Analytical Hierarchy Process for Construction Safety Management and Resource Allocation

Abstract

:1. Introduction

1.1. Research Objective

1.2. Research Contribution

2. Background

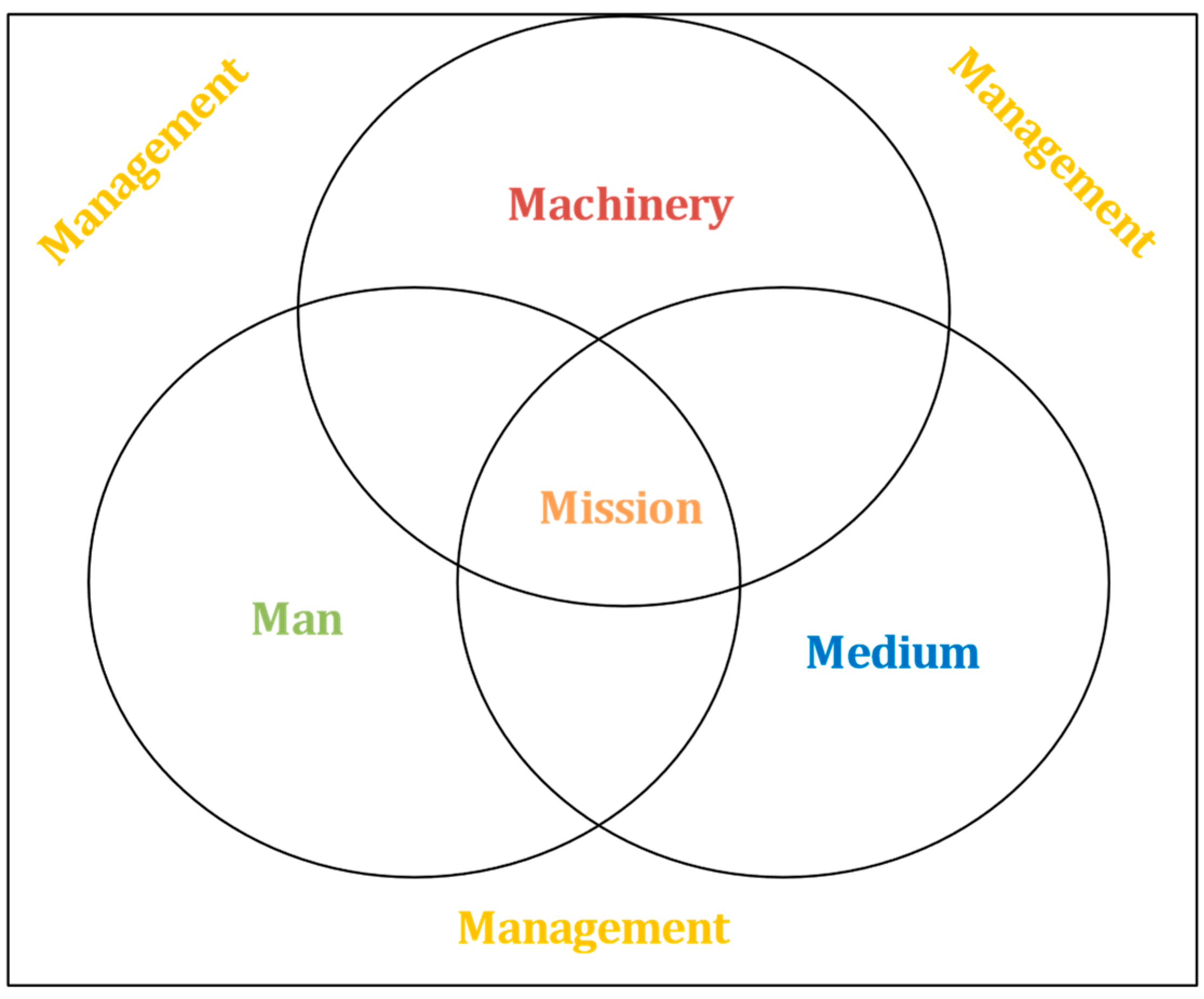

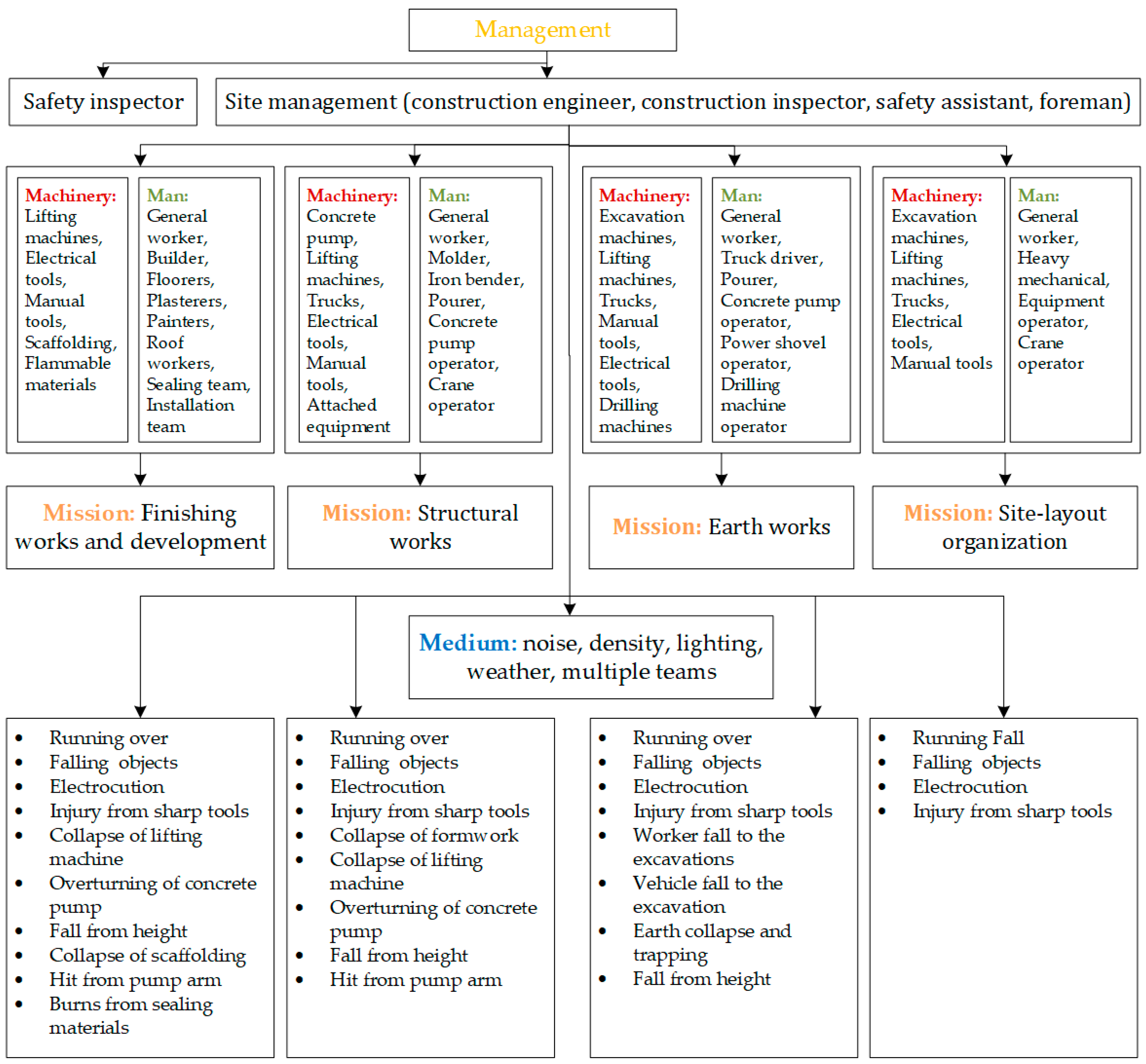

2.1. The 5M Model

2.1.1. Medium

2.1.2. Mission

2.1.3. Man

2.1.4. Machinery

2.1.5. Management

2.2. The AHP Model

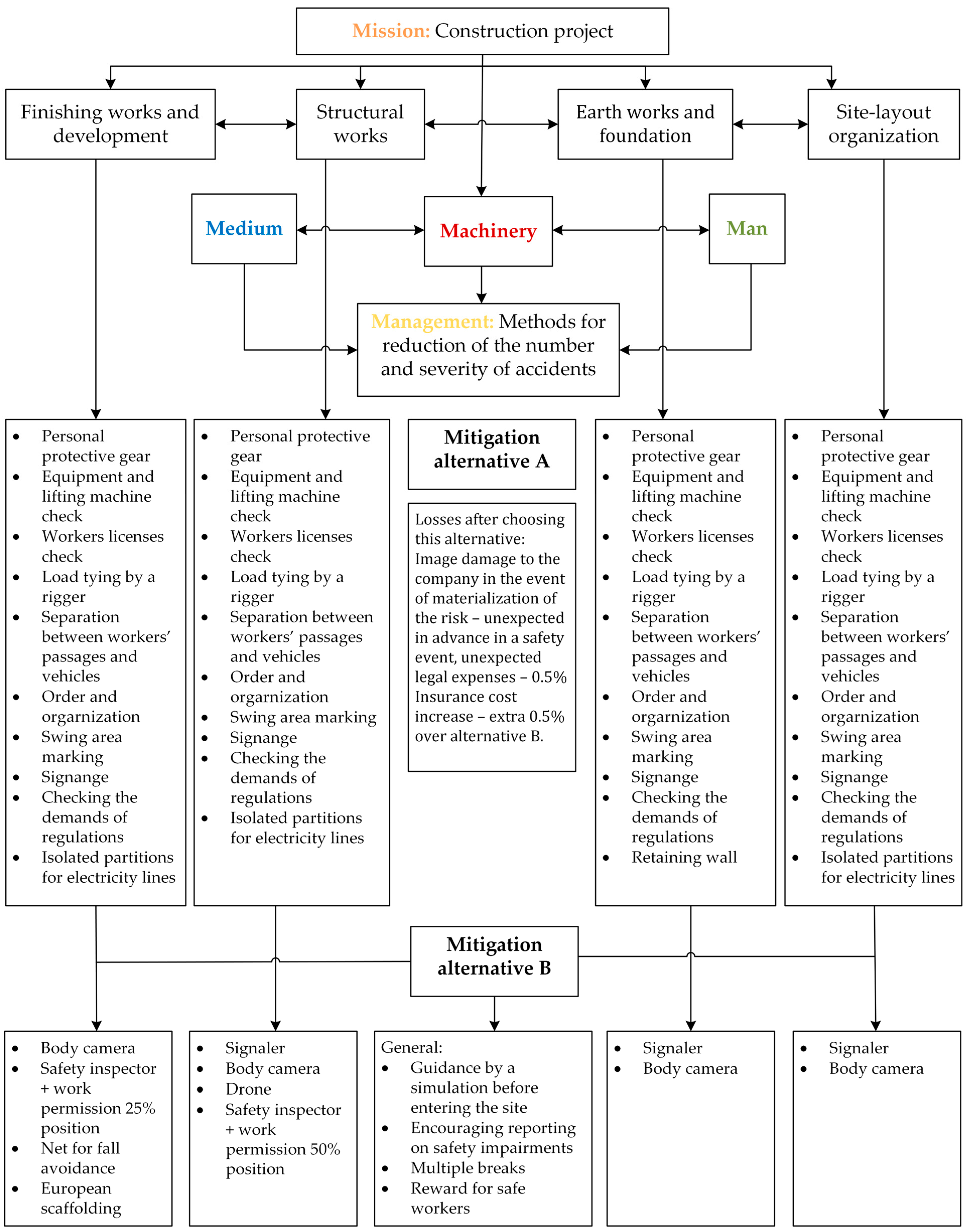

3. Research Methodology

- The first alternative (A) suggests optimizing the safety budget to an optimal ratio of 1% of the project scope, as advocated by Shohet et al. [34]. It should be emphasized that this ratio is suitable for large construction projects and that in other types of projects (e.g., Small and Medium Enterprises’ (SMEs) projects), the optimal ratio may be up to four times higher (3.8%) [7].

- The second alternative (B) suggests allocating a modest safety budget of 0.5% and using technological mitigation activities to enhance project safety with the extra 0.5%, eventually allowing an exception of d% from the optimal safety budget of 1% suggested in A. That means a total safety budget of (1 + d)%.

- The third alternative (C) suggests allocating a modest safety budget of 0.5% and sticking to it without any additional safety resource allocation.

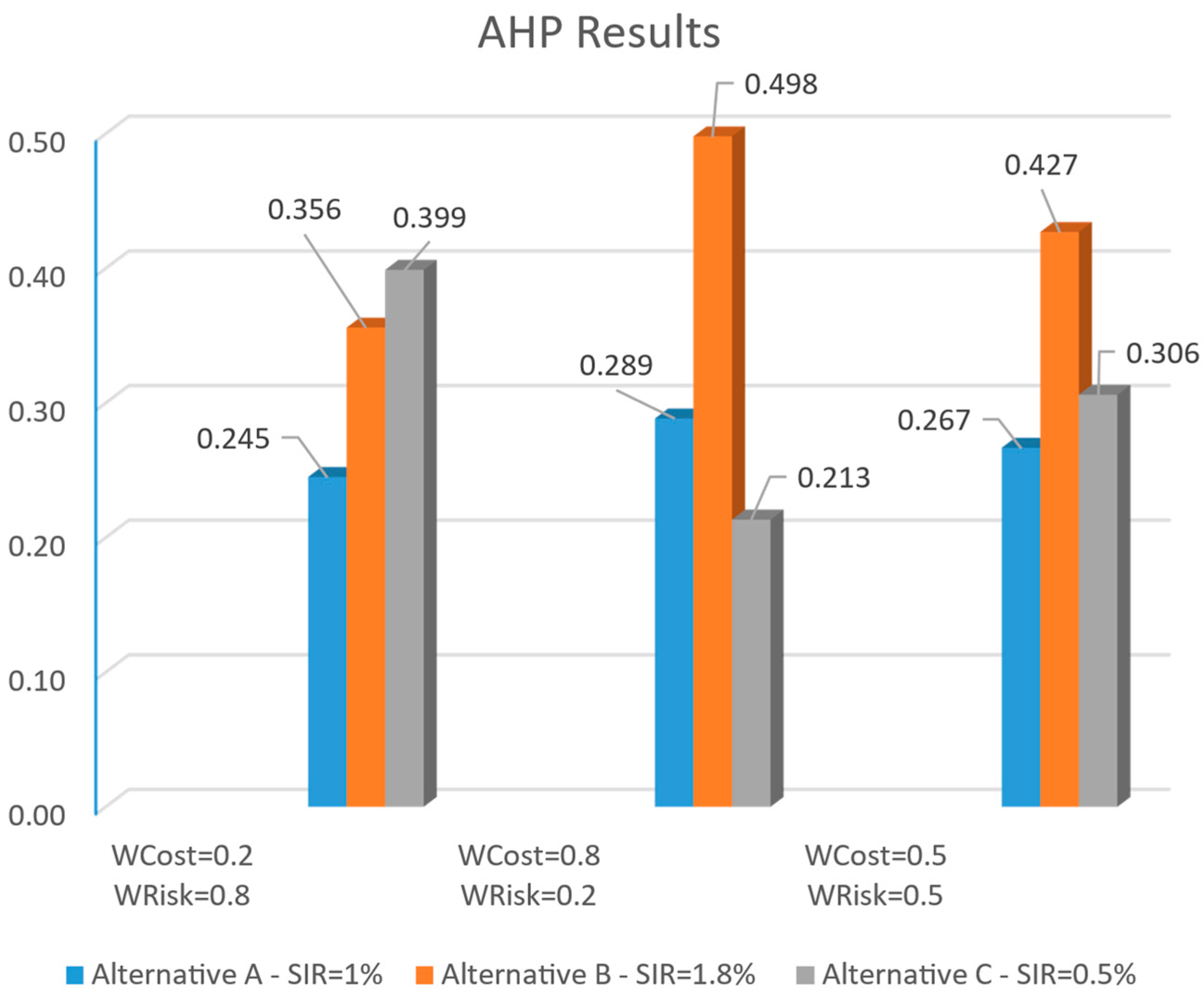

- AHP Test 1: High priority to safety risk—20% for cost and 80% for risk.

- AHP Test 2: High priority to safety cost—80% for cost and 20% for risk.

- AHP Test 3: No criteria are prioritized—50% for cost and 50% for risk.

4. Results and Discussion

4.1. Case Study 1—Cost Analysis

4.1.1. Case Study 1—Alternative A

4.1.2. Case Study 1—Alternative B

- The estimated duration of the structural works is 6 months.

- ◦

- The cost of a safety inspector in a 50% position scope in addition to the existing professional team on site—USD 15,142;

- ◦

- An extra worker for directing concrete trucks for an estimated duration of 20 min in casting—USD 3114;

- ◦

- Three body cameras (one for the workers’ team, one for the foreman, and one for the pump operator)—USD 870;

- ◦

- A drone for two workdays for each (total cost for worker + drone)—USD 5063.

- The estimated duration of the finishing and developing works is 13 months.

- ◦

- The cost of a safety inspector in a 25% position scope in addition to the existing professional team on site—USD 13,880;

- ◦

- Three body cameras (one for the workers’ team, one for the foreman, and one for the lifting machine)—USD 1344;

- ◦

- The cost of an upgrade to a European scaffold—after a cost reduction of the scaffold in a total front area of 4662 m2—USD 12,392.

4.1.3. Case Study 1—Alternative C

4.1.4. Case Study 1—AHP for Decision-Making

4.1.5. Case Study 1—Consistency Test

4.1.6. Case Study 1—AHP Test 1: High Priority to Safety Risk

4.1.7. Case Study 1—AHP Test 2: High Priority to Safety Cost

4.1.8. Case Study 1—AHP Test 3: No Criteria Are Prioritized

4.1.9. Case Study 1—Discussion

- Alternative B will be preferred when the contractor wishes to avoid risk as much as possible (the risk weight is high—risk aversion contractor).

- Alternative C will be preferred when the contractor wishes to save expenses (the cost weight is high).

- Alternative A will be preferred when the weights of risks and costs are equal—what goes along with the optimal investment model.

4.1.10. Case Study 1—Worker’s Questionnaire

4.2. Case Study 2

4.2.1. Case Study 2—Cost Analysis and Alternatives

- Alternative A considers allocating an optimal safety investment ratio that is 1% of the total project cost. The cost to the owner, including safety investment according to alternative A, is therefore USD 11,110,000.

- Alternative B considers allocating an initial safety investment ratio that is 0.5% of the total project cost. The cost to the owner, including initial safety investment according to alternative B, is therefore USD 11,055,000. Considering the optimal safety investment ratio of 1%, an upgraded safety investment is possible with the extra 0.5% available safety budget. However, due to the large number of accidents that occurred at the site, the safety budget was upgraded to a total safety budget of USD 200,000. This results in a supplement of the safety budget of USD 90,000 but without applying any advanced technological solutions. Allocating a supplement of USD 90,000 to the safety budget leads to a total safety budget of 1.8%.

- Alternative C considers allocating a modest safety investment ratio that is 0.5% of the total project cost. The cost to the owner, including initial safety investment according to alternative B, is therefore USD 11,055,000.

4.2.2. Case Study 2—AHP for Decision-Making

4.2.3. Case Study 2—AHP Test 1: High Priority to Safety Risk

4.2.4. Case Study 2—AHP Test 2: High Priority to Safety Cost

4.2.5. Case Study 2—AHP Test 3: No Criteria Are Prioritized

4.2.6. Case Study 2—Discussion

- Alternative B will NOT be preferred when the contractor wishes to avoid risk as much as possible due to the high number of accidents at the project site but without the use of technological solutions. Instead, alternative A is selected.

- Alternative C will be preferred when the contractor wishes to save expenses (the cost weight is high).

- Alternative A will be preferred when the weights of risks and costs are equal—which goes along with the optimal investment model.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Helander, M.G. Safety hazards and motivation for safe work in the construction industry. Int. J. Ind. Ergon. 1991, 8, 205–223. [Google Scholar] [CrossRef]

- Sanni-Anibire, M.O.; Mahmoud, A.S.; Hassanain, M.A.; Salami, B.A. A risk assessment approach for enhancing construction safety performance. Saf. Sci. 2020, 121, 15–29. [Google Scholar] [CrossRef]

- Halabi, Y.; Xu, H.; Long, D.; Chen, Y.; Yu, Z.; Alhaek, F.; Alhaddad, W. Causal factors and risk assessment of fall accidents in the U.S. construction industry: A comprehensive data analysis (2000–2020). Saf. Sci. 2022, 146, 105537. [Google Scholar] [CrossRef]

- Miller, C.O. Investigating the management factors in an airline accident. Flight Saf. Dig. 1991, 10, 1–15. [Google Scholar]

- Li, W.; Zhang, L.; Liang, W. An Accident Causation Analysis and Taxonomy (ACAT) model of complex industrial system from both system safety and control theory perspectives. Saf. Sci. 2017, 92, 94–103. [Google Scholar] [CrossRef]

- Harris, D. The influence of human factors on operational efficiency. Aircr. Eng. Aerosp. Technol. 2006, 78, 20–25. [Google Scholar] [CrossRef]

- Kima, O.; Urlainis, A.; Wang, K.-C.; Shohet, I.M. Safety climate in small and medium construction enterprises. Smart Sustain. Built Environ. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Shohet, I.M.; Wei, H.-H.; Skibniewski, M.J.; Tak, B.; Revivi, M. Integrated Communication, Control, and Command of Construction Safety and Quality. J. Constr. Eng. Manag. 2019, 145, 04019051. [Google Scholar] [CrossRef]

- Bachar, R.; Urlainis, A.; Wang, K.-C.; Shohet, I. Optimal allocation of safety resources in small and medium construction enterprises. Saf. Sci. 2025, 181, 106680. [Google Scholar] [CrossRef]

- Cheng, E.W.; Li, H. Information priority-setting for better resource allocation using analytic hierarchy process (AHP). Inf. Manag. Comput. Secur. 2001, 9, 61–70. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention: A Scientific Approach, 4th ed.; Safety Management; Mcgraw-Hill Book Company: New York, NY, USA, 1959. [Google Scholar]

- Arifin, K.; Ahmad, M.A.; Abas, A.; Juhari, M.L.; Ali, M.X.M.; Fadzil, L.M. Identification of root cause of fatal confined space incidents in Malaysia and strategies for prevention. Discov. Sustain. 2024, 5, 36. [Google Scholar] [CrossRef]

- Choe, S.; Leite, F. Assessing Safety Risk among Different Construction Trades: Quantitative Approach. J. Constr. Eng. Manag. 2017, 143, 04016133. [Google Scholar] [CrossRef]

- Esmaeili, B.; Hallowell, M.R.; Rajagopalan, B. Attribute-Based Safety Risk Assessment. II: Predicting Safety Outcomes Using Generalized Linear Models. J. Constr. Eng. Manag. 2015, 141, 04015022. [Google Scholar] [CrossRef]

- OSHA. Outreach Training Program—Construction Focus Four Training. Available online: https://www.osha.gov/dte/outreach/construction/focus_four/index.html (accessed on 22 April 2024).

- Xiao, L.; Tang, L.C.M.; Wen, Y. An Innovative Construction Site Safety Assessment Solution Based on the Integration of Bayesian Network and Analytic Hierarchy Process. Buildings 2023, 13, 2918. [Google Scholar] [CrossRef]

- Sacks, R.; Whyte, J.; Swissa, D.; Raviv, G.; Zhou, W.; Shapira, A. Safety by design: Dialogues between designers and builders using virtual reality. Constr. Manag. Econ. 2015, 33, 55–72. [Google Scholar] [CrossRef]

- Han, Y.; Feng, Z.; Zhang, J.; Jin, R.; Aboagye-Nimo, E. Employees’ Safety Perceptions of Site Hazard and Accident Scenes. J. Constr. Eng. Manag. 2019, 145, 04018117. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J. Applying SEM in studying factors affecting construction workers’ safety behavior. J. Saf. Environ. 2016, 3, 182–187. [Google Scholar]

- Fan, X.; Wang, D.; Tong, Z.; Wang, X. Investigation and analysis of the safety risk factors of aging construction workers. Saf. Sci. 2023, 167, 106281. [Google Scholar] [CrossRef]

- Chen, Q.; Long, D.; Yang, C.; Xu, H. Knowledge Graph Improved Dynamic Risk Analysis Method for Behavior-Based Safety Management on a Construction Site. J. Manag. Eng. 2023, 39, 04023023. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Saurin, T.A.; Formoso, C.T.; Cambraia, F.B. Analysis of a safety planning and control model from the human error perspective. Eng. Constr. Arch. Manag. 2005, 12, 283–298. [Google Scholar] [CrossRef]

- Shapira, A.; Goldenberg, M. AHP-based equipment selection model for construction projects. J. Constr. Eng. Manag. 2005, 131, 1263–1273. [Google Scholar] [CrossRef]

- Shapira, A.; Simcha, M. AHP-Based Weighting of Factors Affecting Safety on Construction Sites with Tower Cranes. J. Constr. Eng. Manag. 2009, 135, 307–318. [Google Scholar] [CrossRef]

- Opticrane. Crane Safety Viewing Systems—Opticrane. Available online: https://opticrane.com/products/crane-safety-viewing-systems/ (accessed on 22 April 2024).

- HoistCam. HoistCam—Home—Wireless Camera for Cranes and Material Handling Equipment. Available online: https://hoistcam.com/ (accessed on 22 April 2024).

- Wu, B.-J.; Jin, L.-H.; Zheng, X.-Z.; Chen, S. Coupling analysis of crane accident risks based on Bayesian network and the N-K model. Sci. Rep. 2024, 14, 1133. [Google Scholar] [CrossRef] [PubMed]

- Carter, G.; Smith, S.D. Safety hazard identification on construction projects. J. Constr. Eng. Manag. 2006, 132, 197–205. [Google Scholar] [CrossRef]

- Salvendy, G. Handbook of Human Factors and Ergonomics, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022. [Google Scholar]

- Gillen, M.; Kools, S.; Sum, J.; McCall, C.; Moulden, K. Construction workers’ perceptions of management safety practices: A qualitative investigation. Work 2004, 23, 245–256. [Google Scholar] [PubMed]

- Menches, C.L.; Chen, J. Using ecological momentary assessment to understand a construction worker’s daily disruptions and decisions. Constr. Manag. Econ. 2013, 31, 180–194. [Google Scholar] [CrossRef]

- Perlman, A.; Sacks, R.; Barak, R. Hazard recognition and risk perception in construction. Saf. Sci. 2014, 64, 22–31. [Google Scholar] [CrossRef]

- Shohet, I.M.; Luzi, M.; Tarshish, M. Optimal allocation of resources in construction safety: Analytical-empirical model. Saf. Sci. 2018, 104, 231–238. [Google Scholar] [CrossRef]

- She, J.; Guo, Z.; Li, Z.; Liang, S.; Zhou, Y. Research on scenario deduction and emergency decision-making evaluation for construction safety accidents. Reliab. Eng. Syst. Saf. 2024, 251, 110317. [Google Scholar] [CrossRef]

- Saaty, T.L. The analytic hierarchy process (AHP). J. Oper. Res. Soc. 1980, 41, 1073–1076. [Google Scholar]

- Dong, Q.; Saaty, T.L. An analytic hierarchy process model of group consensus. J. Syst. Sci. Syst. Eng. 2014, 23, 362–374. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of application of analytic hierarchy process (AHP) in construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Subramanian, N.; Ramanathan, R. A review of applications of Analytic Hierarchy Process in operations management. Int. J. Prod. Econ. 2012, 138, 215–241. [Google Scholar] [CrossRef]

- Wang, J.-J.; Yang, D.-L. Using a hybrid multi-criteria decision aid method for information systems outsourcing. Comput. Oper. Res. 2007, 34, 3691–3700. [Google Scholar] [CrossRef]

- Skibniewski, M.J.; Chao, L. Evaluation of Advanced Construction Technology with AHP Method. J. Constr. Eng. Manag. 1992, 118, 577–593. [Google Scholar] [CrossRef]

- Gamal, Y.A.S.; Saber, A.M.A. Analyzing the application of the analytical hierarchy process in developing a robust risk management framework for construction projects in Egypt. Asian J. Civ. Eng. 2024, 25, 3729–3745. [Google Scholar] [CrossRef]

- Cabral, M.R.; Blanchet, P. Analytical Hierarchical Process as a Multicriteria Decision Tool in Material Selection for Prefabricated Wood Buildings. Buildings 2023, 13, 2973. [Google Scholar] [CrossRef]

- Chai, Y.; Wang, Y.; Wang, Y.; Peng, L.; Hou, L. Safety evaluation of human-caused errors in civil aviation based on analytic hierarchy process and fuzzy comprehensive evaluation method. Aircr. Eng. Aerosp. Technol. 2024, 96, 826–837. [Google Scholar] [CrossRef]

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2013, 46, 99–105. [Google Scholar] [CrossRef]

- Khodabocus, S.; Seyis, S. Multi-criteria decision-making model for risk management in modular construction projects. Int. J. Constr. Manag. 2023, 24, 240–250. [Google Scholar] [CrossRef]

- Kim, J.; Ishdorj, S.; Jeon, J.; Kim, J. Identifying Vital Factors for Enhancing Safety Communication among Foreign Construction Field Workers. Buildings 2024, 14, 1714. [Google Scholar] [CrossRef]

- Moon, H.; Mirmotalebi, S.; Jang, Y.; Ahn, Y.; Kwon, N. Risk Evaluation of Radioactive Concrete Structure Decommissioning in Nuclear Power Plants Using Fuzzy-AHP. Buildings 2024, 14, 1536. [Google Scholar] [CrossRef]

- Anjamrooz, T.; El-Sayegh, S.M.; Romdhane, L. Key Portfolio Selection Criteria for Sustainable Construction. Buildings 2024, 14, 1777. [Google Scholar] [CrossRef]

- Xiang, P.; Yang, Y.; Yan, K.; Jin, L. Identification of Key Safety Risk Factors and Coupling Paths in Mega Construction Projects. J. Manag. Eng. 2024, 40, 04024023. [Google Scholar] [CrossRef]

- Saah, A.E.N.; Yee, J.-J.; Choi, J.-H. Securing Construction Workers’ Data Security and Privacy with Blockchain Technology. Appl. Sci. 2023, 13, 13339. [Google Scholar] [CrossRef]

- Ran, R.; Wang, S.; Fang, J.; Wang, Y. Safety Risk Analysis of Urban Viaduct Construction Based on Dynamic Weight. Buildings 2024, 14, 1014. [Google Scholar] [CrossRef]

- Nikbakht, M.V.; Gheibi, M.; Montazeri, H.; Khaksar, R.Y.; Moezzi, R.; Vadiee, A. Identification and Ranking of Factors Affecting the Delay Risk of High-Rise Construction Projects Using AHP and VIKOR Methods. Infrastructures 2024, 9, 24. [Google Scholar] [CrossRef]

- Peng, J.L.; Liu, X.; Peng, C.; Shao, Y. Comprehensive factor analysis and risk quantification study of fall from height accidents. Heliyon 2023, 9, e22167. [Google Scholar] [CrossRef]

- Hinze, J.; Pedersen, C.; Fredley, J. Identifying Root Causes of Construction Injuries. J. Constr. Eng. Manag. 1998, 124, 67–71. [Google Scholar] [CrossRef]

- Abdelhamid, T.S.; Everett, J.G. Identifying Root Causes of Construction Accidents. J. Constr. Eng. Manag. 2000, 126, 52–60. [Google Scholar] [CrossRef]

- Newaz, M.T.; Ershadi, M.; Carothers, L.; Jefferies, M.; Davis, P. A review and assessment of technologies for addressing the risk of falling from height on construction sites. Saf. Sci. 2021, 147, 105618. [Google Scholar] [CrossRef]

- Shafei, H.; Rahman, R.A.; Lee, Y.S. Evaluating Construction 4.0 technologies in enhancing safety and health: Case study of a national strategic plan. J. Eng. Des. Technol. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Rasouli, S.; Alipouri, Y.; Chamanzad, S. Smart Personal Protective Equipment (PPE) for construction safety: A literature review. Saf. Sci. 2024, 170, 106368. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I.; Celik, T.; Arditi, D. The effectiveness of an integrated BIM/UAV model in managing safety on construction sites. Int. J. Occup. Saf. Ergon. 2020, 26, 829–844. [Google Scholar] [CrossRef]

| Question Number | Question Drafting | Mean | Standard Deviation |

|---|---|---|---|

| 1 | How do you assess safety on a construction site during the swinging of cargo using a crane? For example, how would you evaluate safety during the swinging of a concrete heater for wall casting? | 7.23 | 2.27 |

| 2 | To what extent do you estimate that the implementation of hazardous situation identification technology would enhance the safety rating in the scenario described in the previous question? | 7.77 | 1.66 |

| 3 | What safety rating would you assign to the execution of plaster works on the balcony bottom at the construction site where you work? | 6.63 | 1.53 |

| 4 | To what extent do you estimate that using a body camera for identifying hazardous situations would improve the safety rating for the execution of plaster works on the balcony bottom as mentioned in the previous question? | 7.83 | 1.83 |

| 5 | What safety rating would you assign to the execution of works on the building’s exterior fronts (e.g., exterior plaster, rigid cover, etc.)? | 6.66 | 1.45 |

| 6 | To what extent do you estimate that using a European scaffold would improve the safety rating in the previous question? | 7.43 | 1.79 |

| 7 | What safety rating would you assign to the construction site while a cement mixer is entering it? | 6.31 | 2.2 |

| 8 | To what extent do you estimate that an extra worker, whose duty is only to direct the entrance and exit to the construction site, would improve the safety rating in the previous question? | 8.97 | 1.03 |

| 9 | On a scale of 1–10, please rate the level of safety that you feel during daily work on the construction site. | 6.77 | 1.64 |

| Worker # | Do You Have Any Suggestions for Improving Safety in Construction Sites? |

|---|---|

| Worker 1 | Enforcing |

| Worker 2 | Order and organization |

| Worker 3 | |

| Worker 4 | |

| Worker 5 | |

| Worker 6 | Guidance days for workers, conducting surprise inspections, and more… |

| Worker 7 | More supervision, confirming regulations implementation, strict punishment |

| Worker 8 | |

| Worker 9 | |

| Worker 10 | |

| Worker 11 | I believe a more effective approach would involve continuous supervision with a wide reach. This means having safety supervisors and project safety agents closely connected to the ongoing work. Regular site tours would help identify potential hazards, including pre-planned risky situations. Implementing safety protocols for specific tasks, along with clear instructions and appropriate consequences, would enhance the overall safety of the construction site. |

| Worker 12 | |

| Worker 13 | To make sure that foremen will take care of safety and not execution |

| Worker 14 | From my perspective, safety professionals are increasingly burdened with safety paperwork to shift accountability. However, prioritizing worker advocacy holds greater significance. It is essential to prioritize worker safety and find solutions for safe work practices, even if it increases project costs. In summary, prioritizing safety over cost savings is critical: it’s the cause of disasters. |

| Worker 15 | |

| Worker 16 | A safety representative will enter hazardous areas and oversee safety. |

| Worker 17 | Due to the limitations of a foreman, separate manpower is necessary to supervise both work-in-progress and safety domains. |

| Worker 18 | |

| Worker 19 | |

| Worker 20 | |

| Worker 21 | To enhance safety on construction sites, it is essential to provide guidance and strict supervision and utilize technological means for monitoring and improving worker behavior. Lessons learned and recommendations should be implemented. |

| Worker 22 | Consider appointing a safety officer responsible for daily safety inspections, with the authority to suspend workers who violate safety rules, even minor ones, and impose fines. This appointment should be made by the project owner rather than the contractor. |

| Worker 23 | Providing instructions to workers and imposing fines for safety violations |

| Worker 24 | |

| Worker 25 | |

| Worker 26 | |

| Worker 27 | |

| Worker 28 | |

| Worker 29 | |

| Worker 30 | |

| Worker 31 | |

| Worker 32 | |

| Worker 33 | After the main contractor has fulfilled all requirements related to equipment and guidance, the constructor is allowed to impose fines on workers or subcontractors who violate the safety orders they have agreed to |

| Worker 34 | Implement ongoing education programs for management and work teams. |

| Worker 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeibak-Shini, R.; Malka, H.; Kima, O.; Shohet, I.M. Analytical Hierarchy Process for Construction Safety Management and Resource Allocation. Appl. Sci. 2024, 14, 9265. https://doi.org/10.3390/app14209265

Zeibak-Shini R, Malka H, Kima O, Shohet IM. Analytical Hierarchy Process for Construction Safety Management and Resource Allocation. Applied Sciences. 2024; 14(20):9265. https://doi.org/10.3390/app14209265

Chicago/Turabian StyleZeibak-Shini, Reem, Hofit Malka, Ovad Kima, and Igal M. Shohet. 2024. "Analytical Hierarchy Process for Construction Safety Management and Resource Allocation" Applied Sciences 14, no. 20: 9265. https://doi.org/10.3390/app14209265

APA StyleZeibak-Shini, R., Malka, H., Kima, O., & Shohet, I. M. (2024). Analytical Hierarchy Process for Construction Safety Management and Resource Allocation. Applied Sciences, 14(20), 9265. https://doi.org/10.3390/app14209265