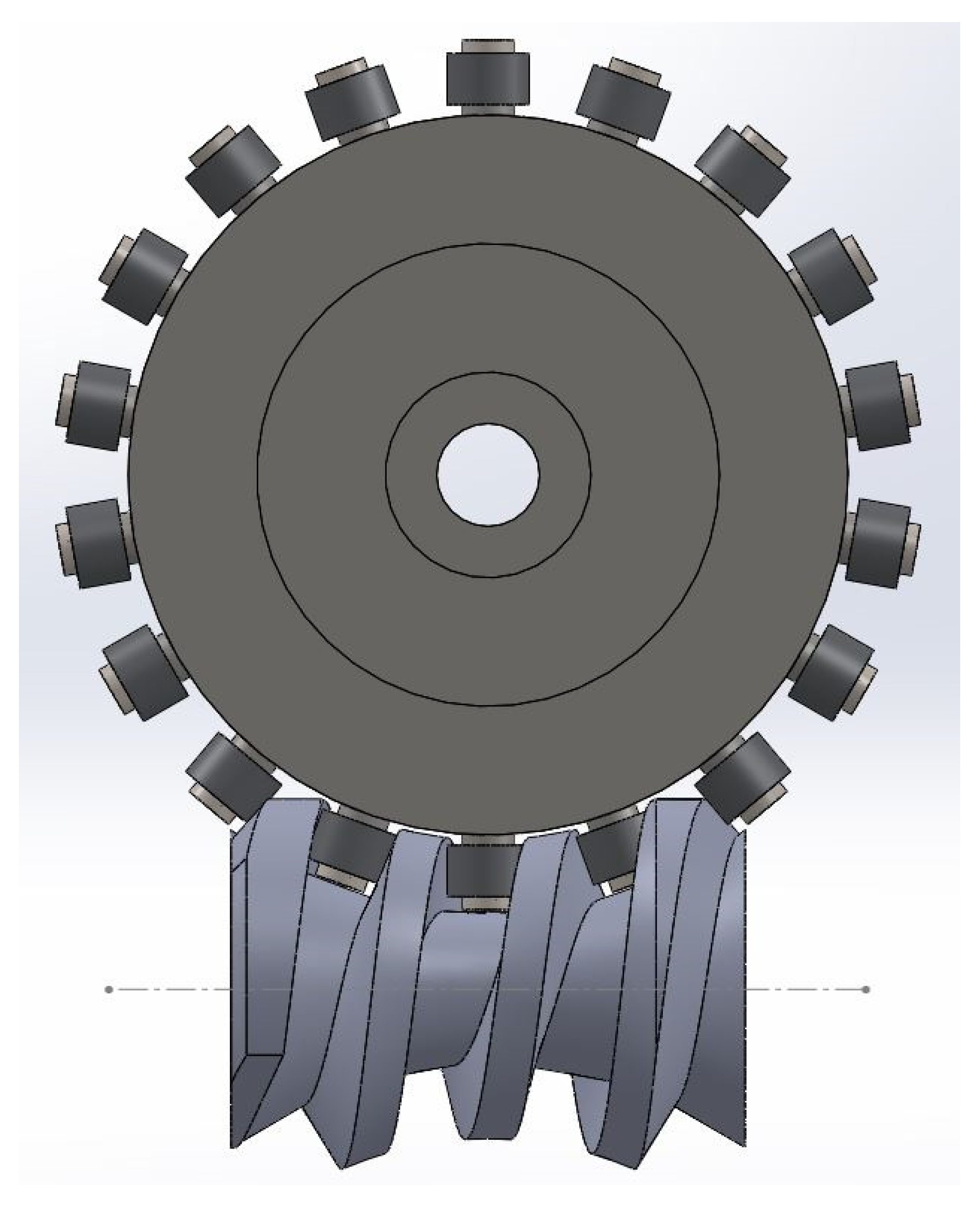

An Attempt to Establish a Mathematical Model for an Unconventional Worm Gear with Bearings

Abstract

1. Introduction

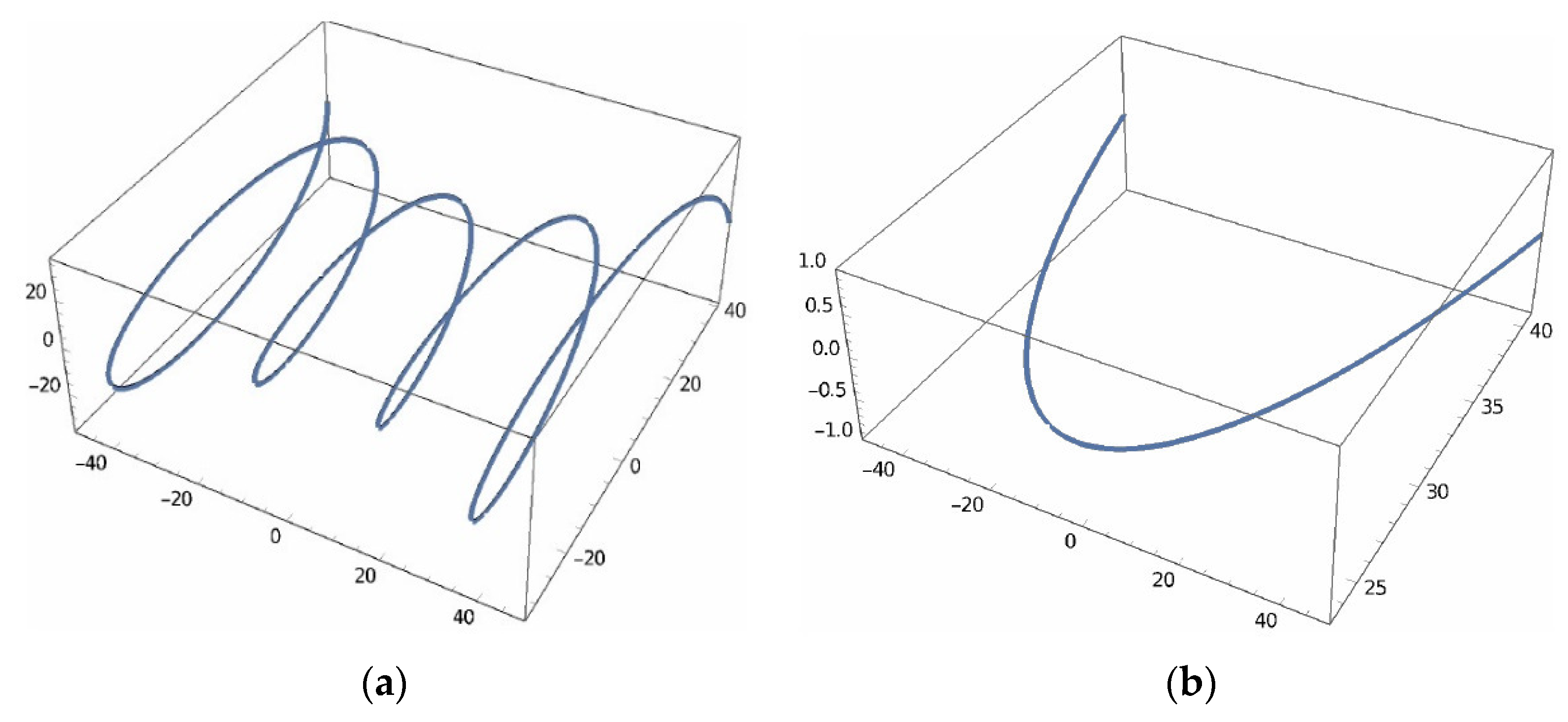

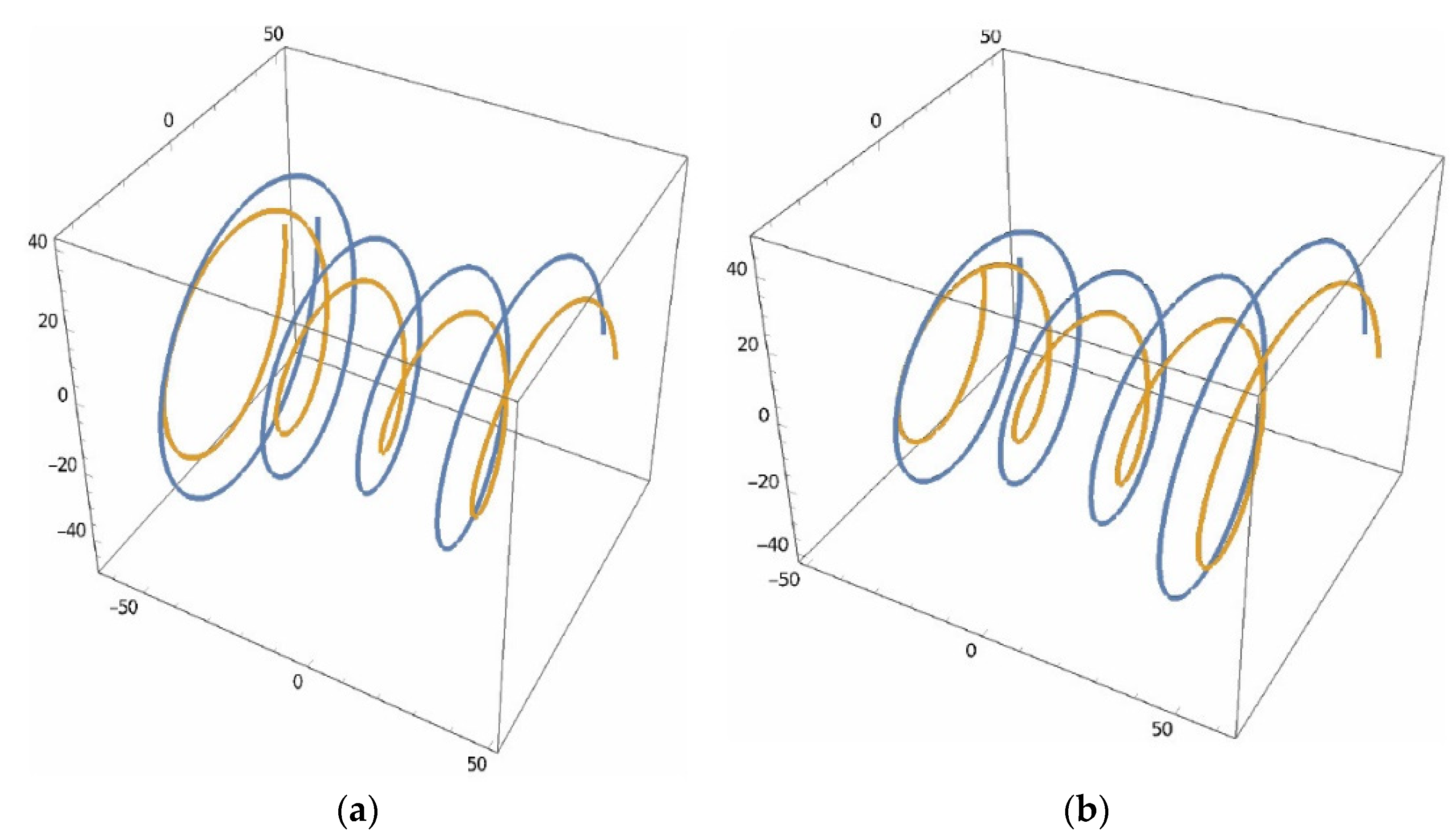

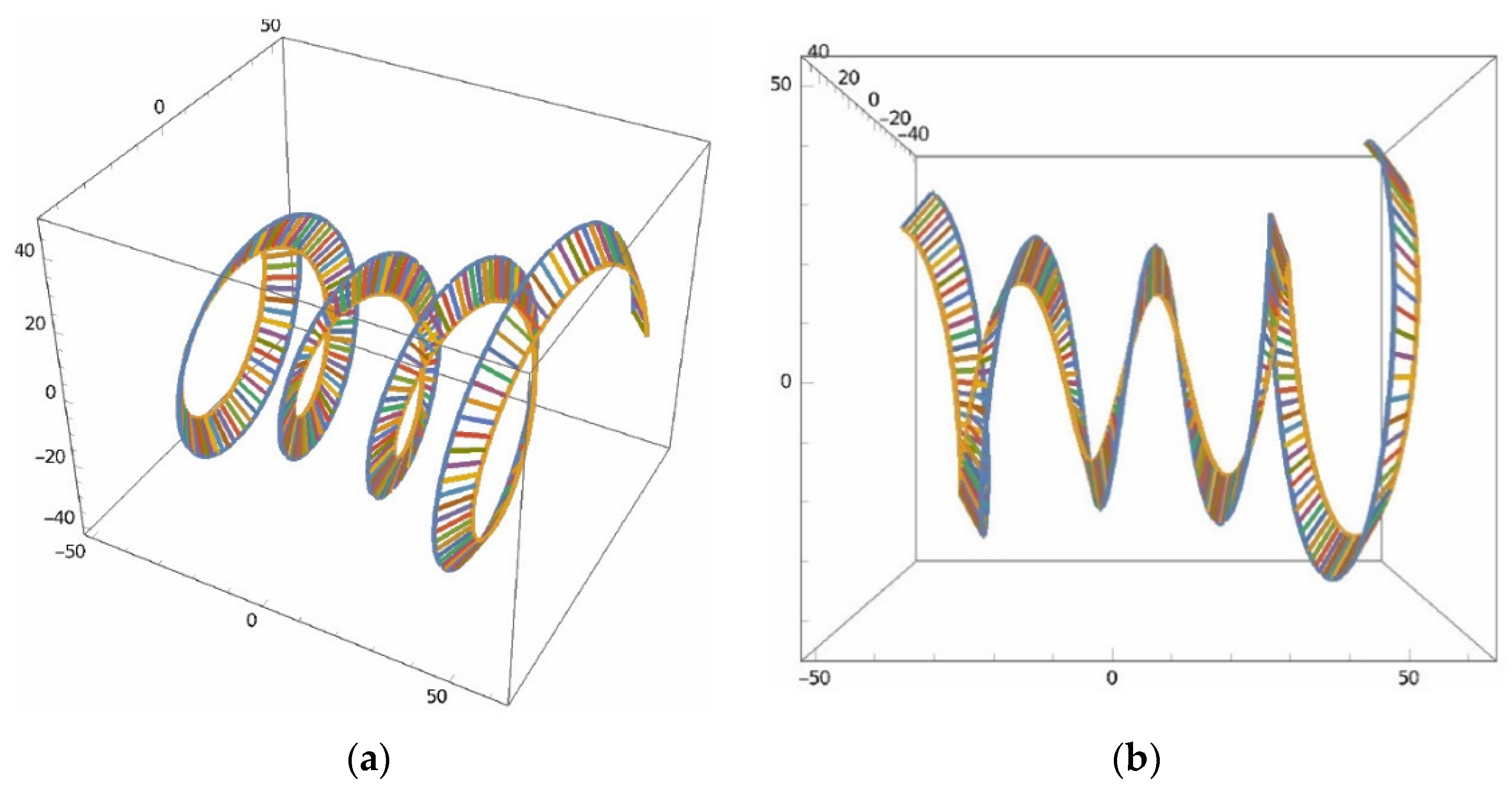

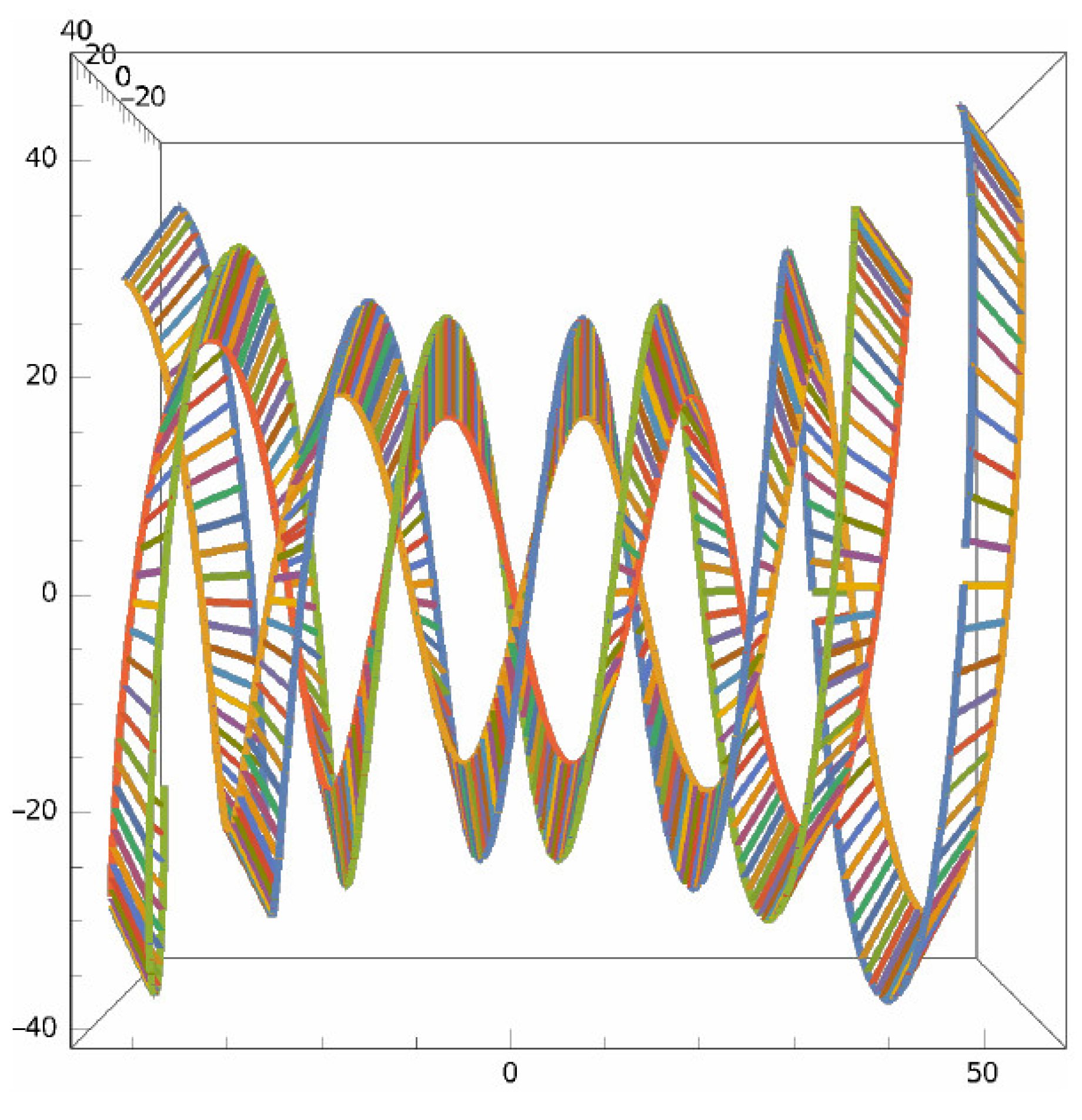

2. Materials and Methods

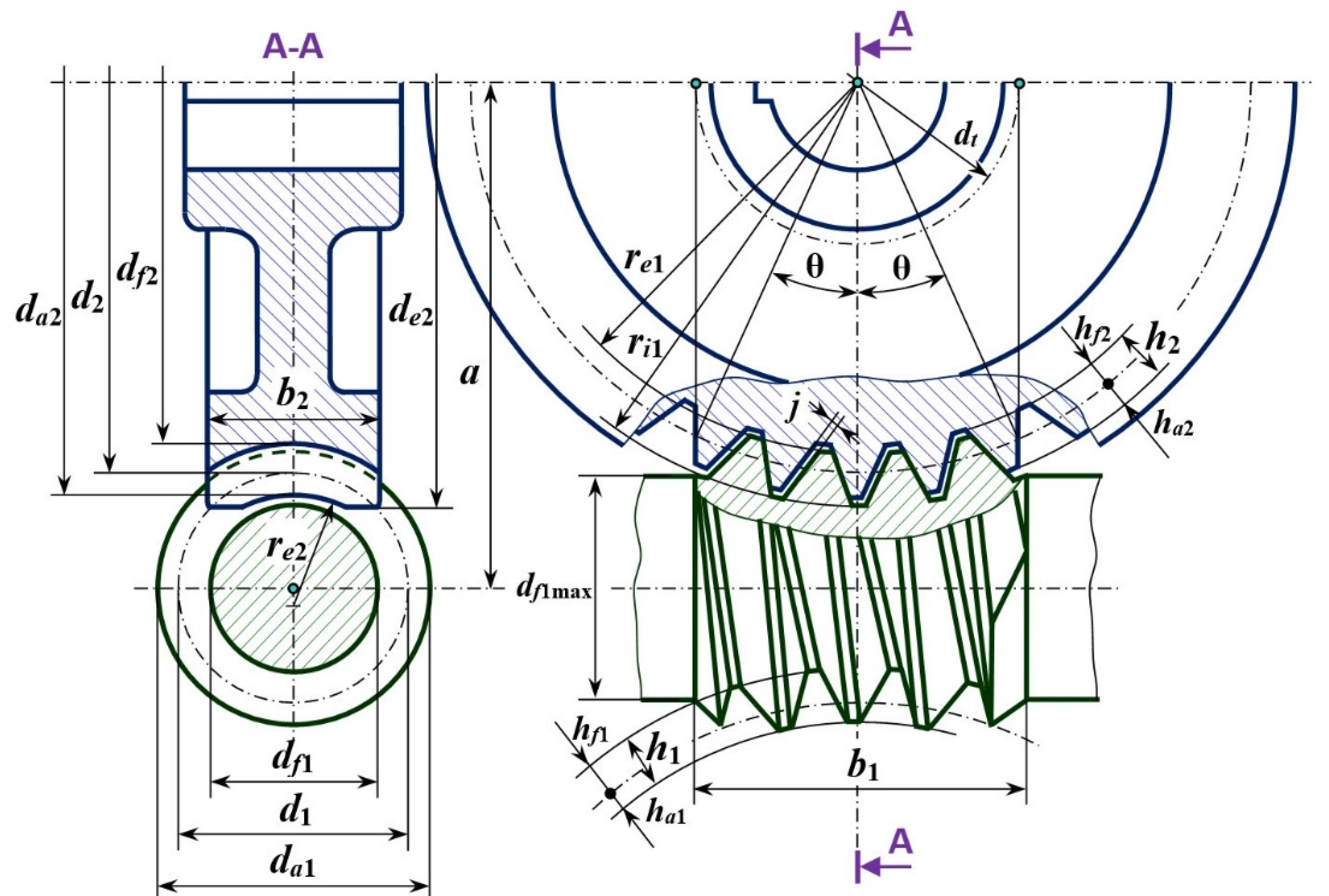

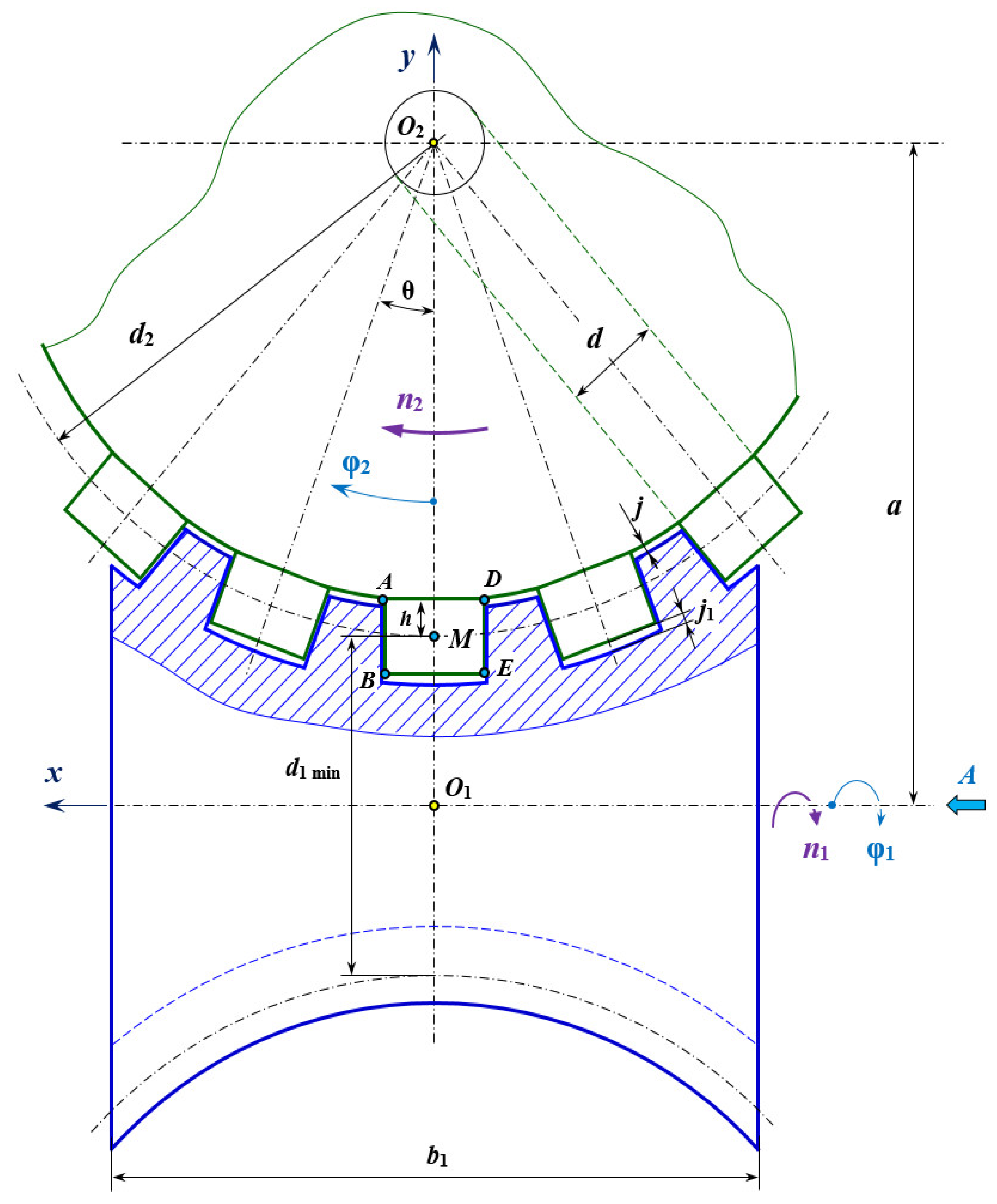

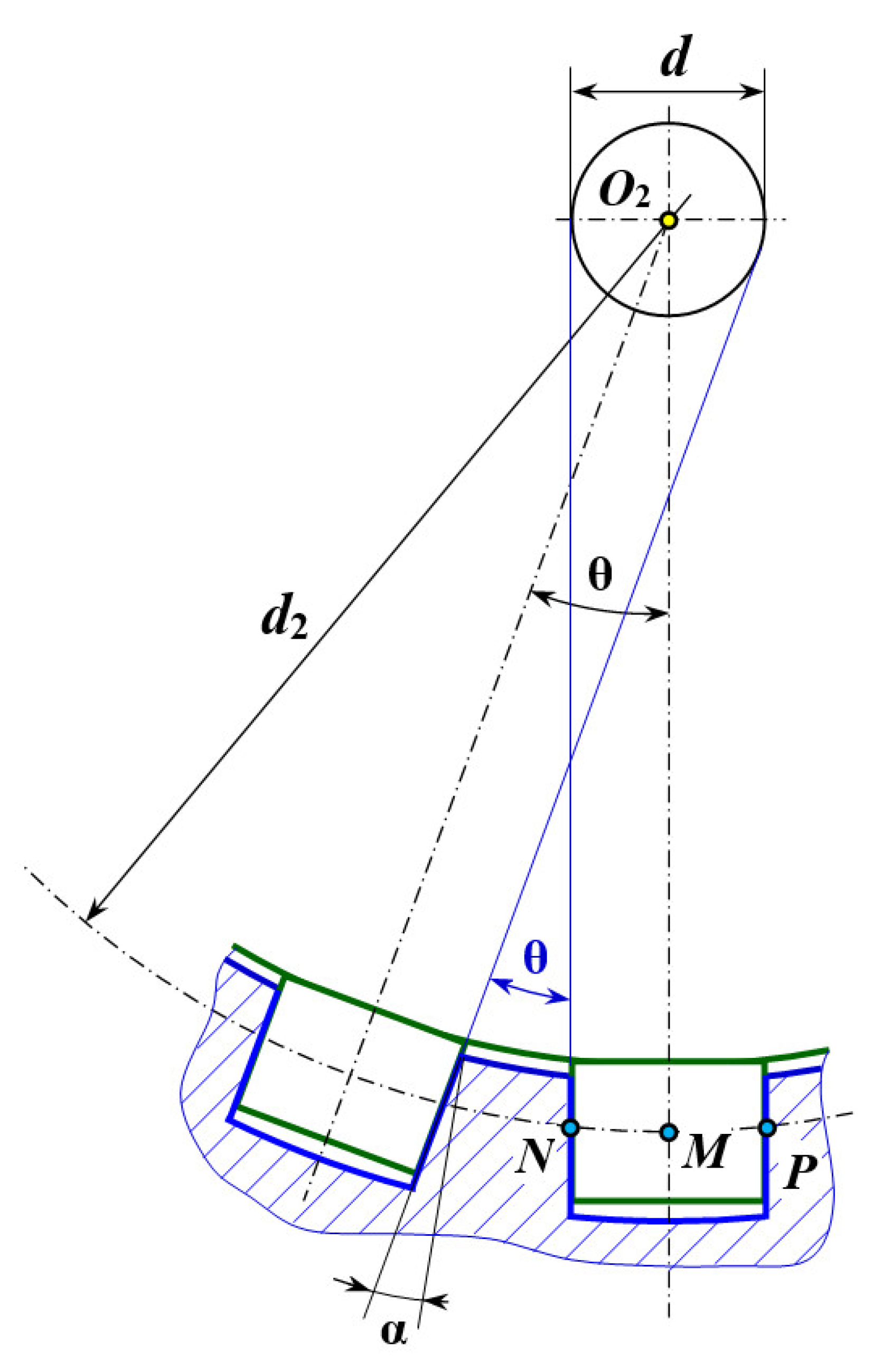

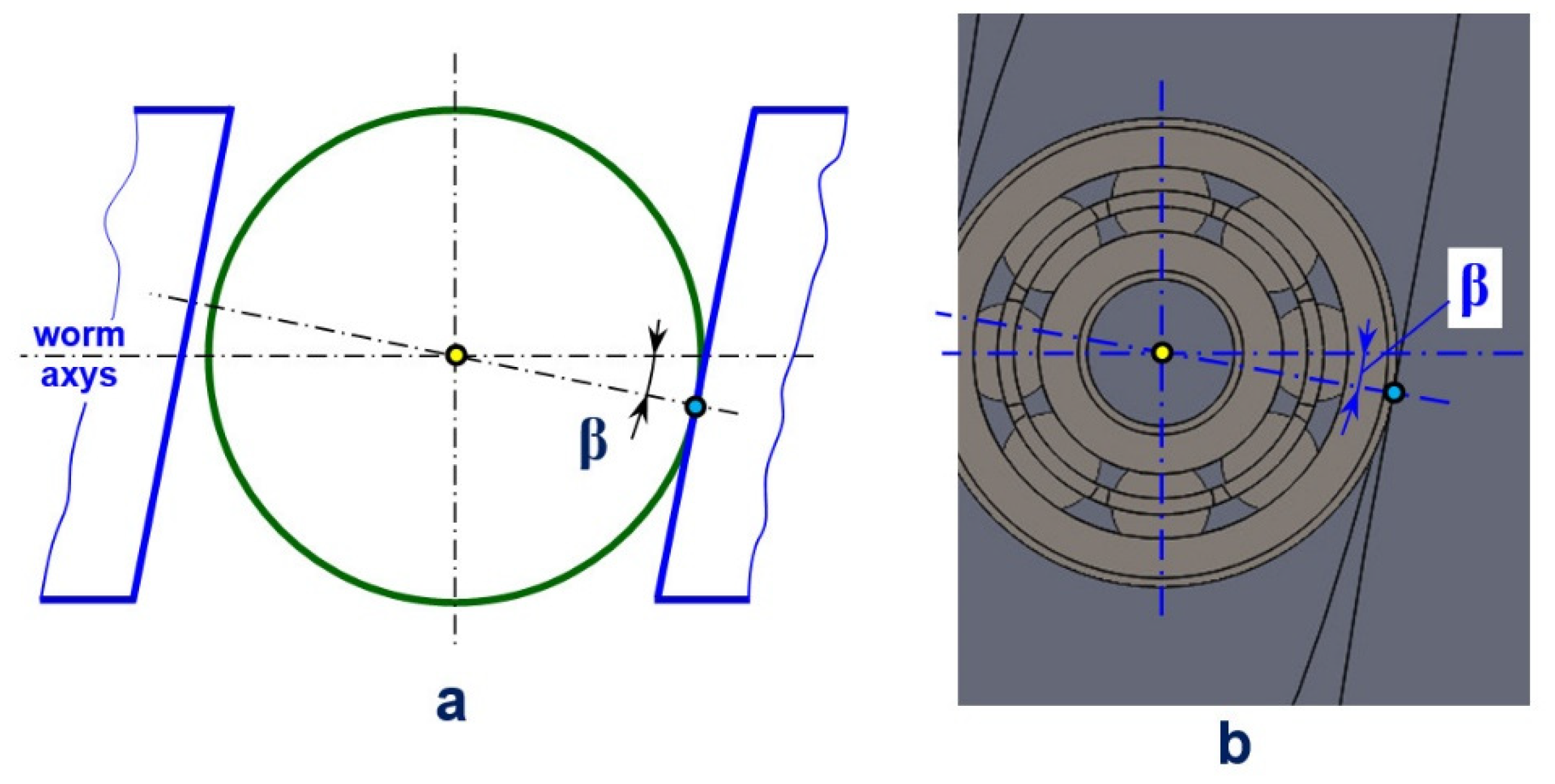

2.1. Geometry of the Unconventional Worm Gear with Bearings, Kinematic Analysis, and Mathematical Model Formulation

- d2 is the worm wheel pitch diameter, mm;

- a represents the center distance, mm;

- φ1 is the angle of the position for the worm wheel, ° (degrees);

- φ2 is the angle of the position for the worm wheel, ° (degrees).

- u12 represents the gear ratio

- is the worm wheel number of radial ball bearings, i.e., the number of teeth (in a classic worm gearing);

- represents the thread number of the worm;

- and represent the rotational speed of the worm and wheel, respectively.

- is the outer diameter of the bearing.

- is the bearing width.

- v2 is the peripheral speed of the driven wheel (constant).

- v1 is the peripheral speed of the worm (variable).

2.2. Analytic Validation of the 3D Model

3. Results

Experimental Validation of the Physical Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dudás, I. The Theory and Practice of Worm Gear Drives; Penton Press: London, UK, 2000. [Google Scholar]

- Grote, K.H.; Antonsson, E.K. Springer Handbook of Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Zhao, Y.; Kong, X. Meshing principle of conical surface enveloping spiroid drive. Mech. Mach. Theory 2018, 123, 1–26. [Google Scholar] [CrossRef]

- Crosher, W.P. Design and Application of the Worm Gear; ASME Press: New York, NY, USA, 2002. [Google Scholar]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Ninacs, R.; Cristea, A.F.; Haragâș, S. Study regarding the kinematic and functional aspects of globoidal worm gear. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2022, 65, 499–504. [Google Scholar]

- Cristea, A.F.; Ninacs, R.; Haragâș, S. Study regarding the kinematic and functional aspects of unconventional worm gear. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2022, 65, 437–442. [Google Scholar]

- Zhao, Y.; Huai, C.; Zhang, Y. Compound modification of globoidal worm drive with variable parameters. Appl. Math. Model. 2017, 50, 17–38. [Google Scholar] [CrossRef]

- Xu, W.; Qin, D.; Shi, W. Direct digital design and simulation of meshing in worm-gear drive. Chin. J. Mech. Eng. 2006, 19, 428–433. [Google Scholar] [CrossRef]

- Polowniak, P.; Sobolak, M.; Marciniec, A. Double enveloping worm gear modeling using CAD environment. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e136736. [Google Scholar]

- Zhao, Y.; Zhang, Y. Novel methods for curvature analysis and their application to TA worm. Mech. Mach. Theory 2016, 97, 155–170. [Google Scholar] [CrossRef]

- Zhao, Y. Meshing analysis for TA worm. Mech. Mach. Sci. 2016, 43, 13–20. [Google Scholar] [CrossRef]

- Andrianto, M.; Wu, Y.R.; Arifin, A. A novel manufacturing method for double-enveloping worms using a whirl-machining process. Mech. Mach. Theory 2023, 179, 105099. [Google Scholar] [CrossRef]

- Rui, C.; Li, H.; Yang, J.; Wei, W. Research on a method for designing land surfaces of a dual-cone double enveloping hourglass worm wheel hob. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0090. [Google Scholar] [CrossRef]

- Lei, Z.; Bi, Q.; Wang, Y.; Ding, H. Five-Axis Flank Milling Method of Plane Double Enveloping Hourglass Worm. Adv. Mater. Res. 2011, 314–316, 1523–1532. [Google Scholar]

- Dong, L.; Wang, J.; Liu, P.; Wei, W.; Li, H. An NC rough turning method of an enveloping toroidal worm. Prod. Eng. 2012, 6, 129–135. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, G.; Chen, B.; Luo, W.; Li, F.; Chen, Y. A novel enveloping worm pair via employing the conjugating planar internal gear as counterpart. Mech. Mach. Theory 2013, 67, 17–31. [Google Scholar] [CrossRef]

- Deng, X.; Wang, J.; Wang, S.; Wang, S.; Wang, J.; Li, S.; Liu, Y.; He, G. Investigation on the Backlash of Roller Enveloping Hourglass Worm Gear: Theoretical Analysis and Experiment. J. Mech. Des. 2018, 141, 053302. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Wang, J.; Deng, X. Temperature Field Simulation and Experimental Study of Anti-backlash Single-Roller Enveloping Hourglass Worm Gear. Chin. J. Mech. Eng. 2020, 33, 59. [Google Scholar] [CrossRef]

- Gao, S.; Wang, X. Theoretical modeling and transmission characteristics analysis of a novel double-roller hourglass worm drive based on enveloping principle. Discov. Mech. Eng. 2023, 2, 20. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Wang, S.; Wang, S.; He, G. A comparative investigation of meshing characteristics of antibacklash single-and double-roller enveloping hourglass worm gears. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0064. [Google Scholar] [CrossRef]

- Available online: https://www.wolframalpha.com/ (accessed on 10 May 2024).

- Polowniak, P.; Sobolak, M.; Marciniec, A. Mathematical model of the worm wheel tooth flank of a double-enveloping worm gear. Alex. Eng. J. 2021, 60, 3037–3046. [Google Scholar] [CrossRef]

- Polowniak, P.; Sobolak, M. Mathematical description of tooth flank surface of globoidal worm gear with straight axial tooth profile. Open Eng. 2017, 7, 407–415. [Google Scholar] [CrossRef]

- Dudás, L. New technology for manufacturing quasi-globoid worm gearings. IOP Conf. Ser. Mater. Sci. Eng. 2018, 448, 012035. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Luo, W.; Zhang, G. Development and Classification of Worm Drive. In Proceedings of the 14th IFToMM World Congress, Taipei, Taiwan, 25–30 October 2015. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, W.; Ma, H.; Pu, Y.; Chen, Y. A Novel Precision Grinding Method for Roller Enveloping Hourglass Worm. Int. J. Precis. Eng. Manuf. 2024, 25, 2223–2234. [Google Scholar] [CrossRef]

- Deng, X.; Wang, J.; Horstemeyer, M.F. Modification design method for an enveloping hourglass worm gear with consideration of machining and misalignment errors. Chin. J. Mech. Eng. 2013, 26, 948–956. [Google Scholar] [CrossRef]

- Deng, X.; Liu, Y.; He, G. Design and Assessment of an Antibacklash Single Roller Enveloping Hourglass Worm Gear. SAE Tech. Pap. 2019, 2019-01-1071. [Google Scholar] [CrossRef]

- Deng, X.; Wang, J.; Wang, S.; Wang, S.; Liu, Y.; He, G. An optimal process of machining complex surfaces of anti-backlash roller enveloping hourglass worms. J. Manuf. Process. 2020, 49, 472–480. [Google Scholar] [CrossRef]

- Pop, D.; Haragâş, S.; Buiga, O. Organe de Maşini; Editura Risoprint: Cluj-Napoca, Romania, 2024; Volume 3. [Google Scholar]

- Haragâș, S.; Ninacs, R.; Cristea, A.F. Contributions on the Kinematics of Unconventional Worm Gears. In Proceedings of the 14th International Conference on Mechanical and Aerospace Engineering (ICMAE), Porto, Portugal, 18–21 July 2023; pp. 89–94, ISBN 979-8-3503-4031-0. [Google Scholar]

- Jiang, Y.; Deng, X. Parametric study on the cylindrical roller enveloping end-face internal engagement worm gear. J. Adv. Mech. Des. Syst. Manuf. 2017, 11, JAMDSM0024. [Google Scholar] [CrossRef][Green Version]

- Kacalak, W.; Majewski, M.; Budniak, Z.; Ponomarenkow, J. Worm Gear Drives with Improved Kinematic Accuracy. Materials 2021, 14, 7825. [Google Scholar] [CrossRef] [PubMed]

- Maros, D. Angrenaje Melcate; Editura Tehnică: București, Romania, 1966. [Google Scholar]

- Ninacs, R.; Haragâș, S. Design and optimal modeling of unconventional worm gear with bearings. In Proceedings of the 27th Edition of Innovative Manufacturing Engineering & Energy Conference, (IMANEE), Chișinău, Republic of Moldova, 12–14 October 2023. [Google Scholar]

- Ninacs, R.; Haragâș, S. Contributions on mathematical determination of surfaces in unconventional worm gear. In Proceedings of the 12th International Conference on Machine and Industrial Design in Mechanical Engineering (KOD 2024), Balatonfȕred, Hungary, 23–26 May 2024. [Google Scholar]

- Sohn, J.; Park, N. Modified worm gear hobbing for symmetric longitudinal crowning in high lead cylindrical worm gear drives. Mech. Mach. Theory 2017, 117, 133–147. [Google Scholar] [CrossRef]

- Vyathin, A. Analysis of the geometry and contact density of globoid gearing. In MATEC Web of Conferences ICMTMTE 2020; EDP Sciences: Les Ulis, France, 2020; Volume 329, p. 03008. [Google Scholar] [CrossRef]

- Zhao, T.; Li, K.; Ma, H. Study on dynamic characteristics of a rotating cylindrical shell with uncertain parameters. Anal. Math. Phys. 2022, 12, 97. [Google Scholar] [CrossRef]

- Chen, L.; Cheng, C.; Zhou, C.; Zhang, Y.; Wu, J. Flapping rotary wing: A novel low-Reynolds number layout merging bionic features into micro rotors. Prog. Aerosp. Sci. 2024, 146, 100984. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haragâș, S.; Ninacs, R.; Buiga, O.; Tudose, L.; Haragâș, A.; Sas-Boca, I.M.; Cristea, F.A. An Attempt to Establish a Mathematical Model for an Unconventional Worm Gear with Bearings. Appl. Sci. 2024, 14, 10833. https://doi.org/10.3390/app142310833

Haragâș S, Ninacs R, Buiga O, Tudose L, Haragâș A, Sas-Boca IM, Cristea FA. An Attempt to Establish a Mathematical Model for an Unconventional Worm Gear with Bearings. Applied Sciences. 2024; 14(23):10833. https://doi.org/10.3390/app142310833

Chicago/Turabian StyleHaragâș, Simion, Roland Ninacs, Ovidiu Buiga, Lucian Tudose, Alexandru Haragâș, Ioana Monica Sas-Boca, and Felicia Aurora Cristea. 2024. "An Attempt to Establish a Mathematical Model for an Unconventional Worm Gear with Bearings" Applied Sciences 14, no. 23: 10833. https://doi.org/10.3390/app142310833

APA StyleHaragâș, S., Ninacs, R., Buiga, O., Tudose, L., Haragâș, A., Sas-Boca, I. M., & Cristea, F. A. (2024). An Attempt to Establish a Mathematical Model for an Unconventional Worm Gear with Bearings. Applied Sciences, 14(23), 10833. https://doi.org/10.3390/app142310833