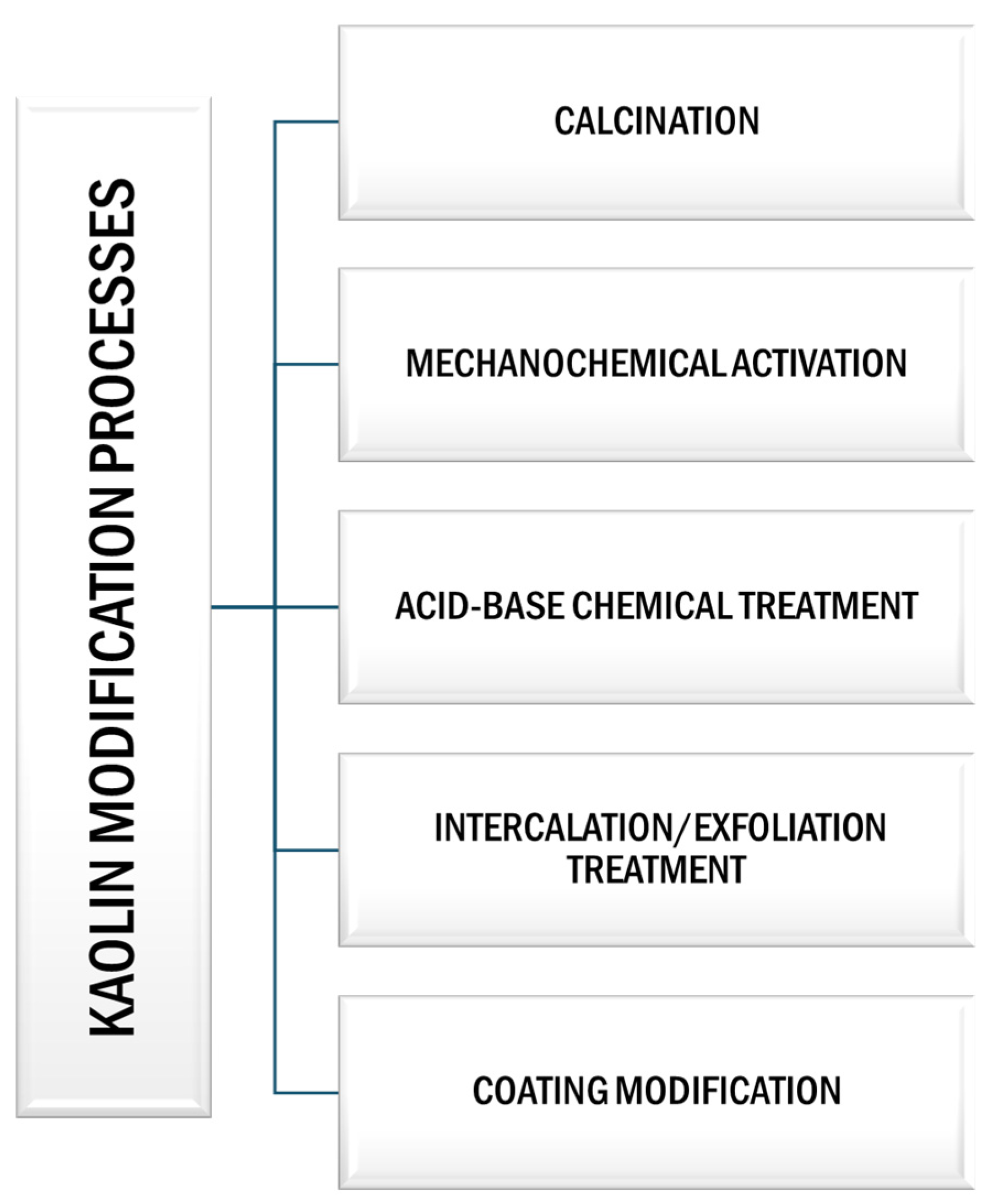

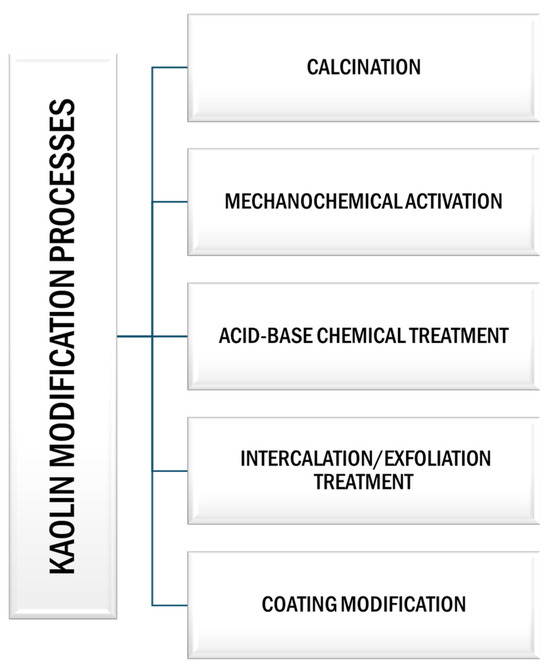

These modification techniques include heat treatment by calcination, mechanochemical activation, chemical (acid–base) modification, intercalation/exfoliation treatment, and coating modification, among others (Figure 6).

Figure 6.

Schematic representation of different modification processes of kaolin.

5.1. Calcination Process

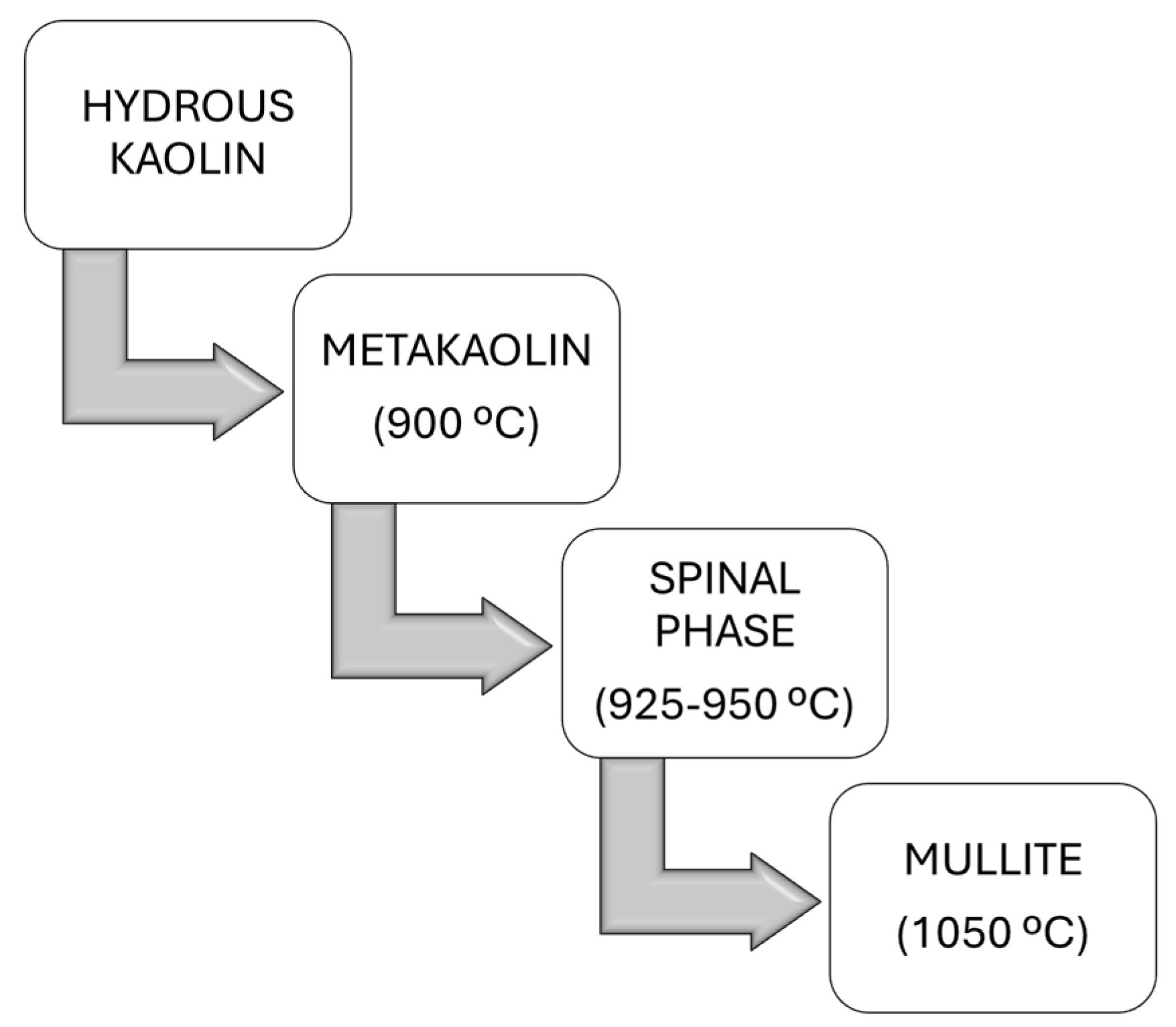

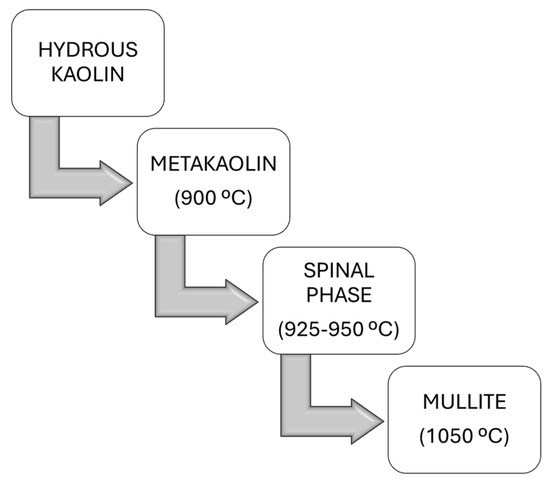

Kaolin containing an attached water molecule is classified as hydrous. The chemical formula of hydrous kaolin is ((Al2O3)(2SiO2)(2H2O)), and this form of kaolin, also referred to as washed kaolin, is extracted from raw kaolin in the earth’s crust through a process commonly known as levigation. The water molecule can be removed from hydrous clay through calcination, a process involving heating the clay to high temperatures, which enhances its color. This process produces calcined clay. By varying the calcination temperature, the following distinct phases can be achieved (Figure 7): metakaolin (550–900 °C), spinel (925–1050 °C), or mullite (>1050 °C) [38].

Figure 7.

Phase transition of hydrous kaolin to mullite via calcination temperature adjustment.

Endothermic dehydroxylation, or dehydration, is the process by which disordered metakaolin (Al2Si2O7) is formed through the removal of structural hydroxyl groups and the emission of water vapor [39,40]. The dehydroxylation of hydroxyl groups in kaolinite begins at 800 °C, leading to the disintegration of its crystal lattice and resulting in an amorphous structure of metakaolin enriched with active alumina and silica. This dehydroxylation process is activated when kaolin undergoes thermal treatment at 800 °C and can persist up to 900 °C, as detailed in Equation (1).

2Al2Si2O5(OH)4 → 2Al2Si2O7 + 4H2O

This induces the breakdown of the crystal lattice structure, resulting in the formation of an amorphous metakaolin structure, which is rich in both active silica and alumina. Research indicates that metakaolin is not merely a mixture of amorphous alumina (Al2O3) and silica (SiO2) but rather has a complex amorphous structure with hexagonal layers and some degree of long-range order that is not fully crystalline [41]. Further heating to temperatures between 925 and 950 °C transforms metakaolin into a phase known as aluminum–silicon spinel (Si3Al4O12), also referred to as a gamma-alumina-type structure. This transformation is represented by the following reaction (Equation (2)):

2Al2Si2O7 → Si3Al4O12 + SiO2

The calcination temperature significantly affects the environment of the aluminum atoms within the metakaolin, leading to variations in the material’s structure and properties, including its mechanical strength and thermal conductivity [42]. During calcination at 1050 °C, the spinel phase (Si3Al4O12) nucleates and subsequently transforms into mullite (3Al2O3·2SiO2) and highly crystalline cristobalite (SiO2), as illustrated by the following reaction (Equation (3)):

3Si3Al4O12 → 2Si2Al6O13 + 5SiO2

5.2. Mechanochemical Activation

Mechanochemical activation is a modification technique that involves the reduction of particle size, leading to the increased pore volume and surface area of kaolinite materials [43]. This process enhances the surface reactivity of kaolinite and improves its ion exchange capacity. Mechanochemical activation can be achieved through specific micronization processes (dry pulverization of kaolin raw materials, vibratory mills, jet mills, cyclone autogenous mills, high-speed mechanical impact, ultrafine pulverizes, etc.) or industrial grinding techniques (wet grinding, extrusion, chemical immersion, and dry superfine grinding) [44]. During mechanochemical activation, kaolinite particles undergo delamination, resulting in the formation of large spheroidal agglomerates from the delaminated particles. The delaminated product is a wet xerogel with a randomly structured network, in which hydroxyl units interact to form coordinated water molecules. This interaction is a result of proton migration between hydroxyl units, a process known as prototropy (Equations (4) and (5)).

OH− ⇔ H+ + O2−

H+ + OH− ⇔ H2O

The grinding process leads to a decrease in the structural order of kaolinite, which coexists with disordered materials. The degree of structural order in the delaminated precursor significantly influences the physicochemical properties of the mechanochemically activated kaolinite. Specifically, kaolinite with high structural order experiences a more pronounced effect from mechanochemical activation compared to kaolinite with lower structural order [45]. Excessive grinding, however, can negatively impact the kaolinite crystal structure, transforming it into an amorphous material with reduced surface area and pore volume. This alteration affects the overall performance and application potential of the kaolinite material in various industrial processes.

5.3. Acid–Base Chemical Treatment

Chemical activation is a widely utilized method for modifying kaolin clay, with numerous studies documenting the improvement of surface properties through this procedure. The chemically modified kaolin acquires improved physical and chemical properties, making it suitable for more specialized applications, particularly in catalysis, to improve the activity and product selectivity of chemical reactions of interest [16]. This technique has been extensively researched not only for kaolin but also for enhancing the surface and catalytic properties of fibrous clays, such as sepiolite and palygorskite, and smectites clays, including saponite and montmorillonite [37].

5.3.1. Acid Activation

Acid-activated kaolinite is widely utilized in adsorption and ion exchange due to its enhanced properties post-activation, but also for increasing the catalytic properties and adsorption capacity due to the acid activation process improves the acidity, surface area, pore size, and volume of kaolinite [46,47]. This treatment leads to dealumination, the removal of mineral impurities, the disaggregation of kaolinite particles, and the dissolution of the external layers, altering both the structure and chemical composition of the material [48]. As a result, acid-activated kaolinite is an excellent precursor for synthesizing solid acid catalysts used for catalytic cracking in petrochemical processes [49]. The activation process not only increases the porosity of kaolinite but also enhances its acid centers and surface area, making it suitable as an inorganic host for intercalation and exfoliation. Acid activation involves the protonation of aluminol (AlOH) groups by hydrogen ions from the acidic medium, which leads to dealumination and an increase in the Si/Al ratio of the synthesized materials. This process facilitates absorption by increasing the cation exchange capacity (CEC), pore volume, and surface area [50,51], thereby enhancing the material’s ability to physically absorb water. However, high concentrations of acid can reduce the structural and coordinated water in kaolinite, which is reflected in increased endothermic peaks during recrystallization and dehydroxylation. Regarding solubility, several factors influence this parameter, such as the type of acid used, kaolinite-to-acid ratio, operating temperature, leaching period, and particle size. Generally, kaolinite solubility increases with higher acid concentrations and longer leaching periods, although excessive leaching can decrease the surface area [52].

Inorganic acids are more effective than organic acids in generating new surface acid sites, although they may cause the kaolinite structure to collapse due to excessive leaching of the octahedral layer. Conversely, organic acids preserve the structure of kaolinite better but are less effective at generating new acid sites. Specific surface area and pore volume increase with higher molarity of the activator and longer activation times. Under the same conditions, kaolinite solubility in HCl is less than in H2SO4, with the order of solubility and subsequent increase in surface area as follows: CH3COOH < H3PO4 < HCl < H2SO4 < HClO4 < HNO3 [48,52,53]. Recent interest has focused on synthesizing solid acid zeolites from kaolinite for the petrochemical industry, as the process is cost-effective and produces zeolites with enhanced pore size and structure compared to conventional zeolites [17,54,55]. Both organic and inorganic acids can chemically activate kaolinite, highlighting its potential as a precursor for zeolite synthesis in converting heavy molecules in petrochemical processes [56]. The process requires higher calcination temperatures (550 to 950 °C) to effectively activate kaolinite and obtain metakaolin due to the strong hydrogen bonds between its layers, which make the material resistant to chemical attack. The reactions involved in the dealumination process are as follows (Equations (6) and (7)):

3H2SO4 + Al2Si2O5(OH)4 → Al2(SO4)3 + 2H4SiO4 + H2O

3SO3 + Al2O3 → Al2(SO4)3

Research has shown that kaolin’s strong passivity makes it less susceptible to the effects of acid treatment alone. However, metakaolin, which is produced by heating kaolin, shows increased reactivity when subjected to acid treatment. Calcined kaolin clay, when converted to metakaolin and subsequently treated with hydrochloric acid (HCl) under reflux conditions, can achieve high surface areas, even with minimal alumina removal. This process results in metakaolin with both stable surface areas and significant Brønsted acidity. The properties of the treated metakaolin, including its surface area, stability, and pore size, are influenced by the calcination temperature of the clay and the amount and temperature of HCl treatment. Deviations from the optimal calcination temperature range can significantly reduce alumina solubility and surface area. Additionally, while excessive HCl treatment can enhance the surface area, it may also lead to the over-removal of aluminum, compromising the catalytic activity of the treated metakaolin [57]. Belver Carolina et al. [58] investigated the acid activation of metakaolin by treating it with 6 M hydrochloric acid at room temperature and at 90 °C under reflux for 6 and 24 h. They found that at room temperature, the structure and properties of metakaolin remained unchanged. However, a six-hour reflux treatment removed most octahedral Al3+ cations, forming an amorphous silica phase with a surface area of up to 219 m2/g. Conversely, a more potent acid treatment (reflux for 24 h) resulted in further amorphization of the silica, reducing the surface area to 23 m2/g. These acid-treated solids have potential as substrates for catalysts and adsorbents.

5.3.2. Alkaline Activation

Alkali activation significantly modifies the acidity, surface area, pore size, and volume, as well as the adsorption strength of kaolinite, making it an ideal precursor for solid basic catalysts [59]. This process involves the deprotonation of aluminol and silanol groups, resulting in the simultaneous dealumination and desilication of the kaolinite material [60,61]. Alkali activation is also effective in developing various basic zeolites with low Si/Al ratios, including K–F zeolite, 13X zeolite, A, P, and X zeolites, zeolite N, Na–Y zeolite, MCM-41, and zeolite NaA [62,63,64,65,66,67]. The alkali activation of kaolinite and other clays has received significantly less research attention than acid treatment. Given the solubility of silica and aluminates in alkaline solutions, the gradual leaching of silicic and aluminic layers can be expected during alkali activation. Recent studies, however, have reported the selective removal of silicon sheets to create γ-alumina with intriguing properties [68]. During these alkaline treatments, concentrated solutions were used both at ambient temperature and under reflux conditions. As a result, metakaolin was broken down and transformed into highly crystalline K-F zeolite. Treatments were performed using 1 M and 5 M potassium hydroxide (KOH) solutions, with the strength of the treatment influencing the formation of zeolite crystals and the breakdown of metakaolinite layers. This strong crystallinity led to extremely low surface areas in the treated samples [58].

Interestingly, aluminum is more readily dissolved in acidic treatments than silicon, whereas the opposite is observed in alkali treatments. X-ray diffraction (XRD) patterns reveal significant alterations in the crystal structure after acid treatments, while XRD peaks generally become more distinct following alkali treatments. This suggests that alkali treatments have a smaller impact on mineral structures, although they often create new mineral phases. The dissolution of amorphous mineral particles during alkali treatment enhances basal reflections, effectively “cleaning” the minerals [69]. Considering the high concentrations of silicon dissolved in alkaline solutions, the exterior silica sheets of the minerals may also be removed. In kaolin, the presence of SiO2 undergoes a conversion process resulting in the formation of free SiO2, which readily reacts with alkaline substances [70]. Sodium hydroxide modification facilitates the leaching of silicon from calcined kaolin, increasing the small pore structure [71]. As the duration of alkali treatment increases, the pore size distribution of calcined coal-series kaolin becomes wider, its specific surface area decreases, its pore volume increases, and its cracking activity and selectivity improve.

5.4. Intercalation/Exfoliation Treatment

Intercalation involves the effective insertion of a neutral polar organic substance into the interlamellar spaces of an inorganic host lattice, resulting in nanosized composite materials with a regularly spaced stack. Wide interlamellar spaces are crucial as they prevent interactions between randomly dispersed layers within a consistent polymer matrix, thereby facilitating the exfoliation of the synthesized material. The unique, notably non-centrosymmetric structure of kaolinite renders it an ideal host for intercalation [72], although the efficiency of intercalation is influenced by factors such as the crystallinity and the particle size of the host material. Higher crystallinity typically results in an increased rate of intercalation, while smaller particle sizes generally lead to a reduced intercalation rate [73]. This is due to the fact that a decrease in particle size is associated with a reduction in structural order, which affects the intercalation process. The primary challenge impeding the use of kaolinite as a host material is its rigid interlamellar spacing and absence of charge. Consequently, only a limited range of interlamellar compounds—such as methanol, acetamide, octadecyl amine, dimethylformamide, potassium acetate, N-dimethylformamide, deuterated dimethylsulfoxide, and dimethylsulfoxide (DMSO)—are capable of intercalating directly into the kaolinite layers. Nonetheless, after introducing initial guest compounds into kaolinite, it is possible for further intercalation to occur with additional organic guests that cannot penetrate the kaolinite layers directly [74]. This can be achieved through the covalent grafting of small polar molecules, such as DMSO or methanol, which form Al–O–C bonds with the aluminol basal plane of the kaolinite, thereby expanding the interlamellar spacing [75]. This expansion creates an environment in which subsequent guest compounds can replace the initially intercalated ones. Another approach to facilitating intercalation involves mechanochemical methods, in which the organic guest is co-ground with the inorganic host to achieve the desired insertion [76].

5.5. Coating Modification

Coating modification is an effective technique for enhancing the properties of kaolinite by preventing powder agglomeration and improving fluidity and dispersion characteristics [6]. This process involves applying a coating layer to kaolinite particles, which significantly influences their performance and structural integrity [32,77,78].

One of the primary advantages of coating modification is its ability to inhibit powder agglomeration [79]. Uncoated kaolinite particles tend to clump together due to van der Waals forces and other intermolecular interactions, which can lead to reduced processability and performance. By applying a coating, these interactions are minimized as the coating creates a protective layer around the particles. This protective layer effectively prevents clumping, allowing the particles to remain dispersed and resulting in a more homogeneous powder. Consequently, the coated kaolinite demonstrates improved flow properties and is better suited for various applications.

In addition to addressing agglomeration, the application of a coating layer enhances the fluidity of kaolinite powders [80]. Improved fluidity is crucial for several processes, including mixing, handling, and application in industries in which uniform powder distribution is essential. The coating modification improves the dispersion properties of kaolinite, ensuring that the particles are distributed more evenly when used in composite materials or as fillers. This uniform distribution contributes to the consistency and quality of the final product, making it more effective in diverse formulations.

Beyond improving fluidity and dispersion, coating modification plays a vital role in reinforcing the structural integrity of kaolinite [81]. The coating layer enhances the mechanical strength of the powder by enveloping the kaolinite particles, which helps to maintain their structural cohesion under mechanical stress or during processing. This reinforcement improves the stability and performance of the kaolinite in various applications, ensuring that the powder remains effective even under challenging conditions.

The success of coating modification depends on several factors, with reaction conditions and the specific surface area of the kaolinite particles being particularly critical. Reaction conditions, such as temperature, pH, and coating material concentration, significantly impact the quality and uniformity of the coating layer. Additionally, the specific surface area of the kaolinite particles influences how well the coating adheres and covers the particles. Generally, larger surface areas allow for better coating coverage and more effective modification.

6. Unlocking the Potential: Advanced Applications of Kaolin in Industry

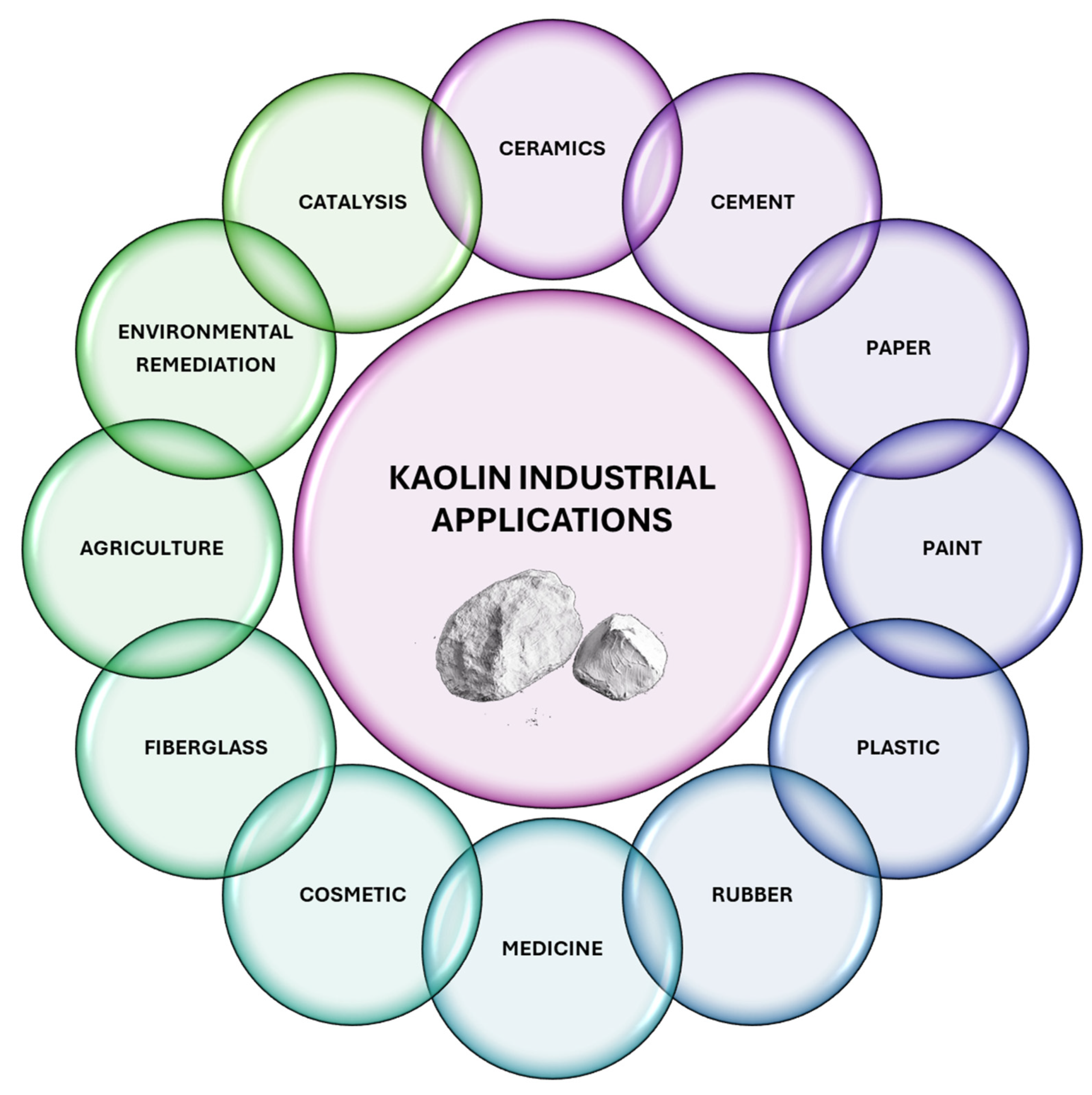

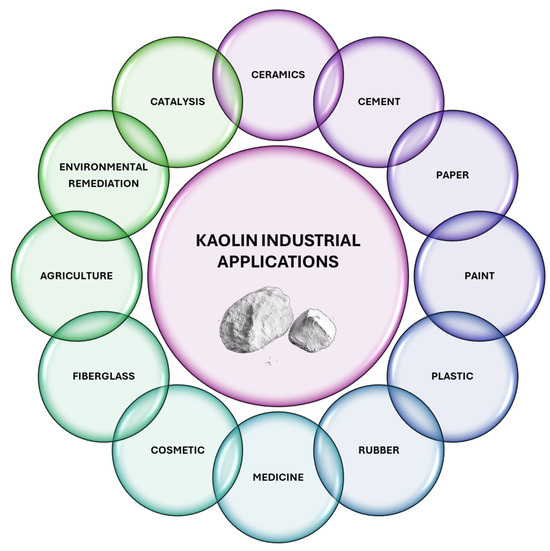

Kaolin, which is primarily composed of the clay mineral kaolinite, has garnered significant interest due to its wide-ranging applications across numerous industries. Its unique physical and chemical properties, such as high brightness, fine particle size, and chemical inertness, make it indispensable in various domains, such as ceramics, cement, paper, paint, plastics, rubber, pharmaceutical, cosmetic, fiberglass, environmental decontamination, and catalysis. This section delves into the multifaceted applications of kaolin, underscoring its pivotal role in advancing technological innovations and its economic significance in industrial processes (Figure 8).

Figure 8.

Schematic representation of industrial applications of kaolin-based materials.

6.1. Ceramic Industry

The industry of ceramics encompasses a wide range of products, including dinnerware, sanitaryware, tile, electrical porcelain, pottery, and refractories, all of which utilize kaolin [82]. Both kaolin and ball clay (kaolinitic clay) are primary ingredients in many ceramic products. The specific ceramic product and the conditions of the manufacturing plant determine the parameters of the kaolin clay used. Key variables include the proportions of kaolin, other clays, silica, and flux in the ceramic body. The consistent chemical composition of kaolin is essential to ensure stable firing and vitrifying properties [83].

Ceramics, which are made by applying high temperatures to earthen materials, date back to prehistoric times when early humans used clay for cooking and found that heat could solidify shapes made from plastic clays [84]. Over time, ceramics evolved into an engineering profession. The properties of ceramic materials vary based on their clay mineral composition, particle size, organic content, and non-clay minerals, with kaolinite being the most crucial due to its beneficial physical and chemical properties.

Key properties provided by kaolin and ball clay include plasticity, green strength, dry strength, fired strength and color, refractoriness, thermal conductivity, water absorption, and controlled shrinkage [7,32,85,86]. Plasticity refers to a material’s ability to deform under stress without breaking and to retain its shape once the stress is removed. Measuring plasticity can be performed by assessing water content, penetration resistance, or deformation under stress. Green strength, which is measured by the breaking strength of a clay bar, must be sufficient for handling without damage. Drying shrinkage occurs as clay dries, and firing shrinkage happens during firing; both are influenced by water content and particle size. Dry strength, which is higher than green strength, relates to particle size and is essential for the final product’s durability [87]. During firing, kaolinite transforms, losing its structure and forming new phases at high temperatures, such as mullite [88,89,90]. The fired color of kaolinite is white, while ball clays are light cream. The modulus of rupture (MOR) of fired pieces, which indicates strength, is significantly higher than that of dried pieces.

In refractories, kaolin and ball clay have been used since the early 1800s for products like firebricks and insulating bricks [6]. Refractory clays must withstand high temperatures and are measured using pyrometric cones that indicate heat resistance. Flint clays, while refractory, lack plasticity and are mixed with plastic clays for shaping. Companies like Villeroy & Boch and Royal Doulton rely on kaolin to achieve the desired aesthetic and functional properties of their ceramic products.

6.2. Cement-Based Material Industry

Concrete is the most commonly used building material worldwide, with ordinary Portland cement (OPC) traditionally serving as the binding agent. Cement is made by combining materials rich in lime, silica, alumina, and iron oxide. This blend is then sintered and ground, with gypsum added as a setting retardant. As reducing carbon dioxide emissions becomes crucial in combating global warming, it is essential to seek alternative low-emission binding agents for concrete. Kaolin, which is a good source of alumina and silica, also contributes to a whiter cement. Although kaolin’s use in cement is currently minimal, the potential of metakaolin as a pozzolan is considerable [91]. The reactive alumina and silica in metakaolin react with excess calcium to form calcium aluminum silicate, enhancing the concrete’s strength, workability, and durability while preventing autogenous shrinkage. Recently, metakaolin, a partially calcined form of kaolin, has been introduced as a pozzolanic additive in high-strength cement. Moreover, studies have shown that incorporating metakaolin can boost the strength of oil well cements by up to 40%. Therefore, Kaolin-based cement materials offer excellent versatility, making their development prospects highly promising. The LafargeHolcim company utilizes kaolin in their products to enhance performance.

6.3. Paper Industry

Kaolin is essential in the paper industry and is primarily used for coating and filling [77,92]. As a filler, kaolin mixes with cellulose fibers in wood pulp, enhancing the paper’s internal structure. For coating, it combines with water, adhesives, and additives, improving smoothness, brightness, gloss, opacity, and printability. Uncoated paper does not meet high-quality printing standards, but the fine particle size and platy shape of kaolinite provide a smooth, dense, and uniformly porous surface for better ink absorption.

Kaolin’s hydrophilic nature makes it easily dispersible in aqueous systems, which is ideal for coating formulations applied to paper surfaces at high speeds. Proper rheology, which should be Newtonian or thixotropic, ensures even coating distribution [93]. Kaolin grades used for coatings typically have particles, of which 80% are less than 2 μm. Delaminated kaolins, which are used in lightweight coatings (LWC), offer a shingle-like structure that enhances ink holdout and smoothness, reducing the paper’s weight and lowering postal costs for publications. Rheology is crucial for kaolin in paper coatings, with viscosity affected by particle size, shape, surface area, and impurities [80,94]. Engineered kaolins are designed to improve specific properties like opacity, gloss, and brightness. Kaolin fillers, typically coarser and less bright, mix with paper pulp to enhance brightness, opacity, smoothness, and printability, offering a cost-effective alternative to pulp [95]. Despite the rise of calcium carbonate fillers in neutral/alkaline papermaking, kaolin remains significant in certain applications.

Additionally, kaolin serves as a fiber extender in automotive gaskets, replacing asbestos due to health concerns, and as a cost-effective extender for titanium dioxide in paper filling and coating, maintaining brightness and opacity while reducing costs [6]. Calcined kaolins, with their high brightness and opacity, enhance light scattering and overall paper quality. Major companies, like Georgia-Pacific and Imerys, utilize kaolin in their paper manufacturing processes to improve surface properties and printability.

6.4. Paint Industry

Kaolin is a critical component in the paint industry, albeit with a smaller market compared to its use in paper coating and filling. Annually, around 600,000 tons of kaolin are incorporated into paints worldwide as extender pigments [96]. It has extensive applications in water-based interior latex paints and is also utilized in oil-based exterior industrial primers. Calcined and delaminated kaolins are particularly favored in interior water-based paints, which are characterized by pigment volume concentrations (PVC) between 50% and 70%. In contrast, semi-gloss and high-gloss water-based systems employ fine particle size kaolins at PVCs below 50% [92].

Kaolin’s fine particle size, with 98% of particles being less than 2 μm, significantly enhances paint properties such as suspension, viscosity, and leveling. As an economical extender for titanium dioxide (TiO2), the dominant pigment in paints, kaolin effectively reduces production costs [97,98]. The high aspect ratio and thin plate-like structure of delaminated kaolins contribute to a smoother paint film surface and improved sheen. The incorporation of calcined kaolins in paint formulations improves the scrubbability and mechanical strength of the paint films. These kaolins also enhance washability, facilitate stain removal, and improve enamel holdout by preventing enamel penetration into the paint structure. In flat paints, calcined kaolin increases hiding power, film toughness, and scrubbability, although it may compromise stain resistance [99]. Paint formulations can be optimized for specific performance criteria by blending various extenders and pigments.

In essence, kaolin’s role in the paint industry is multifaceted, providing cost-efficient improvements to multiple paint properties. Its contributions to suspension, viscosity, and surface smoothness and its function as a TiO2 extender underscore its value in both water-based and oil-based paint formulations. The Krebs & Hiebert and BASF companies utilize kaolin to enhance the performance characteristics of their coatings, such as opacity and durability.

6.5. Plastic Industry

Kaolin-based materials are widely utilized as fillers in the plastics industry due to their various beneficial properties. Kaolin enhances the surface finish of plastics, mitigates cracking and shrinkage during curing, and conceals the fiber pattern in fiberglass-reinforced composites [100]. Additionally, kaolin contributes to improved thermal stability, high impact strength, and resistance to both chemical action and weathering [101,102]. It also aids in regulating the flow properties of plastic materials. The concentration of kaolin fillers in plastic formulations can range from 15% to as high as 60%.

A primary application of kaolin is in polyvinyl chloride (PVC) coatings for wire and cable insulation [103]. Calcined kaolin, along with silane-treated kaolin, is employed to enhance electrical resistance and reduce costs. Calcination, which is typically performed at approximately 1000 °C, lowers the surface energy of kaolin, imparting some degree of hydrophobicity and making it a preferred filler for PVC. Surface modification with silanes further increases this hydrophobicity, optimizing the performance of kaolin in electrical insulation. The effectiveness of kaolin as a filler is highly influenced by particle size, with finer particles generally offering better reinforcement of physical properties across various polymers. Enhanced strength and impact resistance in plastics, such as polypropylene and PVC, can be achieved through the use of fine kaolin particles combined with coupling agents that facilitate chemical bonding between the filler and the polymer matrix [104]. Silane treatments improve the dispersion of kaolin and its interaction with the polymer [92]. Furthermore, the thin plate-like shape of kaolinite benefits certain polymers by improving the flexural modulus, dimensional stability, surface smoothness, and barrier properties [105].

Recent developments continue to emphasize the advantages of kaolin in plastics, with ongoing research focusing on optimizing its properties for enhanced performance in diverse plastic applications. The versatile role of kaolin in improving the physical characteristics and cost efficiency of plastics underscores its value as a critical filler material in the industry. For example, the DuPont company incorporates kaolin in the manufacturing of certain plastic products to enhance stiffness and thermal stability.

6.6. Rubber Industry

In the rubber manufacturing sector, kaolin is a valued material due to its ability to reinforce and stiffen rubber compounds while being more cost-effective than alternative pigments [106]. Although carbon black dominates as the pigment for black rubber products, kaolin is widely utilized for its advantages in non-black rubber [107].

Kaolin’s role is categorized based on particle size, distinguishing between hard and soft clays. Hard clays, which are characterized by their fine particles, are essential in products demanding high durability and wear resistance, such as in the production of shoe heels, tires, conveyor belts, and bicycle tires. These clays provide the necessary stiffness to uncured rubber, thereby preventing deformation during manufacturing. They are also crucial in mitigating mechanical molding challenges in hard rubber goods, including household items, toys, and various novelties [108]. Moreover, they find application in gloves, adhesives, butyl inner tubes, reclaimed rubber, and neoprene compounds.

On the other hand, soft clays are preferred in rubber formulations in which cost efficiency is a primary concern and wear resistance is of lesser importance [109]. These clays are incorporated into a range of products, including tire bead insulation, household items, blown sponges, and rubber toys. They allow for higher filler loadings and enable more rapid extrusion than hard clays. High-aspect ratio, delaminated kaolins are specifically used in white sidewall tires to effectively mitigate air leakage. Additionally, kaolins that have been surface-modified are employed to improve dispersion and reinforcement within rubber compounds [110].

6.7. Medicine Industry

Related to medicine, kaolin is valued in the pharmaceutical industry for its multifunctional roles due to its inherent properties of high purity and stability [111]. Primarily, kaolin serves as an excipient in various formulations, in which it functions as a binding agent and a filler [112,113]. Its use in tablet formulations is particularly notable, as it contributes to the structural integrity of the tablets, ensuring that they remain intact during storage and handling. The adsorption properties of kaolin are also exploited in the preparation of suspensions and gels, in which it helps to stabilize the formulation by preventing the settling of active ingredients.

Moreover, kaolin’s high surface area and particle size distribution make it effective in adsorbing impurities and controlling the release of active pharmaceutical ingredients (APIs) [114]. Its inert nature ensures minimal interaction with other components of the pharmaceutical formulation, making it suitable for sensitive applications. Recent developments have also explored the use of kaolin in controlled-release drug delivery systems, in which its role in modifying the release kinetics of drugs is under investigation [115]. The annual usage of kaolin in pharmaceutical applications underscores its importance as a reliable and versatile component in the production of various medicinal products. Companies like Merck utilize kaolin in the formulation of specific medications, benefiting from its inertness and safety.

6.8. Cosmetic Industry

Kaolin is extensively utilized for its desirable properties in a range of formulations related to the cosmetic industry [93,116]. Its primary function is as an absorbent agent, effectively removing excess oils and impurities from the skin, which makes it a valuable component in facial masks and powders [117]. The fine, platy structure of kaolin contributes to a smooth texture in cosmetic products, enhancing their application and feel on the skin.

Kaolin’s mildness and inert nature render it suitable for use in products designed for sensitive skin. It helps in stabilizing emulsions and preventing the separation of components in creams and lotions. Additionally, its high absorption capacity is advantageous in controlling the oiliness of cosmetic formulations, which improves their performance and longevity [118]. Recent advancements have also explored kaolin’s role in the formulation of mineral-based cosmetics, in which its inclusion contributes to the opacity and coverage of products. The widespread use of kaolin in cosmetics highlights its versatility and efficacy in enhancing both the functional and aesthetic qualities of personal care products. Major cosmetic brands, such as L’Oréal and Estée Lauder, incorporate kaolin in their products for its beneficial effects in skin care.

6.9. Fiberglass Industry

Kaolin plays a vital role in the fiberglass industry, in which it is a key raw material in the production of various fiberglass products [37]. Fiberglass is widely used for applications such as thermal and acoustic insulation, reinforcement in plastics, textile yarns, electronic circuit boards, and even paper, cloth, and roofing shingles. The production of fiberglass requires a blend of several components, with kaolin being a significant part of this mix. The primary materials for fiberglass include silica, kaolin, and limestone, which are complemented by smaller amounts of boric acid, soda ash, and sodium sulfate. Kaolin’s contribution is crucial due to its specific properties, which help in achieving the desired characteristics of fiberglass. For instance, kaolin must meet the following stringent chemical specifications: it should contain approximately 38.5 ± 0.6% alumina (Al2O3), 45.0 ± 0.5% silica (SiO2), no more than 1.5 ± 0.3% titanium dioxide (TiO2), and a maximum of 0.6% iron oxide (Fe2O3) [119]. These specifications ensure that the kaolin integrates well with other materials and contributes to the strength, durability, and overall quality of the final product. The extensive use of kaolin in fiberglass production is reflected in the substantial quantities required annually. The kaolin used is typically processed to a dry form to meet the specific demands of fiberglass production. This large-scale use underscores kaolin’s importance in the fiberglass sector, in which its properties enhance the performance and reliability of various fiberglass applications. Its role in providing stability, improving mechanical strength, and contributing to the structural integrity of fiberglass products makes it an indispensable component in this industry.

6.10. Agriculture Industry

One of the primary uses of kaolin in agriculture is as a pesticide and growth enhancer. Kaolin-based sprays are applied to crops to form a protective film that helps to deter insect pests, reduce heat stress, and prevent sunburn on plants [120]. This physical barrier not only protects the plants but also reduces the need for chemical pesticides, promoting a more sustainable agricultural practice. Additionally, kaolin improves soil health and fertility [121]. When used as a soil amendment, kaolin enhances water retention and nutrient availability, contributing to better root development and overall plant growth. Its fine particle size and high surface area allow it to retain moisture and release it slowly to the plants, which is particularly beneficial in drought-prone areas. Recent studies have also highlighted the role of kaolin in improving the quality of harvested produce [122]. The reflective properties of kaolin sprays help to manage the light environment around the plants, leading to improved photosynthesis and potentially higher yields. Moreover, kaolin treatments can reduce the incidence of certain fungal diseases by creating a hostile environment for the growth of pathogens.

In terms of environmental impact, kaolin is a naturally occurring mineral that is non-toxic and environmentally friendly, making it an ideal choice for sustainable agriculture. Its use can lead to reduced chemical inputs, lower production costs, and healthier ecosystems. The versatility and efficacy of kaolin in various agricultural applications underscore its importance as a tool for enhancing crop production and promoting sustainable farming practices.

6.11. Environmental Decontamination

Kaolin is crucial in environmental remediation, owing to its superior adsorption capabilities and chemical resilience. A key application of kaolin in this domain is the extraction of heavy metals and organic pollutants from polluted water and soil. Its fine particles and extensive surface area offer abundant active sites for contaminant adsorption, making kaolin a highly efficient material for water purification and soil enhancement. In water treatment processes, kaolin is utilized to adsorb and remove toxic metals such as lead, cadmium, and mercury [50,123,124]. Its high cation exchange capacity allows kaolin to bind with these metal ions, reducing their mobility and bioavailability in aquatic systems. This helps in preventing the entry of these harmful substances into the food chain and protecting aquatic life and human health.

Kaolin is also employed in the treatment of industrial effluents. It can be used to coagulate and flocculate suspended particles in wastewater, facilitating their removal through sedimentation or filtration [125,126]. This application is particularly valuable in industries such as mining, textiles, and paper manufacturing, in which large volumes of wastewater are generated. Moreover, kaolin’s role in soil remediation involves the immobilization of pollutants, thus preventing their leaching into groundwater [127]. By incorporating kaolin into contaminated soils, the mobility of contaminants can be significantly reduced, making the environment safer for plant growth and reducing the risk of groundwater contamination. Recent research has focused on enhancing the remediation capabilities of kaolin by modifying its surface with various functional groups or combining it with other materials like activated carbon or biochar [128,129]. These modifications aim to increase kaolin’s adsorption capacity and selectivity for specific pollutants, thus broadening its applicability in environmental cleanup efforts.

Overall, kaolin’s natural abundance, non-toxic nature, and effectiveness in pollutant adsorption make it a valuable resource in the field of environmental remediation. Its use contributes to cleaner water and soil, thereby supporting ecological health and sustainability.

6.12. Catalysis

Kaolin is widely recognized for its catalytic applications beyond the petrochemical industry due to its high surface area, porosity, and chemical inertness. This mineral can be utilized both as catalyst support and as a stand-alone catalyst for the synthesis of microspherical zeolitic molecular sieves and silica aluminophosphate (SAPO) sieves [16]. In environmental catalysis, kaolin-supported catalysts are effective in breaking down organic pollutants in water and soil, such as pesticides and dyes, and are also used in the reduction of nitrogen oxides (NOx) in automotive and industrial exhaust treatment [130]. In fine chemical synthesis, kaolin acts as a catalyst in the production of pharmaceutical intermediates, enhancing reaction selectivity and yields, and is utilized in hydrogenation reactions crucial for manufacturing various fine chemicals and pharmaceuticals [131,132]. Kaolin-based catalysts also play a significant role in renewable energy processes, aiding in the conversion of biomass into biofuels and in water-splitting reactions to produce hydrogen [133,134]. In the polymer industry, kaolin serves as a catalyst support in polymerization reactions [135], facilitating the production of polymers with desired properties, and oxidation reactions essential for manufacturing a range of industrial products. The green chemistry applications of kaolin include the development of catalytic converters that enhance reaction efficiency and minimize waste and photocatalysis for environmental cleanup processes under light irradiation [136,137].

Kaolin’s role in catalysis is notably significant, but its most critical application is within the petrochemical industry. Here, kaolin is pivotal in fluid catalytic cracking (FCC), which is a crucial process that transforms heavy hydrocarbons into valuable lighter products, such as gasoline and petrochemical feedstocks. The upcoming section will offer an in-depth exploration of kaolin’s fundamental contributions to petrochemical catalysis, which stands as the most relevant point of this review study.

7. Kaolin in Petrochemical Catalysis: From Fundamentals to Innovations

The petrochemical industry underpins much of modern life and the global economy, driving advancements in everything from everyday consumer products to high-tech innovations. The utilization of kaolin in catalytic processes holds substantial relevance for the petrochemical industry, offering promising advancements in reaction efficiency and selectivity.

This section delves into the significant role of kaolin in catalytic operations relevant to this critical industry. Initially, an overview of the current state of the global petrochemical industry will be provided. Subsequently, the petrochemical processes designed to transform heavy feedstocks into light distillates will be described. Finally, we will detail the specific catalytic reactions—such as cracking, isomerization, and alkylation—in which kaolin is utilized. By analyzing recent studies and industrial implementations, we aim to elucidate the practical impacts and enhancements that kaolin contributes to these crucial petrochemical processes.

7.1. The Current Global Oil Landscape: Production Giants, Geopolitical Tensions, and Market Volatility

The global oil industry remains one of the most powerful sectors in the world economy. The data and information shown below have been taken from the bibliographic source Statista, which is a statistics portal for market data, research, and studies (80,000 topics from 22,500 sources in 170 industries) [138].

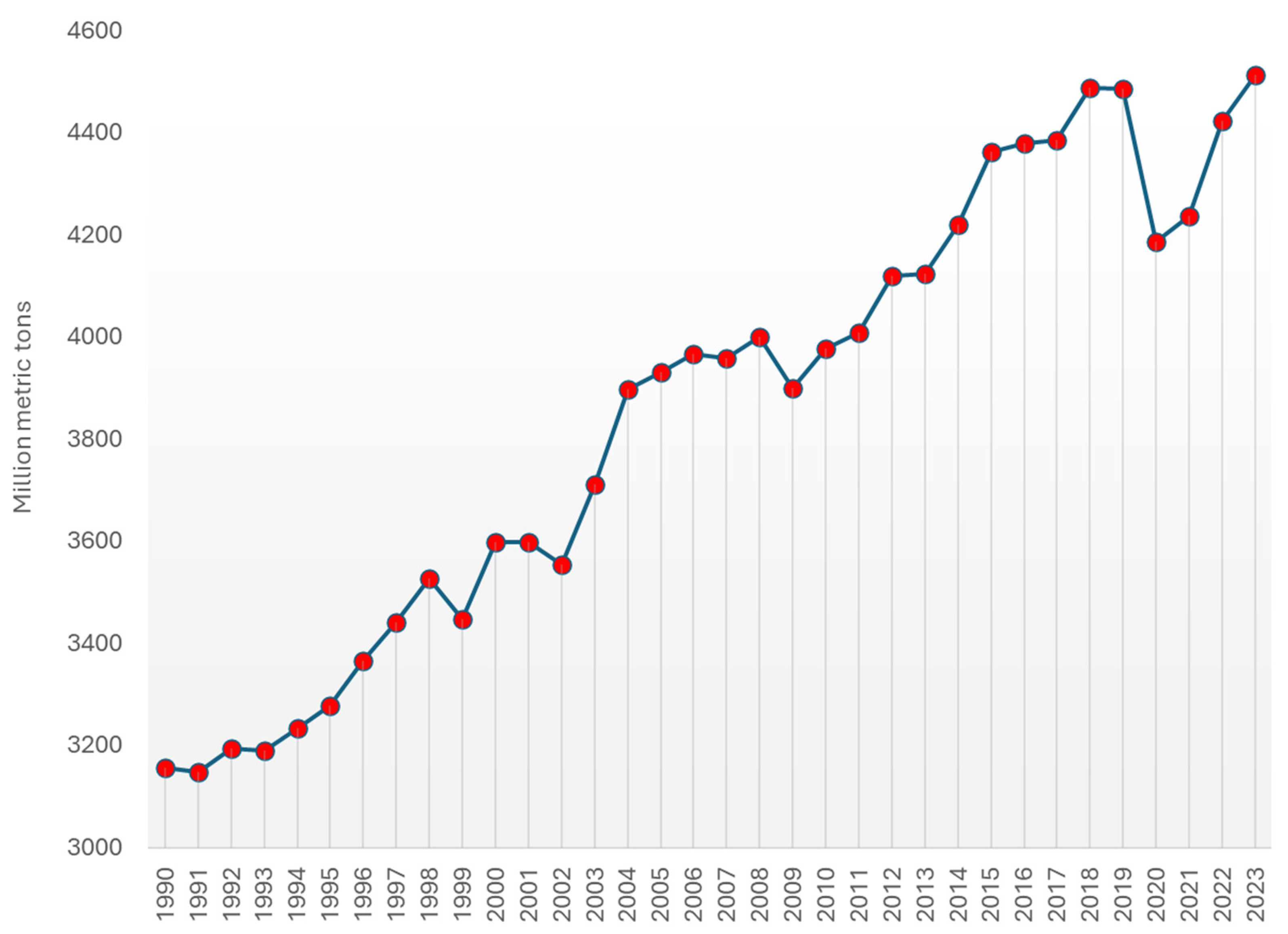

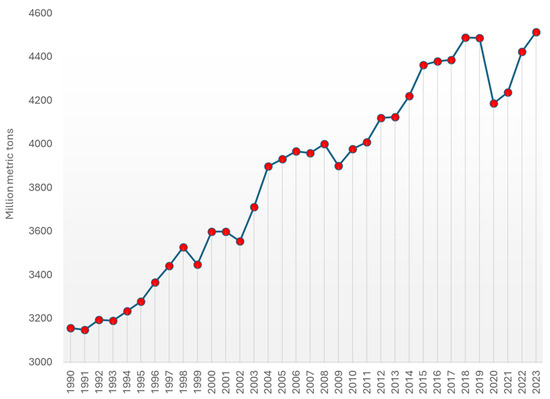

Annually, more than 4 billion tons of crude oil are produced (Figure 9) [139], with a significant portion—approximately one-third—originating from the United States, Saudi Arabia, and Russia. Although Middle Eastern countries continue to hold over half of the world’s proven oil reserves (Table 1) [140], the United States has surpassed these nations in production volumes, largely thanks to advancements in shale oil and tar sand extraction. In 2023, the U.S. alone accounted for more than one-fifth of the daily global oil production.

Figure 9.

World oil production from 1990 to 2023 (in million metric tons) [139].

Table 1.

Percentage distribution of global oil reserves from 1992 to 2020, by region [140].

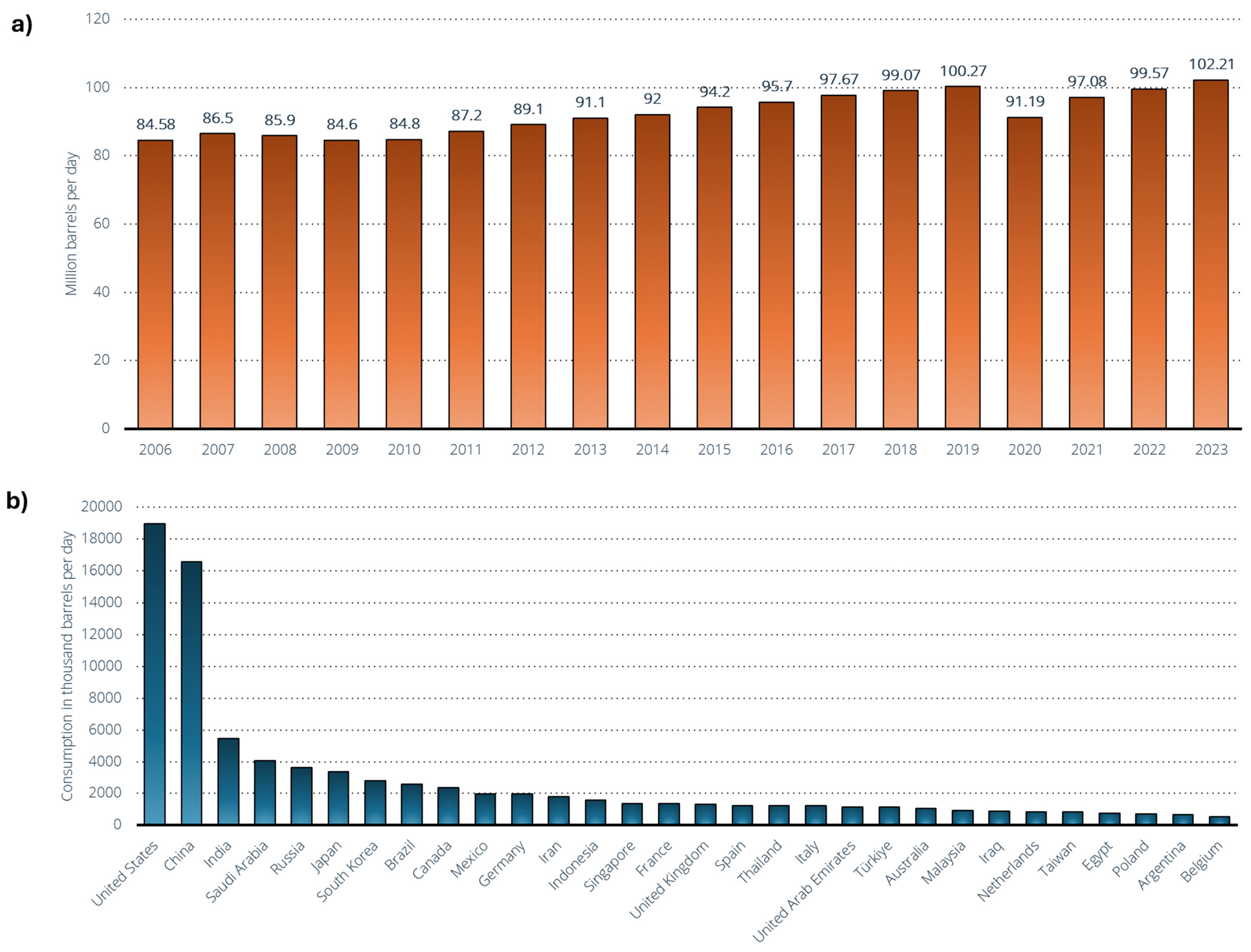

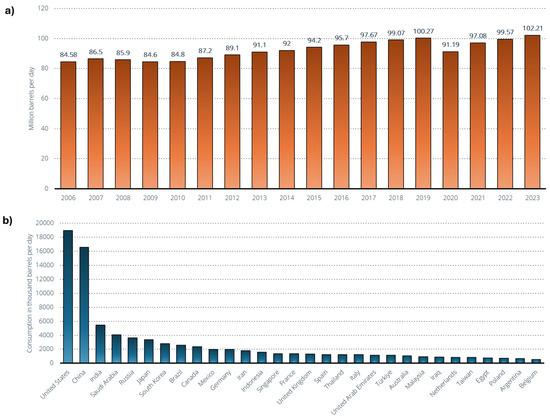

Figure 10 represents the demand for crude oil worldwide from 2005 to 2023 (Figure 10a) and the leading oil-consuming countries worldwide in 2023 (Figure 10b). Global oil demand hovers around 102 million barrels per day in 2023 [141], but the source anticipates that economic activity and corresponding oil demand will rise by the end of the year, with projections indicating that it could exceed 104 million barrels per day. The road transport sector is the largest oil consumer worldwide, comprising nearly half of the global oil demand, primarily due to the heavy reliance on petroleum-based motor fuels. The Organization of the Petroleum Exporting Countries (OPEC) projects that global demand for oil products will reach 110 million barrels per day by 2045 [141], with transportation fuels like gasoline and diesel expected to remain the most consumed products. Diesel and gasoil demand are projected to increase to 30.1 million barrels per day by 2045, up from 27.6 million barrels in 2021. Gasoline demand is forecasted to reach 27.6 million barrels per day by 2045.

Figure 10.

(a) Demand for crude oil worldwide from 2005 to 2023 [141]. (b) Leading oil-consuming countries worldwide in 2023 (in 1000 barrels per day) [142].

The United States and China rank as the leading oil consumers worldwide, each using 19 million and 16.6 million barrels per day, respectively [142]. The United States has seen a rapid increase in its oil usage, making it one of the leading importers despite possessing significant domestic reserves. Over the past decade, the proportion of global oil consumption from Europe and North America has begun to decline, while consumption in the Asia–Pacific region and other areas has increased. As alternative energy sources become more cost-effective and new transportation technologies gain prominence, global oil consumption is anticipated to reach its peak in the near future.

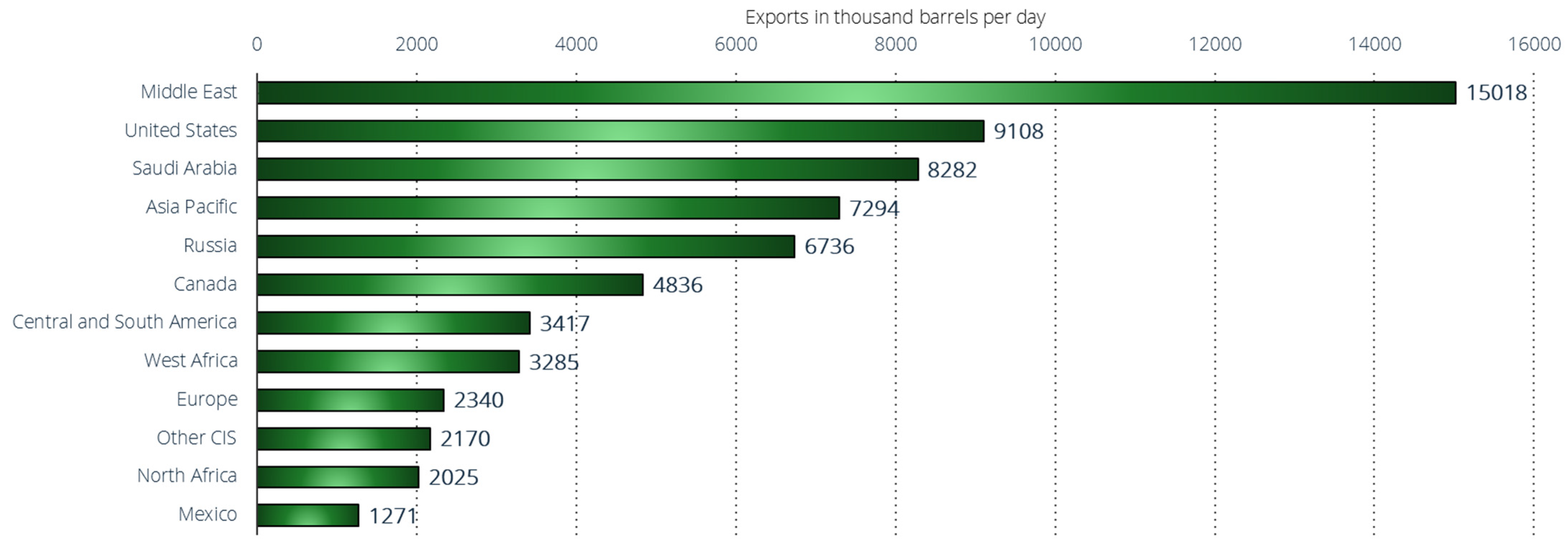

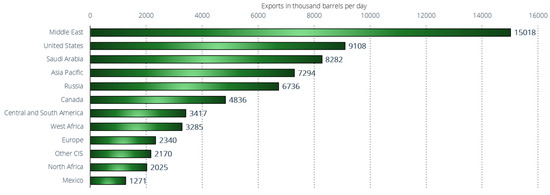

The Middle East, as a region, is the world’s largest oil exporter, with approximately 15 million barrels per day exported in 2022 (Figure 11) [143]. Approximately one-third of global oil production originates from the Middle East. Many countries in this region are members of OPEC, which is an organization that wields considerable influence by collectively setting oil prices. OPEC was founded in Iraq in 1960 and currently comprises 13 member nations. Beyond the Middle East, the United States, Saudi Arabia, Asia–Pacific region, and Russia are the principal oil-exporting nations, each exporting in a range of 7 to 9 million barrels per day in 2022. Russia has maintained a significant and stable role in global oil exports over the past decade. Nowadays, the reliance on Russian oil exports continues to pose a significant challenge to the global economy. Russia, although not the top exporter, remains a crucial geopolitical supplier, pumping over 11 million barrels per day. The lack of readily available substitutes for Russian oil further complicates the situation, emphasizing the global market’s vulnerability. In contrast, the United States has emerged as a major player more recently. Since 2010, U.S. petroleum exports have nearly quadrupled, surpassing Saudi Arabia’s export volumes in 2021.

Figure 11.

Leading crude oil and oil products exporters worldwide in 2022, by region or country (in 1000 barrels per day) [143].

In response to fluctuating market conditions, OPEC and its allies have extended their production cuts until 31 December 2025. These reductions, amounting to nearly 6% of global demand, set the collective production ceiling at 39.7 million barrels per day. The primary motivations for these cuts are to support oil prices and to stabilize the crude oil market amidst anticipated demand declines. However, this measure does not fully address the existing bottleneck in refining capacity. Recent studies by Wood Mackenzie indicate that over 20% of refining capacity may be at risk of closure due to diminishing gasoline margins and increasing pressure to reduce carbon dioxide emissions [144]. China has significantly expanded its refining capabilities, with the China Petroleum and Chemical Corporation (Sinopec) now operating one of the largest distillation capacities. Despite these advancements, the United States remains the leading oil refiner, processing more than 18 million barrels per day as of 2023 [139].

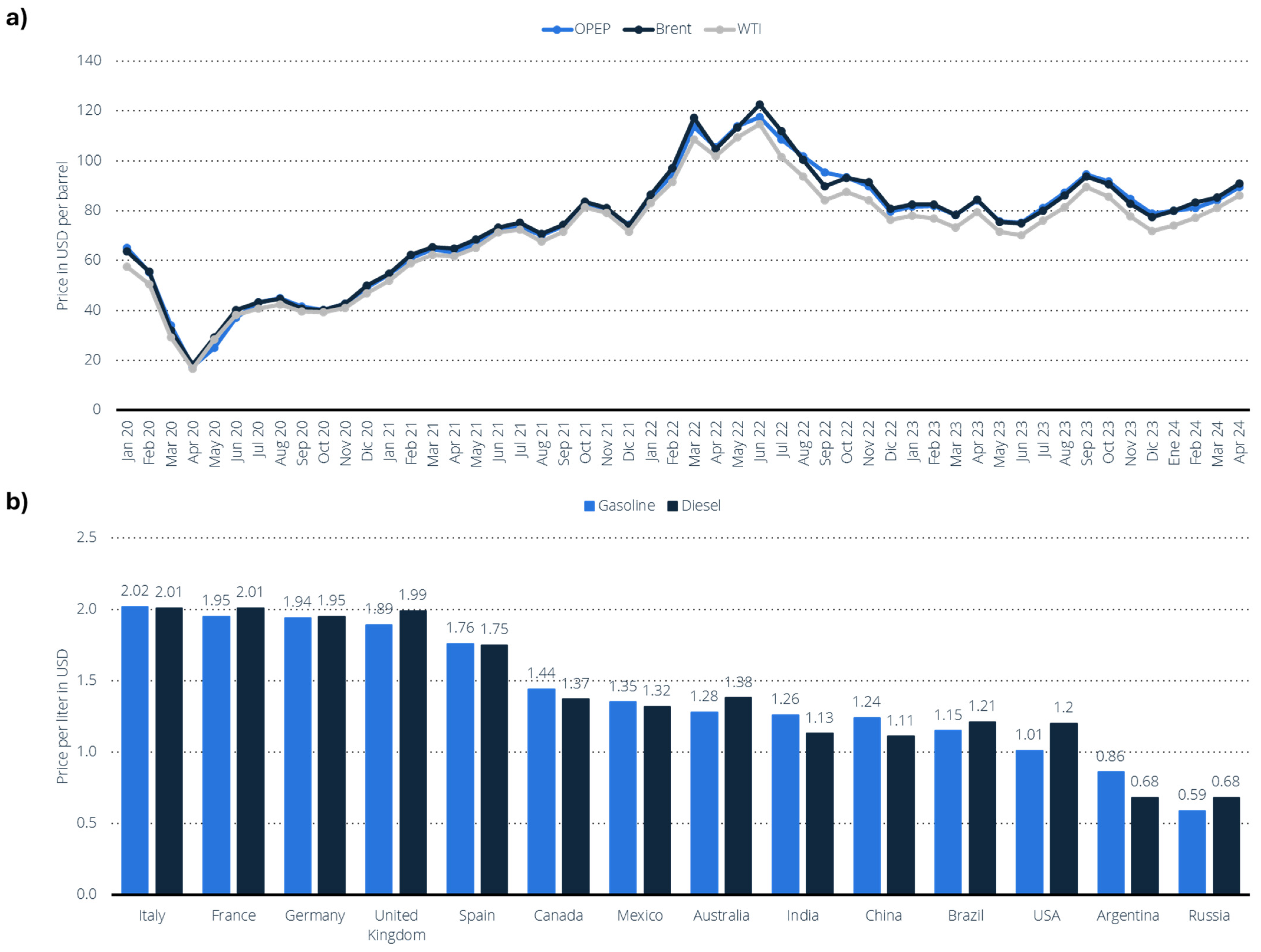

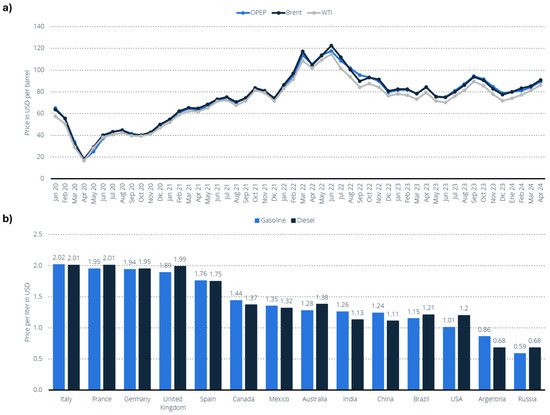

Regarding price volatility, the oil market has experienced significant price fluctuations (Figure 12a) due to a combination of factors, including the COVID-19 pandemic, sanctions on Russia, and geopolitical tensions in the Middle East, particularly the ongoing conflict between Gaza and Israel [145]. Indeed, the prices of derived oil products, such as gasoline and diesel, have also been impacted, varying according to the country (Figure 12b) [146]. In January 2022, the spot prices for key crude oils (OPEC, Brent, and WTI) were around USD 85 per barrel. However, prices surged to as high as USD 140 per barrel within the next six months. More recently, in January 2024, the prices of these key benchmarks had fallen below USD 90 per barrel, reflecting a complex and shifting market landscape. Nonetheless, ongoing regional conflicts suggest that prices may rise again by the end of the year.

Figure 12.

(a) Average price of Brent, OPEC, and West Texas Intermediate (WTI) crude oil from January 2020 to April 2024 (in dollars per barrel) [145]. (b) Average price per liter of gasoline and diesel (gasoil) in certain countries as of October 2023 (in dollars per liter USD) [146].

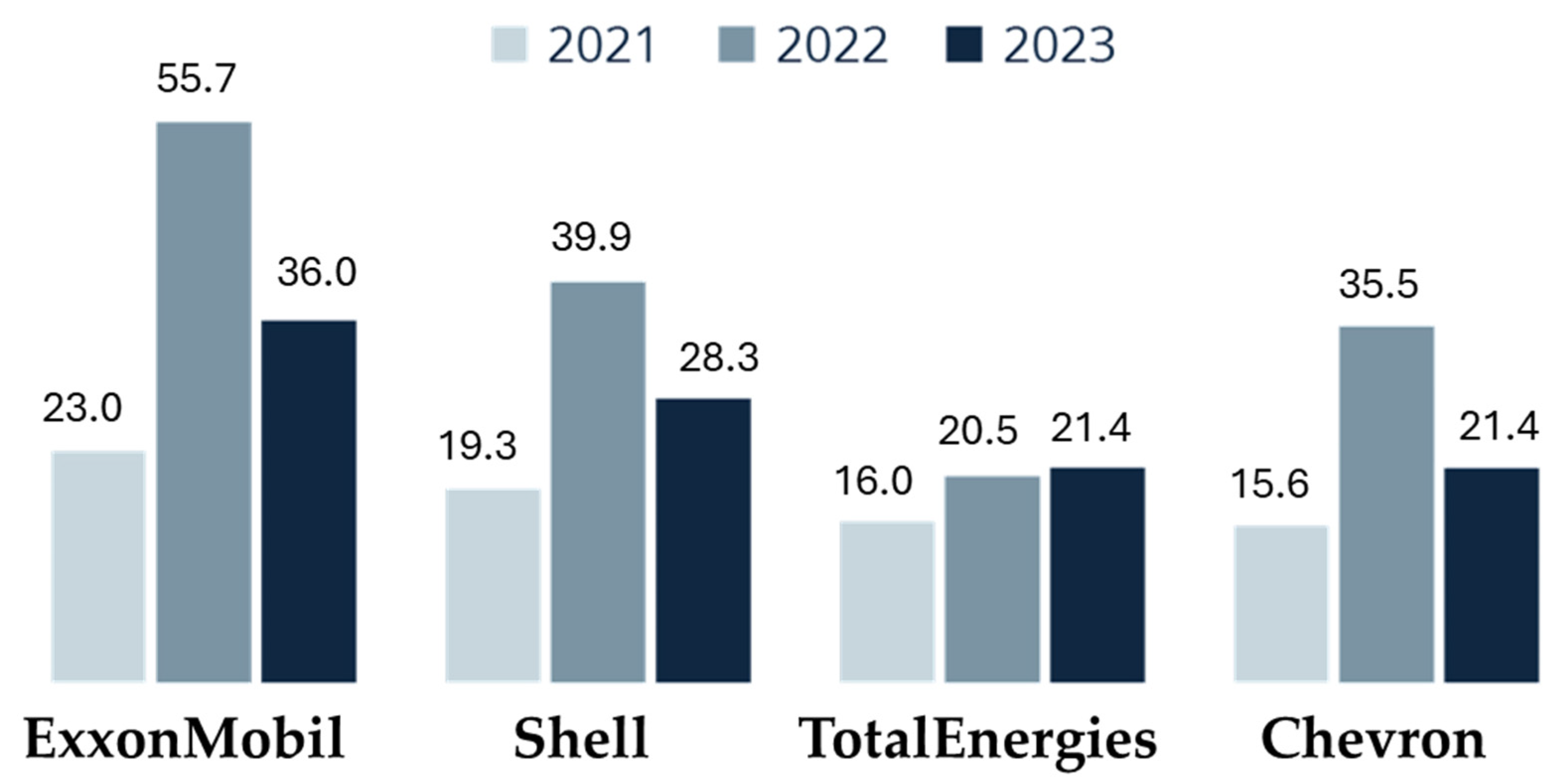

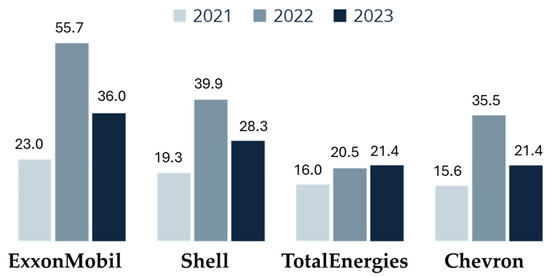

In turbulent times, oil companies often emerge as significant beneficiaries (Figure 13) [147]. For instance, ExxonMobil reported a net profit of USD 11.4 billion between January and March 2023, more than double its earnings from the same period in 2022. This pattern of increased profitability, although less pronounced, is mirrored by other major industry players such as Shell, Chevron, and TotalEnergies.

Figure 13.

Net earnings of oil and gas companies in the first quarters of 2021, 2022, and 2023 (in billions of USD) [147].

In summary, the global oil industry is characterized by high production levels, complex geopolitical dynamics, and significant economic impacts. The interplay between supply and demand, refining capacity constraints, and geopolitical tensions continues to shape the industry’s trajectory and profitability.

7.2. Petrochemical Processes for Transforming Heavy Feedstocks into Light Distillates

The petrochemical industry employs a range of sophisticated processes to convert heavy feedstocks into lighter, more valuable distillates [148,149]. Heavy feedstocks, such as crude oils with high molecular weights, often contain undesirable components and have limited applications in their raw form. By converting these heavy feedstocks into lighter distillates, the industry can produce more valuable and versatile products, such as gasoline, jet fuel, and diesel, which are essential for meeting global energy demands and compliance with environmental regulations. Light distillates offer improved performance characteristics and are in higher demand due to their utility in various applications, from transportation to industrial processes. This transformation not only enhances the economic value of the raw materials but also optimizes the overall efficiency and sustainability of the petrochemical production processes. The principal petrochemical processes for converting heavy feedstocks into light distillates are outlined as follows:

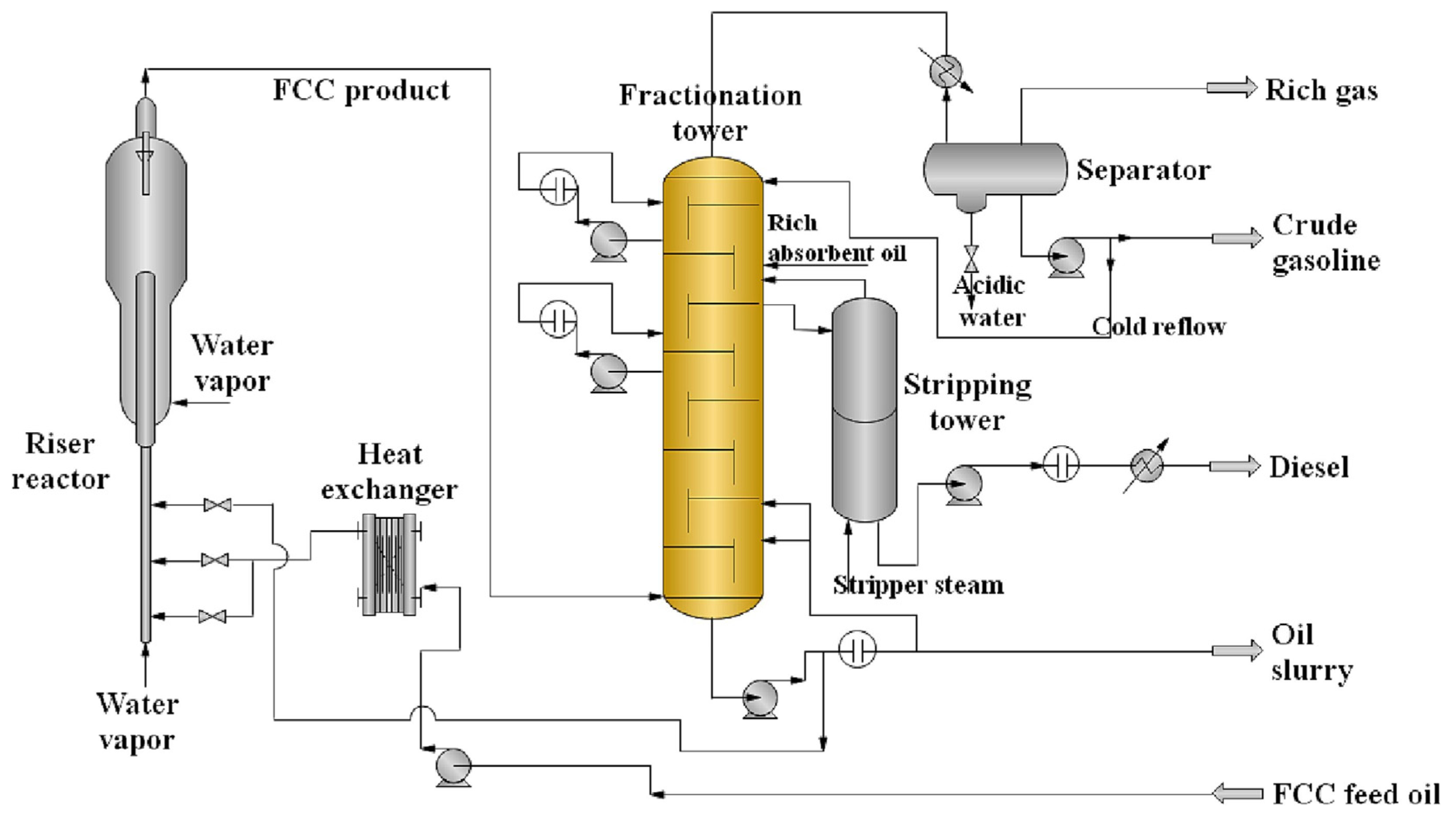

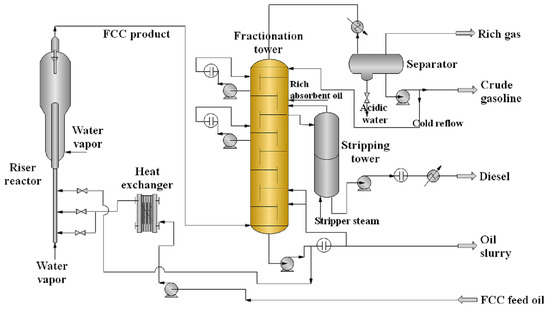

- Cracking: Cracking is a fundamental process in the petrochemical industry, breaking down large hydrocarbon molecules into smaller, more useful fragments. Thermal cracking utilizes high temperatures to achieve this breakdown, while catalytic cracking employs catalysts to enhance the reaction efficiency and selectivity [150]. Catalytic cracking is particularly important for producing high-octane gasoline and other valuable light hydrocarbons [151].

- Reforming: Reforming enhances the quality of lighter hydrocarbons by restructuring their molecular configuration [152]. This process is crucial for producing high-octane gasoline components and aromatic hydrocarbons such as benzene, toluene, and xylenes. Catalytic reforming typically involves the use of a platinum-based catalyst to facilitate the rearrangement of hydrocarbons, improving their performance in various applications.

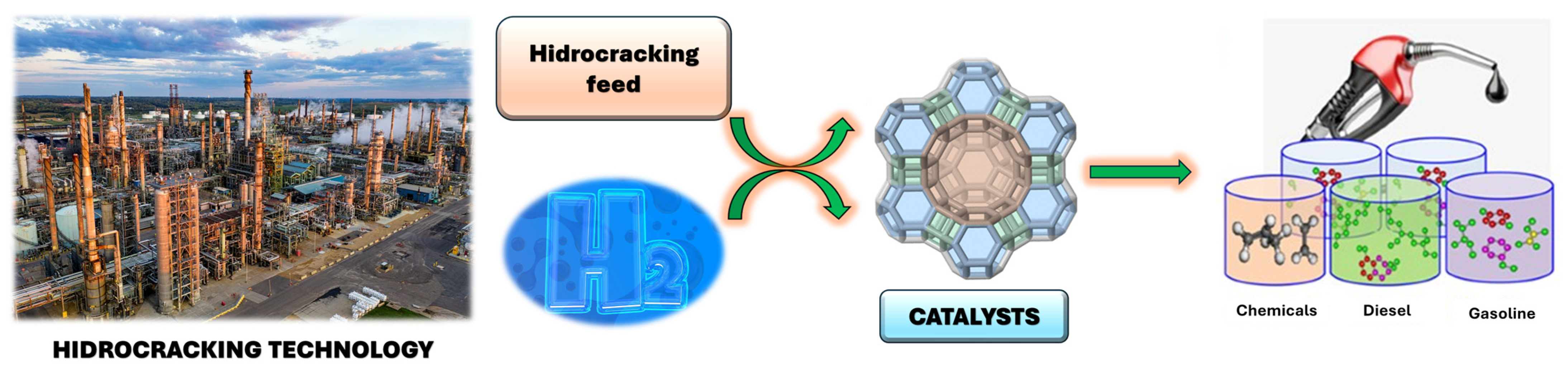

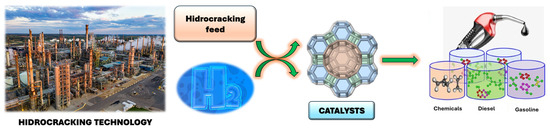

- Hydrocracking: Hydrocracking combines high pressure, hydrogen, and a catalyst to convert heavy hydrocarbons into lighter, more saturated products [153]. This process effectively produces a wide range of lighter hydrocarbons, including high-quality diesel and jet fuels. Hydrocracking is valued for its ability to produce a high yield of desired products while reducing the sulfur and nitrogen content of the end products.

- Distillation: Distillation is a key separation technique that utilizes differences in boiling points to divide crude oil into various fractions [154]. Fractional distillation is commonly employed to separate the crude oil into light and heavy fractions, which are further processed into specific products. This method is crucial for isolating components such as gasoline, kerosene, and diesel.

- Steam cracking: Steam cracking is a high-temperature process that uses steam to break down hydrocarbons into lighter molecules, including ethylene and propylene [155]. This process is pivotal for producing key building blocks for the petrochemical industry, such as ethylene, which is used to manufacture a wide range of products including plastics and synthetic rubber.

- Extraction and refining: Extraction and refining processes involve the separation of valuable components from heavy feedstocks using physical or chemical methods [156]. Techniques such as solvent extraction and hydroprocessing are employed to purify and enhance the quality of the extracted components, making them suitable for further processing or direct use.

Each of these processes plays a crucial role in the petrochemical industry, enabling the transformation of heavy feedstocks into a diverse array of lighter, more valuable products. The selection and optimization of these processes are vital for meeting the demands of the industry and advancing the development of new and improved petrochemical products.

7.3. Complementary Processes in the Petrochemical Industry

While the primary focus of conversion processes in the petrochemical industry often revolves around transforming heavy feedstocks into lighter distillates, there are a number of additional processes that play a crucial role in optimizing and enhancing the quality of the final products. These processes, including alkylation, polymerization, and oxidation, do not directly involve the conversion of heavy raw materials but are nonetheless essential for improving the properties and value of petrochemical products.

1. Alkylation: Alkylation is a critical refining process in which light hydrocarbons, such as olefins, react with isoparaffins in the presence of an acid catalyst to produce high-octane gasoline components [157]. This process significantly enhances the performance characteristics of gasoline, particularly in terms of increasing the octane rating, which is key to preventing engine knocking and improving fuel efficiency. While alkylation does not contribute to the direct conversion of heavy feedstocks, it plays a pivotal role in refining lighter hydrocarbons into more valuable, high-performance products. The production of alkylate through this process is vital in meeting the growing demand for cleaner-burning, high-octane fuels.