Shelf Life and Organoleptic Attributes of Multifruit Smoothies Treated by Combined Mild Preservation Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. Total Colony Count Evaluation

2.4. Sensory Evaluation

- From least brown to most brown;

- From least to most fruity;

- From least to most dense;

- From least fruity flavour to most fruity character;

- From least to most popular.

2.5. Colourimetry

2.6. Examination of the Rheological Properties of Smoothie Samples

2.7. Electronic Tongue Alaysis

2.8. Electronic Nose Analysis

2.9. Data Analysis and Chemometrics

3. Results and Discussion

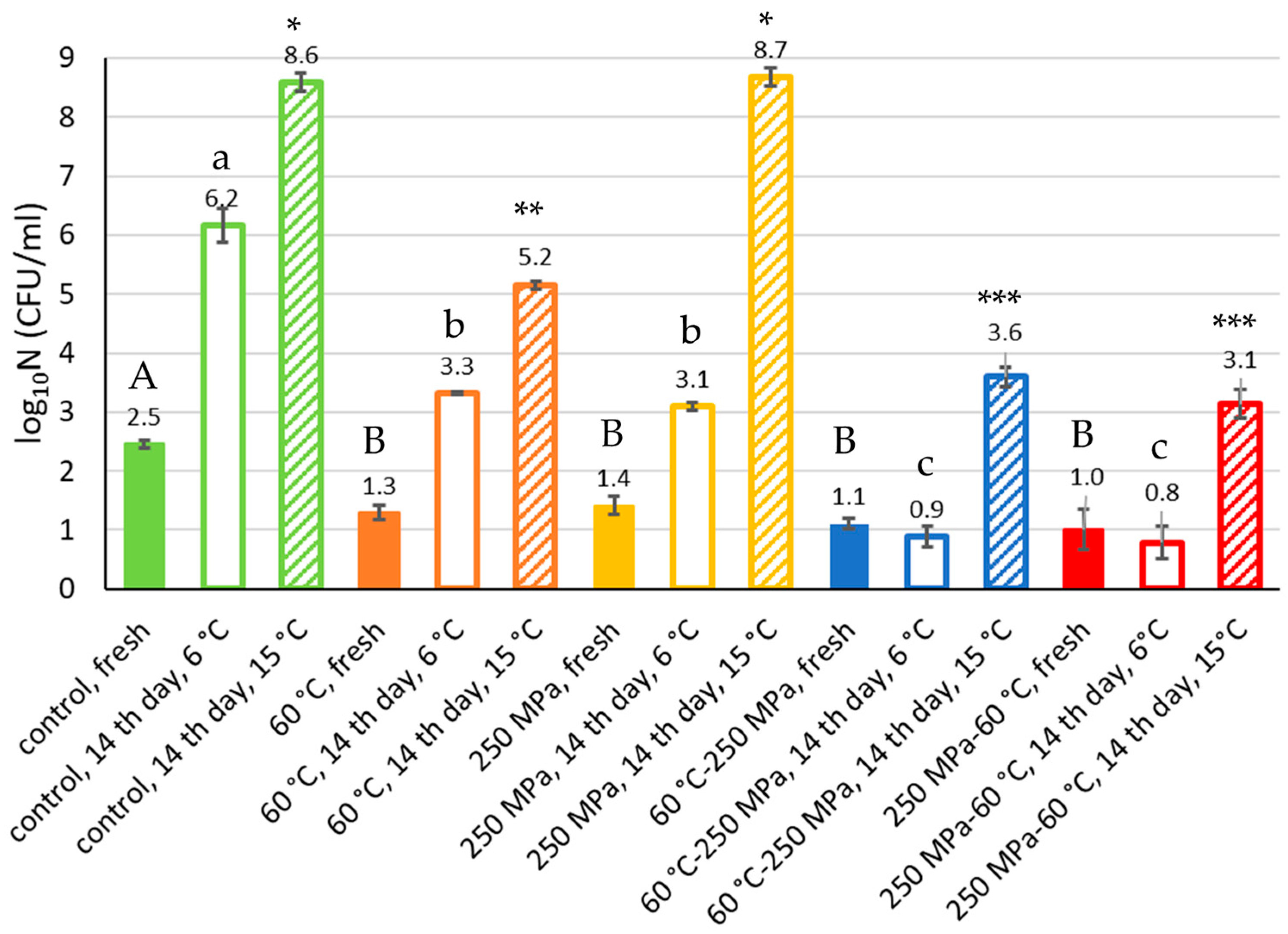

3.1. Microbiological Aspects

- Control, fresh;

- Control, stored for 14 days at 6 °C;

- 60 °C-250 MPa, fresh;

- 60 °C-250 MPa, stored for 14 days at 6 °C;

- 250 MPa-60 °C, fresh;

- 250 MPa-60 °C, stored for 14 days at 6 °C.

3.2. Evaluation of Sensory Properties

3.3. Evaluation of Colourimetric Properties

3.4. Evaluation of Viscosity of Smoothie Samples

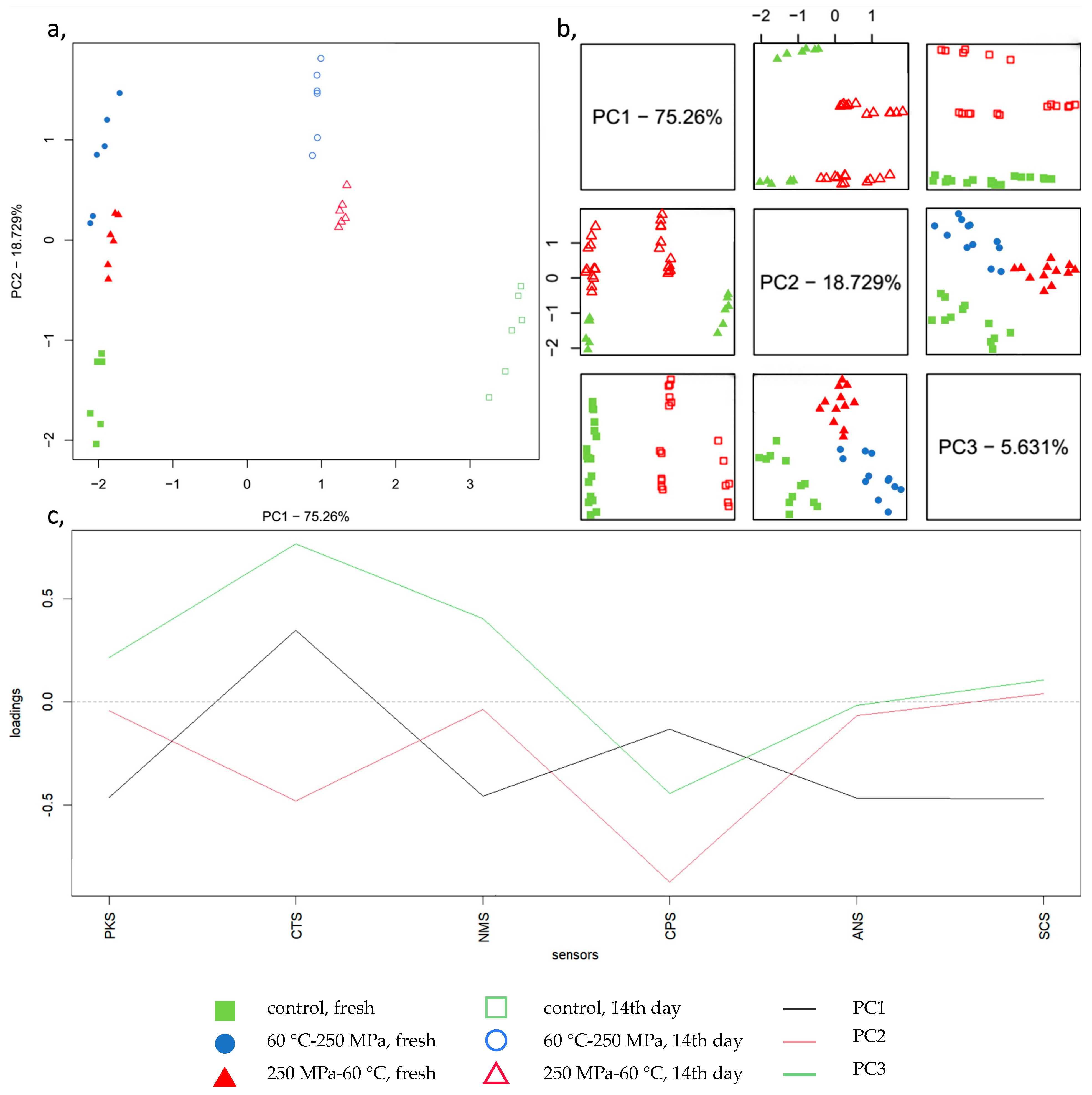

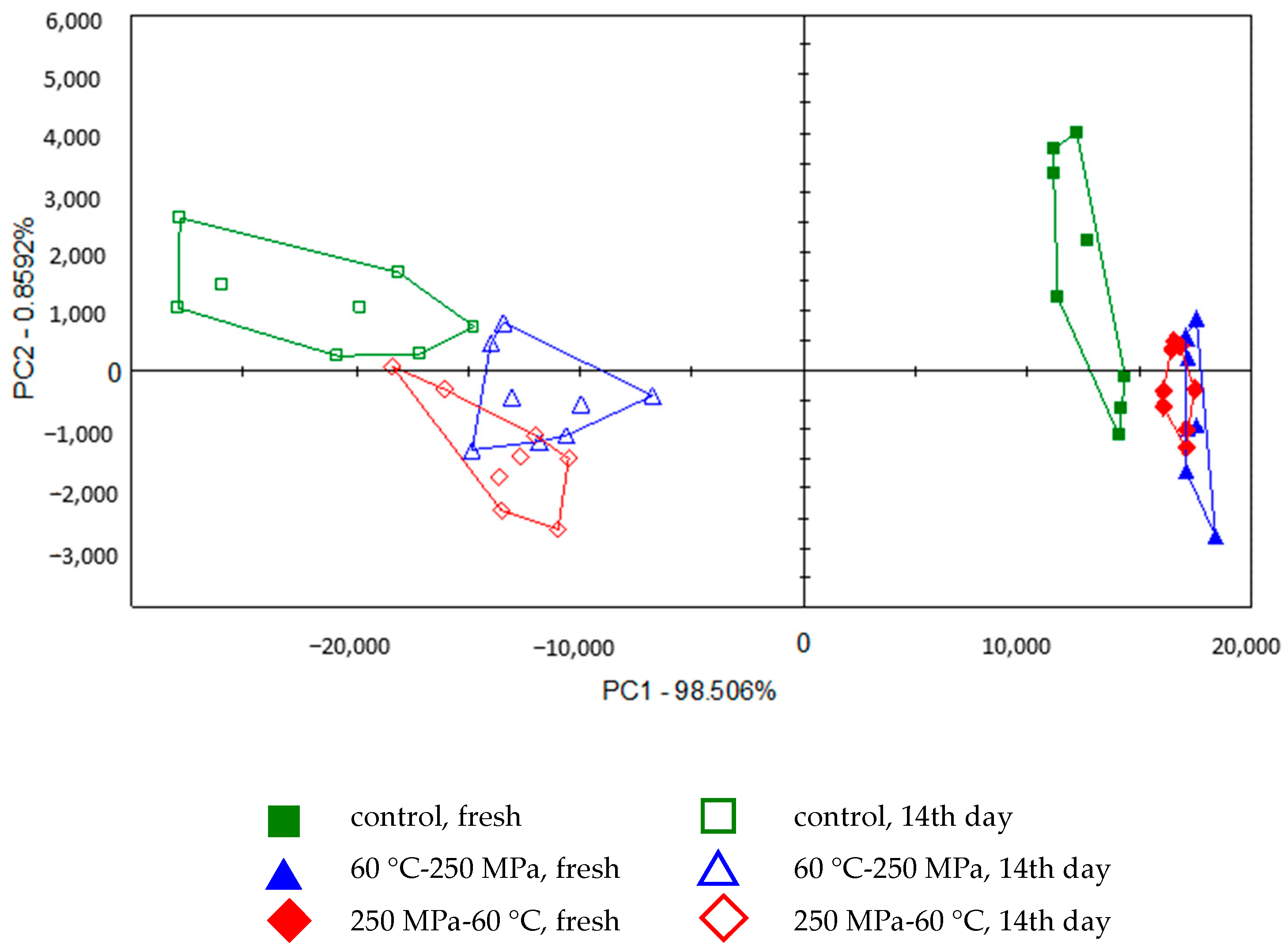

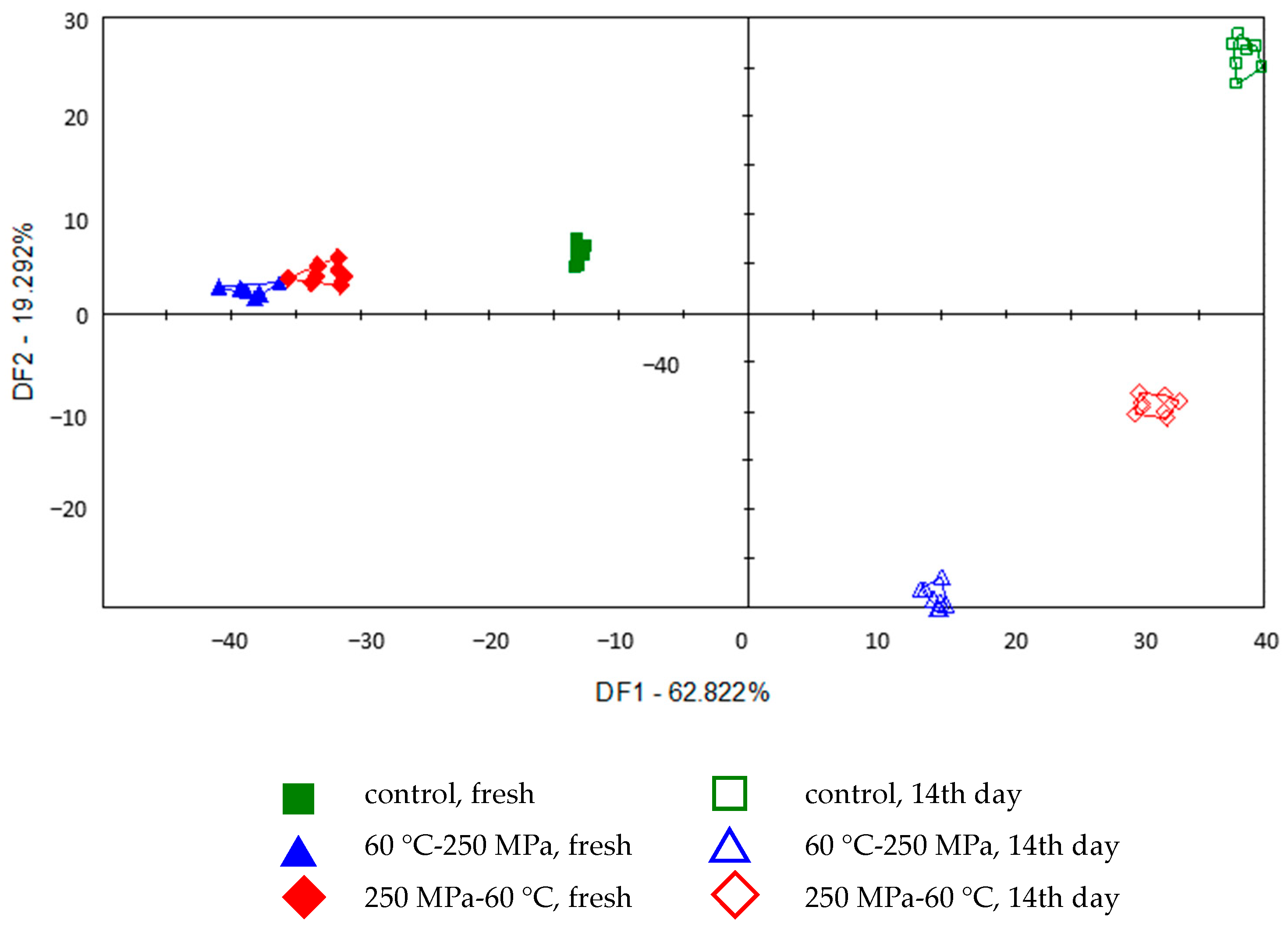

3.5. Electronic Tongue Measurements

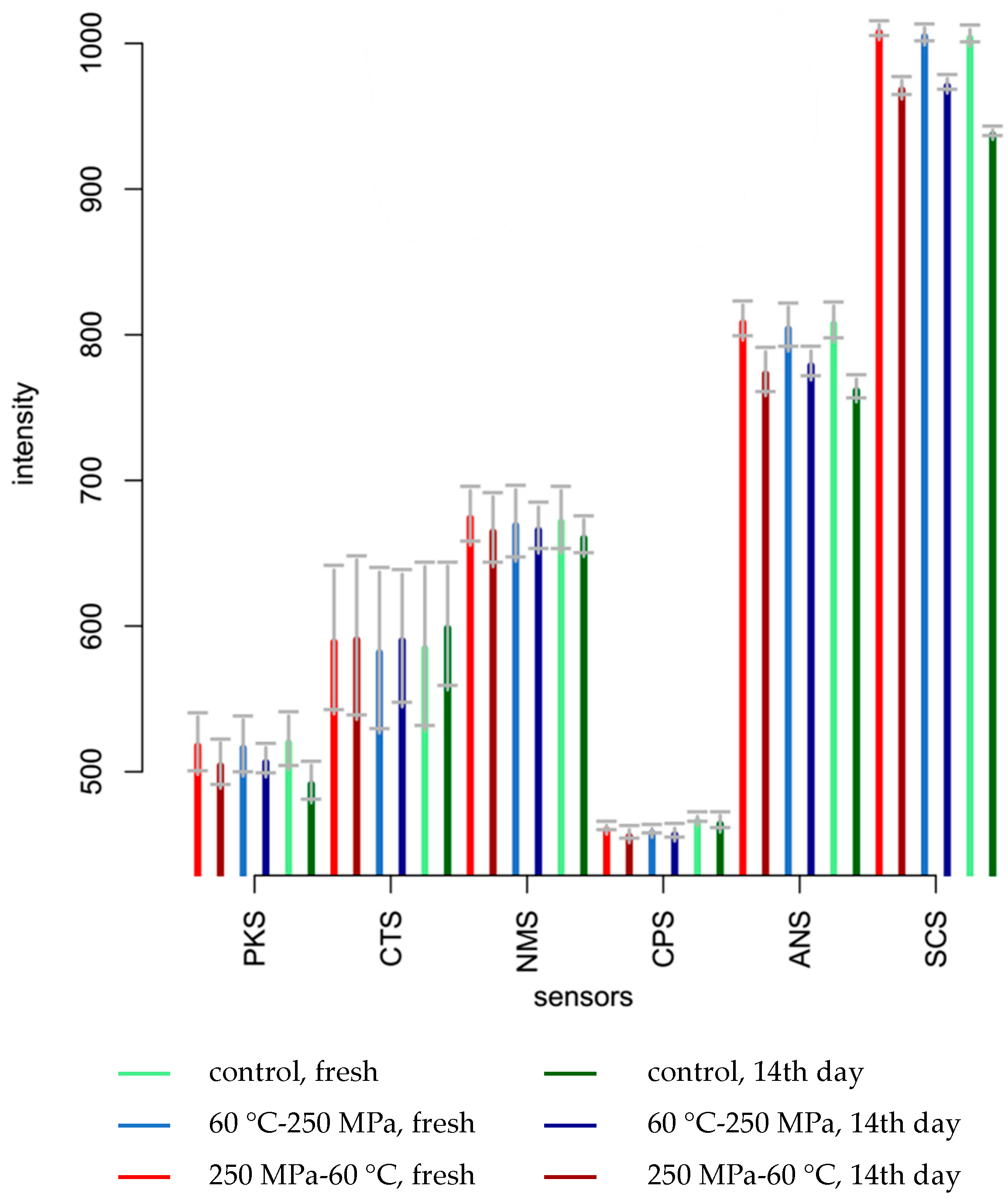

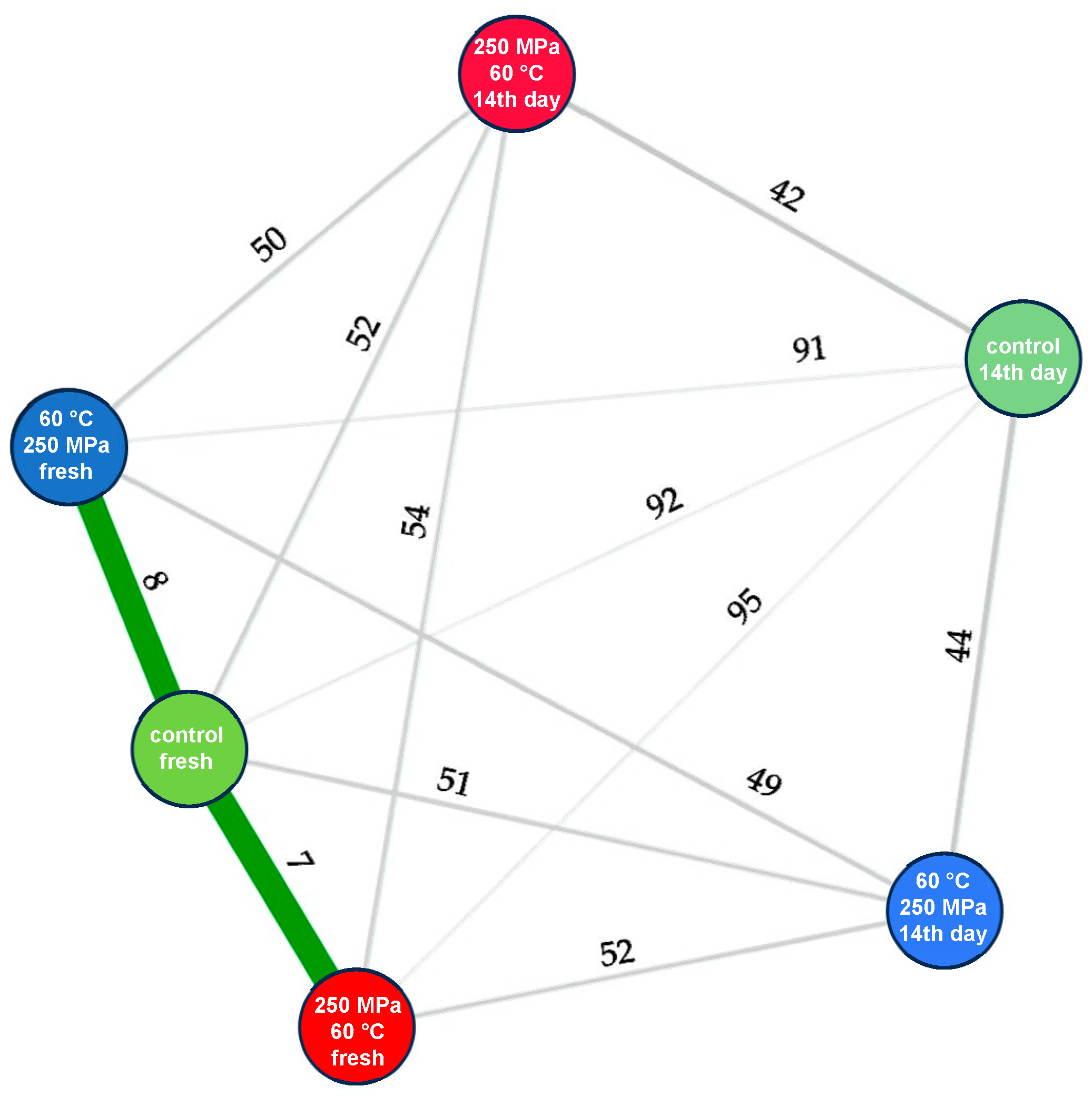

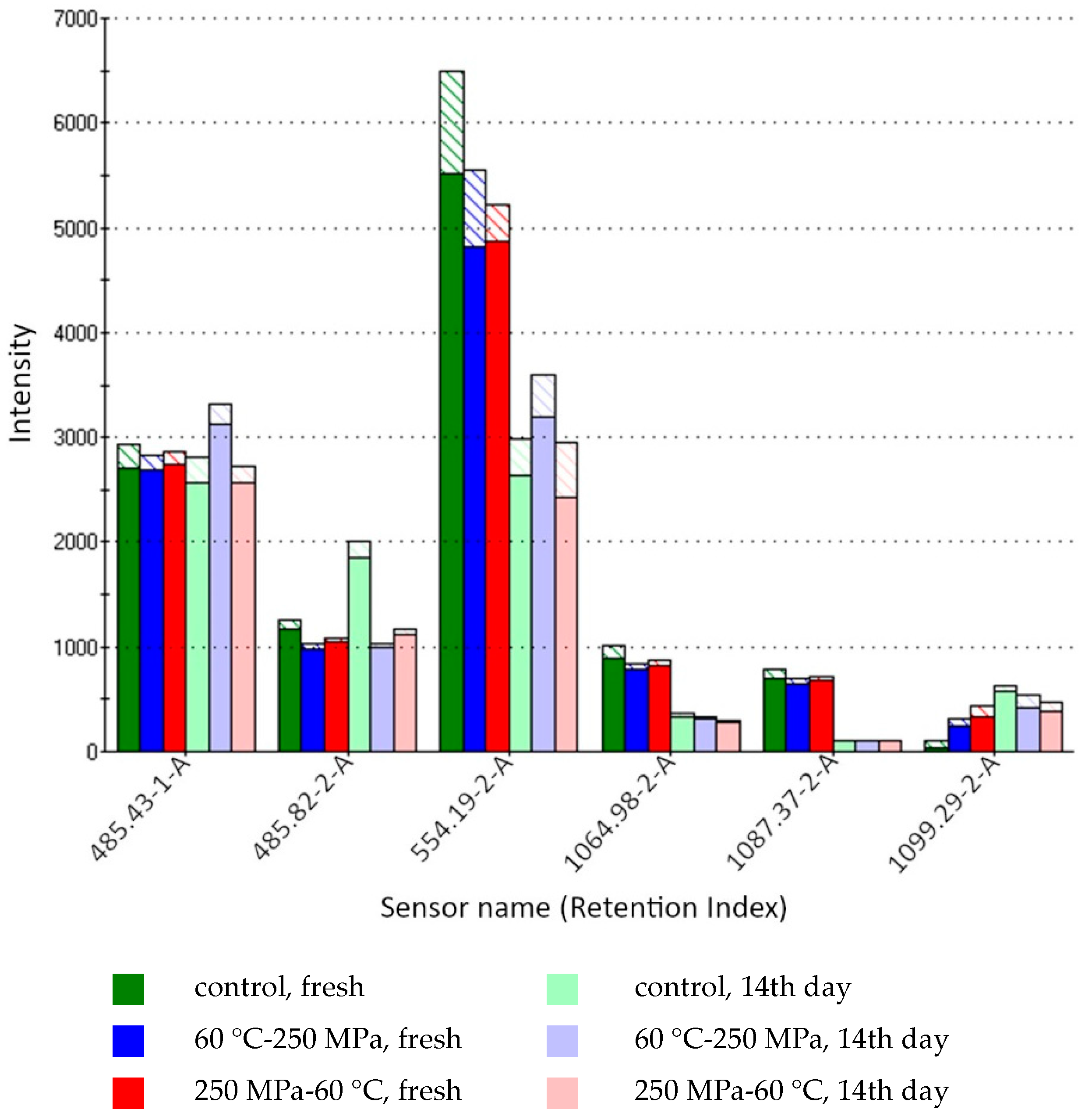

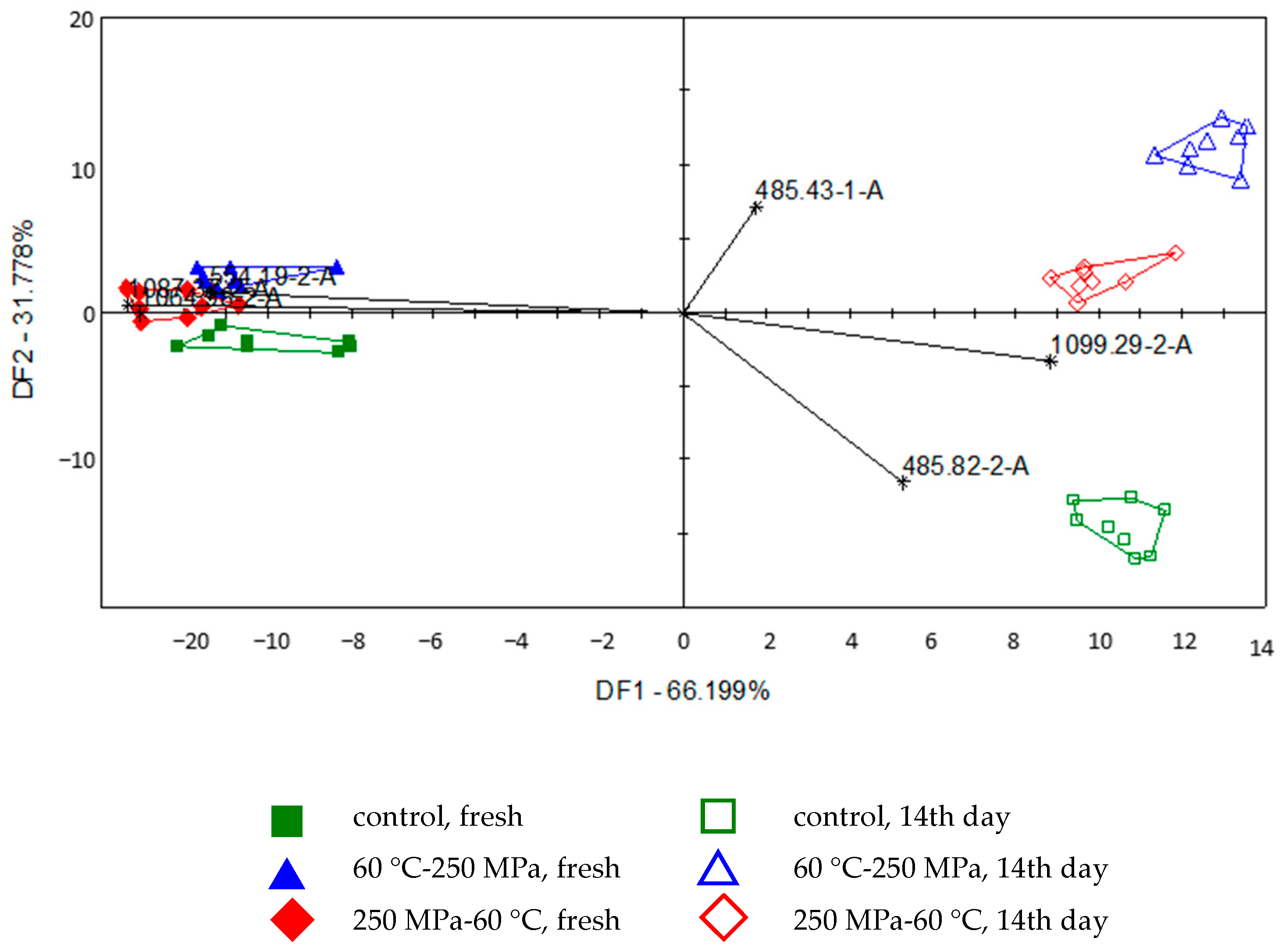

3.6. Electronic Nose Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boeing, H.; Bechthold, A.; Bub, A.; Ellinger, S.; Haller, D.; Kroke, A.; Leschik-Bonnet, E.; Muller, M.J.; Oberritter, H.; Schulze, M.; et al. Critical review: Vegetables and fruit in the prevention of chronic diseases. Eur. J. Nutr. 2012, 51, 637–663. [Google Scholar] [CrossRef]

- Mullen, W.; Marks, S.C.; Crozier, A. Evaluation of phenolic compounds in commercial fruit juices and fruit drinks. J. Agric. Food Chem. 2007, 55, 3148–3157. [Google Scholar] [CrossRef]

- Valenzuela, A.; Sanhueza, J.; Nieto, S. Cholesterol oxidation: Health hazard and the role of antioxidants in prevention. Biol. Res. 2003, 36, 291–302. [Google Scholar] [CrossRef] [PubMed]

- Briz, T.; Sijtsema, S.J.; Jasiulewicz, A.; Kyriakidi, A.; Guàrdia, M.D.; Van Der Berg, I.; Van Der Lans, I.A. Barriers to fruit consumption: Driving forces behind consumer behaviour. Scr. Hortic. 2009, 8, 7–18. [Google Scholar]

- Serafini, M. The role of antioxidants in disease prevention. Medicine 2006, 34, 533–535. [Google Scholar] [CrossRef]

- Morales-de la Peña, M.; Welti-chanes, J.; Martín-belloso, O. Application of novel processing methods for greater retention of functional compounds in fruitbased beverages. Beverages 2016, 2, 14. [Google Scholar] [CrossRef]

- Abadias, M.; Usall, J.; Anguera, M.; Solsona, C.; Viñas, I. Microbiology Quality of Fresh, Minimally-Processed Fruit and Vegetables, and Sprouts from Retail Establishments. Int. J. Food Microbiol. 2008, 123, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Jay, J.M.; Loessner, M.J.; Golden DAIn: Jay, J.M.; Loessner, M.J.; Golden, D.A. Modern Food Microbiology, 7th ed.; Springer Science + Business Media Inc.: New York, NY, USA, 2005; pp. 423–424. [Google Scholar]

- Lešková, E.; Kubíková, J.; Kováčiková, E.; Košická, M.; Porubská, J.; Holčíková, K. Vitamin losses: Retention during heat treatment and continual changes expressed by mathematical models. J. Food Compos. Anal. 2006, 19, 252–276. [Google Scholar] [CrossRef]

- Rickman, J.C.; Bruhn, C.M.; Barrett, D.M. Review: Nutritional comparison of fresh, frozen, and canned fruits and vegetables. Part I. Vitamins C and B and phenolic compounds. J. Sci. Food Agric. 2007, 87, 930–944. [Google Scholar] [CrossRef]

- Gómez, P.L.; Welti-Chanes, J.; Alzamora, S.M. Hurdle technology in fruit processing. Annu. Rev. Food Sci. Technol. 2011, 2, 447–465. [Google Scholar] [CrossRef] [PubMed]

- Oey, I.; Van der Plancken, I.; Van Loey, A.; Hendrickx, M. Does high pressure processing influence nutritional aspects of plant based food systems? Trends Food Sci. Technol. 2008, 19, 300–308. [Google Scholar] [CrossRef]

- Raso, J.; Barbosa-Cánovas, G.V. Nonthermal preservation of foods using combined processing techniques. Crit. Rev. Food Sci. Nutr. 2003, 43, 265–285. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frígola, A. High pressure treatment effect on physicochemical and nutritional properties of fluid foods during storage: A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 307–322. [Google Scholar] [CrossRef]

- Dalmadi, I.; Polyak-Fehér, K.; Farkas, J. Effects of pressure-and thermal-pasteurization on volatiles of some berry fruits. High Press. Res. 2007, 27, 169–171. [Google Scholar] [CrossRef]

- Gimenez, J.; Kajda, P.; Margomenou, L.; Piggott, J.R.; Zabetakis, I. A study on the colour and sensory attributes of high-hydrostatic-pressure jams as compared with traditional jams. J. Sci. Food Agric. 2001, 81, 1228–1234. [Google Scholar] [CrossRef]

- Echenique-Martínez, A.A.; Ramos-Parra, P.A.; Rodríguez-Sánchez, D.G.; Troncoso-Rojas, R.; Islas-Rubio, A.R.; Montoya-Ballesteros, L.D.C.; Hernández-Brenes, C. Botrytis cinerea induced phytonutrient degradation of strawberry puree: Effects of combined preservation approaches with high hydrostatic pressure and synthetic or natural antifungal additives. CyTA-J. Food 2023, 21, 451–463. [Google Scholar] [CrossRef]

- Xu, Z.; Lin, T.; Wang, Y.; Liao, X. Quality assurance in pepper and orange juice blend treated by high pressure processing and high temperature short time. Innov. Food Sci. Emerg. Technol. 2015, 31, 28–36. [Google Scholar] [CrossRef]

- Hartyáni, P.; Dalmadi, I.; Knorr, D. Electronic nose investigation of Alicyclobacillus acidoterrestris inoculated apple and orange juice treated by high hydrostatic pressure. Food Control 2013, 32, 262–269. [Google Scholar] [CrossRef]

- Laboissière, L.H.E.S.; Deliza, R.; Barros-Marcellini, A.M.; Rosenthal, A.; Camargo, L.M.A.Q.; Junqueira, R.G. Effects of high hydrostatic pressure (HHP) on sensory characteristics of yellow passion fruit juice. Innov. Food Sci. Emerg. Technol. 2007, 8, 469–477. [Google Scholar] [CrossRef]

- Liu, S.; Xu, Q.; Li, X.; Wang, Y.; Zhu, J.; Ning, C.; Meng, X. Effects of high hydrostatic pressure on physicochemical properties, enzymes activity, and antioxidant capacities of anthocyanins extracts of wild Lonicera caerulea berry. Innov. Food Sci. Emerg. Technol. 2016, 36, 48–58. [Google Scholar] [CrossRef]

- Olsen, N.V.; Menichelli, E.; Grunert, K.G.; Sonne, A.M.; Szabó, E.; Bánáti, D.; Næs, T. Choice probability for apple juice based on novel processing techniques: Investigating the choice relevance of mean-end-chains. Food Qual. Prefer. 2011, 22, 48–59. [Google Scholar] [CrossRef]

- Huang, H.W.; Lung, H.M.; Yang, B.B.; Wang, C.Y. Responses of microorganisms to high hydrostatic pressure processing. Food Control 2014, 40, 250–259. [Google Scholar] [CrossRef]

- Aganovic, K.; Hertel, C.; Vogel, R.F.; Johne, R.; Schlüter, O.; Schwarzenbolz, U.; Jäger, H.; Holzhauser, T.; Bergmair, J.; Roth, A.; et al. Aspects of high hydrostatic pressure food processing: Perspectives on technology and food safety. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3225–3266. [Google Scholar] [CrossRef]

- Rastogi, N.K.; Raghavarao, K.S.M.S.; Balasubramaniam, V.M.; Niranjan, K.; Knorr, D. Opportunities and challenges in high pressure processing of foods. Crit. Rev. Food Sci. Nutr. 2007, 47, 69–112. [Google Scholar] [CrossRef] [PubMed]

- Buzrul, S.; Alpas, H.; Largeteau, A.; Demazeau, G. Inactivation of Escherichia coli and Listeria innocua in kiwifruit and pineapple juices by high hydrostatic pressure. Int. J. Food Microbiol. 2008, 124, 275–278. [Google Scholar] [CrossRef]

- Tiwari, B.K.; O’Donnell, C.P.; Cullen, P.J. Effect of non thermal processing technologies on the anthocyanin content of fruit juices. Trends Food Sci. Technol. 2009, 20, 137–145. [Google Scholar] [CrossRef]

- Guerrero-Beltrán, J.A.; Barbosa-Cánovas, G.V.; Swanson, B.G. High Hydrostatic Pressure Processing of Fruit and Vegetable Products. Food Rev. Int. 2005, 21, 411–425. [Google Scholar] [CrossRef]

- Song, X.; Pendenza, P.; Díaz Navarro, M.; Valderrama García, E.; Di Monaco, R.; Giacalone, D. European consumers’ perceptions and attitudes towards nonthermally processed fruit and vegetable products. Foods 2020, 9, 1732. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Bredahl, L.; Navarro, M.D.; Pendenza, P.; Stojacic, I.; Mincione, S.; Pellegrini, G.; Schlüter, O.K.; Torrieri, E.; Di Monaco, R.; et al. Factors affecting consumer choice of novel non-thermally processed fruit and vegetables products: Evidence from a 4-country study in Europe. Food Res. Int. 2022, 153, 110975. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef]

- Zhu, D.; Ren, X.; Wei, L.; Cao, X.; Ge, Y.; Liu, H.; Li, J. Collaborative Analysis on Difference of Apple Fruits Flavour Using Electronic Nose and Electronic Tongue. Sci. Hortic. 2020, 260, 108879. [Google Scholar] [CrossRef]

- Gaggiotti, S.; Mascini, M.; Pittia, P.; Della Pelle, F.; Compagnone, D. Headspace Volatile Evaluation of Carrot Samples— Comparison of GC/MS and AuNPs-HpDNA-Based E-Nose. Foods 2019, 8, 293. [Google Scholar] [CrossRef] [PubMed]

- Palumbo, M.; Attolico, G.; Capozzi, V.; Cozzolino, R.; Corvino, A.; de Chiara, M.L.V.; Pace, B.; Pelosi, S.; Ricci, I.; Romaniello, R.; et al. Emerging postharvest technologies to enhance the shelf-life of fruit and vegetables: An overview. Foods 2022, 11, 3925. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.; Ding, W.; Zhang, D.; Wang, J.; Reed, K.; Zhang, B. Adulterant identification in mutton by electronic nose and gas chromatography-mass spectrometer. Food Control 2019, 98, 431–438. [Google Scholar] [CrossRef]

- Marx, Í.M.G.; Veloso, A.C.A.; Casal, S.; Pereira, J.A.; Peres, A.M. Sensory analysis using electronic tongues. In Innovative Food Analysis, 1st ed.; Galanakis, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 323–343. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Bhandari, B.; Adhikari, B. Application of electronic tongue for fresh foods quality evaluation: A review. Food Rev. Int. 2018, 34, 746–769. [Google Scholar] [CrossRef]

- Vlasov, Y.; Leign, A.; Rudnitskaya, A.; Di Natale, C.; D’aminco, A. Nonspecific sensor arrays (“electronic tongue”) for chemical analysis of liquids (IUPAC Technical Report). Pure Appl. Chem. 2005, 77, 1965–1983. [Google Scholar] [CrossRef]

- Maimunah, M.A.; Norhashila, H.; Samsuzana, A.A.; Ola, L. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar] [CrossRef]

- Christensen, Z.T.; Ogden, L.V.; Dunn, M.L.; Eggett, D.L. Multiple comparison procedures for analysis of ranked data. J. Food Sci. 2006, 71, S132–S143. [Google Scholar] [CrossRef]

- Lukács, G.Y. Színmérés, 1st ed.; Műszaki Könyvkiadó: Budapest, Hungary, 1982; p. 341. [Google Scholar]

- Hidas, K.I.; Nyulas-Zeke, I.C.; Szepessy, A.; Romvári, V.; Gerhart, K.; Surányi, J.; Laczay, P.; Darnay, L. Physical properties of hemp drink-based ice cream with different plant proteins guar gum and microbial transglutaminase. LWT 2023, 182, 114865. [Google Scholar] [CrossRef]

- Wang, S.; Lin, T.; Man, G.; Li, H.; Zhao, L.; Wu, J.; Liao, X. Effects of Anti-browning Combinations of Ascorbic Acid, Citric Acid, Nitrogen and Carbon Dioxide on the Quality of Banana Smoothies. Food Bioprocess. Technol. 2014, 7, 161–173. [Google Scholar] [CrossRef]

- Yakubu, H.G.; Ali, O.; Ilyés, I.; Vigyázó, D.; Bóta, B.; Bazar, G.; Tóth, T.; Szabó, A. Micro- Encapsulated Microalgae Oil Supplementation Has No Systematic Effect on the Odor of Vanilla Shake-Test of an Electronic Nose. Foods 2022, 11, 3452. [Google Scholar] [CrossRef] [PubMed]

- Roszkos, R.; Bazar, G.; Tóth, T.; Kovacs, Z.; Febel, H.; Mezes, M. Effect of n-3 polyunsaturated fatty acid feeding on the fatty acid profile and odor of milk in danbred sows. J. Appl. Anim. Res. 2021, 49, 447–459. [Google Scholar] [CrossRef]

- Worku, A.; Tóth, T.; Orosz, S.; Fébel, H.; Kacsala, L.; Húth, B.; Hoffmann, R.; Yakubu, H.G.; Bazar, G.; Tóthi, R. Aroma Profile, Microbial and Chemical Quality of Ensiled Green Forages Mixtures of Winter Cereals and Italian Ryegrass. Agriculture 2021, 11, 512. [Google Scholar] [CrossRef]

- Ito, M.; Ikehama, K.; Yoshida, K.; Haraguchi, T.; Yoshida, M. Bitterness prediction of H 1 -antihistamines and prediction of masking effects of artificial sweeteners using an electronic tongue. Int. J. Pharm. 2013, 441, 121–127. [Google Scholar] [CrossRef]

- Legin, A.; Rudnitskaya, A.; Kirsanov, D.; Frolova, Y.; Clapham, D.; Caricofe, R.; Pardo, M.; Sberveglieri, G. Assessment of bitterness intensity and suppression effects using an Electronic Tongue. In Proceedings of the 13th International Symposium on Olfaction and Electronic Nose, Brescia, Italy, 15–17 April 2009; Volume 1137, pp. 271–274. [Google Scholar]

- Kovacs, Z.; Szöllősi, D.; Zaukuu, J.-L.Z.; Bodor, Z.; Vitális, F.; Aouadi, B.; Zsom-Muha, V.; Gillay, Z. Factors Influencing the Long-Term Stability of Electronic Tongue and Application of Improved Drift. Biosensors 2020, 10, 74. [Google Scholar] [CrossRef] [PubMed]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2023; Available online: https://www.R-project.org/ (accessed on 23 November 2023).

- Kovacs, Z.; Bodor, Z.; Zinia Zaukuu, J.L.; Kaszab, T.; Bazar, G.; Tóth, T.; Mohácsi-Farkas, C. Electronic nose for monitoring odor changes of Lactobacillus species during milk fermentation and rapid selection of probiotic candidates. Foods 2020, 9, 1539. [Google Scholar] [CrossRef] [PubMed]

- Leistner, L. Basic aspects of food preservation by hurdle technology. Int. J. Food Microbiol. 2000, 55, 181–186. [Google Scholar] [CrossRef] [PubMed]

- Subasi, B.G.; Alpas, H. Effect of high hydrostatic pressure processing and squeezing pressure on some quality properties of pomegranate juice against thermal treatment. High Press. Res. 2017, 37, 78–92. [Google Scholar] [CrossRef]

- Keenan, D.F.; Brunton, N.P.; Mitchell, M.; Gormley, R.; Butler, F. Flavour profiling of fresh and processed fruit smoothies by instrumental and sensory analysis. Food Res. Int. 2012, 45, 17–25. [Google Scholar] [CrossRef]

- Terefe, N.S.; Matthies, K.; Simons, L.; Versteeg, C. Combined high pressure mild temperature processing for optimal retention of physical and nutritional quality of strawberries (Fragaria × ananassa). Innov. Food Sci. Emerg. Technol. 2009, 10, 297–307. [Google Scholar] [CrossRef]

- Škegro, M.; Putnik, P.; Kovačević, D.B.; Kovač, A.P.; Salkić, L.; Čanak, I.; Frece, J.; Zavadlav, S.; Ježek, D. Chemometric Comparison of High-Pressure Processing and Thermal Pasteurization: The Nutritive, Sensory, and Microbial Quality of Smoothies. Foods 2021, 10, 1167. [Google Scholar] [CrossRef] [PubMed]

- Salamon, B.; Zakariás, F.; Csehi, B.; Kiskó, G.; Dalmadi, I. Different sequence of high-hydrostatic pressure and mild-heat treatment on the colour and sensory characteristics of strawberry puree. Acta Aliment. 2021, 50, 93–101. [Google Scholar] [CrossRef]

- Figura, L.O.; Teixeira, A.A. Food Physics Physical Properties—Measurement and Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 117–206. [Google Scholar] [CrossRef]

- de Oliveira Ribeiro, L.; Almeida, A.C.S.; de Carvalho, C.W.P.; Borguini, R.G.; Ferreira, J.C.S.; Freitas, S.P.; da Matta, V.M. Effect of Processing on Bioactive Compounds, Physicochemical and Rheological Characteristics of Juçara, Banana and Strawberry Smoothie. Plant Foods Hum. Nutr. 2018, 73, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Keenan, D.F.; Tiwari, B.K.; Patras, A.; Gormley, R.; Butler, F.; Brunton, N.P. Effect of sonication on the bioactive, quality and rheological characteristics of fruit smoothies. Int. J. Food Sci. Technol. 2012, 47, 827–836. [Google Scholar] [CrossRef]

- Ozcan, G.; Barringer, S. Effect of Enzymes on Strawberry volatiles during storage, at different ripeness level, in different cultivars, and during eating. J. Food Sci. 2011, 76, 324–333. [Google Scholar] [CrossRef]

- Mitchell, W.C.; Jelenkovic, G. Characterizing NAD- and NADP-dependent alcohol dehydrogenase enzymes of strawberries. J. Am. Soc. Horti. Sci. 1995, 120, 798–801. [Google Scholar] [CrossRef]

| ΔE*ab Values | Perceived Difference |

|---|---|

| ΔE*ab ≤ 0.5 | not noticeable |

| 0.5 < ΔE*ab ≤ 1.5 | barely noticeable |

| 1.5 < ΔE*ab ≤ 3.0 | noticeable |

| 3.0 < ΔE*ab ≤ 6.0 | clearly visible |

| 6.0 < ΔE*ab | large |

| Fresh | 14th Day | |||||

|---|---|---|---|---|---|---|

| Control | 60 °C-250 MPa | 250 MPa-60 °C | Control | 60 °C-250 MPa | 250 MPa-60 °C | |

| Texture | 60 ab | 47 a | 47 a | 115 c | 67 ab | 84 bc |

| Smell | 77 ab | 74 ab | 89 b | 80 b | 46 ab | 54 ab |

| Colour | 71 b | 51 ab | 33 a | 87 b | 87 b | 91 b |

| Taste | 105 b | 91 b | 97 b | 44 a | 40 a | 43 a |

| Preference | 102 c | 96 bc | 89 bc | 32 a | 49 a | 52 a |

| Fresh | 14th Day | |||||

|---|---|---|---|---|---|---|

| Control | 60 °C-250 MPa | 250 MPa-60 °C | Control | 60 °C-250 MPa | 250 MPa-60 °C | |

| L* | 49.85 ± 0.55 aA | 50.70 ± 0.51 aA | 50.89 ± 0.36 aA | 50.87 ± 1.04 aA | 49.61 ± 1.15 aA | 49.61 ± 1.35 aA |

| a* | 11.67 ± 0.25 aA | 10.27 ± 0.20 aB | 10.33 ± 0.13 aB | 10.56 ± 0.31 bA | 12.10 ± 0.27 bB | 11.60 ± 0.25 bC |

| b* | 9.62 ± 0.27 aA | 11.06 ± 0.16 aB | 11.35 ± 0.18 aB | 10.04 ± 0.37 aA | 10.53 ± 0.30 bA | 10.53 ± 0.28 bA |

| C* | 15.12 ± 0.32 aA | 15.09 ± 0.14 aA | 15.34 ± 0.17 aA | 14.57 ± 0.47 aA | 16.04 ± 0.40 bB | 15.67 ± 0.34 aB |

| h° | 0.69 ± 0.01 aA | 0.82 ± 0.01 aB | 0.83 ± 0.01 aB | 0.76 ± 0.01 bA | 0.72 ± 0.00 bB | 0.74 ± 0.01 bC |

| Control, Fresh | 60 °C-250 MPa, Fresh | 250 MPa-60 °C, Fresh | Control, 14th Day | 60 °C-250 MPa, 14th Day | 250 MPa-60 °C, 14th Day | |

|---|---|---|---|---|---|---|

| Control, fresh | 2.18 noticeable | 2.42 noticeable | 1.57 noticeable | 1.04 barely noticeable | 0.93 barely noticeable | |

| 60 °C-250 MPa, fresh | 0.35 barely noticeable | 1.08 barely noticeable | 2.20 noticeable | 1.80 noticeable | ||

| 250 MPa-60 °C, fresh | 1.33 barely noticeable | 2.34 noticeable | 1.99 noticeable | |||

| Control, 14th day | 2.06 noticeable | 1.71 noticeable | ||||

| 60 °C-250 MPa, 14th day | 0.50 barely noticeable | |||||

| 250 MPa-60 °C, 14th day |

| Fresh | 14th Day | |||||

|---|---|---|---|---|---|---|

| Control | 60 °C-250 MPa | 250 MPa-60 °C | Control | 60 °C-250 MPa | 250 MPa-60 °C | |

| τ0 (Pa) | 13.758 ± 0.384 aA | 14.437 ± 0.660 aA | 14.292 ± 0.518 aA | 6.837 ± 1.383 bA | 11.182 ± 0.505 bB | 9.347 ± 0.306 bAB |

| K (Pa·sn) | 0.778 ± 0.068 aA | 0.767 ± 0.087 aA | 0.780 ± 0.001 aA | 0.560 ± 0.169 aA | 0.700 ± 0.043 aA | 0.672 ± 0.089 aA |

| n | 0.609 ± 0.014 aA | 0.615 ± 0.153 aA | 0.612 ± 0.005 aA | 0.586 ± 0.042 aA | 0.594 ± 0.013 aA | 0.598 ± 0.030 aA |

| R2 | 0.998 ± 0.001 | 0.999 ± 0.001 | 0.998 ± 0.010 | 0.979 ± 0.017 | 0.984 ± 0.018 | 0.982 ± 0.016 |

| η100 (mPa·s) | 272.6 ± 5.4 aA | 277.8 ± 9.9 aA | 278.6 ± 4.6 aA | 157.4 ± 6.6 bA | 236.5 ± 13.1 bB | 218.2 ± 25.1 bB |

| η1000 (mPa·s) | 67.55 ± 0.43 aA | 69.15 ± 1.68 aA | 68.83 ± 0.39 aA | 37.89 ± 0.93 bA | 54.84 ± 0.81 bB | 51.33 ± 3.07 bB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakariás, F.; Hidas, K.I.; Kovacs, Z.; Bázár, G.; Taczman-Brückner, A.; Dalmadi, I.; Kiskó, G. Shelf Life and Organoleptic Attributes of Multifruit Smoothies Treated by Combined Mild Preservation Technologies. Appl. Sci. 2024, 14, 11223. https://doi.org/10.3390/app142311223

Zakariás F, Hidas KI, Kovacs Z, Bázár G, Taczman-Brückner A, Dalmadi I, Kiskó G. Shelf Life and Organoleptic Attributes of Multifruit Smoothies Treated by Combined Mild Preservation Technologies. Applied Sciences. 2024; 14(23):11223. https://doi.org/10.3390/app142311223

Chicago/Turabian StyleZakariás, Fanni, Karina Ilona Hidas, Zoltan Kovacs, György Bázár, Andrea Taczman-Brückner, István Dalmadi, and Gabriella Kiskó. 2024. "Shelf Life and Organoleptic Attributes of Multifruit Smoothies Treated by Combined Mild Preservation Technologies" Applied Sciences 14, no. 23: 11223. https://doi.org/10.3390/app142311223

APA StyleZakariás, F., Hidas, K. I., Kovacs, Z., Bázár, G., Taczman-Brückner, A., Dalmadi, I., & Kiskó, G. (2024). Shelf Life and Organoleptic Attributes of Multifruit Smoothies Treated by Combined Mild Preservation Technologies. Applied Sciences, 14(23), 11223. https://doi.org/10.3390/app142311223