Reduced-Order Modeling for Dynamic System Identification with Lumped and Distributed Parameters via Receptance Coupling Using Frequency-Based Substructuring (FBS)

Abstract

1. Introduction

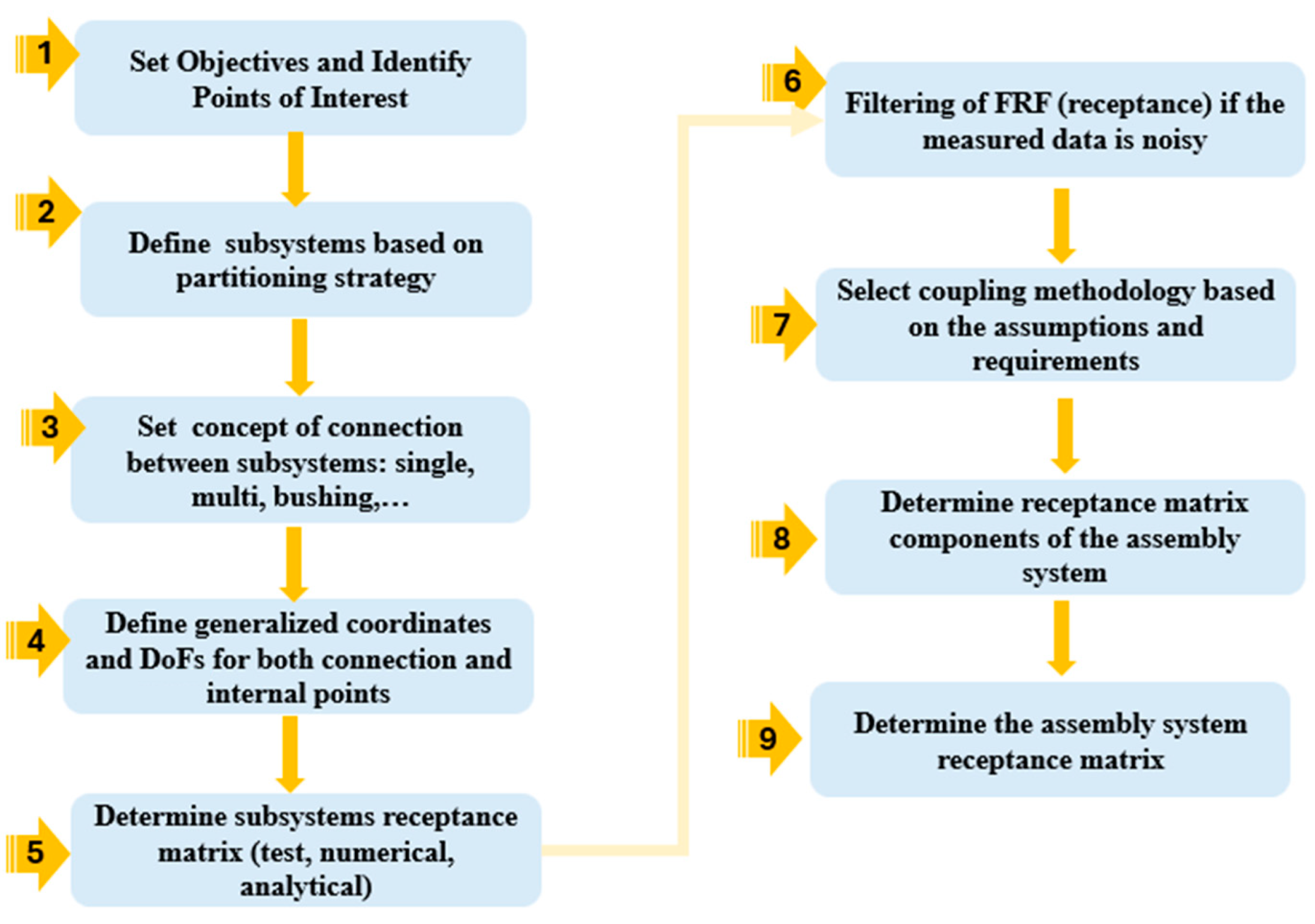

2. Methodology

2.1. Theoretical Background

2.2. Determining Receptance Coupling Using RCFBS

2.3. Direct Method for Determining Receptance Coupling Matrix

2.4. Modal Analysis Method

2.5. Numerical FEA

3. Case Studies: Application to Continuous and Lumped-Parameters Systems

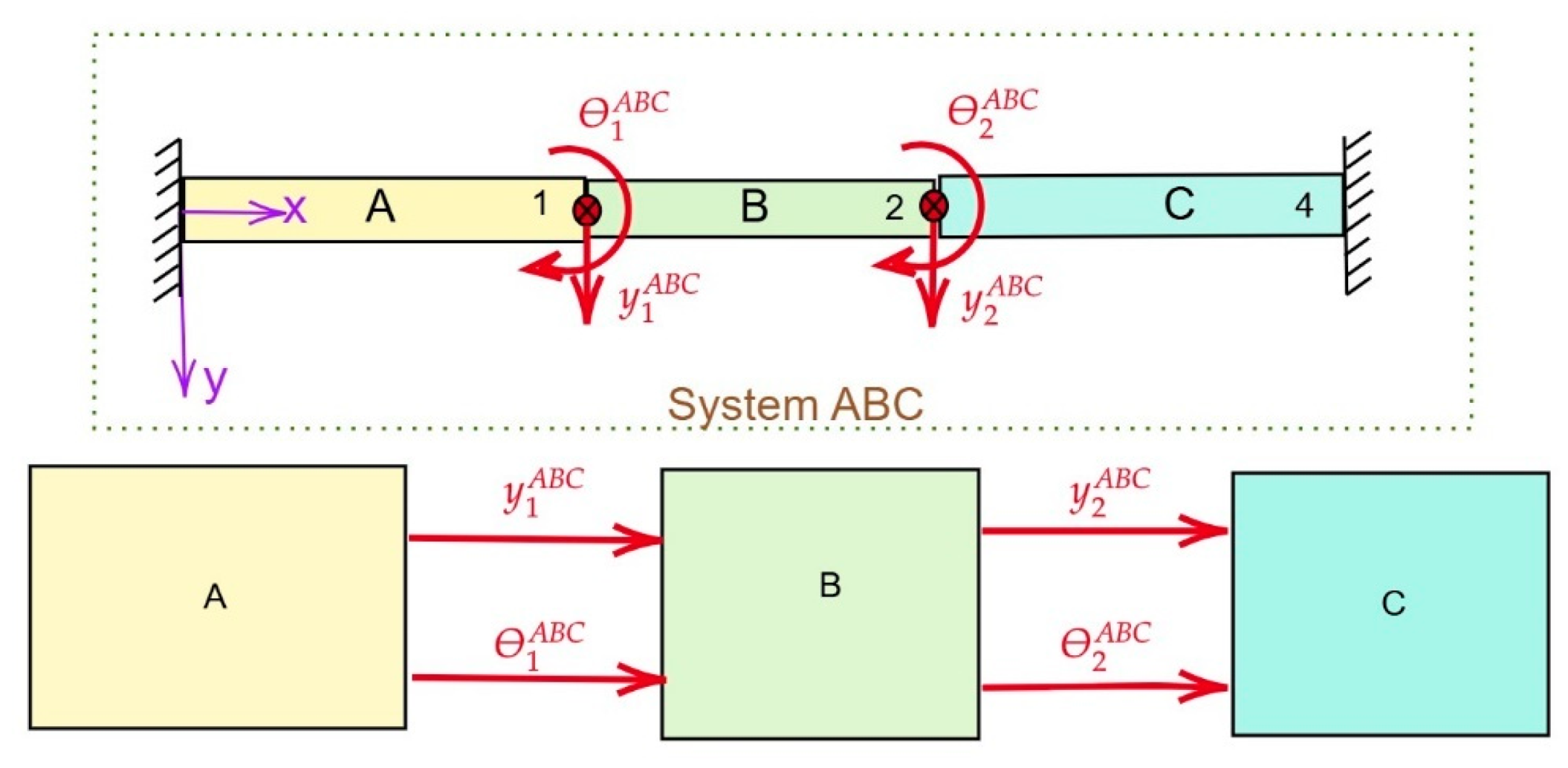

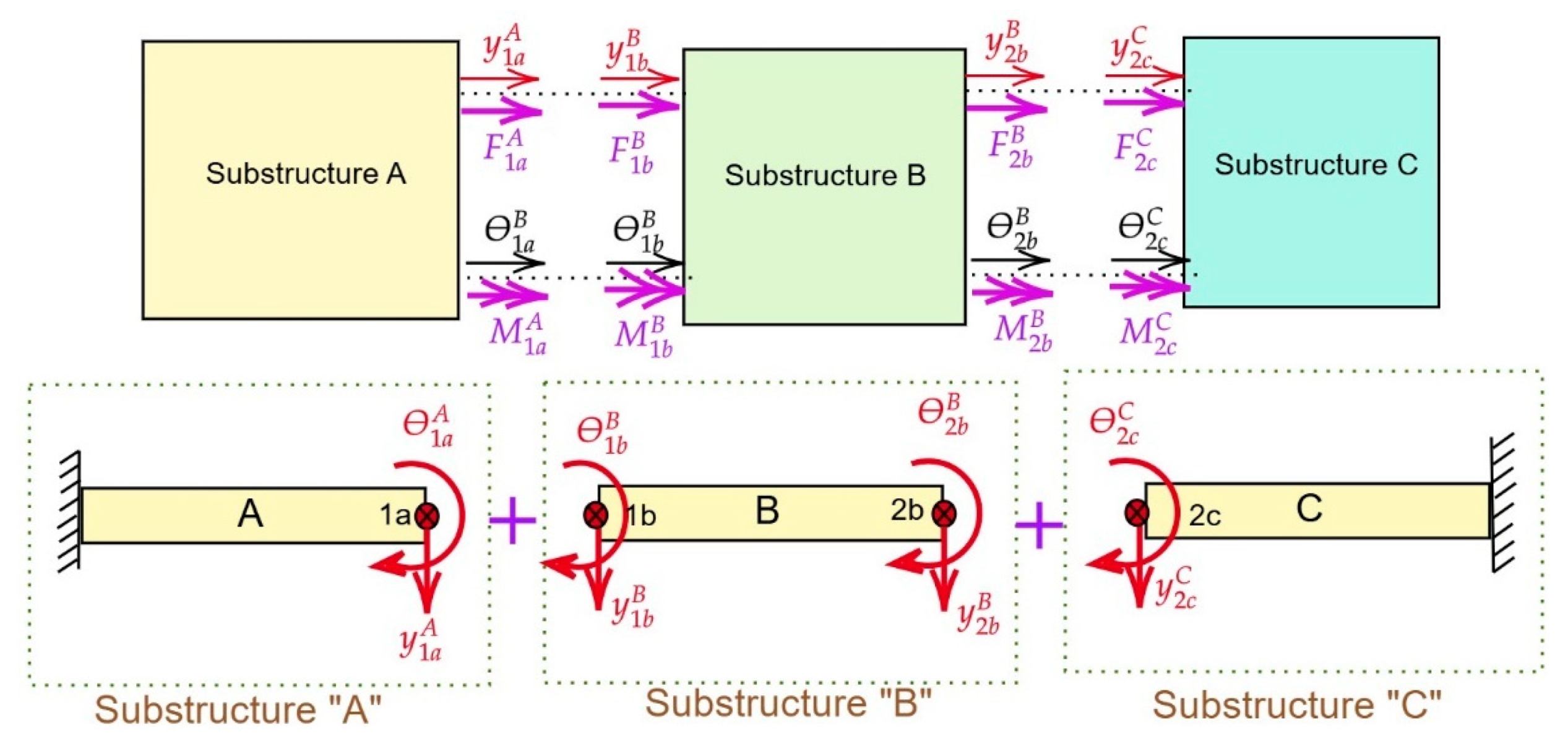

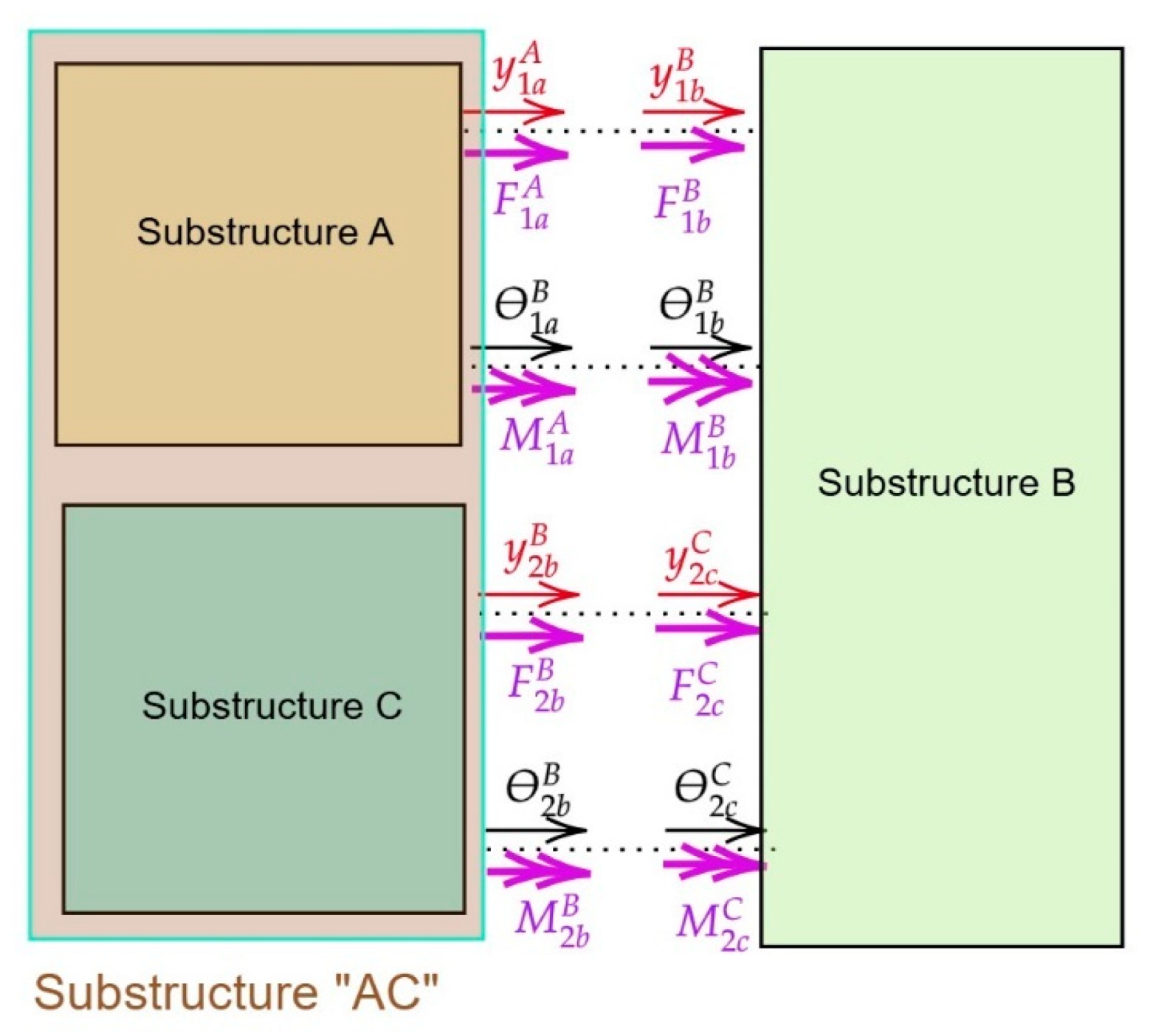

3.1. Case Study 1: Coupling of Continuous Substructures

3.1.1. RCFBS Method

3.1.2. Validation of RCFBS Using Numerical FEA

3.1.3. Validation of RCFBS Using Modal Method

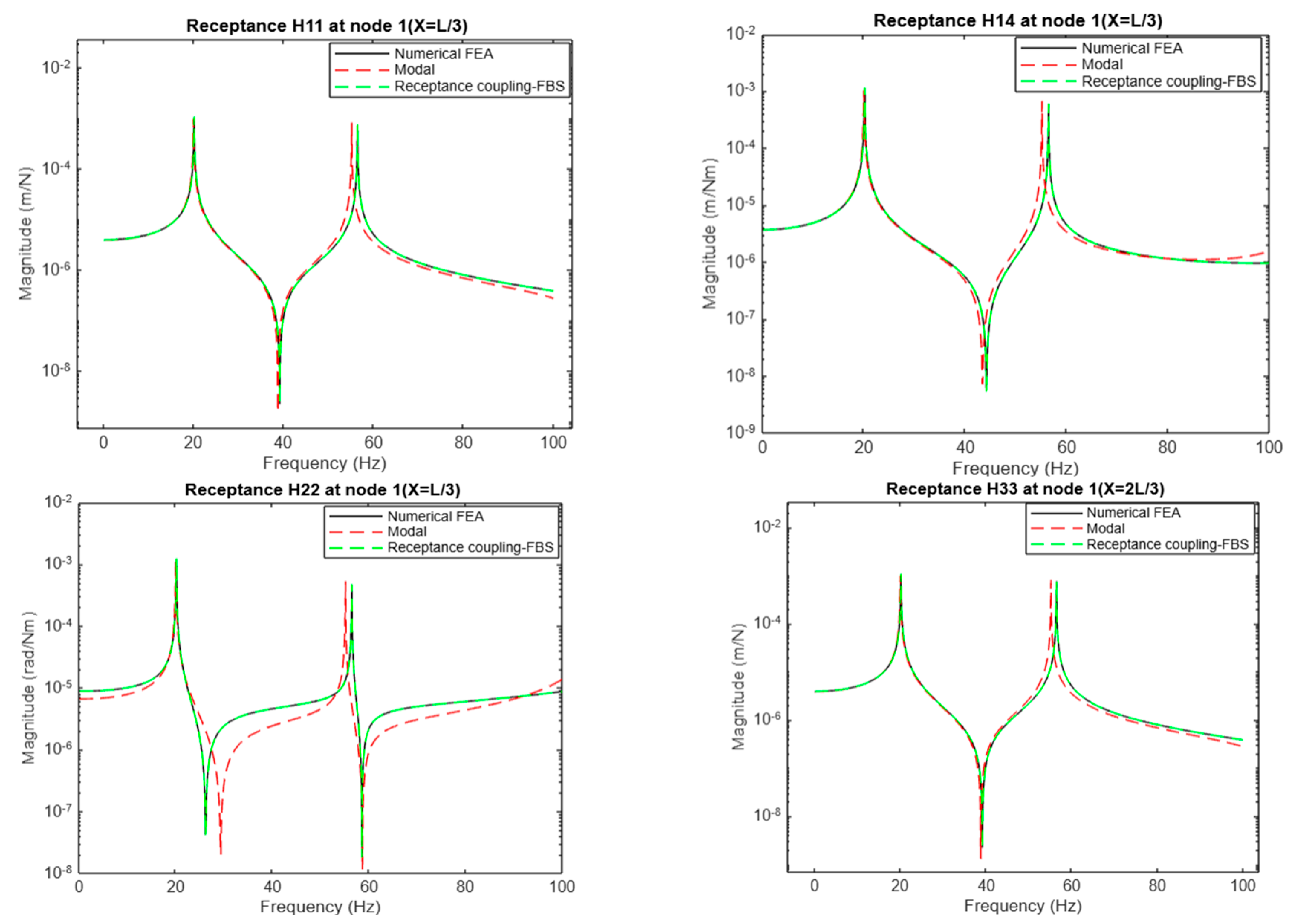

3.1.4. Results: Comparison Between Receptance Coupling from Different Methods

3.1.5. Discrepancy Analysis

3.1.6. Validation and Reliability

3.2. Case Study 2: Coupling of Subsystems with Lumped Parameters

3.2.1. RCFBS Method and Governing Equations

- Equations of motion for subsystem A:

- Equations of motion for subsystem B:

3.2.2. Validation Approach Using Direct Method

3.2.3. Validation Approach Using the Modal Method

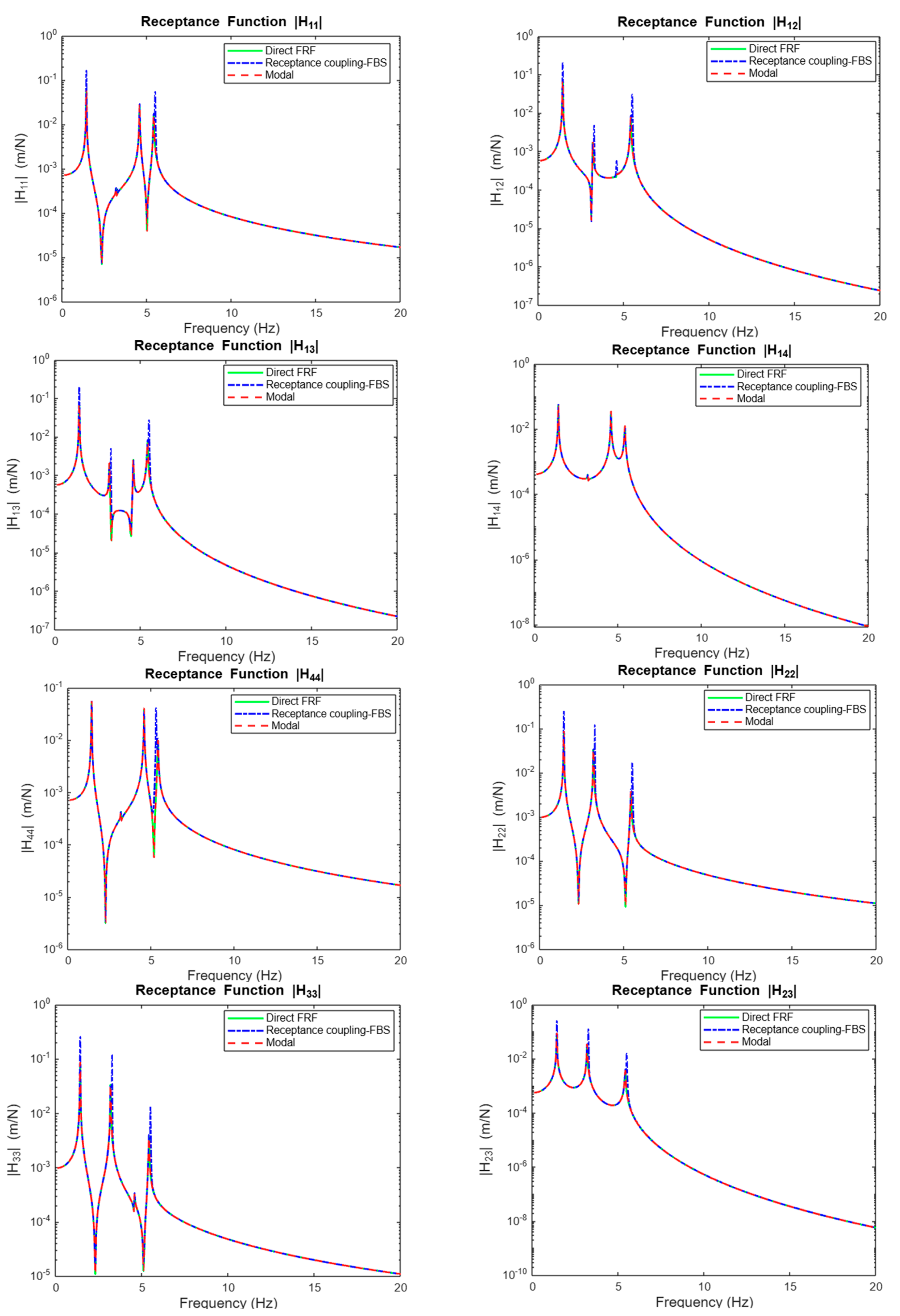

3.2.4. Results: Comparison of Receptance Components Across Different Methods

4. Discussion

- Assumption of Linearity: RCFBS relies on frequency-based substructuring, which operates in the frequency domain. This approach assumes linear dynamic behavior, which may lead to inaccuracies in systems with non-linear characteristics, such as large deformations or complex materials.

- Sensitivity to Measurement Errors: The accuracy of RCFBS heavily depends on the quality of the receptance/FRF data from experiments or simulations. Errors in measuring translational or rotational receptances can propagate through the model, resulting in incorrect dynamic response predictions. Effective filtering is crucial for reliable experimental FRF measurements.

- Non-Modular Systems: The RCFBS method may be less effective for inherently non-modular systems. Complex geometries or dynamically changing boundary conditions can complicate the application of receptance coupling and substructuring techniques.

- Complex Interactions: In systems with intricate component interactions, simplifying the system into subsystems may overlook important dynamic complexities. Highly coupled components or significant non-linearities may require a more holistic modeling approach than RCFBS can provide.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bishop, R.E.D.; Johnson, D.C. The Mechanics of Vibration; Cambridge University Press: Cambridge, UK, 1960. [Google Scholar]

- Jetmundsen, B.; Bielawa, R.L.; Flannelly, W.G. Flannelly, Generalized frequency domain substructures synthesis. J. Am. Helicopter Soc. 1988, 33, 55–64. [Google Scholar] [CrossRef]

- Ewins, D.J. On predicting point mobility plots from measurements of other mobility parameters. J. Sound Vib. 1980, 70, 69–75. [Google Scholar] [CrossRef]

- Duarte, M.L.M.; Ewins, D.J. Rotational degrees of freedom for structural coupling analysis via finite-difference technique with residual compensation. Mech. Syst. Signal Process. 2000, 14, 205–227. [Google Scholar] [CrossRef]

- Özşahin, O.; Ertürk, A.; Özgüven, H.N.; Budak, E. A closed-form approach for identification of dynamical contact parameters in spindle-holder-tool assemblies. Int. J. Mach. Tools Manuf. 2009, 49, 1901–1912. [Google Scholar] [CrossRef]

- Park, S.S.; Chae, J. Joint identification of modular tools using a novel receptance coupling method. Int. J. Adv. Manuf. Technol. 2008, 35, 1251–1262. [Google Scholar] [CrossRef]

- Mao, K.; Li, B.; Wu, J.; Shao, X. Stiffness influential factors-based dynamic modeling and its parameter identification method of fixed joints in machine tools. Int. J. Mach. Tools Manuf. 2010, 50, 156–164. [Google Scholar] [CrossRef]

- Albertelli, P.; Goletti, M.; Monno, M. A new receptance coupling substructure analysis methodology to improve chatter free cutting conditions prediction. Mech. Syst. Signal Process. 2013, 40, 747–759. [Google Scholar] [CrossRef]

- Weaver, W., Jr.; Timoshenko, S.; Young, D. Vibration Problems in Engineering, 5th ed.; John Wiley and Sons: Hoboken, NJ, USA, 1990. [Google Scholar]

- Ertürk, A.; Özgüven, H.N.; Budak, E. Analytical modeling of spindle-tool dynamics on machine tools using Timoshenko beam model and receptance coupling for the prediction of tool point FRF. Int. J. Mach. Tool Manuf. 2006, 46, 1901–1912. [Google Scholar] [CrossRef]

- Özşahin, O.; Altintas, Y. Altintas, Prediction of frequency response function (FRF) of asymmetric tools from the analytical coupling of spindle and beam models of holder and tool. Int. J. Mach. Tool Manuf. 2015, 92, 31–40. [Google Scholar] [CrossRef]

- Hutchinson, J.R. Shear coefficients for Timoshenko beam theory. J. Appl. Mech. 2001, 68, 87–92. [Google Scholar] [CrossRef]

- D’Ambrogio, W.; Fregolent, A. Sensitivity of decoupling techniques to uncertainties in the properties. In Proceedings of the ISMA2008 Conference, Leuven, Belgium, 15–17 September 2008. [Google Scholar]

- Schmitz, T.L.; Davies, M.A.; Kennedy, M.D. Tool Point Frequency Response Prediction for High-Speed Machining by RCSA. J. Manuf. Sci. Eng. 2001, 123, 700–707. [Google Scholar] [CrossRef]

- Tsai, S.H.; Ouyang, H.; Chang, J.Y. A receptance-based method for frequency assignment via coupling of subsystems. Arch. Appl. Mech. 2020, 90, 449–465. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Smith, K.S. Receptance Coupling. In Mechanical Vibrations; Springer: Boston, MA, USA, 2012. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Donalson, R.R. Predicting High-Speed Machining Dynamics by Substructure Analysis. CIRP Ann. 2000, 49, 303–308. [Google Scholar] [CrossRef]

- Liu, W.; Ewins, D.J. Substructure Synthesis via Elastic Media. J. Sound Vib. 2001, 246, 59–80. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Powell, K.; Won, D.; Duncan, G.S.; Sawyer, W.G.; Ziegert, J.C. Shrink fit tool holder connection stiffness/damping modeling for frequency response prediction in milling. Int. J. Mach. Tool Manuf. 2007, 47, 1368–1380. [Google Scholar] [CrossRef]

- Movahhedy, M.R.; Gerami, J.M. Prediction of spindle dynamics in milling by sub-structure coupling. Int. J. Mach. Tool Manuf. 2006, 46, 243–251. [Google Scholar] [CrossRef]

- Wang, D.; Penter, L.; Hanel, A.; Yang, Y.; Ihlenfeldt, S. Investigation on dynamic tool deflection and runout-dependent analysis of the micro-milling process. Mech. Syst. Signal Process. 2022, 178, 109282. [Google Scholar] [CrossRef]

- Schmitz, T.; Cornelius, A.; Karandikar, J.; Tyler, C.; Smith, S. Receptance coupling substructure analysis and chatter frequency-informed machine learning for milling stability. CIRP Ann. 2022, 71, 321–324. [Google Scholar] [CrossRef]

- Hamedi, B.; Taheri, S. Fundamental Review of Hybrid and Modular Modeling Approaches for Road Noise Prediction: Insights from a Fundamental Quarter Car Model. Univers. J. Mech. Eng. 2024, 12, 25–35. [Google Scholar] [CrossRef]

- Hou, Y.; Yao, P.; Liu, X.; Xu, J.; Guo, M.; Li, Y.; Liang, S.; Niu, J.; Liu, H.; Huang, C.; et al. Modeling and prediction for frequency response functions of parameter-varying mechanical systems based on generalized receptance coupling substructure analysis. Mech. Syst. Signal Process. 2023, 194, 110278. [Google Scholar] [CrossRef]

- Ji, Y.; Bi, Q.; Zhang, S.; Wang, Y. A new receptance coupling substructure analysis methodology to predict tool tip dynamics. Int. J. Mach. Tools Manuf. 2018, 126, 18–26. [Google Scholar] [CrossRef]

- De Klerk, D.; Rixen, D.J.; De Jong, J. Advanced algorithms for subsystem coupling in frequency-based substructuring. Mech. Syst. Signal Process. 2021, 151, 107368. [Google Scholar]

- De Klerk, D.; Rixen, D.J.; De Jong, J. The frequency-based substructuring method as a basis for component mode synthesis. J. Sound Vib. 2006, 308, 303–329. [Google Scholar] [CrossRef]

- Thulasiraman, K.; Swamy, M.N.S. Graphs: Theory and Algorithms, 1st ed.; Wiley: Hoboken, NJ, USA, 1992. [Google Scholar]

- Kim, J.-W.; Lee, J.-W.; Kim, K.-W.; Kang, J.-H.; Yang, M.-S.; Kim, D.-Y.; Lee, S.-Y.; Jang, J.-S. Estimation of the Frequency Response Function of the Rotational Degree of Freedom. Appl. Sci. 2021, 11, 8527. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Duncan, G.S. Three-component receptance coupling substructure analysis for tool point dynamics prediction. J. Manuf. Sci. Eng. 2005, 127, 781–790. [Google Scholar] [CrossRef]

| Parameters | Modulus of Elasticity (E) | Moment of Inertia (I) | Length of Beam Element (L) | Cross-Sectional Area (A) | Section Diameter (d) | Density (ρ) |

|---|---|---|---|---|---|---|

| value | 200 × 109 Pa | 1.25 × 10−7 m4 | 1 m | 0.0013 m2 | 0.04 m | 7850 kg/m3 |

| Stiffness (N/m) | ||||||||

| 900 | 1300 | 1200 | 900 | 1100 | 1200 | |||

| Damping (Ns/m) | ||||||||

| 0.1 | 0.2 | 0.2 | 0.1 | 0.2 | 0.2 | |||

| Mass (kg) | ||||||||

| 4 | 3 | 3 | 4 | 3 | 3 | 6 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamedi, B.; Taheri, S. Reduced-Order Modeling for Dynamic System Identification with Lumped and Distributed Parameters via Receptance Coupling Using Frequency-Based Substructuring (FBS). Appl. Sci. 2024, 14, 9550. https://doi.org/10.3390/app14209550

Hamedi B, Taheri S. Reduced-Order Modeling for Dynamic System Identification with Lumped and Distributed Parameters via Receptance Coupling Using Frequency-Based Substructuring (FBS). Applied Sciences. 2024; 14(20):9550. https://doi.org/10.3390/app14209550

Chicago/Turabian StyleHamedi, Behzad, and Saied Taheri. 2024. "Reduced-Order Modeling for Dynamic System Identification with Lumped and Distributed Parameters via Receptance Coupling Using Frequency-Based Substructuring (FBS)" Applied Sciences 14, no. 20: 9550. https://doi.org/10.3390/app14209550

APA StyleHamedi, B., & Taheri, S. (2024). Reduced-Order Modeling for Dynamic System Identification with Lumped and Distributed Parameters via Receptance Coupling Using Frequency-Based Substructuring (FBS). Applied Sciences, 14(20), 9550. https://doi.org/10.3390/app14209550